Cover Crop Termination Methods and Custom Residue Manager Effects on Collard Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Site Description and Weather

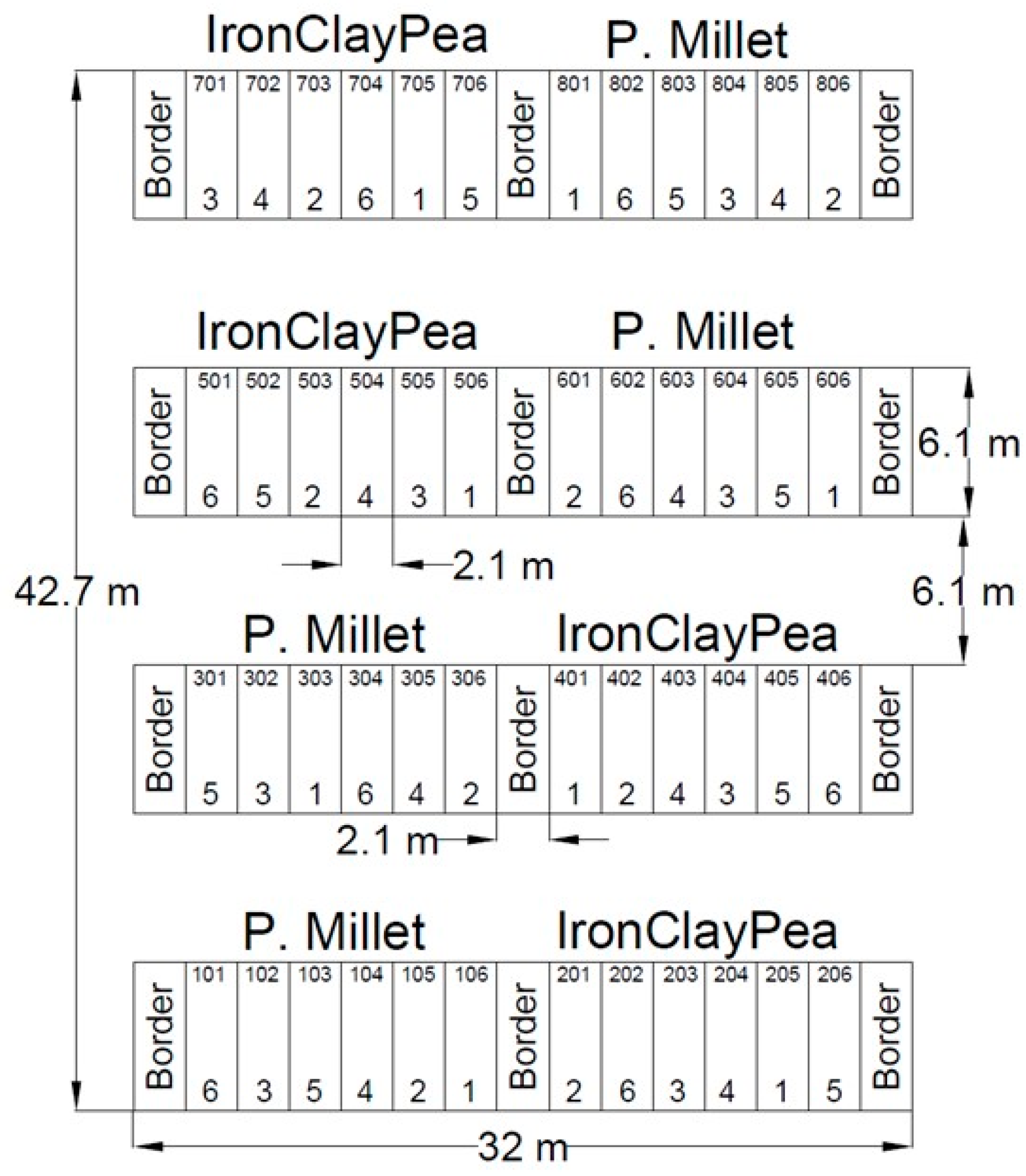

2.2. Experimental Design

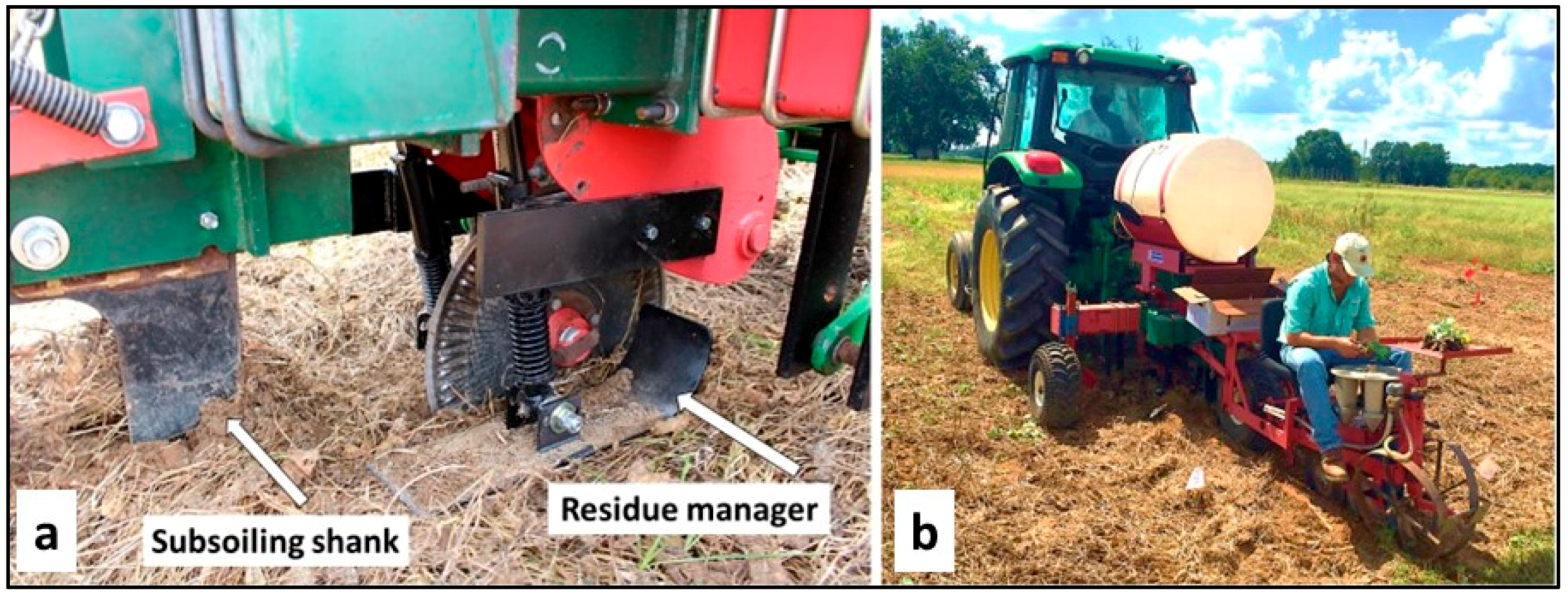

2.3. Agronomic Management and Treatment Application

2.4. Sample Collection and Analyses

2.5. Statistical Description

3. Results and Discussion

3.1. Cover Crop Biomass

3.2. Volumetric Soil Moisture Content

3.3. Soil Properties

3.3.1. Total Soil Carbon

3.3.2. Total Soil Nitrogen

3.4. Collard Population, Height, Weight per Plant, and Yield

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delaney, D.; Iversen, K.; Balkcom, K.; Caylor, A. Cover Crops for Alabama; Alabama Cooperative Extension System: Auburn, AL, USA, 2018. [Google Scholar]

- Sustainable Agriculture Network (SAN). Managing Cover Crops Profitably, 3rd ed.; Sustainable Agriculture Network: College Park, MD, USA, 2007. [Google Scholar]

- Ashford, D.L.; Reeves, D.W. Use of a mechanical roller-crimper as an alternative kill method for cover crops. Am. J. Altern. Agric. 2003, 18, 37–45. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Price, A.J. Management of High-Residue Cover Crops in a Conservation Tillage Organic Vegetable On-Farm Setting. Agronomy 2019, 9, 640. [Google Scholar] [CrossRef]

- Scavo, A.; Fontanazza, S.; Restuccia, A.; Pesce, G.R.; Abbate, C.; Mauromicale, G. The role of cover crops in improving soil fertility and plant nutritional status in temperate climates. A review. Agron. Sustain. Dev. 2022, 42, 93. [Google Scholar] [CrossRef]

- Bloszies, S.A.; Reberg-Horton, S.C.; Heitman, J.L.; Woodley, A.L.; Grossman, J.M.; Hu, S. Legume cover crop type and termination method effects on labile soil carbon and nitrogen and aggregation. Agron. J. 2022, 114, 1817–1832. [Google Scholar] [CrossRef]

- Wortman, S.E.; Francis, C.A.; Bernards, M.L.; Drijber, R.A.; Lindquist, J.L. Optimizing Cover Crop Benefits with Diverse Mixtures and an Alternative Termination Method. Agron. J. 2012, 104, 1425–1435. [Google Scholar] [CrossRef]

- Price, A.J.; Balkcom, K.S.; Monks, C.D.; Barentine, R.M.; Iversen, K.V.; Patterson, M.G. Controlling Glyphosate-Resistant Pigweed in Conservation Tillage cotton Systems (09). USDA ARS NSDL, 2008. Available online: https://www.ars.usda.gov/ARSUserFiles/60100500/SpecialPubs/SP09.pdf (accessed on 22 March 2023).

- Kebede, E. Contribution, utilization, and improvement of legumes-driven biological nitrogen fixation in agricultural systems. Front. Sustain. Food Syst. 2021, 5, 767998. [Google Scholar] [CrossRef]

- Abdul-Baki, A.A.; Morse, R.D.; Devine, T.E.; Teasdale, J.R. Broccoli production in forage soybean and foxtail millet cover crop mulches. Hortscience 1997, 32, 836–839. [Google Scholar] [CrossRef]

- USDA ARS. FoodData Central. 2019. Available online: https://fdc.nal.usda.gov/fdc-app.html#/food-details/170406/nutrients (accessed on 23 March 2023).

- Morse, R.D. No-till vegetable production—Its time is now. HortTechnology 1999, 9, 373–379. [Google Scholar] [CrossRef]

- Balkcom, K.S.; Duzy, L.M.; Kornecki, T.S.; Price, A.J. Timing of cover crop termination: Management considerations for the Southeast. Crop Forage Turfgrass Manag. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Torbert, H.A.; Prior, S.A. Cover Crop Residue Manager. U.S. Patent 8,770,119 B1, 8 July 2014. [Google Scholar]

- Kornecki, T.S.; Prior, S.A.; Torbert, H.A. Effects of a Custom Cover Crop Residue Manager in a No-Till Cotton System. Appl. Eng. Agric. 2016, 32, 333–340. [Google Scholar]

- Official Soil Series Descriptions and Series Classification. USDA Natural Resource Conservation Service. Available online: https://soilseries.sc.egov.usda.gov/# (accessed on 14 September 2023).

- Web Soil Survey. USDA Natural Resource Conservation Service. Available online: https://websoilsurvey.nrcs.usda.gov/app/ (accessed on 15 May 2023).

- Current Results Weather and Science Facts. Available online: https://www.currentresults.com/Weather/Alabama/average-alabama-weather.php (accessed on 14 September 2023).

- Medius—Auburn University. Available online: https://medius.re/tag/auburn-university (accessed on 15 January 2023).

- SAS. Proprietary Software Release 9.4; SAS Institute: Cary, NC, USA, 2013. [Google Scholar]

- Mitchell, C.C.; Huluka, G. Nutrient Recommendation Tables for Alabama Crops; Auburn University: Auburn, AB, USA, 2012. [Google Scholar]

- Kornecki, T.S. Multistage Crop Roller. U.S. Patent 7,987,917 B1, 2 August 2011. [Google Scholar]

- SAS. Proprietary Software Release JMP 16.2.0; SAS Institute: Cary, NC, USA, 2022. [Google Scholar]

- Balkcom, K.S.; Arriaga, F.J.; Van Santen, E. Conservation systems to enhance soil carbon sequestration in the Southeast US Coastal Plain. Soil Sci. Soc. Am. J. 2013, 77, 1774–1783. [Google Scholar] [CrossRef]

- Lu, Y.-C.; Watkins, K.B.; Teasdale, J.R.; Abdul-Baki, A.A. Cover crops in sustainable food production. Food Rev. Int. 2000, 16, 121–157. [Google Scholar] [CrossRef]

- Beri, V.; Meelu, O.; Khind, C. Biomass production, N accumulation, symbiotic effectiveness and mineralization of green manures in relation to yield of wetland rice. Trop. Agric. 1989, 66, 11–16. [Google Scholar]

- Creamer, N.G.; Baldwin, K.R. An evaluation of summer cover crops for use in vegetable production systems in North Carolina. Hortscience 2000, 35, 600–603. [Google Scholar] [CrossRef]

- Brady, N.C.; Weil, R.R. The Nature and Properties of Soils; Prentice Hall: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Hubbard, R.K.; Strickland, T.C.; Phatak, S. Effects of cover crop systems on soil physical properties and carbon/nitrogen relationships in the coastal plain of southeastern USA. Soil Tillage Res. 2013, 126, 276–283. [Google Scholar] [CrossRef]

- Ghahremani, S.; Ebadi, A.; Tobeh, A.; Hashemi, M.; Sedghi, M.; Gholipoouri, A.; Barker, A.V. Short-term impact of monocultured and mixed cover crops on soil properties, weed suppression, and lettuce yield. Commun. Soil Sci. Plant Anal. 2021, 52, 406–415. [Google Scholar] [CrossRef]

- Havlin, J.L.; Tisdale, S.L.; Nelson, W.L.; Beaton, J.D. Soil Fertility and Fertilizers; Pearson Education India: Noida, India, 2016. [Google Scholar]

- Adeli, A.; Brooks, J.P.; Read, J.J.; Feng, G.; Miles, D.; Shankle, M.W.; Barksdale, N.; Jenkins, J.N. Management strategies on an upland soil for improving soil properties. Commun. Soil Sci. Plant Anal. 2020, 51, 413–429. [Google Scholar] [CrossRef]

- Scavo, A.; Restuccia, A.; Abbate, C.; Lombardo, S.; Fontanazza, S.; Pandino, G.; Anastasi, U.; Mauromicale, G. Trifolium subterraneum cover cropping enhances soil fertility and weed seedbank dynamics in a Mediterranean apricot orchard. Agron. Sustain. Dev. 2021, 41, 70. [Google Scholar] [CrossRef]

- Sainju, U.; Whitehead, W.; Singh, B. Cover crops and nitrogen fertilization effects on soil aggregation and carbon and nitrogen pools. Can. J. Soil Sci. 2003, 83, 155–165. [Google Scholar] [CrossRef]

- Mulvaney, M.J.; Price, A.J.; Wood, C.W. Cover Crop Residue and Organic Mulches Provide Weed Control during Limited-Input No-Till Collard Production. J. Sustain. Agric. 2011, 35, 312–328. [Google Scholar] [CrossRef]

- Kornecki, T.S. Impact of different cover crop and termination methods on collard yield. Eur. Agrophysical J. 2019. [Google Scholar]

| 2015 | 2016 | 2017 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Month | Min(°C) | Max (°C) | Prec. (cm) | Min (°C) | Max (°C) | Prec. (cm) | Min (°C) | Max (°C) | Prec. (cm) |

| January | 1.2 | 14.7 | 9.8 | 2.2 | 14.0 | 12.0 | 11.9 | 19.1 | 29.9 |

| February | 0.7 | 13.4 | 11.7 | 4.5 | 18.1 | 12.0 | 13.6 | 20.8 | 11.3 |

| March | 9.9 | 22.4 | 5.0 | 9.7 | 23.4 | 14.4 | 15.1 | 22.4 | 7.2 |

| April | 14.2 | 25.9 | 13.3 | 11.7 | 25.4 | 20.6 | 19.9 | 27.8 | 12.5 |

| May | 16.1 | 29.7 | 13.0 | 15.8 | 29.0 | 5.4 | 21.7 | 28.5 | 23.1 |

| June | 21.2 | 32.8 | 14.8 | 20.6 | 33.6 | 14.5 | 24.8 | 30.6 | 22.4 |

| July | 22.6 | 34.7 | 12.4 | 22.6 | 35.1 | 13.9 | 26.9 | 34.0 | 9.5 |

| August | 21.8 | 33.5 | 15.5 | 23.1 | 34.3 | 15.3 | 26.1 | 32.3 | 15.7 |

| September | 19.1 | 30.2 | 4.6 | 19.9 | 33.6 | 2.3 | 23.3 | 30.2 | 10.9 |

| October | 13.0 | 25.9 | 5.9 | 12.5 | 30.0 | 0.2 | 19.0 | 25.7 | 13.7 |

| November | 10.6 | 22.2 | 15.8 | 6.3 | 24.2 | 5.3 | 13.5 | 19.5 | 3.3 |

| December | 9.1 | 20.8 | 36.2 | 5.4 | 16.8 | 13.1 | 8.8 | 14.5 | 7.0 |

| Treatment | Description |

|---|---|

| 1 | Rolling/crimping (Roll) + Residue Manager |

| 2 | Mowing (Mow) + Residue Manager |

| 3 | Mowing and incorporating (MowIncorp) + Residue Manager |

| 4 | Rolling/crimping (Roll)+ No Residue Manager |

| 5 | Mowing (Mow) + No Residue Manager |

| 6 | Mowing and incorporating (MowIncorp) + No Residue Manager |

| Field Activity | Growing Season | ||

|---|---|---|---|

| 2014–2015 | 2015–2016 | 2016–2017 | |

| Rye cover crop planted | 17 December 2014 | 10 December 2015 | 16 December 2016 |

| Collection of plant hts/biomass of rye | 6 May 2015 | 19 April 2016 | 19 April 2017 |

| Application of glyphosate to rye | 6 May 2015 | 19 April 2016 | 19 April 2017 |

| Pre-season soil sample collection | 11 May 2015 | 10 May 2016 | 7 June 2017 |

| Mowing and tilling of test area | 12 May 2015 | 4 May 2016 | 15 May 2017 |

| Incorporated soil amendments and pre-plant nitrogen for pearl millet | 12 May 2015 | 11 May 2016 | 8 June 2017 |

| Planted summer cover crops | 13 May 2015 | 12 May 2016 | 8 June 2017 |

| Applied nitrogen to pearl millet | 2 July 2015 | 29 June 2016 | 21 July 2017 |

| Collection of plant hts/biomass of pearl millet and performed termination treatments | 27 July 2015 | 15 August 2016 | 29 August 2017 |

| Collection of soil samples for pearl millet at termination | 28 July 2015 | 16 August 2016 | 29 August 2017 |

| Collection of plant hts/biomass of iron clay peas and performed termination treatments | 25 August 2015 | 31 August 2016 | 14 September 2017 |

| Collection of soil samples for iron clay peas at termination | 26 August 2015 | 1 September 2016 | 14 September 2017 |

| Applied glyphosate to entire test area | 3 September 2015 | 19 September 2016 | 18 September 2017 |

| Transplanted collards | 10 September 2015 | 21 September 2016 28 September 2016 | 5 October 2017 |

| Collection of soil samples 1 month after planting | 8 October 2015 | 21 October 2016 | 1 November 2017 |

| Harvested collards | 12 November 2015 | 16 December 2016 | 11 December 2017 |

| Year | Height (cm) | Biomass (kg ha−1) | Total Carbon (kg C ha−1) | Total Nitrogen (kg N ha−1) |

|---|---|---|---|---|

| 2015 | 41.9 c* | 1284.0 c | 570.1 c | 26.1 c |

| 2016 | 159.4 a | 5197.5 a | 2515.7 a | 68.6 a |

| 2017 | 127.1 b | 3384.0 b | 1576.8 b | 42.1 b |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 |

| Iron Clay Pea | Pearl Millet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year | Biomass (kg ha−1) | Ht. (cm) | C (kg ha−1) | N (kg ha−1) | C:N | Biomass (kg ha−1) | Ht. (cm) | C (kg ha−1) | N (kg ha−1) | C:N |

| 2015 | 4422 b* | 47.3 b | 1950.7 c | 117.2 b | 16.5 b | 8613 ab | 156.7 b | 3842.7 a | 69.9 b | 55.4 a |

| 2016 | 7119 a | 47.5 b | 2874.1 b | 178.4 a | 17.2 b | 7232 b | 128.2 c | 3098.4 b | 68.7 b | 46.9 b |

| 2017 | 7854 a | 54.5 a | 3483.9 a | 179.1 a | 20.4 a | 9539 a | 167.2 a | 4290.6 a | 98.3 a | 44.3 b |

| Average | 6465 | 49.8 | 2769.6 | 158.2 | 18.0 | 8461.3 | 150.7 | 3743.9 | 79.0 | 48.9 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.0016 | 0.0108 | <0.0001 | 0.0027 | <0.0001 | 0.0007 |

| Effect | p-Value |

|---|---|

| REP | <0.0001 |

| YEAR | <0.0001 |

| CROP | <0.0001 |

| WEEK | <0.0001 |

| TERM | 0.0025 |

| ATTACH | 0.4431 |

| TERM × CROP | 0.0065 |

| YEAR × WEEK | <0.0001 |

| CROP × YEAR | <0.0001 |

| TERM × CROP × YEAR | 0.0019 |

| TERM × YEAR × WEEK | 0.0472 |

| Iron Clay Peas | Pearl Millet | ||||||

|---|---|---|---|---|---|---|---|

| Year | Term Meth | 1 WAP | 2 WAP | 3 WAP | 1 WAP | 2 WAP | 3 WAP |

| 2015 | Roll | 12.2 a* | 16.4 | 18.5 ab | 10.5 a | 13.7 ab | 16.3 |

| Mow | 10.1 b | 14.8 | 16.6 b | 9.3 b | 13.8 a | 16.7 | |

| MowIncorp | 10.4 ab | 15.4 | 19.0 a | 8.8 b | 12.5 b | 15.6 | |

| Average | 10.9 | 15.3 | 18.0 | 9.5 | 13.3 | 16.2 | |

| p-value | 0.0202 | 0.1400 | 0.0310 | 0.0128 | 0.0597 | 0.3584 | |

| Prev Precip | 0.0 | 0.94 | 2.16 | 0.0 | 0.94 | 2.16 | |

| Prev Low T | 16.2 | 17.4 | 19.4 | 16.2 | 17.4 | 19.4 | |

| Prev High T | 29.1 | 30.2 | 26.8 | 29.1 | 30.2 | 26.8 | |

| 2016 | Roll | 11.9 | 10.6 | 14.4 | 12.8 a | 12.0 a | 14.5 a |

| Mow | 11.3 | 9.6 | 13.4 | 10.1 b | 10.3 b | 13.0 ab | |

| MowIncorp | 12.2 | 10.1 | 13.3 | 10.8 ab | 10.1 b | 12.6 b | |

| Average | 11.8 | 10.1 | 13.7 | 11.2 | 10.8 | 13.4 | |

| p-value | 0.5233 | 0.4283 | 0.3550 | 0.0380 | 0.0396 | 0.0382 | |

| Prev Precip | 0.0 | 0.0 | 0.23 | 0.0 | 0.0 | 0.23 | |

| Prev Low T | 13.6 | 14.8 | 12.7 | 13.6 | 14.8 | 12.7 | |

| Prev High T | 30.2 | 30.2 | 29.8 | 30.2 | 30.2 | 29.8 | |

| 2017 | Roll | 14.6 | 11.2 a | 13.8 a | 13.7 b | 11.1 a | 12.7 |

| Mow | 14.7 | 10.4 ab | 13.7 a | 13.2 b | 9.8 ab | 12.6 | |

| MowIncorp | 14.6 | 9.6 b | 12.0 b | 15.6 a | 9.2 b | 11.8 | |

| Average | 14.6 | 10.4 | 13.2 | 14.2 | 10.0 | 12.4 | |

| p-value | 0.9790 | 0.0488 | 0.0168 | 0.0139 | 0.0167 | 0.1937 | |

| Prev Precip | 9.53 | 0.05 | 2.74 | 9.53 | 0.05 | 2.74 | |

| Prev Low T | 24.0 | 20.0 | 16.1 | 24.0 | 20.0 | 16.1 | |

| Prev High T | 29.6 | 26.2 | 24.1 | 29.6 | 26.2 | 24.1 | |

| Soil Carbon | Soil Nitrogen | |

|---|---|---|

| Effect | p-Value | p-Value |

| REP | <0.0001 | <0.0001 |

| YEAR | 0.0027 | <0.0001 |

| CROP | 0.2238 | <0.0001 |

| TERM | 0.2753 | 0.1143 |

| DEPTH | <0.0001 | <0.0001 |

| TIMING | 0.0578 | <0.0001 |

| DEPTH × YEAR | <0.0001 | <0.0001 |

| DEPTH × TIMING | 0.0245 | 0.0009 |

| YEAR × TIMING | <0.0001 | 0.0239 |

| YEAR × CROP | 0.0422 | 0.0018 |

| TIMING × CROP | 0.0722 | 0.8532 |

| DEPTH × TIMING × CROP | 0.0257 | 0.1255 |

| YEAR × TIMING × CROP | 0.0205 | 0.7144 |

| ICP | PMILL | ||||||

|---|---|---|---|---|---|---|---|

| DEPTH | TIMING | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 |

| TOP | PRE | 5.08 b* | 5.00 b | 5.27 | 5.04 | 4.93 b | 5.26 c |

| AT TERM | 4.93 b | 5.51 a | 5.38 | 5.19 | 5.45 a | 6.03 a | |

| MONTH AFTER | 5.44 a | 5.47 a | 5.49 | 4.91 | 5.51 a | 5.57 b | |

| p-value | 0.0004 | 0.0020 | 0.4890 | 0.2873 | 0.0012 | <0.0001 | |

| BOTTOM | PRE | 3.36 a | 2.79 b | 2.85 ab | 3.14 a | 3.00 | 2.74 c |

| AT TERM | 2.85 b | 3.07 ab | 2.81 b | 2.85 b | 3.03 | 3.25 a | |

| MONTH AFTER | 2.96 b | 3.14 a | 3.08 a | 2.99 ab | 3.17 | 2.99 b | |

| p-value | <0.0001 | 0.0435 | 0.0370 | 0.0122 | 0.5255 | <0.0001 | |

| ICP | PMILL | ||||||

|---|---|---|---|---|---|---|---|

| DEPTH | TIMING | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 |

| TOP | PRE | 0.47 c* | 0.52 b | 0.55 b | 0.43 b | 0.51 | 0.54 b |

| AT TERM | 0.53 b | 0.57 a | 0.59 a | 0.49 a | 0.53 | 0.60 a | |

| MONTH AFTER | 0.57 a | 0.53 b | 0.58 ab | 0.49 a | 0.53 | 0.58 a | |

| p-value | <0.0001 | 0.0035 | 0.0278 | 0.0003 | 0.1686 | 0.0149 | |

| BOTTOM | PRE | 0.35 | 0.35 | 0.34 | 0.32 | 0.35 | 0.35 |

| AT TERM | 0.36 | 0.36 | 0.38 | 0.33 | 0.34 | 0.35 | |

| MONTH AFTER | 0.35 | 0.35 | 0.38 | 0.34 | 0.35 | 0.38 | |

| p-value | 0.5540 | 0.5091 | 0.0936 | 0.1343 | 0.7476 | 0.1257 | |

| Collard Population | Collard Height | Weight per Plant | Collard Yield | |

|---|---|---|---|---|

| Effect | p-Value | p-Value | p-Value | p-Value |

| REP | 0.5196 | <0.0001 | <0.0001 | 0.0002 |

| YEAR | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| CROP | 0.5116 | <0.0001 | <0.0001 | <0.0001 |

| TRT | 0.1930 | 0.9733 | 0.4333 | 0.4273 |

| TRT × YEAR | 0.1269 | 0.6344 | 0.2868 | 0.4199 |

| CROP × YEAR | <0.0001 | 0.0267 | <0.0001 | <0.0001 |

| TRT × CROP | 0.0239 | 0.8031 | 0.5774 | 0.0890 |

| TRT × CROP × YEAR | 0.0628 | 0.9955 | 0.8348 | 0.6637 |

| ICP | PMILL | ||||||

|---|---|---|---|---|---|---|---|

| TERM | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | |

| With RM | Roll | 11,083.1 | 5186.7 | 5946.1 a* | 7954.9 | 1625.1 | 5266.0 |

| Mow | 13,154.7 | 4559.0 | 6042.0 a | 5914.7 | 1790.8 | 5203.3 | |

| MowIncorp | 10,063.0 | 4638.3 | 4029.7 b | 8012.4 | 2259.0 | 3020.1 | |

| Without RM | Roll | 12,232.2 | 4722.9 | 5602.6 a | 8943.6 | 2164.0 | 4551.1 |

| Mow | 13,168.6 | 5302.7 | 5743.8 a | 7743.9 | 2292.1 | 4348.8 | |

| MowIncorp | 12,739.7 | 2880.6 | 3724.6 b | 8308.8 | 1354.0 | 4279.1 | |

| Average | 12,073.6 | 4548.4 | 5181.5 | 7813.1 | 1914.2 | 4444.7 | |

| p-value | 0.6331 | 0.2059 | 0.0002 | 0.3640 | 0.7864 | 0.1630 | |

| ICP | PMILL | ||||||

|---|---|---|---|---|---|---|---|

| TERM | 2015 | 2016 | 2017 | 2015 | 2016 | 2017 | |

| With RM | Roll | 9043.3 | 11,159.9 a* | 10,775.0 | 11,544.7 a | 7119.2 | 10,775.0 ab |

| Mow | 10,005.4 | 10,582.6 ab | 10,582.6 | 7119.2 b | 7888.9 | 11,159.9 a | |

| MowIncorp | 7888.9 | 9620.6 ab | 10,197.8 | 9813.0 a | 6734.4 | 7696.5 b | |

| Without RM | Roll | 10,390.2 | 9428.2 ab | 9620.6 | 10,005.4 a | 5387.5 | 10,197.8 ab |

| Mow | 10,005.4 | 9620.6 ab | 10,775.0 | 9620.6 a | 6926.8 | 9235.7 ab | |

| MowIncorp | 9428.2 | 9043.3 b | 10,775.0 | 10,582.6 a | 5772.3 | 10,967.4 ab | |

| Average | 9460.2 | 9909.2 | 10,454.4 | 9780.9 | 6638.2 | 10,005.4 | |

| p-value | 0.4182 | 0.0786 | 0.6970 | 0.0033 | 0.6208 | 0.0828 | |

| Collard wt. per Plant | Collard Height (cm) | |||

|---|---|---|---|---|

| Year | Iron Clay Peas | Pearl Millet | Iron Clay Peas | Pearl Millet |

| 2015 | 1.28 a* | 0.80 a | 47.4 a | 40.1 b |

| 2016 | 0.46 b | 0.28 c | 43.1 b | 33.9 c |

| 2017 | 0.50 b | 0.45 b | 48.5 a | 44.9 a |

| Average | 0.75 | 0.51 | 46.3 | 39.7 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kichler, C.M.; Kornecki, T.S.; Torbert, H.A.; Watts, D.B.; Prasad, R. Cover Crop Termination Methods and Custom Residue Manager Effects on Collard Production. Agronomy 2023, 13, 2595. https://doi.org/10.3390/agronomy13102595

Kichler CM, Kornecki TS, Torbert HA, Watts DB, Prasad R. Cover Crop Termination Methods and Custom Residue Manager Effects on Collard Production. Agronomy. 2023; 13(10):2595. https://doi.org/10.3390/agronomy13102595

Chicago/Turabian StyleKichler, Corey M., Ted S. Kornecki, H. Allen Torbert, Dexter B. Watts, and Rishi Prasad. 2023. "Cover Crop Termination Methods and Custom Residue Manager Effects on Collard Production" Agronomy 13, no. 10: 2595. https://doi.org/10.3390/agronomy13102595

APA StyleKichler, C. M., Kornecki, T. S., Torbert, H. A., Watts, D. B., & Prasad, R. (2023). Cover Crop Termination Methods and Custom Residue Manager Effects on Collard Production. Agronomy, 13(10), 2595. https://doi.org/10.3390/agronomy13102595