Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview

Abstract

:1. Introduction

2. Influence of Drying Temperature on Bioactive Compounds

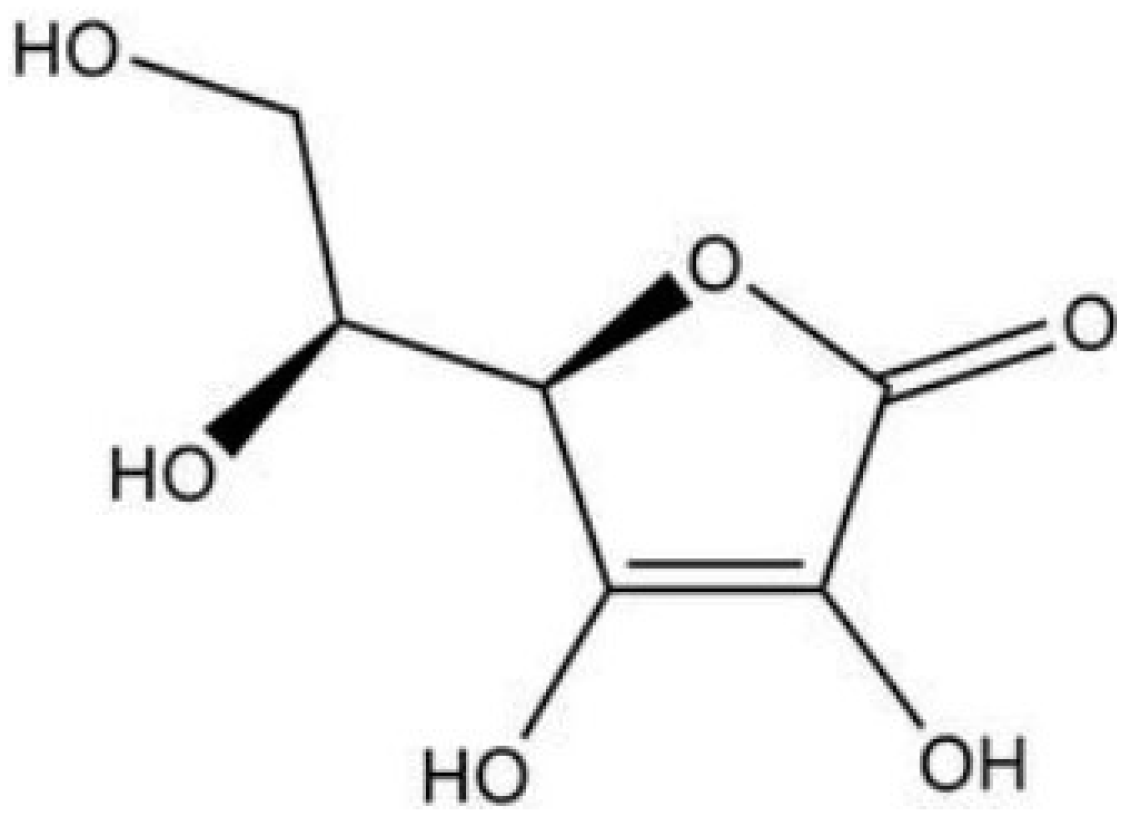

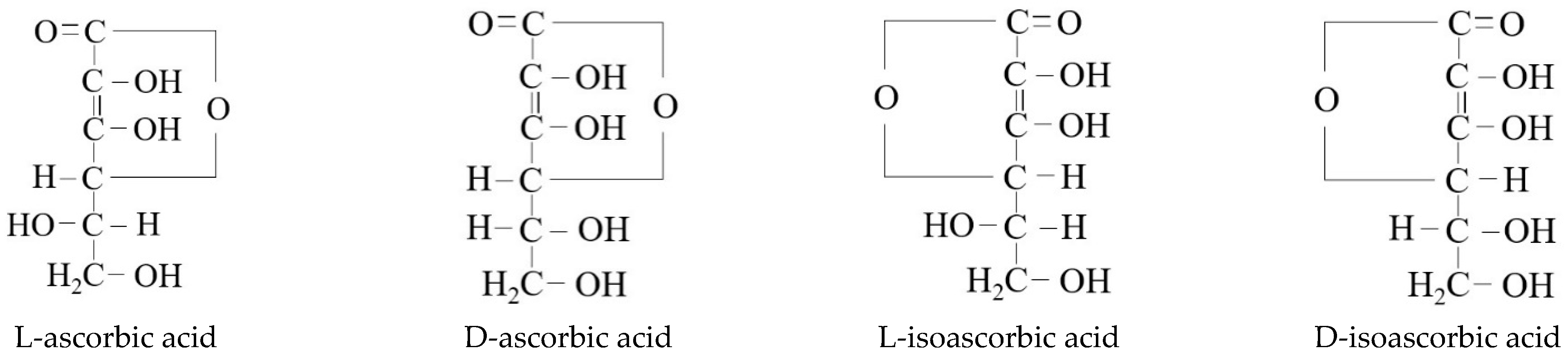

2.1. Influence of Drying Temperature on Vitamin C

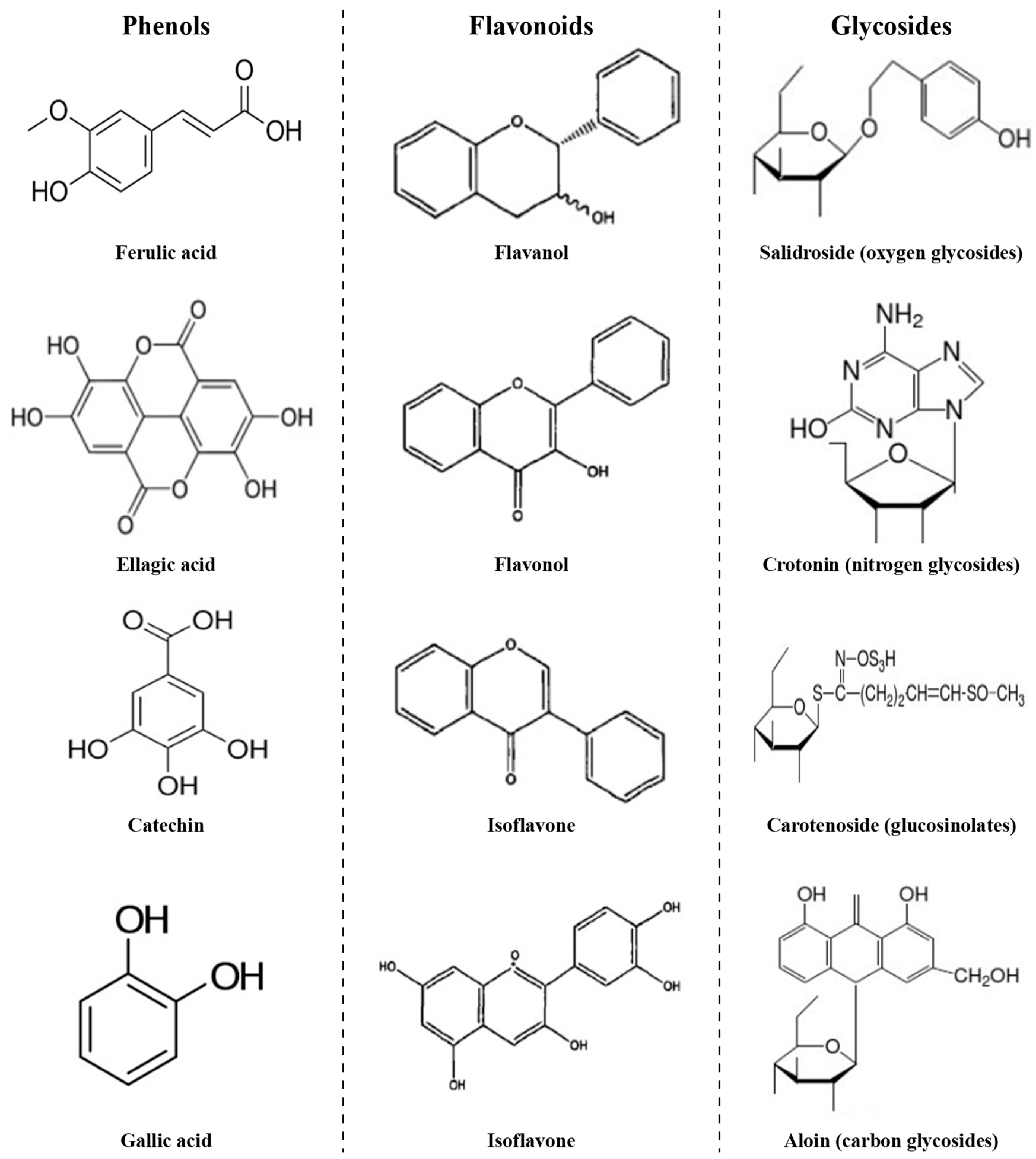

2.2. Influence of Drying Temperature on Phenols, Flavonoids and Glycosides

| Compounds | Product | Temperature | References |

|---|---|---|---|

| Phenols | Bee pollen | Fresh > 65 °C > 35 °C > 50 °C | [32] |

| Bitter orange | 45 °C > 60 °C | [68] | |

| Blueberry | 50 °C > 40 °C > 30 °C | [69] | |

| Blueberry | Fresh > 90 °C > 80 °C > 60 °C > 70 °C = 50 °C | [36] | |

| Cherry | Fresh > 50 °C > 60 °C > 70 °C | [70] | |

| Chrysanthemum | 45 °C > 75 °C | [71] | |

| Chrysanthemum | 55 °C > 65 °C > 75 °C | [37] | |

| Cordyceps militaris | 70 °C > 60 °C > 50 °C > 40 °C | [72] | |

| Ganoderma lucidum | 70 °C > 50 °C | [64] | |

| Lemon | 75 °C > 50 °C | [73] | |

| Lemon myrtle- leaf | 90 °C > 70 °C > 50 °C | [74] | |

| Mango | 55 °C > 65 °C | [63] | |

| Mango | 50 °C > 65 °C > Fresh | [38] | |

| Maquiberries | Fresh > 60 °C > 70 °C > 50 °C > 40 °C > 80 °C | [10] | |

| Papaya | 60 °C > 70 °C > 80 °C | [75] | |

| Papaya | Fresh > 50 °C > 60 °C > 70 °C | [76] | |

| Pomegranate leather | 70 °C > 60 °C > 50 °C | [42] | |

| Red pepper | Fresh > 60 °C = 90 °C > 70 °C > 80 °C > 50 °C | [44] | |

| Strawberry | 50 °C > 60 °C | [77] | |

| Sweet pepper | Fresh > 60 °C > 50 > 40 °C | [34] | |

| Tomato | Fresh > 60 °C > 50 > 40 °C | [34] | |

| Tomato | Fresh > 70 °C > 60 °C > 50 °C | [78] | |

| Flavonoids | Chrysanthemum | 75 °C > 45 °C | [71] |

| Chrysanthemum | 55 °C > 65 °C > 75 °C | [37] | |

| Ganoderma lucidum | 70 °C > 50 °C | [64] | |

| Lemon | 75 °C > 50 °C | [73] | |

| Lemon myrtle-leaf | 90 °C > 70 °C > 50 °C | [74] | |

| Mango | 45 °C > 60 °C | [63] | |

| Mango | 50 °C > 65 °C | [38] | |

| Maquiberries | Fresh > 70 °C > 50 °C > 60 °C > 40 °C > 80 °C | [10] | |

| Myrciaria jaboticaba | 55 °C > 65 °C > 75 °C | [79] | |

| Pomegranate leather | 50 °C > 70 °C > 60 °C | [42] | |

| Sweet pepper | Fresh > 60 °C > 50 > 40 °C | [34] | |

| Tomato | Fresh > 60 °C > 50 > 40 °C | [34] | |

| Tomato | Fresh > 60 °C > 70 °C > 50 °C | [78] | |

| Glycosides | Ganoderma lucidum | 70 °C > 50 °C | [64] |

| Ginseng | 50 °C > 60 °C > 70 °C | [80] | |

| Mango | 45 °C > 60 °C | [63] |

2.3. Influence of Drying Temperature on Volatile Compounds

2.4. Influence of Drying Temperature on Antioxidant Activity

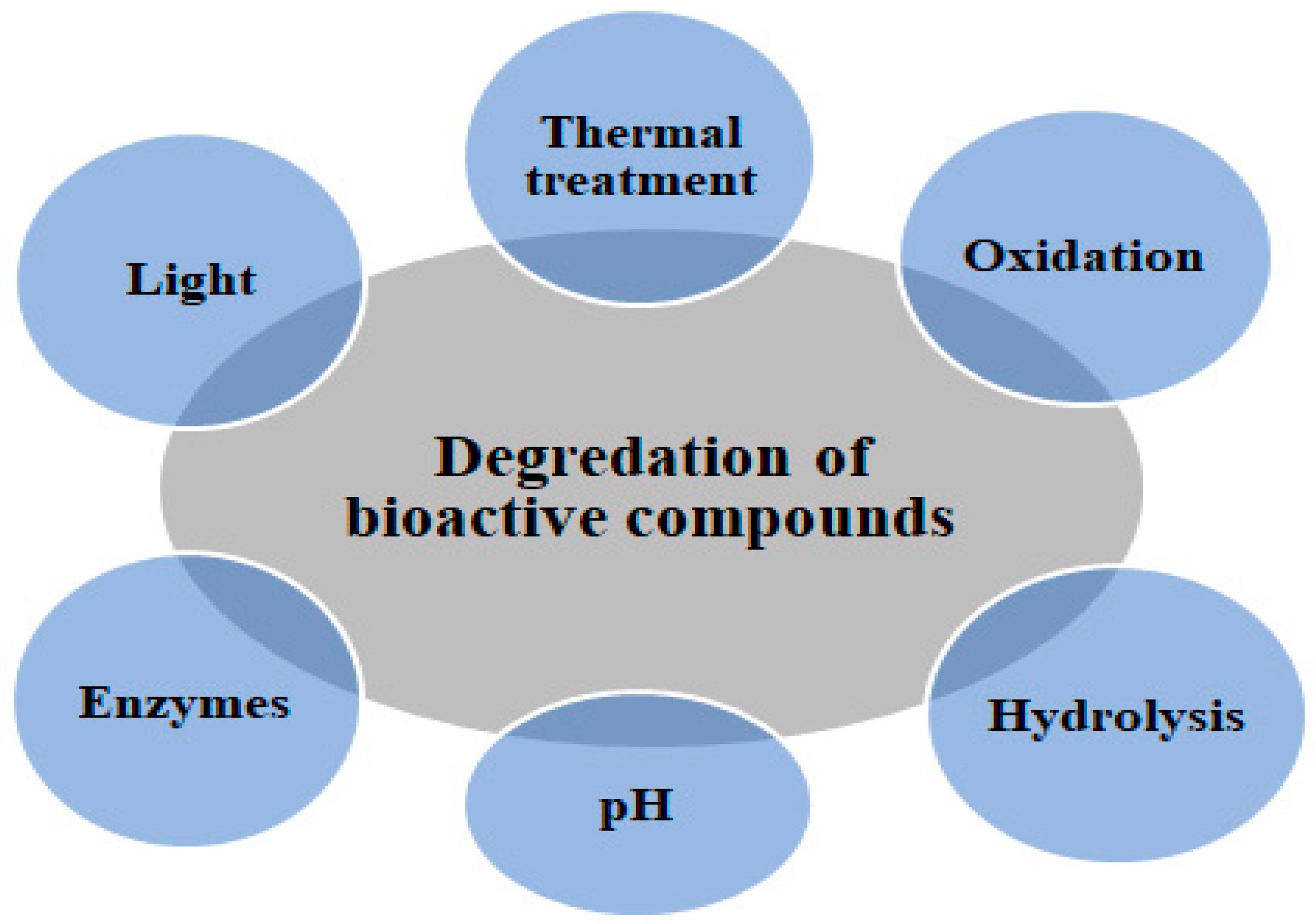

3. Degradation Mechanisms of Bioactive Compounds

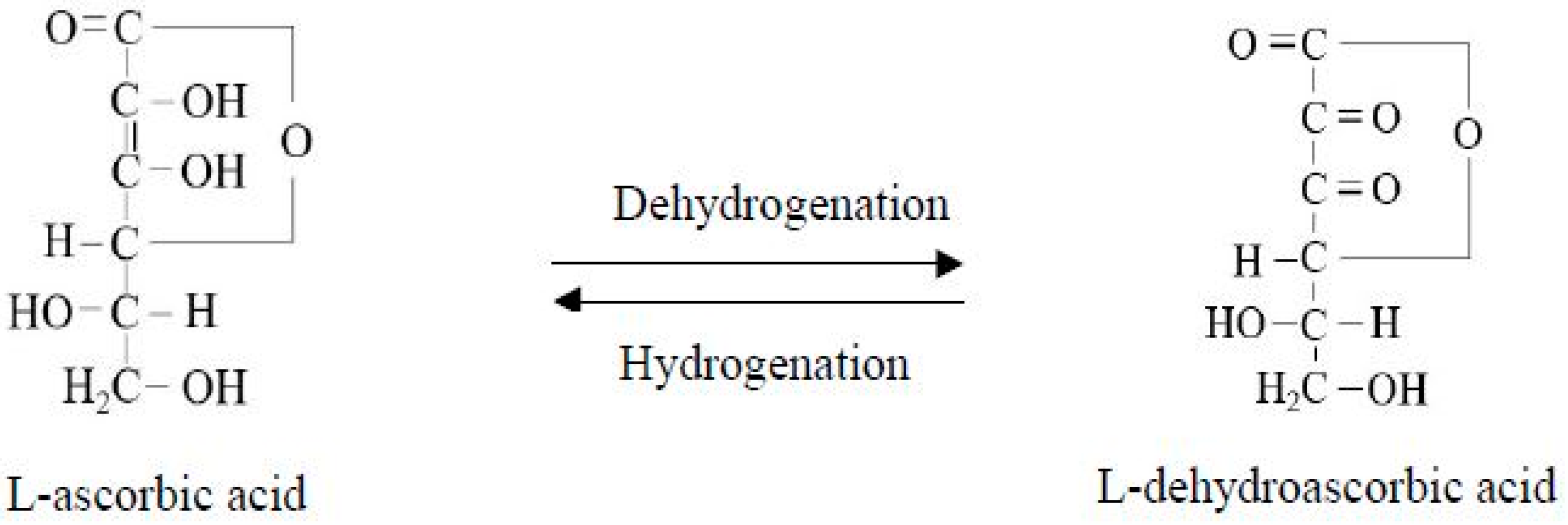

3.1. Degradation Mechanism of Vitamin C

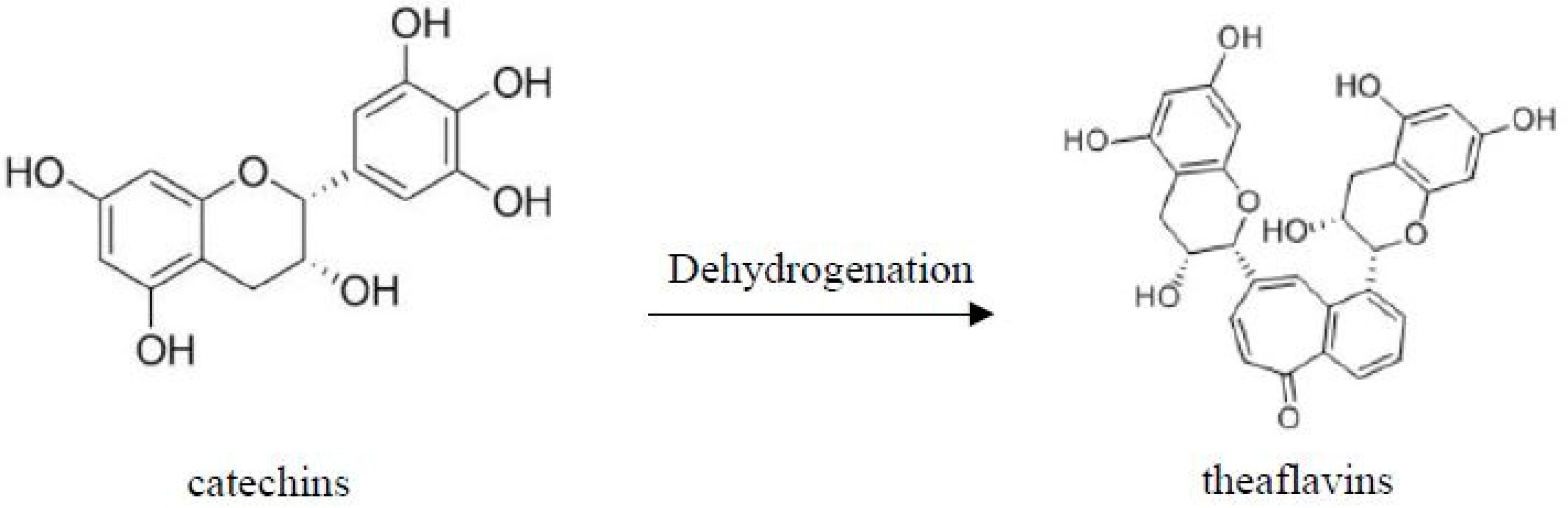

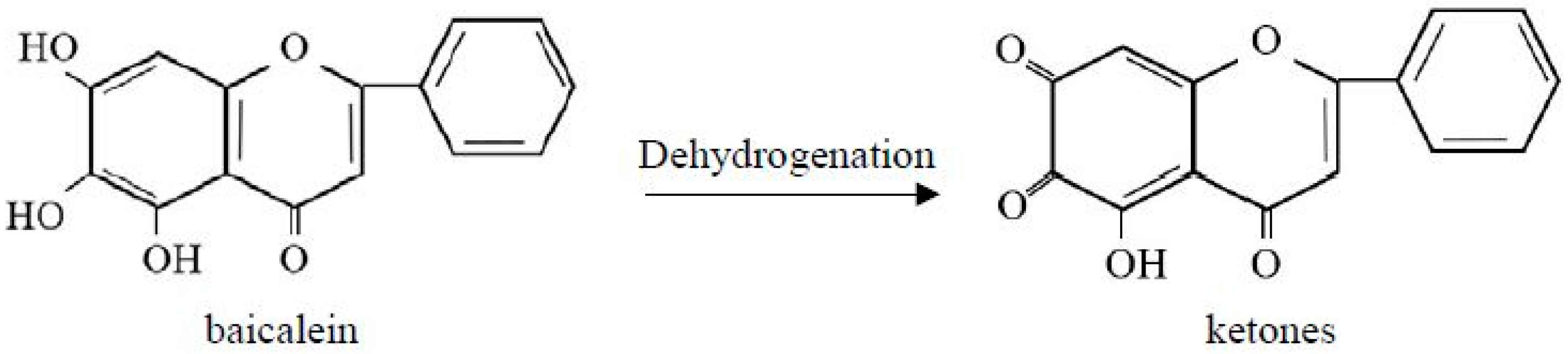

3.2. Degradation Mechanisms of Phenols, Flavonoids and Glycosides

3.3. Degradation Mechanism of Volatile Compounds

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rocha, P.R.; Melo, E.C. Influence of drying process on the quality of medicinal plants: A review. J. Med. Plants Res. 2011, 5, 7076–7084. [Google Scholar] [CrossRef]

- Thamkaew, G.; Sjöholm, I.; Galindo, F.G. A review of drying methods for improving the quality of dried herbs. Crit. Rev. Food Sci. Nutr. 2020, 61, 1763–1786. [Google Scholar] [CrossRef]

- ElGamal, R.; Liu, C. Experimental and simulation study on shrinkage of Radix Paeoniae Alba slices during drying process. Dry Technol. 2021, 40, 1994–2005. [Google Scholar] [CrossRef]

- Singhal, S.; Rasane, P.; Kaur, S.; Singh, J.; Gupta, N. Thermal degradation kinetics of bioactive compounds in button mushroom (Agaricus bisporus) during tray drying process. J. Food Process Eng. 2020, 43, e13555. [Google Scholar] [CrossRef]

- Salinas, J.G.; Alvarado, J.A.; Bergenståhl, B.; Tornberg, E. The influence of convection drying on the physicochemical properties of yacón (Smallanthus sonchifolius). Heat Mass Transf. 2018, 54, 2951–2961. [Google Scholar] [CrossRef] [Green Version]

- Benjamin, M.A.Z.; Ng, S.Y.; Saikim, F.H.; Rusdi, N.A. The Effects of Drying Techniques on Phytochemical Contents and Biological Activities on Selected Bamboo Leaves. Molecules 2022, 27, 6458. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Song, C.; ElGamal, R.; Liu, C. Relationship between heat/mass transfer and color change during drying process. J. Food Meas. Charact. 2022, 16, 4151–4160. [Google Scholar] [CrossRef]

- Alp, D.; Bulantekin, Ö. The microbiological quality of various foods dried by applying different drying methods: A review. Eur. Food Res. Technol. 2021, 247, 1333–1343. [Google Scholar] [CrossRef]

- Llave, Y.; Takemori, K.; Fukuoka, M.; Takemori, T.; Tomita, H.; Sakai, N. Mathematical modeling of shrinkage deformation in eggplant undergoing simultaneous heat and mass transfer during convection-oven roasting. J. Food Eng. 2016, 178, 124–136. [Google Scholar] [CrossRef]

- Rodríguez, K.; Ah-Hen, K.S.; Vega-Gálvez, A.; Vásquez, V.; Quispe-Fuentes, I.; Rojas, P.; Lemus-Mondaca, R. Changes in bioactive components and antioxidant capacity of maqui, Aristotelia chilensis [Mol] Stuntz, berries during drying. LWT–Food Sci. Technol. 2016, 65, 537–542. [Google Scholar] [CrossRef]

- Cao, X.; Chen, J.; Islam, M.N.; Xu, W.; Zhong, S. Effect of intermittent microwave volumetric heating on dehydration, energy consumption, antioxidant substances, and sensory qualities of Litchi fruit during vacuum drying. Molecules 2019, 24, 4291. [Google Scholar] [CrossRef] [Green Version]

- Amit, S.K.; Uddin, M.; Rahman, R.; Islam, S.M.R.; Khan, M.S. A review on mechanisms and commercial aspects of food preservation and processing. Agric. Food Secur. 2017, 6, 51. [Google Scholar] [CrossRef]

- Haghi, A.K.; Amanifard, N. Analysis of heat and mass transfer during microwave drying of food products. Braz. J. Chem. Eng. 2008, 25, 491–501. [Google Scholar] [CrossRef] [Green Version]

- Santos, D.I.; Saraiva, J.M.A.; Vicente, A.A.; Moldão-Martins, M. Methods for determining bioavailability and bioaccessibility of bioactive compounds and nutrients. In Innovative Thermal and Non-Thermal Processing, Bioaccessibility and Bioavailability of Nutrients and Bioactive Compounds; Elsevier: Amsterdam, The Netherlands, 2019; pp. 23–54. [Google Scholar]

- Câmara, J.S.; Albuquerque, B.R.; Aguiar, J.; Corrêa, R.C.G.; Gonçalves, J.L.; Granato, D.; Pereira, J.A.M.; Barros, L.; Ferreira, I.C.F.R. Food Bioactive Compounds and Emerging Techniques for Their Extraction: Polyphenols as a Case Study. Foods 2020, 10, 37. [Google Scholar] [CrossRef]

- Song, C.; Liu, C.; Chen, J. Relationship between heat/mass transfer and ingredient degradation during drying process. J. Food Process Eng. 2021, 45, e13917. [Google Scholar] [CrossRef]

- Nambi, V.E.; Gupta, R.K.; Kumar, S.; Sharma, P.C. Degradation kinetics of bioactive components, antioxidant activity, colour and textural properties of selected vegetables during blanching. J. Food Sci. Technol. 2016, 53, 3073–3082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, C.; Karim, M.; Joardder, M.U. Intermittent drying of food products: A critical review. J. Food Eng. 2013, 121, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Mudiyanselage, C.R.; Karunasena, H.; Gu, Y.; Guan, L.; Senadeera, W. Novel trends in numerical modelling of plant food tissues and their morphological changes during drying—A review. J. Food Eng. 2017, 194, 24–39. [Google Scholar] [CrossRef] [Green Version]

- Arvaniti, O.S.; Samaras, Y.; Gatidou, G.; Thomaidis, N.S.; Stasinakis, A.S. Review on fresh and dried figs: Chemical analysis and occurrence of phytochemical compounds, antioxidant capacity and health effects. Food Res. Int. 2019, 119, 244–267. [Google Scholar] [CrossRef]

- Kamiloglu, S.; Capanoglu, E. Polyphenol Content in Figs (Ficus Carica L.): Effect of Sun-Drying. Int. J. Food Prop. 2015, 18, 521–535. [Google Scholar] [CrossRef]

- McSweeney, M.; Seetharaman, K. State of polyphenols in the drying process of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2014, 55, 660–669. [Google Scholar] [CrossRef]

- Petikirige, J.; Karim, A.; Millar, G. Effect of drying techniques on quality and sensory properties of tropical fruits. Int. J. Food Sci. Technol. 2022, 57, 6963–6979. [Google Scholar] [CrossRef]

- Kim, S.; Lee, K.W.; Park, J.; Lee, H.J.; Hwang, I.K. Effect of drying in antioxidant activity and changes of ascorbic acid and colour by different drying and storage in Korean red pepper (Capsicum annuum, L.). Int. J. Food Sci. Technol. 2006, 41, 90–95. [Google Scholar] [CrossRef]

- Chang, C.-H.; Lin, H.-Y.; Chang, C.-Y.; Liu, Y.-C. Comparisons on the antioxidant properties of fresh, freeze-dried and hot-air-dried tomatoes. J. Food Eng. 2006, 77, 478–485. [Google Scholar] [CrossRef]

- Hacisevkd, A. An overview of ascorbic acid biochemistry. J. Fac. Pharm. Ank. Univ. 2009, 38, 233–255. [Google Scholar]

- Akbari, A.; Jelodar, G.; Nazifi, S.; Sajedianfard, J. An Overview of the Characteristics and Function of Vitamin C in Various Tissues: Relying on its Antioxidant Function. Zahedan J. Res. Med. Sci. 2016, 18, e4037. [Google Scholar] [CrossRef] [Green Version]

- Santos, P.H.S.; Silva, M.A. Retention of vitamin C in drying processes of fruits and vegetables—A review. Dry Technol. 2008, 26, 1421–1437. [Google Scholar] [CrossRef]

- Hal, P.H.-V.; Bosschaart, C.; van Twisk, C.; Verkerk, R.; Dekker, M. Kinetics of thermal degradation of vitamin C in marula fruit (Sclerocarya birrea subsp. caffra) as compared to other selected tropical fruits. LWT 2012, 49, 188–191. [Google Scholar] [CrossRef]

- Mieszczakowska-Frąc, M.; Celejewska, K.; Płocharski, W. Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products. Antioxidants 2021, 10, 54. [Google Scholar] [CrossRef]

- Takougnadi, E.; Boroze, T.-E.T.; Azouma, O.Y. Effects of drying conditions on energy consumption and the nutritional and organoleptic quality of dried bananas. J. Food Eng. 2019, 268, 109747. [Google Scholar] [CrossRef]

- Kanar, Y.; Mazı, B.G. Effect of different drying methods on antioxidant characteristics of bee-pollen. J. Food Meas. Charact. 2019, 13, 3376–3386. [Google Scholar] [CrossRef]

- Tajudin, N.H.A.; Tasirin, S.M.; Ang, W.L.; Rosli, M.; Lim, L.C. Comparison of drying kinetics and product quality from convective heat pump and solar drying of roselle calyx. Food Bioprod. Process. 2019, 118, 40–49. [Google Scholar] [CrossRef]

- Kaur, R.; Kaur, K.; Ahluwalia, P. Effect of drying temperatures and storage on chemical and bioactive attributes of dried tomato and sweet pepper. LWT–Food Sci. Technol. 2019, 117, 108604. [Google Scholar] [CrossRef]

- Idah, P.A.; Musa, J.J.; Olaleye, S.T. Effect of Temperature and Drying Time on Some Nutritional Quality Parameters of Dried Tomatoes. Agric. Bioresour. Eng. 2010, 14, 25–32. [Google Scholar]

- López, J.; Uribe, E.; Vega-Gálvez, A.; Miranda, M.; Vergara, J.; Gonzalez, E.; Di Scala, K. Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O´Neil. Food Bioprocess Technol. 2010, 3, 772–777. [Google Scholar] [CrossRef]

- Shi, X.-F.; Chu, J.-Z.; Zhang, Y.-F.; Liu, C.-Q.; Yao, X.-Q. Nutritional and active ingredients of medicinal chrysanthemum flower heads affected by different drying methods. Ind. Crop. Prod. 2017, 104, 45–51. [Google Scholar] [CrossRef]

- Nyangena, I.O.; Owino, W.O.; Imathiu, S.; Ambuko, J. Effect of pretreatments prior to drying on antioxidant properties of dried mango slices. Sci. Afr. 2019, 6, e00148. [Google Scholar] [CrossRef]

- Alibas, I. Determination of drying parameters, ascorbic acid contents and color characteristics of nettle leaves during microwave, air and combined microwave air drying. J. Food Process Eng. 2010, 33, 213–233. [Google Scholar] [CrossRef]

- Seifu, M.; Tola, Y.B.; Mohammed, A.; Astatkie, T. Effect of variety and drying temperature on physicochemical quality, functional property, and sensory acceptability of dried onion powder. Food Sci. Nutr. 2018, 6, 1641–1649. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kurozawa, L.E.; Terng, I.; Hubinger, M.D.; Park, K.J. Ascorbic acid degradation of papaya during drying: Effect of process conditions and glass transition phenomenon. J. Food Eng. 2014, 123, 157–164. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Effects of different drying methods on the physicochemical properties of pomegranate leather (pestil). LWT 2017, 80, 294–303. [Google Scholar] [CrossRef]

- Arslan, D.; Özcan, M. Dehydration of red bell-pepper (Capsicum annuum L.): Change in drying behavior, colour and antioxidant content. Food Bioprod. Process. 2011, 89, 504–513. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Di Scala, K.; Rodríguez, K.; Lemus-Mondaca, R.; Miranda, M.; López, J.; Perez-Won, M. Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem. 2009, 117, 647–653. [Google Scholar] [CrossRef]

- Erenturk, S.; Gulaboglu, M.S.; Gultekin, S. The effects of cutting and drying medium on the vitamin C content of rosehip during drying. J. Food Eng. 2005, 68, 513–518. [Google Scholar] [CrossRef]

- Kosasih, E.A.; Rafdi, M. Firdaus Experimental investigation of vitamin C yield of tomatoes and vitamin C essence by spray drying and dehumidifying the drying air: Product quality and energy consumption. AIP Conf. Proc. 2018, 2001, 040007. [Google Scholar] [CrossRef]

- Adam, E.; Mühlbauer, W.; Esper, A.; Wolf, W.; Spiess, W. Quality changes of anion by drying. Nahrung 2000, 44, 32–37. [Google Scholar] [CrossRef]

- Kerkhofs, N.S.; Lister, C.; Savage, G.P. Change in colour and antioxidant content of tomato cultivars following forced air drying. Plant Foods Hum. Nutr. 2005, 60, 117–121. [Google Scholar] [CrossRef]

- Igwemmar, N.C.; Kolawole, S.A.; Imran, I.A. Effect of Heating on Vitamin C Content of some selected Vegetables. Int. J. Sci. Technol. Res. 2013, 2, 209–212. [Google Scholar]

- Ojike, O.; Nwoke, O.O.; Okonkwo, W.I. The influence of different solar drying systems on the vitamin content of Pawpaw (Carica papaya). Aust. J. Agric. Eng. 2011, 2, 8–11. [Google Scholar]

- Dağhan, Ş.; Yildirim, A.; Yilmaz, F.M.; Vardin, H.; Karaaslan, M. The effect of temperature and method of drying on Isot (Urfa pepper) and its vitamin C degradation kinetics. Ital. J. Food Sci. 2018, 30, 504–521. [Google Scholar] [CrossRef]

- Goula, A.; Adamopoulos, K.G. Retention of Ascorbic Acid during Drying of Tomato Halves and Tomato Pulp. Dry Technol. 2006, 24, 57–64. [Google Scholar] [CrossRef]

- Demiray, E.; Tulek, Y. Color degradation kinetics of carrot (Daucus carota L.) slices during hot air drying. J. Food Process. Preserv. 2014, 39, 800–805. [Google Scholar] [CrossRef]

- Alseekh, S.; de Souza, L.P.; Benina, M.; Fernie, A.R. The style and substance of plant flavonoid decoration; towards defining both structure and function. Phytochemistry 2020, 174, 112347. [Google Scholar] [CrossRef]

- De Llano, D.G.; Liu, H.; Khoo, C.; Moreno-Arribas, M.V.; Bartolomé, B. Some New Findings Regarding the Antiadhesive Activity of Cranberry Phenolic Compounds and Their Microbial-Derived Metabolites against Uropathogenic Bacteria. J. Agric. Food Chem. 2019, 67, 2166–2174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Craft, B.D.; Kerrihard, A.L.; Amarowicz, R.; Pegg, R.B. Phenol-based antioxidants and the in vitro methods used for their assessment. Compr. Rev. Food Sci. Food Saf. 2012, 11, 148–173. [Google Scholar] [CrossRef]

- Shahidi, F.; Naczk, M. Phenolics in Food and Nutraceuticals, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Panche, A.N.; Diwan, A.D.; Chandra, S.R. Flavonoids: An overview. J. Nutr. Sci. 2016, 5, e47. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W.; Dong, W.; Zhang, P.; Qianqian, S.U.; Fan, R.; Liu, Y. Detection of Related Substances and Preliminary Study on the Degradation Mechanism of Baicalein. China Pharm. 2017, 28, 803–808. [Google Scholar]

- Xiao, J. Dietary flavonoid aglycones and their glycosides: Which show better biological significance? Crit. Rev. Food Sci. Nutr. 2015, 57, 1874–1905. [Google Scholar] [CrossRef]

- Brito-Arias, M. Hydrolysis of glycosides. In Synthesis and Characterization of Glycosides; Springer: Boston, MA, USA, 2007; pp. 304–313. [Google Scholar]

- Jeong, S.-M.; Kim, S.-Y.; Kim, D.-R.; Jo, S.-C.; Nam, K.C.; Ahn, D.U.; Lee, S.-C. Effect of Heat Treatment on the Antioxidant Activity of Extracts from Citrus Peels. J. Agric. Food Chem. 2004, 52, 3389–3393. [Google Scholar] [CrossRef]

- Oliver-Simancas, R.; Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Alañón, M.E. Viability of pre-treatment drying methods on mango peel by-products to preserve flavouring active compounds for its revalorisation. J. Food Eng. 2020, 279, 109953. [Google Scholar] [CrossRef]

- Dong, Q.; He, D.; Ni, X.; Zhou, H.; Yang, H. Comparative study on phenolic compounds, triterpenoids, and antioxidant activity of Ganoderma lucidum affected by different drying methods. J. Food Meas. Charact. 2019, 13, 3198–3205. [Google Scholar] [CrossRef]

- Abrol, G.S.; Vaidya, D.; Sharma, A.; Sharma, S. Effect of solar drying on physico-chemical and antioxidant properties of mango, banana and papaya. Natl. Acad. Sci. Lett. 2014, 37, 51–57. [Google Scholar] [CrossRef]

- Elsheshetawy, H.; Mossad, A.; Elhelew, W.; Farina, V. Comparative study on the quality characteristics of some Egyptian mango cultivars used for food processing. Ann. Agric. Sci. 2016, 61, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Chaaban, H.; Ioannou, I.; Chebil, L.; Slimane, M.; Gérardin, C.; Paris, C.; Charbonnel, C.; Chekir, L.; Ghoul, M. Effect of heat processing on thermal stability and antioxidant activity of six flavonoids. J. Food Process. Preserv. 2017, 41, e13203. [Google Scholar] [CrossRef]

- Farahmandfar, R.; Tirgarian, B.; Dehghan, B.; Nemati, A. Comparison of different drying methods on bitter orange (Citrus aurantium L.) peel waste: Changes in physical (density and color) and essential oil (yield, composition, antioxidant and antibacterial) properties of powders. J. Food Meas. Charact. 2019, 14, 862–875. [Google Scholar] [CrossRef]

- Martín-Gómez, J.; Varo, M.; Mérida, J.; Serratosa, M.P. Influence of drying processes on anthocyanin profiles, total phenolic compounds and antioxidant activities of blueberry (Vaccinium corymbosum). LWT–Food Sci. Technol. 2019, 120, 108931. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.; Ma, D.; Li, X.; Gao, X.; Miao, J.; Gao, W. Improving the contents of the active components and bioactivities of Chrysanthemum morifolium Ramat.: The effects of drying methods. Food Biosci. 2019, 29, 9–16. [Google Scholar] [CrossRef]

- Wu, X.-F.; Zhang, M.; Li, Z. Influence of infrared drying on the drying kinetics, bioactive compounds and flavor of Cordyceps militaris. LWT 2019, 111, 790–798. [Google Scholar] [CrossRef]

- M’hiri, N.; Ghali, R.; Ben Nasr, I.; Boudhrioua, N. Effect of different drying processes on functional properties of industrial lemon byproduct. Process. Saf. Environ. Prot. 2018, 116, 450–460. [Google Scholar] [CrossRef]

- Saifullah; McCullum, R.; McCluskey, A.; Vuong, Q. Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon 2019, 5, e03044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yap, J.Y.; Hii, C.L.; Ong, S.P.; Lim, K.H.; Abas, F.; Pin, K.Y. Effects of drying on total polyphenols content and antioxidant properties of Carica papaya leaves. J. Sci. Food Agric. 2020, 100, 2932–2937. [Google Scholar] [CrossRef] [PubMed]

- Szychowski, P.J.; Lech, K.; Sendra-Nadal, E.; Hernández, F.; Figiel, A.; Wojdyło, A.; Carbonell-Barrachina, A. Kinetics, biocompounds, antioxidant activity, and sensory attributes of quinces as affected by drying method. Food Chem. 2018, 255, 157–164. [Google Scholar] [CrossRef]

- Méndez-Lagunas, L.; Rodríguez-Ramírez, J.; Cruz-Gracida, M.; Sandoval-Torres, S.; Barriada-Bernal, G. Convective drying kinetics of strawberry (Fragaria ananassa): Effects on antioxidant activity, anthocyanins and total phenolic content. Food Chem. 2017, 230, 174–181. [Google Scholar] [CrossRef]

- Azeez, L.; Adebisi, S.A.; Oyedeji, A.O.; Adetoro, R.O.; Tijani, K.O. Bioactive compounds’ contents, drying kinetics and mathematical modelling of tomato slices influenced by drying temperatures and time. J. Saudi Soc. Agric. Sci. 2019, 18, 120–126. [Google Scholar] [CrossRef]

- Inada, K.O.P.; Nunes, S.; Martínez-Blázquez, J.A.; Tomás-Barberán, F.A.; Perrone, D.; Monteiro, M. Effect of high hydrostatic pressure and drying methods on phenolic compounds profile of jabuticaba (Myrciaria jaboticaba) peel and seed. Food Chem. 2019, 309, 125794. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Song, C.; Li, J.; Song, F.; Zhu, G.; Liu, M. Effects of combined infrared and hot-air drying on ginsenosides and sensory properties of ginseng root slices (Panax ginseng Meyer). J. Food Process. Preserv. 2019, 44, e14312. [Google Scholar] [CrossRef]

- Pinto, T.; Aires, A.; Cosme, F.; Bacelar, E.; Morais, M.C.; Oliveira, I.; Ferreira-Cardoso, J.; Anjos, R.; Vilela, A.; Gonçalves, B. Bioactive (poly)phenols, volatile compounds from vegetables, medicinal and aromatic plants. Foods 2021, 10, 106. [Google Scholar] [CrossRef]

- Navarro, V.; Teruel, N.; Carratalá, M. Oxidation stability of almond oil. Acta Hortic. 2002, 591, 125–131. [Google Scholar] [CrossRef]

- Ka, M.-H.; Choi, E.H.; Chun, H.-S.; Lee, K.-G. Antioxidative activity of volatile extracts isolated from Angelica tenuissimae roots, peppermint leaves, pine needles, and sweet flag leaves. J. Agric. Food Chem. 2005, 53, 4124–4129. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Hao, N.; Meng, Z.; Li, Y.; Zhao, Z. Identification, Comparison and Classification of Volatile Compounds in Peels of 40 Apple Cultivars by HS–SPME with GC–MS. Foods 2021, 10, 1051. [Google Scholar] [CrossRef] [PubMed]

- Gou, M.; Bi, J.; Chen, Q.; Wu, X.; Fauconnier, M.-L.; Qiao, Y. Advances and Perspectives in Fruits and Vegetables Flavor Based on Molecular Sensory Science. Food Rev. Int. 2021. [Google Scholar] [CrossRef]

- Xu, L.; Zang, E.; Sun, S.; Li, M. Main flavor compounds and molecular regulation mechanisms in fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2022. [Google Scholar] [CrossRef] [PubMed]

- Hansen, R.C.; Keener, H.M.; ElSohly, H.N. Thin-layer drying of cultivated Taxus clippings. Trans. ASAE 1993, 36, 1387–1391. [Google Scholar] [CrossRef]

- Radünz, L.; Melo, E.; Rocha, R.; Berbert, P.; Gracia, L. Study of essential oil from guaco leaves submitted to different drying air temperature. Eng. Na Agric. 2010, 18, 241–247. [Google Scholar] [CrossRef]

- Krokida, M.; Philippopoulos, C. Volatility of apples during air and freeze drying. J. Food Eng. 2006, 73, 135–141. [Google Scholar] [CrossRef]

- Deans, S.; Svoboda, K. Effect of drying regime on volatile oil and microflora of aromatic plants. Acta Hortic. 1992, 306, 450–452. [Google Scholar] [CrossRef]

- Soares, R.D.; Chaves, M.A.; Silva, A.A.L.d.; Silva, M.V.d.; Souza, B.d.S. Influence of drying temperature and air velocity related to essential oil and linalol contents of the basil (Ocimum basilicum L.). Ciência E Tecnol. De Aliment. 2007, 31, 1108–1113. [Google Scholar] [CrossRef]

- Müller, J.; Köll-Weber, M.; Kraus, W.; Mühlbauer, W. Trocknungsverhalten von Kamille (Chamomilla recutita (L.) Rauschert). Zeitschrift fuer Arzneiund Gewuerzpflanzen 1996, 1, 104–110. [Google Scholar]

- Buggle, V.; Ming, L.C.; Furtado, E.L.; Rocha, S.F.R.; Marques, M.O.M. Influence of different drying temperatures on the amount of essential oils and citral content in Cymbopogon Citratus (dc) stap-fpoaceae. ISHS Acta Hortic. 1997, 500, 71–74. [Google Scholar] [CrossRef]

- Radünz, L.L. Dried Rosemary Pepper, and Mint together on Guaco Different Temperatures and Its Influence on the Quantity and Quality of Active Ingredients. Ph.D. Thesis, University of Viçosa, Viçosa, Brazil, 2004. [Google Scholar]

- Radünz, L.L. Influência da temperatura do ar secagem no rendimento do óleo essencial d hortelã-comum (Mentha x villosa Huds). Engenharia na Agricultura 2006, 14, 250–257. [Google Scholar]

- Braga, N.P.; Cremasco, M.A.; Valle, R.D.C.S.C. The effects of fixed-bed drying on the yield and composition of essential oil from long pepper (Piper hispidinervium C. DC) leaves. Braz. J. Chem. Eng. 2005, 22, 257–262. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.; Oon, C.C.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdylo, A.; Turkiewicz, I.P.; Szumny, A.; Łyczko, J. Volatile and polyphenol composition, anti-oxidant, anti-diabetic and anti-aging properties, and drying kinetics as affected by convective and hybrid vacuum microwave drying of Rosmarinus officinalis L. Ind. Crop. Prod. 2020, 151, 112463. [Google Scholar] [CrossRef]

- Arabhosseini, A.; Padhye, S.; van Beek, T.A.; van Boxtel, A.J.B.; Huisman, W.; Posthumus, M.A.; Müller, J. Loss of essential oil of tarragon (Artemisia dracunculus L.) due to drying. J. Sci. Food Agric. 2006, 86, 2543–2550. [Google Scholar] [CrossRef]

- Venskutonis, P.R. Effect of drying on the volatile constituents of thyme (Thymus vulgaris L.) and sage (Salvia officinalis L.). Food Chem. 1997, 59, 219–227. [Google Scholar] [CrossRef]

- Shahidi, F.; Zhong, Y. Measurement of antioxidant activity. J. Funct. Foods 2015, 18, 757–781. [Google Scholar] [CrossRef]

- Huang, D.; Ou, B.; Prior, R.L. The chemistry behind antioxidant capacity assays. J. Agric. Food Chem. 2005, 53, 1841–1856. [Google Scholar] [CrossRef]

- Pellegrini, N.; Vitaglione, P.; Granato, D.; Fogliano, V. Twenty-five years of total antioxidant capacity measurement of foods and biological fluids: Merits and limitations. J. Sci. Food Agric. 2020, 100, 5064–5078. [Google Scholar] [CrossRef]

- Demarchi, S.M.; Quintero Ruiz, N.A.; Concellón, A.; Ginera, S.A. Effect of Temperature on Hot-Air Drying Rate and on Retention of Antioxidant Capacity in Apple Leathers. Food Bioprod. Process. 2010, 91, 310–318. [Google Scholar] [CrossRef]

- Miranda, M.; Maureira, H.; Rodríguez, K.; Vega-Gálvez, A. INFLUENCE of Temperature on the Drying Kinetics, Physicochemical Properties, and Antioxidant Capacity of Aloe Vera (Aloe Barbadensis Miller) gel. J. Food Eng. 2009, 91, 297–304. [Google Scholar] [CrossRef]

- Kuljarachanan, T.; Devahastin, S.; Chiewchan, N. Evolution of Antioxidant Compounds in Lime Residues during Drying. Food Chem. 2009, 113, 944–949. [Google Scholar] [CrossRef]

- Katsube, T.; Tsurunaga, Y.; Sugiyama, M.; Furuno, T.; Yamasaki, Y. Effect of Air-Drying Temperature on Antioxidant Capacity and Stability of Polyphenolic Compounds in Mulberry (Morus alba L.) Leaves. Food Chem. 2009, 113, 964–969. [Google Scholar] [CrossRef]

- López-Vidaña, E.C.; Rojano, B.A.; Figueroa, I.P.; Zapata, K.; Cortés, F.B. Evaluation of the Sorption Equilibrium and Effect of Drying Temperature on the Antioxidant Capacity of the Jaboticaba (Myrciaria Cauliflora). Chem. Eng. Commun. 2016, 203, 809–821. [Google Scholar] [CrossRef]

- Chen, J.-P.; Wang, Y.; Zhang, X.-Y.; Sun, P.; Wu, Z.-F.; Shang, Y.-F.; Yang, S.-H.; Ma, Y.-L.; Wei, Z.-J. Effect of air drying temperature on the phenolics and antioxidant activity of Xuan-Mugua fruit. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Vashisth, T.; Singh Rakesh, K.; Pegg Ronald, B. Effects of Drying on the Phenolic Content and Antioxidant Activity of Muscadine Pomace. LWT–Food Sci. Technol. 2011, 44, 1649–1657. [Google Scholar] [CrossRef]

- Methakhup, S.; Chiewchan, N.; Devahastin, S. Effects of Drying Methods and Conditions on Drying Kinetics and Quality of Indian Gooseberry Flake. LWT–Food Sci. Technol. 2005, 38, 579–587. [Google Scholar] [CrossRef]

- Kamiloglu, S.; Toydemir, G.; Boyacioglu, D.; Beekwilder, J.; Hall, R.D.; Capanoglu, E. A review on the effect of drying on antioxidant potential of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2015, 56, S110–S129. [Google Scholar] [CrossRef]

- Piga, A.; Del Caro, A.; Corda, G. From Plums to Prunes: Influence of Drying Parameters on Polyphenols and Antioxidant Activity. J. Agric. Food Chem. 2003, 51, 3675–3681. [Google Scholar] [CrossRef] [PubMed]

- López-Vidaña, E.C.; Figueroa, I.P.; Cortés, F.B.; Rojano, B.A.; Ocaña, A.N. Effect of temperature on antioxidant capacity during drying process of mortiño (Vaccinium meridionale Swartz). Int. J. Food Prop. 2016, 20, 294–305. [Google Scholar] [CrossRef] [Green Version]

- Vidinamo, F.; Fawzia, S.; Karim, M.A. Effect of drying methods and storage with agro-ecological conditions on phytochemicals and antioxidant activity of fruits: A review. Crit. Rev. Food Sci. Nutr. 2020, 62, 353–361. [Google Scholar] [CrossRef] [PubMed]

- Dalla Nora, C.; Müller, C.D.-R.; de Bona, G.S.; de Oliveira Rios, A.; Hertz, P.F.; Jablonski, A.; de Jong, E.V.; Flôres, S.H. Effect of processing on the stability of bioactive compounds from red guava (Psidium cattleyanum Sabine) and guabiju (Myrcianthes pungens). J. Food Compos. Anal. 2014, 34, 18–25. [Google Scholar] [CrossRef]

- Roman, M.C.; Fabani, M.P.; Luna, L.C.; Feresin, G.E.; Mazza, G.; Rodriguez, R. Convective drying of yellow discarded onion (Angaco INTA): Modelling of moisture loss kinetics and effect on phenolic compounds. Inf. Process. Agric. 2020, 7, 333–341. [Google Scholar] [CrossRef]

- Tiwari, B.K.; O’Donnell, C.P.; Muthukumarappan, K.; Cullen, P.J. Anthocyanin and colour degradation in ozone treated blackberry juice. Innov. Food Sci. Emerg. Technol. 2009, 10, 70–75. [Google Scholar] [CrossRef]

- Rashmi, H.B.; Negi, P.S. Phenolic acids from vegetables: A review on processing stability and health benefits. Food Res. Int. 2020, 136, 109298. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Bari, S.S.; Singh, H.P. Biotransformation of tea catechins into theaflavins with immobilized polyphenol oxidase. J. Mol. Catal. B Enzym. 2009, 56, 253–258. [Google Scholar] [CrossRef]

- Alem, H.; Rigou, P.; Schneider, R.; Ojeda, H.; Torregrosa, L. Impact of agronomic practices on grape aroma composition: A review. J. Sci. Food Agric. 2018, 99, 975–985. [Google Scholar] [CrossRef]

- Gąsecka, M.; Siwulski, M.; Magdziak, Z.; Budzyńska, S.; Stuper-Szablewska, K.; Niedzielski, P.; Mleczek, M. The effect of drying temperature on bioactive compounds and antioxidant activity of Leccinum scabrum (Bull.) Gray and Hericium erinaceus (Bull.) Pers. J. Food Sci. Technol. 2019, 57, 513–525. [Google Scholar] [CrossRef] [Green Version]

- Teles, A.S.C.; Chávez, D.W.H.; Gomes, F.D.S.; Cabral, L.M.C.; Tonon, R.V. Effect of temperature on the degradation of bioactive compounds of Pinot Noir grape pomace during drying. Braz. J. Food Technol. 2017, 21, e2017059. [Google Scholar] [CrossRef] [Green Version]

| Product | Temperature | References |

|---|---|---|

| Banana | Fresh > 65 °C > 45 °C | [31] |

| Bee pollen | Fresh > 35 °C > 50 °C > 65 °C | [32] |

| Blueberry | Fresh > 90 °C > 50 °C > 60 °C > 70 °C > 80 °C | [36] |

| Chrysanthemum | 55 °C > 65 °C > 75 °C | [37] |

| Mango | 50 °C > 65 °C | [38] |

| Nettle leaves | Fresh > 75 °C > 50 °C | [39] |

| Onion | Fresh > 50 °C > 60 °C > 70 °C > 80 °C > 90 °C | [40] |

| Papaya | 40 °C > 50 °C > 60 °C > 70 °C | [41] |

| Pomegranate leather | 50 °C > 60 °C > 70 °C | [42] |

| Red bell-pepper | Fresh > 50 °C > 60 °C > 70 °C | [43] |

| Red pepper | Fresh > 50 °C > 60 °C > 70 °C > 80 °C > 90 °C | [44] |

| Rosehip | 50 °C > 60 °C > 70 °C | [45] |

| Roselle calyx | Fresh > 50 °C > 40 °C > 60 °C | [33] |

| Sweet pepper | Fresh > 40 °C > 50 °C > 60 °C | [34] |

| Tomato | Fresh > 40 °C > 50 °C > 60 °C | [34] |

| Tomato | 60 °C > 90 °C | [46] |

| Tomato | Fresh > 30 °C > 90 °C | [35] |

| Volatile Compounds | Odor Descriptions |

|---|---|

| Alcohols | |

| (E)-2-hexenol | green, fruity |

| 1-butanol | overall flavor, sweet aroma |

| 1-hexanol | fresh, green, earthy |

| 1-octen-3-ol | mushroom |

| 3-mercaptohexan-1-ol | sulfur and passion fruit |

| 3-octanol | earthy, mushroom, herbal |

| Benzyl alcohol | bitter almond-like, fruity |

| Benzene ethanol | flowery, floral, vegetal, woody |

| Linalool | citrus-like, flowery |

| Furaneol | sweet, caramel, candy |

| Methanethiol | sulfur, gasoline, and garlic |

| Octanol | jasmine, lemon |

| Menthol | mint-like |

| Aldehydes | |

| (E)-2-heptenal and (E)-2-octenal | green, leaf, and fat |

| 3-methylbutanal | malty |

| Benzaldehyde | sweet, fruity, roasted, almond, fragrant |

| Phenylacetaldehyde | sweet and fruity |

| Hexanal and heptanal | green, grassy |

| Furfural | bread, almond, and sweet |

| Nonanal and octanal | fat, citrus, green and fruity |

| (E)-2-octenal | green and leaf |

| Pentanal | almond, malt, pungent |

| Octanal | green, fruity, orange, citrus |

| Vanillin | vanilla-like, sweet |

| Decanal and nonanal | sweet, aldehydic, waxy and rose |

| Acids | |

| Propanoic acid and acetic acid | sour-like, sweaty |

| Hexanoic acid and butyric acid | sweaty, sour, cheesy and stink |

| Decanoic acid | soapy, musty |

| Nonanoic acid | moldy, pungent |

| Esters | |

| γ-octalactone | sweet, coconut, and peach |

| γ-hexalactone | sweet, spicy, coconut, and hay |

| Methyl benzoate, ethyl 2-methylbutanoate | herbal, fruity and flower |

| Ethyl propanoate | fruity, strawberry |

| Pentyl acetate | fruity, banana |

| Butyrolactone | sweet, flowery |

| Butyl butanoate | rotten apple |

| Hexyl butanoate | green |

| Methyl butanoate | fruity, sweet (lulo-like) |

| Ethyl butanoate, ethyl heptanoate | fruity |

| Methyl hexanoate | fruity, sweet (pineapple-like) |

| Ethyl hexanoate | fruity and wine |

| Ethyl octanoate | fat |

| 3-mercapohexyl acetate | sulfur, grapefruit, and fruity |

| Butyl acetate, ethyl acetate | sweets, fruity and ethereal |

| Products | Temperature | References |

|---|---|---|

| Apple | Fresh > 30 °C > 50 °C > 70 °C | [89] |

| Aromatic plants | 40 °C > 50 °C = 60 °C > 70 °C = 80 °C = 90 °C | [90] |

| Brazilian linalool | 40 °C > 50 °C > 60 °C > 70 °C | [91] |

| Chamomilla recutita | Fresh > 40 °C > 30 °C > 90 °C > 60 °C = 70 °C > 50 °C = 80 °C | [92] |

| Cordyceps militaris | 40 °C > 50 °C > 60 °C > 70 °C | [72] |

| Cymbopogon citratus | 50 °C > 30 °C > 70 °C > 90 °C | [93] |

| Guaco leaves | 50 °C > 70 °C > 40 °C > 60 °C > 80 °C > fresh | [88] |

| Mint | 50 °C > 60 °C > 70 °C | [94] |

| Mint | 50 °C > 40 °C > 60 °C > 70 °C > 80 °C | [95] |

| Pepper | 50 °C > 35 °C > 45 °C > 55 °C > 60 °C > 40 °C | [96] |

| Rosmarinus | 60 °C > 50 °C > 70 °C | [97] |

| Rosmarinus officinalis | 40 °C > 50 °C = 60 °C >> 70 °C = 80 °C > 90 °C | [90] |

| Tarragon | fresh > 90 °C > 45 °C > 60 °C | [98] |

| Taxus | 60 °C = 50 °C = 40 °C > 30 °C | [87] |

| Thymus vulgaris | Fresh > 30 °C > 60 °C | [99] |

| Products | Temperature | References |

|---|---|---|

| Bee pollen | Fresh > 50 °C > 35 °C > 65 °C | [32] |

| Bell pepper | Fresh > 60 °C > 50 °C > 40 °C | [34] |

| Bitter orange | 60 °C > 45 °C | [68] |

| Blueberry | 50 °C > 40 °C > 30 °C | [69] |

| Cherry | Fresh > 70 °C > 60 °C > 50 °C | [70] |

| Chrysanthemum | 75 °C > 45 °C | [71] |

| Ganoderma | 70 °C > 50 °C | [64] |

| Lemon myrtle leaf | 90 °C > 70 °C > 50 °C | [74] |

| Mango | 50 °C > 65 °C | [38] |

| Maquiberries | Fresh > 80 °C = 60 °C > 70 °C > 50 °C > 40 °C | [10] |

| Onion | 70 °C > 60 °C > fresh | [116] |

| Papaya | 60 °C > 70 °C > 80 °C | [75] |

| Papaya | Fresh > 60 °C > 50 °C > 70 °C | [76] |

| Pomegranate | 60 °C > 50 °C = 70 °C | [42] |

| Red bell-pepper | 70 °C > 50 °C > fresh | [43] |

| Red pepper | 70 °C > 50 °C > 60 °C > 90 °C > 80 °C > fresh | [44] |

| Strawberry | 50 °C > 60 °C | [77] |

| Tomato | Fresh > 60 °C > 50 °C > 40 °C | [34] |

| Tomato | Fresh > 70 °C > 60 °C > 50 °C | [78] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

ElGamal, R.; Song, C.; Rayan, A.M.; Liu, C.; Al-Rejaie, S.; ElMasry, G. Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview. Agronomy 2023, 13, 1580. https://doi.org/10.3390/agronomy13061580

ElGamal R, Song C, Rayan AM, Liu C, Al-Rejaie S, ElMasry G. Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview. Agronomy. 2023; 13(6):1580. https://doi.org/10.3390/agronomy13061580

Chicago/Turabian StyleElGamal, Ramadan, Cheng Song, Ahmed M. Rayan, Chuanping Liu, Salim Al-Rejaie, and Gamal ElMasry. 2023. "Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview" Agronomy 13, no. 6: 1580. https://doi.org/10.3390/agronomy13061580

APA StyleElGamal, R., Song, C., Rayan, A. M., Liu, C., Al-Rejaie, S., & ElMasry, G. (2023). Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products: A Comprehensive Overview. Agronomy, 13(6), 1580. https://doi.org/10.3390/agronomy13061580