The Economic and Environmental Aspects of Miscanthus × giganteus Phytomanagement Applied to Non-Agricultural Land

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Establishment

2.2. Soil Amendment

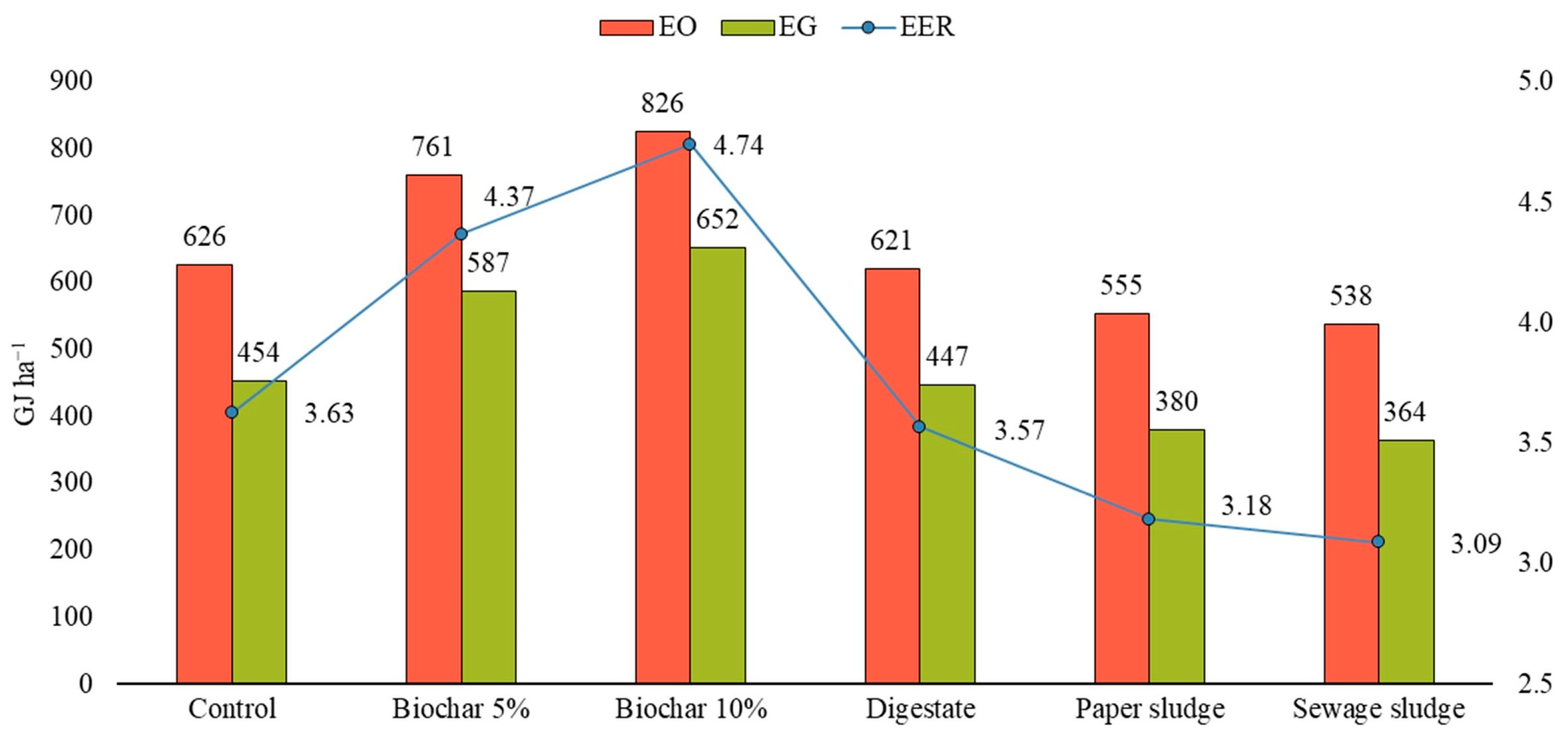

2.3. Energy and Economic Efficiency

2.4. Statistical Analysis

3. Results

3.1. Harvest Value Modelling

3.1.1. Field Conditions

3.1.2. Optimisation of M × g Cultivation at the Field Scale

3.2. Miscanthus Production Cycle

3.3. SWOT Analysis of M × g Phytotechnology

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prabha, J.; Kumar, M.; Tripathi, R. Chapter 17—Opportunities and Challenges of Utilizing Energy Crops in Phytoremediation of Environmental Pollutants: A Review. In Bioremediation for Environmental Sustainability; Kumar, V., Saxena, G., Shah, M.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 383–396. ISBN 978-0-12-820318-7. [Google Scholar]

- Evangelou, M.W.H.; Papazoglou, E.G.; Robinson, B.H.; Schulin, R. Phytomanagement: Phytoremediation and the Production of Biomass for Economic Revenue on Contaminated Land. In Phytoremediation: Management of Environmental Contaminants; Ansari, A.A., Gill, S.S., Gill, R., Lanza, G.R., Newman, L., Eds.; Springer International Publishing: Cham, Germany, 2015; Volume 1, pp. 115–132. ISBN 978-3-319-10395-2. [Google Scholar]

- European Commission; Joint Research Centre; Fritsche, U.; Brunori, G.; Chiaramonti, D.; Galanakis, C.; Matthews, R.; Panoutsou, C.; Avraamides, M.; Borzacchiello, M.; et al. Future Transitions for the Bioeconomy towards Sustainable Development and a Climate-Neutral Economy—Foresight Scenarios for the EU Bioeconomy in 2050; Avraamides, M., Borzacchiello, M., Stoermer, E., Eds.; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-28414-7. [Google Scholar]

- FAO. Bioenergy Environmental Impact Analysis (BIAS): Analytical Framework; Environment and Natural Resources Management Working Paper; Land and Water Division: Rome, Italy, 2010; p. 177. [Google Scholar]

- Kang, S.; Post, W.M.; Nichols, J.A.; Wang, D.; West, T.O.; Bandaru, V.; Izaurralde, R.C. Marginal Lands: Concept, Assessment and Management. J. Agric. Sci. 2013, 5, 129. [Google Scholar] [CrossRef]

- Schroers, J. Towards the Development of Marginal Land Use Depending on the Framework of Agricultural Market, Policy and Production Techniques; University of Giessen: Giessen, Germany, 2006. [Google Scholar]

- Alker, S.; Joy, V.; Roberts, P.; Smith, N. The Definition of Brownfield. J. Environ. Plan. Manag. 2000, 43, 49–69. [Google Scholar] [CrossRef]

- EPA. The Small Business Liability Relief and Brownfields Revitalization Act: A Critique. 2002; p. 27. Available online: https://www.congress.gov/107/plaws/publ118/PLAW-107publ118.pdf (accessed on 18 March 2024).

- Newton, R.A.; Pidlisnyuk, V.; Wildová, E.; Nováková, L.; Trögl, J. State of Brownfields in the Northern Bohemia, Saxony, and Lower Silesian Regions and Prospects for Regeneration by Utilization the Phytotechnology with the Second-Generation Crops. Land 2023, 12, 354. [Google Scholar] [CrossRef]

- Tang, Y.-T.; Nathanail, C.P. Sticks and Stones: The Impact of the Definitions of Brownfield in Policies on Socio-Economic Sustainability. Sustainability 2012, 4, 840–862. [Google Scholar] [CrossRef]

- GUS. Environment 2022; Statistical Analyses; Statistics Poland, Spatial and Environmental Surveys Department: Warsaw, Poland, 2023; p. 191. [Google Scholar]

- Oliver, L.; Ferber, U.; Grimski, D.; Millar, K.; Nathanail, P. The Scale and Nature of European Brownfields. In Proceedings of the CABERNET 2005-International Conference on Managing Urban Land LQM Ltd., Nottingham, UK, 13–15 April 2005; pp. 5–6. [Google Scholar]

- Rey, E.; Laprise, M.; Lufkin, S. The Multiple Potentials of Urban Brownfields. In Neighbourhoods in Transition: Brownfield Regeneration in European Metropolitan Areas; Rey, E., Laprise, M., Lufkin, S., Eds.; The Urban Book Series; Springer International Publishing: Cham, Germany, 2022; pp. 47–63. ISBN 978-3-030-82208-8. [Google Scholar]

- Hammond, E.B.; Coulon, F.; Hallett, S.H.; Thomas, R.; Hardy, D.; Kingdon, A.; Beriro, D.J. A Critical Review of Decision Support Systems for Brownfield Redevelopment. Sci. Total Environ. 2021, 785, 147132. [Google Scholar] [CrossRef]

- da Silva, J.; Rosa, G.B.; Sganzerla, W.G.; Ferrareze, J.P.; Simioni, F.J.; Campos, M.L. Strategies and Prospects in the Recovery of Contaminated Soils by Phytoremediation: An Updated Overview. Commun. Plant Sci. 2023, 13, 1–12. [Google Scholar] [CrossRef]

- Singh, H.; Pant, G. Phytoremediation: Low Input-Based Ecological Approach for Sustainable Environment. Appl. Water Sci. 2023, 13, 85. [Google Scholar] [CrossRef]

- Ali, M.H.; Khan, M.I.; Bashir, S.; Azam, M.; Naveed, M.; Qadri, R.; Bashir, S.; Mehmood, F.; Shoukat, M.A.; Li, Y.; et al. Biochar and Bacillus sp. MN54 Assisted Phytoremediation of Diesel and Plant Growth Promotion of Maize in Hydrocarbons Contaminated Soil. Agronomy 2021, 11, 1795. [Google Scholar] [CrossRef]

- Gomes, H.I. Phytoremediation for Bioenergy: Challenges and Opportunities. Environ. Technol. Rev. 2012, 1, 59–66. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Kołodziej, B.; Dubis, B.; Sugier, D.; Antonkiewicz, J.; Szatkowski, A. The Effect of Sewage Sludge on the Energy Balance of Cup Plant Biomass Production. A Six-Year Field Experiment in Poland. Energy 2023, 276, 127478. [Google Scholar] [CrossRef]

- Couto, N.D.; Silva, V.B.; Monteiro, E.; Rouboa, A.; Brito, P. An Experimental and Numerical Study on the Miscanthus Gasification by Using a Pilot Scale Gasifier. Renew. Energy 2017, 109, 248–261. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass Gasification Technology: The State of the Art Overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Bocianowski, J.; Fabisiak, E.; Joachimiak, K.; Wojech, R.; Wojciak, A. Miscanthus × giganteus as an Auxiliary Raw Material in NSSC Birch Pulp Production. Cellul. Chem. Technol. 2019, 53, 271–279. [Google Scholar] [CrossRef]

- Cappelletto, P.; Mongardini, F.; Barberi, B.; Sannibale, M.; Brizzi, M.; Pignatelli, V. Papermaking Pulps from the Fibrous Fraction of Miscanthus × giganteus. Ind. Crop. Prod. 2000, 11, 205–210. [Google Scholar] [CrossRef]

- Ivanovski, M.; Goričanec, D.; Urbancl, D. The Evaluation of Torrefaction Efficiency for Lignocellulosic Materials Combined with Mixed Solid Wastes. Energies 2023, 16, 3694. [Google Scholar] [CrossRef]

- Marín, F.; Sánchez, J.L.; Arauzo, J.; Fuertes, R.; Gonzalo, A. Semichemical Pulping of Miscanthus × giganteus. Effect of Pulping Conditions on Some Pulp and Paper Properties. Bioresour. Technol. 2009, 100, 3933–3940. [Google Scholar] [CrossRef] [PubMed]

- Andrejić, G.; Šinžar-Sekulić, J.; Prica, M.; Dželetović, Ž.; Rakić, T. Phytoremediation Potential and Physiological Response of Miscanthus × giganteus Cultivated on Fertilized and Non-Fertilized Flotation Tailings. Environ. Sci. Pollut. Res. 2019, 26, 34658–34669. [Google Scholar] [CrossRef] [PubMed]

- Jeżowski, S.; Głowacka, K.; Kaczmarek, Z. Variation on Biomass Yield and Morphological Traits of Energy Grasses from the Genus Miscanthus during the First Years of Crop Establishment. Biomass Bioenergy 2011, 35, 814–821. [Google Scholar] [CrossRef]

- Zhang, Y.; Zahid, I.; Danial, A.; Minaret, J.; Cao, Y.; Dutta, A. Hydrothermal Carbonization of Miscanthus: Processing, Properties, and Synergistic Co-Combustion with Lignite. Energy 2021, 225, 120200. [Google Scholar] [CrossRef]

- Nebeská, D.; Pidlisnyuk, V.; Stefanovska, T.; Trögl, J.; Shapoval, P.; Popelka, J.; Černý, J.; Medkow, A.; Kvak, V.; Malinská, H. Impact of Plant Growth Regulators and Soil Properties on Miscanthus × giganteus Biomass Parameters and Uptake of Metals in Military Soils. Rev. Environ. Health 2019, 34, 283–291. [Google Scholar] [CrossRef]

- Al Souki, K.S.; Burdová, H.; Mamirova, A.; Kuráň, P.; Kříženecká, S.; Oravová, L.; Tolaszová, J.; Nebeská, D.; Popelka, J.; Ust’ak, S.; et al. Evaluation of the Miscanthus × giganteus Short Term Impacts on Enhancing the Quality of Agricultural Soils Affected by Single and/or Multiple Contaminants. Environ. Technol. Innov. 2021, 24, 101890. [Google Scholar] [CrossRef]

- Burdová, H.; Kwoczynski, Z.; Nebeská, D.; Souki, K.S.A.; Pilnaj, D.; Grycová, B.; Klemencová, K.; Leštinský, P.; Kuráň, P.; Trögl, J. The Influence of Diesel Contaminated Soil on Miscanthus × giganteus Biomass Thermal Utilization and Pyrolysis Products Composition. J. Clean. Prod. 2023, 406, 136984. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.; Trindade, L.M.; van der Linden, G.C.; Schwarz, K.-U.; Müller-Sämann, K.; Anisimov, A.; Chen, C.-L.; Dolstra, O.; Donnison, I.S.; et al. Progress on Optimizing Miscanthus Biomass Production for the European Bioeconomy: Results of the EU FP7 Project OPTIMISC. Front. Plant Sci. 2016, 7, 1620. [Google Scholar] [CrossRef] [PubMed]

- Clifton-Brown, J.; Hastings, A.; Mos, M.; McCalmont, J.P.; Ashman, C.; Awty-Carroll, D.; Cerazy, J.; Chiang, Y.-C.; Cosentino, S.; Cracroft-Eley, W.; et al. Progress in Upscaling Miscanthus Biomass Production for the European Bio-Economy with Seed-Based Hybrids. GCB Bioenergy 2017, 9, 6–17. [Google Scholar] [CrossRef]

- Kiesel, A. The Potential of Miscanthus as Biogas Feedstock. Doctor Scientiarum Agriculturae; University of Hohenheim: Stuttgart, Germany, 2020. [Google Scholar]

- Kiesel, A.; Wagner, M.; Lewandowski, I. Environmental Performance of Miscanthus, Switchgrass and Maize: Can C4 Perennials Increase the Sustainability of Biogas Production? Sustainability 2017, 9, 5. [Google Scholar] [CrossRef]

- Licht, L.A.; Isebrands, J.G. Linking Phytoremediated Pollutant Removal to Biomass Economic Opportunities. Biomass Bioenergy 2005, 28, 203–218. [Google Scholar] [CrossRef]

- Parajuli, R.; Sperling, K.; Dalgaard, T. Environmental Performance of Miscanthus as a Fuel Alternative for District Heat Production. Biomass Bioenergy 2015, 72, 104–116. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Tworkowski, J.; Szczukowski, S. Perennial Herbaceous Crops as a Feedstock for Energy and Industrial Purposes: Organic and Mineral Fertilizers versus Biomass Yield and Efficient Nitrogen Utilization. Ind. Crop. Prod. 2017, 107, 244–259. [Google Scholar] [CrossRef]

- Erickson, L.E.; Pidlisnyuk, V. (Eds.) Phytotechnology with Biomass Production: Sustainable Management of Contaminated Sites, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2021; ISBN 978-0-367-52280-3. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Miscanthus × giganteus Stalks as a Potential Non-Wood Raw Material for the Pulp and Paper Industry. Influence of Pulping and Beating Conditions on the Fibre and Paper Properties. Ind. Crop. Prod. 2019, 141, 111744. [Google Scholar] [CrossRef]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J.M. Production of Nanocrystalline Cellulose from Lignocellulosic Biomass: Technology and Applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef]

- Quesada-Salas, M.C.; Vuillemin, M.E.; Dillies, J.; Dauwe, R.; Firdaous, L.; Bigan, M.; Lambertyn, V.; Cailleu, D.; Jamali, A.; Froidevaux, R.; et al. 1-Ethyl-3-Methyl Imidazolium Acetate, Hemicellulolytic Enzymes and Laccase-Mediator System: Toward an Integrated Co-Valorization of Polysaccharides and Lignin from Miscanthus. Ind. Crop. Prod. 2023, 197, 116627. [Google Scholar] [CrossRef]

- Babicka, M.; Woźniak, M.; Bartkowiak, M.; Peplińska, B.; Waliszewska, H.; Zborowska, M.; Borysiak, S.; Ratajczak, I. Miscanthus and Sorghum as Sustainable Biomass Sources for Nanocellulose Production. Ind. Crop. Prod. 2022, 186, 115177. [Google Scholar] [CrossRef]

- Roik, M.; Sinchenko, V.; Purkin, V.; Kvak, V.; Humentik, M. (Eds.) Miscanthus in Ukraine; FOP Yamchinskiy Press: Kyiv, Ukraine, 2019; ISBN 978-617-7804-11-5. [Google Scholar]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and Future Köppen-Geiger Climate Classification Maps at 1-Km Resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [PubMed]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger Climate Classification Updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- FAO. World Reference Base for Soil Resources 2014: International Soil Classification Systems for Naming Soils and Creating Legends for Soil Maps (Update 2015); World Soil Resources: Rome, Italy, 2014. [Google Scholar]

- Vodyanitskii, Y.N. Equations for Assessing the Total Contamination of Soils with Heavy Metals and Metalloids. Eurasian Soil Sci. 2010, 43, 1184–1188. [Google Scholar] [CrossRef]

- Pidlisnyuk, V.; Mamirova, A.; Newton, R.A.; Stefanovska, T.; Zhukov, O.; Tsygankova, V.; Shapoval, P. The Role of Plant Growth Regulators in Miscanthus × giganteus Growth on Trace Elements-Contaminated Soils. Agronomy 2022, 12, 2999. [Google Scholar] [CrossRef]

- 275/1998 Sb; Release of the Ministry of Agriculture Related the Agrochemical Testing of the Soils and Evaluation the Land Properties of the Forest Land (with Amendments 335/2017 Sb). Ministry of Agriculture: Prague, Czech Republic, 2017.

- Stefanovska, T.; Skwiercz, A.; Pidlisnyuk, V.; Zhukov, O.; Kozacki, D.; Mamirova, A.; Newton, R.A.; Ust’ak, S. The Short-Term Effects of Amendments on Nematode Communities and Diversity Patterns under the Cultivation of Miscanthus × giganteus on Marginal Land. Agronomy 2022, 12, 2063. [Google Scholar] [CrossRef]

- ASTM E711-87; Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter (Re-Approved 2004). American Society for Testing and Materials: West Conshohocken, PN, USA, 2012; p. 9.

- Sokólski, M.; Jankowski, K.J.; Załuski, D.; Szatkowski, A. Productivity, Energy and Economic Balance in the Production of Different Cultivars of Winter Oilseed Rape. A Case Study in North-Eastern Poland. Agronomy 2020, 10, 508. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Sokólski, M.; Szatkowski, A.; Kozak, M. Crambe—Energy Efficiency of Biomass Production and Mineral Fertilization. A Case Study in Poland. Ind. Crop. Prod. 2022, 182, 114918. [Google Scholar] [CrossRef]

- Clements, D.R.; Weise, S.F.; Brown, R.; Stonehouse, D.P.; Hume, D.J.; Swanton, C.J. Energy Analysis of Tillage and Herbicide Inputs in Alternative Weed Management Systems. Agric. Ecosyst. Environ. 1995, 52, 119–128. [Google Scholar] [CrossRef]

- Dubis, B.; Jankowski, K.J.; Załuski, D.; Bórawski, P.; Szempliński, W. Biomass Production and Energy Balance of Miscanthus over a Period of 11 Years: A Case Study in a Large-Scale Farm in Poland. GCB Bioenergy 2019, 11, 1187–1201. [Google Scholar] [CrossRef]

- Muylle, H.; Van Hulle, S.; De Vliegher, A.; Baert, J.; Van Bockstaele, E.; Roldán-Ruiz, I. Yield and Energy Balance of Annual and Perennial Lignocellulosic Crops for Bio-Refinery Use: A 4-Year Field Experiment in Belgium. Eur. J. Agron. 2015, 63, 62–70. [Google Scholar] [CrossRef]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life Cycle Assessment of Biochar Systems: Estimating the Energetic, Economic, and Climate Change Potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef] [PubMed]

- West, T.O.; Marland, G. A Synthesis of Carbon Sequestration, Carbon Emissions, and Net Carbon Flux in Agriculture: Comparing Tillage Practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Nemecek, T.; Kägi, T.; Blaser, S. Life Cycle Inventories of Agricultural Production Systems. Final Report Ecoinvent v2.0. Chapter 6. Agricultural Machinery. 6.2.7 Functional Unit and Application of the Modules; EcoInvent Centre: Zürich, Switzerland, 2007; p. 360. [Google Scholar]

- Angelini, L.G.; Ceccarini, L.; Nassi o Di Nasso, N.; Bonari, E. Comparison of Arundo donax L. and Miscanthus × giganteus in a Long-Term Field Experiment in Central Italy: Analysis of Productive Characteristics and Energy Balance. Biomass Bioenergy 2009, 33, 635–643. [Google Scholar] [CrossRef]

- Jeżowski, S.; Mos, M.; Buckby, S.; Cerazy-Waliszewska, J.; Owczarzak, W.; Mocek, A.; Kaczmarek, Z.; McCalmont, J.P. Establishment, Growth, and Yield Potential of the Perennial Grass Miscanthus × giganteus on Degraded Coal Mine Soils. Front. Plant Sci. 2017, 8, 726. [Google Scholar] [CrossRef] [PubMed]

- MECR. Ministry of the Environment of the Czech Republic. Decree Laying down Detailed Rules for the Protection of Quality of Agricultural Land and Amending. Decree Specifying Some Details of Agricultural Land Resources Protection; Ministry of the Environment of the Czech Republic (MECR): Praha, Czech Republic, 2016. [Google Scholar]

- HS ES. Hygienic Standards for the Safety of the Environment (Soil). In Order of the Minister of Health of the Republic of Kazakhstan dated April 21, 2021 No. RK DSM-32. Registered with the Ministry of Justice of the Republic of Kazakhstan on April 22, 2021 No. 22595; HS ES: Astana, Republic of Kazakhstan, 2021. [Google Scholar]

- GOST 17.4.1.02-83 USSR; Protection of the Environment. Soils. Classification of the Chemical Substances for the Control of Pollutants. StandardInform: Moscow, Russia, 1983.

- Sudhakaran, M.; Ramamoorthy, D.; Savitha, V.; Balamurugan, S. Assessment of Trace Elements and Its Influence on Physico-Chemical and Biological Properties in Coastal Agroecosystem Soil, Puducherry Region. Geol. Ecol. Landsc. 2018, 2, 169–176. [Google Scholar] [CrossRef]

- Bilandžija, N.; Zgorelec, Ž.; Pezo, L.; Grubor, M.; Velaga, A.G.; Krička, T. Solid Biofuels Properites of Miscanthus × giganteus Cultivated on Contaminated Soil after Phytoremediation Process. J. Energy Inst. 2022, 101, 131–139. [Google Scholar] [CrossRef]

- Bilandžija, N.; Voća, N.; Leto, J.; Jurišić, V.; Grubor, M.; Matin, A.; Geršić, A.; Krička, T. Yield and Biomass Composition of Miscanthus × giganteus in the Mountain Area of Croatia. Trans. FAMENA 2018, 42, 51–60. [Google Scholar] [CrossRef]

- Pidlisnyuk, V.; Zgorelec, Ž. Impact of Nutrients and Trace Elements in Soil on Plant Growth: Case of the Second-Generation Energy Crops. Agronomy 2022, 12, 2768. [Google Scholar] [CrossRef]

- Ericsson, K.; Rosenqvist, H.; Nilsson, L.J. Energy Crop Production Costs in the EU. Biomass Bioenergy 2009, 33, 1577–1586. [Google Scholar] [CrossRef]

- Hastings, A.; Mos, M.; Yesufu, J.A.; McCalmont, J.; Schwarz, K.; Shafei, R.; Ashman, C.; Nunn, C.; Schuele, H.; Cosentino, S.; et al. Economic and Environmental Assessment of Seed and Rhizome Propagated Miscanthus in the UK. Front. Plant Sci. 2017, 8, 1058. [Google Scholar] [CrossRef] [PubMed]

- Mantziaris, S.; Iliopoulos, C.; Theodorakopoulou, I.; Petropoulou, E. Perennial Energy Crops vs. Durum Wheat in Low Input Lands: Economic Analysis of a Greek Case Study. Renew. Sustain. Energy Rev. 2017, 80, 789–800. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Bochtis, D.; Busato, P.; Sopegno, A. A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems. Energies 2017, 10, 831. [Google Scholar] [CrossRef]

- Winkler, B.; Mangold, A.; von Cossel, M.; Clifton-Brown, J.; Pogrzeba, M.; Lewandowski, I.; Iqbal, Y.; Kiesel, A. Implementing Miscanthus into Farming Systems: A Review of Agronomic Practices, Capital and Labour Demand. Renew. Sustain. Energy Rev. 2020, 132, 110053. [Google Scholar] [CrossRef]

- Witzel, C.-P.; Finger, R. Economic Evaluation of Miscanthus Production—A Review. Renew. Sustain. Energy Rev. 2016, 53, 681–696. [Google Scholar] [CrossRef]

- Panoutsou, C.; Alexopoulou, E. Costs and Profitability of Crops for Bioeconomy in the EU. Energies 2020, 13, 1222. [Google Scholar] [CrossRef]

- Soldatos, P. Economic Aspects of Bioenergy Production from Perennial Grasses in Marginal Lands of South Europe. BioEnergy Res. 2015, 8, 1562–1573. [Google Scholar] [CrossRef]

- Wagner, M.; Mangold, A.; Lask, J.; Petig, E.; Kiesel, A.; Lewandowski, I. Economic and Environmental Performance of Miscanthus Cultivated on Marginal Land for Biogas Production. GCB Bioenergy 2019, 11, 34–49. [Google Scholar] [CrossRef]

- CZSO. The Development of the Czech Labour Market—1. Quarter of 2023; Czech Statistical Office: Prague, Czech Republic, 2023; p. 6. [Google Scholar]

- Harsono, S.S.; Grundman, P.; Lau, L.H.; Hansen, A.; Salleh, M.A.M.; Meyer-Aurich, A.; Idris, A.; Ghazi, T.I.M. Energy Balances, Greenhouse Gas Emissions and Economics of Biochar Production from Palm Oil Empty Fruit Bunches. Resour. Conserv. Recycl. 2013, 77, 108–115. [Google Scholar] [CrossRef]

- Maroušek, J.; Strunecký, O.; Stehel, V. Biochar Farming: Defining Economically Perspective Applications. Clean Technol. Environ. Policy 2019, 21, 1389–1395. [Google Scholar] [CrossRef]

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A Techno-Economic Analysis of Biochar Production and the Bioeconomy for Orchard Biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Shackley, S.; Sohi, S.; Ibarrola, R.; Hammond, J.; Mašek, O.; Brownsort, P.; Cross, A.; Prendergast-Miller, M.; Haszeldine, S. Biochar, Tool for Climate Change Mitigation and Soil Management. In Geoengineering Responses to Climate Change: Selected Entries from the Encyclopedia of Sustainability Science and Technology; Lenton, T., Vaughan, N., Eds.; Springer: New York, NY, USA, 2013; pp. 73–140. ISBN 978-1-4614-5770-1. [Google Scholar]

- Aso, S.N. Digestate: The Coproduct of Biofuel Production in a Circular Economy, and New Results for Cassava Peeling Residue Digestate. In Renewable Energy—Technologies and Applications; IntechOpen: Rijeka, Croatia, 2020; ISBN 978-1-83881-001-6. [Google Scholar]

- Huber, P.; Ossard, S.; Fabry, B.; Bermond, C.; Craperi, D.; Fourest, E. Conditions for Cost-Efficient Reuse of Biological Sludge for Paper and Board Manufacturing. J. Clean. Prod. 2014, 66, 65–74. [Google Scholar] [CrossRef]

- Domini, M.; Abbà, A.; Bertanza, G. Analysis of the Variation of Costs for Sewage Sludge Transport, Recovery and Disposal in Northern Italy: A Recent Survey (2015–2021). Water Sci. Technol. 2022, 85, 1167–1175. [Google Scholar] [CrossRef] [PubMed]

- Inpest.cz Roundup Klasik PRO. Available online: https://www.inpest.cz/postriky-na-plevele-v-bramborach/roundup-klasik-pro-20l (accessed on 30 June 2023).

- Ceskybenzin.cz Ceny Benzínu a Nafty Jako na Dlani. Available online: https://www.ceskybenzin.cz/index.php?akce=okoli&pumpa=68&typ_palivo=3 (accessed on 19 August 2023).

- Mangold, A.; Lewandowski, I.; Möhring, J.; Clifton-Brown, J.; Krzyżak, J.; Mos, M.; Pogrzeba, M.; Kiesel, A. Harvest Date and Leaf:Stem Ratio Determine Methane Hectare Yield of Miscanthus Biomass. GCB Bioenergy 2019, 11, 21–33. [Google Scholar] [CrossRef]

- Kiesel, A.; Lewandowski, I. Miscanthus as Biogas Substrate—Cutting Tolerance and Potential for Anaerobic Digestion. GCB Bioenergy 2017, 9, 153–167. [Google Scholar] [CrossRef]

- Suhartini, S.; Lestari, Y.P.; Nurika, I. Estimation of Methane and Electricity Potential from Canteen Food Waste. IOP Conf. Ser. Earth Environ. Sci. 2019, 230, 012075. [Google Scholar] [CrossRef]

- Kononchuk, O.; Pidlisnyuk, V.; Mamirova, A.; Khomenchuk, V.; Herts, A.; Grycová, B.; Klemencová, K.; Leštinský, P.; Shapoval, P. Evaluation of the Impact of Varied Biochars Produced from M. × giganteus Waste and Application Rate on the Soil Properties and Physiological Parameters of Spinacia oleracea L. Environ. Technol. Innov. 2022, 28, 102898. [Google Scholar] [CrossRef]

- Mangold, A.; Lewandowski, I.; Hartung, J.; Kiesel, A. Miscanthus for Biogas Production: Influence of Harvest Date and Ensiling on Digestibility and Methane Hectare Yield. GCB Bioenergy 2019, 11, 50–62. [Google Scholar] [CrossRef]

- Kalabić, D.; Drazić, G.; Drazić, N.; Ikanović, J. Production of Agri-Energy Crop Miscanthus × giganteus on Land Degraded by Power Industry: SWOT Analysis. Pol. J. Environ. Stud. 2019, 28, 3243–3251. [Google Scholar] [CrossRef]

- Liu, T.T.; McConkey, B.G.; Ma, Z.Y.; Liu, Z.G.; Li, X.; Cheng, L.L. Strengths, Weaknesses, Opportunities and Threats Analysis of Bioenergy Production on Marginal Land. Energy Procedia 2011, 5, 2378–2386. [Google Scholar] [CrossRef]

- Paschalidou, A.; Tsatiris, M.; Kitikidou, K. Perennial vs Annual Energy Crops-SWOT Analysis (Case Study: Greece). Int. Ref. J. Eng. Sci. 2018, 7, 01–24. [Google Scholar]

- FAO. AQUASTAT Climate Information Tool; FAO: Rome, Italy, 2023. [Google Scholar]

| Parameters | CZ | KZ | UA |

|---|---|---|---|

| GPS coordinates | 50°27′38″ N | 43°13′38.161″ N | 48°58′01.4″ N |

| 13°23′07″ E | 76°54′59.443″ E | 23°59′33.3″ E | |

| Climate: Köppen–Geiger classification a | 2006: Cfb | 2006: Dfa | 2016: Dfb |

| 2016: Dfb | 2016: BSk | 2016: Dfb | |

| Year of establishment | 2021 | 2017 | 2018 |

| Plantation age | 3 (2023) | 3 (2019) | 3 (2020) |

| Soil type b | Cambisols | Kastanozems | Cambisols |

| Soil amendments | No | No | No |

| Plot size, m2 | 5 | 5 | 25 |

| Plot replication | 4 | 3 | 3 |

| Rhizomes plot−1, pcs | 30 | 30 | 56 |

| Rhizomes ha−1, pcs | 40,000 | 40,000 | 22,000 |

| Zci c | 8.40 | 3.24 | 13.2 |

| Parameter | Unit | Control | Biochar | Digestate | Paper Mill Sludge | Sewage Sludge | |

|---|---|---|---|---|---|---|---|

| Area | m2 | 30 | 30 | 30 | 30 | 30 | 30 |

| Rhizomes | pcs | 120 | 120 | 120 | 120 | 120 | 120 |

| Application rate | %.vol | - | 5 | 10 | 5 | 5 | 5 |

| Amount of amendment | g pl−1 | - | 111 | 221 | 219 | 347 | 413 |

| TE | MPC CR 1 | CZ | MPC KZ 2 | KZ | MPC UA 3 | UA |

|---|---|---|---|---|---|---|

| V | 130 | <LOD | 43 | 24.1 ± 0.30 | - | <LOD |

| Cr | 90 | 172 ± 11.5 | 6 | 19.8 ± 0.20 | 100 | 145 ± 49.0 |

| Mn | - | 1086 ± 1.53 | 1500 | 409 ± 9.00 | 1500 | 825 ± 38.0 |

| Fe | - | 46,623 ± 1541 | - | 15,570 ± 105 | - | 42,481 ± 148 |

| Co | 30 | <LOD | 20 | 6.60 ± 0.10 | - | <LOD |

| Ni | 50 | 50.7 ± 4.23 | 20 | 22.3 ± 0.50 | 85 | 63.0 ± 11.0 |

| Cu | 60 | 50.1 ± 3.57 | 33 | 19.9 ± 1.20 | 100 | 40.0 ± 7.00 |

| Zn | 120 | 240 ± 8.06 | 55 | 52.4 ± 4.30 | 300 | 111 ± 6.00 |

| As | 20 | <LOD | 2 | 2.70 ± 0.10 | 20 | 15.0 ± 2.00 |

| Sr | 200 4 | 209 ± 1.32 | 7 | 127 ± 2.40 | 1000 | 148 ± 2.00 |

| Pb | 60 | 106 ± 7.17 | 32 | 17.0 ± 1.00 | 30 | 22.0 ± 3.00 |

| Parameter | Unit | Control | Biochar | Digestate | Paper Mill Sludge | Sewage Sludge | |

|---|---|---|---|---|---|---|---|

| Biomass yield after 3rd year of vegetation | |||||||

| Harvest value | t ha−1 | 12.4 ± 1.50 | 18.0 ± 1.20 | 24.1 ± 1.06 | 14.3 ± 1.68 | 10.7 ± 1.31 | 12.9 ± 1.41 |

| c | b | a | bc | c | c | ||

| Energy capacity | |||||||

| HHV | MJ kg−1 | 17.3 bc | 17.4 ab | 17.1 d | 17.5 a | 17.3 bc | 17.2 c |

| Farming Operation | Labour | Machinery | Diesel | Materials | Total Input | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| man h−1 ha−1 | EUR ha−1 | MJ ha−1 | kg ha−1 | MJ ha−1 | L ha−1 | EUR ha−1 | MJ ha−1 | EUR ha−1 | MJ ha−1 | EUR ha−1 | MJ ha−1 | ||

| Soil tillage | Ploughing | 2.00 | 15.9 | 80.0 | 0.38 | 42.6 | 25.0 | 37.0 | 1200 | - | - | 52.9 | 1323 |

| Harrowing | 1.29 | 10.2 | 51.6 | 0.13 | 14.6 | 3.33 | 4.93 | 160 | - | - | 15.2 | 226 | |

| Soil amendment | Normative | - | - | - | - | ||||||||

| Biochar | 23.48 a | 186 | 939 | 4.44 t × EUR 499 | 2216 | 506 b | 2402 | 1445 | |||||

| 23.48 a | 186 | 939 | 8.84 t × EUR 499 | 4411 | 506 b | 4597 | 1445 | ||||||

| Digestate | 23.48 a | 186 | 939 | 8.76 t × EUR 5.47 [84] | 47.9 | 506 b | 234 | 1445 | |||||

| Paper mill sludge (PMS) | 23.48 a | 186 | 939 | 13.9 t × EUR 50.0 [85] | 694 | 506 b | 880 | 1445 | |||||

| Sewage sludge (SS) | 23.48 a | 186 | 939 | 16.5 t × EUR 129 [86] | 2131 | 506 b | 2317 | 1445 | |||||

| Planting | 23.48 | 186 | 939 | 0.88 | 98.6 | 11.7 | 17.3 | 562 | 12,000 | 160,000 | 12,204 | 161,599 | |

| Plant material | 40,000 rhizomes × EUR 0.30 d | ||||||||||||

| Weed control | 3.00 | 23.8 | 120 | 1.17 | 132 | 22.5 | 33.3 | 1080 | 74.7 | 531 | 132 | 1862 | |

| Herbicide (RoundUp) | 5.00 L × EUR 14.9 [87] | ||||||||||||

| Harvest | 3.00 | 23.8 | 120 | 1.17 | 131 | 22.5 | 33.3 | 1080 | - | - | 57.1 | 1331 | |

| Total expenses | |||||||||||||

| 1st year | Control | 32.8 | 260 | 1311 | 3.73 | 418 | 85.0 | 126 | 4081 | 12,075 | 160,531 | 12,460 | 166,341 |

| Biochar | 56.3 | 446 | 2250 | 3.73 | 418 | 85.0 | 126 | 4081 | 14,291 | 161,037 | 14,863 | 167,786 | |

| 56.3 | 446 | 2250 | 3.73 | 418 | 85.0 | 126 | 4081 | 16,486 | 161,037 | 17,058 | 167,786 | ||

| Digestate | 56.3 | 446 | 2250 | 3.73 | 418 | 85.0 | 126 | 4081 | 12,123 | 161,037 | 12,695 | 167,786 | |

| PMS | 56.3 | 446 | 2250 | 3.73 | 418 | 85.0 | 126 | 4081 | 12,769 | 161,037 | 13,341 | 167,786 | |

| SS | 56.3 | 446 | 2250 | 3.73 | 418 | 85.0 | 126 | 4081 | 14,206 | 161,037 | 14,778 | 167,786 | |

| 2nd year and following years | 6.00 | 47.6 | 240 | 2.34 | 262 | 45.0 | 66.6 | 2160 | 74.7 | 531 | 189 | 3193 | |

| Equivalents | Value | - | 7.93 | 40.0 | - | 112 | - | 1.48 c | 48 | 4 | 295 | - | - |

| Unit | - | EUR h−1 | MJ h−1 | - | MJ kg−1 | - | EUR L−1 | MJ L−1 | MJ pl−1 | MJ kg−1 | EUR ha−1 | MJ ha−1 | |

| Treatment | Scenario 1 | Scenario 2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Year 1 | Year 2 | Year 3 | Total | Year 1 | Year 2 | Year 3 | Total | |

| Control | −4121 | 8150 | 8150 | 12,179 | −12,378 | 1603 | 5283 | −5492 |

| Biochar 5% | −6523 | 8150 | 8150 | 9777 | −14,700 | 2318 | 7754 | −4628 |

| Biochar 10% | −8718 | 8150 | 8150 | 7582 | −16,863 | 2838 | 10,446 | −3578 |

| Digestate | −4355 | 8150 | 8150 | 11,945 | −12,539 | 1356 | 6122 | −5062 |

| PMS | −5001 | 8150 | 8150 | 11,299 | −13,248 | 1276 | 4533 | −7439 |

| SS | −6438 | 8150 | 8150 | 9862 | −14,710 | 1122 | 5504 | −8084 |

| S (Strengths) | W (Weaknesses) |

|---|---|

|

|

| O (Opportunities) | T (Threats) |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamirova, A.; Pidlisnyuk, V. The Economic and Environmental Aspects of Miscanthus × giganteus Phytomanagement Applied to Non-Agricultural Land. Agronomy 2024, 14, 791. https://doi.org/10.3390/agronomy14040791

Mamirova A, Pidlisnyuk V. The Economic and Environmental Aspects of Miscanthus × giganteus Phytomanagement Applied to Non-Agricultural Land. Agronomy. 2024; 14(4):791. https://doi.org/10.3390/agronomy14040791

Chicago/Turabian StyleMamirova, Aigerim, and Valentina Pidlisnyuk. 2024. "The Economic and Environmental Aspects of Miscanthus × giganteus Phytomanagement Applied to Non-Agricultural Land" Agronomy 14, no. 4: 791. https://doi.org/10.3390/agronomy14040791