Effects of Controlled-Release Nitrogen Fertilizer at Different Release Stages on Rice Yield and Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Experimental Design

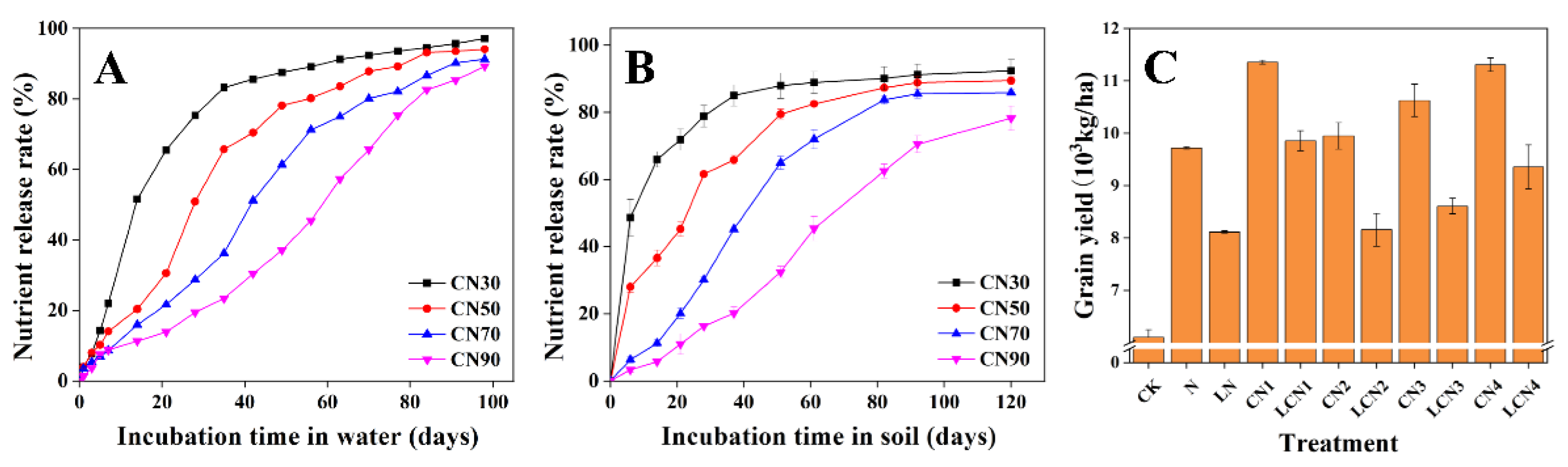

2.2. Nitrogen Release Characteristics in Water and Soil

2.3. Rice Yield and Appearance Quality

2.4. Extraction of Rice Starch

2.5. Analysis of Rice Starch

2.6. Rice Starch Pasting Characteristics

2.7. Statistical Analysis

3. Results and Discussion

3.1. Effect of Different Nitrogen Fertilizer on Rice Yield

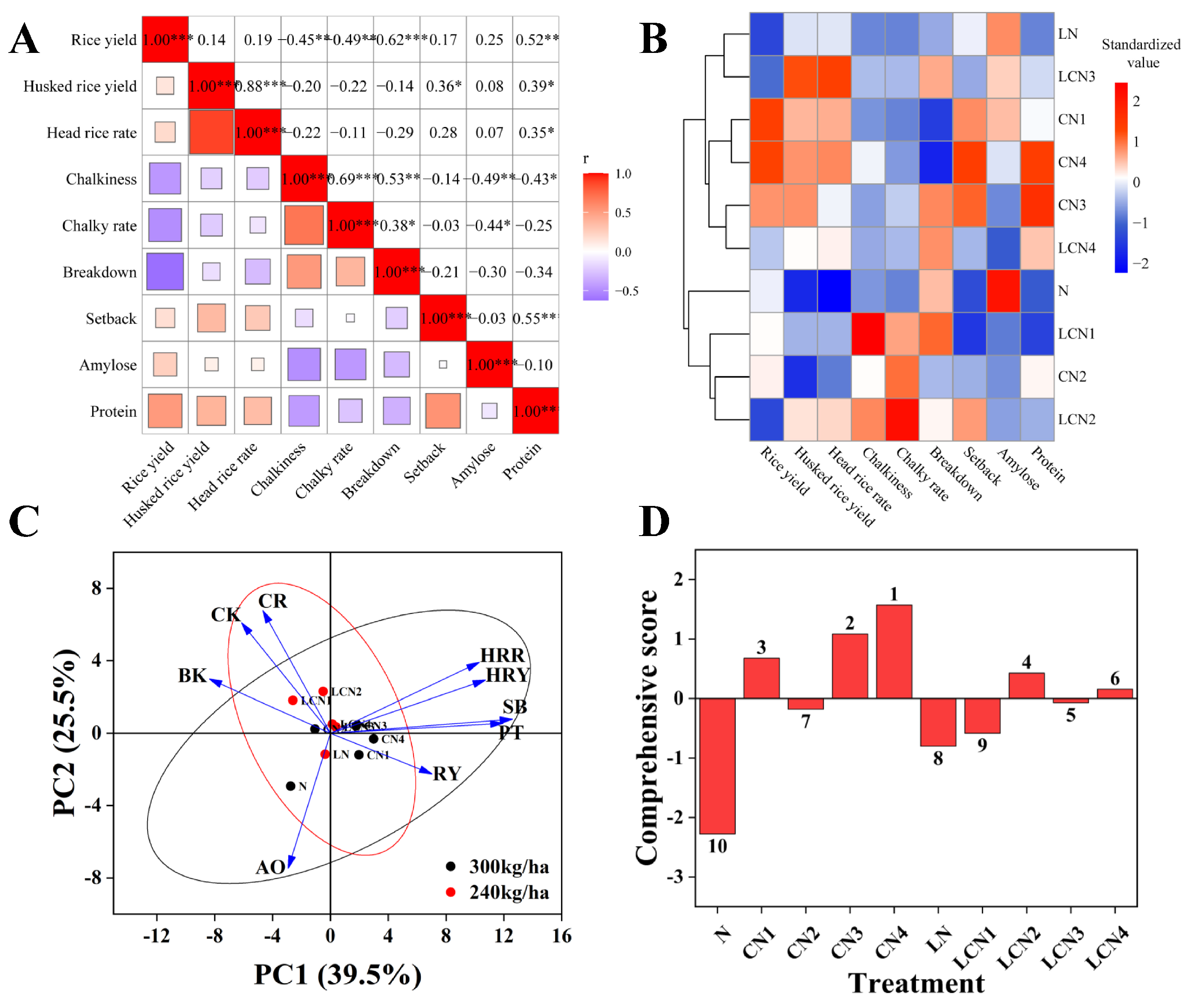

3.2. Effect of Different Nitrogen Fertilizers on Rice Quality

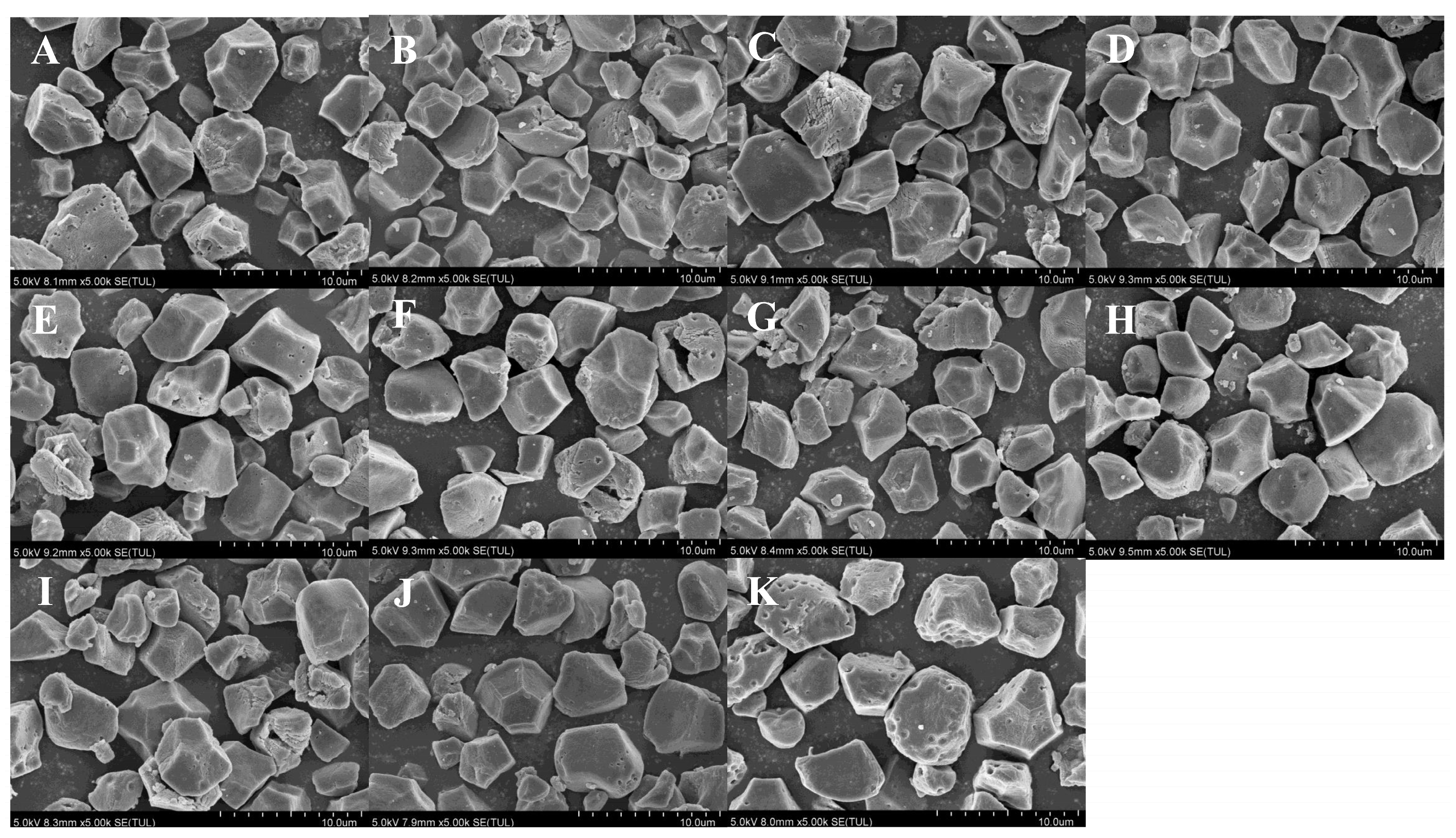

3.3. Effect of Different Nitrogen Fertilizers on Rice Starch Structure

3.4. Comprehensive Evaluation of Rice Commodity Value

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ch, R.; Chevallier, O.; McCarron, P.; McGrath, T.F.; Wu, D.; Nguyen Doan Duy, L.; Kapil, A.P.; McBride, M.; Elliott, C.T. Metabolomic fingerprinting of volatile organic compounds for the geographical discrimination of rice samples from China, Vietnam and India. Food Chem. 2021, 334, 127553. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Liu, Q.; Jiang, W.; Qiu, S.; Wei, H.; Zhang, H.; Liu, G.; Xing, Z.; Hu, Y.; Guo, B.; et al. Effects of mid-stage nitrogen application timing on the morphological structure and physicochemical properties of japonica rice starch. J. Sci. Food Agric. 2021, 101, 2463–2471. [Google Scholar] [CrossRef] [PubMed]

- Lee, S. Recent Advances on Nitrogen Use Efficiency in Rice. Agronomy 2021, 11, 753. [Google Scholar] [CrossRef]

- Liu, C.; Chen, F.; Li, Z.; Cocq, K.L.; Liu, Y.; Wu, L. Impacts of nitrogen practices on yield, grain quality, and nitrogen-use efficiency of crops and soil fertility in three paddy-upland cropping systems. J. Sci. Food Agric. 2021, 101, 2218–2226. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Xu, X.; He, P.; Ullah, S.; Zhang, J.; Cui, Z.; Zhou, W. Improving yield and nitrogen use efficiency through alternative fertilization options for rice in China: A meta-analysis. Field Crops Res. 2018, 227, 11–18. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, Y.; Wang, C.; Shi, G.; Xie, J.; Gao, B.; Li, Y.C.; Wan, Y.; Cheng, D.; Shen, T.; et al. Nano-soy-protein microcapsule-enabled self-healing biopolyurethane-coated controlled-release fertilizer: Preparation, performance, and mechanism. Mater. Today Chem. 2021, 20, 100413. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, Q.; Li, E.; Yuan, L.; Wang, W.; Zhang, H.; Liu, L.; Wang, Z.; Yang, J.; Gu, J. Effects of nitrogen fertilizer on structure and physicochemical properties of ‘super’ rice starch. Carbohydr. Polym. 2020, 239, 116237. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Fang, C.; Qian, Z.; Guo, B.; Huo, Z. Differences in starch structure, physicochemical properties and texture characteristics in superior and inferior grains of rice varieties with different amylose contents. Food Hydrocoll. 2021, 110, 106170. [Google Scholar] [CrossRef]

- Bian, J.-l.; Xu, F.-f.; Han, C.; Qiu, S.; Ge, J.-l.; Xu, J.; Zhang, H.-c.; Wei, H.-y. Effects of planting methods on yield and quality of different types of japonica rice in northern Jiangsu plain, China. J. Integr. Agric. 2018, 17, 2624–2635. [Google Scholar] [CrossRef]

- Deng, F.; Li, Q.; Chen, H.; Zeng, Y.; Li, B.; Zhong, X.; Wang, L.; Ren, W. Relationship between chalkiness and the structural and thermal properties of rice starch after shading during grain-filling stage. Carbohydr. Polym. 2021, 252, 117212. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, H.; Liu, W.; Dou, Z.; Zhou, Q.; Chen, W.; Wang, S.; Ding, Y. Nitrogen fertilizer at heading stage effectively compensates for the deterioration of rice quality by affecting the starch-related properties under elevated temperatures. Food Chem. 2019, 277, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.-j.; Zhao, C.-f.; Zhu, Z.; Zhou, L.-h.; Zheng, Q.-h.; Wang, C.-l. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Integr. Agric. 2020, 19, 988–998. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y.; Chen, T.; Zheng, J.; Sun, Y.; Chi, D. Soil nitrogen regulation using clinoptilolite for grain filling and grain quality improvements in rice. Soil Tillage Res. 2020, 199, 104547. [Google Scholar] [CrossRef]

- Ni, B.; Liu, M.; Lu, S.; Xie, L.; Wang, Y. Environmentally friendly slow-release nitrogen fertilizer. J. Agric. Food Chem. 2011, 59, 10169–10175. [Google Scholar] [CrossRef] [PubMed]

- El Halal, S.L.M.; Kringel, D.H.; Zavareze, E.d.R.; Dias, A.R.G. Methods for Extracting Cereal Starches from Different Sources: A Review. Starch-Stärke 2019, 71, 1900128. [Google Scholar] [CrossRef]

- Bhat, F.M.; Riar, C.S. Effect of composition, granular morphology and crystalline structure on the pasting, textural, thermal and sensory characteristics of traditional rice cultivars. Food Chem. 2019, 280, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.; Simko, V. R Package ‘Corrplot’: Visualization of a Correlation Matrix (Version 0.92). 2021. Available online: https://github.com/taiyun/corrplot (accessed on 20 May 2022).

- Qiu, Y. Sysfonts: Loading Fonts into R (R Package Version 0.8.9). 2024. Available online: https://github.com/yixuan/sysfonts (accessed on 20 May 2022).

- Tian, C.; Zhou, X.; Ding, Z.; Liu, Q.; Xie, G.; Peng, J.; Rong, X.; Zhang, Y.; Yang, Y.; Eissa, M.A. Controlled-release N fertilizer to mitigate ammonia volatilization from double-cropping rice. Nutr. Cycl. Agroecosyst. 2021, 119, 123–137. [Google Scholar] [CrossRef]

- Ishibashi, Y.; Hanyu, N.; Nakada, K.; Suzuki, Y.; Yamamoto, T.; Takahashi, T.; Kawasaki, N.; Kawakami, M.; Matsushima, M.; Urashima, M. Endothelin protein expression as a significant prognostic factor in oesophageal squamous cell carcinoma. Eur. J. Cancer 2003, 39, 1409–1415. [Google Scholar] [CrossRef] [PubMed]

- Yoshioka, Y.; Iwata, H.; Tabata, M.; Ninomiya, S.; Ohsawa, R. Chalkiness in Rice: Potential for Evaluation with Image Analysis. Crop Sci. 2007, 47, 2113–2120. [Google Scholar] [CrossRef]

- Yoon, D.-K.; Ishiyama, K.; Suganami, M.; Tazoe, Y.; Watanabe, M.; Imaruoka, S.; Ogura, M.; Ishida, H.; Suzuki, Y.; Obara, M.; et al. Transgenic rice overproducing Rubisco exhibits increased yields with improved nitrogen-use efficiency in an experimental paddy field. Nat. Food 2020, 1, 134–139. [Google Scholar] [CrossRef] [PubMed]

- Tao, K.; Yu, W.; Prakash, S.; Gilbert, R.G. High-amylose rice: Starch molecular structural features controlling cooked rice texture and preference. Carbohydr. Polym. 2019, 219, 251–260. [Google Scholar] [CrossRef] [PubMed]

- Wani, A.A.; Singh, P.; Shah, M.A.; Schweiggert-Weisz, U.; Gul, K.; Wani, I.A. Rice Starch Diversity: Effects on Structural, Morphological, Thermal, and Physicochemical Properties-A Review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 417–436. [Google Scholar] [CrossRef]

- Martin, M.; Fitzgerald, M.A. Proteins in rice grains influence cooking properties! J. Cereal Sci. 2002, 36, 285–294. [Google Scholar] [CrossRef]

- Blazek, J.; Gilbert, E.P. Application of small-angle X-ray and neutron scattering techniques to the characterisation of starch structure: A review. Carbohydr. Polym. 2011, 85, 281–293. [Google Scholar] [CrossRef]

- Lin, L.; Cai, C.; Gilbert, R.G.; Li, E.; Wang, J.; Wei, C. Relationships between amylopectin molecular structures and functional properties of different-sized fractions of normal and high-amylose maize starches. Food Hydrocoll. 2016, 52, 359–368. [Google Scholar] [CrossRef]

- Lv, X.; Ding, Y.; Long, M.; Liang, W.; Gu, X.; Liu, Y.; Wen, X.J. Effect of foliar application of various nitrogen forms on starch accumulation and grain filling of wheat (Triticum aestivum L.) under drought stress. Front. Plant Sci. 2021, 12, 463. [Google Scholar] [CrossRef] [PubMed]

- Warren, F.J.; Gidley, M.J.; Flanagan, B.M. Infrared spectroscopy as a tool to characterise starch ordered structure—A joint FTIR–ATR, NMR, XRD and DSC study. Carbohydr. Polym. 2016, 139, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Sevenou, O.; Hill, S.; Farhat, I.; Mitchell, J.R. Organisation of the external region of the starch granule as determined by infrared spectroscopy. Int. J. Biol. Macromol. 2002, 31, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Cheetham, N.W.; Tao, L. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohydr. Polym. 1998, 36, 277–284. [Google Scholar] [CrossRef]

| pH | Organic Matter (g/kg) | Total Nitrogen (g/kg) | Available Phosphorus (mg/kg) | Available Potassium (mg/kg) |

|---|---|---|---|---|

| 7.04 | 9.76 | 1.46 | 33.24 | 78.52 |

| Number | Treatment | N Level (kg/ha) |

|---|---|---|

| 1 | CK | 0 |

| 2 | N | 300 |

| 3 | LN | 240 |

| 4 | CN1 | 300 |

| 5 | LCN1 | 240 |

| 6 | CN2 | 300 |

| 7 | LCN2 | 240 |

| 8 | CN3 | 300 |

| 9 | LCN3 | 240 |

| 10 | CN4 | 300 |

| 11 | LCN4 | 240 |

| Treatment | Husked Rice Rate (%) | Head Rice Rate (%) | Chalky Rate (%) | Chalkiness (%) | Content of Amylose (%) | Protein Content (%) | Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|---|---|

| N level | ||||||||

| N300 | 75.83a | 67.16a | 5.13a | 0.93b | 18.01a | 9.92a | 655b | 739a |

| N240 | 76.64a | 67.96a | 7.47a | 1.48a | 17.69a | 9.63a | 724a | 706a |

| Types of N fertilizers | ||||||||

| Urea | 74.65c | 66.07b | 3.00c | 0.64c | 18.83a | 9.48d | 691b | 690b |

| CN30 | 76.37abc | 67.71ab | 6.17b | 1.92a | 17.75b | 9.57c | 675b | 705ab |

| CN50 | 75.08bc | 67.27ab | 13.17a | 1.60a | 17.43b | 9.73b | 682b | 731ab |

| CN70 | 78.03a | 68.51a | 5.00bc | 0.84bc | 17.75b | 10.02a | 748a | 737ab |

| CN90 | 77.04ab | 68.28a | 4.17bc | 1.02b | 17.47b | 10.08a | 652b | 749a |

| N level × Types interaction | ||||||||

| CK | 75.63ab | 66.27bc | 12.7ab | 3.17a | 17.37de | 9.53ef | 900a | 745abc |

| N300 × Urea | 73.21b | 64.62c | 3.0c | 0.69e | 19.27a | 9.43fg | 730bcd | 658de |

| N240 × Urea | 76.09ab | 67.51ab | 3.0c | 0.60e | 18.40b | 9.53ef | 651de | 723abcd |

| N300 × CN30 | 77.27a | 68.40ab | 3.0c | 0.67e | 18.20bc | 9.80c | 577ef | 765abc |

| N240 × CN30 | 75.47ab | 67.01abc | 9.3b | 3.17a | 17.30e | 9.33g | 773b | 645e |

| N300 × CN50 | 73.39b | 66.47bc | 10.7b | 1.31c | 17.40de | 9.83bc | 661cde | 700cde |

| N240 × CN50 | 76.77a | 68.06ab | 15.7a | 1.89b | 17.47cde | 9.63de | 703bcd | 761abc |

| N300 × CN70 | 76.77a | 67.63ab | 5.3c | 0.75de | 17.37de | 10.30a | 756b | 778ab |

| N240 × CN70 | 77.66a | 69.39a | 4.7c | 0.93cde | 18.13bcd | 9.73cd | 740bcd | 697cde |

| N300 × CN90 | 78.40a | 68.71ab | 3.7c | 1.23cd | 17.80bcde | 10.23a | 553f | 795a |

| N240 × CN90 | 77.61a | 67.84ab | 4.67c | 0.80de | 17.13e | 9.93b | 752bc | 702bcde |

| Source of variance | ||||||||

| N level | - | - | - | *** | - | - | * | - |

| Types of N fertilizers | ** | - | *** | *** | *** | *** | * | - |

| N level × Types | * | - | * | *** | ** | *** | *** | ** |

| Treatment | Length (mm) | Width (mm) | Length/Width (mm) |

|---|---|---|---|

| CK | 5.76 ± 0.02a | 2.57 ± 0.01a | 2.26 ± 0.01d |

| N | 5.70 ± 0.04a | 2.47 ± 0.02c | 2.32 ± 0.00ab |

| LN | 5.64 ± 0.05a | 2.47 ± 0.02bc | 2.29 ± 0.00bc |

| CN1 | 5.68 ± 0.04a | 2.48 ± 0.01bc | 2.30 ± 0.01abc |

| LCN1 | 5.69 ± 0.03a | 2.52 ± 0.01abc | 2.28 ± 0.02cd |

| CN2 | 5.70 ± 0.03a | 2.49 ± 0.02bc | 2.30 ± 0.01bc |

| LCN2 | 5.76 ± 0.05a | 2.50 ± 0.02bc | 2.32 ± 0.02ab |

| CN3 | 5.75 ± 0.03a | 2.46 ± 0.02c | 2.34 ± 0.01a |

| LCN3 | 5.76 ± 0.05a | 2.53 ± 0.03ab | 2.29 ± 0.00bcd |

| CN4 | 5.68 ± 0.02a | 2.48 ± 0.01bc | 2.31 ± 0.00abc |

| LCN4 | 5.70 ± 0.02a | 2.51 ± 0.00abc | 2.29 ± 0.01bcd |

| Treatment | Peak Viscosity (cP) | Hot Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback (cP) | Peaking Time (S) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|---|

| CK | 2774a | 2153a | 900a | 3628a | 745abc | 6.53a | 75.10d |

| N | 2487cd | 1757cd | 730bcd | 3144d | 658de | 6.40a | 89.38bc |

| LN | 2396de | 1745cd | 651de | 3119d | 723abcd | 6.33a | 88.57c |

| CN1 | 2254f | 1637d | 577ef | 3019e | 765abc | 6.51a | 91.47a |

| LCN1 | 2509c | 1736cd | 773b | 3154d | 645e | 6.40a | 88.78c |

| CN2 | 2406de | 1821c | 661cde | 3106de | 700cde | 6.47a | 89.85abc |

| LCN2 | 2547c | 1774cd | 703bcd | 3326b | 761abc | 6.49a | 90.42abc |

| CN3 | 2483cd | 1644d | 756b | 3183d | 778ab | 6.33a | 90.52abc |

| LCN3 | 2653b | 1988b | 740bcd | 3284bc | 697cde | 6.47a | 89.27bc |

| CN4 | 2342ef | 1804c | 553f | 3192cd | 795a | 6.56a | 90.95ab |

| LCN4 | 2349ef | 1762cd | 752bc | 3207cd | 702bcde | 6.36a | 89.88abc |

| Treatment | IR Ratio | |

|---|---|---|

| 1045/1022 cm−1 | 1022/995 cm−1 | |

| CK | 0.545 | 1.139 |

| N | 0.776 | 2.100 |

| LN | 0.538 | 1.184 |

| CN1 | 0.513 | 1.129 |

| LCN1 | 0.508 | 1.170 |

| CN2 | 0.492 | 1.064 |

| LCN2 | 0.512 | 1.132 |

| CN3 | 0.491 | 1.176 |

| LCN3 | 0.590 | 1.358 |

| CN4 | 0.503 | 1.066 |

| LCN4 | 0.479 | 1.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Wang, R.; Yao, Y.; Wang, X.; He, J.; Yang, Y. Effects of Controlled-Release Nitrogen Fertilizer at Different Release Stages on Rice Yield and Quality. Agronomy 2024, 14, 1685. https://doi.org/10.3390/agronomy14081685

Yu Z, Wang R, Yao Y, Wang X, He J, Yang Y. Effects of Controlled-Release Nitrogen Fertilizer at Different Release Stages on Rice Yield and Quality. Agronomy. 2024; 14(8):1685. https://doi.org/10.3390/agronomy14081685

Chicago/Turabian StyleYu, Zhen, Runnan Wang, Yuanyuan Yao, Xiaoqi Wang, Jiali He, and Yuechao Yang. 2024. "Effects of Controlled-Release Nitrogen Fertilizer at Different Release Stages on Rice Yield and Quality" Agronomy 14, no. 8: 1685. https://doi.org/10.3390/agronomy14081685

APA StyleYu, Z., Wang, R., Yao, Y., Wang, X., He, J., & Yang, Y. (2024). Effects of Controlled-Release Nitrogen Fertilizer at Different Release Stages on Rice Yield and Quality. Agronomy, 14(8), 1685. https://doi.org/10.3390/agronomy14081685