Preparation and Application of Multi-Walled Carbon Nanotube-Supported Metconazole Suspension Concentrate for Seed Coating to Control Wheat Sharp Eyespot

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material, Fungal Pathogen, and Chemical Reagents

2.2. Adsorption Rate and Loading Capacity of MWCNTs

2.3. Selection of Different Adjuvant for the Suspension Concentrate for Seed Coating

2.4. Development of the Suspension Concentrate for Seed Coating and Verification of Field Effect

2.5. Effect of Metconazole Concentration on Wheat Sharp Eyespot under Controlled Conditions

2.6. Statistical Analysis

3. Results

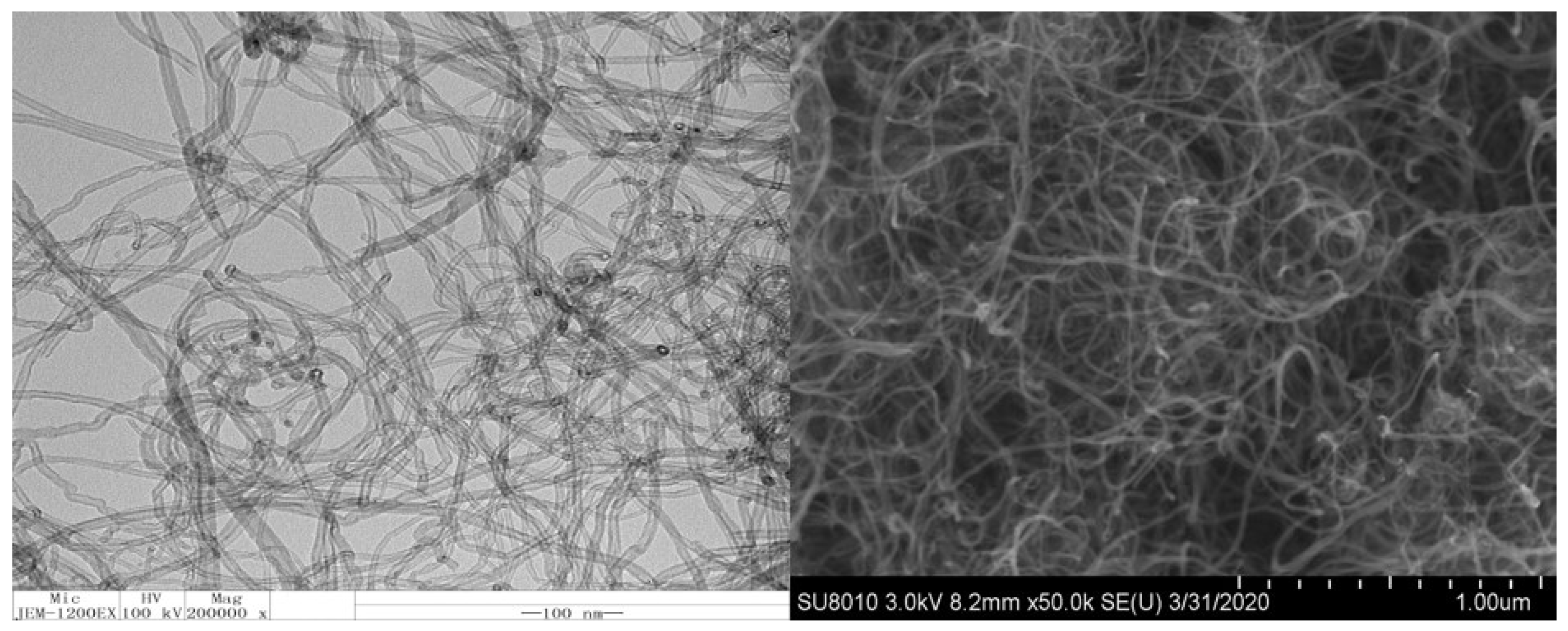

3.1. Electron Microscope Pictures of MWCNTs

3.2. Establishment of a Standard Curve for Metconazole

3.3. Optimum Preparation Conditions of MWCNTs–Metconazole

3.4. Determination of the Optimal Composition of the Suspension Concentrate for Seed Coating

3.4.1. Optimal Dispersant Selection

3.4.2. Emulsifier and Antifreeze Selection

3.5. The Field Effect of Different Suspension Concentrates for Seed Coating

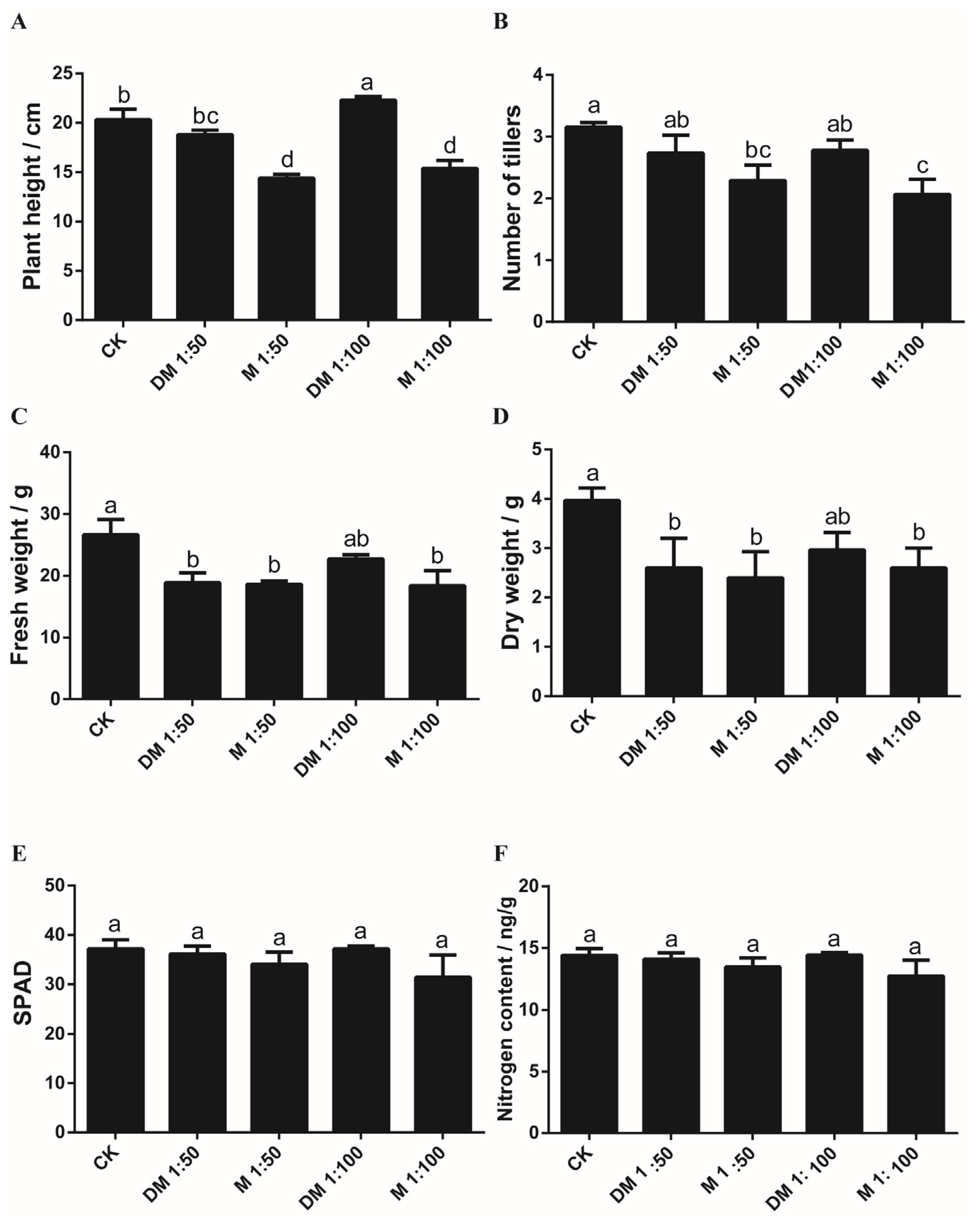

3.5.1. The Field Effect of Different Suspension Concentrates for Seed Coating at the Seedling Stage

3.5.2. The Field Effect of Different Suspension Concentrates for Seed Coating at the Tillering Stage

3.6. FSC (DM) Treatment Significantly Improves the Effectiveness of Wheat Sharp Eyespot

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Su, J.; Zhao, J.; Zhao, S.; Li, M.; Pang, S.; Kang, Z.; Zhen, W.; Chen, S.; Chen, F.; Wang, X. Genetics of resistance to common root rot (spot blotch), Fusarium crown rot, and sharp eyespot in wheat. Front. Genet. 2021, 12, 699342. [Google Scholar] [CrossRef]

- Liu, J.; Anderson, N.P.; Mundt, C.C. Methods for screening wheat genotypes for resistance to sharp eyespot in the field and greenhouse. Plant Dis. 2020, 104, 3192–3196. [Google Scholar] [CrossRef]

- Wu, X.; Wang, J.; Wu, D.; Jiang, W.; Gao, Z.; Li, D.; Wu, R.; Gao, D.; Zhang, Y. Identification of new resistance loci against wheat sharp eyespot through genome-wide association study. Front. Plant Sci. 2022, 13, 1056935. [Google Scholar] [CrossRef] [PubMed]

- Vasilchenko, A.V.; Poshvina, D.V.; Semenov, M.V.; Timofeev, V.N.; Iashnikov, A.V.; Stepanov, A.A.; Pervushina, A.N.; Vasilchenko, A.S. Triazoles and strobilurin mixture affects soil microbial community and incidences of wheat diseases. Plants 2023, 12, 660. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Fan, S.; Zhang, Y.; Zhang, X.; Luo, J.; Liu, C. Toxicity, bioactivity of triazole fungicide metconazole and its effect on mycotoxin production by Fusarium verticillioides: New perspective from an enantiomeric level. Sci. Total Environ. 2022, 828, 154432. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Khan, Z.; Yu, Q.; Qu, Z.; Liu, J.; Luo, T.; Zhu, K.; Bi, J.; Hu, L.; Luo, L. Biochar coating is a sustainable and economical approach to promote seed coating technology, seed germination, plant performance, and soil health. Plants 2022, 11, 2864. [Google Scholar] [CrossRef]

- Javed, T.; Afzal, I.; Shabbir, R.; Ikram, K.; Saqlain Zaheer, M.; Faheem, M.; Haider Ali, H.; Iqbal, J. Seed coating technology: An innovative and sustainable approach for improving seed quality and crop performance. J. Saudi Soc. Agric. Sci. 2022, 21, 536–545. [Google Scholar] [CrossRef]

- Bayda, S.; Adeel, M.; Tuccinardi, T.; Cordani, M.; Rizzolio, F. The history of nanoscience and nanotechnology: From chemical-physical applications to nanomedicine. Molecules 2020, 25, 112. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Sheng, X.; Li, N.; Ping, Q. Adsorption and release kinetics, equilibrium, and thermodynamic studies of hymexazol onto diatomite. ACS Omega 2020, 5, 29504–29512. [Google Scholar] [CrossRef]

- Xu, C.; Cao, L.; Zhao, P.; Zhou, Z.; Cao, C.; Li, F.; Huang, Q. Emulsion-based synchronous pesticide encapsulation and surface modification of mesoporous silica nanoparticles with carboxymethyl chitosan for controlled azoxystrobin release. Chem. Eng. J. 2018, 348, 244–254. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, H.; Cao, C.; Zhang, J.; Li, F.; Huang, Q. Quaternized chitosan-capped mesoporous silica nanoparticles as nanocarriers for controlled pesticide release. Nanomater 2016, 6, 126. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Zhou, Z.; Niu, S.; Cao, C.; Li, X.; Shan, Y.; Huang, Q. Positive-charge functionalized mesoporous silica nanoparticles as nanocarriers for controlled 2,4-Dichlorophenoxy acetic acid sodium salt release. J. Agric. Food Chem. 2018, 66, 6594–6603. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Cao, L.; Ma, D.; Zhou, Z.; Huang, Q.; Pan, C. Synthesis of pyrimethanil-loaded mesoporous silica nanoparticles and its distribution and dissipation in cucumber plants. Molecules 2017, 22, 817. [Google Scholar] [CrossRef]

- Zhao, Y.; Hua, X.; Rui, Q.; Wang, D. Exposure to multi-walled carbon nanotubes causes suppression in octopamine signal associated with transgenerational toxicity induction in C.elegans. Chemosphere 2023, 318, 137986. [Google Scholar] [CrossRef]

- Pereira, H.A.; da Boit Martinello, K.; Vieira, Y.; Diel, J.C.; Netto, M.S.; Reske, G.D.; Lorenzett, E.; Silva, L.F.O.; Burgo, T.A.L.; Dotto, G.L. Adsorptive behavior of multi-walled carbon nanotubes immobilized magnetic nanoparticles for removing selected pesticides from aqueous matrices. Chemosphere 2023, 325, 138384. [Google Scholar] [CrossRef]

- Zhao, J.; Tan, S.; Li, H.; Wang, Y.; Yao, T.; Liu, L.; Liu, K. Multi-walled carbon nanotubes remediate the phytotoxicity of quinclorac to tomato. Bull. Environ. Contam. Toxicol. 2022, 109, 477–483. [Google Scholar] [CrossRef]

- Li, J.; Huo, L.; Gong, Z.; Xu, H.; Wang, Y.; Guo, C.; Yang, X.; Luo, X. Preparation of sodium lignosulfonate adsorptionmaterials and their sdsorption properties for Congo red. J. Zhejiang AF Univ. 2024, 41, 870–878. (In Chinese) [Google Scholar]

- Su, X.; Jiang, L.; Yu, S.; Xu, C. Functionalization of multi-walled carbon nanotubes preparation and efficient of the chaff amine adsorption. J. Ion Exch. Adsorpt. 2022, 38, 426–436. (In Chinese) [Google Scholar]

- Gálvez, A.; López-Galindo, A.; Peña, A. Effect of different surfactants on germination and root elongation of two horticultural crops: Implications for seed coating. N. Z. J. Crop Hortic. Sci 2019, 47, 83–98. [Google Scholar] [CrossRef]

- Zhang, X.; Ru, L.; Zheng, X.; Zhang, Z.; Wu, H.; Ren, X.; Li, H.; Liu, C. Fungicidal activity of SYP-4288 against soil-born e diseases. Plant Prot. 2016, 42, 255–260. [Google Scholar]

- Iquebal, M.A.; Mishra, P.; Maurya, R.; Jaiswal, S.; Rai, A.; Kumar, D. Centenary of soil and air borne wheat karnal bunt disease research: A review. Biology 2021, 10, 1152. [Google Scholar] [CrossRef]

- Okubara, P.A.; Dickman, M.B.; Blechl, A.E. Molecular and genetic aspects of controlling the soilborne necrotrophic pathogens Rhizoctonia and Pythium. Plant Sci. 2014, 228, 61–70. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Que, Y.; Yu, D.; Wang, H. The influence of rhizosphere soil fungal diversity and complex community structure on wheat root rot disease. PeerJ 2021, 9, e12601. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Chen, S.; Yan, X.; Wang, Z.; Yuan, H.; Yang, D. Factors underlying the prevalence of pythium infection of corn seeds following seed treatment application of tebuconazole. Plant Dis. 2022, 106, 1134–1142. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forró, L.; Zuppiroli, W.B. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Hayat, K.; Zhang, D.; Zhou, P. Small structures with big impact: Multi-walled carbon nanotubes enhanced remediation efficiency in hyperaccumulator Solanum nigrum L. under cadmium and arsenic stress. Chemosphere 2021, 276, 130130. [Google Scholar] [CrossRef]

- Fu, X.; Wais, A.M.H.; Yasin, Y.; Ibrahim, I.T.; Ali, A.S.; Al-Majdi, K.; Khazaal, W.M.; Hadrawi, S.K.; Abed, A.S.; Riyahi, Y.; et al. Molecular modeling investigation on mechanism of diazinon pesticide removal from water by single- and multi-walled carbon nanotubes. Ecotoxicol. Environ. Saf. 2023, 256, 114857. [Google Scholar] [CrossRef]

- Kthiri, Z.; Jabeur, M.B.; Chairi, F.; López-Cristoffanini, C.; López-Carbonell, M.; Serret, M.D.; Araus, J.L.; Karmous, C.; Hamada, W. Exploring the potential of Meyerozyma guilliermondii on physiological performances and defense response against Fusarium crown rot on durum wheat. Pathogens 2021, 10, 52. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Liang, S.; Zheng, W.; Chen, X.; Liu, J.; Wang, A. Study on the preparation and effect of tomato seedling disease biocontrol compound seed-coating agent. Life 2022, 12, 849. [Google Scholar] [CrossRef]

- Tu, L.; He, Y.; Shan, C.; Wu, Z. Preparation of microencapsulated bacillus subtilis SL-13 seed coating agents and their effects on the growth of cotton seedlings. Biomed Res. Int. 2016, 2016, 3251357. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.N.; Liu, Y.T.; Li, Y.L.; Sun, Y.Y.; Yang, B.M.; Lai, H.X.; Xue, Q.H. Effects and mechanism of two Streptomyces strains on promoting plant growth and increasing grain yield of maize. J. Appl. Ecol. 2017, 28, 315–326. (In Chinese) [Google Scholar]

- Lüth, P.; Nzioki, H.S.; Sands Baker, C.; Sands, D.C. A microbial bioherbicide for Striga hermonthica control: Production, development, and effectiveness of a seed coating agent. Pest Manag. Sci. 2024, 80, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Ehsanfar, S.; Modarres-Sanavy, S.A.M. Crop protection by seed coating. Commun. Agric. Appl. Biol. Sci. 2005, 70, 225–229. [Google Scholar]

- Mattei, V.; Motta, A.; Saracchi, M.; Kunova, A.; Cortesi, P.; Pizzatti, C.; Pasquali, M. Wheat Seed Coating with Streptomyces sp. Strain DEF39 spores protects against Fusarium head blight. Microorganisms 2022, 10, 1536. [Google Scholar] [CrossRef]

- Huang, F.; Hao, Z.; Yan, F. Influence of oilseed rape seed treatment with imidacloprid on survival, feeding behavior, and detoxifying enzymes of mustard aphid, Lipaphis erysimi. Insects 2019, 10, 144. [Google Scholar] [CrossRef]

| Dispersant and Concentration (%) | Volume Mean Diameter (μm) | Area Mean Diameter (μm) | |

|---|---|---|---|

| Sodium lignosulfonate | 1 | 32.91 ± 0.47 d | 21.86 ± 0.67 d |

| 1.5 | 24.72 ± 1.88 g | 14.81 ± 1.14 g | |

| 2 | 28.11 ± 4.13 f | 16.15 ± 3.02 e | |

| 2.5 | 30.63 ± 0.43 e | 15.46 ± 1.33 f | |

| NNO | 1 | 37.76 ± 1.04 b | 25.35 ± 1.16 b |

| 1.5 | 33.80 ± 1.90 c | 23.51 ± 1.75 c | |

| 2 | 34.86 ± 1.31 c | 20.82 ± 2.59 d | |

| 2.5 | 45.13 ± 1.21 a | 30.35 ± 2.03 a | |

| Number | Layering Rate (%) |

|---|---|

| PEG4000 | 7.5 ± 0.26 k |

| TX-50 | 10.0 ± 0.77 j |

| JFC-1 | 65.0 ± 3.21 a |

| HEL-40 | 5.0 ± 0.14 l |

| BY-112 | 2.5 ± 0.10 m |

| EL-10 | 17.5 ± 1.10 h |

| O-10 | 20.0 ± 1.71 g |

| SG-10 | 67.5 ± 3.20 a |

| SG-9 | 65.0 ± 3.31 a |

| MOA-7 | 30.0 ± 2.10 c |

| MOA-15 | 30.0 ± 1.55 c |

| S-20 | 27.5 ± 1.77 d |

| L-65 | 25.0 ± 1.35 e |

| PPG600 | 45.0 ± 2.10 b |

| L-35 | 22.5 ± 1.66 f |

| O-20 | 12.5 ± 0.71 i |

| E-1303 | 10.0 ± 0.52 j |

| OS-15 | 17.5 ± 1.21 h |

| AEO-15 | 0 ± 0.00 n |

| HSH-206 | 5.0 ± 0.41 l |

| Number | BY-112 (%) | AEO-15 (%) | Ethynediol (%) | Area Mean Diameter (μm) | Volume Mean Diameter (μm) |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 2 | 20.58 ± 0.29 e | 31.57 ± 0.51 g |

| 2 | 1 | 2 | 3 | 16.16 ± 1.22 f | 30.27 ± 2.91 g |

| 3 | 1 | 3 | 4 | 15.51 ± 1.60 f | 40.48 ± 2.11 f |

| 4 | 2 | 1 | 3 | 21.36 ± 0.6 e | 38.71 ± 2.19 f |

| 5 | 2 | 2 | 4 | 42.63 ± 2.36 c | 81.78 ± 2.68 d |

| 6 | 2 | 3 | 2 | 29.09 ± 0.78 d | 88.43 ± 4.68 c |

| 7 | 3 | 1 | 4 | 65.99 ± 7.99 a | 136.46 ± 4.69 a |

| 8 | 3 | 2 | 2 | 57.12 ± 7.26 b | 125.82 ± 7.15 b |

| 9 | 3 | 3 | 3 | 20.35 ± 0.75 e | 47.85 ± 2.01 e |

| Treatment | Coating Ratio (g/g) | Disease Index | Control Efficiency (%) |

|---|---|---|---|

| 0.5% MWCNT–metconazole FSC (DM) | 1:25 | 3.17 ± 0.55 e | 86.14 ± 0.37 a |

| 1:50 | 4.13 ± 1.45 de | 82.25 ± 0.91 ab | |

| 1:100 | 5.40 ± 1.09 de | 75.86 ± 1.09 ab | |

| 1:200 | 7.30 ± 0.54 cde | 67.42 ± 0.56 abc | |

| 0.5% metconazole FSC (M) | 1:25 | 6.98 ± 3.06 cde | 68.61 ± 1.13 abc |

| 1:50 | 8.57 ± 4.95 bcd | 61.04 ± 0.47 bcd | |

| 1:100 | 10.48 ± 3.43 bc | 52.60 ± 0.87 cd | |

| 1:200 | 12.38 ± 1.90 b | 45.12 ± 0.66 d | |

| CK | — | 22.86 ± 3.30 a | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, X.; Qi, D.; Li, Z.; Chi, Y.; Su, X.; Gu, K.; Ye, Z.; He, S.; Chen, L. Preparation and Application of Multi-Walled Carbon Nanotube-Supported Metconazole Suspension Concentrate for Seed Coating to Control Wheat Sharp Eyespot. Agronomy 2024, 14, 1985. https://doi.org/10.3390/agronomy14091985

Ren X, Qi D, Li Z, Chi Y, Su X, Gu K, Ye Z, He S, Chen L. Preparation and Application of Multi-Walled Carbon Nanotube-Supported Metconazole Suspension Concentrate for Seed Coating to Control Wheat Sharp Eyespot. Agronomy. 2024; 14(9):1985. https://doi.org/10.3390/agronomy14091985

Chicago/Turabian StyleRen, Xuexiang, Dongdong Qi, Zhao Li, Yu Chi, Xianyan Su, Kaixin Gu, Zhenghe Ye, Shun He, and Li Chen. 2024. "Preparation and Application of Multi-Walled Carbon Nanotube-Supported Metconazole Suspension Concentrate for Seed Coating to Control Wheat Sharp Eyespot" Agronomy 14, no. 9: 1985. https://doi.org/10.3390/agronomy14091985