Impact of Integrating Flameless Combustion Technology and Sludge–Fly Ash Recirculation on PCDE Emissions in Hazardous Waste Thermal Treatment Systems

Abstract

:1. Introduction

2. Material and Methods

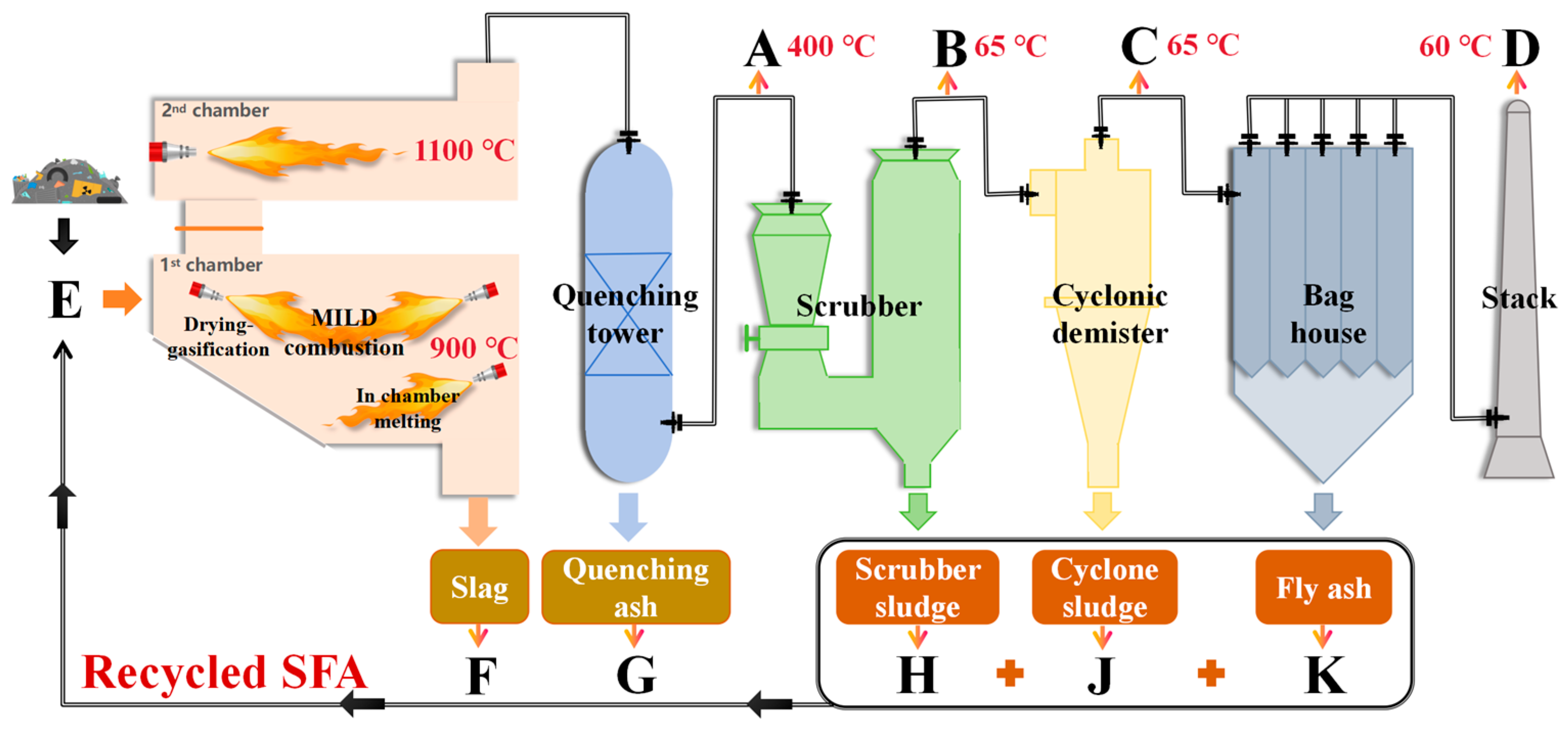

2.1. HAWTTS Overview

2.1.1. Flameless Combustion System

2.1.2. Air Pollution Control System (APCS)

2.2. Experimental Design

2.3. PCDE Measurement

2.4. Calculation of PCDE Congener Removal Efficiency and Net Emissions

3. Results and Discussion

3.1. PCDE Congeners in Incinerators

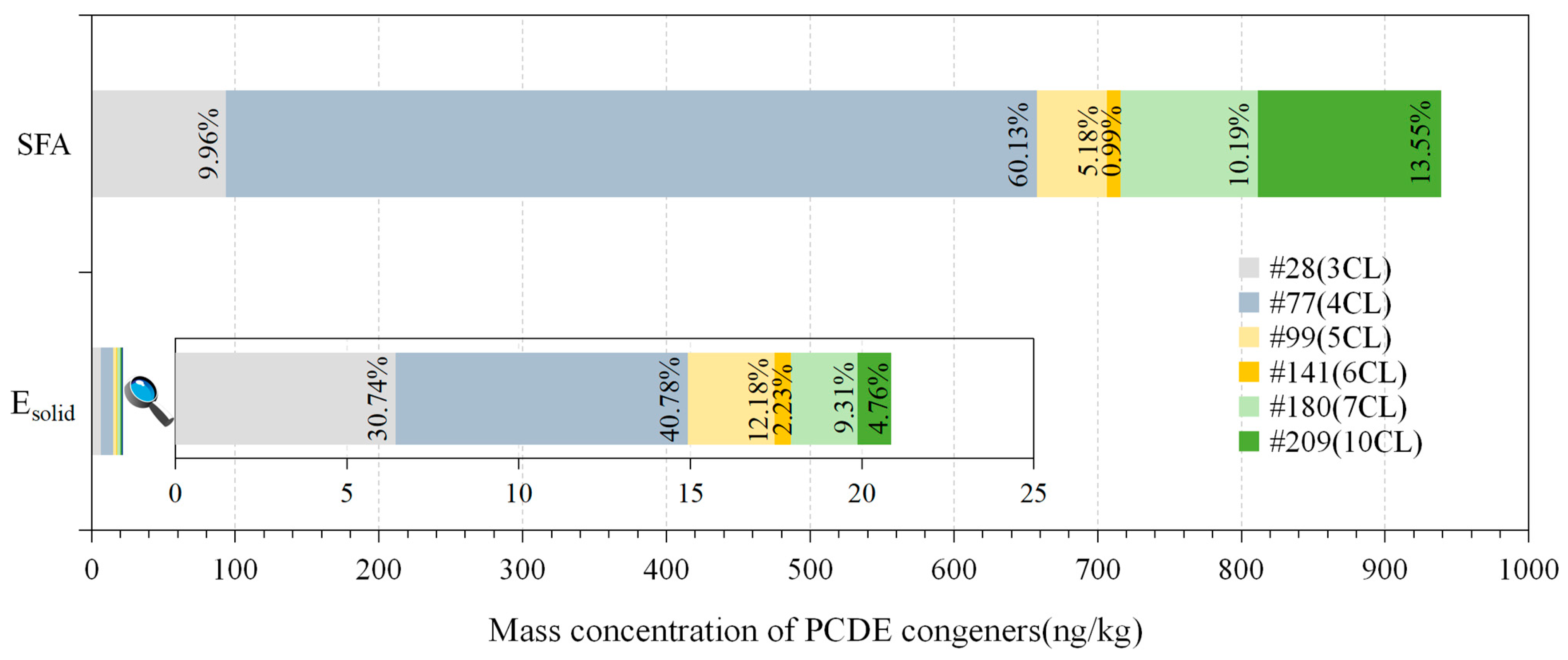

3.1.1. Input of PCDE Congeners

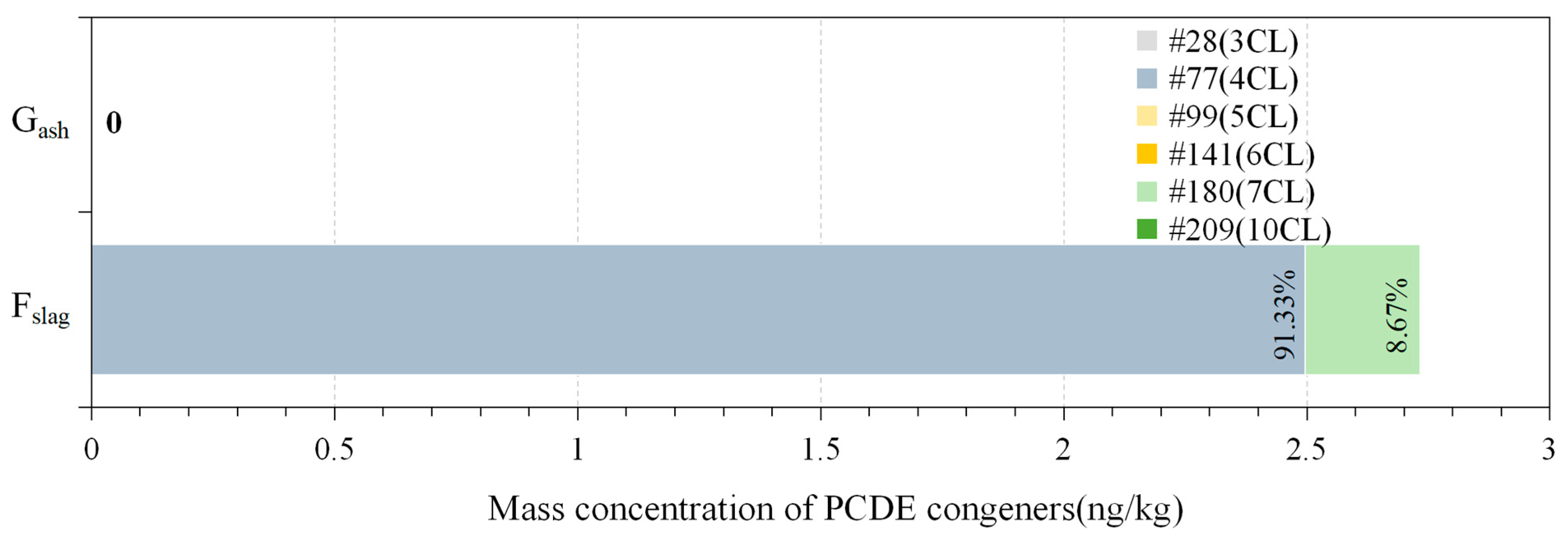

3.1.2. Output of PCDE Congeners

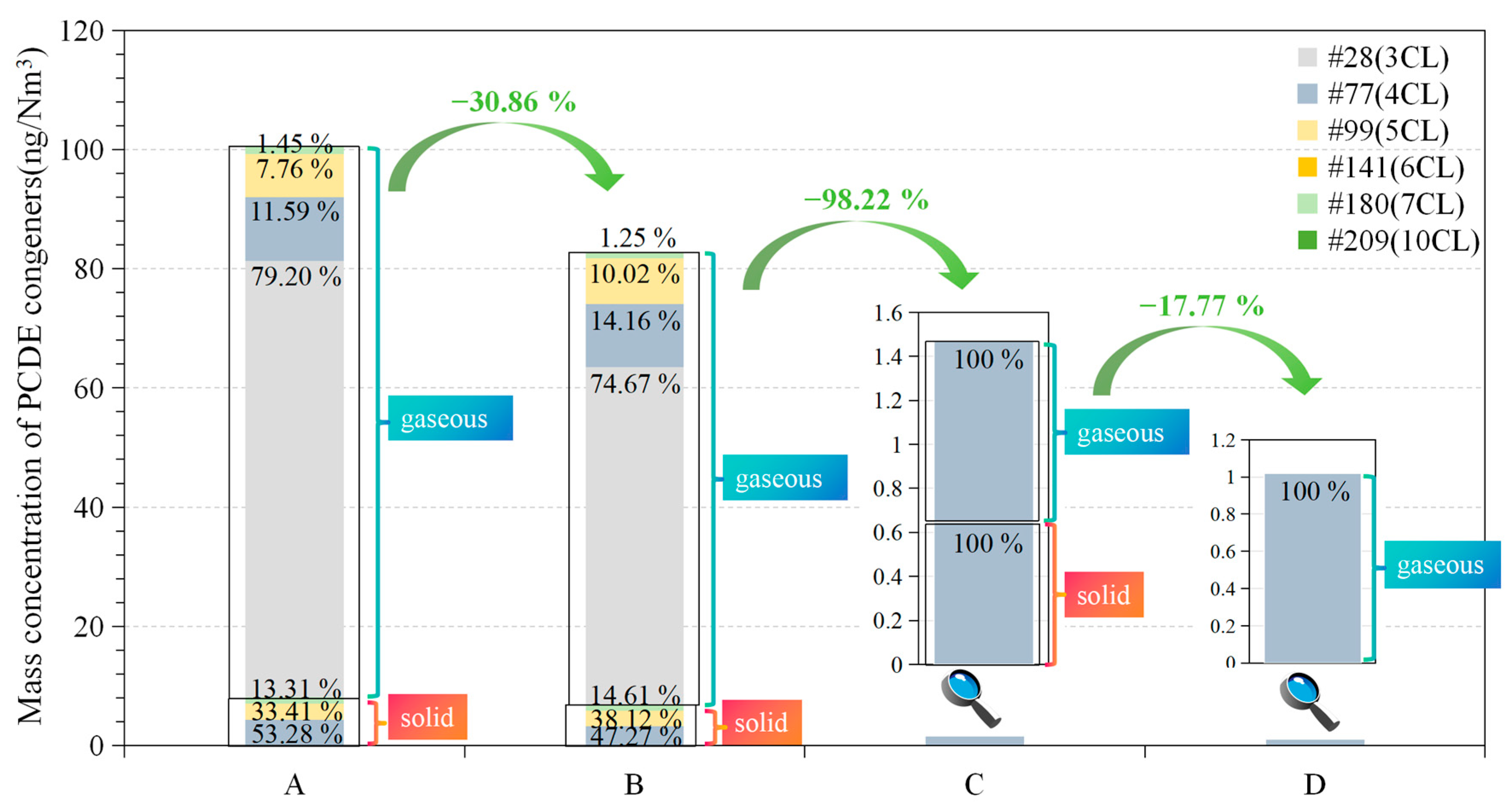

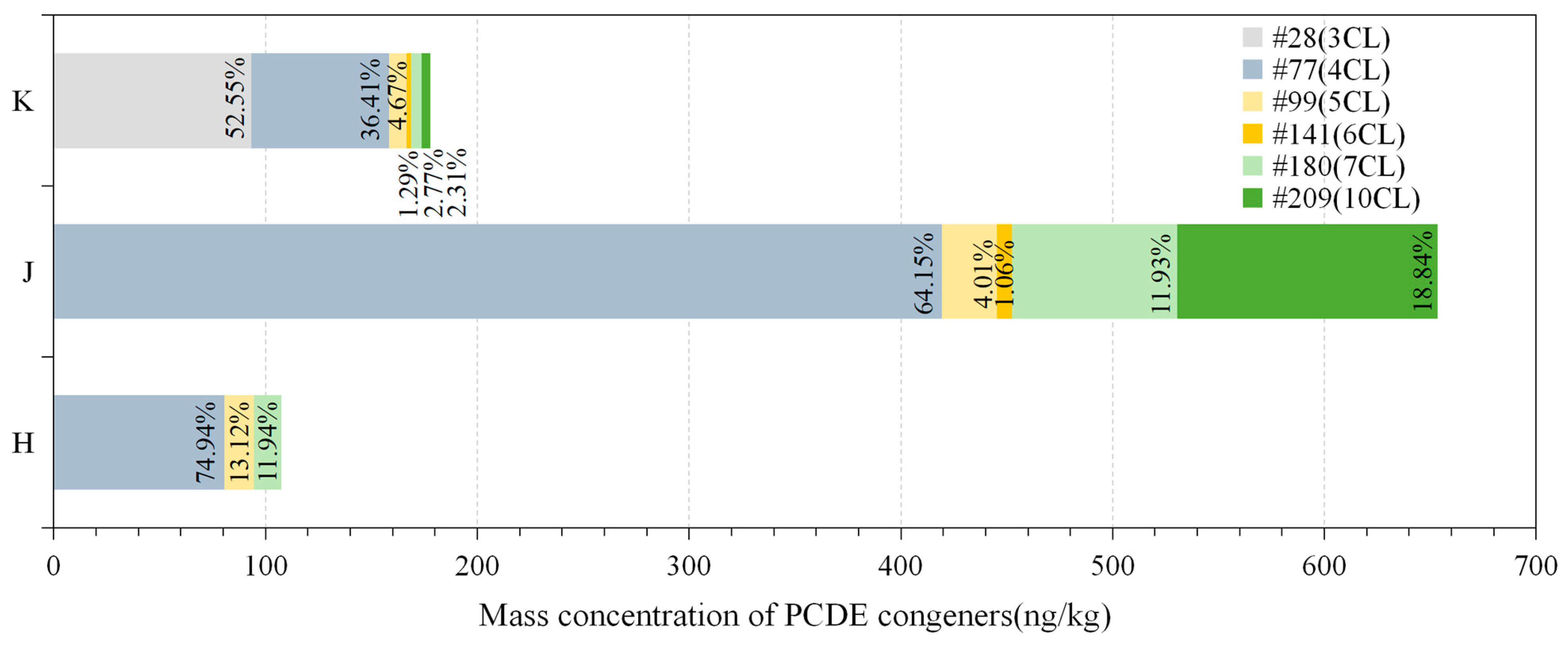

3.2. Distribution of PCDE Congeners in the APCS

3.2.1. Mass Concentration of PCDE Congeners in APCS Flue Gas

3.2.2. Mass Concentration of PCDE Congeners in Recirculated SFA

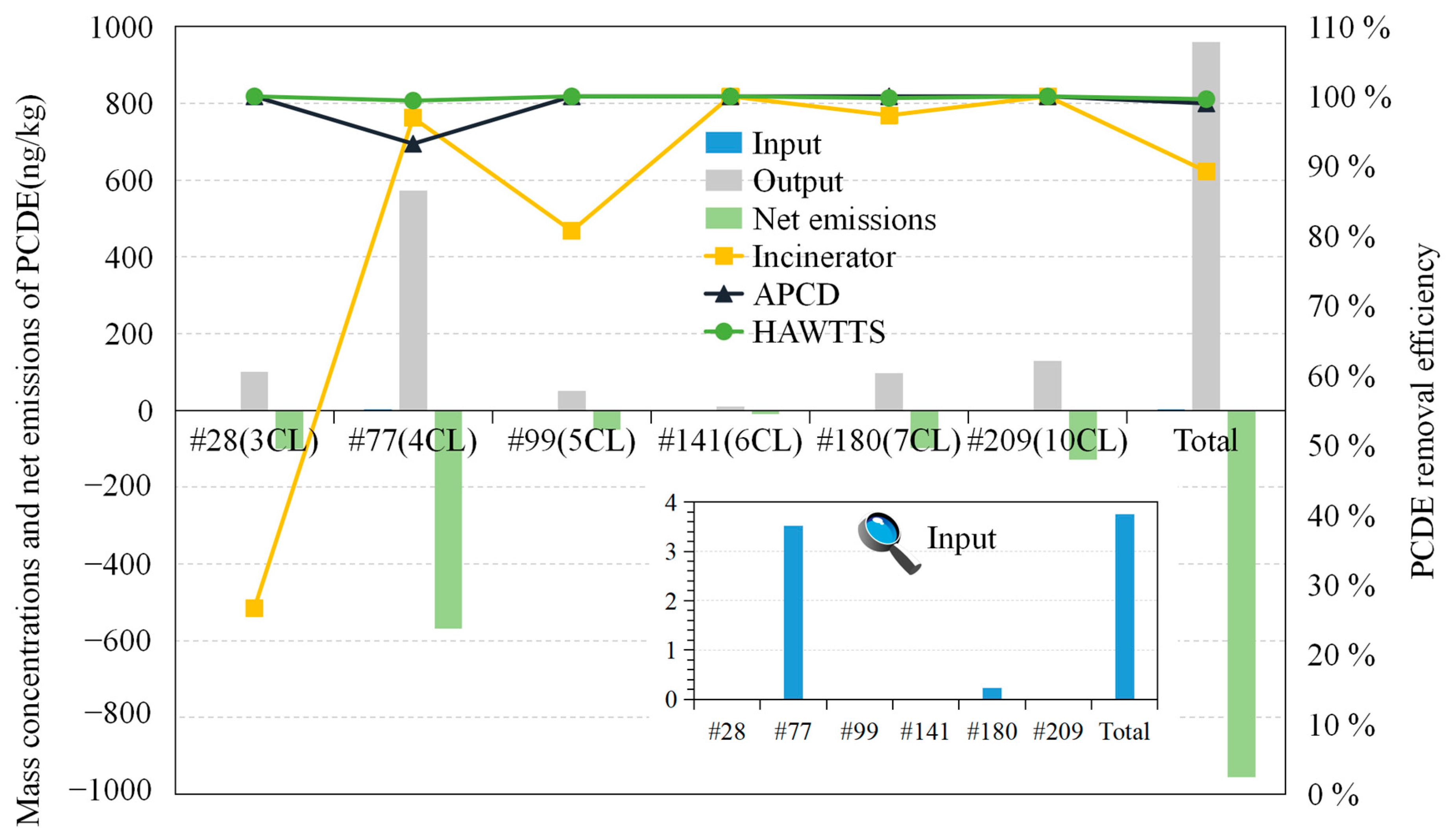

3.3. Removal Efficiency and Net Emissions of PCDE Congeners by the HAWTTS

4. Conclusions

- Flameless combustion: This technology promotes uniform temperature distribution and complete combustion, minimizing PCDE formation in the slag. Additionally, the high-temperature, rapid-cooling quenching process further prevents PCDE presence in the bottom slag. Flameless combustion also addresses challenges like high moisture content in raw materials and carbon adhesion during SFA recovery.

- Air pollution control system: While the incinerator demonstrates variable removal efficiencies due to volatility differences among PCDEs, the APCS effectively compensates for this by achieving high removal efficiencies (93.21% to 100%). Notably, the cyclone demister (CYCD) exhibits exceptional performance, reaching complete removal for CDE congeners #28, #99, and #180.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC(I) | activated carbon (injection) |

| APCDs | air pollution control devices |

| APCS | air pollution control system |

| BHs | bag houses |

| CYCDs | cyclone demisters |

| FLOX | flameless oxidation |

| HAWTTS | hazardous waste thermal treatment system |

| HTAC | high-temperature air combustion |

| INC | incinerator |

| MILD | moderate or intense low-oxygen dilution |

| PAHs | polycyclic aromatic hydrocarbons |

| PCBs | polychlorinated biphenyls |

| PCDEs | polychlorinated diphenyl ethers |

| PCDDs/Fs | polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans |

| PCDFs | polychlorinated dibenzo-p-furans |

| SCBs | scrubbers |

| SFA | sludge and/or fly ash |

References

- Wu, Q.; Wu, Q.; Wang, X.; Zhang, X.; Zhang, R. Polychlorinated Diphenyl Ethers in the Environment: A Review and Future Perspectives. Int. J. Environ. Res. Public Health 2023, 20, 3982. [Google Scholar] [CrossRef] [PubMed]

- Koistinen, J. Polychlorinated Diphenyl Ethers (PCDE); Anthropogenic Compounds Part K; Springer: Berlin/Heidelberg, Germany, 2000; Volume 3, pp. 157–201. [Google Scholar]

- Kurz, J.; Ballschmiter, K. Vapour pressures, aqueous solubilities, Henry’s law constants, partition coefficients between gas/water (Kgw), n-octanol/water (Kow) and gas/n-octanol (Kgo) of 106 polychlorinated diphenyl ethers (PCDE). Chemosphere 1999, 38, 573–586. [Google Scholar] [CrossRef] [PubMed]

- Lake, J.L.; Rogerson, P.F.; Norwood, C.B. A polychlorinated dibenzofuran and related compounds in an estuarine ecosystem. Environ. Sci. Technol. 1981, 15, 549–553. [Google Scholar] [CrossRef] [PubMed]

- Niimi, A.; Huestis, S.; Metcalfe, C. Chlorinated diphenyl ethers in Great Lakes fish and their environmental implication. Environ. Toxicol. Chem. Int. J. 1994, 13, 1133–1138. [Google Scholar] [CrossRef]

- Williams, D.T.; Kennedy, B.; LeBel, G.L. Chlorinated diphenyl ethers in human adipose tissue. Part 2. Chemosphere 1991, 23, 601–608. [Google Scholar] [CrossRef]

- Igbinosa, E.O.; Odjadjare, E.E.; Chigor, V.N.; Igbinosa, I.H.; Emoghene, A.O.; Ekhaise, F.O.; Igiehon, N.O.; Idemudia, O.G. Toxicological profile of chlorophenols and their derivatives in the environment: The public health perspective. Sci. World J. 2013, 2013, 460215. [Google Scholar] [CrossRef] [PubMed]

- Kurz, J.; Ballschmiter, K. Isomer-Specific Determination of 79 Polychlorinated Diphenyl Ethers (Pcde) in Cod-Liver Oils, Chlorophenols and in a Fly Ash. Fresenius J. Anal. Chem. 1995, 351, 98–109. [Google Scholar] [CrossRef]

- Yang, J.-S.; Lin, S.-L.; Lin, T.-C.; Wu, Y.-L.; Wang, L.-C.; Chang-Chien, G.-P. Emissions of polychlorinated diphenyl ethers from a municipal solid waste incinerator during the start-up operation. J. Hazard. Mater. 2015, 299, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Cheruiyot, N.K.; Yang, H.-H.; Wang, L.-C.; Lin, C.-C. Feasible and effective control strategies on extreme emissions of chlorinated persistent organic pollutants during the start-up processes of municipal solid waste incinerators. Environ. Pollut. 2020, 267, 115469. [Google Scholar] [CrossRef] [PubMed]

- Huestis, S.; Sergeant, D. Removal of chlorinated diphenyl ether interferences for analyses of PCDDs and PCDFs in fish. Chemosphere 1992, 24, 537–545. [Google Scholar] [CrossRef]

- Wang, S.; Hao, C.; Gao, Z.; Chen, J.; Qiu, J. Theoretical investigations on direct photolysis mechanisms of polychlorinated diphenyl ethers. Chemosphere 2014, 111, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Altarawneh, M.; Dlugogorski, B.Z. Mechanisms of transformation of polychlorinated diphenyl ethers into polychlorinated dibenzo-p-dioxins and dibenzofurans. Chemosphere 2014, 114, 129–135. [Google Scholar] [CrossRef] [PubMed]

- Lindahl, R.; Rappe, C.; Buser, H.R. Formation of polychlorinated dibenzofurans (PCDFs) and polychlorinated dibenzo-p-dioxins (PCDDs) from the pyrolysis of polychlorinated diphenyl ethers. Chemosphere 1980, 9, 351–361. [Google Scholar] [CrossRef]

- Abuelnuor, A.; Wahid, M.; Hosseini, S.E.; Saat, A.; Saqr, K.M.; Sait, H.H.; Osman, M. Characteristics of biomass in flameless combustion: A review. Renew. Sustain. Energy Rev. 2014, 33, 363–370. [Google Scholar] [CrossRef]

- Zheng, L.; Song, J.; Li, C.; Gao, Y.; Geng, P.; Qu, B.; Lin, L. Preferential policies promote municipal solid waste (MSW) to energy in China: Current status and prospects. Renew. Sustain. Energy Rev. 2014, 36, 135–148. [Google Scholar] [CrossRef]

- Werther, J.; Ogada, T. Sewage sludge combustion. Prog. Energy Combust. Sci. 1999, 25, 55–116. [Google Scholar] [CrossRef]

- Blasiak, W.; Yang, W.; Narayanan, K.; Von Schéele, J. Flameless oxyfuel combustion for fuel consumption and nitrogen oxides emissions reductions and productivity increase. J. Energy Inst. 2007, 80, 3–11. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A.; Abuelnuor, A.A.A. Biogas flameless combustion: A review. Appl. Mech. Mater. 2013, 388, 273–279. [Google Scholar] [CrossRef]

- Zhong, Z.; Jin, B.; Huang, Y.; Zhou, H.; Zhang, M. Experimental study on flue gas purifying of MSW incineration using in-pipe jet adsorption techniques. Waste Manag. 2008, 28, 1923–1932. [Google Scholar] [CrossRef]

- Zhou, H.-C.; Zhong, Z.-P.; Jin, B.-S.; Huang, Y.-J.; Xiao, R. Experimental study on the removal of PAHs using in-duct activated carbon injection. Chemosphere 2005, 59, 861–869. [Google Scholar] [CrossRef]

- Lin, X.; Ma, Y.; Chen, Z.; Li, X.; Lu, S.; Yan, J. Effect of different air pollution control devices on the gas/solid-phase distribution of PCDD/F in a full-scale municipal solid waste incinerator. Environ. Pollut. 2020, 265, 114888. [Google Scholar] [CrossRef] [PubMed]

- Sam-Cwan, K.; Hwan, J.S.; Il-Rok, J.; Ki-Hun, K.; Myung-Hee, K.; Jae-Hyung, K.; Jun-Heung, Y.; Seung-Jin, K.; Jae-Cheon, Y.; Dong-Hee, J. Removal efficiencies of PCDDs/PCDFs by air pollution control devices in municipal solid waste incinerators. Chemosphere 2001, 43, 773–776. [Google Scholar] [CrossRef] [PubMed]

- Vehlow, J. Air pollution control systems in WtE units: An overview. Waste Manag. 2015, 37, 58–74. [Google Scholar] [CrossRef] [PubMed]

- Bacon, G.H.; Li, R.; Liang, K.Y. Control particulate and metals HAPs. Chem. Eng. Prog. 1997, 93, 59–67. [Google Scholar]

- Liu, W.; Zheng, M.; Liu, W.; Gao, L.; Su, G.; Zhang, B. Mechanism of polychlorinated diphenyl ether formation on a simulated fly ash surface. J. Hazard. Mater. 2011, 186, 814–819. [Google Scholar] [CrossRef] [PubMed]

- Fermo, P.; Cariati, F.; Pozzi, A.; Demartin, F.; Tettamanti, M.; Collina, E.; Lasagni, M.; Pitea, D.; Puglisi, O.; Russo, U. The analytical characterization of municipal solid waste incinerator fly ash: Methods and preliminary results. Fresenius’ J. Anal. Chem. 1999, 365, 666–673. [Google Scholar] [CrossRef]

- Sajwan, K.; Paramasivam, S.; Alva, A.; Adriano, D.; Hooda, P. Assessing the feasibility of land application of fly ash, sewage sludge and their mixtures. Adv. Environ. Res. 2003, 8, 77–91. [Google Scholar] [CrossRef]

- Zacco, A.; Borgese, L.; Gianoncelli, A.; Struis, R.P.; Depero, L.E.; Bontempi, E. Review of fly ash inertisation treatments and recycling. Environ. Chem. Lett. 2014, 12, 153–175. [Google Scholar] [CrossRef]

- Kilgroe, J.D. Control of dioxin, furan, and mercury emissions from municipal waste combustors. J. Hazard. Mater. 1996, 47, 163–194. [Google Scholar] [CrossRef]

- Geiger, T.; Hagenmaier, H.; Hartmann, E.; Römer, R.; Siefert, H. Einfluss des Schwefels auf die Dioxin-und Furanbildung bei der Klärschlammverbrennung. VGB Kraftwerkstechnik 1992, 72, 159–165. [Google Scholar]

- Liang, Y.; Xu, D.; Feng, P.; Hao, B.; Guo, Y.; Wang, S. Municipal sewage sludge incineration and its air pollution control. J. Clean. Prod. 2021, 295, 126456. [Google Scholar] [CrossRef]

- Lin, H.; Ma, X. Simulation of co-incineration of sewage sludge with municipal solid waste in a grate furnace incinerator. Waste Manag. 2012, 32, 561–567. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Xu, J.; Liao, Y.; Yu, Z.; Cai, Z.; Ma, X.; Dai, M.; Fang, S. Co-combustion of paper sludge in a 750 t/d waste incinerator and effect of sludge moisture content: A simulation study. Fuel 2018, 217, 617–625. [Google Scholar] [CrossRef]

- Han, J.; Qin, L.; Ye, W.; Li, Y.; Liu, L.; Wang, H.; Yao, H. Emission of polycyclic aromatic hydrocarbons from coal and sewage sludge co-combustion in a drop tube furnace. Waste Manag. Res. 2012, 30, 875–882. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Xia, Y.; Ma, X. Combustion characteristics of co-combusted municipal solid wastes and sewage sludge. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–13. [Google Scholar] [CrossRef]

- Yu, L.; Zheng, J.; Yuan, X.; Song, H.; Peng, J.; Ren, M. Characterization and mass balance of PCDD/Fs during the co-combustion of sewage sludge in a grate-type municipal solid waste incineration. Procedia Environ. Sci. 2016, 31, 303–308. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, G.; Yan, B.; Cheng, Z.; Ma, W. Behaviour of mercury during Co-incineration of sewage sludge and municipal solid waste. J. Clean. Prod. 2020, 253, 119969. [Google Scholar] [CrossRef]

- Lin, S.-L.; Wu, J.-L.; Lin, K.C.; Wu, H.; Guo, Z.; Tu, C.-W. A novel flameless oxidation and in-chamber melting system coupled with advanced scrubbers for a laboratory waste plant. Waste Manag. 2021, 126, 706–718. [Google Scholar] [CrossRef]

- Tang, W.; Wu, C.-W.; Lin, S.-L.; Wu, J.-L.; Huang, S.-W.; Song, M. Enhanced mitigation of inhalable particles and fine particle-bound PAHs from a novel hazardous waste-power plant candidate. Environ. Pollut. 2024, 343, 123220. [Google Scholar] [CrossRef]

- Lin, S.-L.; Wu, J.-L.; Chen, W.-H.; Wu, H.; Tang, W. Ultra-low PCDD/F emissions and their particle size and mass distribution in a hazardous waste treatment system. J. Hazard. Mater. 2022, 423, 127032. [Google Scholar] [CrossRef]

- Weber, R.; Gupta, A.K.; Mochida, S. High temperature air combustion (HiTAC): How it all started for applications in industrial furnaces and future prospects. Appl. Energy 2020, 278, 115551. [Google Scholar] [CrossRef]

- Sakai, S.; Urano, S.; Takatsuki, H. Leaching behavior of PCBs and PCDDs/DFs from some waste materials. Waste Manag. 2000, 20, 241–247. [Google Scholar] [CrossRef]

- Lundin, L.; Marklund, S. Thermal degradation of PCDD/F, PCB and HCB in municipal solid waste ash. Chemosphere 2007, 67, 474–481. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.-J.; Ni, Y.-W.; Chen, J.-P.; Zhang, Q. Influence of variation in the operating conditions on PCDD/F distribution in a full-scale MSW incinerator. Chemosphere 2008, 70, 721–730. [Google Scholar] [CrossRef]

- Takaoka, M.; Takeda, N.; Miura, S. The behaviour of heavy metals and phosphorus in an ash melting process. Water Sci. Technol. 1997, 36, 275–282. [Google Scholar] [CrossRef]

- Feng, Z.; Zhuo, X.; Luo, Z.; Cheng, Q. Modeling Analysis and Research on the Evaporation System of a Multisource Organic Solid Waste Incinerator. Sustainability 2023, 15, 16375. [Google Scholar] [CrossRef]

- Parikh, D.M. Solids drying: Basics and applications. Chem. Eng. 2014, 121, 42–45. [Google Scholar]

- Liu, W.; Zheng, M.; Liu, W.; Ma, X.; Qian, Y.; Zhang, B. Formation of polychlorinated diphenyl ethers from condensation of chlorophenols with chlorobenzenes. Environ. Sci. Pollut. Res. 2008, 15, 84–88. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, S.; Liu, B. Degradation technologies and mechanisms of dioxins in municipal solid waste incineration fly ash: A review. J. Clean. Prod. 2020, 250, 119507. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Gao, L.; Feng, M.; Qin, L.; Shi, J.; Cheng, D. Polychlorinated diphenyl ethers (PCDEs) in surface sediments, suspended particulate matter (SPM) and surface water of Chaohu Lake, China. Environ. Pollut. 2018, 241, 441–450. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Buekens, A.; Li, X. Dioxins from biomass combustion: An overview. Waste Biomass Valorization 2017, 8, 1–20. [Google Scholar] [CrossRef]

- Tsuji, H.; Gupta, A.K.; Hasegawa, T.; Katsuki, M.; Kishimoto, K.; Morita, M. High Temperature Air Combustion: From Energy Conservation to Pollution Reduction; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Hamdi, M.; Benticha, H.; Sassi, M. Detailed chemical modelling of a flameless combustion turbine for pollution prevention. Int. J. Environ. Pollut. 2008, 32, 410–421. [Google Scholar] [CrossRef]

- Stadler, H.; Toporov, D.; Förster, M.; Kneer, R. On the influence of the char gasification reactions on NO formation in flameless coal combustion. Combust. Flame 2009, 156, 1755–1763. [Google Scholar] [CrossRef]

- Lin, S.-L.; Lee, K.-L.; Wu, J.-L.; Cheruiyot, N.K. Effects of a quenching treatment on PCDD/F reduction in the bottom ash of a lab waste incinerator to save the energy and cost incurred from post-thermal treatment. Waste Manag. 2019, 95, 316–324. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.-T.; Wang, Y.-F.; Tsai, C.-H.; Tsai, Y.-I.; Wu, Z.-L.; Kuo, Y.-M. Polychlorinated dibenzo-p-dioxin and dibenzofuran (PCDD/F) emission behavior during incineration of laboratory wastes. Part 2: PCDD/F profiles and characteristics of output materials. Aerosol Air Qual. Res. 2014, 14, 1206–1214. [Google Scholar] [CrossRef]

- Yang, P.; Chen, J.; Chen, S.; Yuan, X.; Schramm, K.-W.; Kettrup, A. QSPR models for physicochemical properties of polychlorinated diphenyl ethers. Sci. Total Environ. 2003, 305, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Tuppurainen, K.; Halonen, I.; Ruokojärvi, P.; Tarhanen, J.; Ruuskanen, J. Formation of PCDDs and PCDFs in municipal waste incineration and its inhibition mechanisms: A review. Chemosphere 1998, 36, 1493–1511. [Google Scholar] [CrossRef]

- Vermeulen, I.; Van Caneghem, J.; Vandecasteele, C. Indication of PCDD/F formation through precursor condensation in a full-scale hazardous waste incinerator. J. Mater. Cycles Waste Manag. 2014, 16, 167–171. [Google Scholar] [CrossRef]

- Lin, S.-L.; Tang, W.; Wu, J.-L.; Lee, Y.-Y.; Wang, C.-L.; Chen, W.-H. Particulate PCDD/F size distribution and potential deposition in respiratory system from a hazardous waste thermal treatment process. Environ. Res. 2022, 214, 113806. [Google Scholar] [CrossRef]

- Trivedi, J.; Majumdar, D. Memory effect driven emissions of persistent organic pollutants from industrial thermal processes, their implications and management: A review. J. Environ. Manag. 2013, 119, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.-I.; Lee, D.-H.; Osako, M.; Kim, S.-C. The prediction of PCDD/DF levels in wet scrubbers associated with waste incinerators. Chemosphere 2007, 66, 1131–1137. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.-H.; Lu, I.-C.; Huang, P.-W.; Wu, Y.-J.; Whang, L.-M. Biological treatment of volatile organic compounds (VOCs)-containing wastewaters from wet scrubbers in semiconductor industry. Chemosphere 2021, 282, 131137. [Google Scholar] [CrossRef] [PubMed]

- Lyytikäinen, M.; Hirva, P.; Minkkinen, P.; Hämäläinen, H.; Rantalainen, A.-L.; Mikkelson, P.; Paasivirta, J.; Kukkonen, J.V. Bioavailability of sediment-associated PCDD/Fs and PCDEs: Relative importance of contaminant and sediment characteristics and biological factors. Environ. Sci. Technol. 2003, 37, 3926–3934. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, R.V.; Eiceman, G.A.; Long, Y.T.; Collins, M.C.; Lu, M.Q. Mechanism of chlorination of aromatic compounds adsorbed on the surface of fly ash from municipal incinerators. Environ. Sci. Technol. 1990, 24, 1635–1641. [Google Scholar] [CrossRef]

- Feng, J.; Chen, W.; Wang, L.; Peng, X. Separation performance of new type of multi-stage axial cyclone used as demister in power plant emission system. J. Dispers. Sci. Technol. 2019, 41, 1643–1656. [Google Scholar] [CrossRef]

- Chi, K.H.; Chang, M.B. Evaluation of PCDD/F congener partition in vapor/solid phases of waste incinerator flue gases. Environ. Sci. Technol. 2005, 39, 8023–8031. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Hao, J.; Duan, L.; Tang, X.; Ning, P.; Li, X. Fine particle and trace element emissions from an anthracite coal-fired power plant equipped with a bag-house in China. Fuel 2008, 87, 2050–2057. [Google Scholar] [CrossRef]

- Li, H.-W.; Wang, L.-C.; Chen, C.-C.; Yang, X.-Y.; Chang-Chien, G.-P.; Wu, E.M.-Y. Influence of memory effect caused by aged bag filters on the stack PCDD/F emissions. J. Hazard. Mater. 2011, 185, 1148–1155. [Google Scholar] [CrossRef]

- Hutzinger, O. The Handbook of Environmental Chemistry; Part, A. Air Pollution; Springer: Berlin/Heidelberg, Germany, 1986; Volume 4. [Google Scholar]

- Song, G.-J.; Kim, S.H.; Seo, Y.-C.; Kim, S.-C. Dechlorination and destruction of PCDDs/PCDFs in fly ashes from municipal solid waste incinerators by low temperature thermal treatment. Chemosphere 2008, 71, 248–257. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Primary combustion chamber | |

| Treatment capacities | |

| Organic waste, ton yr−1 | 800 |

| Inorganic waste, ton yr−1 | 400 |

| Combustion condition | Φ > 1.0 |

| Solid feeding rate, kg h−1 | 100 |

| Liquid feeding rate, kg h−1 | 120 |

| Recycled SFA, kg h−1 | 24.6 |

| Air feeding, Nm3 min−1 | 1.0–1.2 |

| Residual O2, % | <3.0 |

| In-chamber gas-phase temperature, °C | 1050–1150 |

| Secondary combustion chamber | |

| Combustion condition | Φ = 1.0–1.2 |

| Auxiliary diesel feeding, kg h−1 | 0–60 |

| Air feeding, Nm3 min−1 | 6 |

| Excess air, % | 14.9–15.1 |

| Parameters | Values |

|---|---|

| Scrubber | |

| Liquid flow rate (L/min) | 21 |

| pH | 9.6 |

| Cyclone demister | |

| Flow velocity (m/s) | 7–9 |

| Flow temperature (°C) | 60–70 |

| Relative humidity (%) | 100 |

| Bag house | |

| Area of fabric filter (m2) | 298 |

| Powder activated carbon | |

| Charcoal diameter (μm) | <75 |

| Moisture (%) | <3 |

| Ash (%) | <18 |

| pH | 8–11 |

| Apparent specific gravity (g/mL) | 0.4–0.5 |

| Position | PCDE Morphology | Mass Conc. ng/kg ng/Nm3 |

|---|---|---|

| Raw material (E) | Solid waste | 20.9 |

| Liquid waste | 0 | |

| Scrubber sludge (H) | Solid | 107 |

| Liquid | 0 | |

| Cyclone sludge (J) | Solid | 654 |

| Liquid | 0 | |

| Fly ash (K) | Fly ash | 178 |

| Recycled SFA (H + J + K) | Solid | 939 |

| Liquid | 0 | |

| Feedback (E + SFA) | Solid | 960 |

| Liquid | 0 | |

| Bottom ash (F) | Bottom ash | 2.73 |

| Quenching ash (G) | Quenching ash | 0 |

| SCB inlet (A) | Solid | 8.06 |

| Gaseous | 92.5 | |

| CYCD inlet (B) | Solid | 6.90 |

| Gaseous | 75.8 | |

| BH inlet (C) | Solid | 0.646 |

| Gaseous | 0.829 | |

| Stack outlet (D) | Solid | 0 |

| Gaseous | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.-L.; Duan, L.-L.; Wu, J.-L.; Huang, C.-E.; Song, M.-J. Impact of Integrating Flameless Combustion Technology and Sludge–Fly Ash Recirculation on PCDE Emissions in Hazardous Waste Thermal Treatment Systems. Atmosphere 2024, 15, 710. https://doi.org/10.3390/atmos15060710

Lin S-L, Duan L-L, Wu J-L, Huang C-E, Song M-J. Impact of Integrating Flameless Combustion Technology and Sludge–Fly Ash Recirculation on PCDE Emissions in Hazardous Waste Thermal Treatment Systems. Atmosphere. 2024; 15(6):710. https://doi.org/10.3390/atmos15060710

Chicago/Turabian StyleLin, Sheng-Lun, Lu-Lu Duan, Jhong-Lin Wu, Chien-Er Huang, and Meng-Jie Song. 2024. "Impact of Integrating Flameless Combustion Technology and Sludge–Fly Ash Recirculation on PCDE Emissions in Hazardous Waste Thermal Treatment Systems" Atmosphere 15, no. 6: 710. https://doi.org/10.3390/atmos15060710