Study on Dust Hazard Levels and Dust Suppression Technologies in Cabins of Typical Mining Equipment in Large Open-Pit Coal Mines in China

Abstract

:1. Introduction

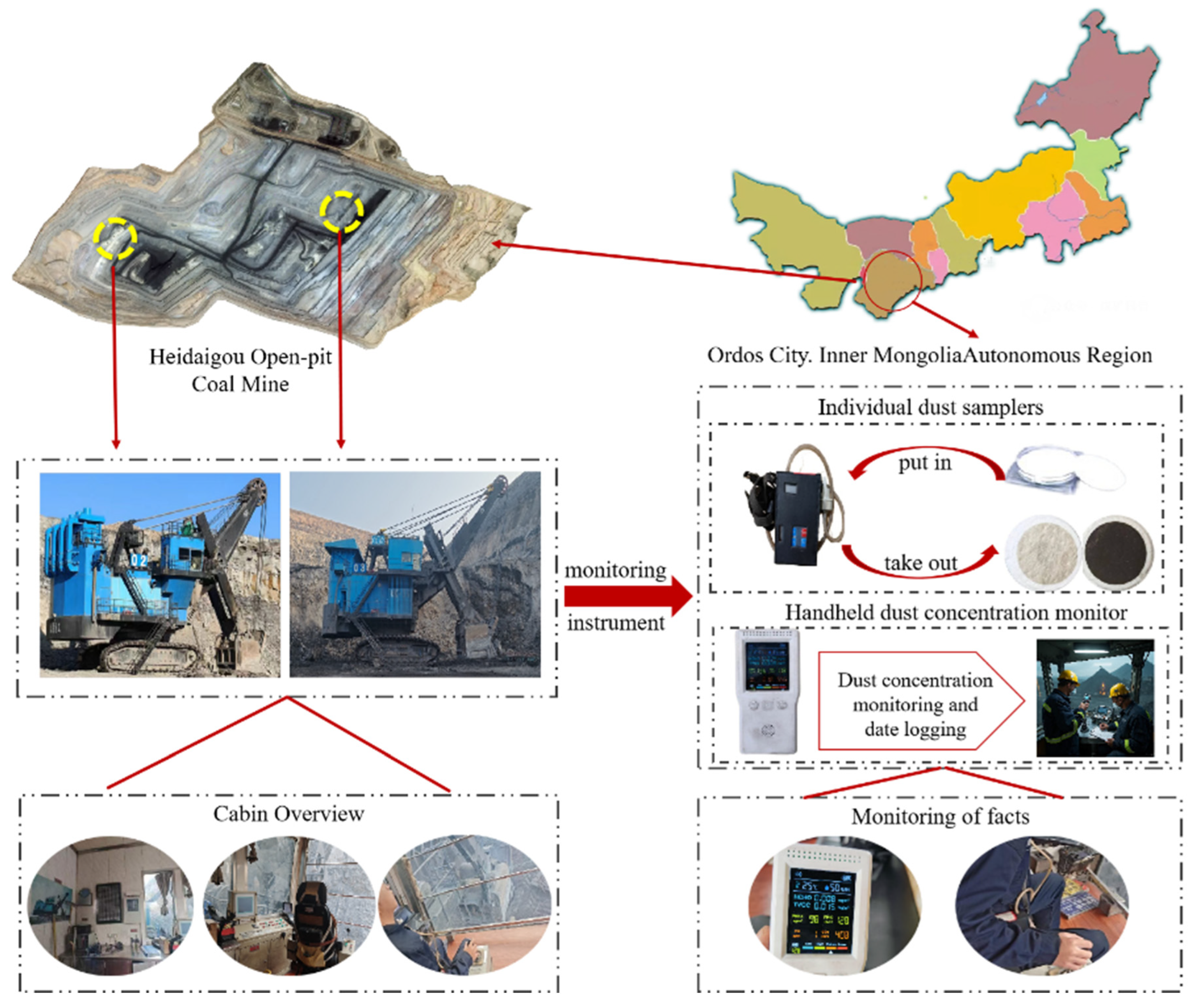

2. Materials and Methods

2.1. Materials and Data Collection

2.2. Test Methods for Physicochemical Characteristics of Cabin Dust

- (1)

- Particle size distribution analysis

- (2)

- Mineralogical composition analysis

- (3)

- Elemental composition analysis

- (4)

- Proximate analysis methods

- (5)

- Microscopic morphology analysis

- (6)

- Free silica content determination

2.3. Method for Analyzing the Level of Hazard of Cabin Dust to the Human Body and Protection Technology

2.3.1. Method for Analyzing the Level of Hazard of Cabin Dust to the Human Body

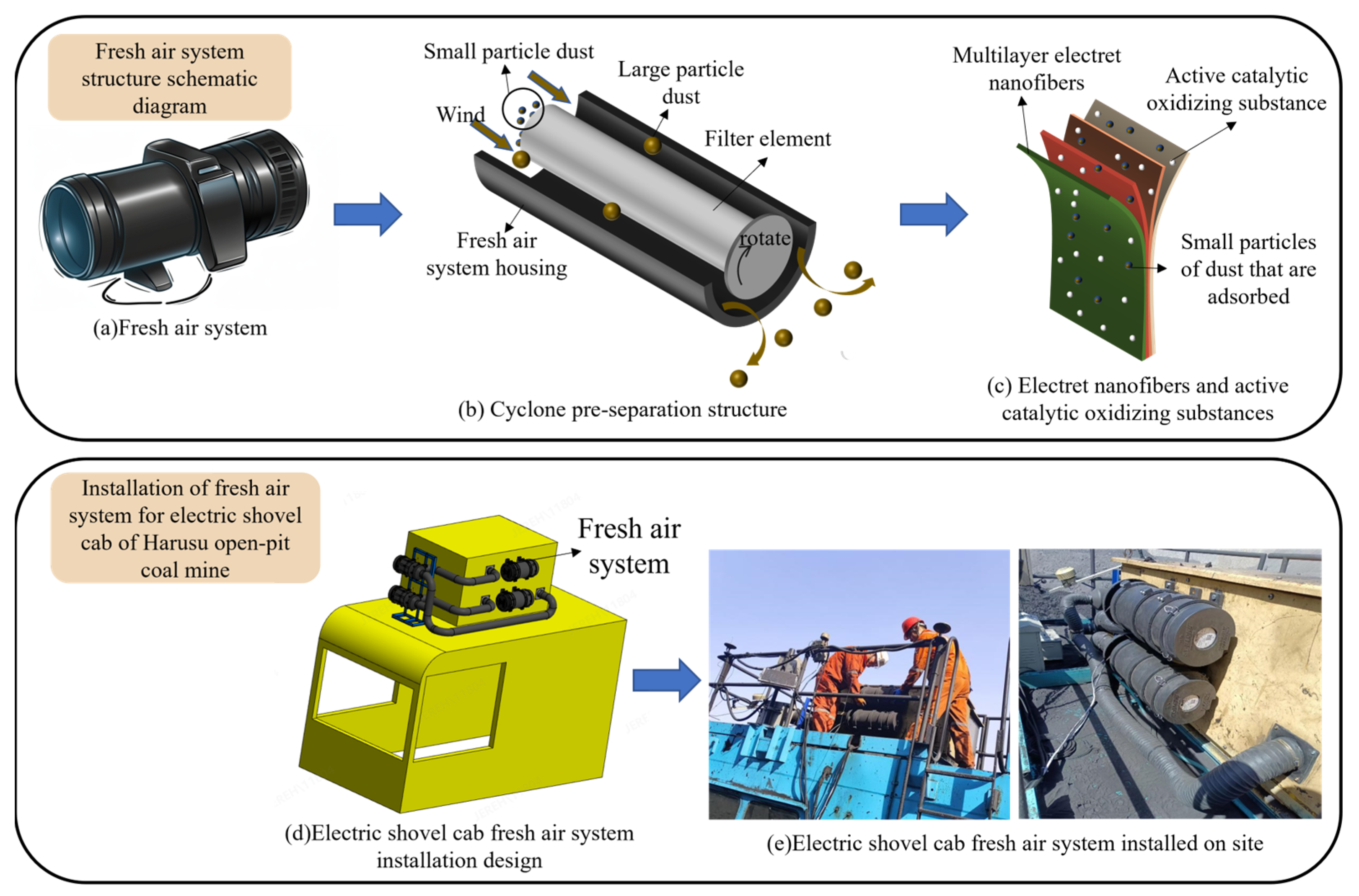

2.3.2. Protection Technology of Cabin Dust

3. Results and Discussion

3.1. Physicochemical Characterization of Dust in the Cabins of Mining Machinery in Open-Pit Coal Mines

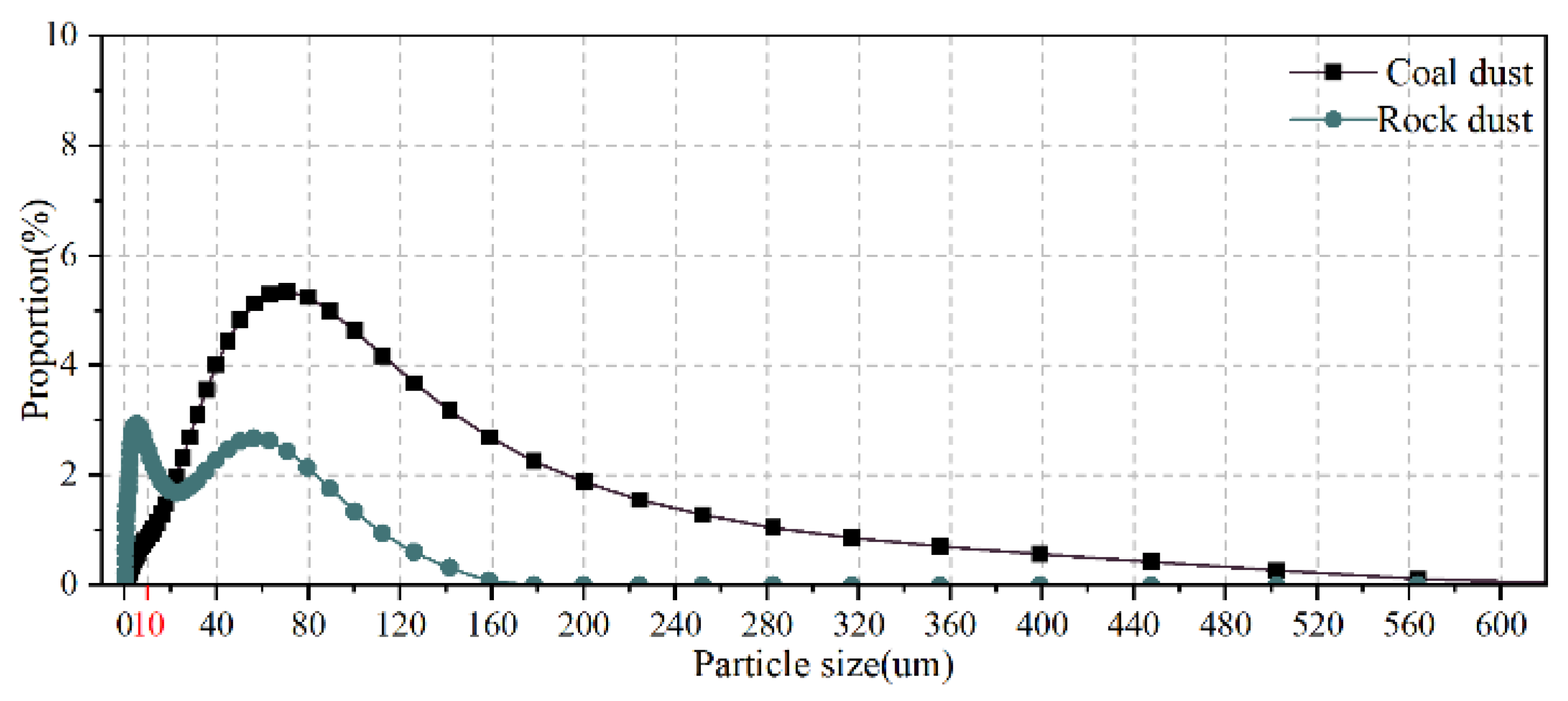

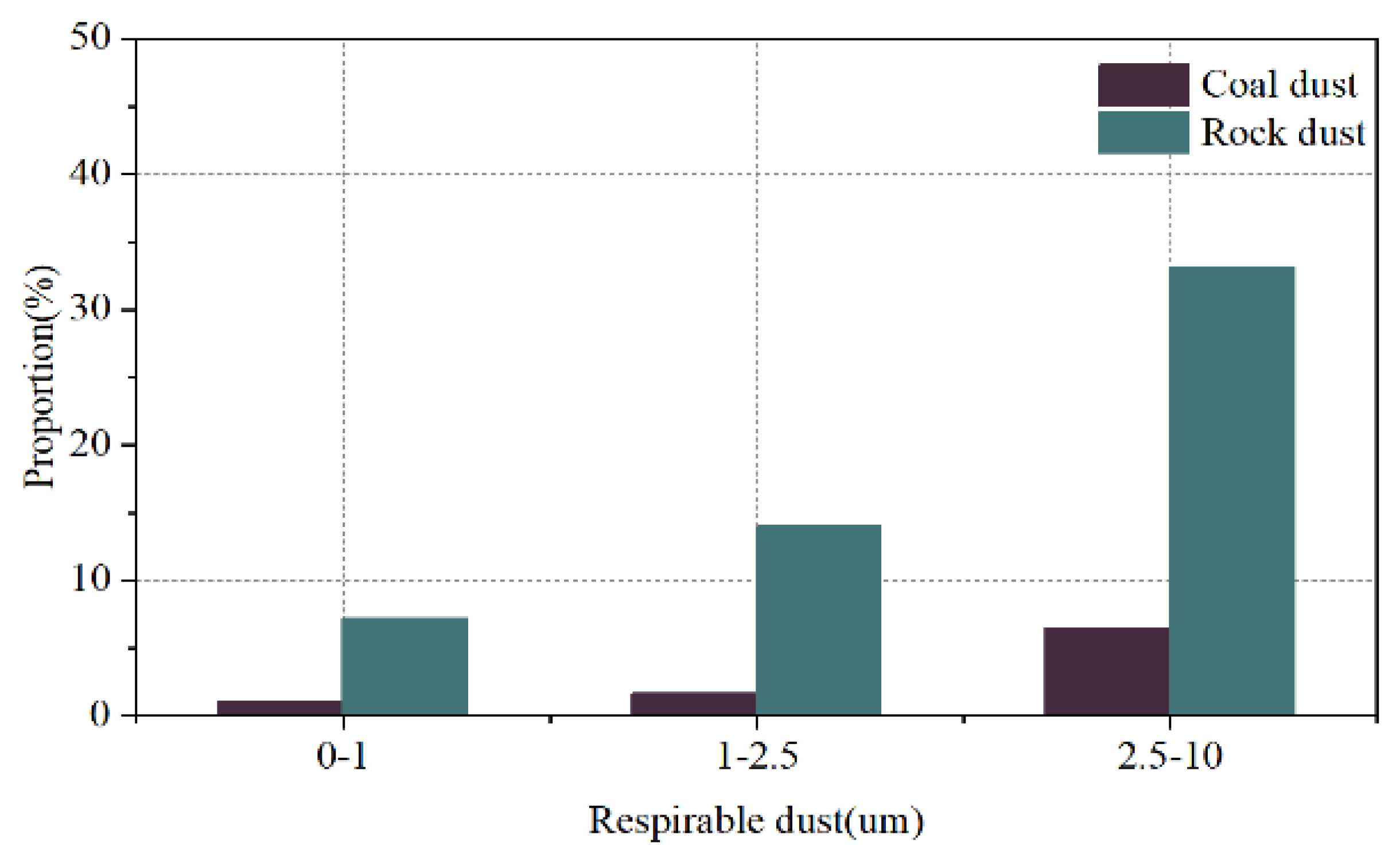

3.1.1. Particle Size Distribution Analysis

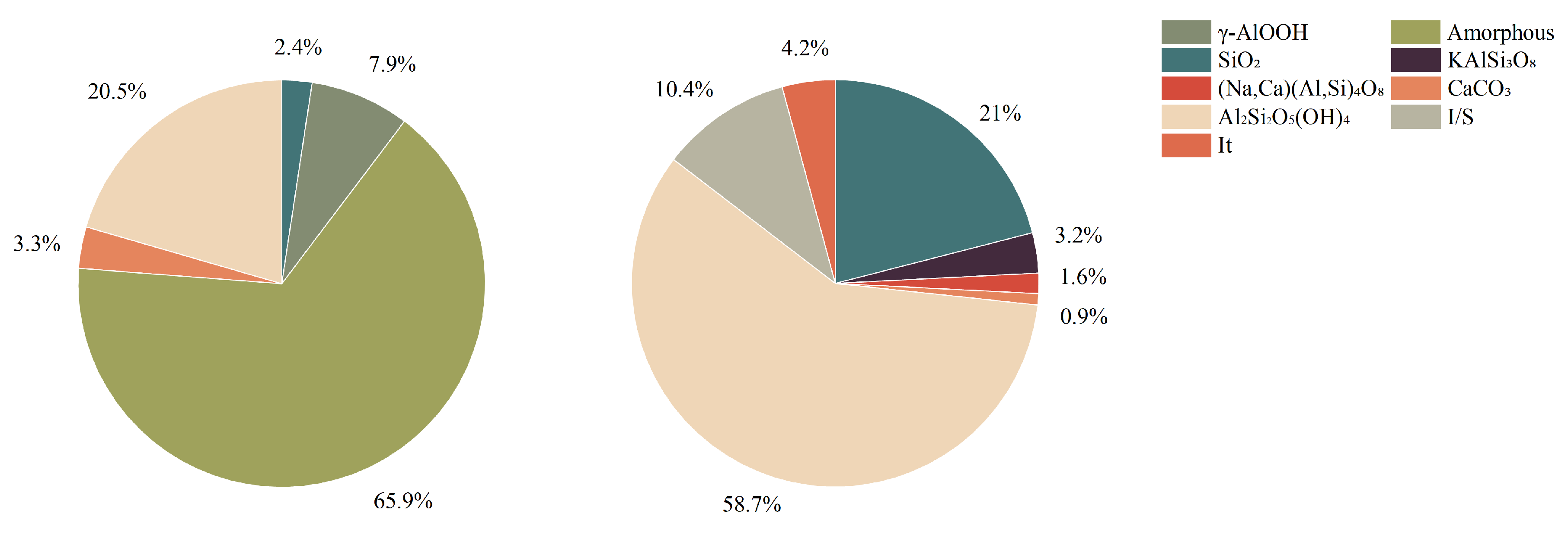

3.1.2. Mineralogical Composition Analysis

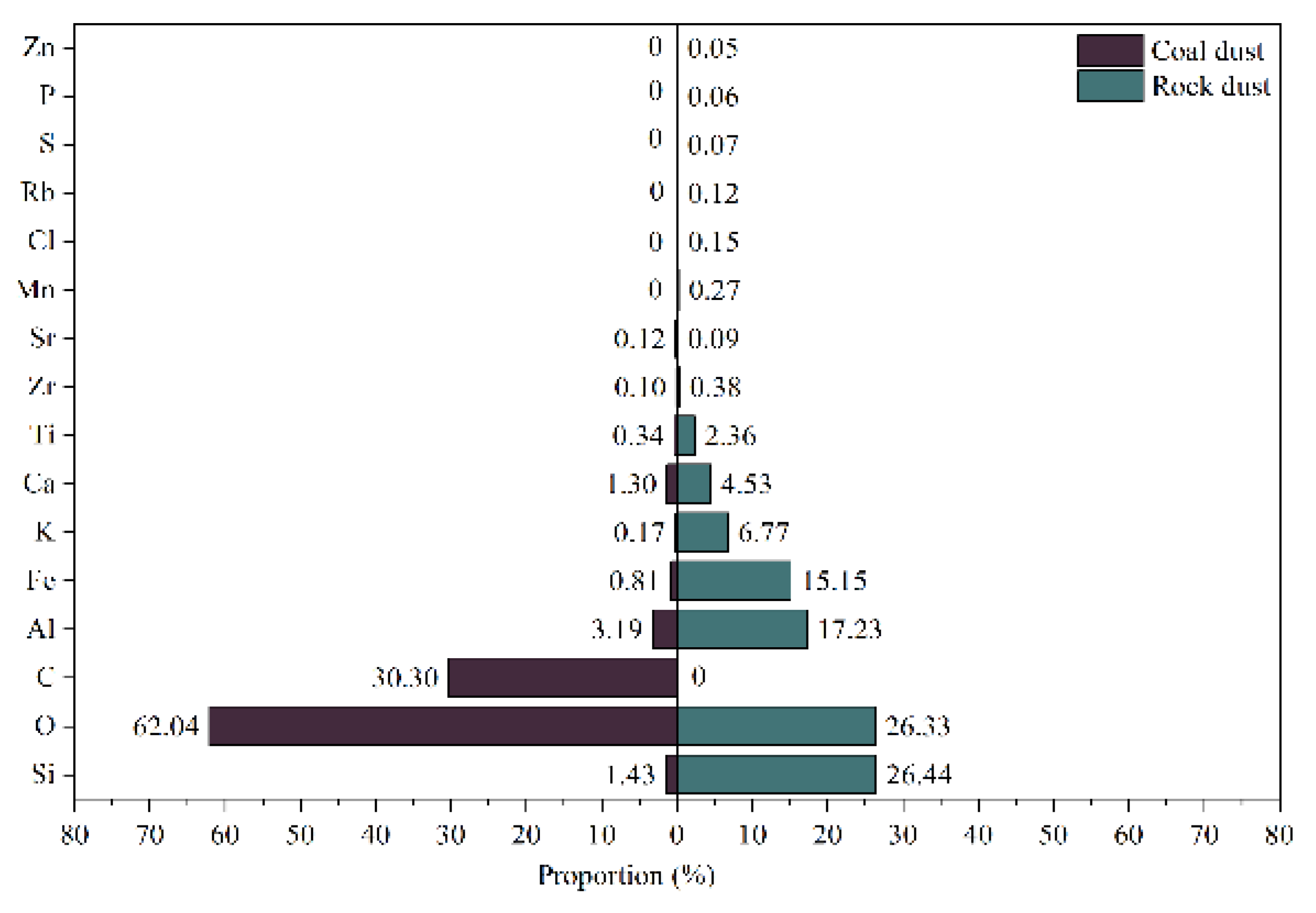

3.1.3. Elemental Composition Analysis

3.1.4. Industrial Proximate Analysis

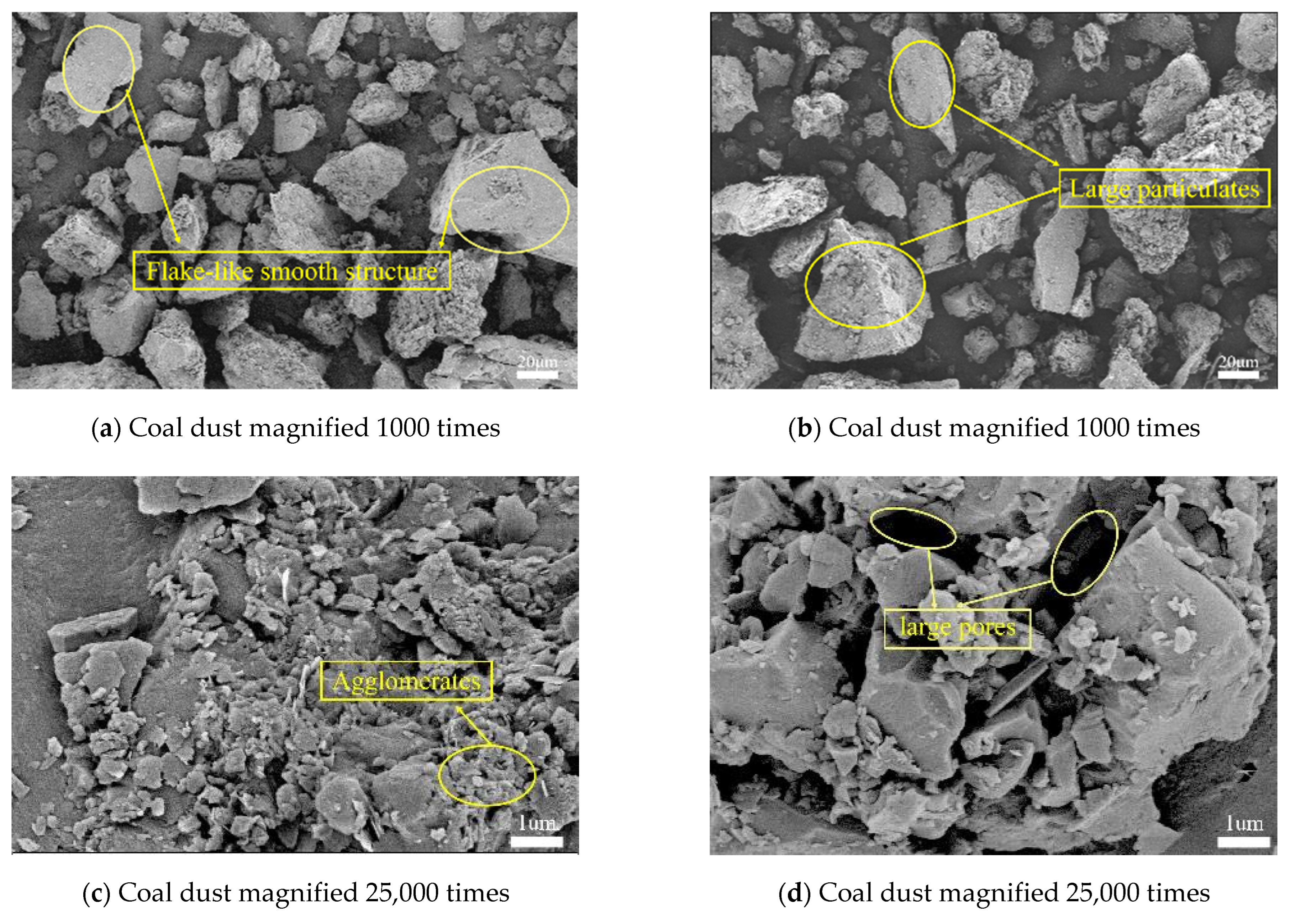

3.1.5. Microscopic Morphology Analysis

- (1)

- Analysis of sem results for coal dust samples

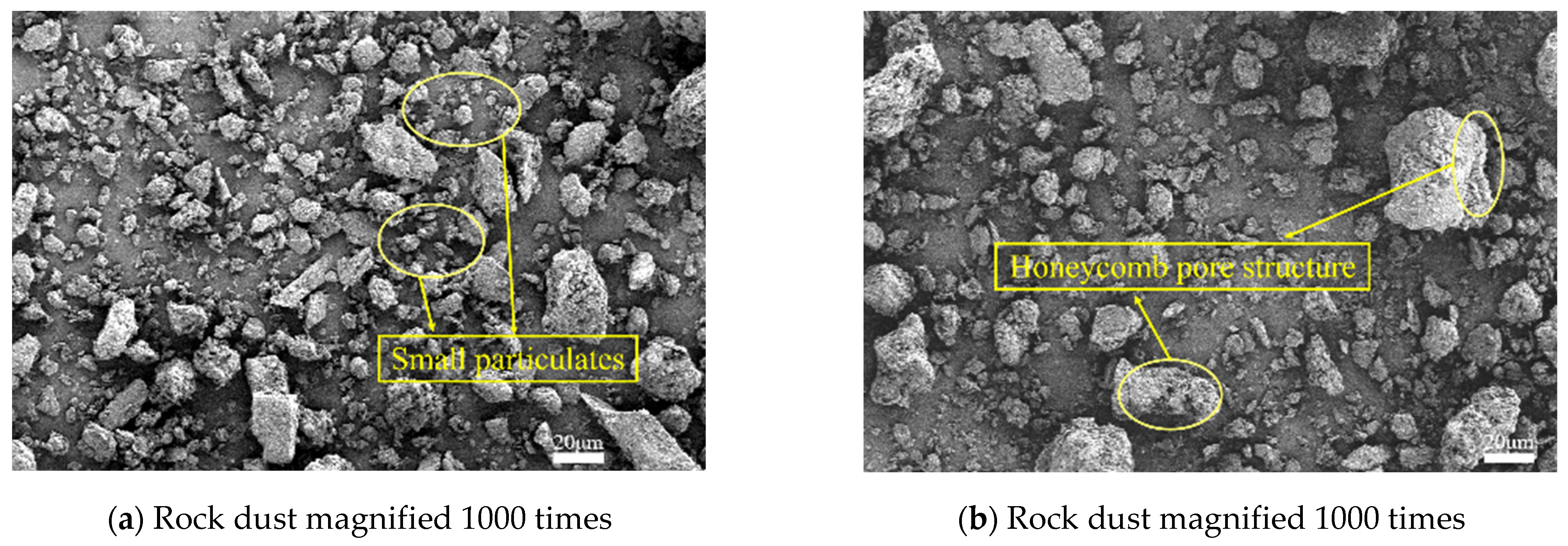

- (2)

- Analysis of sem results for rock dust samples

3.1.6. Free Silica Content Determination Analysis

3.2. Analysis of Pollutants in the Cabins of Mining Machinery in Open-Pit Coal Mines

3.2.1. Analysis of Pollutants

- (1)

- Analysis of pollutants in the cabin of the no. 3 WK35 coal shovel

- (2)

- Analysis of pollutants in the cabin of the no. 3 wk55 rock shovel

3.2.2. Analysis of the Degree of Hazard of Dust to the Human Body

- (1)

- Degree of dust hazard to coal shovel operators

- (2)

- Degree of dust hazard to rock shovel operators

3.3. Assessment of the Dust Purification Effect of the Cabin Fresh Air System

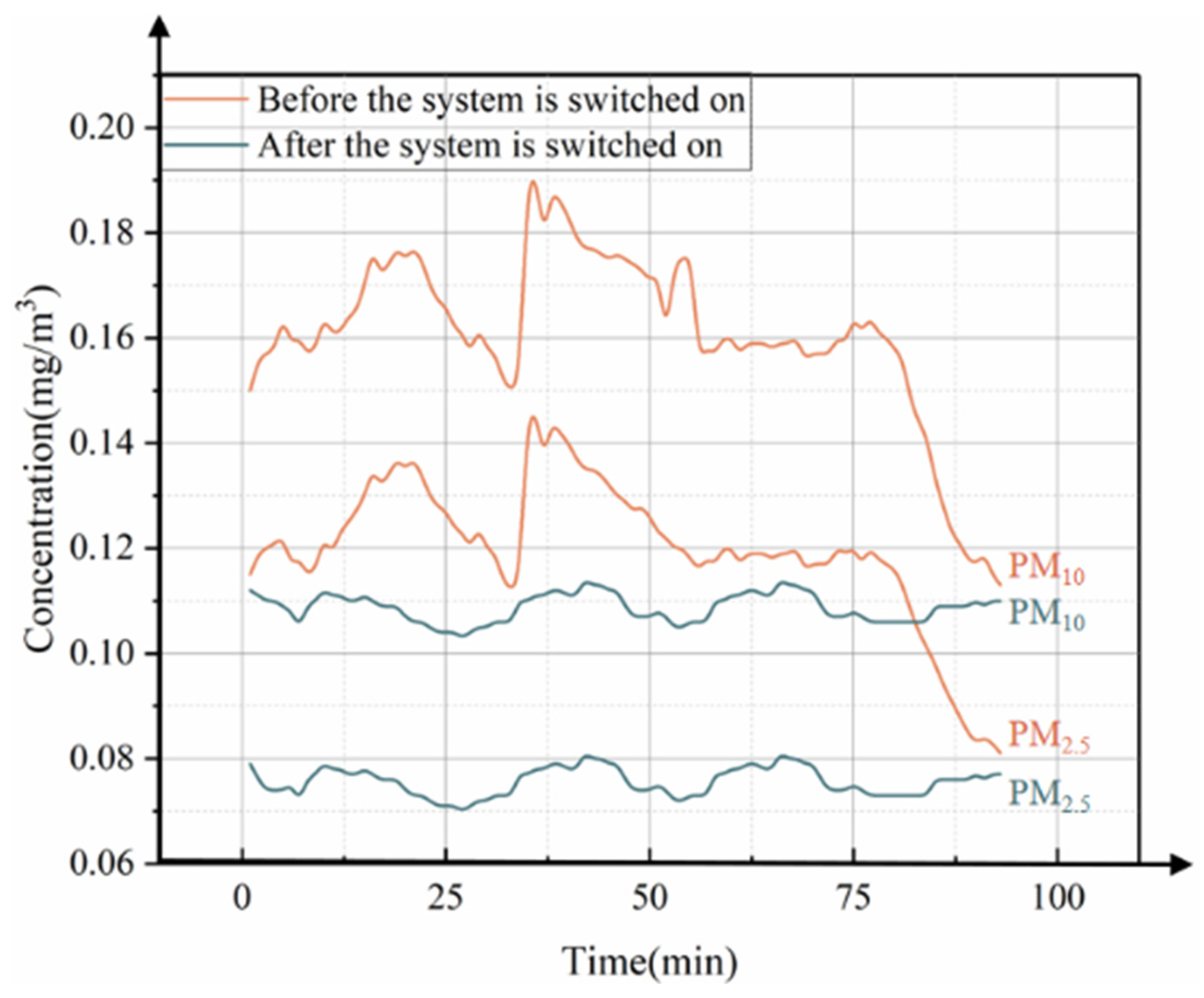

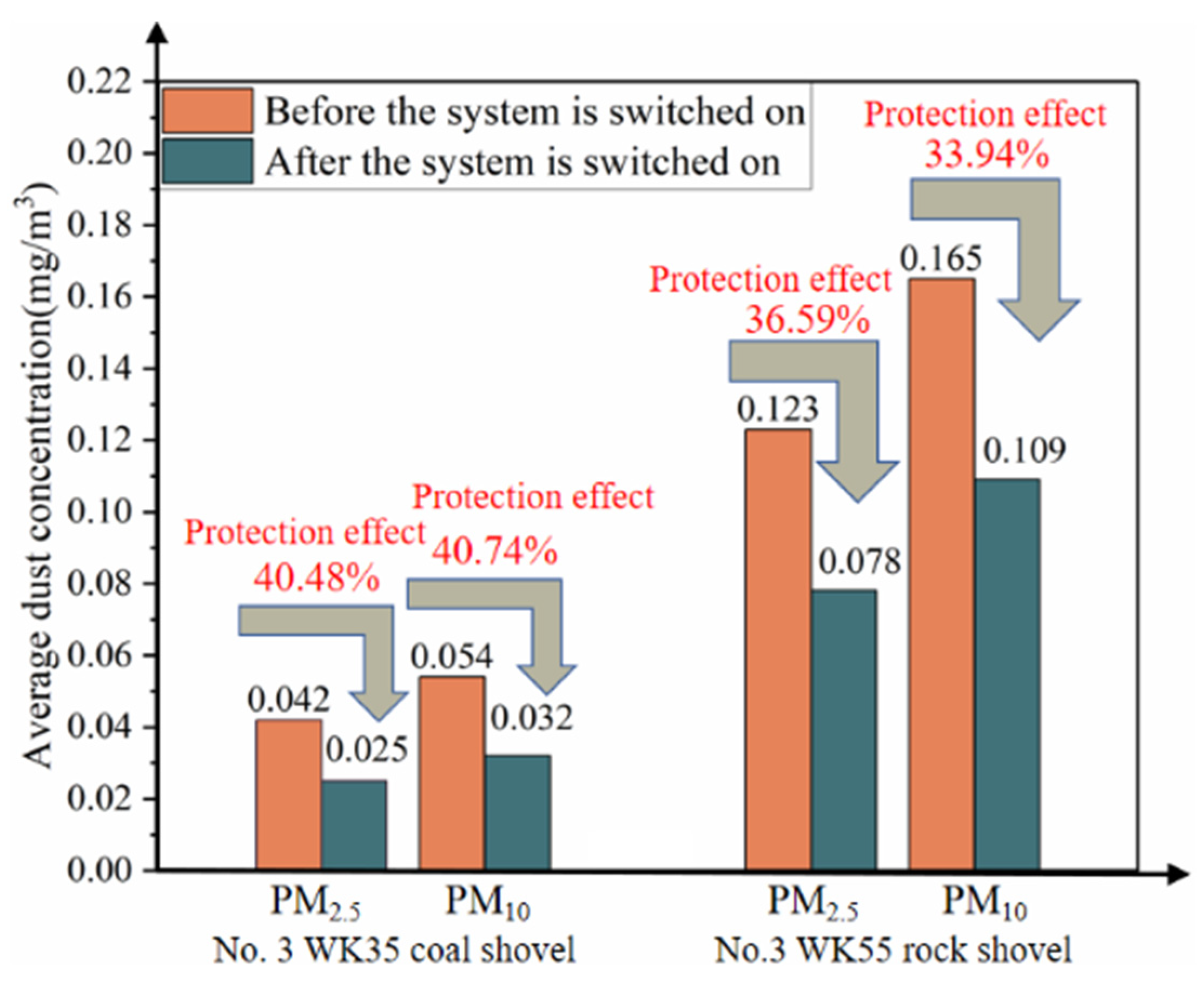

3.3.1. Effectiveness Assessment of the Monitoring System Based on a Handheld Dust Concentration Detector

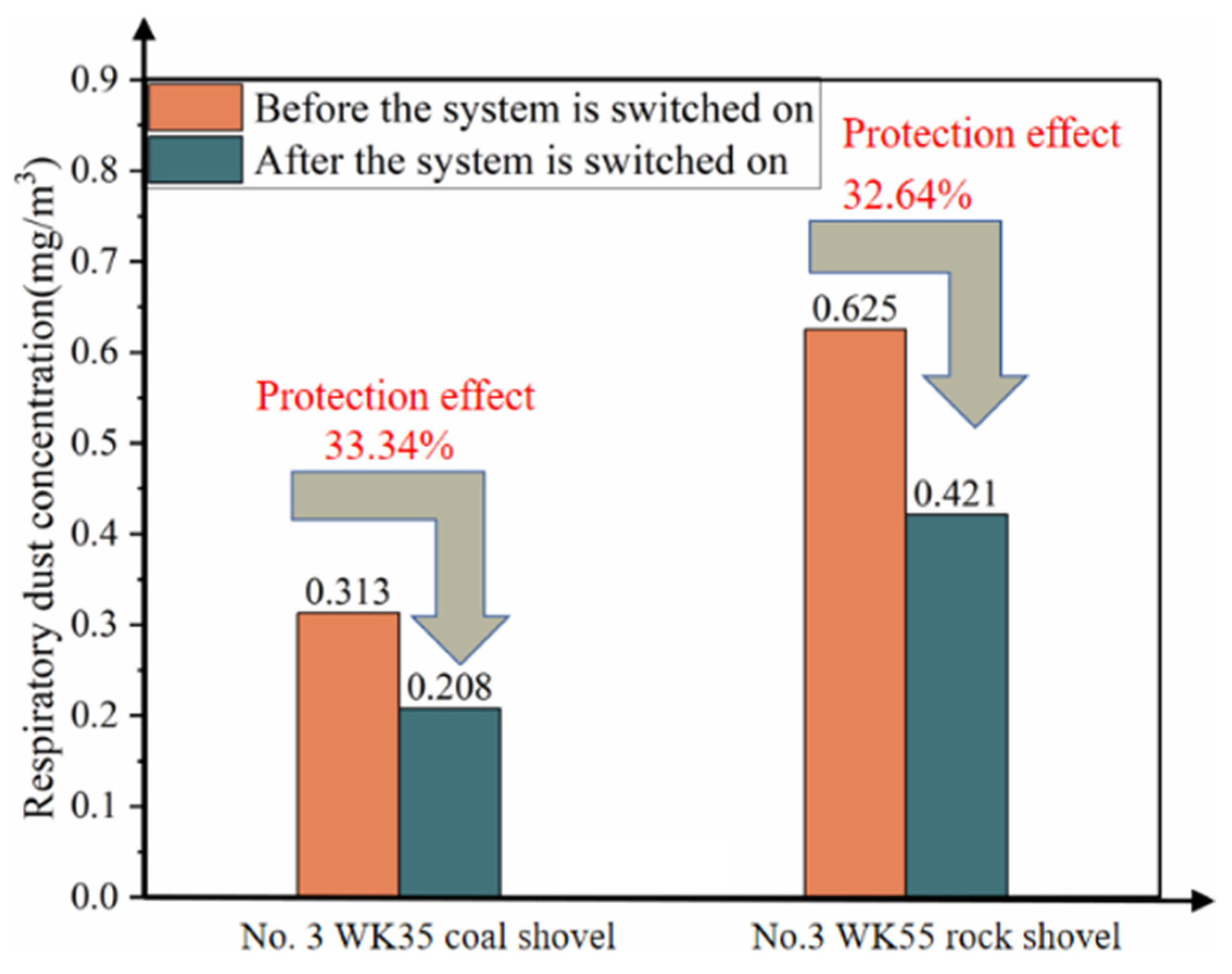

3.3.2. Effectiveness Assessment of the Monitoring System Based on a Personal Sampler

4. Conclusions

- (1)

- The total proportion of inhalable particles with a diameter of less than 10 μm in coal dust and rock dust is 9.82% and 45.8%, respectively, indicating that rock dust is more likely to be inhaled into the lungs. The heavy metal content in coal dust and rock dust is 1.25% and 15.85%, respectively, indicating that rock dust has a greater toxic hazard. The free silica content in coal dust and rock dust is 0.74% and 24.6%, respectively, indicating that rock shovel operators are more likely to cause silicosis.

- (2)

- Operators of coal shovels and rock shovels in the Heidaigou open-pit coal mine are exposed to a dusty environment for a long time, and both are at Level I (mild hazard level) hazard level, but the hazard level for rock shovel operators is about to reach Level II (moderate hazard level).

- (3)

- The dust prevention effect of the fresh air system in the electric shovel cab is good. After the fresh air system is activated, the concentration of respirable dust in the coal shovel cab is reduced from 0.313 mg/m3 to 0.208 mg/m3, and the protection effect is at least increased by 33.34%. The concentration of respirable dust in the rock shovel cab is reduced from 0.625 mg/m3 to 0.421 mg/m3, and the protection effect is at least increased by 32.64%. Given the outstanding performance of the fresh air system in the electric shovel cab, we will investigate the dust prevention performance of the fresh air system in the cabins of other mining equipment and study the possibility of its large-scale promotion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, G.; Zhang, J.; Liu, Z.; Pang, Y.; Wang, T.; Sang, C. Progress in digital and intelligent technologies for complex giant systems in green coal development. Coal Sci. Technol. 2024, 52, 1–16. [Google Scholar]

- Jing, Z.; Min, X.; Li, S.; Li, J.; Song, W. Trade-off or synergy? The impacts of coal energy consumption on compound system vulnerability: A perspective from coal resource base assessment. Ecol. Indic. 2025, 170, 113124. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Li, Q.; Zhang, K.; Liu, Z.; Ren, Z. Multidimensional spatial monitoring of open pit mine dust dispersion by unmanned aerial vehicle. Sci. Rep. 2023, 13, 4567. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Yan, J.; Luo, H. Optimizing open-pit coal mining operations: Leveraging meteorological conditions for dust removal and diffusion. Int. J. Coal Sci. Technol. 2024, 11, 23–35. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, Z.; Chen, J.; Chen, Y.; Yang, B. Numerical Simulation Study on Dust Diffusion Law of Single Bucket Truck Loading in Open-Pit Mine Under the Action of Airflow. Mining Metall. Explor. 2024, 41, 567–578. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Z.; Zhao, Z.; Sun, P.; Tang, L.; Shabir, U. Insight into dust control performance of a reverse circulation drill bit using multiphase flow simulation. Eng. Appl. Comput. Fluid Mech. 2022, 16, 841–857. [Google Scholar] [CrossRef]

- Zhou, W.; Cui, Y.; Wang, H.; Chen, L.; Xu, K.; Wu, C.; Ren, G. Study on the characteristics of dust diffusion during a truck travelling in an open-pit coal mine affected by the vertical wind shear. J. Hazard. Mater. 2025, 483, 124567. [Google Scholar] [CrossRef]

- Wang, J.; Du, C.; Chen, Z.; Wang, Y. Influence of vehicle and pavement characteristics on dust resuspension from soil pavement of open-pit mine. Sci. Total Environ. 2023, 878, 163025. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, T.; Liu, Y.; Jiang, Q.; Shang, H.; Zheng, C. Montmorillonite combined with microbially induced carbonate precipitation for wind erosion control of bare surface soil in arid mining area. Process Saf. Environ. Prot. 2024, 187, 926–939. [Google Scholar] [CrossRef]

- Li, W.J.; Zhu, Q.H. Comparison and analysis research on occupational exposure limits of coal dust between China and foreign countries. J. Ind. Hyg. Occup. Dis. [Zhonghua Lao Dong Wei Sheng Zhi Ye Bing Za Zhi] 2024, 42, 107–111. [Google Scholar]

- Chang, T.B.; Lin, Y.S.; Hsu, Y.T. CFD simulations of effects of recirculation mode and fresh air mode on vehicle cabin indoor air quality. Atmos. Environ. 2023, 293, 119456. [Google Scholar] [CrossRef]

- Yu, H.X.; Zahidi, I. Environmental hazards posed by mine dust, and monitoring method of mine dust pollution using remote sensing technologies: An overview. Sci. Total Environ. 2023, 864, 161234. [Google Scholar] [CrossRef]

- Baur, X.; Sanyal, S.; Abraham, J.L. Mixed-dust pneumoconiosis: Review of diagnostic and classification problems with presentation of a work-related case. Sci. Total Environ. 2019, 652, 413–421. [Google Scholar] [CrossRef] [PubMed]

- Begin, R.; Cantin, A.; Masse, S. Recent advances in the pathogenesis and clinical assessment of mineral dust pneumoconioses: Asbestosis, silicosis and coal pneumoconiosis. Eur. Respir. J. 1989, 2, 988–1001. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Luo, H.; Ao, Z.; Mvula, E.M. Annual dust pollution characteristics and its prevention and control for environmental protection in surface mines. Sci. Total Environ. 2022, 825, 153987. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, T.; Sun, S.; Ji, Y.; Zhao, D.; Zhuang, D.; Lian, Y.; Rong, Y.; Yan, J.; Sun, H. Influence of Air Volume and Temperature in the Air Inlet Tunnel on the Characteristics of Dust Movement. ACS Omega 2023, 9, 866–878. [Google Scholar] [CrossRef]

- Nie, W.; Jiang, C.; Sun, N.; Guo, L.; Liu, Q.; Liu, C.; Niu, W. CFD-based simulation study of dust transport law and air age in tunnel under different ventilation methods. Environ. Sci. Pollut. Res. 2023, 30, 114484–114500. [Google Scholar] [CrossRef]

- Rim, D.; Siegel, J.; Spinhirne, J.; Webb, A.; McDonald-Buller, E. Characteristics of cabin air quality in school buses in Central Texas. Atmos. Environ. 2008, 42, 6453–6464. [Google Scholar] [CrossRef]

- Cha, Y.; Tu, M.; Elmgren, M.; Silvergren, S.; Olofsson, U. Factors affecting the exposure of passengers, service staff and train drivers inside trains to airborne particles. Environ. Res. 2018, 166, 16–24. [Google Scholar] [CrossRef]

- Lexén, J.; Bernander, M.; Cotgreave, I.; Andersson, P.L. Assessing exposure of semi-volatile organic compounds (SVOCs) in car cabins: Current understanding and future challenges in developing a standardized methodology. Environ. Int. 2021, 157, 106823. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, D.; Chen, J.; Ren, S.; Fan, J.; He, Y. Blasting dust diffuse characteristics of spiral tunnel and dust distribution model: Similar experiment and numerical modeling. Environ. Sci. Pollut. Res. 2023, 30, 52340–52357. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Abbasi, B.; Elahifard, M.; Osho, B.; Chen, L.W.A.; Chow, J.C.; Watson, J.G. Coal Mine Dust Size Distributions, Chemical Compositions, and Source Apportionment. Minerals 2024, 14, 1122. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.; Jiao, X.; Tong, L.; Huang, J. Study on the impact of humidity on dust dispersion in open-pit mining under different environmental temperatures. Part. Sci. Technol. 2025, 43, 133–143. [Google Scholar] [CrossRef]

- Wang, J.; Du, C.; Du, S.; Jin, W.; Fan, D. Dust dispersion law and high-pressure air curtain control technology of crossheading during the process of ore unloading. J. Wind Eng. Ind. Aerodyn. 2022, 230, 105234. [Google Scholar] [CrossRef]

- Bai, Z.; Yan, H.; Zhang, H.; Su, C.; Zhang, L.; Wang, J. Numerical Simulation Study of the Optimal Parameters for Dust Reduction by an External Air Curtain (EAC) in Continuous Mining Tunnel. J. Environ. Eng. 2024, 150, 04024012. [Google Scholar] [CrossRef]

- Ao, Z.; Wang, Z.; Zhou, W.; Qiao, Y.; Wahab, A.; Yang, Z.; Nie, S.; Liu, Z.; Zhu, L. CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines-A Case of Coal Shed. Sustainability 2023, 15, 11651. [Google Scholar] [CrossRef]

- Zhu, S.; Zhao, Y.; Hu, X.; Wu, M.; Cheng, W.; Fan, Y.; Song, C.; Tang, X. Study on preparation and properties of mineral surfactant—Microbial dust suppressant. Powder Technol. 2021, 383, 233–243. [Google Scholar] [CrossRef]

- Chen, X.L.; Wheeler, C.A.; Donohue, T.J.; McLean, R.; Roberts, A.W. Evaluation of dust emissions from conveyor transfer chutes using experimental and CFD simulation. Int. J. Miner. Process. 2012, 110, 101–108. [Google Scholar] [CrossRef]

- Zhou, G.; Kong, Y.; Meng, Q.; Jiang, B.; Liu, Y.; Li, G.; Sun, B.; Wang, J.; Yan, D.; Li, Z. Research on dust dispersion law of fully mechanized mining faces under different inclinations and tracking closed dust control method. Sci. Rep. 2022, 12, 8765. [Google Scholar]

- Azam, S.; Liu, S.; Bhattacharyya, S.; Liu, A. Measurement and modeling of water vapor sorption on nano-sized coal particulates and its implication on its transport and deposition in the environment. Sci. Total Environ. 2023, 889, 164312. [Google Scholar] [CrossRef]

- Organiscak, J.A.; Cecala, A.B.; Noll, J.D. Assessment of Enclosed Cab Filtration System Performance Using Particle Counting Measurements. J. Occup. Environ. Hyg. 2013, 10, 468–477. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.H.; Shi, R.Y. Production efficiency evaluation of open-pit coal mines considering environment and safety factors. J. Environ. Prot. Ecol. 2021, 22, 1880–1887. [Google Scholar]

- Determination of Dust in the Air of Workplace-Part 4: Content of Free Silica in Dust. Available online: http://www.nhc.gov.cn/wjw/pyl/200707/39005.shtml (accessed on 18 July 2007).

- Classification of Occupational Hazards at Workplaces-Part 1: Occupational Exposure to Industrial Dust. Available online: http://www.nhc.gov.cn/wjw/pyl/201005/47206.shtml (accessed on 17 May 2010).

- Measurement of Physical Agents in Workplace-Part 10: Classification of Physical Workload. Available online: https://niohp.chinacdc.cn/zyysjk/zywsbzml/201210/t20121012_70524.htm (accessed on 12 October 2012).

- Qi, C.; Hu, T.; Zheng, Y.; Wu, M.; Tang, F.H.; Liu, M.; Zhang, B.; Derrible, S.; Chen, Q.; Hu, G.; et al. Global and regional patterns of soil metal (loid) mobility and associated risks. Nat. Commun. 2025, 16, 2947. [Google Scholar] [CrossRef] [PubMed]

- Classification for Quality of Coal—Part 1: Ash. Available online: https://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D82B87D3A7E05397BE0A0AB82A (accessed on 14 May 2018).

| Monitoring Equipment | Monitoring Period | Methodology | Targets |

|---|---|---|---|

| SCJCY handheld dust concentration detector | 4 working days (post-shovel maintenance—16:30, day shift, non-fixed intervals) | Day 1: After cleaned ventilation system activated Day 2: Comparative variables (after cleaned system deactivated) Continuous monitoring with non-periodic intervals, recording equipment status and environmental parameters | Days 1–2: Cab of No. 3 WK35 coal shovel |

| Days 3–4: Cab of No. 3 WK55 rock shovel | |||

| CCZG2 personal sampler | 4 working days (16:30–00:30, night shift, 8 h) | Day 1: After cleaned ventilation system activated Day 2: Control experiment (after cleaned system deactivated) Maintained operational loads with calibrated devices properly worn by operators | Days 1–2: Cab of No. 3 WK35 coal shovel |

| Days 3–4: Cab of No. 3 WK55 rock shovel |

| Grading Index | Hazard Levels |

|---|---|

| 0 | 0 (Relatively Harmless) |

| 0 < G ≤ 6 | I (Mild Hazard) |

| 6 < G ≤ 16 | II (Moderate Hazard) |

| G > 16 | IV (High Hazard) |

| Free Silica Content M (%) | ) |

|---|---|

| M < 10 | 1 |

| 10 ≤ M ≤ 50 | 2 |

| 50 < M ≤ 80 | 4 |

| M > 80 | 6 |

| Exposure Ratio (B) | ) |

|---|---|

| B < 1 | 0 |

| 1 ≤ B ≤ 2 | 1 |

| B > 2 | 2 |

| Dust Type | Free Silica Content M (%) | (mg/m3) | Critical Adverse Health Effects | |

|---|---|---|---|---|

| Total Dust | Respirable Dust | |||

| Coal Dust | M < 10% | 4 | 2.5 | Pneumoconiosis |

| Rock Dust | 10% ≤ M < 50% | 1 | 0.7 | Silicosis |

| 50% ≤ M ≤ 80% | 0.7 | 0.3 | ||

| M > 80% | 0.5 | 0.2 | ||

| Labor Intensity Index (N) | ) |

|---|---|

| N ≤ 15 | 1.0 |

| 15 < N ≤ 20 | 1.5 |

| 20 < N ≤ 25 | 2.0 |

| N > 25 | 2.5 |

| Parameter Type | Description |

|---|---|

| Dimensions (L × W × H) | 479 mm × 255 mm × 261 mm |

| Power Supply | 24 V DC |

| Boost Rate | 3.8 m3/min ± 10% |

| Waterproofing of Booster | Suitable for outdoor environments but not for full immersion in water |

| Booster Power | 144 W |

| Filter Element Service Life | 1000 h |

| Moisture Mad (%) | Ash Aad (%) | Volatile Vad (%) | Fixed Carbon FCad (%) |

|---|---|---|---|

| 1.81 | 89.46 | 7.78 | 0.95 |

| Sample Parameters | Dust Samples | |

|---|---|---|

| Coal Dust | Rock Dust | |

| Collection Site | No. 3 WK35 cabin | No. 3 WK55 cabin |

| Results | 0.74% | 24.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, X.; Zhou, W.; Zhu, J.; Zhao, X.; Yan, J.; Wang, R.; Li, Y.; Lu, X. Study on Dust Hazard Levels and Dust Suppression Technologies in Cabins of Typical Mining Equipment in Large Open-Pit Coal Mines in China. Atmosphere 2025, 16, 461. https://doi.org/10.3390/atmos16040461

Jiao X, Zhou W, Zhu J, Zhao X, Yan J, Wang R, Li Y, Lu X. Study on Dust Hazard Levels and Dust Suppression Technologies in Cabins of Typical Mining Equipment in Large Open-Pit Coal Mines in China. Atmosphere. 2025; 16(4):461. https://doi.org/10.3390/atmos16040461

Chicago/Turabian StyleJiao, Xiaoliang, Wei Zhou, Junpeng Zhu, Xinlu Zhao, Junlong Yan, Ruixin Wang, Yaning Li, and Xiang Lu. 2025. "Study on Dust Hazard Levels and Dust Suppression Technologies in Cabins of Typical Mining Equipment in Large Open-Pit Coal Mines in China" Atmosphere 16, no. 4: 461. https://doi.org/10.3390/atmos16040461

APA StyleJiao, X., Zhou, W., Zhu, J., Zhao, X., Yan, J., Wang, R., Li, Y., & Lu, X. (2025). Study on Dust Hazard Levels and Dust Suppression Technologies in Cabins of Typical Mining Equipment in Large Open-Pit Coal Mines in China. Atmosphere, 16(4), 461. https://doi.org/10.3390/atmos16040461