Application of Innovative Technologies for Active Control and Energy Efficiency in Water Supply Systems

1. Introduction

- Definition of dependencies and patterns in the big data analysis to be considered in a proactive multilevel historian application for water networks [14]

- Methodology for historian analysis of malfunctions in sewer networks as a support tool for the management authorities [15]

- Estimates of nodal demands for numerical simulation of water distribution networks [16]

- Assessment of the interaction between head and leak flow in innovative materials for pressurized hydraulic systems [17]

- Existing and emerging desalination technologies, their economic and environmental benefit, their potential application in arid zones [21]

2. Contributed Papers

2.1. Big Data Analysis

2.2. Technologies for Micro to Pico Hydropower

2.3. Industrial Technologies and Control Algorithms

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Acronyms

| CFD | Computational Fluid Dynamics |

| DMA | District Metered Area |

| EPD | Energy Production Device |

| ESOB | End Suction Own Bearing |

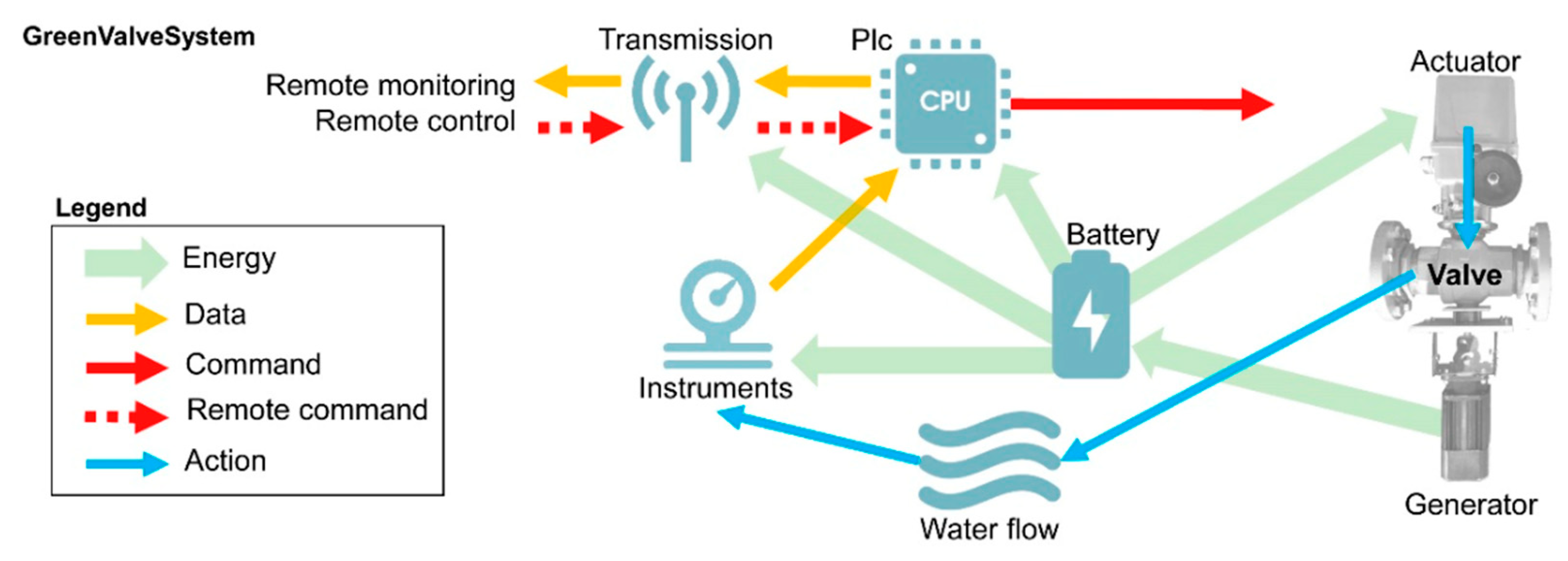

| GVS | GreenValve System |

| IoT | Internet of Things |

| MEI | Minimum Efficiency Index |

| MHP | Micro-hydropower |

| MPC | Model Predictive Control |

| MSV | Multi-Stage Vertical |

| MSH | Multi-Stage Horizontal |

| MSS | Multi-Stage Submersible |

| NPV | Net Present Value |

| PAT | Pump as turbine |

| PRV | Pressure reducing valve |

| PSH | Pumped-storage hydropower |

| WDN | Water distribution network |

| WSS | Water supply system |

References

- Rojek, I. Models for Better Environmental Intelligent Management within the Water Supply Systems. Water Resour. Manag. 2014, 28, 3875. [Google Scholar] [CrossRef]

- Carravetta, A.; Fecarotta, O.; Golia, U.M.; La Rocca, M.; Martino, R.; Padulano, R.; Tucciarelli, T. Optimization of Osmotic Desalination Plants for Water Supply Networks. Water Resour. Manag. 2016, 30, 3965. [Google Scholar] [CrossRef] [Green Version]

- Morani, M.C.; Carravetta, A.; Del Giudice, G.; McNabola, A.; Fecarotta, O. A comparison of energy recovery by pATs against direct variable speed pumping in water distribution networks. Fluids 2018, 3, 41. [Google Scholar] [CrossRef] [Green Version]

- Europe’s Water in Figures: An Overview of the European Drinking Water and Waste Water Sectors 2017 Edition. Available online: www.eureau.org/resources/publications/1460-eureau-data-report-2017-1/file (accessed on 20 November 2020).

- Abd Rahman, N.; Muhammad, N.S.; Wan Mohtar, W.H.M. Evolution of research on water leakage control strategies: Where are we now? Urban Water J. 2018, 15, 812–826. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, R.; Chen, Q.; Li, R. Review on water leakage control in distribution networks and the associated environmental benefits. J. Environ. Sci. (China) 2014, 26, 955–961. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Glielmo, L.; Marini, G.; Zollo, R. Real-time control of pressure for leakage reduction in water distribution network: Field experiments. J. Water Resour. Plan. Manag. 2018, 144, 04017096. [Google Scholar] [CrossRef]

- Gupta, A.; Kulat, K.D. A Selective Literature Review on Leak Management Techniques for Water Distribution System. Water Resour. Manag. 2018, 32, 3247–3269. [Google Scholar] [CrossRef]

- Araujo, L.S.; Ramos, H.; Coelho, S.T. Pressure control for leakage minimisation in water distribution systems management. Water Resour. Manag. 2006, 20, 133–149. [Google Scholar] [CrossRef]

- Fiorillo, D.; Galuppini, G.; Creaco, E.; De Paola, F.; Giugni, M. Identification of Influential User Locations for Smart Meter Installation to Reconstruct the Urban Demand Pattern. Water Resour. Manag. 2020, 146, 04020070. [Google Scholar]

- Blokker, E.J.M. Stochastic Water Demand Modelling for A Better Understanding of Hydraulics in Water Distribution Networks; Water Management Academic Press: Delft, The Netherlands, 2010. [Google Scholar]

- Carravetta, A.; Houreh, S.D.; Ramos, H.M. Pumps as Turbines: Fundamentals and Applications, 1st ed.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Novara, D.; Carravetta, A.; McNabola, A.; Ramos, H.M. Cost Model for Pumps as Turbines in Run-of-River and In-Pipe Microhydropower Applications. J. Water Resour. Plan. Manag. 2019, 145, 04019012. [Google Scholar] [CrossRef]

- Nicolae, A.; Korodi, A.; Silea, I. Identifying Data Dependencies as First Step to Obtain a Proactive Historian: Test Scenario in the Water Industry 4.0. Water 2019, 11, 1144. [Google Scholar] [CrossRef] [Green Version]

- Balacco, G.; Iacobellis, V.; Portincasa, F.; Ragno, E.; Totaro, V.; Piccinni, A.F. Analysis of a Large Maintenance Journal of the Sewer Networks of Three Apulian Provinces in Southern Italy. Water 2020, 12, 1417. [Google Scholar] [CrossRef]

- Ferraiuolo, R.; De Paola, F.; Fiorillo, D.; Caroppi, G.; Pugliese, F. Experimental and Numerical Assessment of Water Leakages in a PVC-A Pipe. Water 2020, 12, 1804. [Google Scholar] [CrossRef]

- Fiorillo, D.; Creaco, E.; De Paola, F.; Giugni, M. Comparison of Bottom-Up and Top-Down Procedures for Water Demand Reconstruction. Water 2020, 12, 922. [Google Scholar] [CrossRef] [Green Version]

- Fontanella, S.; Fecarotta, O.; Molino, B.; Cozzolino, L.; Della Morte, R. A Performance Prediction Model for Pumps as Turbines (PATs). Water 2020, 12, 1175. [Google Scholar] [CrossRef] [Green Version]

- Ferrarese, G.; Malavasi, S. Perspectives of Water Distribution Networks with the GreenValve System. Water 2020, 12, 1579. [Google Scholar] [CrossRef]

- Postacchini, M.; Darvini, G.; Finizio, F.; Pelagalli, L.; Soldini, L.; Di Giuseppe, E. Hydropower Generation Through Pump as Turbine: Experimental Study and Potential Application to Small-Scale WDN. Water 2020, 12, 958. [Google Scholar] [CrossRef] [Green Version]

- Alnajdi, O.; Wu, Y.; Kaiser Calautit, J. Toward a Sustainable Decentralized Water Supply: Review of Adsorption Desorption Desalination (ADD) and Current Technologies: Saudi Arabia (SA) as a Case Study. Water 2020, 12, 1111. [Google Scholar] [CrossRef] [Green Version]

- Morani, M.C.; Carravetta, A.; Fecarotta, O.; McNabola, A. Energy Transfer from the Freshwater to the Wastewater Network Using a PAT-Equipped Turbopump. Water 2020, 12, 38. [Google Scholar] [CrossRef] [Green Version]

- Fecarotta, O.; Martino, R.; Morani, M.C. Wastewater Pump Control under Mechanical Wear. Water 2019, 11, 1210. [Google Scholar] [CrossRef] [Green Version]

- Kong, L.; Lei, X.; Wang, H.; Long, Y.; Lu, L.; Yang, Q. A Model Predictive Water-Level Difference Control Method for Automatic Control of Irrigation Canals. Water 2019, 11, 762. [Google Scholar] [CrossRef] [Green Version]

- Kong, L.; Quan, J.; Yang, Q.; Song, P.; Zhu, J. Automatic Control of the Middle Route Project for South-to-North Water Transfer Based on Linear Model Predictive Control Algorithm. Water 2019, 11, 1873. [Google Scholar] [CrossRef] [Green Version]

- Carravetta, A.; Conte, M.C.; Fecarotta, O.; Ramos, H.M. Evaluation of PAT performances by modified affinity law. Procedia Eng. 2014, 89, 581–587. [Google Scholar] [CrossRef] [Green Version]

- Derakhshan, S.; Nourbakhsh, A. Experimental study of characteristic curves of centrifugal pumps working as turbines in different specific speeds. Exp. Therm. Fluid Sci. 2008, 32, 800–807. [Google Scholar] [CrossRef]

| City | Plant | Length (km) Height (m) | Water Flow (M3/day) | Existing Plan Transmission Pipeline + Current Plants | Proposed Plan Decentralized-ADD without Pipeline | ||

|---|---|---|---|---|---|---|---|

| Water-Transmission Energy Cost (MUSD/year) | Emissions (tons CO2/year) | Water-Production Energy Cost (MUSD/year) | Emissions (tons CO2/year) | ||||

| Makkah | Shoaibah | 90 240 | 550,000 | 82.9 | 653,943 | 12.8 | 101,671 |

| Madinah | Yanbu | 162 631 | 450,000 | 99.5 | 784,530 | 10.5 | 83,186 |

| Abha | Shoqaiq | 105 2084 | 100,000 | 25.1 | 198,165 | 2.3 | 18,485 |

| Riyadh | Jubail | 400 612 | 950,000 | 290.6 | 2,291,034 | 22.2 | 175,615 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carravetta, A.; Giugni, M.; Malavasi, S. Application of Innovative Technologies for Active Control and Energy Efficiency in Water Supply Systems. Water 2020, 12, 3278. https://doi.org/10.3390/w12113278

Carravetta A, Giugni M, Malavasi S. Application of Innovative Technologies for Active Control and Energy Efficiency in Water Supply Systems. Water. 2020; 12(11):3278. https://doi.org/10.3390/w12113278

Chicago/Turabian StyleCarravetta, Armando, Maurizio Giugni, and Stefano Malavasi. 2020. "Application of Innovative Technologies for Active Control and Energy Efficiency in Water Supply Systems" Water 12, no. 11: 3278. https://doi.org/10.3390/w12113278

APA StyleCarravetta, A., Giugni, M., & Malavasi, S. (2020). Application of Innovative Technologies for Active Control and Energy Efficiency in Water Supply Systems. Water, 12(11), 3278. https://doi.org/10.3390/w12113278