The Use of Chemical Methods and Magnetic Field in Conditioning and Dewatering of Digested Sewage Sludge

Abstract

:1. Introduction

2. Research Methodology

2.1. Materials

2.2. Experimental Apparatus for Sludge Conditioning in the Magnetic Field

2.3. Stages of Research

2.4. Analysis

2.5. Statistical Analysis

3. Results and Discussion

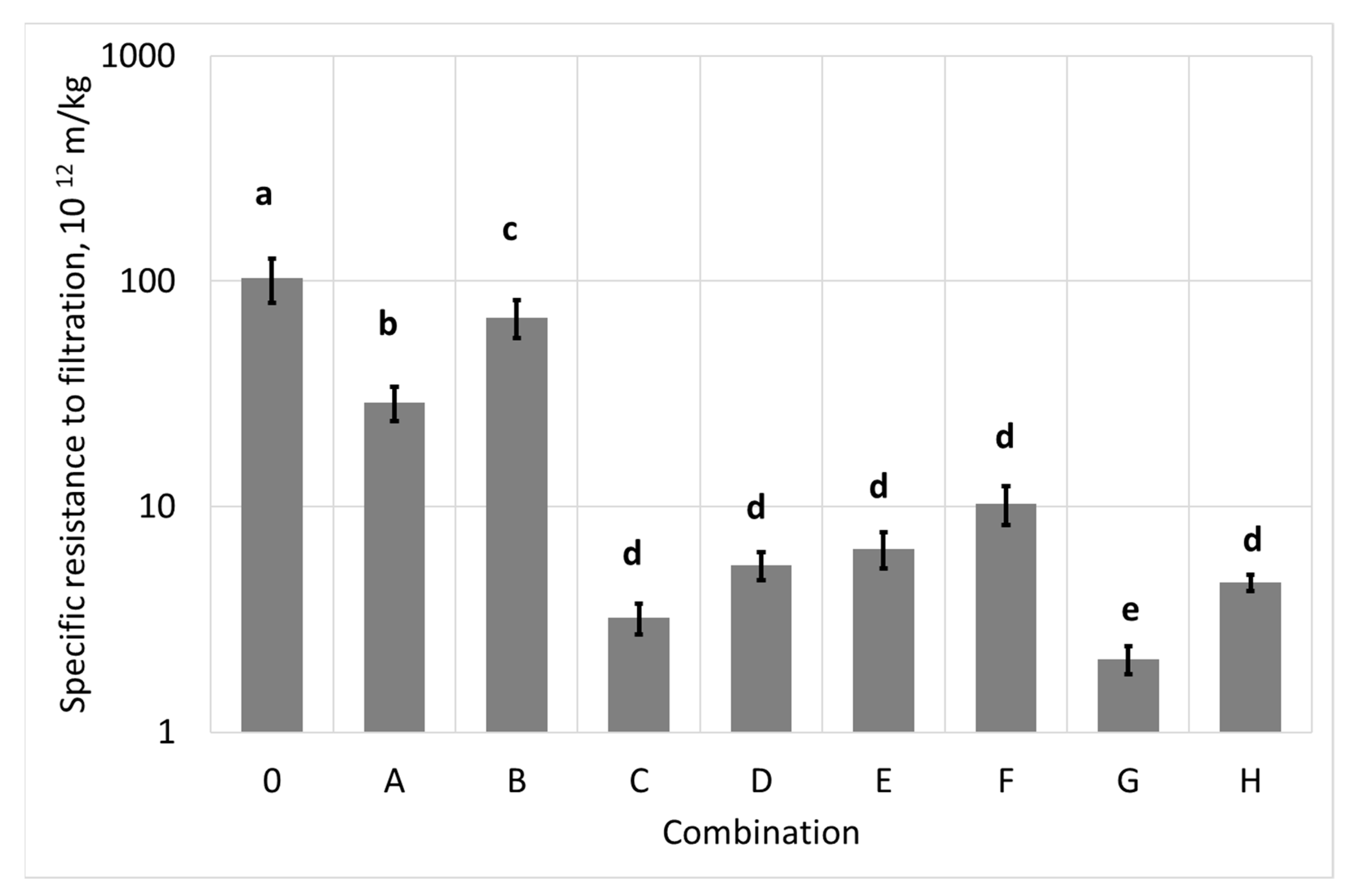

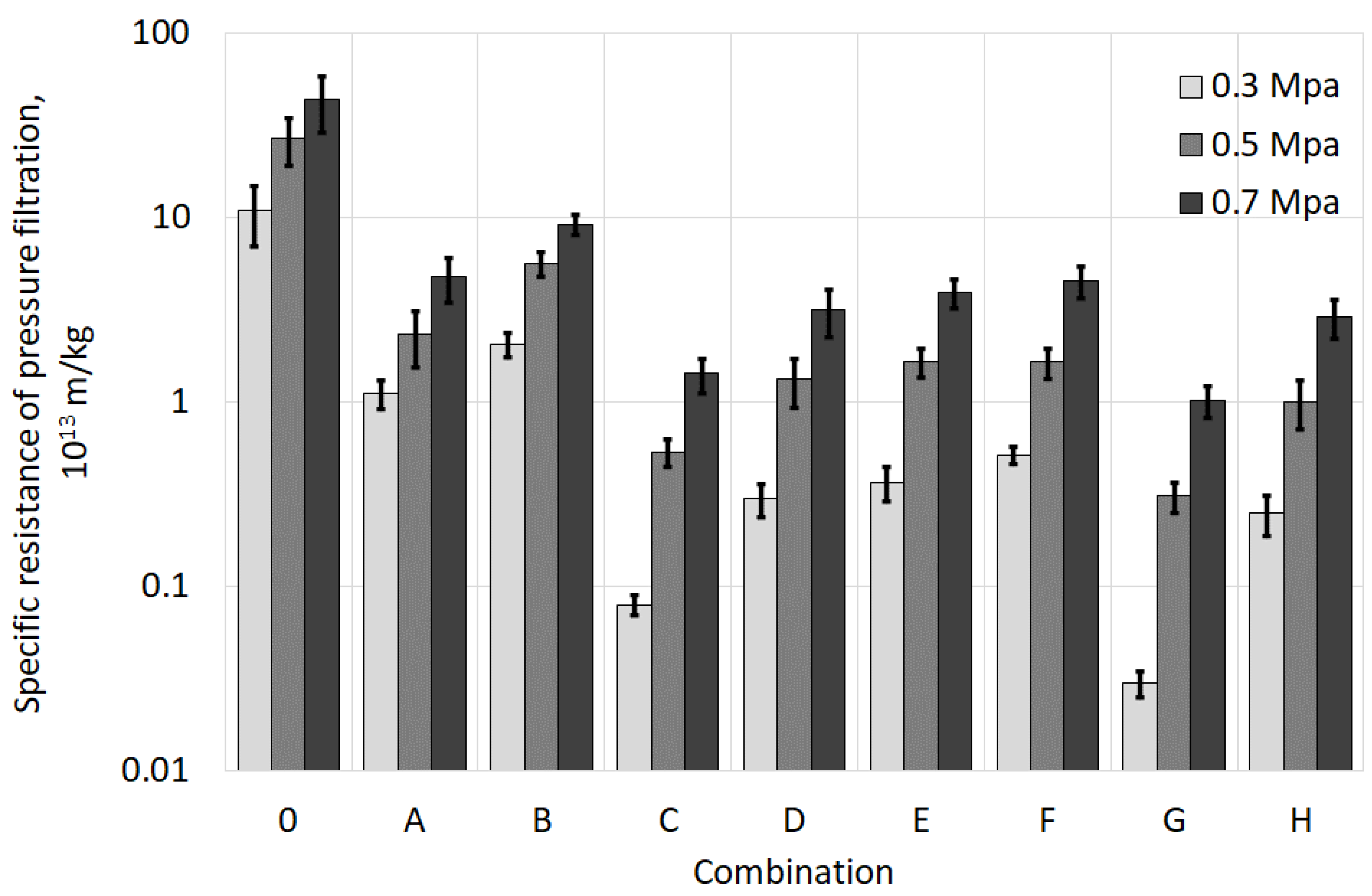

3.1. Filtration Properties

3.2. Rheological Properties

3.3. Supernatant Contamination

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wolny, L.; Kamizela, T. Technika dezintegracji ultradźwiękowej w technologii ścieków i osadów ściekowych. Ekologia I Technika 2003, 1, 3–7. [Google Scholar]

- Skinner, S.; Studer, L.J.; Dixon, D.R.; Hillis, P.; Rees, C.A.; Wall, R.C.; Cavalida, R.G.; Usher, S.P.; Stickland, A.; Scales, P.J. Quantification of wastewater sludge dewatering. Water Res. 2015, 82, 2–13. [Google Scholar] [CrossRef] [PubMed]

- Wójcik, M.; Stachowicz, F. Influence of physical, chemical and dual sewage sludge conditioning methods on the dewatering efficiency. Powder Technol. 2019, 344, 96–102. [Google Scholar] [CrossRef]

- Mowla, D.; Tran, H.; Allen, D.G. A review of the properties of biosludge and its relevance to enhanced dewatering processes. Biomass-Bioenergy 2013, 58, 365–378. [Google Scholar] [CrossRef]

- Qi, Y.; Thapa, K.B.; Hoadley, A.F. Application of filtration aids for improving sludge dewatering properties—A review. Chem. Eng. J. 2011, 171, 373–384. [Google Scholar] [CrossRef]

- Wang, Y.L.; Yan, W.L.; Qian, X.; Sheng, Y.Q.; Chen, Y.J. Characterization of flocculation-conditioning ferric hydroxide gelwith differently charged polyacrylamides. J. Water Process Eng. 2015, 7, 102–111. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Ma, J.; Zhao, X.; Huang, Z.; Mahadevan, G.D.; Qi, J. Improvement of settleability and dewaterability of sludge by newly prepared alkaline ferrate solution. Chem. Eng. J. 2016, 287, 11–18. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Wang, B.; Zhao, Y.; Chai, X.; Niu, D.; Zhao, A.; Li, Y.; Song, Y.; Cao, X. Synergetic pretreatment of waste activated sludge by Fe(II)–activated persulfate oxidation under mild temperature for enhanced dewaterability. Bioresour. Technol. 2012, 124, 29–36. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, J.; Yu, W.; Zhang, S.; Liang, S.; Song, J.; Xu, Q.; Ye, N.; He, S.; Yang, C.; et al. Synergetic conditioning of sewage sludge via Fe2+/persulfate and skeleton builder: Effect on sludge characteristics and dewaterability. Chem. Eng. J. 2015, 270, 572–581. [Google Scholar] [CrossRef]

- Ciborowski, M.; Hrut, K.; Kamizela, T.; Kowalczyk, M.; Potiomkin, K. Dual conditioning of sewage sludge with coagulant and polyelectrolyte. Forum Exploiter. Instal 2014, 3, 34–36. (In Polish) [Google Scholar]

- Łuszczek, B. The problem of nitrogen and phosphorus return charges in leachate from sludge dewatering on the example of Krakow sewage treatment plants. Instal 2014, 4, 47–51. (In Polish) [Google Scholar]

- Cibrowski, M.; Potiomkin, K.; Hrut, K.; Kowalczyk, M.; Kamizela, T. Dualne kondycjonowanie osadów ściekowych koagulantem i polielektrolitem. Instal 2014, 4, 57–59. [Google Scholar]

- Yavuz, H.; Çelebi, S.S. Effects of magnetic field on activity of activated sludge in wastewater treatment. Enzym. Microb. Technol. 2000, 26, 22–27. [Google Scholar] [CrossRef]

- Tomska, A.; Wolny, L. Enhancement of biological wastewater treatment by magnetic field exposure. Desalination 2008, 222, 368–373. [Google Scholar] [CrossRef]

- Zaidi, N.S.; Sohaili, J.; Muda, K.; Sillanpää, M. Magnetic Field Application and its Potential in Water and Wastewater Treatment Systems. Sep. Purif. Rev. 2013, 43, 206–240. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, X.; Ni, S.-Q.; Zhang, J.; Zhang, X.; Ahmad, H.A.; Gao, B. Weak magnetic field: A powerful strategy to enhance partial nitrification. Water Res. 2017, 120, 190–198. [Google Scholar] [CrossRef]

- Łebkowska, M.; Narożniak, A.R.; Pajor, E.; Pochanke, Z. Effect of a static magnetic field on formaldehyde biodegradation in wastewater by activated sludge. Bioresour. Technol. 2011, 102, 8777–8782. [Google Scholar] [CrossRef]

- Hrut, K.; Kamizela, T. Changes in filtration properties of digested sludge under the influence of magnetic field. Desalin. Water Treat. 2018, 117, 282–289. [Google Scholar] [CrossRef] [Green Version]

- Zieliński, M.; Rusanowska, P.; Dębowski, M.; Hajduk, A. Influence of static magnetic field on sludge properties. Sci. Total Environ. 2018, 625, 738–742. [Google Scholar] [CrossRef] [PubMed]

- Hrut, K.; Kamizela, T. Iron compounds and a magnetic field as the conditioning agents for municipal sewage sludge. E3S Web Conf. EDP Sci. 2018, 45, 00022. [Google Scholar] [CrossRef] [Green Version]

- COMSOL® SOFTWARE VERSION 5.2a. Available online: https://www.comsol.com/product-update/5.2a (accessed on 15 January 2020).

- Gilcreas, F.W. Future of standard methods for the examination of water and wastewater. Health Lab. Sci. 1967, 4, 137–141. [Google Scholar] [PubMed]

- The Authority of the Standards Policy and Strategy Committee. Characterization of Sludge-Filtration Properties, Part 1: Capillary Suction Time (CST); PN-EN 14701-1:2007; BSI: London, UK, 2007. (In Polish) [Google Scholar]

- The Authority of the Standards Policy and Strategy Committee. Characterization of Sludge-Filtration Properties, Part 2: Determination of Specific Resistance to Filtration; PN-EN 14701-2:2013-07; BSI: London, UK, 2013. (In Polish) [Google Scholar]

- The Authority of the Standards Policy and Strategy Committee. Characterization of Sludge-Filtration Properties, Part 3: Determination of the Compressibility; PN-EN 14701-3:2007; BSI: London, UK, 2007. (In Polish) [Google Scholar]

- Malkin, A.Y.; Isayev, A.I. Rheology. Concepts, Methods, and Applications, 2nd ed.; ChemTec Publishing: Toronto, ON, Canada, 2011. [Google Scholar]

- ISO, ČSNEN. Determination of Selected Elements by Means of Optical Emission Spectrometry with Inductively Excited Plasma (ICP-OES); BS-EN 11885:2009; BSI: Warsaw, Poland, 2009. [Google Scholar]

| Combination | PIX-113 Dose, kg/kg TS | Polyelectrolyte C-494 Dose, g/kg TS | Magnetic Field Direction | Exposure Time, s | |

|---|---|---|---|---|---|

| 0 | Non-prepared sludge | - | - | - | - |

| A | Sludge conditioned only with polyelectrolyte | - | 4.5 | - | - |

| B | - | 3.6 | - | - | |

| C | Dual chemical conditioning | 0.32 | 4.5 | - | - |

| D | 0.32 | 3.6 | - | - | |

| E | Sludge after dual conditioning exposed to the magnetic field | 0.32 | 3.6 | flow S–N | t1 = 6.6 |

| F | 0.32 | 3.6 | flow S–N | t2 = 3.3 | |

| G | 0.32 | 3.6 | flow N–S | t1 = 6.6 | |

| H | 0.32 | 3.6 | flow N–S | t2 = 3.3 | |

| Combination of Sludge Conditioning/Compressibility Factor | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0 | A | B | C | D | E | F | G | H |

| 1.7 ± 0.3 | 1.7 ± 0.2 | 1.8 ± 0.4 | 3.4 ± 0.5 | 2.8 ± 0.3 | 2.8 ± 0.4 | 2.5 ± 0.5 | 4.2 ± 0.2 | 2.7 ± 0.3 |

| a | a | a | b | c | c | c | d | c |

| Model/Parameter | Combination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | A | B | C | D | E | F | G | H | ||

| Ostwald de Waele | k | 0.195 | 0.344 | 0.316 | 0.782 | 0.724 | 0.567 | 0.525 | 0.961 | 0.610 |

| n | 0.498 | 0.420 | 0.418 | 0.260 | 0.398 | 0.331 | 0.321 | 0.369 | 0.400 | |

| B | 0.989 | 0.998 | 0.997 | 0.996 | 0.982 | 0.986 | 0.936 | 0.993 | 0.994 | |

| S | 0.071 | 0.026 | 0.033 | 0.075 | 0.066 | 0.198 | 0.137 | 0.117 | 0.084 | |

| Bingham | τ0 | 0.568 | 0.893 | 0.810 | 1.739 | 1.497 | 1.119 | 1.030 | 2.113 | 1.254 |

| npl | 0.012 | 0.013 | 0.012 | 0.024 | 0.011 | 0.013 | 0.011 | 0.027 | 0.021 | |

| B | 0.948 | 0.893 | 0.885 | 0.882 | 0.734 | 0.839 | 0.806 | 0.969 | 0.891 | |

| S | 0.189 | 0.309 | 0.28 | 0.582 | 0.428 | 0.366 | 0.354 | 0.695 | 0.481 | |

| Herschley-Bulkley | τ0 | 0.257 | 0.466 | 0.378 | 1.297 | 1.043 | 0.692 | 0.666 | 1.538 | 0.996 |

| Kn | 0.045 | 0.471 | 0.159 | 0.307 | 0.330 | 0.067 | 0.096 | 0.246 | 0.177 | |

| n | 0.752 | 0.752 | 0.235 | 0.553 | 0.378 | 0.630 | 0.609 | 0.585 | 0.600 | |

| B | 0.999 | 0.998 | 0.997 | 0.999 | 0.984 | 0.945 | 0.995 | 0.999 | 0.999 | |

| S | 0.021 | 0.030 | 0.030 | 0.035 | 0.062 | 0.127 | 0.041 | 0.018 | 0.012 | |

| Combination of Sludge Conditioning | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0 | A | B | C | D | E | F | G | H |

| Area of the Hysteresis Loop, T, Pa/s | ||||||||

| 85 | 151 | 119 | 270 | 209 | 143 | 189 | 105 | 150 |

| Combination | TKN, mg/L | N-NH4+, mg/L | TOC, mg C/L |

|---|---|---|---|

| 0 | 896 ± 68 | 775 ± 61 | 319 ± 40 |

| A | 868 ± 104 | 612 ± 92 | 223 ± 41 |

| B | 856 ± 122 | 674 ± 86 | 257 ± 46 |

| C | 778 ± 101 | 528 ± 69 | 148 ± 25 |

| D | 767 ± 117 | 596 ± 98 | 176 ± 37 |

| E | 834 ± 127 | 645 ± 106 | 194 ± 43 |

| F | 750 ± 136 | 553 ± 112 | 181 ± 40 |

| G | 722 ± 94 | 481 ± 174 | 147 ± 18 |

| H | 784 ± 113 | 601 ± 82 | 168 ± 29 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamizela, T.; Kowalczyk, M.; Zawieja, I. The Use of Chemical Methods and Magnetic Field in Conditioning and Dewatering of Digested Sewage Sludge. Water 2020, 12, 1642. https://doi.org/10.3390/w12061642

Kamizela T, Kowalczyk M, Zawieja I. The Use of Chemical Methods and Magnetic Field in Conditioning and Dewatering of Digested Sewage Sludge. Water. 2020; 12(6):1642. https://doi.org/10.3390/w12061642

Chicago/Turabian StyleKamizela, Tomasz, Mariusz Kowalczyk, and Iwona Zawieja. 2020. "The Use of Chemical Methods and Magnetic Field in Conditioning and Dewatering of Digested Sewage Sludge" Water 12, no. 6: 1642. https://doi.org/10.3390/w12061642