1. Introduction

In Korea, drought occurs every 2–3 years, depending on the region, and becomes extreme every seven years [

1]. Major cities have reliable water sources and supply networks. However, surprisingly, the water supply network of South Korea has several blind spots, and, as a result, it is a prime concern for residents in the uppermost part of watersheds. Compared to national and regionals, small-scale supply sources have low water quality and are vulnerable to drought. For example, during a river water freezing-related drought in Gangwon Province in 2016, 3817 people (44 villages) from 1443 households (44 villages) received water supply (285 times, 1845 m

3) using a water truck. Such areas need locally adapted water supply sources and networks. In particular, in the upstream end of watersheds, usually mountainous areas, strategies and technologies need to be developed for alternative supply sources such as conjunctive use of groundwater and river water.

This study focuses on the application of sand dam technology in South Korea. A sand dam is usually built from concrete or beam on the impervious bedrock of a valley or river to accumulate sand materials and store water for later use [

2,

3,

4,

5]. Storing water in intermittent riverbeds has several advantages, including small-scale irrigation, water supply, and ecological use [

6]. Even though sand dam technology has a long history, well-documented data on the worldwide application locations are unavailable [

7,

8,

9]. Recently, the technology has attracted researchers’ attention, and several publications have been produced in the last three years [

7]. Besides the working principles and success stories, the factors affecting the sand dam performance, future directions, and many more aspects are reported [

3,

4,

7,

10]. However, most of the studies, particularly the success stories, are in arid and semi-arid regions, e.g., [

7,

11,

12,

13].

Evaporation losses and water pollution are less in sand storage compared to surface water storage dams, and the construction is also simple [

6,

14,

15,

16]. A sand dam is also considered as an artificial groundwater recharge method and has a groundwater level increasing effect [

5]. In particular, when the connection between rivers and aquifers is strong, it can be used as an artificial recharge facility [

17]. Although it is challenging to quantify inflow into the aquifer through the seepage flow from the riverbed, depending on the groundwater level in the area, continuous water exchange between the artificial aquifer formed by the sand storage and the natural aquifer in the region is an inevitable phenomenon [

10,

11,

17,

18]. This phenomenon will continue year-round, and, as a result, groundwater levels within the sand dam will rise [

5,

17]. Water stored in the sand increases resistance to drought even during dry seasons and is being promoted as a technology to cope with water shortages in long-term climate change [

3,

4,

17,

19,

20].

Besides the general hydrological processes in sand dam areas [

6,

11,

17] and failures related to sand material quality and water pollution [

21], the detailed storage capacity based on layers of the sand is unexplored. The effect of depth-wise properties of accumulated material on the disposable amount of water is an untouched topic. Sand dam material selection lacks clear guidelines [

7,

22], even though both water quality and storage capacity rely on the sand particle property. In this study, the sensitivity of the principal sand material properties was evaluated using a Modular Finite-Difference Groundwater Flow (MODFLOW) model [

23]. The principal goal of this study was to evaluate the water supply capacity of a sand dam constructed in Mullo-ri in Chuncheon, Gangwon-do, South Korea. The water supply in the area is from an intermittent river using a small reservoir to which the river water is supplied through seepage. The sand dam is built to enlarge the water supply capacity of this reservoir. Considering the existing water supply capacity, the amount of water that can be withdrawn from the sand dam was assessed. This technology is applied in Korea with a modified scheme for the first time. The results and conclusions of this study would be valuable inputs to adopt the technology in other parts of similar water supply blind spot mountainous areas of the country, and other parts of the world with related circumstances or climate conditions.

The rest of this paper is organized as follows:

Section 2 outlines the study area, a brief description of sand dam construction, the model used in this study, and description and modeling processes. In

Section 3, typical MODFLOW model simulation results are discussed.

Section 4 summarizes the methods and main findings, including conclusions.

2. Materials and Methods

2.1. Description of the Study Area

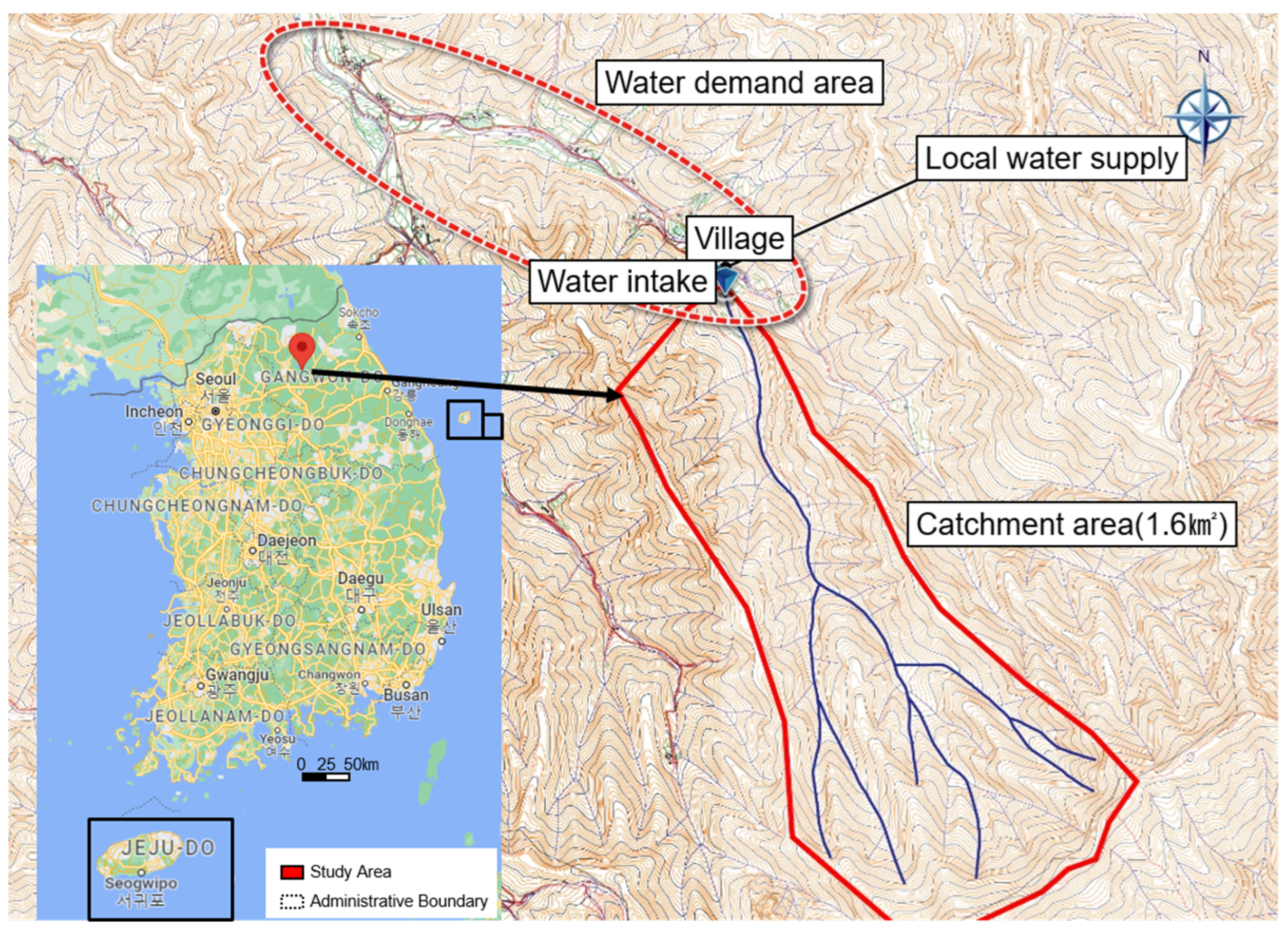

The sand dam is built around Mulo-ri, Buksan-myeon, Chuncheon-si (

Figure 1). The area is one of the water supply blind spots in the country. The regional supply network does not cover this area due to several factors, including the topography and population size. The area is small and could be supplied by water trucks during the 2016 drought. Currently, the local water supply capacity is 30 m

3/day. The water source is mainly from the intermittent river in the mountain, from which the water continuously flows through seepage. A small intake is used to divert water from the river. This bypass-type sand dam was built following the water intake at the side of the main waterway. The catchment area covers around 1.6 km

2. The topography of the catchment area varies from 298 to 950 m above sea level.

2.2. Sand Dam Construction

The dam is built from concrete, with a width of 5 m and a length of 10 m. Commonly, a sand dam is built on the main course of the river in stages and makes the water flow velocity decrease so that the transported sediment would have time to settle in the upstream area [

6,

24]. The accumulated sand materials during the first few flood events create an artificial aquifer that has the functionality to protect water from evaporation and pollution and stores for a longer time. Water abstraction methods also include scooping holes or infiltration galleries. Pumping wells are also used to withdraw water from the riverbed level in the sand dam area. Since the objective is to improve the existing small reservoir used to supply water for the residents in the region, the dam is built at the side of the main waterway connected to the existing small intake reservoir (pond), which is filled by seepage flow. Protection walls on both sides are installed and the storage area is filled with imported materials. The location of the sand dam is presented in

Figure 2.

The right side of the sand dam is in contact with the valley wall. Large natural stone piling was carried out to secure the stability of the structure during flood periods. A maintenance pipe was installed in the downstream part of the sand dam so that portable cleaning technology, such as air surging, could be applied. The water entering the sand storage passes through a gabion to prevent the inflow of debris. The dam has a weir to discharge overflow and the flow rejoins the main downstream waterway.

As shown in

Figure 3, before the sand dam construction, the foundation of the existing water intake was investigated. The geology shows a thick rock layer distributed evenly. Therefore, to build the foundation, a rock cutting was performed. In the dam body, a collection well and filter pack screen were installed. The sand storage area was filled with variable size layers of sand and rock. With the first layer, at the bottom, 2–5 mm size of sand about 0.8 m thick was laid, and at the top of this layer, a similar thickness of about 1–2 mm size filter sand was filled, then covered with 25 mm gravel on the top to prevent the loss of filler material.

Figure 4 shows the cross-section of the sand dam environment. The water stored in the sand is first collected in an intake reservoir width of 1.5 m and a length of 3 m and then directly supplied to the water tank through a steel pipe. The water tank is on the downstream side of the sand dam, and the water could be piped with the help of gravity, but to make the water supply reliable, solar energy was also installed. Plan view of the sand dam and detail showing the connection between the old reservoir (pond) and the sand dam are shown in

Figure 5.

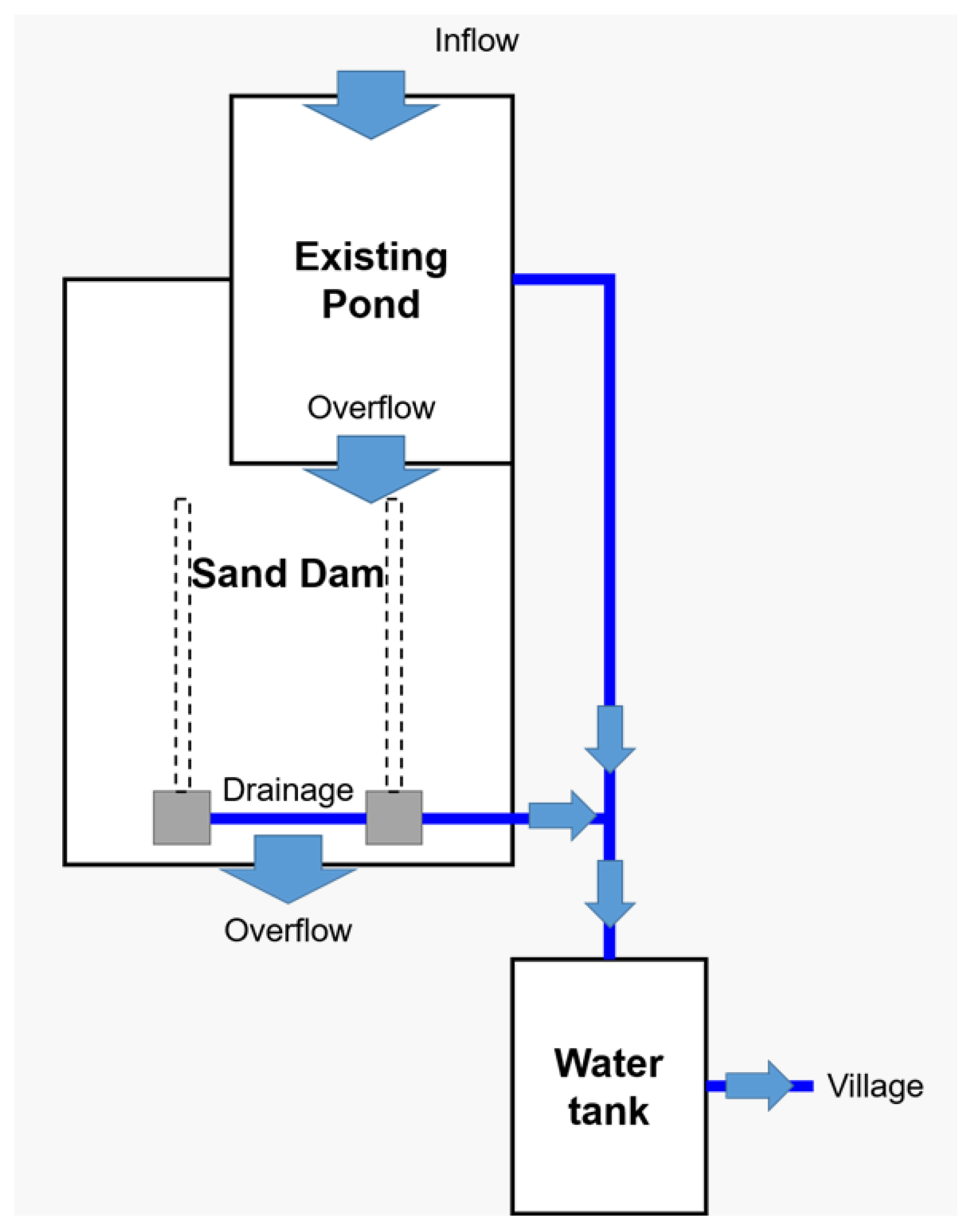

Figure 6 is schematic diagram of water supply system for the study area.

2.3. Groundwater Model

In this study, MODFLOW model [

23] was used to analyze the water supply from the sand dam. Using the model, the amount of water that could be withdrawn from the sand dam via a perforated drain pipe was evaluated. MODFLOW is a three-dimensional groundwater flow model, a widely used groundwater analysis program, distributed by the United States Geological Survey (USGS). MODFLOW is a physically based finite-difference model that solves the three-dimensional groundwater flow through porous earth material. This model combines the continuity equation and Darcy’s law to simulate the groundwater flow in a saturated zone and uses the three-dimensional groundwater equation, Equation (1), as the governing equation. It is widely used to compute the groundwater level (head), particularly in response to recharge and groundwater abstraction,

where

,

, and

are principal components of the hydraulic conductivity tensor in x, y, and z spatial directions,

W is the source or sink,

is specific storage (1/L), h is the hydraulic head (L), and

t is time [

23]. MODFLOW has several packages and independent modules which make up the main program. Packages can be selected according to the user’s needs. The basic (BAS) package forms the overall structure for model building, including the number of grids, the number of layers, boundary and initial conditions, simulation period, and time interval.

The BCF package (Block-Centered Flow package) takes the hydraulic parameters of the aquifer, such as the layer bottom elevation, hydraulic conductivity, and storage coefficient. In MODFLOW, groundwater abstraction is represented using the well package. The package enables inclusion of the well location, pumping rate and schedule, and other details. The natural groundwater recharge can be incorporated using the RCH package (ReCHarge package). Groundwater removal using drainage pipes is also commonly simulated using the DRN package (DRaiN package). The RIV package (RIVer package) simulates the phenomenon of supplying or draining to the surface water body based on the water head difference between rivers, lakes, etc., and groundwater.

2.4. Description of Modeling

In order to simulate the flow of groundwater in the sand dam and the amount of discharge through perforated drainage pipes in the 3rd layer and weir in 1st layer, it was divided into a grid of 1 m × 1 m in the horizontal and vertical directions as shown in

Figure 7. Red dot means observation well.

The open channel flow region was discretized as a virtual medium layer. In addition, the virtual medium layer was set as an unconfined aquifer, and the lower two layers were set as a confined/unconfined convertible layer. The thickness of the 2nd and 3rd layers, which are the sand filling layers, is 0.8 m, respectively, and for the hydraulic conductivity values of each layer, 172 m/d and 280 m/d, the values calculated through the indoor hydraulic test, are inputted, respectively. As shown in

Figure 3, the specific yield of the 2nd (1–2 mm) and 3rd (2–5 mm) layers were entered as 0.45 and 0.39, respectively, considering the porosity, and the storage coefficient was entered as 1/100 of this value considering the sand layer. For the first floor, which is a hypothetical layer with 100% porosity, a storage coefficient value of 1.0 was input, and a hydraulic conductivity value of 50,000 m/d, which was calibrated through observed and simulated groundwater levels, was input. Only the inside of the sand dam was set as an active cell, and the outer part and the bottom of the 3rd floor were given a no-flux boundary condition. As the upper boundary condition of the simulation area, the amount overflowing from the existing pond and flowing into the sand dam was applied only to the active cell according to the location of the calculated water level. As internal boundary conditions, the weir of the 1st layer and the perforated drain pipe of the 3rd layer were simulated using a drain package. The drainage conductance was calculated through calibration of the model. The initial water level and head were entered as the first-floor bottom level for all floors.

MODFLOW’s drain package was used to simulate the two perforated drain pipes (drain pipes) installed on the third layer of the sand dam. In the drain package, it is assumed that the amount of discharge from the aquifer () is proportional to the difference between the head of the aquifer () and the elevation of the drainage pipe (). For the elevation of the drain pipes, the central elevation of the drain pipe is usually used, and if the calculated head is smaller than this, it is treated as no drainage. The equivalent conductivity coefficient (drainage conductivity coefficient) of a drain pipe varies depending on the hydraulic conductivity and head distribution around the pipe, the thickness and hydraulic conductivity of the filter media, and the filtration capacity of the drain pipe, such as the number of screen openings. In this study, it is assumed that the value of the drain conductivity per unit length is the same as the value of the hydraulic conductivity of the lowest model layer.

Excess water from the sand dam flows downstream through the installed weir. This natural weir discharge was conceptualized in MODFLOW using a drain package. Weir discharge was made in proportion to the difference between the calculated water level and weir height. The equivalent conductivity coefficient (weir conductivity coefficient) of the weir was set as the same as the hydraulic conductivity value of the uppermost layer.

3. Results and Discussion

3.1. Model Calibration and Validation

After the sand dam was completed in October 2021, filled with sand material, a water quality check, structural stability check such as for leaks, water level observation hole installation, valve and flow meter installation, a drainage performance check of the perforated drain pipe and maintenance pipe, etc., were carried out. The actual operation started from May 2022. Thus, calibration of the model was performed for the operation period, during which the water level measurement was made in the sand dam.

Figure 8 shows the comparison between the observed data converted to the water level by the water pressure sensor installed in the filler material on the upstream side of the sand dam, about 2 m from the downstream end of the sand dam, and the calculated water level in the cell. Until 15 May 2022, the valve of the drain pipe was shut off and discharge was allowed only through the weir. Therefore, for the valve shut-off period, repeated simulations were performed until the observed and simulated water levels were well-matched while changing the hydraulic conductivity of the first floor, which is the virtual layer, and the drainage coefficient of the weir. The value of the drainage conductance of the drain pipe was also calculated through repeated observation and simulated water level fitting process from 16 May to 7 July.

For the hydraulic conductivity values of the second and third layer fillers, the values calculated through the hydraulic tests were used as they were without calibration. As a result of calibration, the hydraulic conductivity of the first layer was 50,000 m/d, and the drainage conductance per unit length of the perforated drain pipe on the third floor was calculated to be 7 m/d. If the hydraulic conductivity or drainage conductance is smaller than this, the simulated water level is formed above the observed water level.

As shown in

Figure 8, it can be seen that the simulated water level fits the observed level well. During the valve shut-off period, the water level is maintained at a value slightly above about 1.9 m, and the water level fluctuates according to the amount of inflow into the sand dam and the amount of discharge from the drain pipe after the valve was opened on 16 May 2022.

The discharge measured by the flow meter at the time of the weir discharge of the sand dam was about 200 m3/day, and the simulated discharge by formula was also calculated as an amount close to this, indicating that the calibration of the model was well-performed. In the future, we plan to measure the flow rate continuously and accurately by installing an automatic flow meter in the pipeline connected to the water tank.

3.2. The Effect of Water Supply Enhancement

The flow rate was measured several times in the pipeline connected to the drain pipe of the existing water intake source using an ultrasonic flow meter, and the pipe drainage conductance value of the drain pipe was calculated assuming that the flow rate and water level have a linear relationship when the pressure is assumed zero inside the perforated pipe. The value of the drainage conductance per unit length of the existing water intake was calculated to be about 12 m/d, which is slightly larger than that of the sand dam (7 m/d). The perforated drain pipe of the sand dam is a steel screen and has a large opening rate, but it has a filter pack screen, so it is small compared to the existing water intake source.

For the existing water intake source, the discharge amount of the continuous drain pipe was calculated by multiplying the water level automatically observed every hour from 9 March 2020 by the drainage conductance.

Figure 9 shows the discharge amount of the existing water intake for the period immediately before the operation of the new sand dam from the time when the existing water intake was observed. It can be seen that the discharge amount decreased due to the decrease in water level in the winter in January and February, and it ranges from a minimum of 117.5 m

3/day to a maximum of 210.4 m

3/day. During the analysis period, an average of 179.9 m

3/day of water is supplied through the existing water intake source.

For the same period, numerical modeling was performed on the conditions assuming that the sand dam was installed and operated to simulate the amount of discharge through the perforated drain pipe in the sand dam.

Figure 10 shows the simulated results of sand dam discharge as a unit, and indicates the amount of water supplied in addition to the discharge from the existing water intake source. It overflows from the existing water intake and there is no inflow into the sand dam, so there are cases where the discharge is 0 m

3/day, and it occurs up to 251 m

3/day during the flood season. The average discharge amount during the simulation period was calculated to be 110.8 m

3/day, and it was analyzed that the water supply could be increased by 61.6% of the average discharge amount of the existing water intake source. Therefore, it is possible to bring about the effect of improving the water supply in the research area by artificially incubating the surplus water overflowing from the existing water intake source as a sand dam and using it again.

Figure 11 shows the amount of discharge through the drain pipe when the existing water intake source and the new sand dam are operated together. In other words, the result in

Figure 10 is the same as the sum of results from

Figure 8 and

Figure 9. It shows a minimum discharge of 117.5 m

3/day and a maximum of 461.6 m

3/day. The increased availability of water can be used for purposes other than drinking water and can also contribute to meeting the growing demand in the region.

The study area suffered from water shortages such as reliance on water trucks due to limited water supply from existing water sources due to an extreme drought in 2016. Therefore, it is necessary to evaluate the water supply capacity when the inflow to the water intake source is very small. For this, the existing water intake source and sand flow were assumed to be reduced by 50% (Case1) and 90% (Case2) compared to the actual inflow during the simulation period from 9 March 2020 to 16 May 2022. The amount of discharge through the drain pipe of the dam was simulated.

Figure 12 shows the simulated drain pipe discharge when the inflow is reduced by 50%. On average, 139.0 m

3/day from the existing water intake source, 97.8 m

3/day from the new sand dam, and 236.8 m

3/day of water discharged from the two facilities, were analyzed to be possible. This is 80% of the average water supply of 290.7 m

3/day for the actual inflow condition.

Figure 13 shows the simulated results when the inflow is greatly reduced, by 90% compared to the actual. On average, it was analyzed that 87.2 m

3/day from the existing water intake source, 42.8 m

3/day from the new sand dam, and 133.0 m

3/day from the two facilities, would be possible. This is about 50% of the actual inflow condition. However, the minimum supply amount was 11.8 m

3/day in February 2022, which was evaluated as not meeting the minimum domestic water demand of 15.0 m

3/day in this area.

4. Summary and Conclusions

In this study, the water supply capacity of the dam in comparison with the current demand in the study area was assessed. The sand dam was built on an intermittent mountainous stream in South Korea to improve the water supply of an existing small reservoir. Even though the technology has been used widely to harvest water from dry riverbeds in arid and semi-arid regions, the application in South Korea is new. In the study area, the sand dam and the water supply scheme were modified from the usual scheme used in the rural part of arid and semi-arid countries. Commonly, a sand dam is built in stages so that the natural river flow in the rainy season slows and lets the water drop the transported sand. After a few flood events, the upstream area fills with sand materials and creates an artificial aquifer. The water supply and storage capacity of the sand dam depends on the volume and property of the accumulated sand. Thus, understanding of hydraulic properties of the sand material is vital. However, most studies on the characterization of supply and storage capacity of sand storage rely on simplified calculations using dimensions of the artificial aquifer and a few numbers on material properties, i.e., hydraulic conductivity and specific yield. In this study, the sand dam site is mountainous, and the gorge is big. Moreover, the plan was to improve the existing small reservoir, which takes and stores water from the main gorge. Due to these site-specific circumstances, the sand dam was built following the existing reservoir. After the construction of the dam wall, three layers of different sizes and property sand materials were filled. To abstract water from the sand storage, perforated drain pipes were installed in the bottommost layer.

Using the MODFLOW model, the flow of groundwater in the sand dam and the amount of discharge through perforated drainage pipes in the third layer and weir in first layer has been analyzed. The open channel flow region was discretized as a virtual medium layer. In addition, the virtual medium layer was set as an unconfined aquifer, and the lower two layers were set as a confined/unconfined convertible layer. For the first floor, which is a hypothetical layer with 100% porosity, a storage coefficient value of 1.0 was input, and a hydraulic conductivity value of 50,000 m/d, which was calibrated through observed and simulated groundwater levels, was input. Only the inside of the sand dam was set as an active cell, and the outer part and the bottom of the third floor were given a no-flux boundary condition. As the upper boundary condition of the simulation area, the amount overflowing from the existing pond and flowing into the sand dam was applied only to the active cell according to the location of the calculated water level. As internal boundary conditions, the weir of the first layer and the perforated drain pipe of the third layer were simulated using a drain package. The drainage conductance was calculated through calibration of the model. The initial water level and head were entered as the first-floor bottom level for all floors.

For the period from 9 March 2020 to 16 May 2022, the results of calculation of water supply for the installation and operation of existing water sources, new sand dams, and underground water collection tanks are as follows. Regarding the actual inflow condition, compared to the average water supply of the existing water intake source, the sand dam installation increased water supply by 61.6%, and the sand dam installation showed improvement by 36% for the minimum water supply. The calculated water supply for the condition where the inflow was reduced by 50% showed an effect of improving water supply by over 70% on average, due to the installation of the sand dam.