Evaluation of the Purity of Magnesium Hydroxide Recovered from Saltwork Bitterns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

2.2. Solution Preparation and Compositions

2.3. Experimental Tests and Methodological Procedures

2.4. Analytical Equipment and Procedures

- Bittern concentration. Na+, K+, Mg2+, Cl−, SO42− and Br− ions were assessed through ion chromatography (IC, Metrohm 882 Compact IC plus and Dionex ICS-1000/1100, located at UNIPA and UPC laboratories); Ca2+ was measured via flame-atomic absorption spectroscopy (F-AAS, AAnalyst 200 PerkinElmer (Waltham, MA, USA) spectrometer, located at UNIPA) and inductively coupled plasma mass spectrometry (ICP-MS, 7800 ICP-MS from Agilent Technologies (Santa Clara, CA, USA), located at UPC) techniques; and B(III) was determined using inductively coupled plasma optical emission spectrometry (ICP-OES, Optima 2100 DV PerkinElmer (Green Bay, WI, USA) spectrometer, located at UNIPA) and the ICP-MS. Bittern samples were diluted in deionized water before measurement.

- Mg2+ recovery (ion concentrations in filtrates, see Figure 2). Mg2+ and Ca2+ concentrations in the filtrates were measured using the F-AAS technique. Samples were diluted in deionized water before measurement. Samples were diluted and acidified with HNO3 (Sigma–Aldrich, ≥65%, Saint Louis, MO, USA) to reach a pH of around 5 before measurement.

- Mg(OH)2 cationic purity (e.g., total content of cations in the precipitated MH). Approximately 100 mg of MH powder was dissolved in 1 M HCl (Honeywell|FlukaTM). Mg2+, Ca2+ and Na+ concentrations were measured via IC at UNIPA laboratories. B(III) traces were also measured though ICP-OES. The same samples were also analyzed at UPC laboratories by dissolving 50 mg of MH in 100 mL of aqua regia and employing ICP-MS and an inductively coupled plasma optical emission spectrometer (5100 ICP-OES from Agilent Technologies, United States).

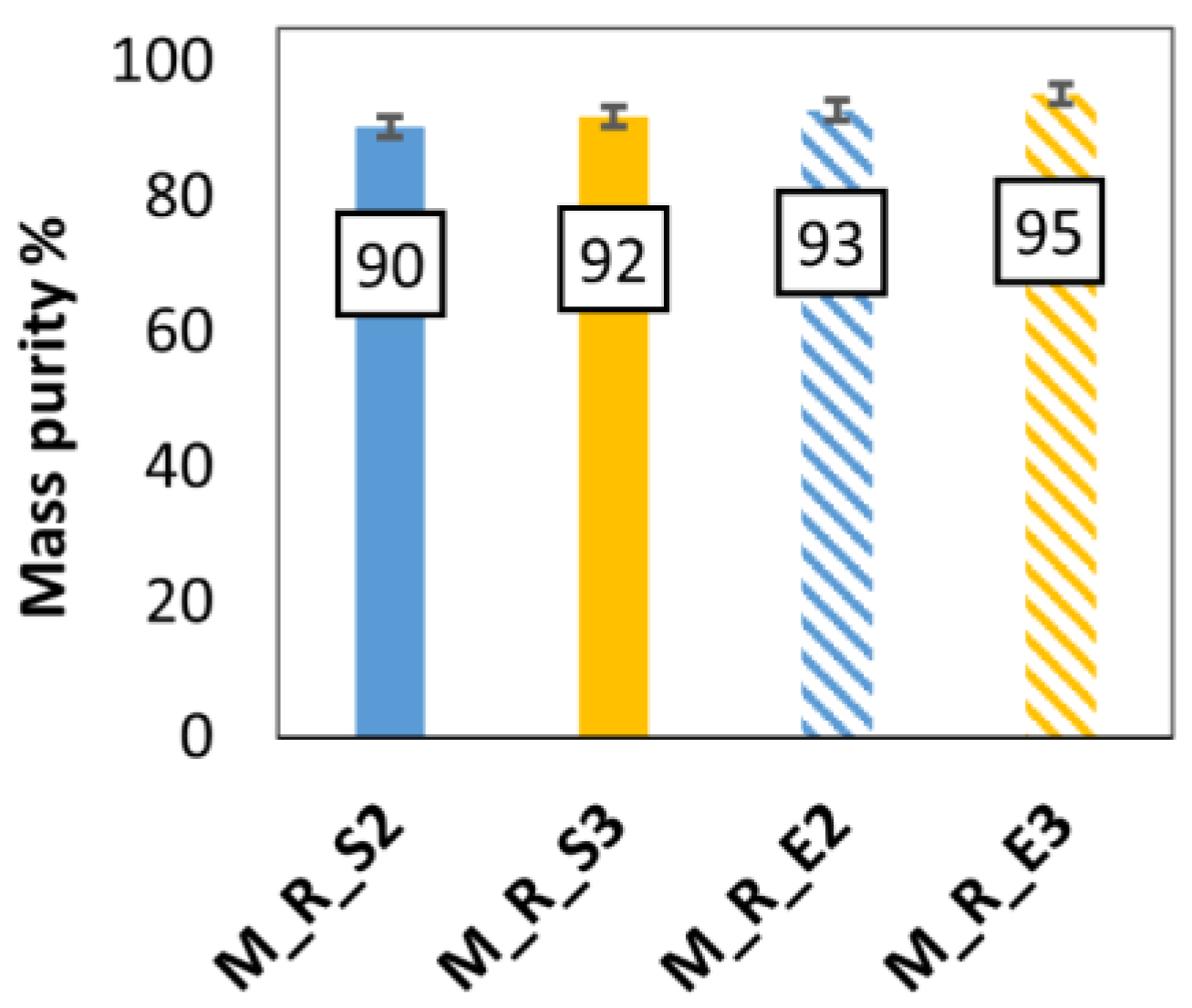

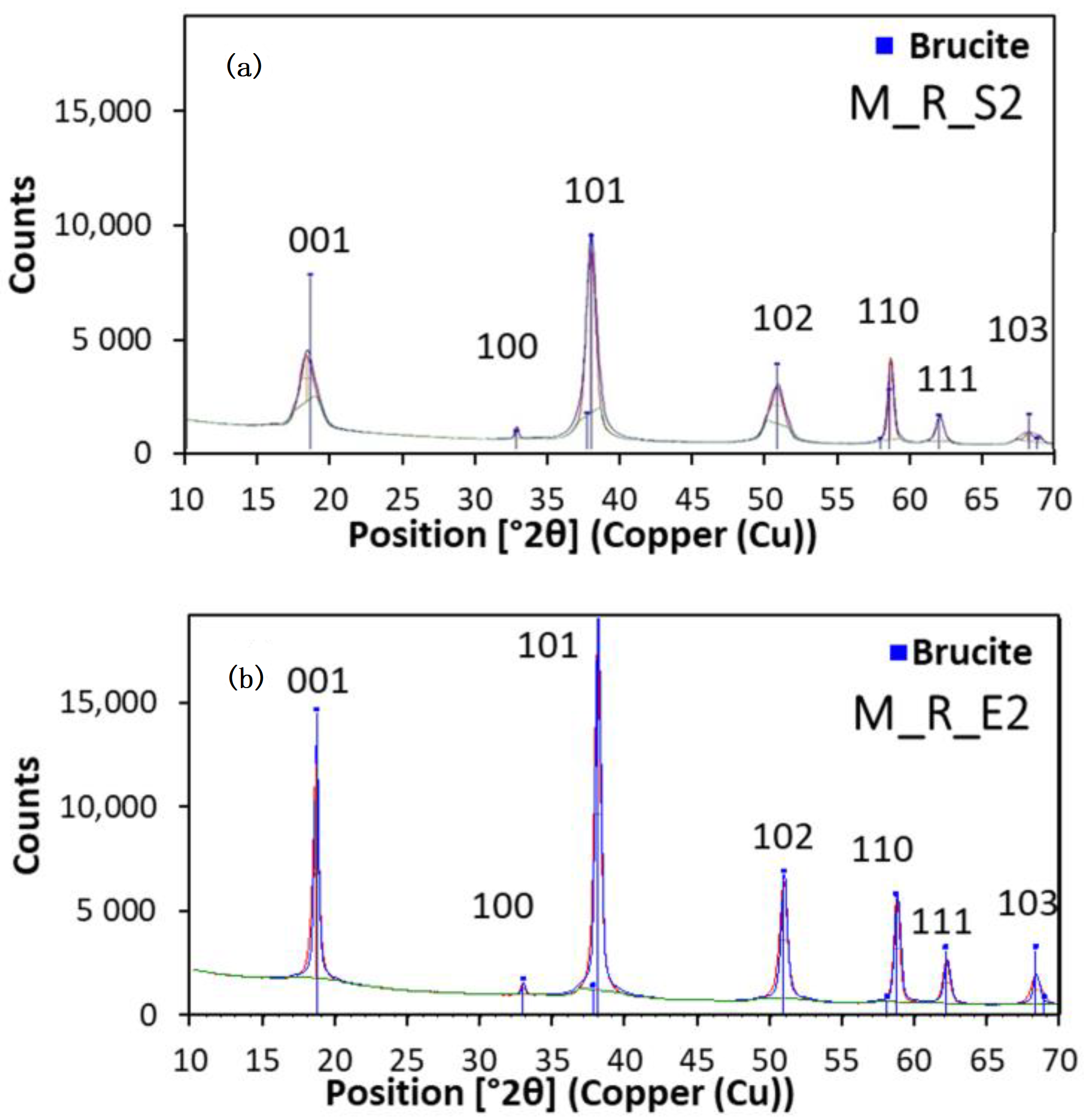

- Mg(OH)2 mass purity. The crystalline structure and impurities present in the Mg(OH)2 powders were semi-quantitatively analyzed through an X-ray diffraction (XRD, Empyrean, Malvern PANalytical, United Kingdom, diffractometer, at UNIPA laboratories) technique using CuKa radiation (1.542° A, 40 KV, 40 mA) in the 2ɵ range of 10–70° at a step size of 0.05 and a step time of 144 s. The solids’ purity was also investigated via thermogravimetric analysis (TGA, STA 449 F1 Jupiter analyzer, NETZSCH, at UNIPA laboratories). TGA analyses were conducted at a heating rate of 10 °C/min from 30 °C to 1000 °C, under a constant nitrogen flow of 20 mL/min. The solids’ mass purity and morphological shapes were further assessed via scanning electron microscopy (SEM FEI, United States, Quanta 200 FEG and JEOL, Japan, JSM-7001F equipment at UNIPA and UPC laboratories, respectively) and via elemental microanalysis adopting energy dispersive X-ray spectroscopy (EDS).

2.5. MH Precipitation Performance Parameters

- The ratio between the Mg2+ ion concentration (mg/g) in the dissolved solids with respect to all the other cations (cationic purity) detected through IC measurements:

- 2.

- The ratio between the Mg(OH)2 mass ( associated with water-mass loss in a temperature range between 320 °C and 480 °C (see Section TG analysis for further details), measured using TG analysis, over the dry sample mass (mass purity). Note that the dry mass was calculated by subtracting the humidity content ( determined in a temperature range between 30 °C and 200 °C to the total initial sample mass. Therefore, mass purity from TG analysis was calculated as:

3. Results

3.1. Magnesium Recovery

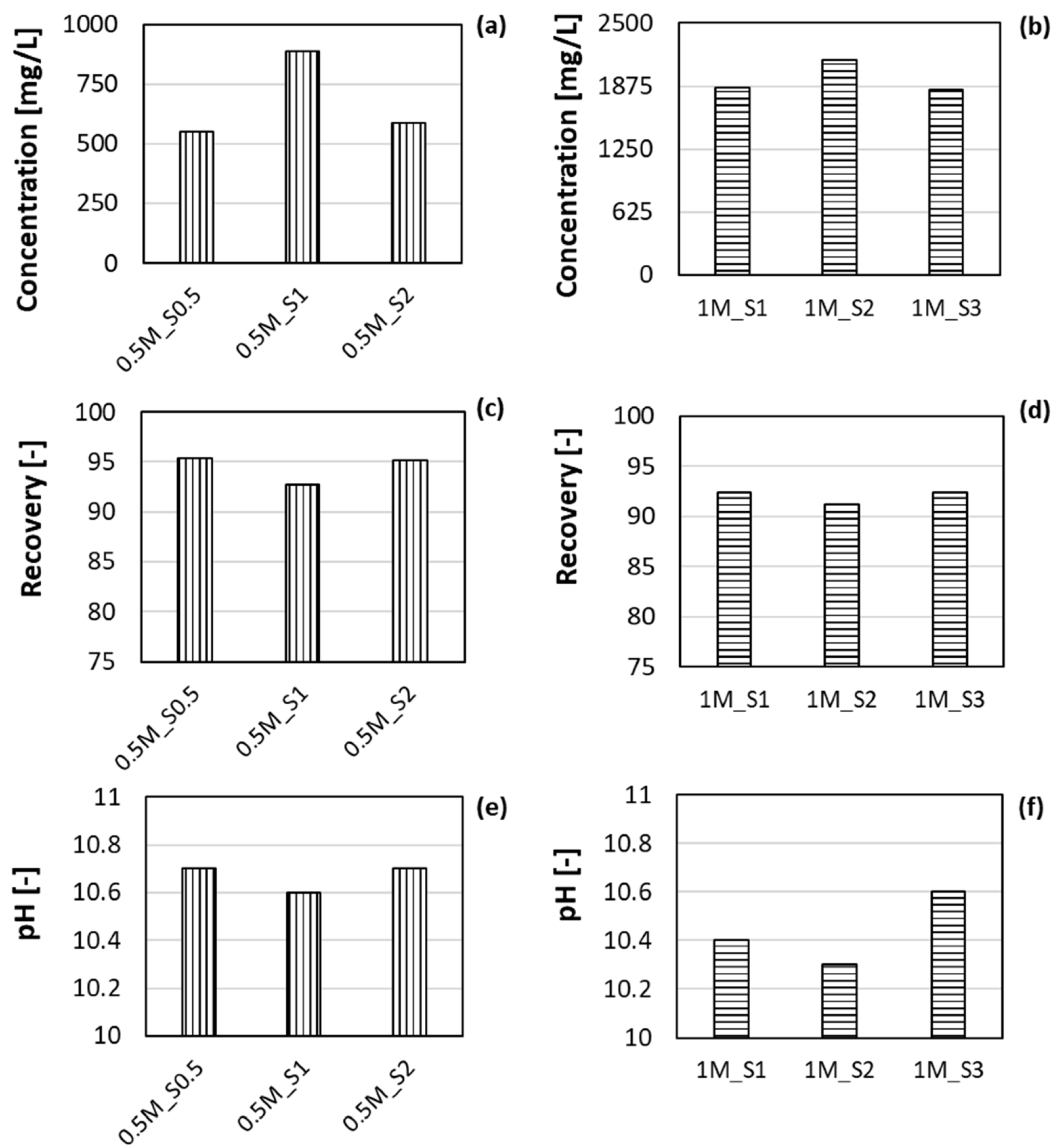

3.1.1. Influence of the NaOH/Mg2+-Solution Flow-Rate Ratio

3.1.2. Influence of the NaOH/Bittern Flow Rate Ratio

3.1.3. Influence of the OH−/Mg2+ Ratio

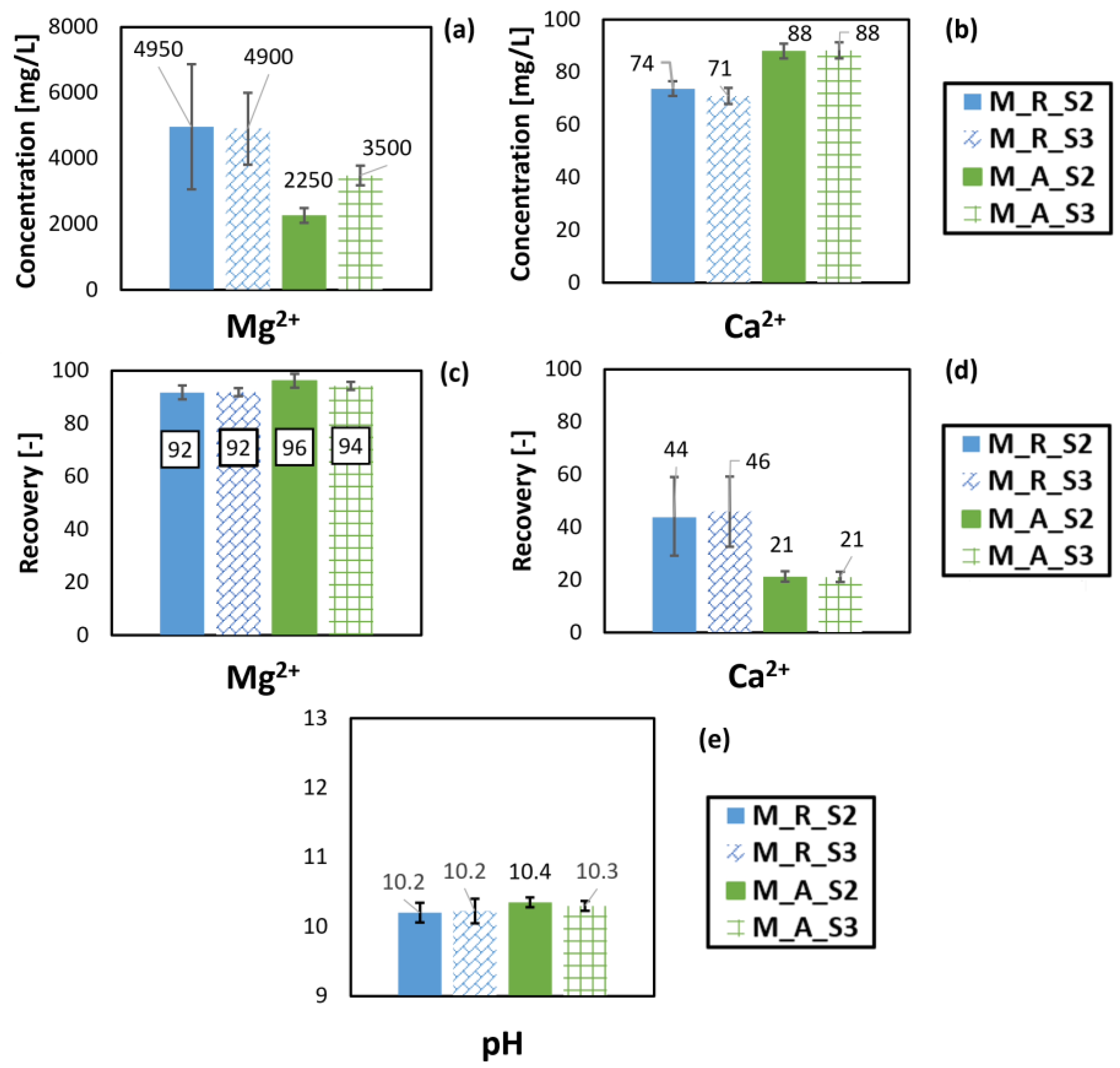

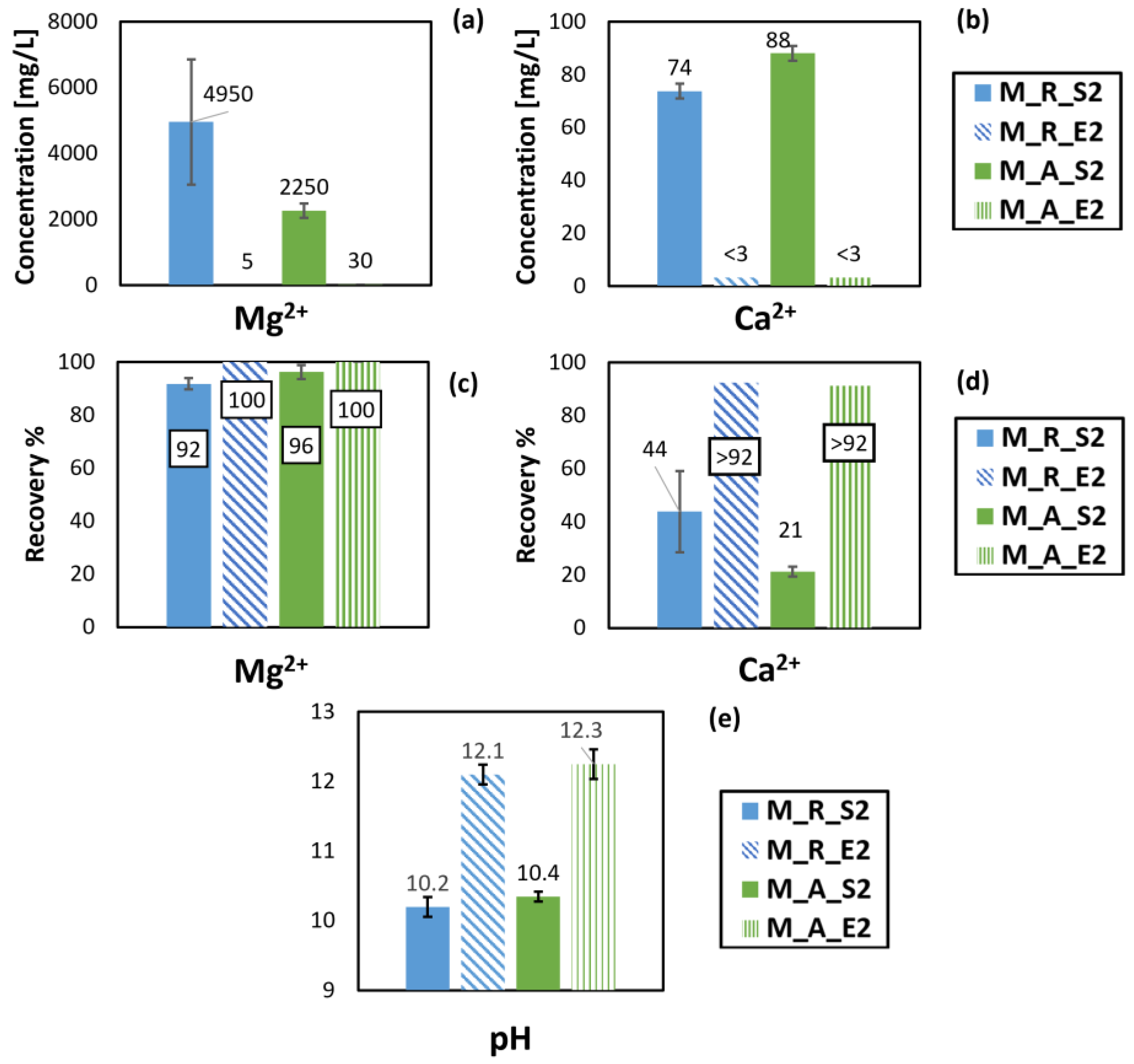

Margi Bittern

Galia Bittern

3.2. Mg(OH)2 Purity Assessment

3.2.1. Cationic Purity of MH

3.2.2. MH Mass Purity

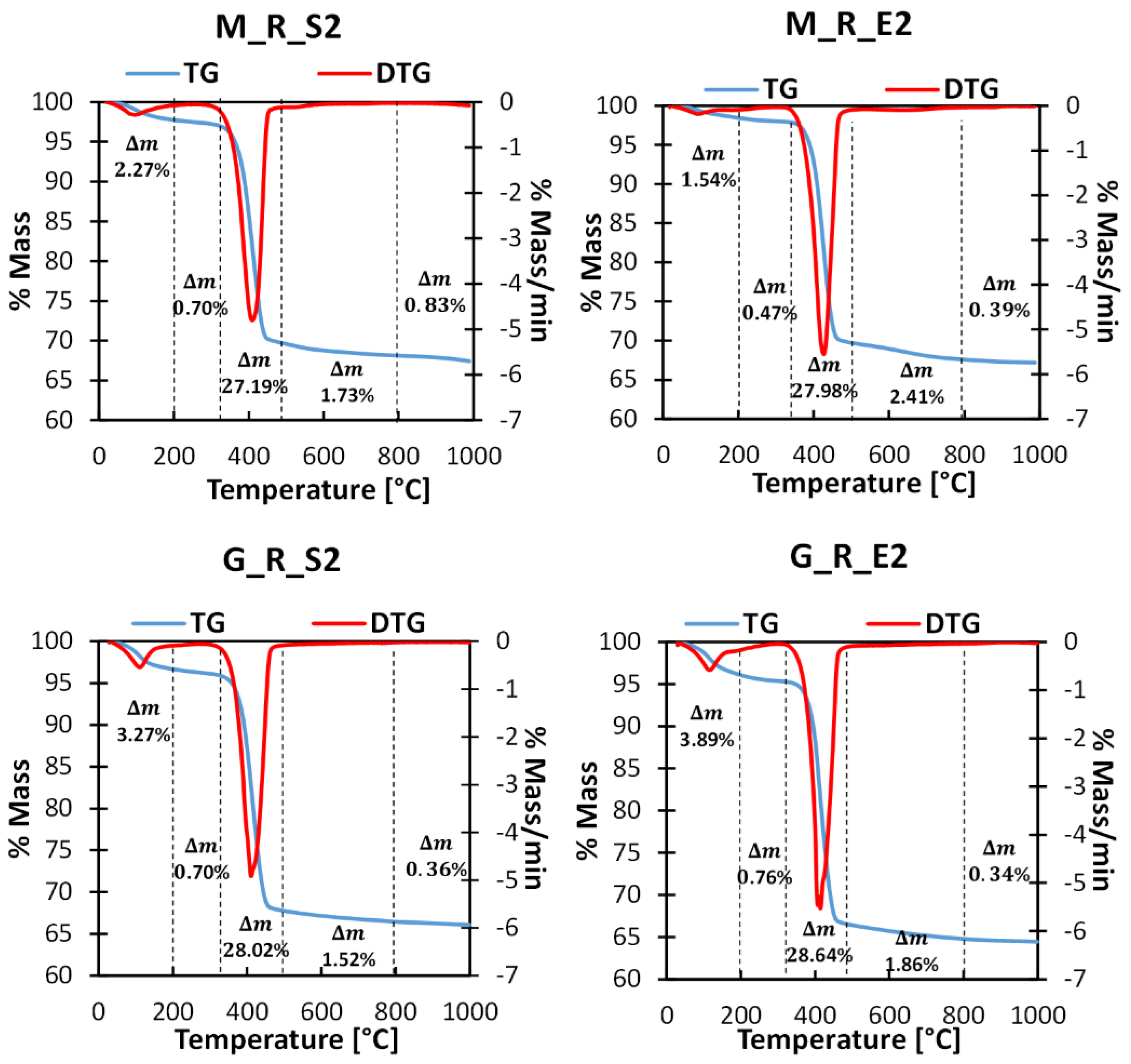

TG Analysis

- The first weight loss, observed between 30 °C and 320 °C, is attributed to the mass sample loss due to residual humidity, free water and adsorbed water in the sample. In this temperature range also, water of crystallization can be lost by hydrate compounds, e.g., hydrate sulphates or borates. The mass loss in the temperature range between 30 °C and 200 °C, however, can be attributed to the samples’ humidity [19,44]; therefore the mass losses in the 30 °C and 200 °C temperature range were subtracted from the total initial sample mass to determine the dry one.

- The second major weight loss occurred in the temperature range between 320 °C and 480 °C. It is related to thermal decomposition of Mg(OH)2(s) and transformation onto MgO(s) particles:

- 3.

- A further mass loss, between 480 °C and 1000 °C, was also noticed after Mg(OH)2 decomposition. Ardizzone et al. [46] and Wang et al. [47] attributed this mass loss to the slow and continuous desorption of residual OH− groups bonded to the MgO(s) lattice. Ardizzone et al. [46] and Wang et al. [47] based their consideration on Fourier transform infrared spectroscopy studies that showed a strong MgO(s) affinity towards the surface chemisorbed-OH groups. It should be noted that, if the mass loss would be correlated to further Mg(OH)2(s) decomposition, the final mass purities of the samples would increase. Therefore, the here-reported mass purity values are likely to be an underestimation of the actual Mg(OH)2(s) powder’s purity.

Mineralogical Characterization of MH Samples Using XRD

Morphological and Chemical Characterization of the MH Solids Using SEM-EDS

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bassioni, G.; Farid, R.; Mohamed, M.; Hammouda, R.M.; Kühn, F.E. Effect of Different Parameters on Caustic Magnesia Hydration and Magnesium Hydroxide Rheology: A Review. Mater. Adv. 2021, 2, 6519–6531. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, H.; Su, Y.L.; Shen, Q.; Wang, D. Influence of Magnesium Source on the Crystallization Behaviors of Magnesium Hydroxide. J. Cryst. Growth 2008, 310, 3771–3778. [Google Scholar] [CrossRef]

- Deng, Y.; Li, X.; Ni, F.; Liu, Q.; Yang, Y.; Wang, M.; Ao, T.; Chen, W. Synthesis of Magnesium Modified Biochar for Removing Copper, Lead and Cadmium in Single and Binary Systems from Aqueous Solutions: Adsorption Mechanism. Water 2021, 13, 599. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Klapiszewski, Ł.; Jesionowski, T. Recent Development in the Synthesis, Modification and Application of Mg(OH)2 and MgO: A Review. Powder Technol. 2017, 319, 373–407. [Google Scholar] [CrossRef]

- Balducci, G.; Bravo Diaz, L.; Gregory, D.H. Recent Progress in the Synthesis of Nanostructured Magnesium Hydroxide. CrystEngComm 2017, 19, 6067–6084. [Google Scholar] [CrossRef] [Green Version]

- Szymoniak, L.; Claveau-Mallet, D.; Haddad, M.; Barbeau, B. Application of Magnesium Oxide Media for Remineralization and Removal of Divalent Metals in Drinking Water Treatment: A Review. Water 2022, 14, 633. [Google Scholar] [CrossRef]

- Luong, V.T.; Amal, R.; Scott, J.A.; Ehrenberger, S.; Tran, T. A Comparison of Carbon Footprints of Magnesium Oxide and Magnesium Hydroxide Produced from Conventional Processes. J. Clean. Prod. 2018, 202, 1035–1044. [Google Scholar] [CrossRef]

- Bhatti, A.S.; Dollimore, D.; Dyer, A. Magnesia from Seawater: A Review. Clay Miner. 1984, 19, 865–875. [Google Scholar] [CrossRef]

- Jakić, J.; Labor, M.; Martinac, V. Characterization of Dolomitic Lime as the Base Reagent for Precipitation of Mg(OH)2 from Seawater. Chem. Biochem. Eng. Q. 2016, 30, 373–379. [Google Scholar] [CrossRef]

- Turek, M.; Gnot, W. Precipitation of Magnesium Hydroxide from Brine. Ind. Eng. Chem. Res. 1995, 34, 244–250. [Google Scholar] [CrossRef]

- Pramanik, B.K.; Shu, L.; Jegatheesan, V. A Review of the Management and Treatment of Brine Solutions. Environ. Sci. Water Res. Technol. 2017, 3, 625–658. [Google Scholar] [CrossRef]

- Gao, L.; Yoshikawa, S.; Iseri, Y.; Fujimori, S.; Kanae, S. An Economic Assessment of the Global Potential for Seawater Desalination to 2050. Water 2017, 9, 763. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.H.; Chen, P.H.; Chen, W.S. Recovery of Alkaline Earth Metals from Desalination Brine for Carbon Capture and Sodium Removal. Water 2021, 13, 3463. [Google Scholar] [CrossRef]

- An, J.W.; Kang, D.J.; Tran, K.T.; Kim, M.J.; Lim, T.; Tran, T. Recovery of Lithium from Uyuni Salar Brine. Hydrometallurgy 2012, 117–118, 64–70. [Google Scholar] [CrossRef]

- Bonin, L.; Deduytsche, D.; Wolthers, M.; Flexer, V.; Rabaey, K. Boron Extraction Using Selective Ion Exchange Resins Enables Effective Magnesium Recovery from Lithium Rich Brines with Minimal Lithium Loss. Sep. Purif. Technol. 2021, 275, 119177. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, W.; Zhang, Y.; Jegatheesan, V. A Review of Resource Recovery from Seawater Desalination Brine. Rev. Environ. Sci. Biotechnol. 2021, 20, 333–361. [Google Scholar] [CrossRef]

- Shaddel, S.; Grini, T.; Andreassen, J.P.; Østerhus, S.W.; Ucar, S. Crystallization Kinetics and Growth of Struvite Crystals by Seawater versus Magnesium Chloride as Magnesium Source: Towards Enhancing Sustainability and Economics of Struvite Crystallization. Chemosphere 2020, 256, 126968. [Google Scholar] [CrossRef] [PubMed]

- Chrispim, M.C.; de Souza, F.; Scholz, M.; Nolasco, M.A. A Framework for Sustainable Planning and Decision-Making on Resource Recovery from Wastewater: Showcase for São Paulo Megacity. Water 2020, 12, 3466. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, S.; Shin, S.; Kim, G. Production of High-Purity MgSO4 from Seawater Desalination Brine. Desalination 2021, 518, 115288. [Google Scholar] [CrossRef]

- Yousefi, S.; Ghasemi, B.; Tajally, M.; Asghari, A. Optical Properties of MgO and Mg(OH)2 Nanostructures Synthesized by a Chemical Precipitation Method Using Impure Brine. J. Alloys Compd. 2017, 711, 521–529. [Google Scholar] [CrossRef]

- Dong, H.; Unluer, C.; Yang, E.H.; Al-Tabbaa, A. Recovery of Reactive MgO from Reject Brine via the Addition of NaOH. Desalination 2018, 429, 88–95. [Google Scholar] [CrossRef]

- Sano, Y.; Hao, Y.; Kuwahara, F. Development of an Electrolysis Based System to Continuously Recover Magnesium from Seawater. Heliyon 2018, 4, 923. [Google Scholar] [CrossRef] [Green Version]

- Lalia, B.S.; Khalil, A.; Hashaikeh, R. Selective Electrochemical Separation and Recovery of Calcium and Magnesium from Brine. Sep. Purif. Technol. 2021, 264, 118416. [Google Scholar] [CrossRef]

- Yu, X.; Cui, J.; Liu, C.; Yuan, F.; Guo, Y.; Deng, T. Separation of Magnesium from High Mg/Li Ratio Brine by Extraction with an Organic System Containing Ionic Liquid. Chem. Eng. Sci. 2021, 229, 116019. [Google Scholar] [CrossRef]

- Casas, S.; Aladjem, C.; Larrotcha, E.; Gibert, O.; Valderrama, C.; Cortina, J.L. Valorisation of Ca and Mg By-Products from Mining and Seawater Desalination Brines for Water Treatment Applications. J. Chem. Technol. Biotechnol. 2014, 89, 872–883. [Google Scholar] [CrossRef]

- Gong, M.H.; Johns, M.; Fridjonsson, E.; Heckley, P. Magnesium Recovery from Desalination Brine. In Proceedings of the CEED Seminar Proceedings, Bali, Indonesia, 17–18 November 2018; pp. 49–54. [Google Scholar]

- Vassallo, F.; La Corte, D.; Cancilla, N.; Tamburini, A.; Bevacqua, M.; Cipollina, A.; Micale, G. A Pilot-Plant for the Selective Recovery of Magnesium and Calcium from Waste Brines. Desalination 2021, 517, 115231. [Google Scholar] [CrossRef]

- Morgante, C.; Vassallo, F.; Battaglia, G.; Cipollina, A.; Vicari, F.; Tamburini, A.; Micale, G. Influence of Operational Strategies for the Recovery of Magnesium Hydroxide from Brines at a Pilot Scale. Ind. Eng. Chem. Res. 2022, 61, 15355–15368. [Google Scholar] [CrossRef]

- La Corte, D.; Vassallo, F.; Cipollina, A.; Turek, M.; Tamburini, A.; Micale, G. A Novel Ionic Exchange Membrane Crystallizer to Recover Magnesium Hydroxide from Seawater and Industrial Brines. Membranes. 2020, 10, 303. [Google Scholar] [CrossRef]

- Vassallo, F.; Morgante, C.; Battaglia, G.; La Corte, D.; Micari, M.; Cipollina, A.; Tamburini, A.; Micale, G. A Simulation Tool for Ion Exchange Membrane Crystallization of Magnesium Hydroxide from Waste Brine. Chem. Eng. Res. Des. 2021, 173, 193–205. [Google Scholar] [CrossRef]

- Yousefi, S.; Ghasemi, B.; Tajally, M. PEG-Assisted Synthesis and Formation Mechanism of Mg(OH)2 Nanostructures Using Natural Brine. Appl. Phys. A Mater. Sci. Process. 2020, 126, 641. [Google Scholar] [CrossRef]

- Shand, M.A. The Chemistry and Technology of Magnesia; Wiley-Interscience: Hoboken, NJ, USA, 2006; ISBN 0471656038. [Google Scholar]

- Fontana, D.; Forte, F.; Pietrantonio, M.; Pucciarmati, S.; Marcoaldi, C. Magnesium Recovery from Seawater Desalination Brines: A Technical Review. Environ. Dev. Sustain. 2022. [Google Scholar] [CrossRef]

- Lee, S.I.; Weon, S.Y.; Lee, C.W.; Koopman, B. Removal of Nitrogen and Phosphate from Wastewater by Addition of Bittern. Chemosphere 2003, 51, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Alamdari, A.; Rahimpour, R.M.; Esfandiari, N.; Nourafkan, E. Kinetics of Magnesium Hydroxide Precipitation from Sea Bittern. Chem. Eng. Process. Process Intensif. 2008, 47, 215–221. [Google Scholar] [CrossRef]

- Cipollina, A.; Bevacqua, M.; Dolcimascolo, P.; Tamburini, A.; Brucato, A.; Glade, H.; Buether, L.; Micale, G. Reactive Crystallisation Process for Magnesium Recovery from Concentrated Brines. Desalin. Water Treat. 2015, 55, 2377–2388. [Google Scholar] [CrossRef] [Green Version]

- Loganathan, P.; Naidu, G.; Vigneswaran, S. Mining Valuable Minerals from Seawater: A Critical Review. Environ. Sci. Water Res. Technol. 2017, 3, 37–53. [Google Scholar] [CrossRef] [Green Version]

- Circular Processing of Seawater Brines from Saltworks for Recovery of Valuable Raw Materials. Available online: https://cordis.europa.eu/project/id/869467 (accessed on 1 January 2021).

- Culcasi, A.; Gurreri, L.; Cipollina, A.; Tamburini, A.; Micale, G. A Comprehensive Multi-Scale Model for Bipolar Membrane Electrodialysis (BMED). Chem. Eng. J. 2022, 437, 135317. [Google Scholar] [CrossRef]

- Romano, S.; Battaglia, G.; Bonafede, S.; Marchisio, D.; Ciofalo, M.; Tamburini, A.; Cipollina, A.; Micale, G. Experimental Assessment of the Mixing Quality in a Circular Cross-Sectional t-Shaped Mixer for the Precipitation of Sparingly Soluble Compounds. Chem. Eng. Trans. 2021, 86, 1165–1170. [Google Scholar] [CrossRef]

- Schikarski, T.; Trzenschiok, H.; Peukert, W.; Avila, M. Inflow Boundary Conditions Determine T-Mixer Efficiency. React. Chem. Eng. 2019, 4, 559–568. [Google Scholar] [CrossRef] [Green Version]

- Battaglia, G.; Romano, S.; Raponi, A.; Marchisio, D.; Ciofalo, M.; Tamburini, A.; Cipollina, A.; Micale, G. Analysis of Particles Size Distributions in Mg(OH)2 Precipitation from Highly Concentrated MgCl2 Solutions. Powder Technol. 2022, 398, 117106. [Google Scholar] [CrossRef]

- Vicari, F.; Randazzo, S.; López, J.; Fernández de Labastida, M.; Vallès, V.; Micale, G.; Tamburini, A.; D’Alì Staiti, G.; Cortina, J.L.; Cipollina, A. Mining Minerals and Critical Raw Materials from Bittern: Understanding Metal Ions Fate in Saltwork Ponds. Sci. Total Environ. 2022, 847, 157544. [Google Scholar] [CrossRef]

- Hanna, A.A.; Abdelmoaty, A.S.; Sherief, M.A. Synthesis, Characterization, and Thermal Behavior of Nanoparticles of Mg(OH)2 to Be Used as Flame Retardants. J. Chem. 2019, 2019, 1805280. [Google Scholar] [CrossRef] [Green Version]

- Meshkani, F.; Rezaei, M. Effect of Process Parameters on the Synthesis of Nanocrystalline Magnesium Oxide with High Surface Area and Plate-like Shape by Surfactant Assisted Precipitation Method. Powder Technol. 2010, 199, 144–148. [Google Scholar] [CrossRef]

- Ardizzone, S.; Bianchi, C.L.; Fadoni, M.; Vercelli, B. Magnesium Salts and Oxide: An XPS Overview. Appl. Surf. Sci. 1997, 119, 253–259. [Google Scholar] [CrossRef]

- Wang, J.A.; Novaro, O.; Bokhimi, X.; López, T.; Gómez, R.; Navarrete, J.; Llanos, M.E.; López-Salinas, E. Characterizations of the Thermal Decomposition of Brucite Prepared by Sol-Gel Technique for Synthesis of Nanocrystalline MgO. Mater. Lett. 1998, 35, 317–323. [Google Scholar] [CrossRef]

- Verri, G. Process for the Purification of Magnesium Hydroxide. U.S. Patent 5,626,825, 6 May 1997. [Google Scholar]

- Wu, X.F.; Hu, G.S.; Wang, B.B.; Yang, Y.F. Synthesis and Characterization of Superfine Magnesium Hydroxide with Monodispersity. J. Cryst. Growth 2008, 310, 457–461. [Google Scholar] [CrossRef]

- Sierra-Fernandez, A.; Gomez-Villalba, L.S.; Milosevic, O.; Fort, R.; Rabanal, M.E. Synthesis and Morpho-Structural Characterization of Nanostructured Magnesium Hydroxide Obtained by a Hydrothermal Method. Ceram. Int. 2014, 40, 12285–12292. [Google Scholar] [CrossRef] [Green Version]

- Henrist, C.; Mathieu, J.P.; Vogels, C.; Rulmont, A.; Cloots, R. Morphological Study of Magnesium Hydroxide Nanoparticles Precipitated in Dilute Aqueous Solution. J. Cryst. Growth 2003, 249, 321–330. [Google Scholar] [CrossRef]

| Real Galia | Artificial Galia | Real Margi | Artificial Margi | |

|---|---|---|---|---|

| Macro Components | g/L | g/L | g/L | g/L |

| Na | 83.7 ± 0.5 | 82.2 ± 0.7 | 44.6 ± 1.6 | 38.0 ± 0.4 |

| K | 7.4 ± 0.3 | 7.7 ± 0.1 | 11.9 ± 2.6 | 14.8 ± 0.1 |

| Mg | 23.0 ± 4.4 | 24.0 ± 1.5 | 60.5 ± 0.5 | 65.4 ± 0.6 |

| Cl | 193 ± 6 | 179.5 ± 0.6 | 200 ± 14 | 176 ± 1 |

| SO4 | 35 ± 1 | 36.0 ± 0.6 | 83.0 ± 5.5 | 85.7 ± 0.2 |

| Br | 1.3 ± 0.2 | - | 2.5 ± 0.2 | - |

| Micro Components | mg/L | mg/L | mg/L | mg/L |

| Ca | 232 ± 40 | 270 ± 20 | 139 ± 32 | 112 ± 2 |

| B | 110 ± 22 | 18.7 ± 0.2 | 187 ± 8 | 46.6 ± 0.5 |

| Tests | Bittern Solution | OH−/Mg2+ | Bittern Flow Rate (mL/min) | NaOH/Bittern Flow Rate Ratio | Mg2+ (M) | NaOH (M) |

|---|---|---|---|---|---|---|

| 1M_S1 | Artificial MgCl2 | Stoichiometric | 1160 ± 30 | 1.0 | 1.00 ± 0.02 | 2.00 ± 0.04 |

| 1M_S2 | 780 ± 20 | 2.0 | 1.00 ± 0.02 | |||

| 1M_S3 | 547 ± 10 | 3.0 | 0.67 ± 0.01 | |||

| 0.5M_S0.5 | Artificial MgCl2 | Stoichiometric | 1560 ± 40 | 0.5 | 0.50 ± 0.01 | 2.00 ± 0.04 |

| 0.5M_S1 | 1160 ± 30 | 1.0 | 1.00 ± 0.02 | |||

| 0.5M_S2 | 780 ± 20 | 2.0 | 0.50 ± 0.01 | |||

| M_R_S2 | Real Margi | Stoichiometric | 780 ± 20 | 2.0 | 2.48 ± 0.05 | 2.50 ± 0.05 |

| M_R_S3 | 547 ± 10 | 3.0 | 1.70 ± 0.03 | |||

| M_R_E2 | 20% excess OH− | 780 ± 20 | 2.0 | 3.00 ± 0.06 | ||

| M_A_S2 | Artificial Margi | Stoichiometric | 780 ± 20 | 2.0 | 2.69 ± 0.05 | 2.70 ± 0.05 |

| M_A_S3 | 547 ± 10 | 3.0 | 1.80 ± 0.03 | |||

| M_A_E2 | 20% excess OH− | 780 ± 20 | 2.0 | 3.00 ± 0.06 | ||

| G_R_S2 | Real Galia | Stoichiometric | 780 ± 20 | 2.0 | 0.96 ± 0.18 | 1.00 ± 0.02 |

| G_R_E2 | 20% excess OH− | 780 ± 20 | 2.0 | 1.20 ± 0.03 | ||

| G_A_S2 | Artificial Galia | Stoichiometric | 780 ± 20 | 2.0 | 0.97 ± 0.06 | 1.00 ± 0.02 |

| G_A_E2 | 20% excess OH− | 780 ± 20 | 2.0 | 1.20 ± 0.03 |

| Tests | Ca (mg/g) | Mg (mg/g) | Na (mg/g) | Cationic Purity (%) |

|---|---|---|---|---|

| M_R_S2 | <2.0 * | 376.0 ± 0.6 | 1.82 ± 0.46 | >99.0 |

| M_R_E2 | <2.0 * | 375.0 ± 1.4 | 3.51 ± 0.03 | >99.0 |

| M_A_S2 | <2.0 * | 387.0 ± 0.8 | <0.5 * | >99.0 |

| M_A_E2 | <2.0 * | 385.0 ± 0.9 | <0.5 * | >99.0 |

| G_R_S2 | <2.0 * | 371.0 ± 3.4 | 2.49 ± 1.14 | >99.0 |

| G_R_E2 | <2.0 * | 376.0 ± 0.1 | <0.5 * | >99.0 |

| G_A_S2 | <2.0 * | 378.0 ± 0.3 | 3.20 ± 0.19 | >99.0 |

| G_A_E2 | <2.0 * | 382.0 ± 0.9 | <0.5 * | >99.0 |

| Tests | B (mg/g) |

|---|---|

| M_R_S2 | 1.71 ± 0.18 |

| M_R_E2 | 0.91 ± 0.33 |

| M_A_S2 | 0.81 ± 0.21 |

| M_A_E2 | 0.38 ± 0.08 |

| G_R_S2 | 1.40 ± 0.05 |

| G_R_E2 | <0.3 * |

| G_A_S2 | 0.45 ± 0.03 |

| G_A_E2 | <0.3 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battaglia, G.; Domina, M.A.; Lo Brutto, R.; Lopez Rodriguez, J.; Fernandez de Labastida, M.; Cortina, J.L.; Pettignano, A.; Cipollina, A.; Tamburini, A.; Micale, G. Evaluation of the Purity of Magnesium Hydroxide Recovered from Saltwork Bitterns. Water 2023, 15, 29. https://doi.org/10.3390/w15010029

Battaglia G, Domina MA, Lo Brutto R, Lopez Rodriguez J, Fernandez de Labastida M, Cortina JL, Pettignano A, Cipollina A, Tamburini A, Micale G. Evaluation of the Purity of Magnesium Hydroxide Recovered from Saltwork Bitterns. Water. 2023; 15(1):29. https://doi.org/10.3390/w15010029

Chicago/Turabian StyleBattaglia, Giuseppe, Maria Alda Domina, Rita Lo Brutto, Julio Lopez Rodriguez, Marc Fernandez de Labastida, Jose Luis Cortina, Alberto Pettignano, Andrea Cipollina, Alessandro Tamburini, and Giorgio Micale. 2023. "Evaluation of the Purity of Magnesium Hydroxide Recovered from Saltwork Bitterns" Water 15, no. 1: 29. https://doi.org/10.3390/w15010029

APA StyleBattaglia, G., Domina, M. A., Lo Brutto, R., Lopez Rodriguez, J., Fernandez de Labastida, M., Cortina, J. L., Pettignano, A., Cipollina, A., Tamburini, A., & Micale, G. (2023). Evaluation of the Purity of Magnesium Hydroxide Recovered from Saltwork Bitterns. Water, 15(1), 29. https://doi.org/10.3390/w15010029