Study on the Analysis of Pile Foundation Deformation and Control Methods during the Excavation of Deep and Thick Sludge Pits

Abstract

:1. Introduction

2. Project Overview

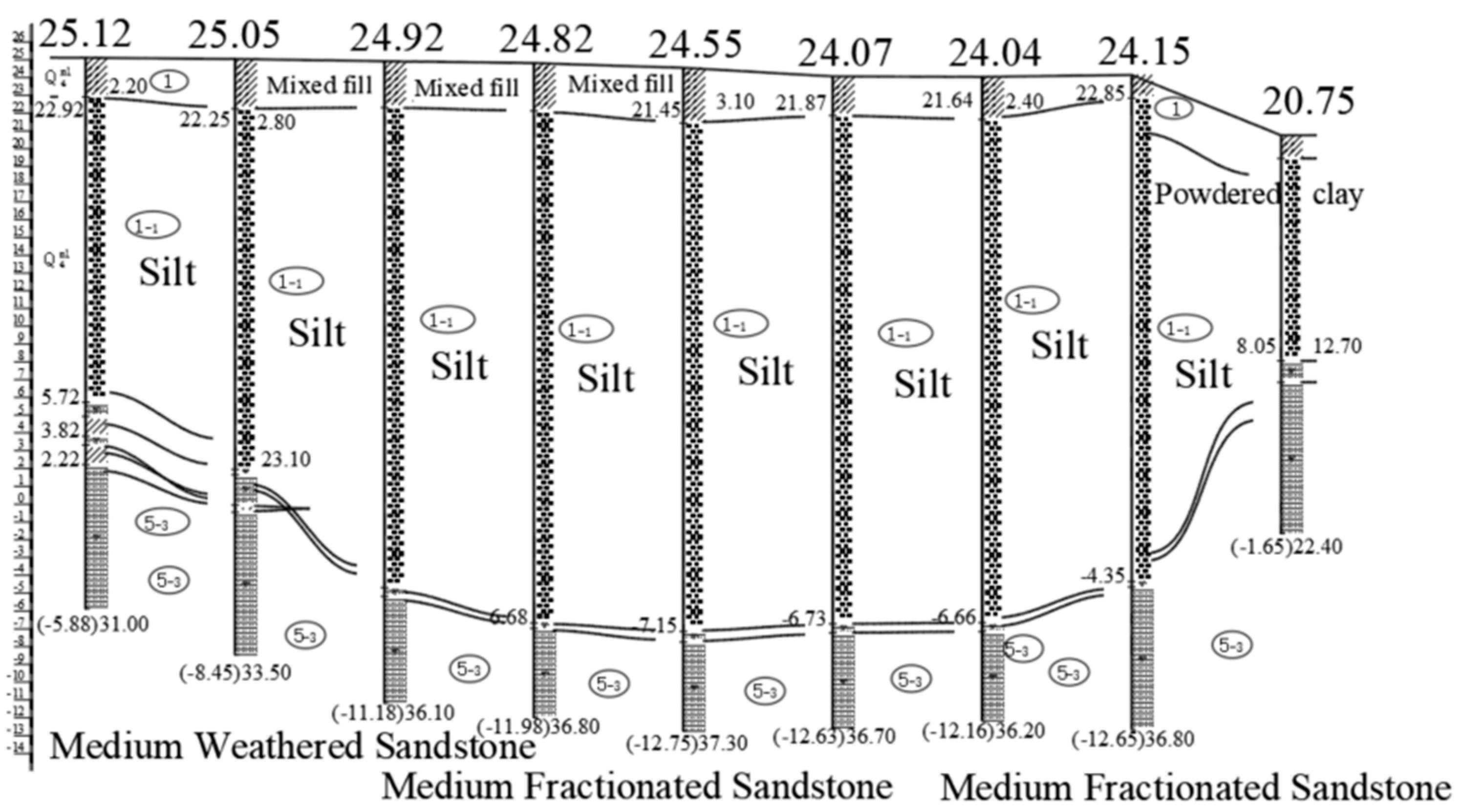

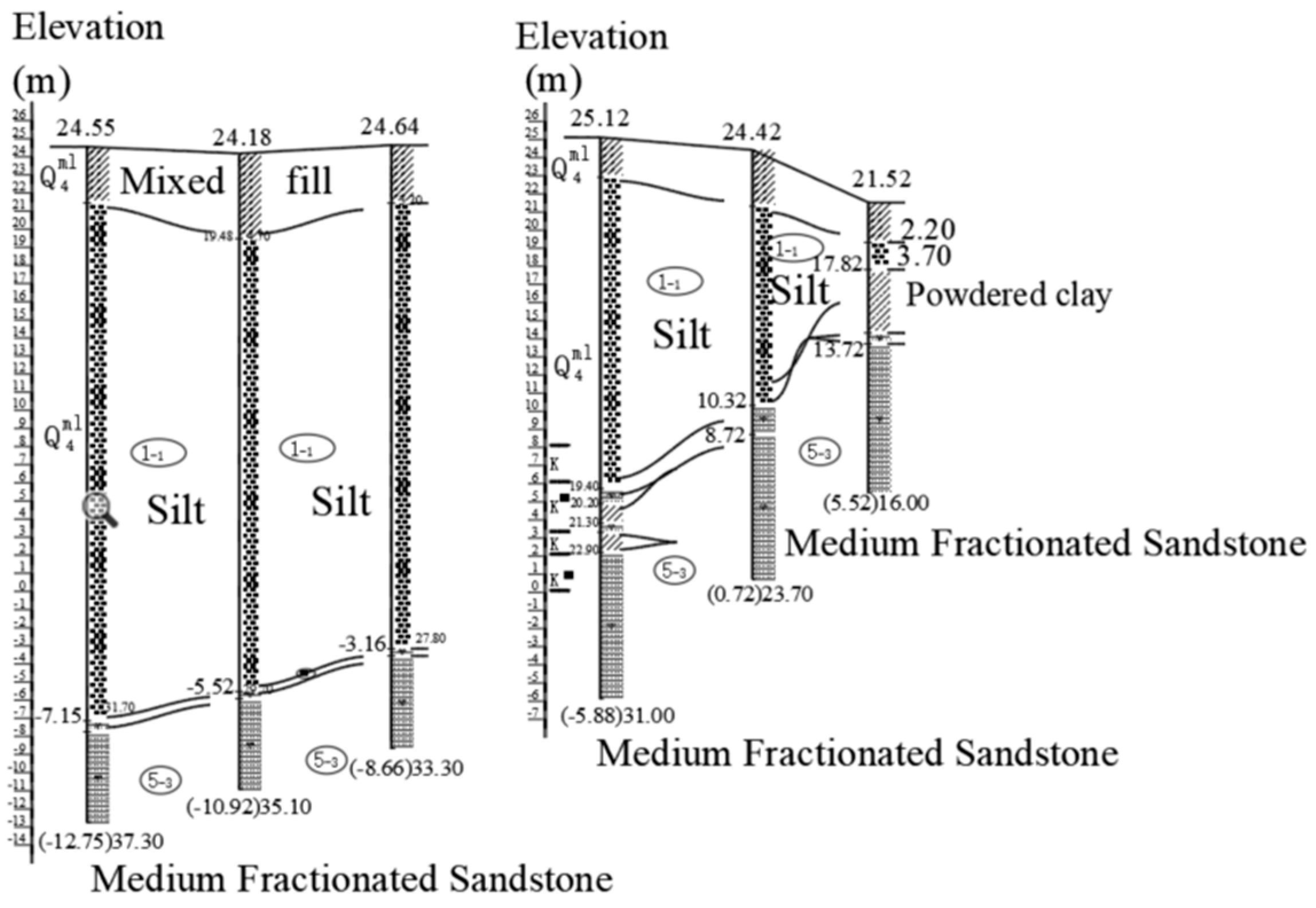

2.1. Introduction to Surrounding Environment and Site Geology

2.1.1. Project Introduction

2.1.2. Composition and Engineering Characteristics of Subsoil and Rock

3. Excavation Support Plan and Construction Plan

Excavation Support Plan

4. Engineering Monitoring Scheme and Monitoring Results Analysis

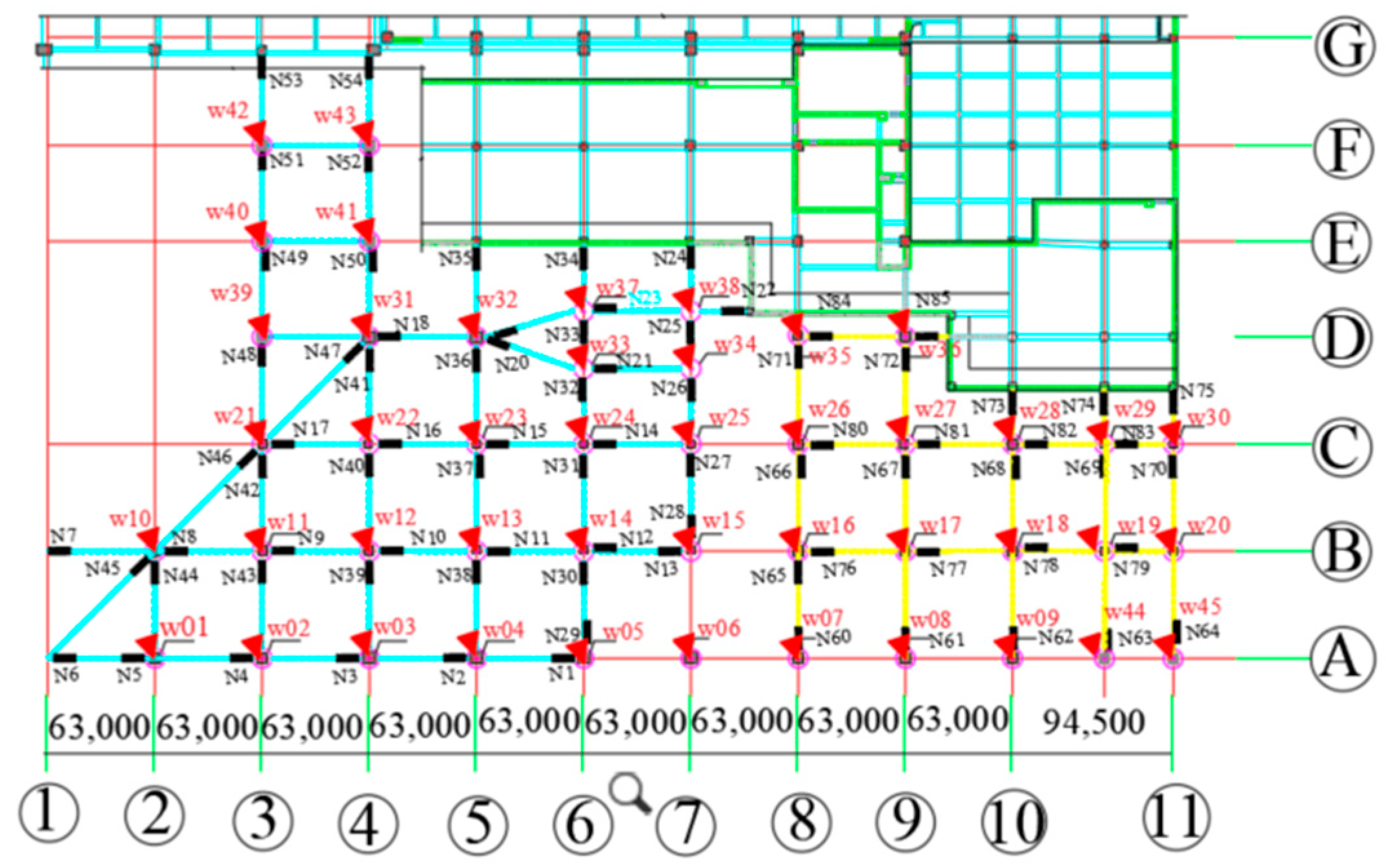

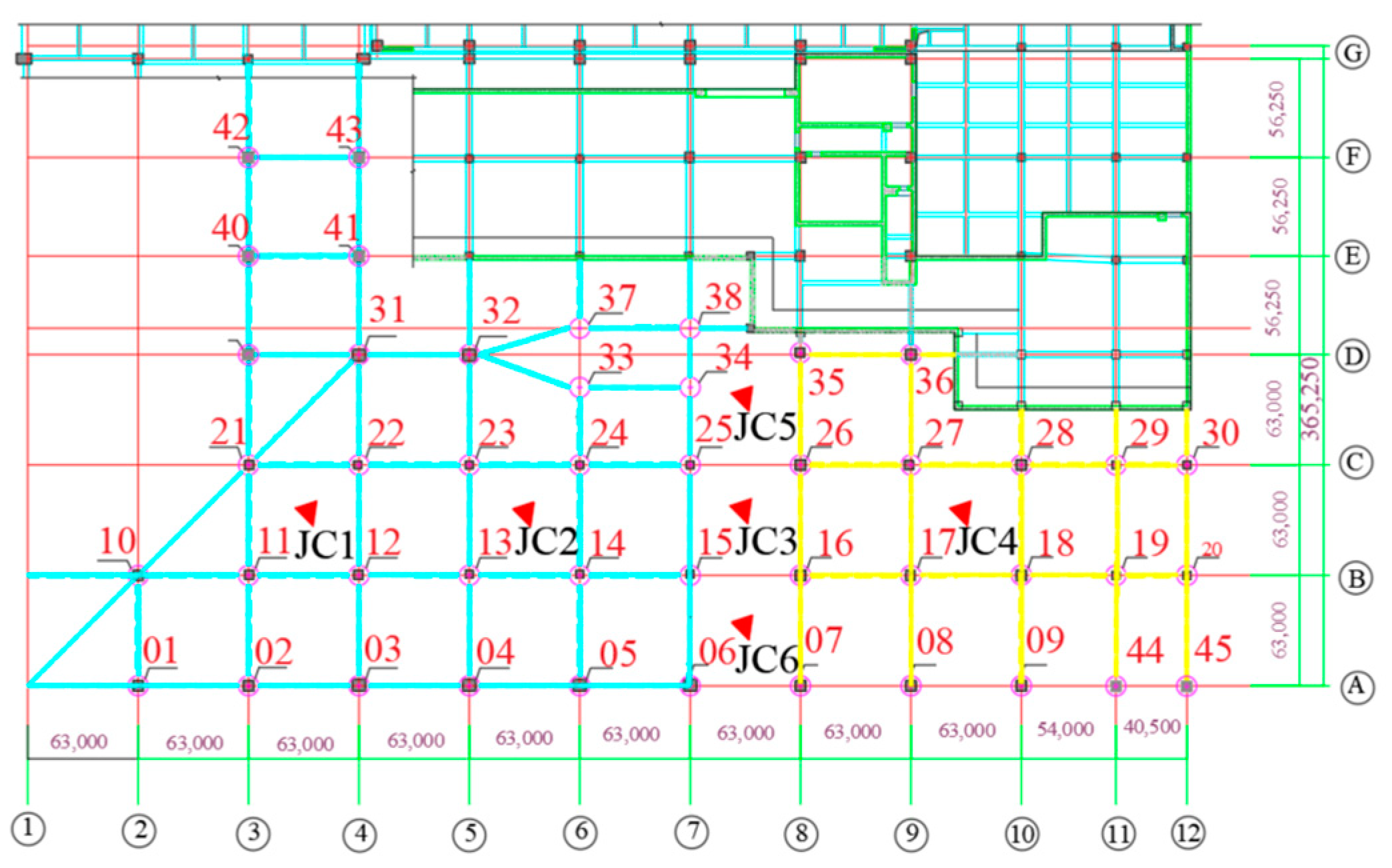

4.1. Monitoring Point Layout and Monitoring Content

4.2. Performance-Based Security Assessment Protocol

4.2.1. Background and Purpose

4.2.2. Performance Objectives and Indicators

4.2.3. Monitoring Methods and Techniques

4.2.4. Data Acquisition and Analysis

4.2.5. Performance-Based Security Assessment

4.2.6. Continuous Monitoring and Improvement

4.2.7. Conclusions

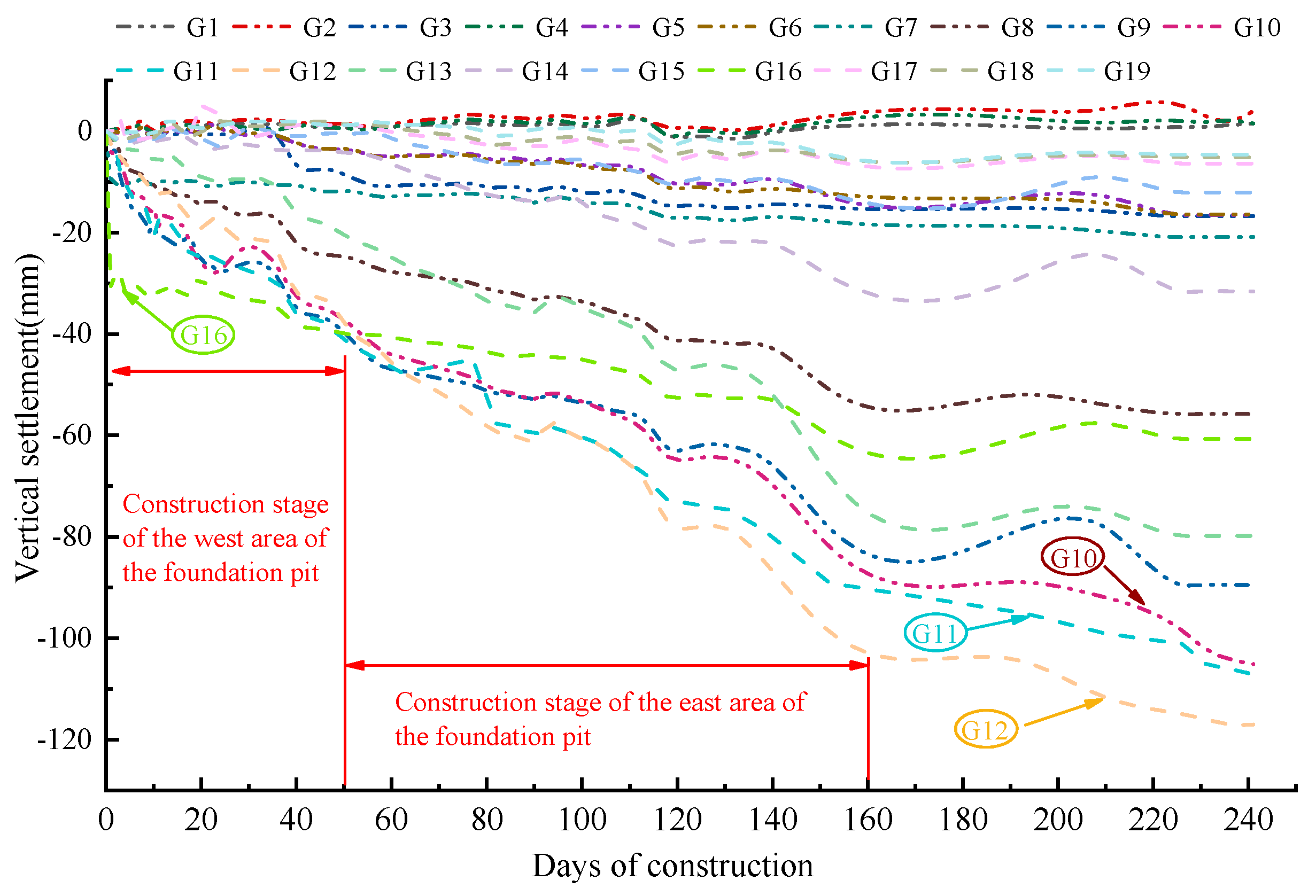

4.3. Analysis of Monitoring Results

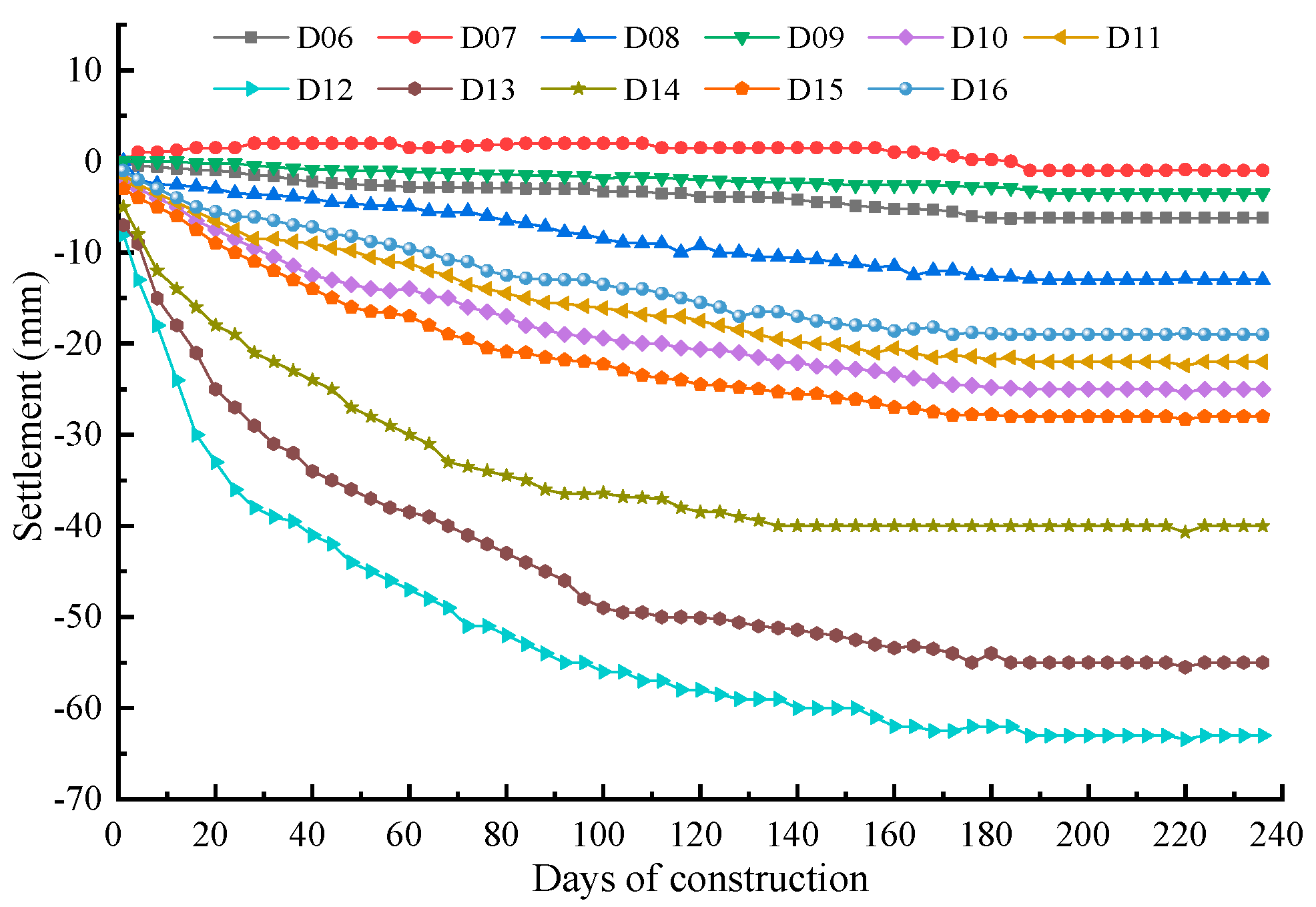

4.3.1. Settlement Analysis of Park on the South Side of Foundation Pit

4.3.2. Analysis of Monitoring Results of Gravity Retaining Wall

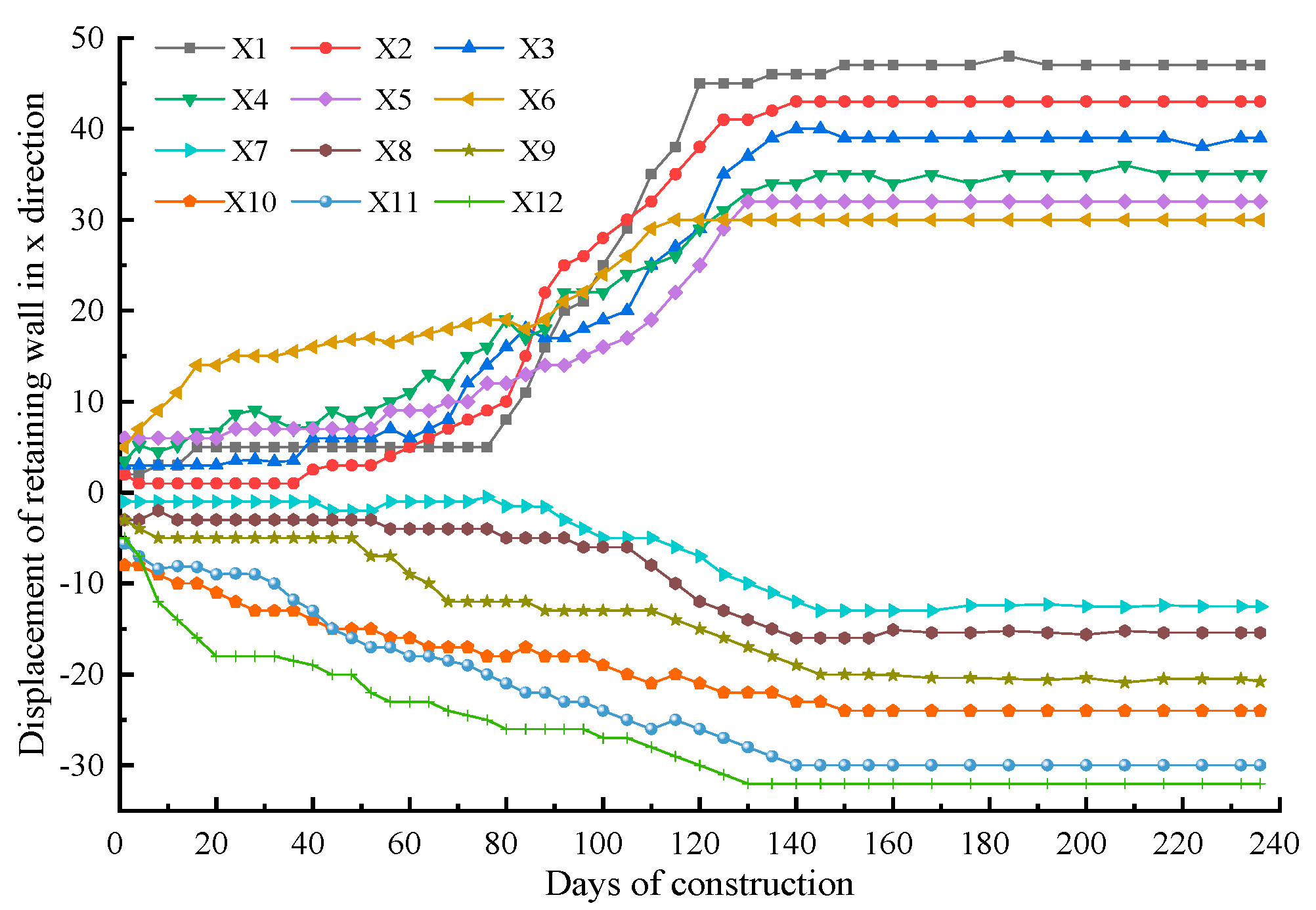

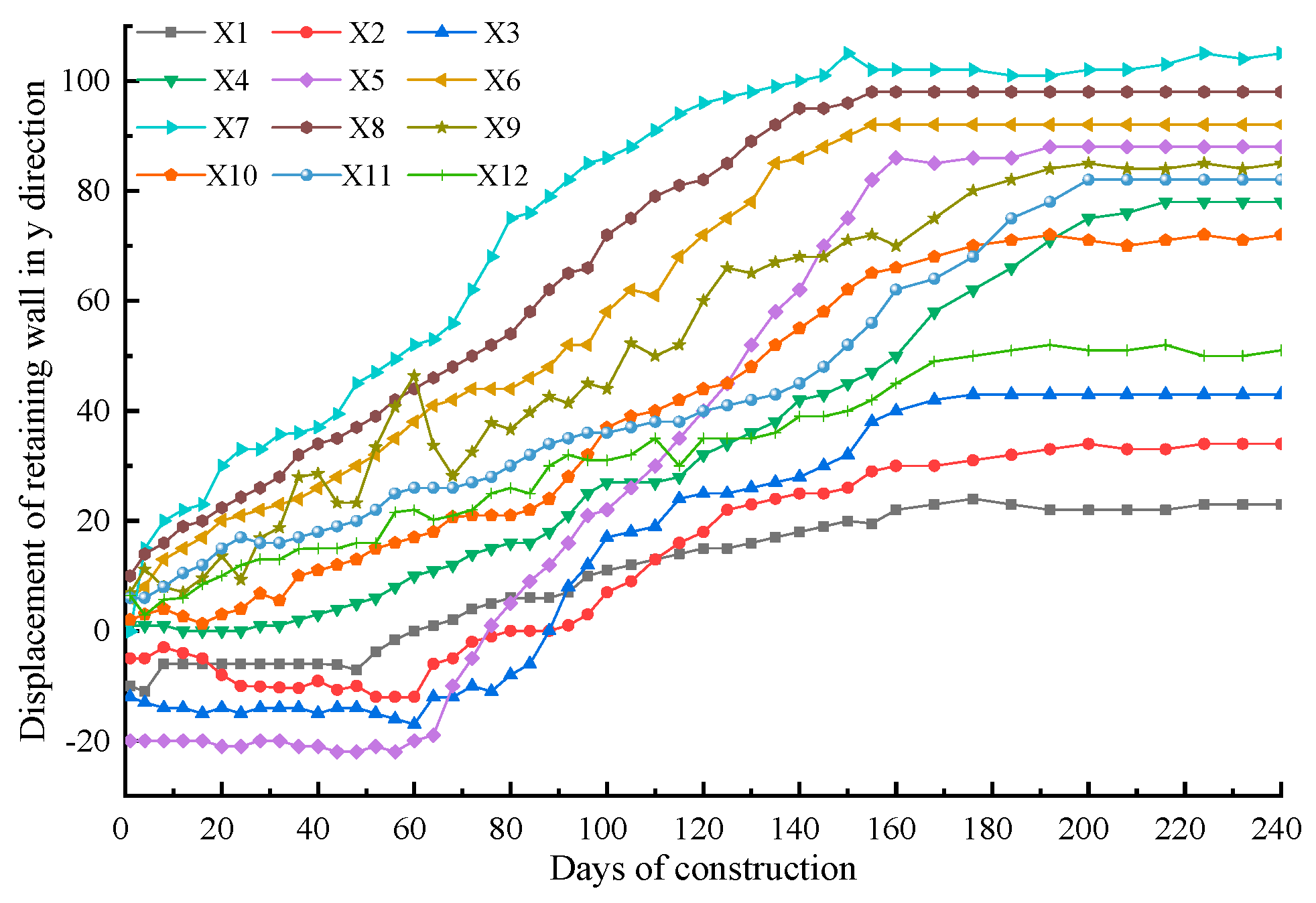

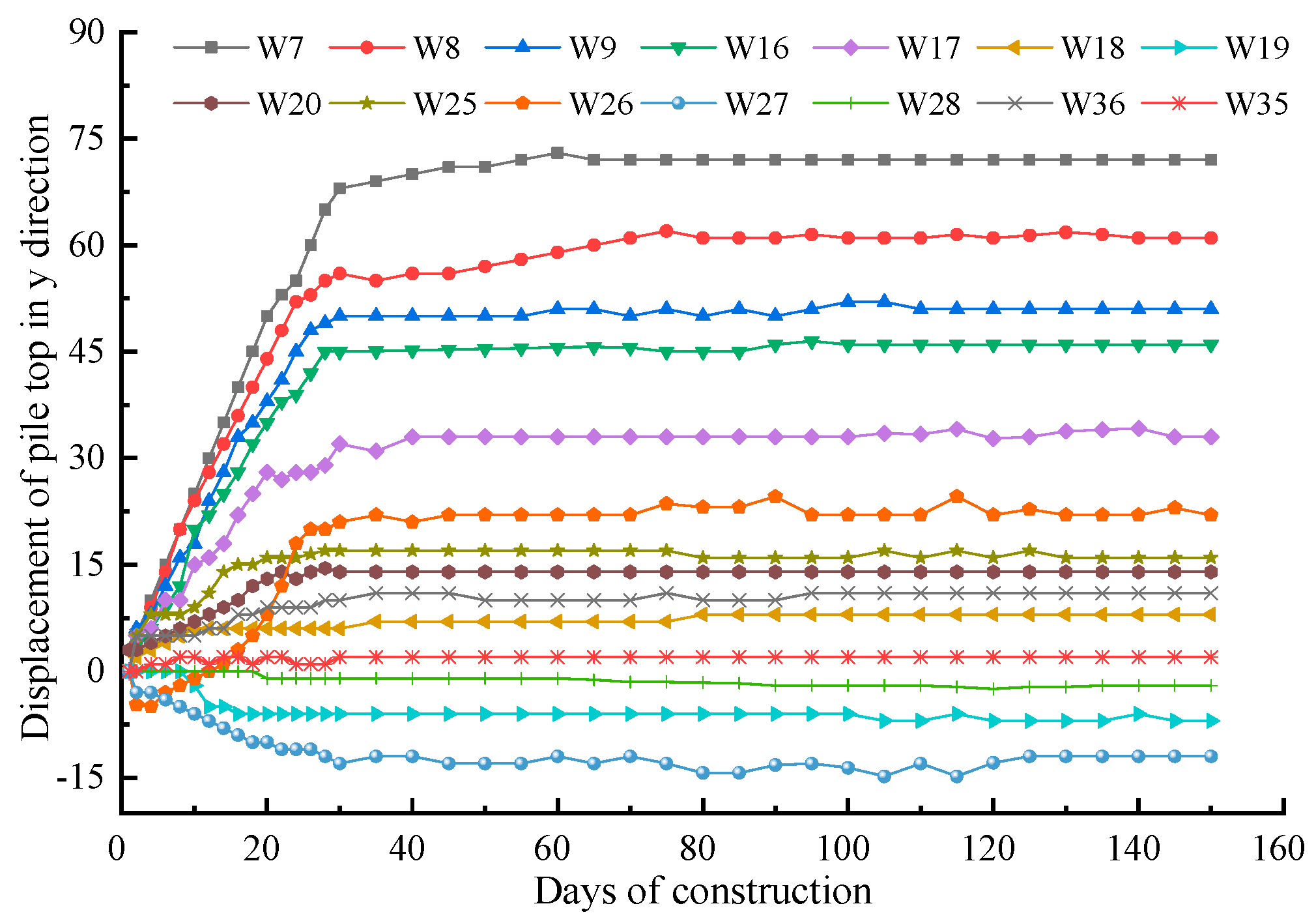

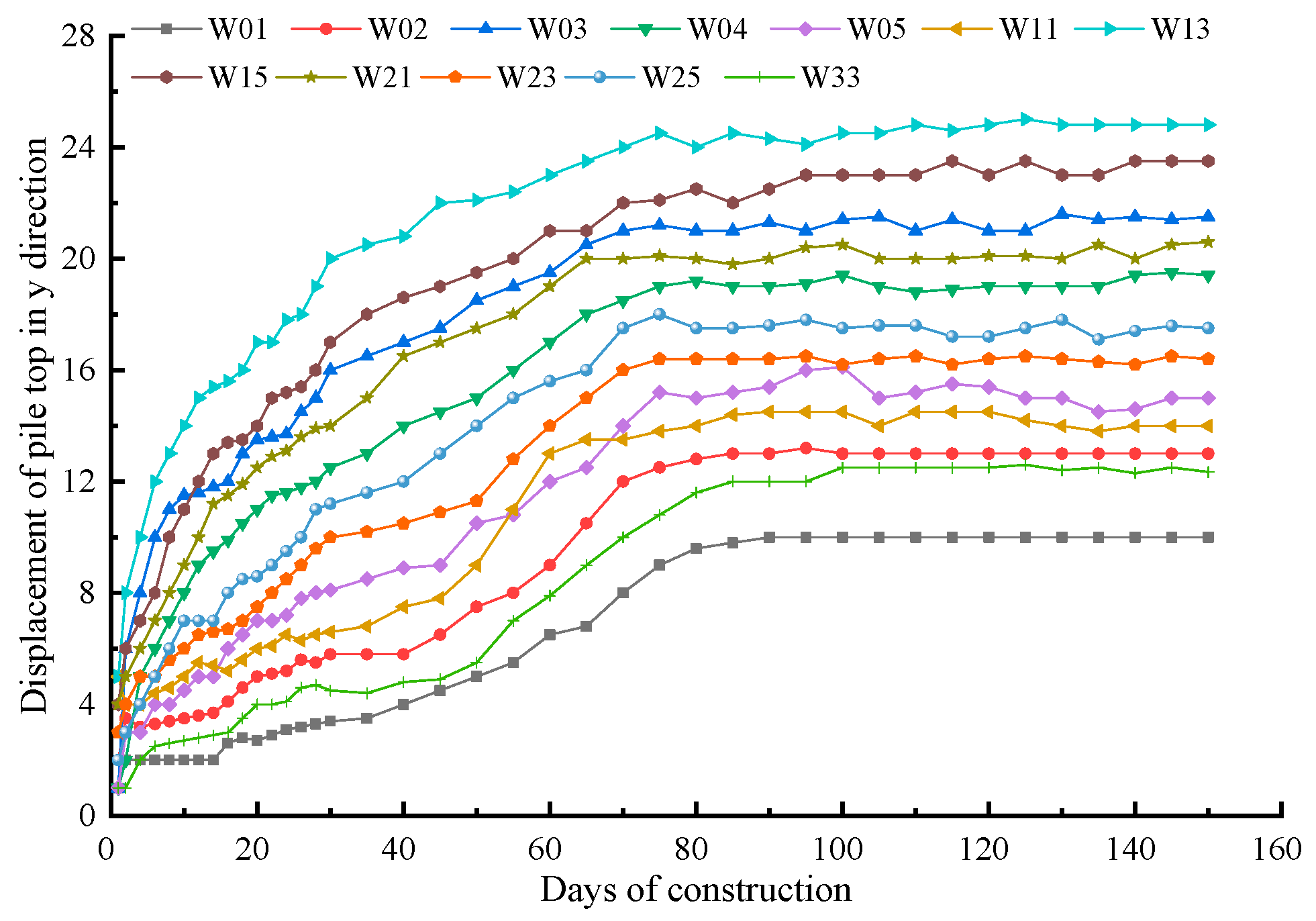

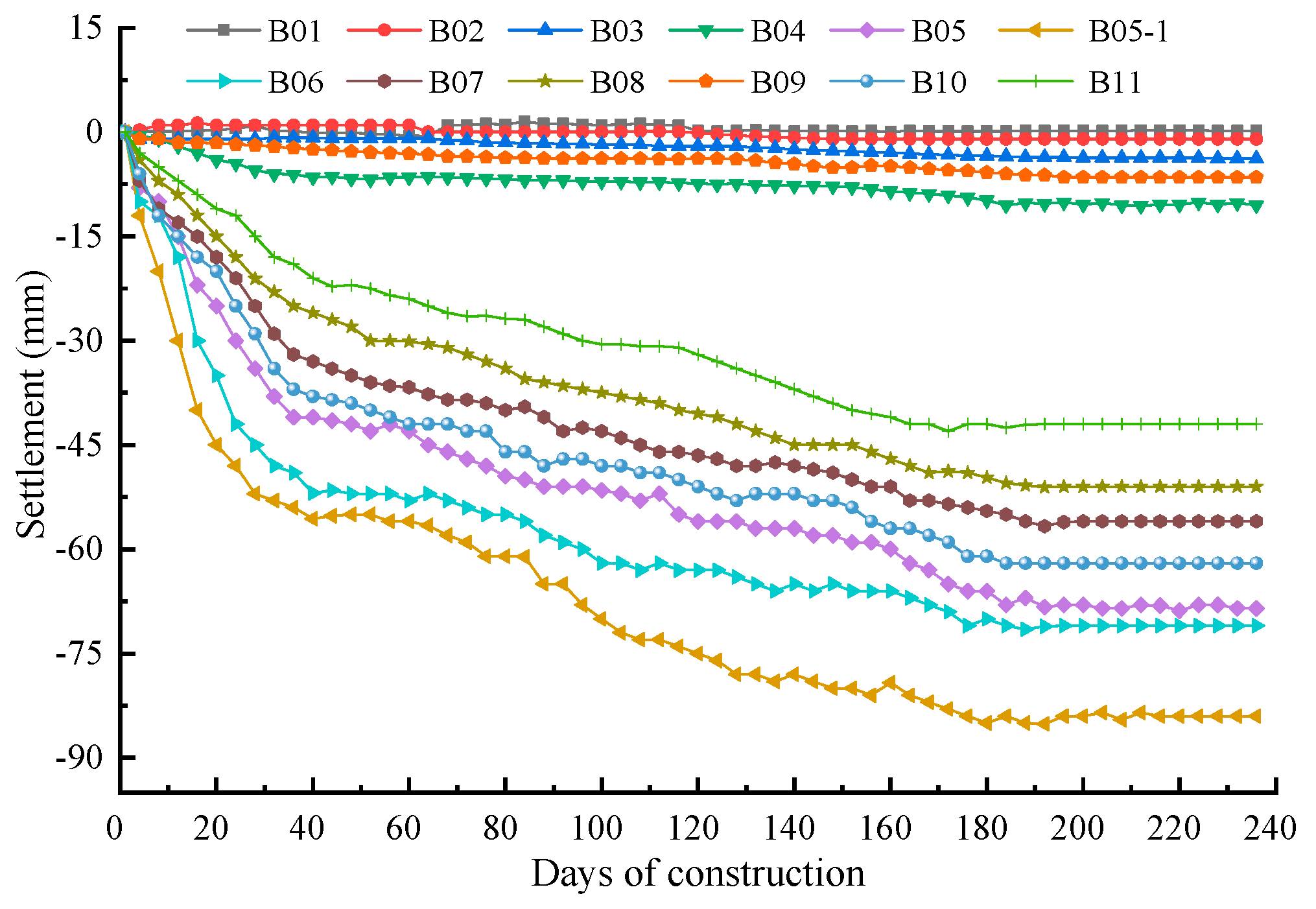

4.3.3. Analysis of Deformation Monitoring Results of Pile Foundation in the Foundation Pit

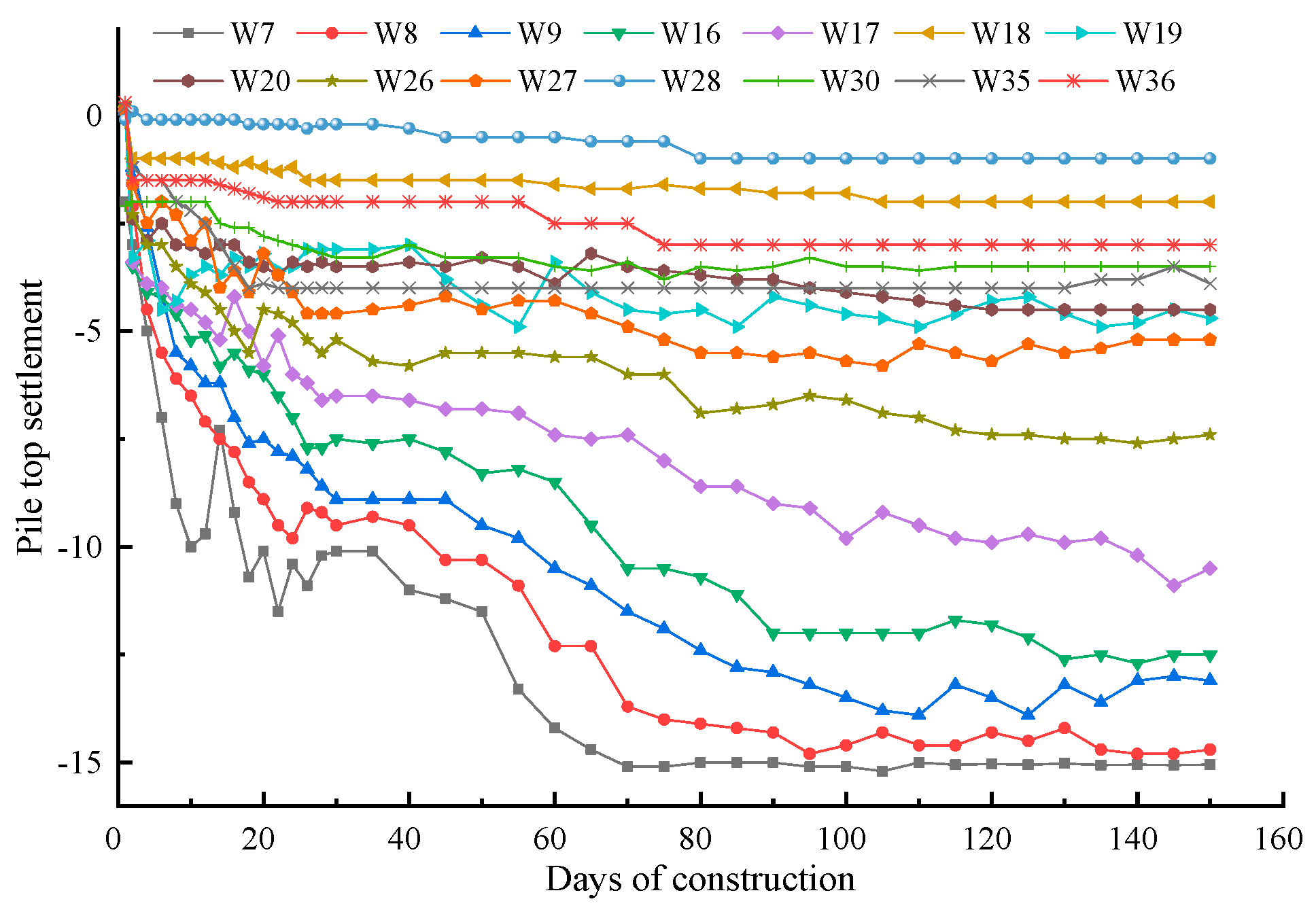

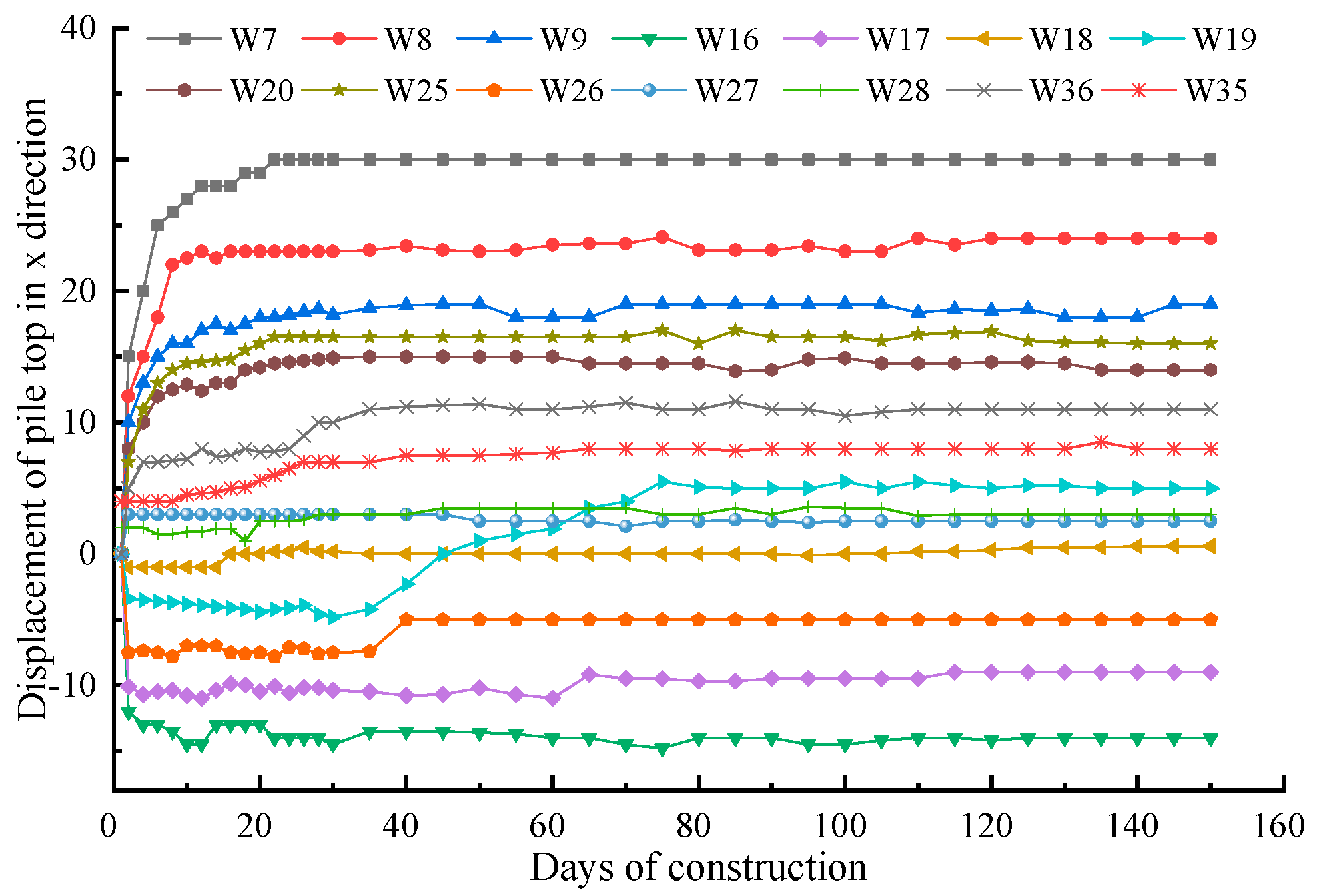

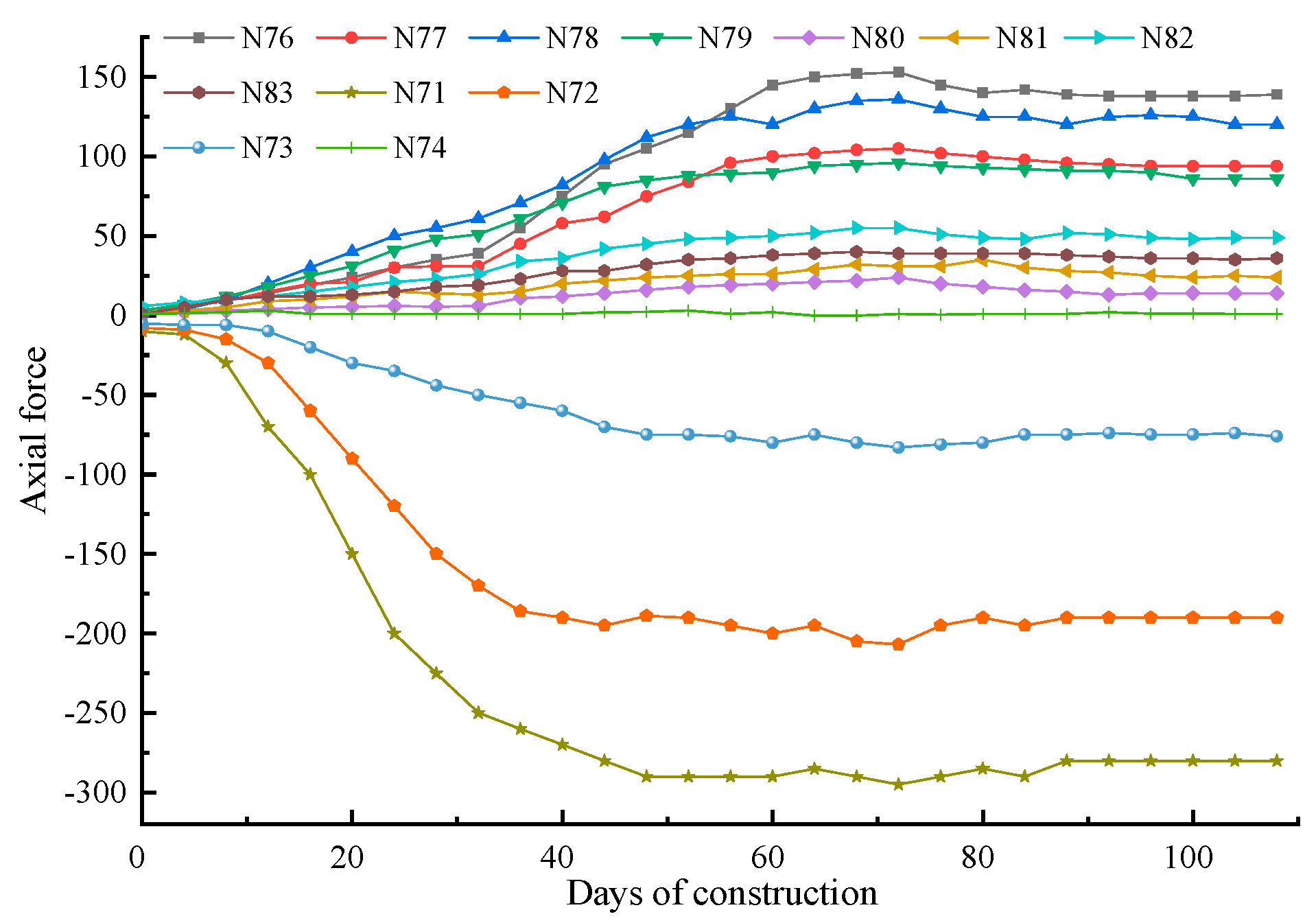

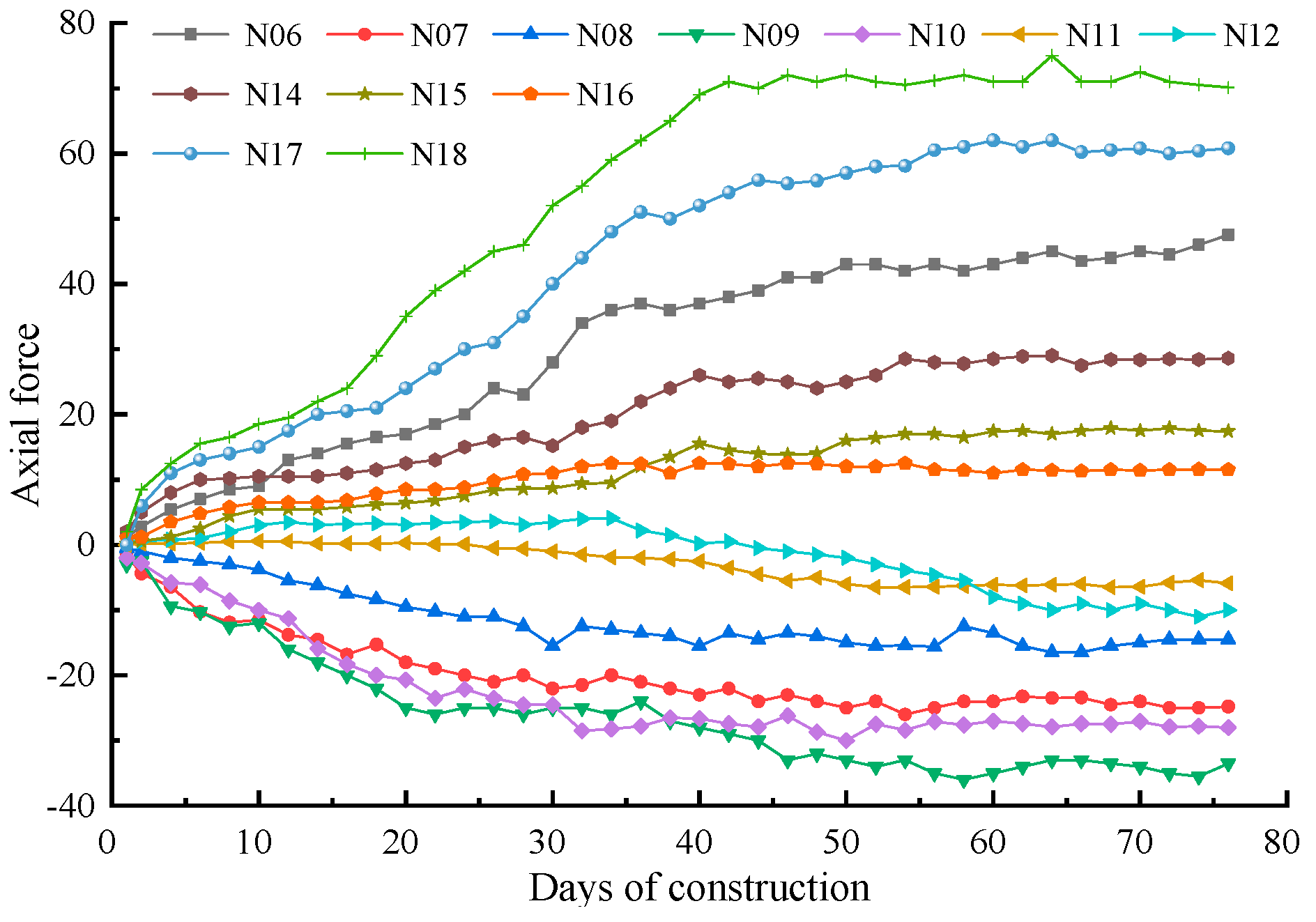

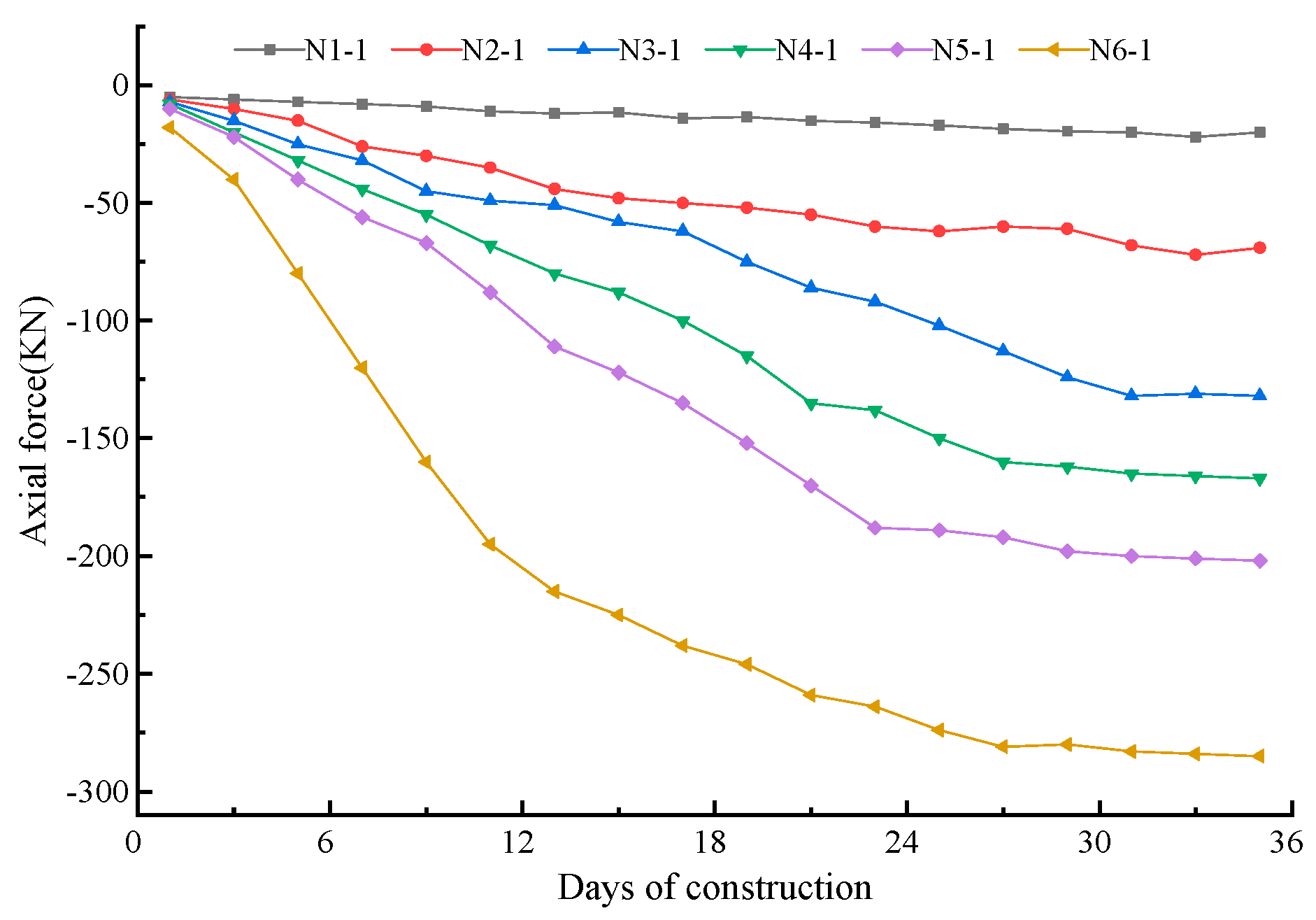

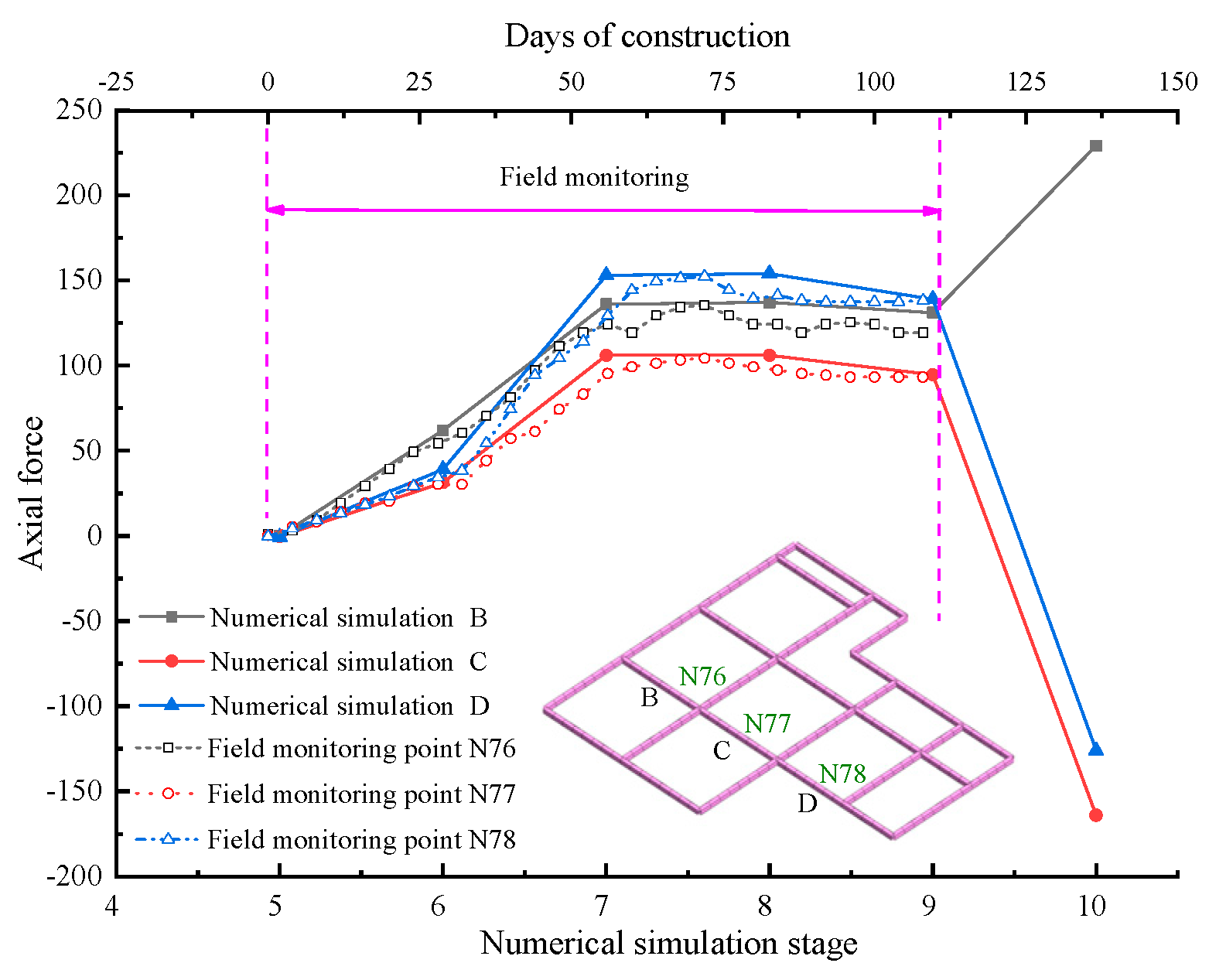

4.3.4. Analysis of Monitoring Results of Axial Force of Steel Support

4.3.5. The Eastern Side of the Excavation Site Is Adjacent to a Road

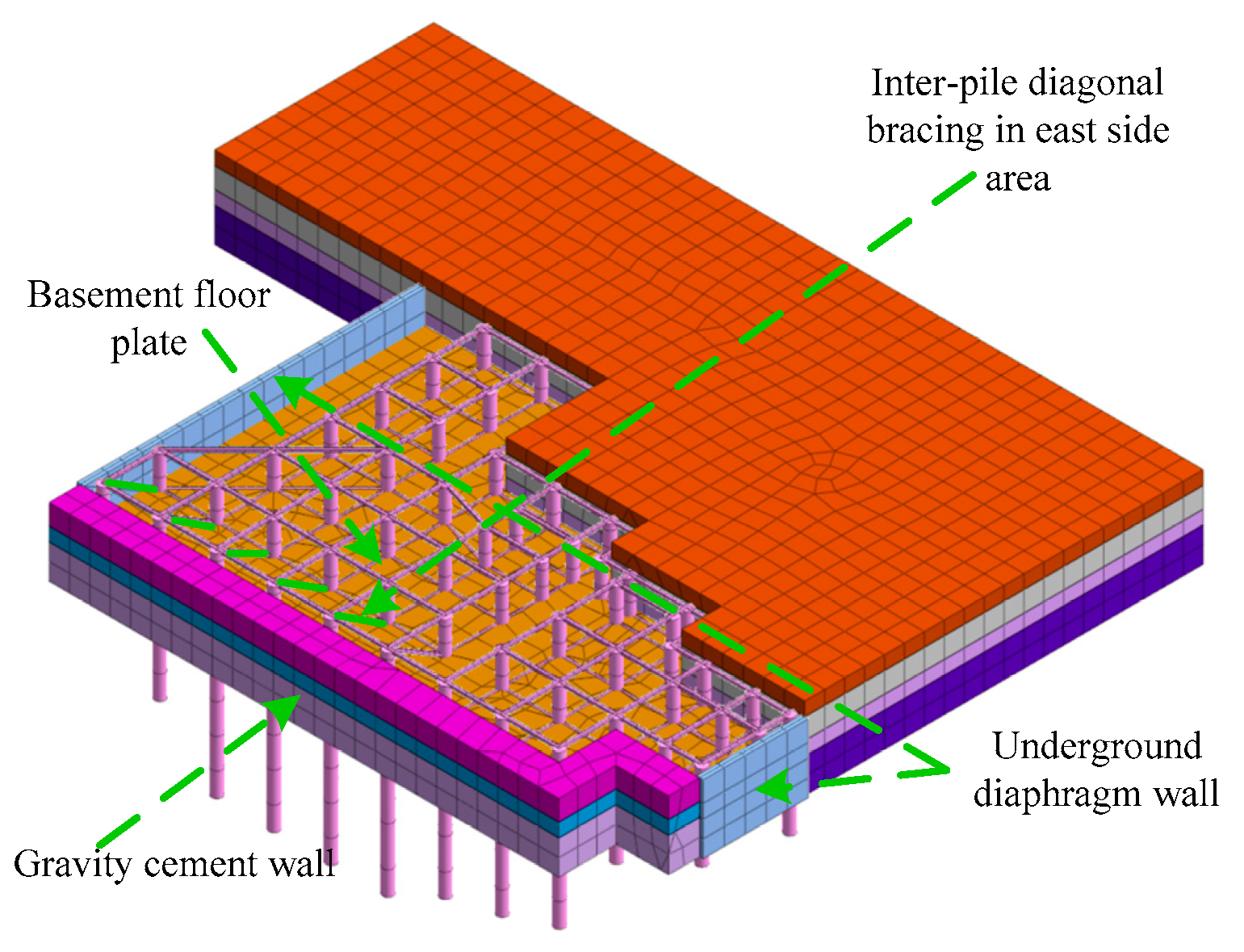

5. Finite Element Simulation Analysis

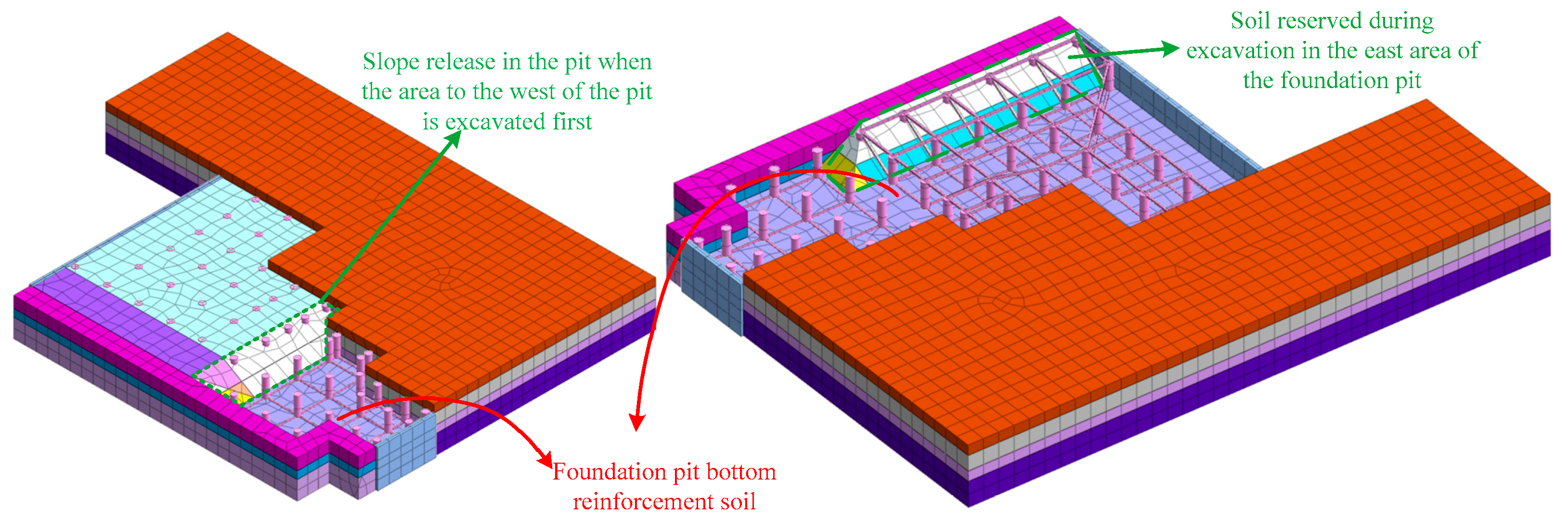

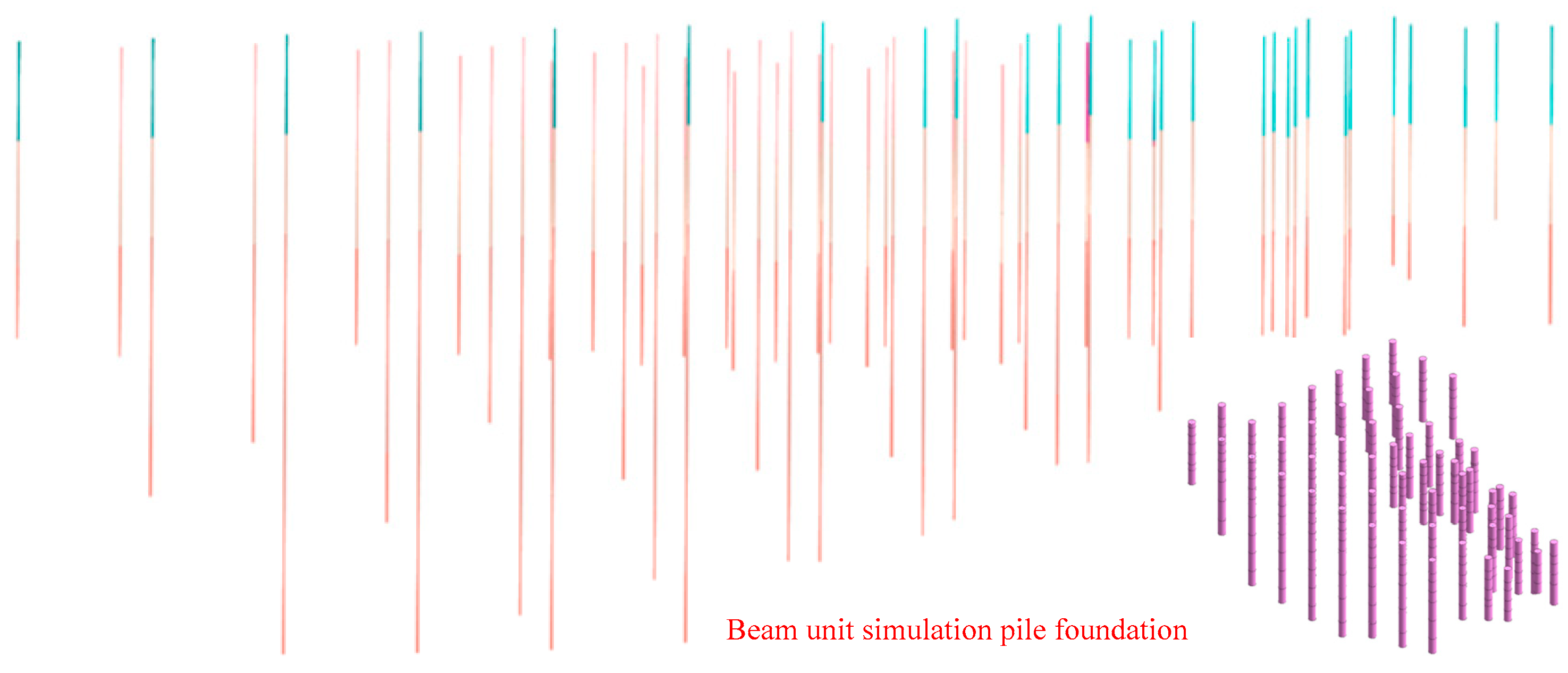

5.1. Establishment of Finite Element Model

5.2. Definition of Numerical Simulation Construction Stage

5.3. Analysis of Numerical Simulation Results

5.3.1. Vertical Displacement Analysis of Soil at the Bottom of Foundation Pit

5.3.2. Comparative Analysis of Axial Force of Steel Support and Numerical Simulation

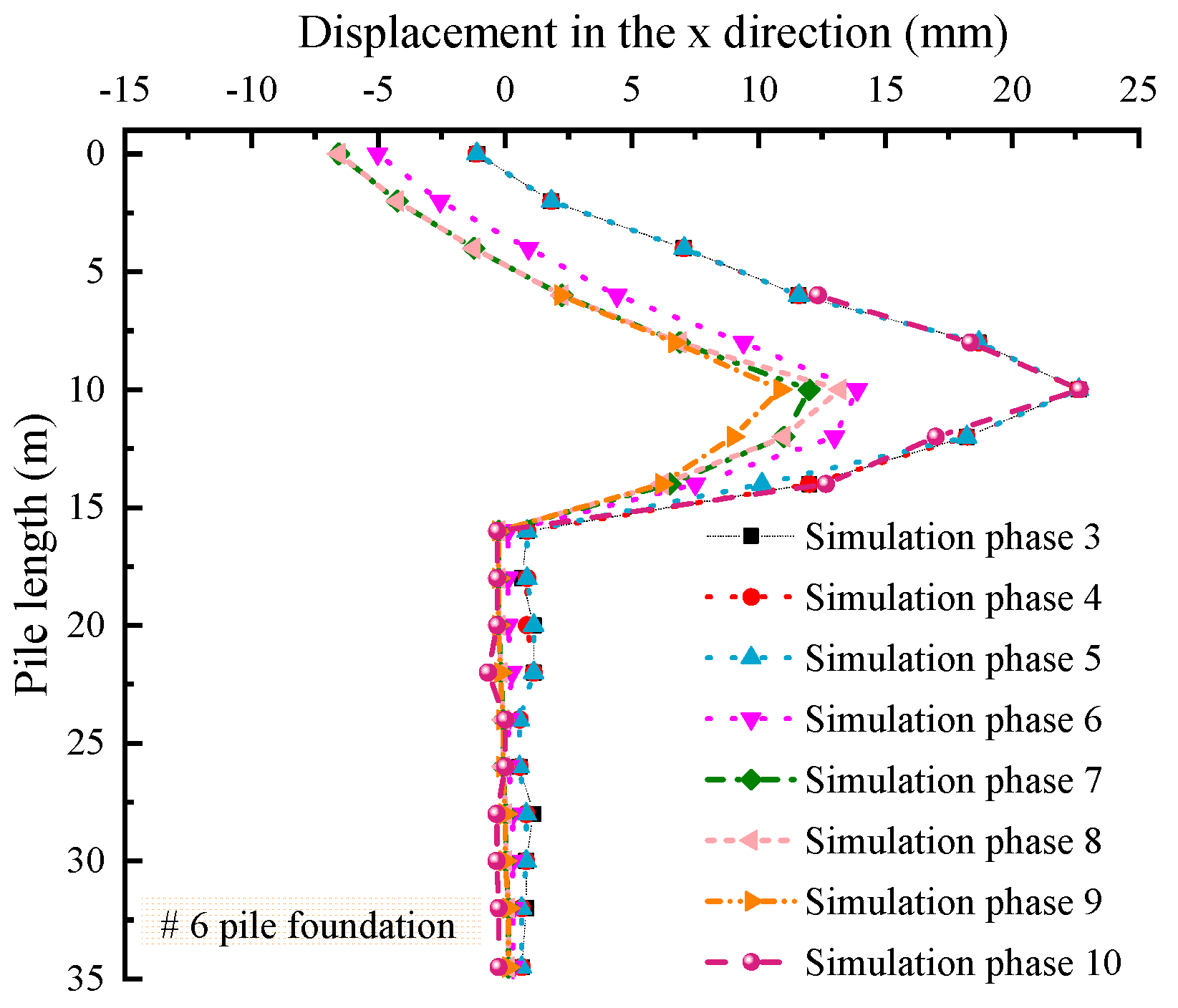

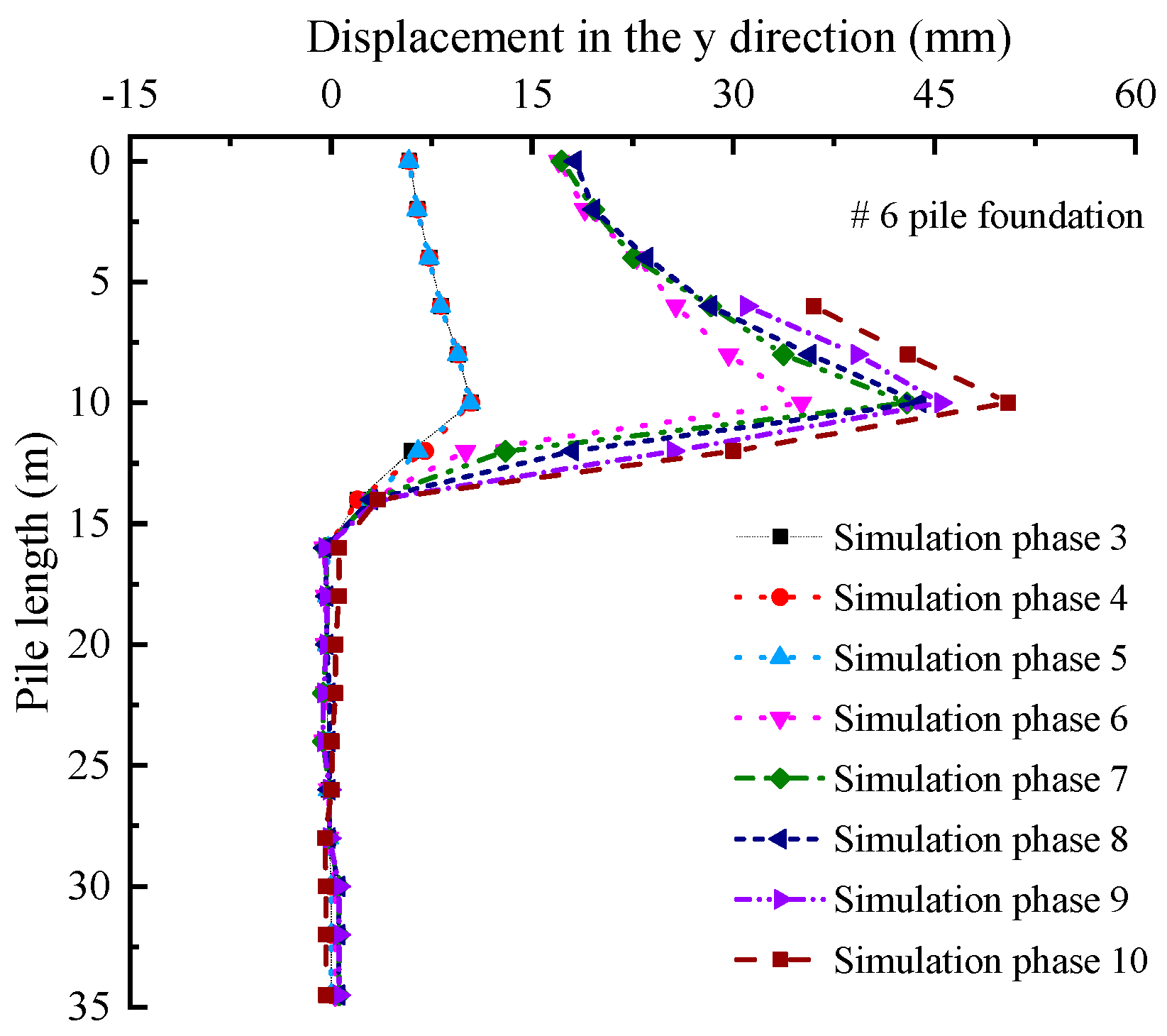

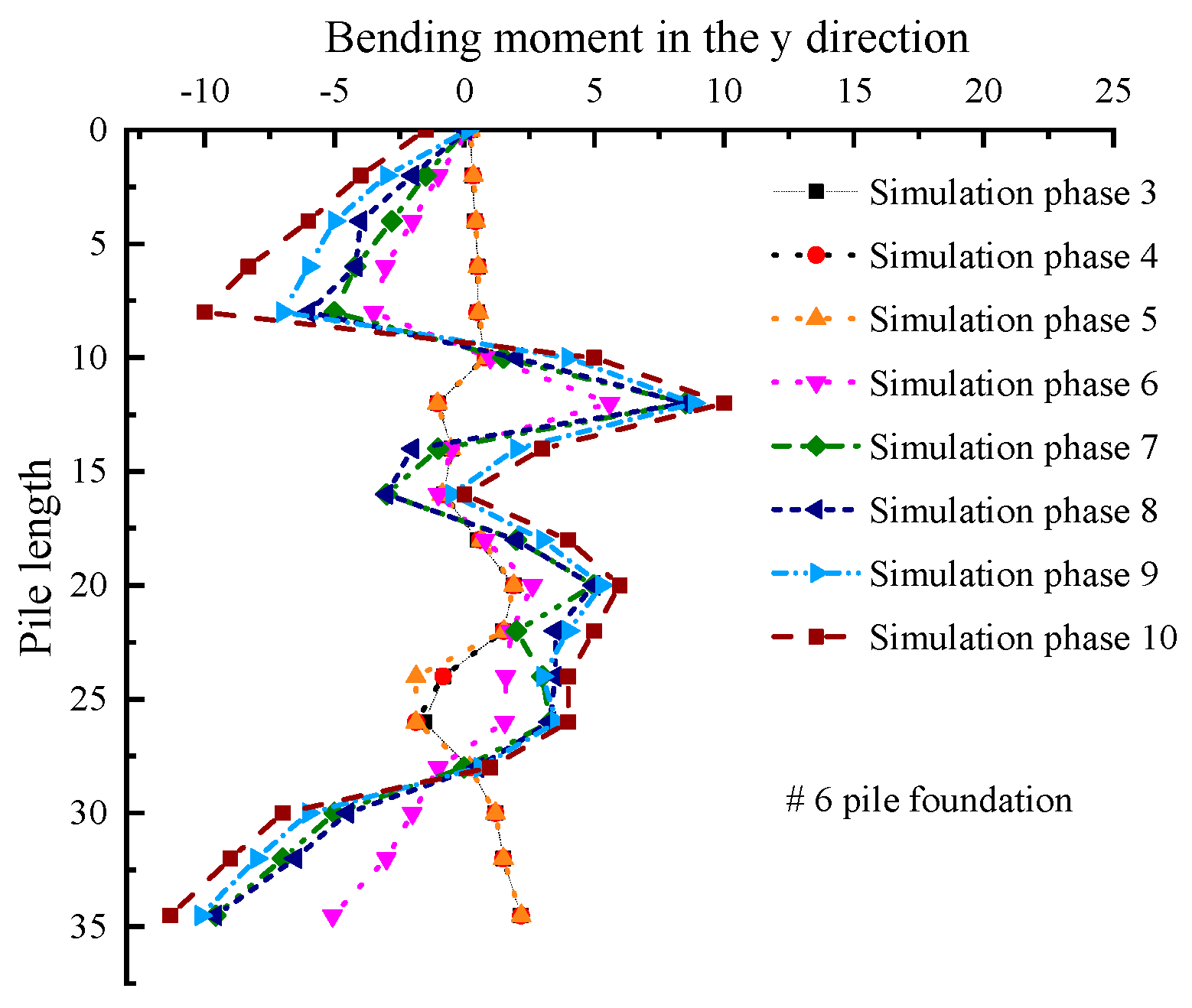

5.3.3. Analysis of Displacement and Bending Moment of Pile Foundation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Whittle, A.J.; Hashash, Y.M.A.; Whitman, R.V. Analysis of Deep Excavation in Boston. J. Geotech. Eng. 1993, 119, 69–90. [Google Scholar] [CrossRef]

- Schäfer, R.; Triantafyllidis, T. Modelling of Earth and Water Pressure Development during Diaphragm Wall Construction in Soft Clay: Pore pressure development during wall construction. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 1305–1326. [Google Scholar] [CrossRef]

- Likitlersuang, S.; Surarak, C.; Wanatowski, D.; Oh, E.; Balasubramaniam, A. Finite Element Analysis of a Deep Excavation: A Case Study from the Bangkok MRT. Soils Found. 2013, 53, 756–773. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Tang, D. Three-Dimensional Effects on Deformation of Deep Excavations. Proc. Inst. Civ. Eng. Geotech. Eng. 2015, 168, 551–562. [Google Scholar] [CrossRef]

- Lee, F.-H.; Hong, S.-H.; Gu, Q.; Zhao, P. Application of Large Three-Dimensional Finite-Element Analyses to Practical Problems. Int. J. Geomech. 2011, 11, 529–539. [Google Scholar] [CrossRef]

- Chheng, C.; Likitlersuang, S. Underground Excavation Behaviour in Bangkok Using Three-Dimensional Finite Element Method. Comput. Geotech. 2018, 95, 68–81. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, D. Characteristics of a Large-Scale Deep Foundation Pit Excavated by the Central-Island Technique in Shanghai Soft Clay. I: Bottom-Up Construction of the Central Cylindrical Shaft. J. Geotech. Geoenviron. Eng. 2013, 139, 1875–1893. [Google Scholar] [CrossRef]

- Li, Z. Displacement Monitoring during the Excavation and Support of Deep Foundation Pit in Complex Environment. Adv. Civ. Eng. 2021, 2021, 5715306. [Google Scholar] [CrossRef]

- Liu, J.; Shi, C.; Cao, C.; Lei, M.; Wang, Z. Improved Analytical Method for Pile Response Due to Foundation Pit Excavation. Comput. Geotech. 2020, 123, 103609. [Google Scholar] [CrossRef]

- Zhang, W.; Goh, A.T.C.; Xuan, F. A Simple Prediction Model for Wall Deflection Caused by Braced Excavation in Clays. Comput. Geotech. 2015, 63, 67–72. [Google Scholar] [CrossRef]

- Arai, Y.; Kusakabe, O.; Murata, O.; Konishi, S. A Numerical Study on Ground Displacement and Stress during and after the Installation of Deep Circular Diaphragm Walls and Soil Excavation. Comput. Geotech. 2008, 35, 791–807. [Google Scholar] [CrossRef]

- Zdravkovic, L.; Potts, D.M.; St John, H.D. Modelling of a 3D Excavation in Finite Element Analysis. Géotechnique 2005, 55, 497–513. [Google Scholar] [CrossRef]

- Finno, R.J.; Harahap, I.S. Finite Element Analyses of HDR-4 Excavation. J. Geotech. Eng. 1991, 117, 1590–1609. [Google Scholar] [CrossRef]

- Song, G.; Xu, J.; Marshall, A.M. Numerical Study on the Effect of Protective Wall Depth in Reducing Structure Deformations Caused by Tunnelling. Comput. Geotech. 2023, 158, 105374. [Google Scholar] [CrossRef]

- Sugimoto, M.; Sramoon, A. Theoretical Model of Shield Behavior During Excavation. I: Theory. J. Geotech. Geoenviron. Eng. 2002, 128, 138–155. [Google Scholar] [CrossRef]

- Finno, R.J.; Blackburn, J.T.; Roboski, J.F. Three-Dimensional Effects for Supported Excavations in Clay. J. Geotech. Geoenviron. Eng. 2007, 133, 30–36. [Google Scholar] [CrossRef]

- Finno, R.J.; Bryson, S.; Calvello, M. Performance of a Stiff Support System in Soft Clay. J. Geotech. Geoenviron. Eng. 2002, 128, 660–671. [Google Scholar] [CrossRef]

- Orazalin, Z.Y.; Whittle, A.J.; Olsen, M.B. Three-Dimensional Analyses of Excavation Support System for the Stata Center Basement on the MIT Campus. J. Geotech. Geoenviron. Eng. 2015, 141, 05015001. [Google Scholar] [CrossRef]

- Tan, Y.; Wei, B. Observed Behaviors of a Long and Deep Excavation Constructed by Cut-and-Cover Technique in Shanghai Soft Clay. J. Geotech. Geoenviron. Eng. 2012, 138, 69–88. [Google Scholar] [CrossRef]

- Liu, G.B.; Ng, C.W.; Wang, Z.W. Observed Performance of a Deep Multistrutted Excavation in Shanghai Soft Clays. J. Geotech. Geoenviron. Eng. 2005, 131, 1004–1013. [Google Scholar] [CrossRef]

- Pile Foundation Analysis and Design: Poulos, H G; Davis, E H New York: Wiley, 1980, 397P. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 100. [CrossRef]

- Cui, X.; Ye, M.; Zhuang, Y. Performance of a Foundation Pit Supported by Bored Piles and Steel Struts: A Case Study. Soils Found. 2018, 58, 1016–1027. [Google Scholar] [CrossRef]

- Dong, Y.P.; Burd, H.J.; Houlsby, G.T. Finite Element Parametric Study of the Performance of a Deep Excavation. Soils Found. 2018, 58, 729–743. [Google Scholar] [CrossRef]

- Goh, A.T.C.; Zhang, F.; Zhang, W.; Zhang, Y.; Liu, H. A Simple Estimation Model for 3D Braced Excavation Wall Deflection. Comput. Geotech. 2017, 83, 106–113. [Google Scholar] [CrossRef]

- Wu, J.; Ye, S.; Wang, Z.; Yang, D. Application and Automatic Monitoring and Analysis of Hybrid Support Structure in Ultra-DEEP Foundation Pit Engineering in the Lanzhou Area under Complex Environmental Conditions. Water 2023, 15, 1335. [Google Scholar] [CrossRef]

- Ye, S.; Zhao, Z.; Wang, D. Deformation Analysis and Safety Assessment of Existing Metro Tunnels Affected by Excavation of a Foundation Pit. Undergr. Space 2021, 6, 421–431. [Google Scholar] [CrossRef]

- Guo, P.; Gong, X.; Wang, Y. Displacement and Force Analyses of Braced Structure of Deep Excavation Considering Unsymmetrical Surcharge Effect. Comput. Geotech. 2019, 113, 103102. [Google Scholar] [CrossRef]

- Mei, Y.; Wang, L.; Zhou, D.; Fu, L. Displacement Characteristics of a Deep Excavation in Hangzhou Soft Clay. Adv. Civ. Eng. 2022, 2022, 5469471. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, C.Q. Safety Assessment of Antiliquefaction Performance of a Constructed Reservoir Embankment. I: Experimental Assessment. J. Perform. Constr. Facil. 2017, 31, 04016101. [Google Scholar] [CrossRef]

- Zhu, C.Q.; Huang, Y. Safety Assessment of Antiliquefaction Performance of a Constructed Reservoir Embankment. II: Numerical Assessment. J. Perform. Constr. Facil. 2017, 31, 04016102. [Google Scholar] [CrossRef]

- GB 50497-2019; Technical Standard for Monitoring of Building Excavation Engineering. National Standardization Administration of China: Beijing, China, 2019.

- JGJ 106-2014; Technical Specification for Testing of Building Foundation Piles. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

| Name of Soil | The Natural Unit Weight γ (kN/m3) | Cohesive Strength Ck (kPa) | Internal Friction Angle φk( ) | Compressive Modulus ES1-2 (MPa) | Permeability Coefficient k (cm/s) |

|---|---|---|---|---|---|

| ① Miscellaneous fill soil | 17.5 | 12.0 | 10.0 | 4.5 | 5.0 × 10−3 |

| ② Silt | 17.9 | 5.0 | 5.0 | 2.0 | 3.0 × 10−5 |

| ③ Silty clay | 19.2 | 42.0 | 12.2 | 7.0 | 3.0 × 10−6 |

| ④ Clay | 19.6 | 50.0 | 16.5 | 11.0 | 6.0 × 10−7 |

| ⑤ Highly weathered sandy claystone | 20.0 | 10.0 | 20.0 | 20.0 | 2.0 × 10−5 |

| ⑥ Moderately weathered sandy claystone | 22.5 | 30.0 | 40.0 | 500 | 2.0 × 10−6 |

| Stage | Construction Area | Construction Duration Days | Construction Content |

|---|---|---|---|

| Before excavation | North side of foundation pit | - | North building basement |

| South side of the foundation pit | - | Gravity retaining wall construction | |

| The whole foundation pit area | - | Pile foundation construction | |

| Under excavation | East and west sides of the foundation pit | - | Diaphragm wall construction |

| East area of foundation pit | 20 | Excavate to 5 m. | |

| East area of foundation pit | 30 | Pile cutting-steel support construction | |

| East area of foundation pit | 10 | The first steel support construction | |

| East area of foundation pit | 25 | Excavation of the first layer of soil | |

| East area of foundation pit | 25 | Excavation of the second layer of soil | |

| East area of foundation pit | 25 | The second steel support construction | |

| East area of foundation pit | 25 | Demolition of steel support | |

| South side of foundation pit | 10 | Basement floor construction | |

| After excavation | - | - | - |

| Structure/Soil Mass | γ (103KN/m3) | E (Mpa) | ( ) | Unit Type | |

|---|---|---|---|---|---|

| Miscellaneous fill | 18.5 | 20 | 15 | 0.40 | Entity unit |

| Clay | 19 | 30 | 20 | 0.35 | Entity unit |

| Silt | 18 | 6 | 5 | 0.45 | Entity unit |

| Strongly weathered sandstone | 26 | 7.0 × 104 | 45 | 0.31 | Entity unit |

| Rock | 28 | 1.8 × 105 | 50 | 0.30 | Entity unit |

| Reinforcement soil at pit bottom | 20 | 45 | 36 | 0.32 | Entity unit |

| Gravity cement soil wall | 19.5 | 50 × 104 | 40 | 0.30 | Entity unit |

| Concrete diaphragm wall | 25 | 4.5 × 104 | - | 0.30 | Entity unit |

| Pile foundation/basement floor | 25 | 3.25 × 104 | - | 0.28 | Beam/plate element |

| Steel support | 78 | 2.1 × 105 | - | 0.26 | Beam element |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Ye, S.; Xin, L. Study on the Analysis of Pile Foundation Deformation and Control Methods during the Excavation of Deep and Thick Sludge Pits. Water 2023, 15, 3121. https://doi.org/10.3390/w15173121

Wang D, Ye S, Xin L. Study on the Analysis of Pile Foundation Deformation and Control Methods during the Excavation of Deep and Thick Sludge Pits. Water. 2023; 15(17):3121. https://doi.org/10.3390/w15173121

Chicago/Turabian StyleWang, Dengqun, Shuaihua Ye, and Liangliang Xin. 2023. "Study on the Analysis of Pile Foundation Deformation and Control Methods during the Excavation of Deep and Thick Sludge Pits" Water 15, no. 17: 3121. https://doi.org/10.3390/w15173121

APA StyleWang, D., Ye, S., & Xin, L. (2023). Study on the Analysis of Pile Foundation Deformation and Control Methods during the Excavation of Deep and Thick Sludge Pits. Water, 15(17), 3121. https://doi.org/10.3390/w15173121