1. Introduction

In recent years, China has conducted annual large-scale river and lake dredging projects to improve the water quality of rivers and lakes and to ensure the flood discharge capacity of rivers. These projects have resulted in substantial volumes of dredged slurry, characterized by high water content, high silt and clay particle content, high plasticity index, high compressibility, and low permeability [

1]. As a consequence of poor settlement and consolidation performance, this type of slurry undergoes an extended period to dewater and consolidate under natural drying conditions and occupies a large storage area, resulting in the waste of land resources and high handling costs [

2,

3]. Geotextile tubes stand out as a prevalent slurry treatment technology that accelerates the dewatering rate of dredged slurry [

4,

5,

6,

7]. Geotextile filtration can be used to reduce the water content and volume of slurry significantly. For example, in Buenos Aires’ urban port, utilizing geotextile tubes for dewatering demonstrated a reduction in sediment volume by 75% within 26 days [

8]. In China, geotextile tubes have been widely used to treat slurry produced by river and lake dredging projects [

9,

10]. Compared with the traditional slurry treatment methods, geotextile tubes present obvious advantages in terms of land conservation, construction convenience, labor requirements, cost-effectiveness, and eco-friendliness. However, the excessive proportion of silt and clay contents in typical filling slurries leads to the gradual accumulation of a mud cake inside geotextile tubes, consequently undermining its permeability and prolonging the dewatering duration.

Many studies have indicated that chemical additives can accelerate the release of water from fines, thereby improving the dewatering rate of various high water content materials [

11,

12,

13,

14]. To mitigate the adverse effects of mud cakes, flocculants are typically added to the dredged slurry during the pumping operation. The filtered flow rate of geotextile tubes filled with slurry is significantly affected by flocculant addition [

15]. In the process of dewatering using geotextile tubes filled with slurry, flocculants are typically added to pretreat the slurry to accelerate the dewatering process. For example, Zhang Jinghui et al. [

16] combined ultrasonic treatment along with flocculants to dehydrate and solidify slurry in geotextile tubes, revealing the influence mechanism of ultrasonic treatment and the dosing sequence of flocculants on slurry dewatering performance. Zhang Rong-jun et al. [

17] proposed a flocculation-solidification combined method to dispose the hydraulically dredged mud slurry.

The dewatering duration of geotextile tubes containing dredged slurry is contingent upon the settling rate of soil particles. A good understanding of the behavior of sedimentation property of slurry is necessary for treating dredged slurries using geotextile tubes. Currently, the settling column test is the predominant method used to investigate and predict the settling characteristics of slurry. On the basis of settling column tests, existing research generally divides the self-weight sedimentation process of the high water content viscous silt into three stages: flocculation, settlement, and consolidation [

18,

19]. Xu et al. [

20] conducted settling column tests to investigate the sedimentation behavior of four clays in China and found that the sedimentary soil development process can be identified as fluid state and consolidation state. Moreover, a settling column test can be used to investigate the influencing factors of mud natural sedimentation quantitatively. For example, Winterwerp [

21] conducted settling column tests and concluded that high viscous powder content in slurry intensifies particle interaction during sedimentation. This process extends from the sedimentation to the consolidation stage. Wang et al. [

22] found that the initial water and clay contents of slurry influence the self-redeposition of dredger fill. According to the settling column test results, Zhang et al. [

23] developed a new Multilayer Extraction Sampling (MES) method to investigate the underlying law of sedimentation and consolidation of soil particles in slurries.

However, the sedimentation behavior of slurries treated with additives may exhibit disparities compared to untreated slurries. Azam [

24] discovered that the sedimentation behavior of polymer-amended laterite slurry was dominated by physicochemical interactions, with the governing role played by the void spaces among flocs. He et al. [

25] tested the sedimentation behavior of flocculant-treated soil slurry using settling column tests and obtained the most effective flocculant content for slurry with different water contents. Jaditager and Sivakugan [

26] examined the sedimentation behavior of fly ash-based geopolymer-stabilized dredged mud slurries, revealing the influence of fly ash-based geopolymer binders on the sedimentation behavior of dredged mud. Salehi and Sivakugan [

27] discovered through laboratory tests that the lime modification of dredged mud slurry induced flocculated settling behavior and increased the porosity, void ratio, permeability, and consolidation coefficient of the final dredged mud sediment. Liu et al. [

28] evaluated the decrement effects of different flocculants on dredged slurry and obtained the optimal mixing ratio of six flocculants according to the settling column test results. Song et al. [

29] concluded from their custom double-cylinder settling column tests that the settling velocity of the soil–water interface initially increased and then decreased with increasing rotation speed of the inner column. Malekzadeh et al. [

30] investigated the effect of salinity and sediment mineralogy on sediment settlement behavior when deposited in saltwater, freshwater, or empty ponds. Zhang et al. [

31] found that the sedimentation behavior of slurry prepared using seawater was significantly different from that of slurry prepared using distilled water, and other hydrochemical conditions, including salt (cation) types and concentrations also affect sedimentation behavior.

Existing research has predominantly concentrated on the sedimentation behavior of flocculant-treated slurry, often overlooking the filtration of geotextile tubes. The sedimentation behavior of flocculant-treated river-dredged slurry pumped into the woven geotextile tubes may differ from that of settling ponds or on land-reclamation sites. Thus far, no definitive conclusions have been drawn. Therefore, this laboratory study investigated the sedimentation behavior of river-dredged slurry treated with flocculants under the filtration conditions of woven geotextiles. Two different flocculants and geotextiles were used in the settling column tests of river-dredged slurry. The soil–water interface of slurries and the quantity of filtered water were monitored during the sedimentation tests to analyze the sedimentation behavior of flocculant-treated slurry. The particle size distribution, water content, and dry density of the final dredged mud sediment were measured and analyzed to elucidate the underlying influence mechanism of flocculants and geotextile filtration.

3. Results and Discussion

3.1. Settlement Curves

3.1.1. Influence of Flocculants on Settlement

Figure 3 presents the settlement curves of flocculant-treated slurries under the filtration of the two types of woven geotextiles. As shown in

Figure 3, under the filtration of woven geotextiles, the slurry sedimentation process is significantly accelerated by adding the flocculant compared with that without adding the flocculant. The volume of the final settlement is larger than the slurry under its natural sedimentation state. All the settlement curves exhibit three stages: settlement stage, flocculation stage, and consolidation stage. The settlement curves indicate a gradual decline, followed by a steep, approximately linear decrease in the settlement stage, and finally, a gradual decline stabilizing in the consolidation stage. The mud–water separation in the entire sedimentation process mainly occurs in the flocculation and sedimentation stages, and the mud–water interface declines the fastest in the sedimentation stage. Therefore, a decrease in the settling rate of the mud–water interface during the sedimentation stage could serve as an indicator for selecting the optimum flocculant concentration.

It is shown in

Figure 3 that, as flocculant concentration increases, both the settling rate of the mud–water interface and the final settlement amount initially rise and subsequently fall. There is an optimal concentration to make the mud–water interface decline the fastest. This is because PAM, as a high molecular flocculant, diminishes the affinity between suspended particles and water through electric neutralization and adsorption bridging, thereby improving slurry dewatering performance. Therefore, an increase in the flocculant concentration will accelerate the mud-water separation of the slurry. However, at excessively high flocculant concentrations, the surfaces of the colloidal particles become overly covered by the adsorbed polymers, and flocculation will cease to occur [

33,

34]. Additionally, an increase in flocculant concentration raises the viscosity of slurry, augmenting the resistance in percolation. This hinders the destabilization of slurry suspension and impedes water discharge. Therefore, once the flocculant concentration exceeds a certain threshold, the rate of mud–water separation decreases. According to the settlement curves with different flocculant contents, the optimal concentration of NPAM and CPAM is 250 mg/L.

3.1.2. Settlement Curves with the Optimal Concentration of Flocculant

Settlement curves of the slurry added with the optimal concentration of flocculant are shown in

Figure 4. Upon adding flocculant at its optimal concentration of 250 mg/L, geotextile 2 outperforms geotextile 1 in promoting the separation of mud and water. Regardless of the geotextile used, NPAM demonstrates a superior efficacy in promoting separation over CPAM. With geotextile 1, the settling ratios (the ratio of the settlement to the initial height) of slurry with 250 mg/L NPAM, 250 mg/L CPAM, and without adding flocculant are 13.6%, 8.8%, and 2.2%, respectively, in 10 min, and the settling ratios are 77.0%, 76.8%, and 73.0% at final states. When using geotextile 2, the settling ratios of slurry with 250 mg/L NPAM, 250 mg/L CPAM, and without flocculant are 32.0%, 8.9%, and 2.2%, respectively, in 10 min, and the final settling ratios reached 78.5%, 77.3%, and 75.1%, respectively.

Therefore, it can be concluded that the settlement of the slurry is more efficient with geotextile 1 than with geotextile 2, when treated with the optimal flocculant concentration. Additionally, in the absence of flocculant addition, geotextiles exert minimal influence on the slurry settling process. This can be attributed to the densely packed particles within the slurry, resulting in a low permeability coefficient. Consequently, the permeability of the sediment column becomes the dominant factor affecting the dewatering rate, thereby eclipsing the significance of geotextile properties in the settling process. After the addition of the flocculant, the particles in the slurry undergo destabilization due to charge neutralization and adsorption bridging, leading to the formation of larger flocs. These flocs create an abundance of voids within the sediment column, significantly augmenting the permeability coefficient of the sediment column. At this juncture, the permeability of the geotextile, characterized by its equivalent aperture O95, becomes a critical factor in determining the dewatering rate of the slurry. The larger equivalent aperture of geotextile 2 (0.38 mm) compared to geotextile 1 (0.30 mm) indicates that it has a higher permeability, allowing for a faster water escape through its voids while retaining the larger flocs. Consequently, geotextile 2 enhances the dewatering rate more effectively than geotextile 1, as it facilitates a quicker reduction in water content from the slurry, capitalizing on the voids created by the flocculation process. This causes geotextile 2 to promote the separation of mud and water more than geotextile 1. The settling curves, therefore, reflect not just the impact of flocculant concentration but also the integral role of geotextile properties in the sedimentation behavior of the slurry.

3.2. Settlement Rates

Figure 5 shows the comparison between different settling rate curves of slurries when treated with flocculants at their optimal concentration of 250 mg/L. For slurries treated with flocculants, the settling rates are higher compared to those without flocculants, and the trend of settling rate curves remains consistent across all four tested conditions involving flocculant addition. That is, the effect of flocculation on sedimentation is significant in the first 1 h, when the settling rate first increases, then decreases, and remains high; after 1 h, the settling rate rapidly decreases to approximately zero. The order of the peak settling rate is geotextile 2-NPAM, geotextile 1-NPAM, geotextile 2-CPAM, geotextile 1-CPAM, geotextile 2-no flocculant, and geotextile 1-no flocculant. The maximum settling rate peak after flocculant addition is 73.95 cm/h, 8.8 times the peak sedimentation velocity (8.43 cm/h) without flocculants. For the same flocculant, geotextile 2 accelerates slurry sedimentation more effectively than geotextile 1, and the settling rate of slurry after using NPAM is higher than that after using CPAM; that is, the flocculant promotes slurry sedimentation. This effect is more substantial than that with geotextiles. This results from the charge interactions between the flocculants with different ionic and slurry particles. NPAM, being nonionic, does not have charge repulsion issues, allowing for more effective absorption bridging regardless of the slurry’s charge. This results in larger flocs that are more effectively retained by larger apertures (O

95). In contrast, the ionic nature of CPAM may lead to charge repulsion with certain soil particles, when the zeta potential of the particle itself exceeds the optimal threshold of destabilization, resulting in less effective flocculation or smaller flocs that do not settle as quickly.

Jiao et al. [

35] incorporated PAM with concentrations of 10, 20, 30, and 40 g/t into the entire tailing mortar of a mine for flocculation and sedimentation tests. Results indicated that the value of the sedimentation rate curve peaked at the flocculant concentration of 20 g/t. The Giddings equation was used as the regression model to fit the sedimentation velocity curve with the largest peak value. After the fitting, the multiple correlation coefficient R

2 was 0.97, and the fitting accuracy was high. As shown in

Figure 5, the ‘geotextile 2-NPAM 250 mg/L’ exhibits the highest peak in the settling rate curve, which aligns with the peak and trend characteristics of the Giddings equation (Equations (1) and (2)). Therefore, the Giddings equation is selected to fit the sedimentation rate curve of this working condition. The fitting result is depicted in

Figure 6. The settling rate curve of this working condition fits well with the Giddings equation. Therefore, when PAM-type flocculants result in a settling rate curve exhibiting similar peak and trend characteristics of the dredged slurry at the optimal flocculant concentrations, the Giddings equation can be used for post-fitting analysis.

Among them,

I(

x) is the first-order type-1 modified Bessel function, as shown in the following formula:

In Equations (1) and (2), y represents the settling rate, cm/h; x represents the sedimentation time, min; y0, A, B, and W represent all regression coefficients. In this fitting result, y0 = 1.36594, A = 10.5638, B = 2025.66724, W = 2.78348, and the multiple correlation coefficient R2 = 0.98991. This regression is significant and has high accuracy.

3.3. Filtered Water

The quantity of cumulative water filtered through the geotextiles as a function of time is shown in

Figure 7. In all instances, the tests continued until the height of the soil–water interface remained unchanged for several hours.

For slurry added with flocculant of different concentrations, the filtered water continues to pass through the two geotextiles for the entire test duration. The collected filtered water was clear, and no sign of clogging or blinding was observed during the test.

As shown in

Figure 7, the quantity of filtered water cumulated increased with time. With the filtration of geotextiles, the outlet rate continues to decrease and finally converges to a stable value. The filtration process can be distinguished into two stages [

36]. At the first stage, as the filter cake inside the geotextile formed a stable structure, the dewatering efficiency of the system was determined by the fabric properties, and the curve slope gradually decreased with time. In the second stage, the filter cake within the geotextile maintains a stable structure. Additionally, the filtration process is mainly determined by the filter cake property (i.e., sludge particle composition). The filtration rate is close to constant, and the curve is linear.

The optimal flocculant concentration for the aforementioned instances is 250 mg/L. When the flocculant concentration is less than 250 mg/L, the filtration efficiency improves as the flocculant concentration increases. When the concentration is higher than this, an increase in the concentration cannot improve filtration efficiency. In contrast, exceeding this concentration tends to produce an inhibiting effect on the efficiency.

The effects of types of geotextiles and flocculants on the dewatering efficiency are comparable, indicating that in this experiment, the most critical factor affecting the dewatering process is neither the type of geotextile nor the type of flocculant, but flocculant concentration, time, and sludge particle composition [

37]. These factors have a more pronounced impact on the dewatering process because they directly influence the physical space (cross-sectional area) through which water must pass and the resistance it encounters. While geotextiles and flocculants are integral to the initial setup of the filtration system, the eventual efficacy of dewatering is dominated by how the slurry interacts within the established filter cake at the final state.

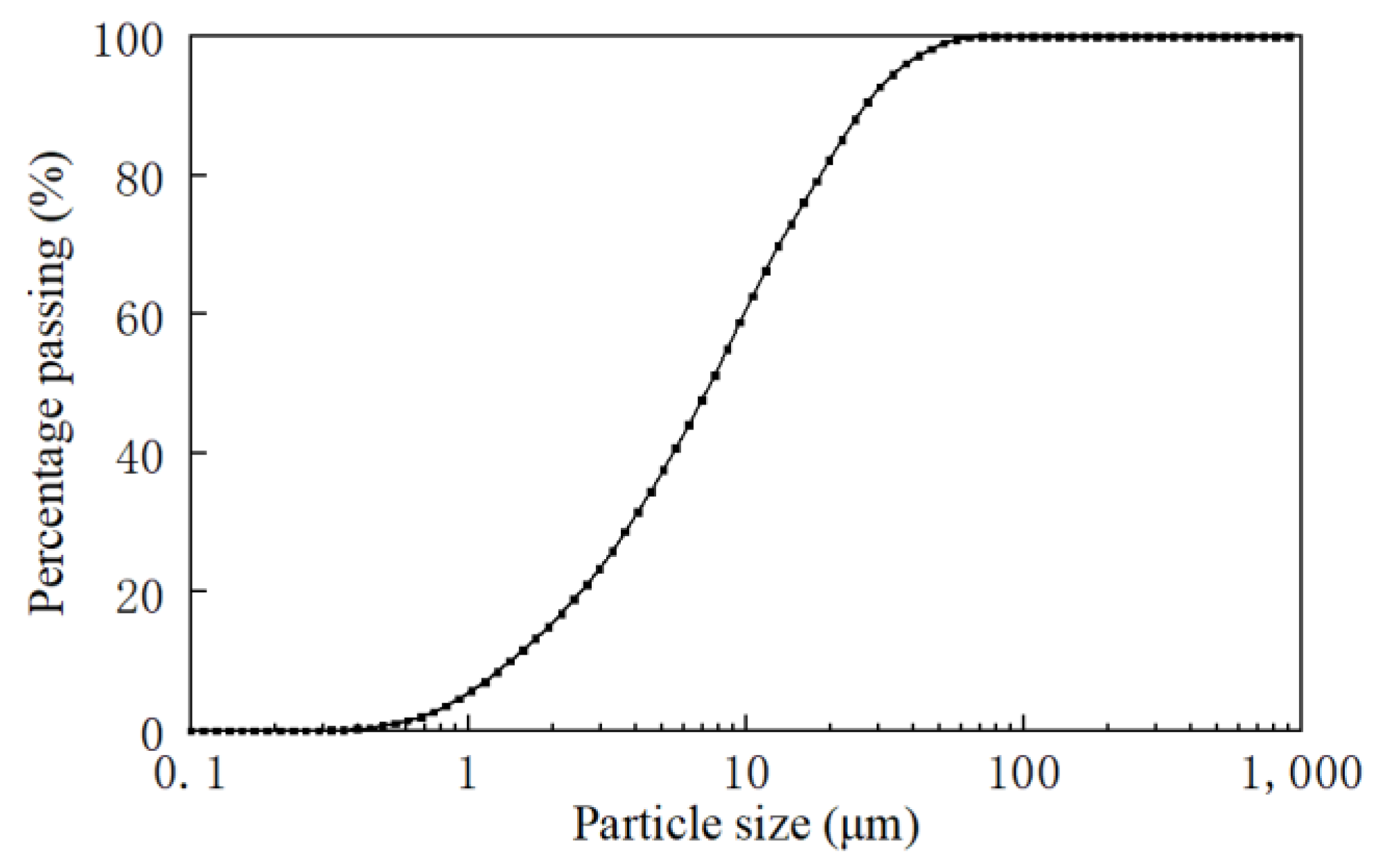

3.4. Particle Size Distribution at Final States

After flocculant addition, flocculation is formed between mud particles, increasing the particle size of fine particles. After the sedimentation tests, the particle size distribution of mud particles is measured, as shown in

Figure 8. It can be found that the particle size of the mud is increased with the concentration of PAM, and the particle size of the mud after flocculant addition is larger than that without flocculant addition. When geotextile 1 is used, the clay particle content of the mud after adding 300 mg/L NPAM is 8.53%, with sand particle content of 14.87%, whereas the clay particle content after adding 300 mg/L CPAM is 9.42%, with sand particle content of 14.31%. In the absence of flocculant addition, the clay content of the mud is 20.14%, and the content of sand is 2.44%. Thus, after flocculant addition, the clay content of mud particles is significantly reduced, whereas the sand content is increased. Therefore, the enlargement of particle size may result in an increase in the permeability of slurries significantly.

This phenomenon occurs because electric neutralization between the flocculant and mud particles compresses the electric double layer of mud particles, thereby reducing the repulsive force among mud particles and leading to the aggregation of mud particles and flocculated particles into larger flocs. This increases the size of the mud particles, thereby accelerating the sedimentation rate. However, when the PAM concentration is excessively high, the anticoagulation of the flocs is enhanced, thereby hindering the sedimentation. Therefore, when the optimal flocculant concentration (250 mg/L) is exceeded, the size of mud particles increases but settles more slowly. Therefore, it was verified that for the mud with an initial water content of 400%, the optimal concentration of NPAM and CPAM is 250 mg/L.

3.5. Water Content at Final States

After sedimentation, the final water content of the mud follows a certain spatial distribution law.

Figure 9 shows the vertical distribution curve of the final water content of the mud after sedimentation. It is shown that the further the distance from the bottom geotextile, the higher the water content of the mud becomes. Compared with that of slurry without adding flocculant, the water content of the mud after adding flocculant is higher at the bottom and lower at the top of the sedimentary layer.

For geotextile 1, after adding CPAM with optimal content, the water content of the mud is 72% at the bottom and 110% at the top, whereas it is 43% and 149%, respectively, in the natural sedimentation state. For geotextile 2, after adding CPAM with optimal content, the water content of the mud is 63% at the bottom and 124% at the top, whereas it is 46% and 143%, respectively, in the natural sedimentation state. The observed differences in final water content distribution can be attributed to the fabric’s properties and how they interact with the flocs. Geotextile 2, with a higher permeability, allows for better drainage conditions, leading to lower water content at the top of the sediment column. At the same time, after flocculant addition, the difference in water content in the vertical direction of the sedimentary soil is more minor, and the water content of each layer is comparable. The formation of flocs reduces the availability of free water that can be encapsulated within the sediment structure. Consequently, the use of flocculants leads to a more consistent water content distribution throughout the sediment column, facilitating uniform dewatering from the bottom to the top.

3.6. Dry Density Analysis at Final States

Figure 10 shows the vertical distribution curve of mud dry density when sedimentation is complete. It is indicated that the greater the distance from the bottom geotextile, the lower the dry density of the mud. Analogous to the vertical distribution of the final water content of the mud, the variation in vertical dry density across different sedimentary layers diminishes after flocculant addition.

For geotextile 1, the addition of CPAM results in a dry density of 1.59 g/cm3 at the bottom and 1.45 g/cm3 at the top, compared to 1.67 and 1.32 g/cm3, respectively, in its natural state. For geotextile 2, these values are 1.62 and 1.47 g/cm3 after the treatment with CAPM under its optimal concentration, vs. 1.66 and 1.34 g/cm3 in its natural state. This implies that while the flocculant promotes a more consistent sediment structure, the type and concentration of the flocculant do not significantly alter the dry density curve.

The addition of flocculants causes sludge particles to aggregate into larger flocs. These flocs bond together to form a cohesive structure that settles downward. Due to the relatively uniform pore sizes between the sediment layers, there is a comparable dry density across the mud layers. Furthermore, as shown in

Figure 10, the type and concentration of the flocculants do not significantly influence the dry density of the sedimented soil, suggesting. This implies that while the flocculant promotes a more consistent sediment structure, the type and concentration of the flocculant do not significantly alter the dry density profile.

3.7. Micromorphology Analysis of the Final State Slurries with SEM

The SEM images of the final state slurries treated with different addition amounts (0 mg/L, 100 mg/L, 250 mg/L) of NPAM are shown in

Figure 11. The particles of the original slurry are dispersive and form a condensed structure after filtration, whereas those treated with NPAM are in floc formation, as shown in

Figure 11g–i. The absorption bridging becomes more pronounced as the level of added (additional) NPAM rises, fine and dispersed slurry particles consolidating into larger flocs with more NPAM chains simultaneously absorbing onto multiple slurry particles. For the final state slurry with 250 mg/L NPAM, the medium particle size of flocs ranges between 10–20 μm, compared to the original slurry the medium size of discreet particles of about 5 μm, which is in good accord with the particle distribution curve shown in

Figure 8a.

Additionally, the addition of NPAM also exerts significant impacts on the micromorphological structures of final state slurries. With the increment of NPAM Addition amount, the surface roughness of the final sate slurries rises significantly, as shown in

Figure 11d–f. Fine particles in the slurry attach to the surface of other particles under the addition of NPAM and form larger flocs. At a NPAM addition level of 250 mg/L, numerous voids are observed between flocs and large particles, as shown in

Figure 11f, which increases the actual cross-sectional area for the percolation of slurry, thereby improving its permeability. This explains the increase in filtration rate with the increment of NPAM addition in

Figure 7a,b.