Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump

Abstract

:1. Introduction

2. Numerical Simulation

2.1. Boundary Condition Setting

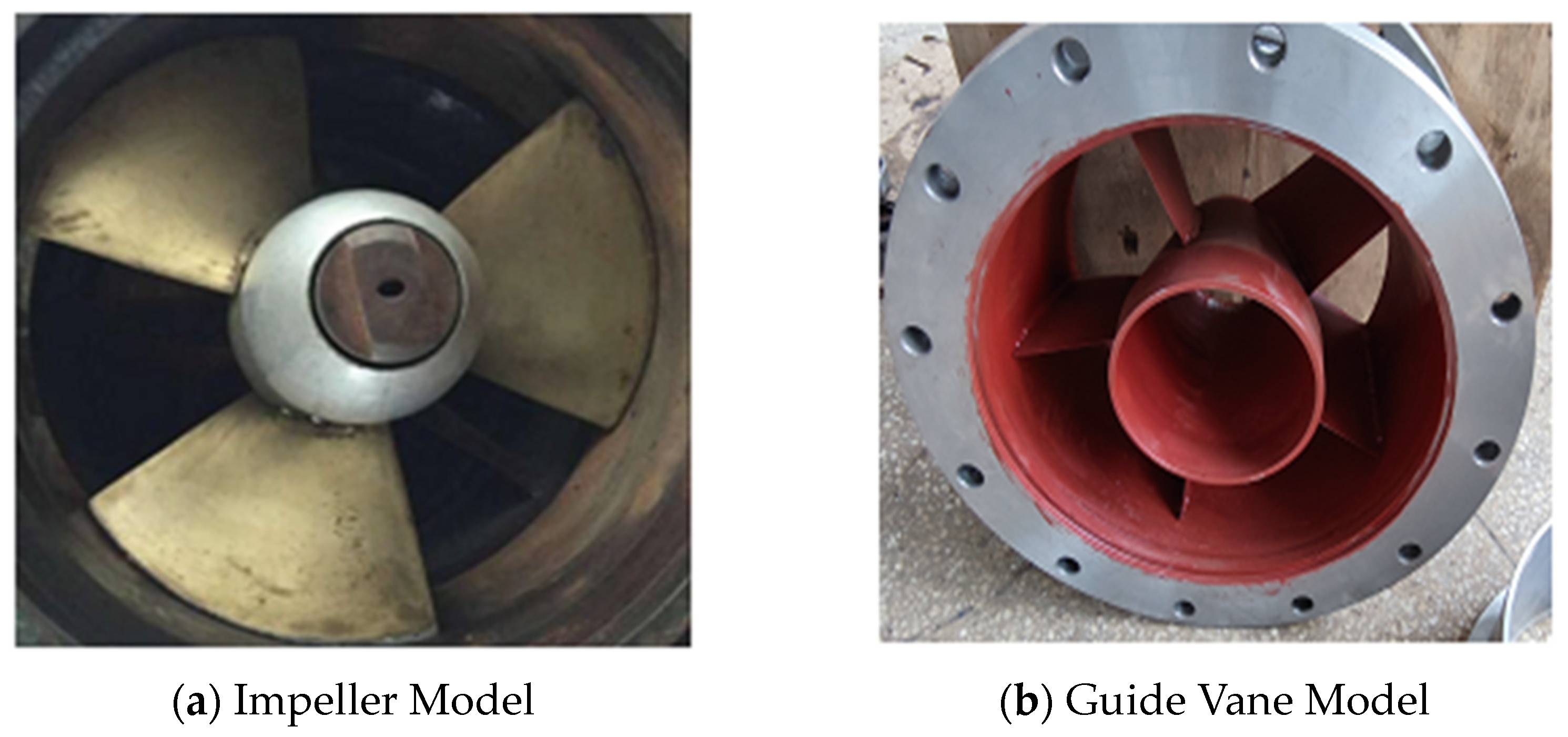

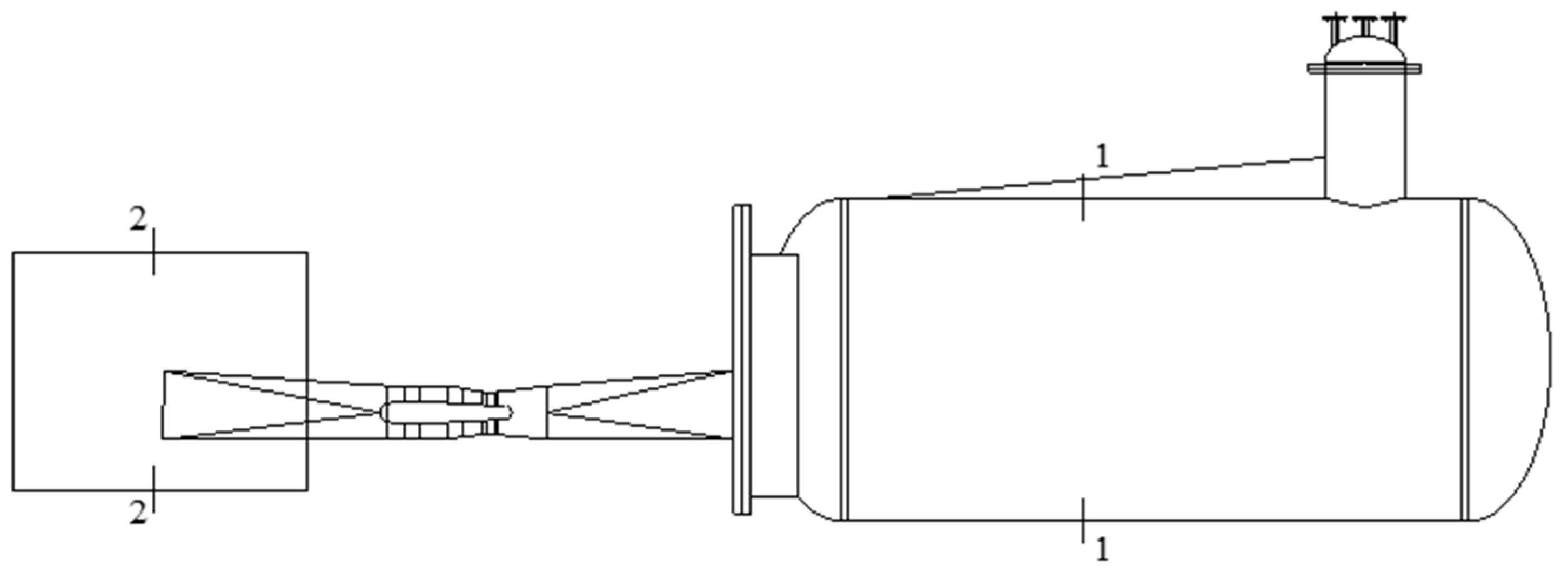

2.2. Computational Domain Modeling and Meshing

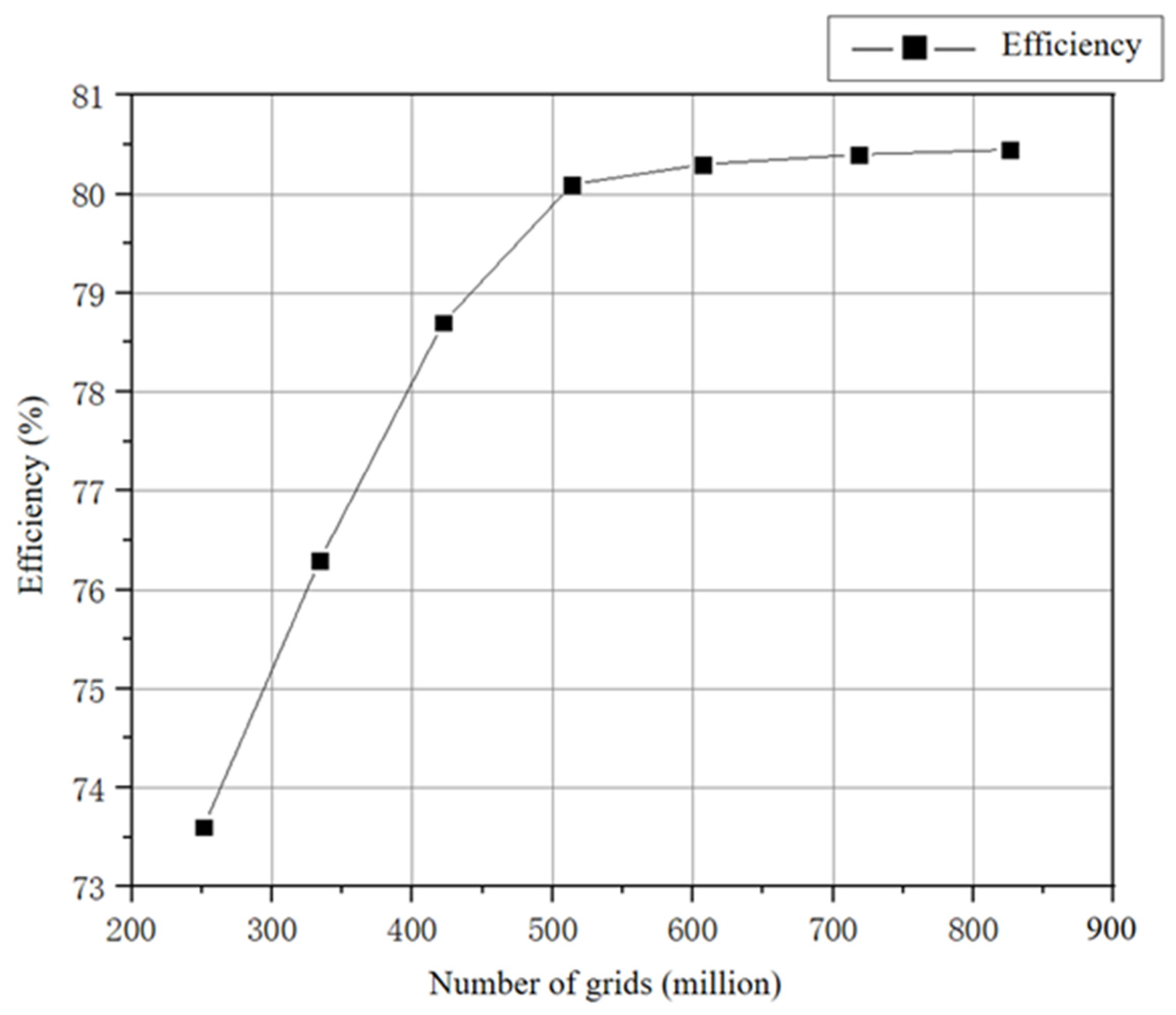

2.3. Grid-Independent Analysis

3. Model Test

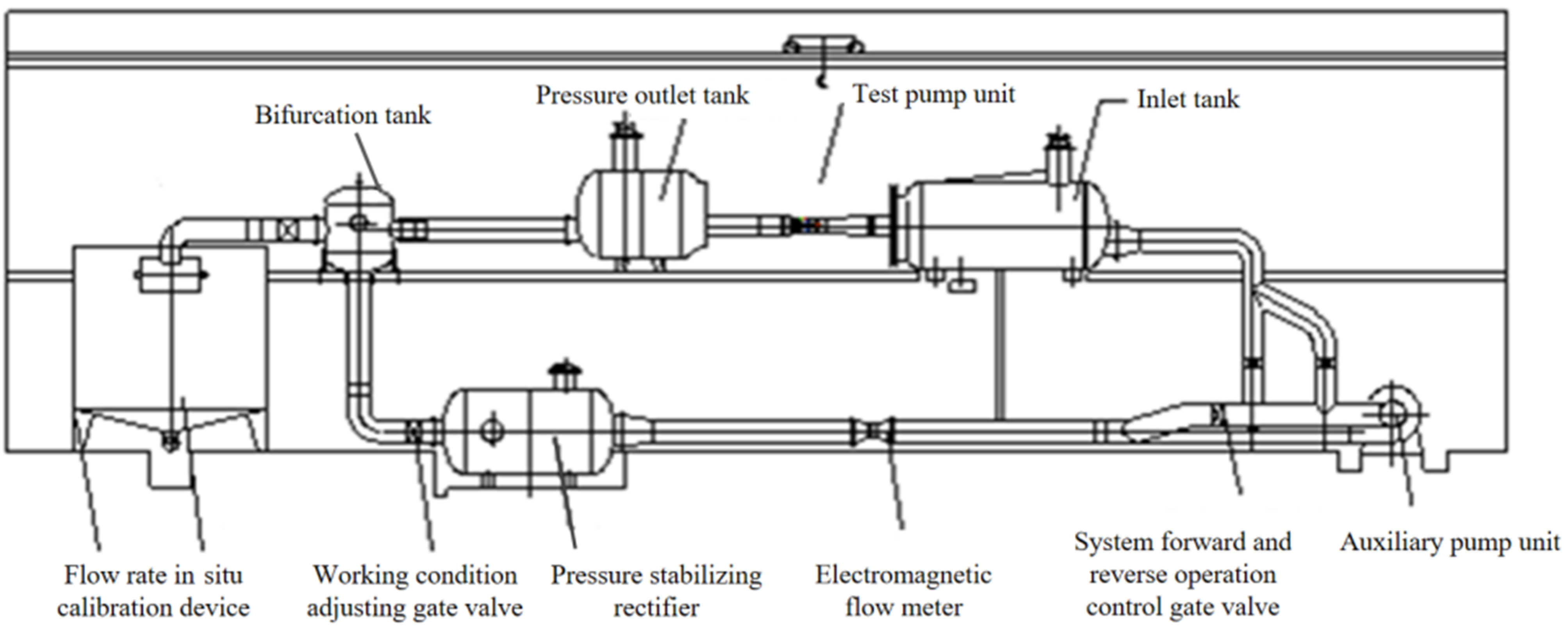

3.1. Model Test System

3.2. Main Parameters of Water Pump

3.3. Test Methods

- (1)

- Test Speed:

- (2)

- Head Measurement:

- (3)

- Flow Measurement:

- (4)

- Shaft Power Measurement:

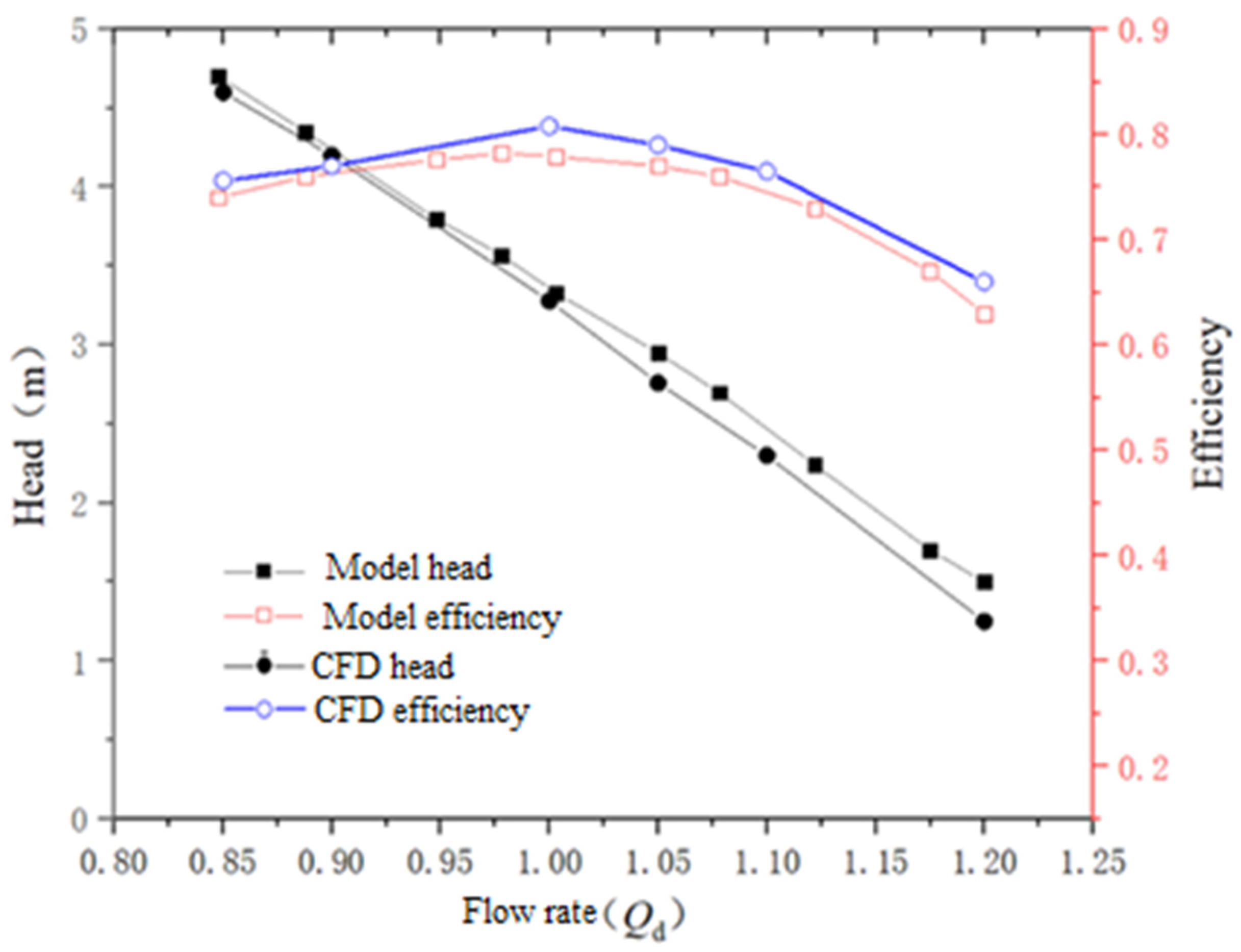

4. Comparative Analysis of Results

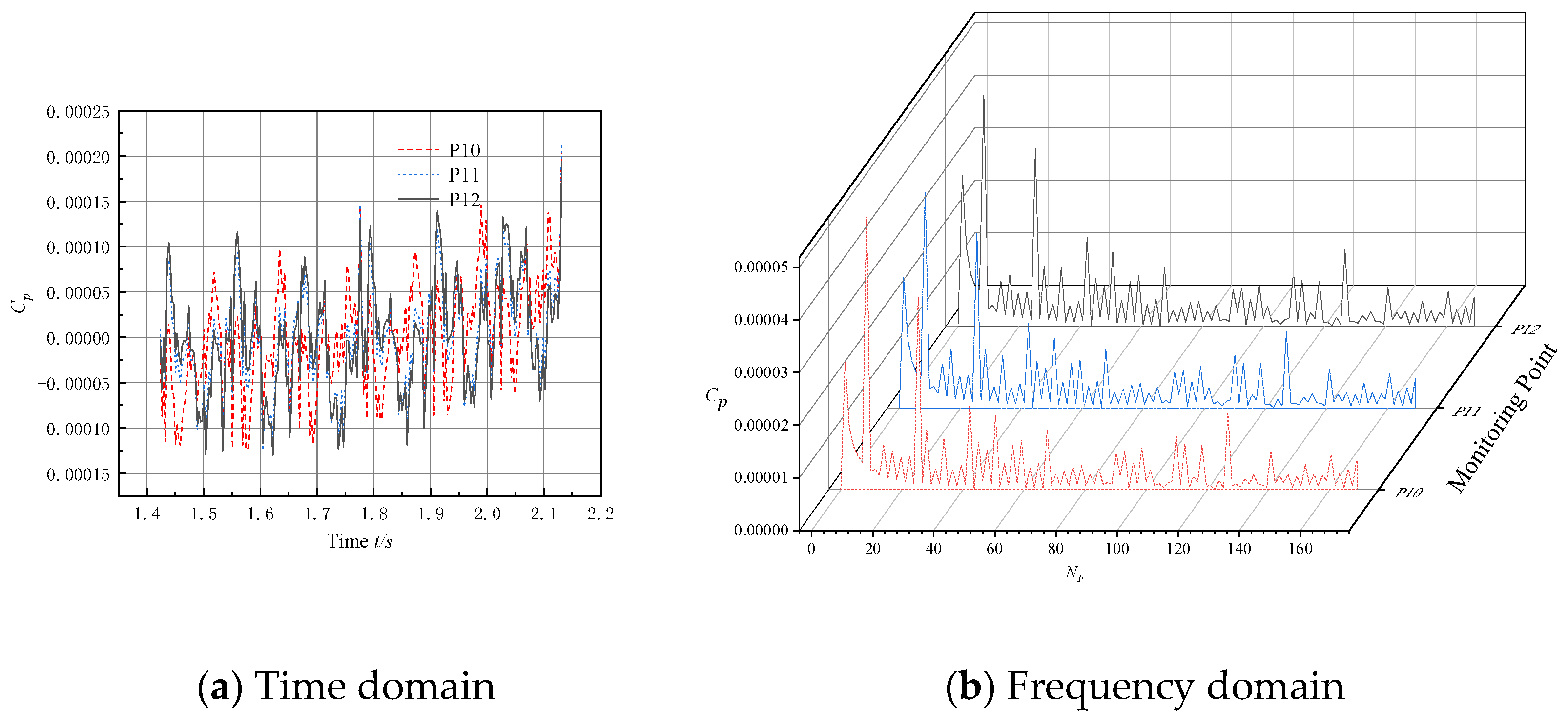

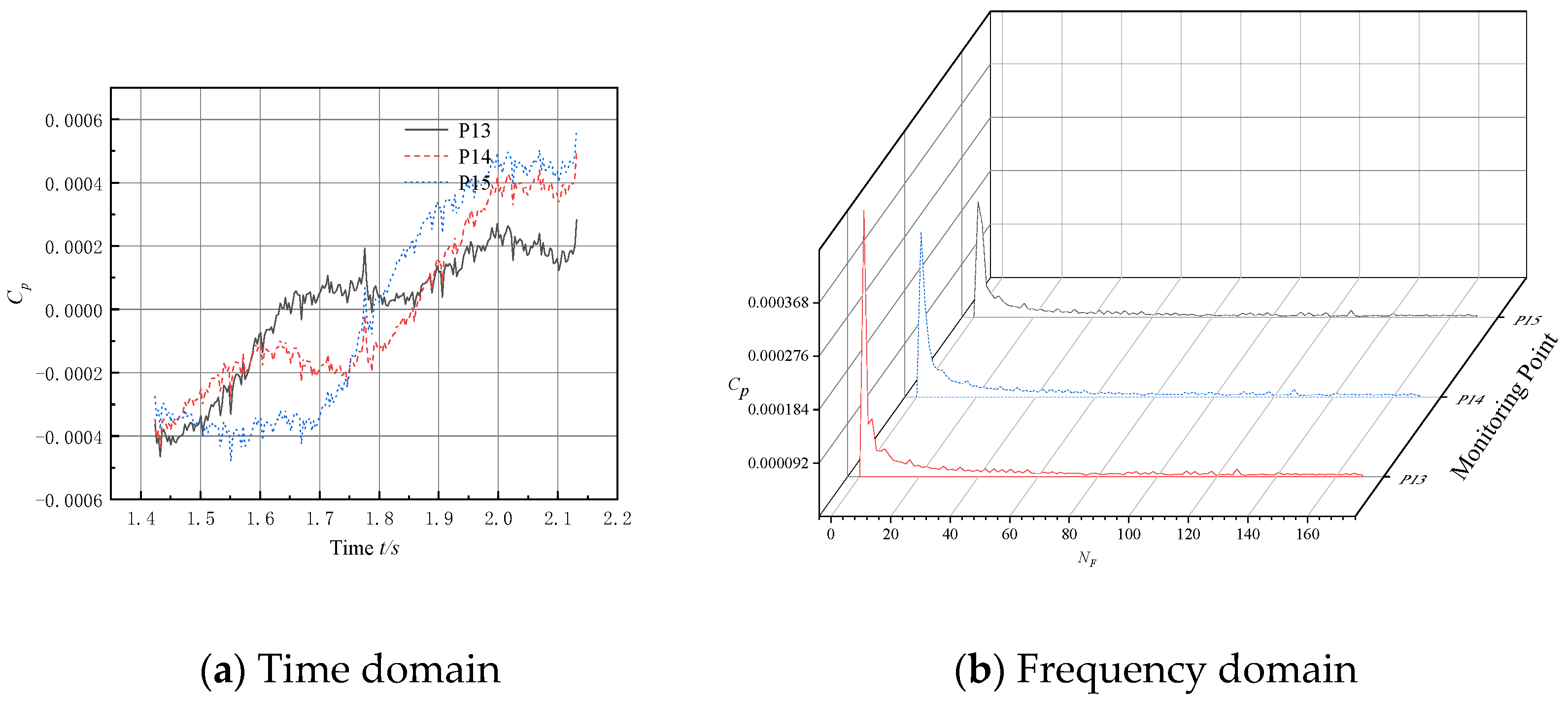

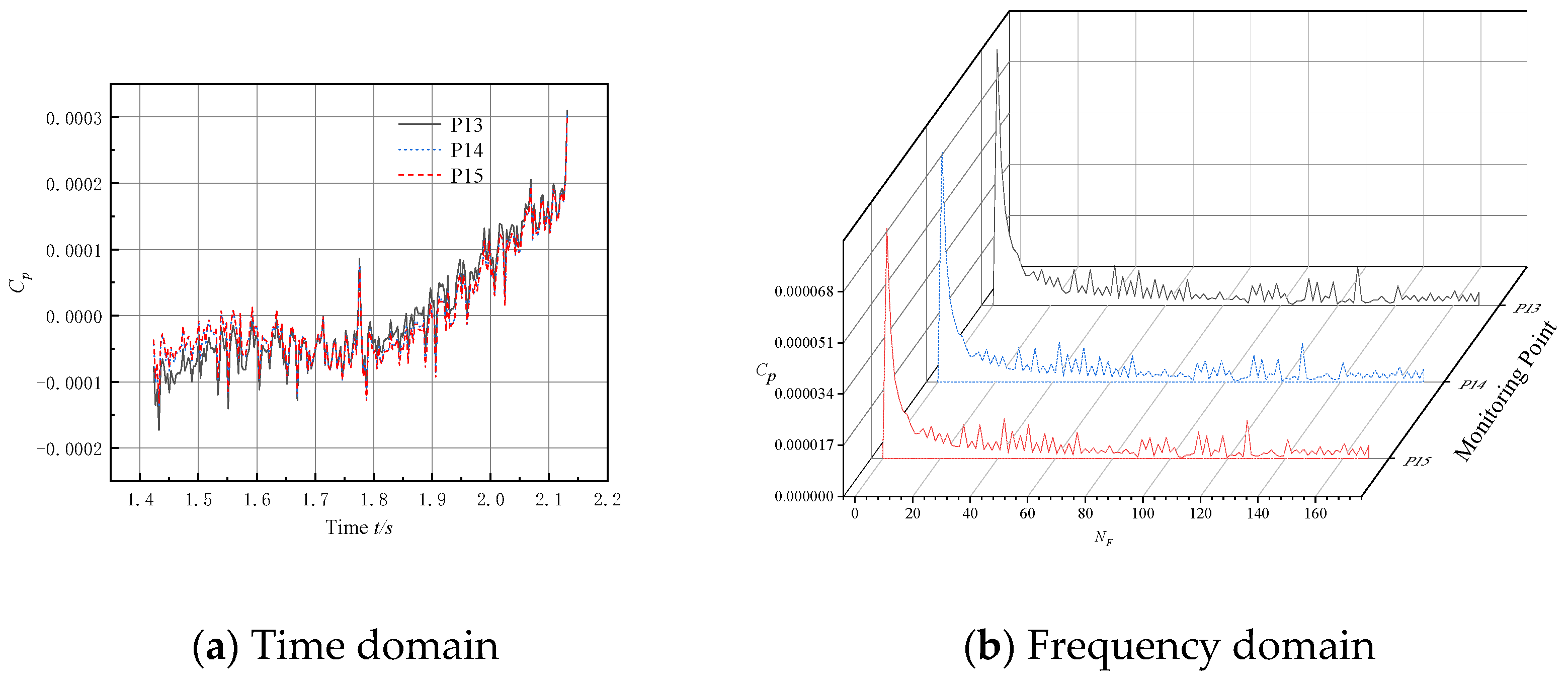

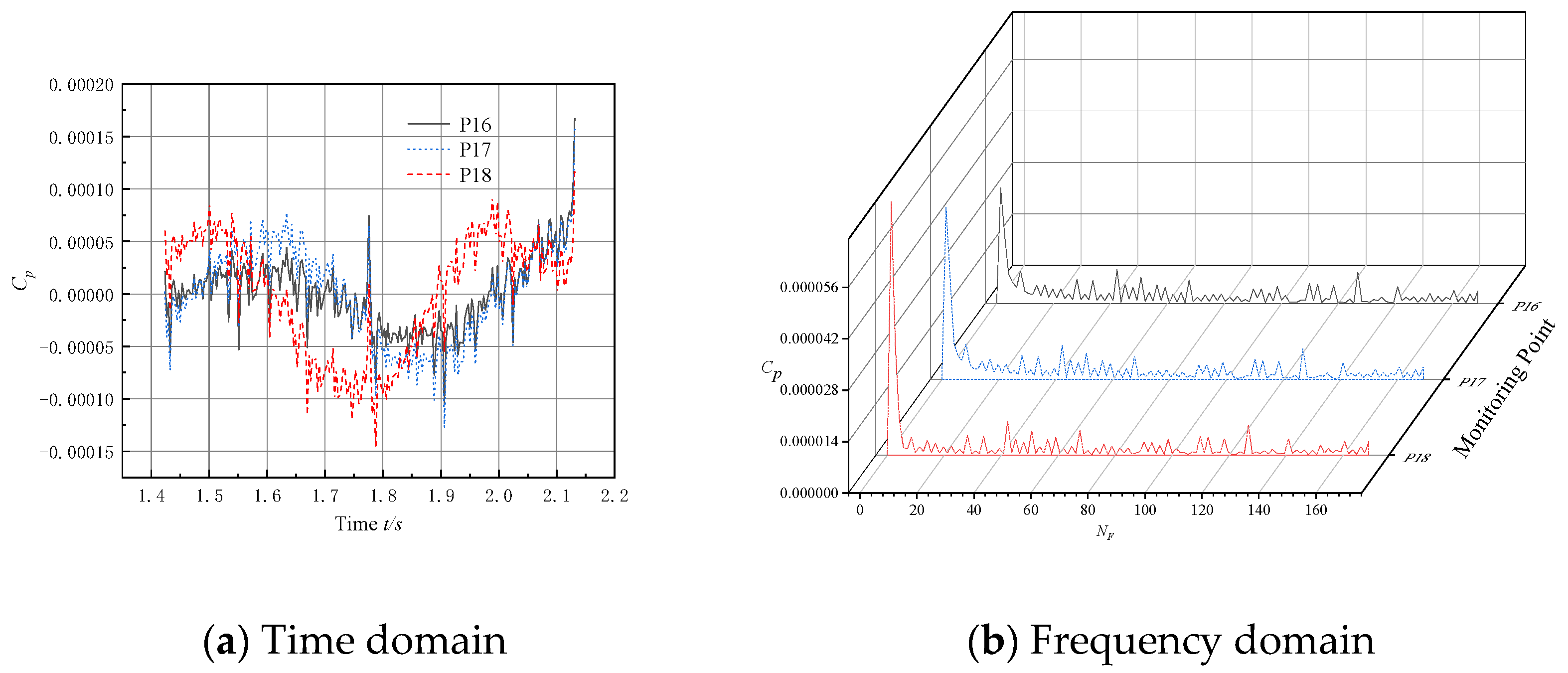

5. Pressure Pulsation Analysis of the Bulb Body

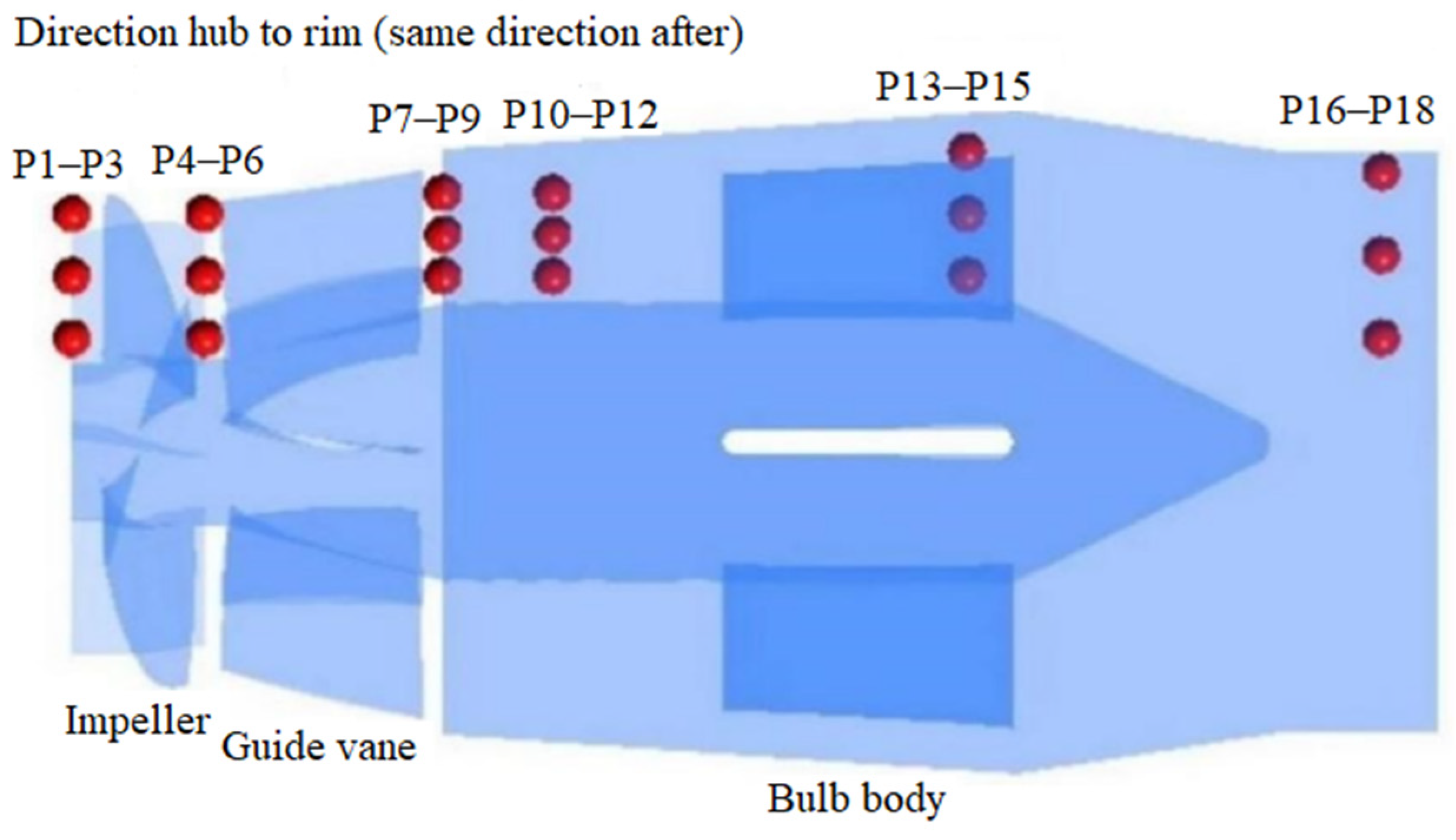

5.1. Layout of Monitoring Points

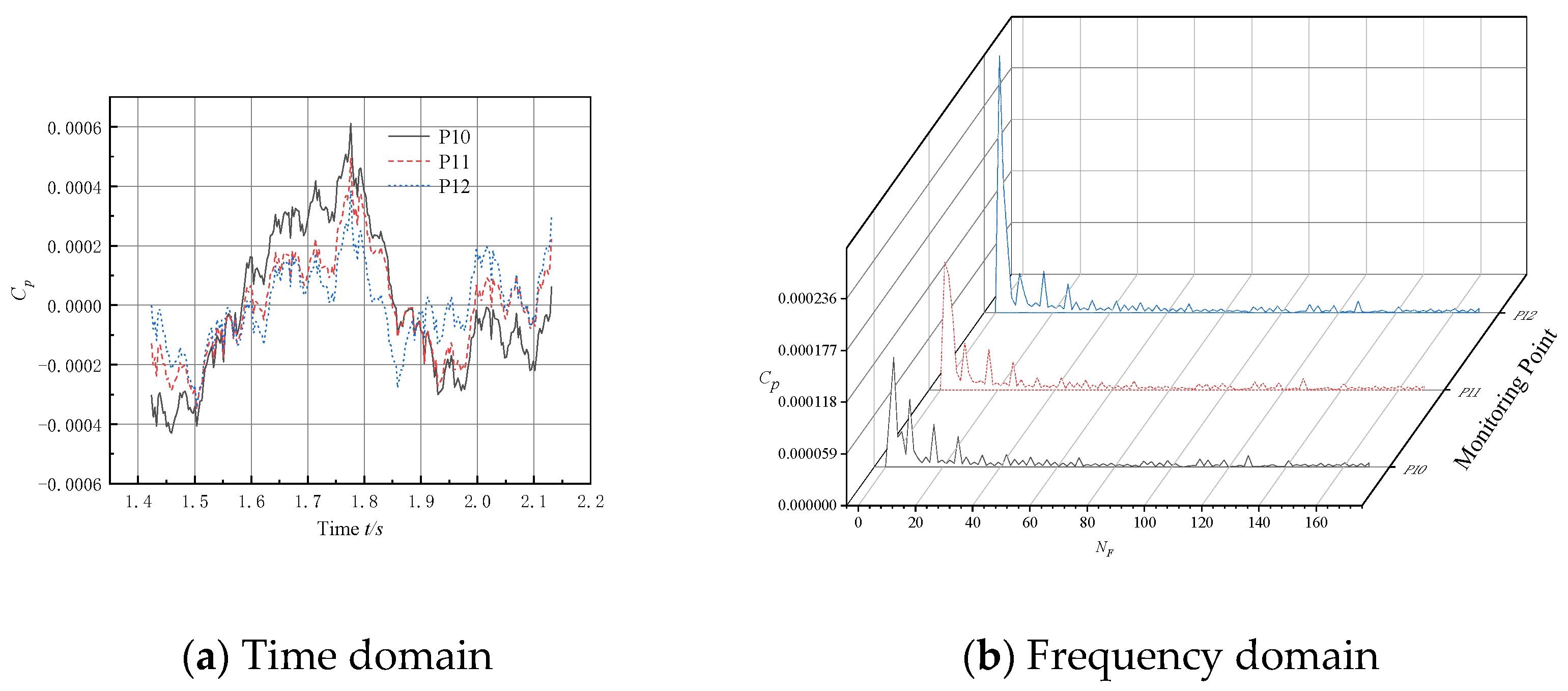

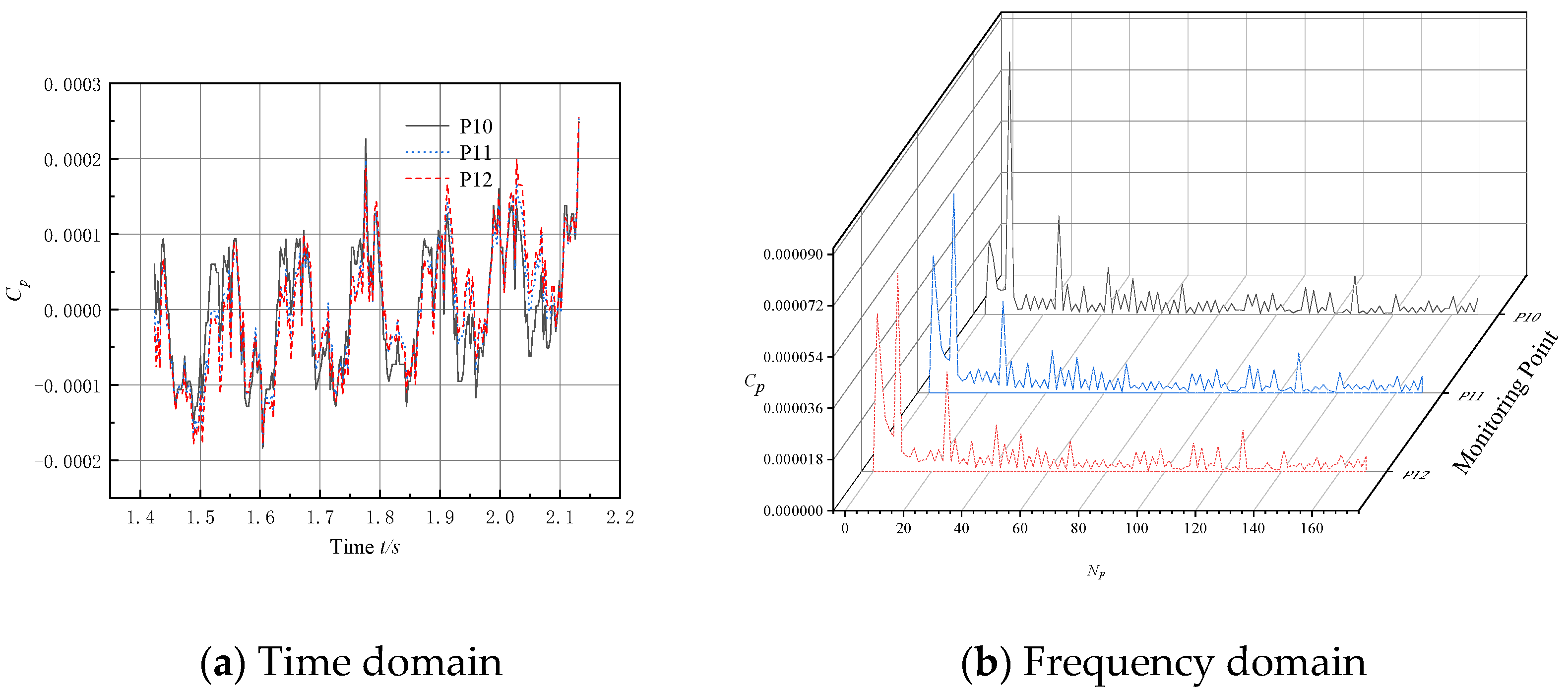

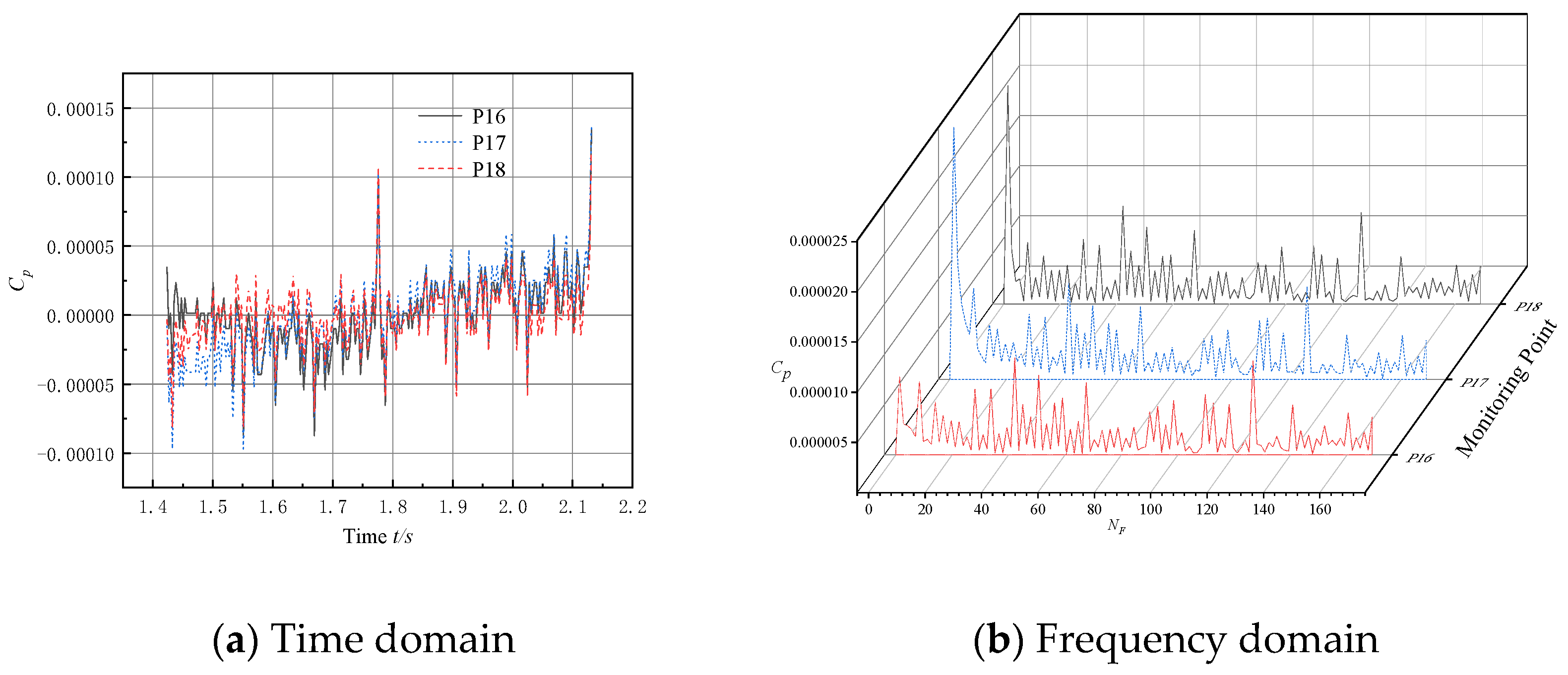

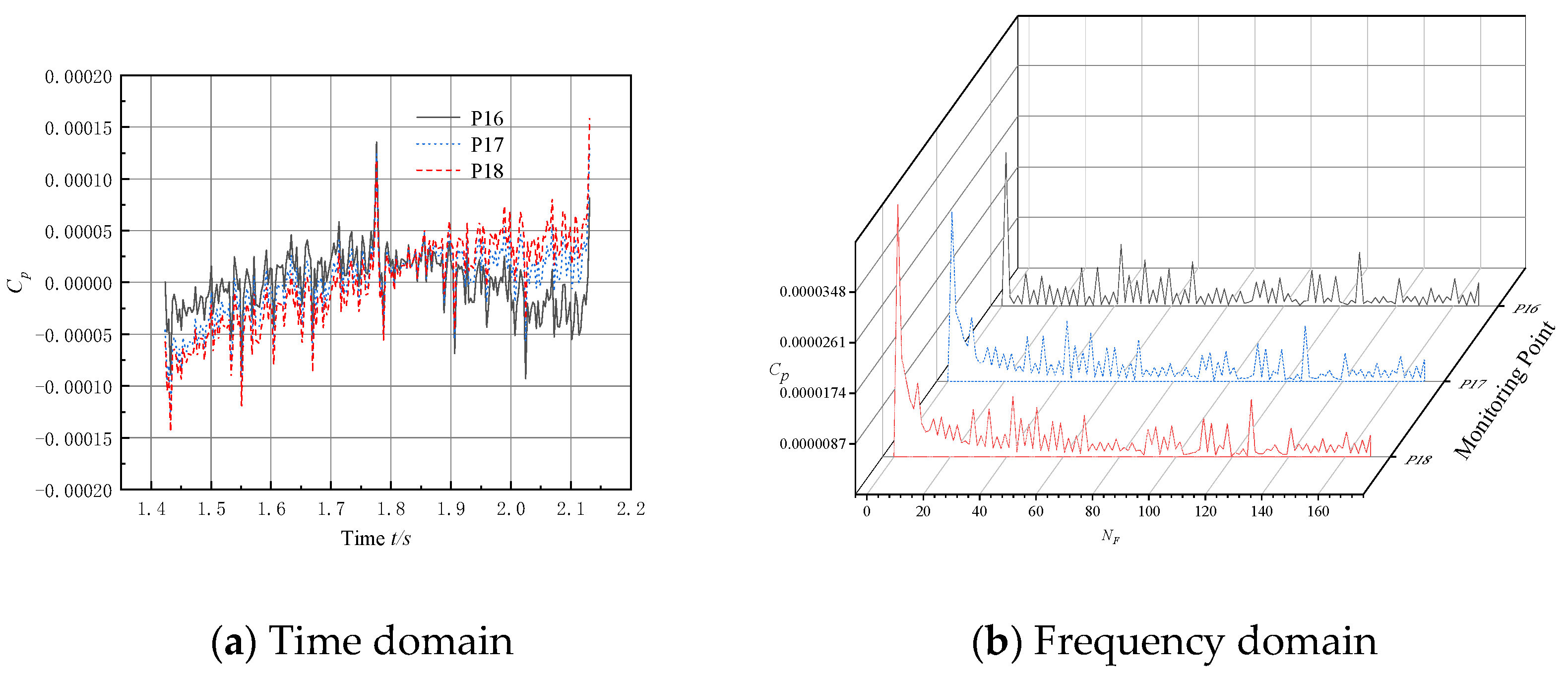

5.2. Analysis of Pulsation Characteristics in the Bulb Body Section

6. Summary

- (1)

- The intensity of the pressure pulsation at the monitoring point on the bulb body is significantly lower compared to the pump section, while the amplitude of the pressure pulsation at the outlet section of the bulb body is significantly lower than that at the inlet section. It is shown that the bulb body support improves the flow field structure and reduces the pressure pulsation intensity of the fluid, thus validating the need to install bulb body components in submersible tubular pumps.

- (2)

- The simulation results of efficiency and head, based on six selected operating conditions, are in good agreement with the experimental model results, indicating the accuracy of numerical simulation on the submersible tubular pump. It is necessary and credible to predict the pump’s external characteristics and internal flow in advance of the pump design process.

- (3)

- The peaks of the two efficiency curves are located near the rated flow condition (1.0 Qd), which indicates that the performance curve of this pump is very good and is exactly as expected. It is shown that the scaling effect of the experimental model of the pump does not affect the change law of the pump’s external characteristics, despite the 7.67-fold reduction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, L.; Yan, W. A fluid mechanical design based on CFD method. J. Heilongjiang Inst. Technol. 2021, 35, 28–32. [Google Scholar]

- Jiang, D.; Yang, F.; Lu, M.; Tang, F.; LYU, Y. Numerical and experimental analysis of flow and hydraulic noise in conduit of a vertical axial-flow pump device. J. Drain. Irrig. Mach. Eng. 2023, 41, 1007–1014. [Google Scholar]

- Ai, Y.; Mao, Y.; Liu, Y.; Tan, X.; Su, S. Simulation optimization and experiment for low flow-resistance mixed-flow pump of artesian water circulation system in marine ship. J. Drain. Irrig. Mach. Eng. 2023, 41, 999–1006. [Google Scholar]

- Gu, Y.; Sun, H.; Wang, C.; Lu, R.; Liu, B.; Ge, J. Effect of trimmed rear shroud on performance and axial thrust of multi-stage centrifugal pump with emphasis on visualizing flow losses. J. Fluids Eng. 2024, 146, 011204. [Google Scholar] [CrossRef]

- Wang, Y.; Xiong, W.; Ding, Z.; Pi, Q.; Yuan, X.; Liu, H.; Li, M. Analysis of water hammer characteristics in pressurized pipeline based on CFD. J. Drain. Irrig. Mach. Eng. 2023, 41, 1156–1162. [Google Scholar]

- Jiang, X.; Zeng, J.; Huang, H. Application and Development of CFD Technology in Fluid Machinery. Light Ind. Mach. 2014, 32, 108–111. [Google Scholar]

- Zhang, X.; Liu, C.; Rong, Y.; Feng, X.; Fu, T.; Sun, Y. Numerical simulation and experimental verification of forward feed array diaphragm rectifier for multi-unit pumping station. J. Drain. Irrig. Mach. Eng. 2022, 41, 378–384. [Google Scholar]

- Zhang, R.; Zhu, F.; Liu, X.; Liang, Y. Performances and control mode for bulb tublar pumps with VFDs. J. Drain. Irrig. Mach. Eng. 2022, 40, 136–143. [Google Scholar]

- Liu, H.; Ding, J. Numerical simulation of hydraulic performance and flow pattern of low-lift bulb tubular pump. Yangtze River 2017, 48, 97–100. [Google Scholar]

- Dai, J.; Dai, Q.; Wang, J. Effect of Diffuser Blade Position on Hydraulic Performance of Bulb Tubular Pump. Water Resour. Power 2017, 35, 168–171. [Google Scholar]

- Dai, J.; Dai, Q.; Liang, H.; Wang, W.; Li, H.; Guo, Z. Numerical simulation of saddle interval of post-positional bulb tubular pump. Yangtze River 2017, 48, 83–88. [Google Scholar]

- Jin, Y.; Liang, H.; Liu, C.; Zhou, J. Numerical simulation of the internal flow of prepositive bulb tubular pumping system. J. Yangzhou Univ. Nat. Sci. Ed. 2013, 16, 71–74. [Google Scholar]

- Dai, Q.; Liang, H.; Meng, X.; Wang, W. Study on the optimization of bulb tubular pump system in Huaian 3rd station. Jiangsu Water Resour. 2016, 38–41+53. [Google Scholar]

- Liang, H.; Dai, Q.; Hua, X.; Wang, H. Optimization design and experimental research on low-speed high-efficiency tubular pump. Yangtze River 2018, 49, 84–89. [Google Scholar]

- Vasel-Be-Hagh, A.R.; Carriveau, R.; Ting, D.S.-K. A balloon bursting underwater. J. Fluid Mech. 2015, 769, 522–540. [Google Scholar] [CrossRef]

- Wang, X.; Zhai, L.; Tang, F.; Shi, L.; Sun, Z.; Zhang, W.; Liu, H. Influence of different guide vane parameters on hydraulic performance of box-culvert axial-flow pump. J. Drain. Irrig. Mach. Eng. 2022, 27, 440–446. [Google Scholar]

- Chen, Y.; Tang, F.; Zhang, X.; Wang, L.; Liu, Y.; Dai, J.; Wang, H. Modification and experimental verification of guide vanes hydraulic model for large vertical axial-flow pumps. J. Drain. Irrig. Mach. Eng. 2023, 41, 655–662. [Google Scholar]

- Dijksman, J.F. Hydrodynamics of small tubular pumps. J. Fluid Mech. 1984, 139, 173–191. [Google Scholar] [CrossRef]

- Wang, W.; Dai, Y.; Tan, X.; Wu, D.; Wang, L.; Chen, D. Unsteady flow and vibration characteristics in micro high-speed fuel pump. J. Drain. Irrig. Mach. Eng. 2023, 41, 1096–1103. [Google Scholar]

- Liu, C. Researches and Developments of Axial-flow Pump System. Trans. Chin. Soc. Agric. Mach. 2015, 46, 49–59. [Google Scholar]

- Zhang, R.; Zhang, J.; Guo, G. Influence of blade shape of liquid-ring pump on inlet reverse flow and its hydraulic characteristics. J. Drain. Irrig. Mach. Eng. 2023, 41, 865–872. [Google Scholar]

- Li, Y.; You, X.; Xu, H.; Zheng, F. Optimization design of compound impeller based on orthogonal experiment. J. Drain. Irrig. Mach. 2023, 41, 556–561. [Google Scholar]

- Zhang, R.; Chen, H. Numerical simulation and flow diagnosis of axial-flow pump at part-load condition. Int. J. Turbo Jet-Engines 2012, 29, 1–7. [Google Scholar]

- Kim, J.H.; Ahn, H.J.; Kim, K.Y. High-efficiency design of a mixed-flow pump. Sci. China Ser. E Technol. Sci. 2010, 53, 24–27. [Google Scholar] [CrossRef]

| Inlet Runner Grid | Impeller | Guide Vane | Bulb Body | Outflow Runner |

| 693,952 | 1,422,252 | 1,366,560 | 1,151,179 | 506,016 |

| Measurement Items | Measuring Instruments Equipment Name | Model | Scope of Work | Calibration Accuracy | Calibration Time |

|---|---|---|---|---|---|

| Head | Differential Pressure Transmitter | EJA110A | 0~200 kPa | ±0.1% | 10 August 2020 |

| Flow rate | Electromagnetic flow meter | E-mag | DN400 mm | ±0.2% | 2 March 2021 |

| Torque Rotation speed | Rotational speed and Torque sensor | JC2C | 200 N·m | ±0.1% | 8 August 2020 |

| Digital torque speed Algorithmic Indicator | TS-3200B | ||||

| Cavitation margin | Absolute Pressure Transmitter | EJA310A | 0~130 kPa | ±1% | 10 August 2020 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Chen, Z.; Li, L.; Wang, C.; Teng, K.; He, Q.; Zhou, J.; Li, S.; Cao, W.; Wang, X.; et al. Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump. Water 2024, 16, 789. https://doi.org/10.3390/w16050789

Wang J, Chen Z, Li L, Wang C, Teng K, He Q, Zhou J, Li S, Cao W, Wang X, et al. Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump. Water. 2024; 16(5):789. https://doi.org/10.3390/w16050789

Chicago/Turabian StyleWang, Jian, Ze Chen, Linghao Li, Chuan Wang, Kangle Teng, Qiang He, Jiren Zhou, Shanshan Li, Weidong Cao, Xiuli Wang, and et al. 2024. "Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump" Water 16, no. 5: 789. https://doi.org/10.3390/w16050789

APA StyleWang, J., Chen, Z., Li, L., Wang, C., Teng, K., He, Q., Zhou, J., Li, S., Cao, W., Wang, X., & Wang, H. (2024). Pressure Pulsation Characteristics on the Bulb Body of a Submersible Tubular Pump. Water, 16(5), 789. https://doi.org/10.3390/w16050789