Uncertainty of Preferences in the Assessment of Supply Chain Management Systems Using the PROMETHEE Method

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Selection of Evaluation Criteria for the Needs of SCM Systems

- Supplier management—a strategic method that allows companies to plan, manage and enhance their relationships with suppliers.

- Purchasing management—a business activity that allows businesses to manage the actions and relations that constitute the purchasing functions.

- Order management—a business process that entails receiving, tracking and completing customer orders.

- Customer relationship management—the strategies, methods and tools that businesses employ to satisfy, keep and acquire customers.

- Warehouse/inventory management—a variety of business tasks, such as predicting, ordering, receiving and allocating goods.

- Handling—transportation, protection and storage of materials and products during the production, warehousing, distribution stages.

- Transportation—transfer of commodities and goods from one point to another.

- Packaging—a process of preparing, enclosing and protecting products for distribution, storage, sale and usage.

- Insuring—a contract that protects resources and goods from a variety of dangers they may face during storage, production and transportation.

- Inspection and customs clearance—the process of checking and passing goods and products through customs at the point of entry or exit from a country.

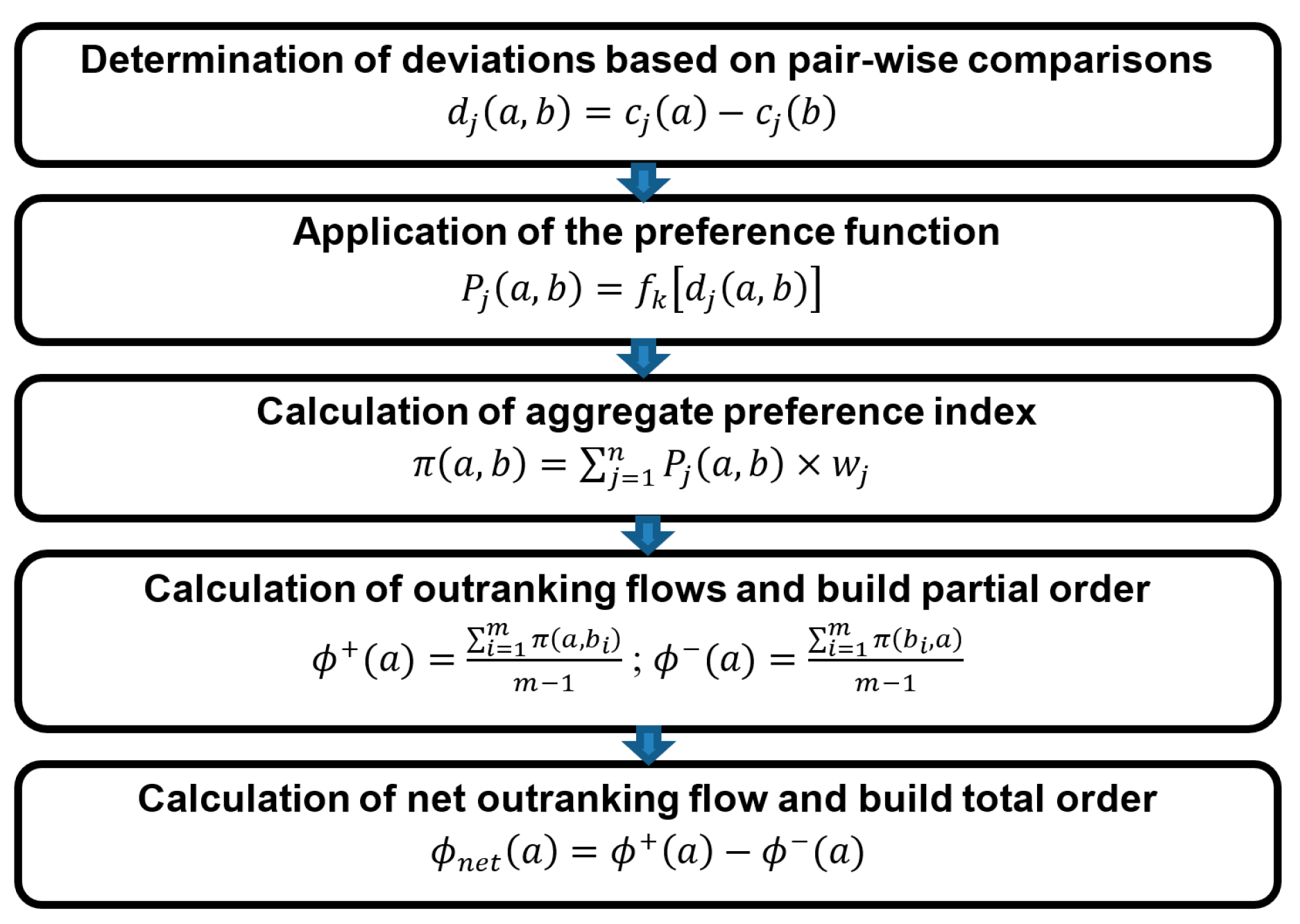

3.2. The PROMETHEE Method

- Determination of deviations based on pair-wise comparisons according to Formula (1):where denotes the difference between the evaluations of a and b on each criterion.

- Application of the preference function using the Formula (2):where denotes the preference of alternative a with regard to alternative b on each criterion, as a function F of [38]. The preference functions represented by F are described by the following Formulas:

- Usual (true) Criterion (3):

- U-shape Criterion (semi-criterion) (4):

- V-shape Criterion (pre-criterion) (5):

- Level Criterion (6):

- V-shape with indifference Criterion (pseudo-criterion) (7):

- Gaussian Criterion (8):where q, p, s are: q—indifference threshold, p—preference threshold, s—gaussian threshold, respectively [27].

- Calculation of an overall or global preference index based on Formula (9):where of a over b (from 0 to 1) is defined as the weighted sum for each criterion, and is the weight associated with j-th criterion.

- Calculation of outranking flows (the PROMETHEE I partial ranking) according to Formulas (10) and (11):where and denote the positive outranking flow and negative outranking flow for each alternative, respectively. Partial ranking is constructed using the following rules:

- alternatives and are indifferent when ,

- alternatives and are incomparable when or ,

- alternative is preferred over when or or [39].

- Calculation of net outranking flow (the PROMETHEE II full ranking) using Formula (12):where denotes the net outranking flow for each alternative. Full ranking is constructed using the following rules:

- alternatives and are indifferent when ,

- alternative is preferred over when [39].

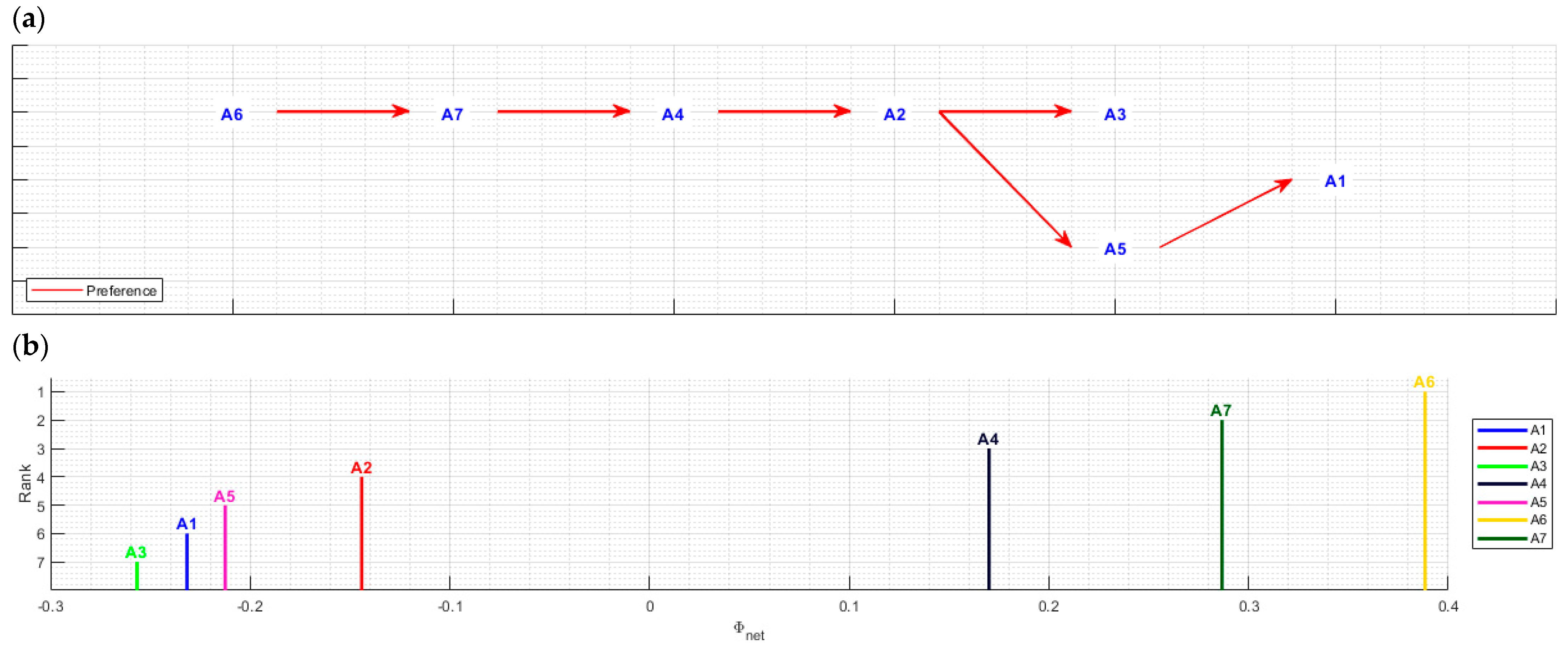

4. Results

- A1—Comarch ERP XL,

- A2—Epicor ERP 10,

- A3—Infor M3,

- A4—JD Edwards EnterpriseOne,

- A5—Microsoft Dynamics 365 Business Central Essentials,

- A6—Oracle E-Business Suite,

- A7—SAP Business One.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gunawan, D.; Hariyati, R.T.S.; Afifah, E.; Afriani, T. The Relationship between the Roles and Management Function of the Head Nurse and Handover Implementation. Enferm. Clin. 2021, 31, S157–S160. [Google Scholar] [CrossRef]

- Taheri, S.; Salem, M.; Yuan, J.-S. Leveraging Image Representation of Network Traffic Data and Transfer Learning in Botnet Detection. Big Data Cogn. Comput. 2018, 2, 37. [Google Scholar] [CrossRef] [Green Version]

- Katoch, R. IoT Research in Supply Chain Management and Logistics: A Bibliometric Analysis Using Vosviewer Software. Mater. Today Proc. 2021, 56, 2505–2515. [Google Scholar] [CrossRef]

- Akkermans, H.A.; Bogerd, P.; Yücesan, E.; van Wassenhove, L.N. The Impact of ERP on Supply Chain Management: Exploratory Findings from a European Delphi Study. Eur. J. Oper. Res. 2003, 146, 284–301. [Google Scholar] [CrossRef] [Green Version]

- Antunes, C.H.; Henriques, C.O. Multi-Objective Optimization and Multi-Criteria Analysis Models and Methods for Problems in the Energy Sector. In Multiple Criteria Decision Analysis; Greco, S., Ehrgott, M., Figueira, J.R., Eds.; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2016; pp. 1067–1165. ISBN 978-1-4939-3093-7. [Google Scholar]

- Wei, C.-C.; Chien, C.-F.; Wang, M.-J.J. An AHP-Based Approach to ERP System Selection. Int. J. Prod. Econ. 2005, 96, 47–62. [Google Scholar] [CrossRef]

- Cebeci, U. Fuzzy AHP-Based Decision Support System for Selecting ERP Systems in Textile Industry by Using Balanced Scorecard. Expert Syst. Appl. 2009, 36, 8900–8909. [Google Scholar] [CrossRef]

- Gürbüz, T.; Alptekin, S.E.; Işıklar Alptekin, G. A Hybrid MCDM Methodology for ERP Selection Problem with Interacting Criteria. Decis. Support Syst. 2012, 54, 206–214. [Google Scholar] [CrossRef]

- Baki, B.; Çakar, K. Determining the ERP Package-selecting Criteria: The Case of Turkish Manufacturing Companies. Bus. Process Manag. J. 2005, 11, 75–86. [Google Scholar] [CrossRef]

- Salmeron, J.L.; Lopez, C. A Multicriteria Approach for Risks Assessment in ERP Maintenance. J. Syst. Softw. 2010, 83, 1941–1953. [Google Scholar] [CrossRef]

- Razmi, J.; Sangari, M.S.; Ghodsi, R. Developing a Practical Framework for ERP Readiness Assessment Using Fuzzy Analytic Network Process. Adv. Eng. Softw. 2009, 40, 1168–1178. [Google Scholar] [CrossRef]

- Xu, L. The Evaluation of ERP Sandtable Simulation Based on AHP. Phys. Procedia 2012, 33, 1924–1931. [Google Scholar] [CrossRef] [Green Version]

- Parthasarathy, S.; Sharma, S. Determining ERP Customization Choices Using Nominal Group Technique and Analytical Hierarchy Process. Comput. Ind. 2014, 65, 1009–1017. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Güler, M. A Combined Hesitant Fuzzy MCDM Approach for Supply Chain Analytics Tool Evaluation. Appl. Soft Comput. 2021, 112, 107812. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. Supply Chain Digitalization: An Integrated MCDM Approach for Inter-Organizational Information Systems Selection in an Electronic Supply Chain. Int. J. Inf. Manag. Data Insights 2021, 1, 100038. [Google Scholar] [CrossRef]

- Gaur, J.; Subramoniam, R.; Govindan, K.; Huisingh, D. Closed-Loop Supply Chain Management: From Conceptual to an Action Oriented Framework on Core Acquisition. J. Clean. Prod. 2017, 167, 1415–1424. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Gupta, R.; Dong, J. Multi-Criteria Evaluation of Real-Time Key Performance Indicators of Supply Chain with Consideration of Big Data Architecture. Comput. Ind. Eng. 2019, 128, 1076–1087. [Google Scholar] [CrossRef] [Green Version]

- Büyüközkan, G.; Güleryüz, S.; Karpak, B. A New Combined IF-DEMATEL and IF-ANP Approach for CRM Partner Evaluation. Int. J. Prod. Econ. 2017, 191, 194–206. [Google Scholar] [CrossRef]

- Öztayşi, B.; Kaya, T.; Kahraman, C. Performance Comparison Based on Customer Relationship Management Using Analytic Network Process. Expert Syst. Appl. 2011, 38, 9788–9798. [Google Scholar] [CrossRef]

- Meira, D.; Lopes, I.; Pires, C. Selection of Computerized Maintenance Management Systems to Meet Organizations’ Needs Using AHP. Procedia Manuf. 2020, 51, 1573–1580. [Google Scholar] [CrossRef]

- Yang, C.-H.; Hsu, W.; Wu, Y.-L. A Hybrid Multiple-Criteria Decision Portfolio with the Resource Constraints Model of a Smart Healthcare Management System for Public Medical Centers. Socio-Econ. Plan. Sci. 2022, 80, 101073. [Google Scholar] [CrossRef]

- Roy, B. Foreword. In Multicriteria Methodology for Decision Aiding; Roy, B., Ed.; Nonconvex Optimization and Its Applications; Springer: Boston, MA, USA, 1996; pp. XV–XX. ISBN 978-1-4757-2500-1. [Google Scholar]

- Roy, B. Decision-Aid and Decision-Making. Eur. J. Oper. Res. 1990, 45, 324–331. [Google Scholar] [CrossRef]

- Roy, B.; Figueira, J.R.; Almeida-Dias, J. Discriminating Thresholds as a Tool to Cope with Imperfect Knowledge in Multiple Criteria Decision Aiding: Theoretical Results and Practical Issues. Omega 2014, 43, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Figueira, J.R.; Mousseau, V.; Roy, B. ELECTRE Methods. In Multiple Criteria Decision Analysis; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2016; pp. 155–185. ISBN 978-1-4939-3093-7. [Google Scholar]

- Ziemba, P. NEAT F-PROMETHEE—A New Fuzzy Multiple Criteria Decision Making Method Based on the Adjustment of Mapping Trapezoidal Fuzzy Numbers. Expert Syst. Appl. 2018, 110, 363–380. [Google Scholar] [CrossRef]

- Brans, J.-P.; De Smet, Y. PROMETHEE Methods. In Multiple Criteria Decision Analysis: State of the Art Surveys; Greco, S., Ehrgott, M., Figueira, J.R., Eds.; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2016; pp. 187–219. ISBN 978-1-4939-3094-4. [Google Scholar]

- Polatidis, H.; Haralambopoulos, D.A.; Munda, G.; Vreeker, R. Selecting an Appropriate Multi-Criteria Decision Analysis Technique for Renewable Energy Planning. Energy Sources Part B Econ. Plan. Policy 2006, 1, 181–193. [Google Scholar] [CrossRef]

- Løken, E. Use of Multicriteria Decision Analysis Methods for Energy Planning Problems. Renew. Sustain. Energy Rev. 2007, 11, 1584–1595. [Google Scholar] [CrossRef]

- Al-Shemmeri, T.; Al-Kloub, B.; Pearman, A. Model Choice in Multicriteria Decision Aid. Eur. J. Oper. Res. 1997, 97, 550–560. [Google Scholar] [CrossRef]

- Haulder, N.; Kumar, A.; Shiwakoti, N. An Analysis of Core Functions Offered by Software Packages Aimed at the Supply Chain Management Software Market. Comput. Ind. Eng. 2019, 138, 106116. [Google Scholar] [CrossRef]

- Gunduz, M.A.; Demir, S.; Paksoy, T. Matching Functions of Supply Chain Management with Smart and Sustainable Tools: A Novel Hybrid BWM-QFD Based Method. Comput. Ind. Eng. 2021, 162, 107676. [Google Scholar] [CrossRef]

- Smith, J.R.; Yost, J.; Lopez, H. Electronic Data Interchange and Enterprise Resource Planning Technology in Supply Chain Contracts. Comput. Ind. Eng. 2020, 142, 106330. [Google Scholar] [CrossRef] [Green Version]

- Mojský, V.; Kolarovszki, P. Simulation Model of Logistic Chain in GS1 Slovakia Laboratory. Transp. Res. Procedia 2019, 40, 389–396. [Google Scholar] [CrossRef]

- Syed, N.F.; Shah, S.W.; Trujillo-Rasua, R.; Doss, R. Traceability in Supply Chains: A Cyber Security Analysis. Comput. Secur. 2022, 112, 102536. [Google Scholar] [CrossRef]

- Ziemba, P.; Wątróbski, J.; Karczmarczyk, A.; Jankowski, J.; Wolski, W. Integrated Approach to E-Commerce Websites Evaluation with the Use of Surveys and Eye Tracking Based Experiments. In Proceedings of the 2017 Federated Conference on Computer Science and Information Systems (FedCSIS), Prague, Czech Republic, 3–6 September 2017; pp. 1019–1030. [Google Scholar]

- Behzadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. PROMETHEE: A Comprehensive Literature Review on Methodologies and Applications. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Ziemba, P. Multi-Criteria Stochastic Selection of Electric Vehicles for the Sustainable Development of Local Government and State Administration Units in Poland. Energies 2020, 13, 6299. [Google Scholar] [CrossRef]

- Ziemba, P. Uncertain Multi-Criteria Analysis of Offshore Wind Farms Projects Investments—Case Study of the Polish Economic Zone of the Baltic Sea. Appl. Energy 2022, 309, 118232. [Google Scholar] [CrossRef]

- Fong, P.S.-W.; Choi, S.K.-Y. Final Contractor Selection Using the Analytical Hierarchy Process. Constr. Manag. Econ. 2000, 18, 547–557. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process, 2nd ed.; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2012; ISBN 978-1-4614-3596-9. [Google Scholar]

- Whitaker, R. Criticisms of the Analytic Hierarchy Process: Why They Often Make No Sense. Math. Comput. Model. 2007, 46, 948–961. [Google Scholar] [CrossRef]

- Ziemba, P.; Wątróbski, J.; Jankowski, J.; Piwowarski, M. Research on the Properties of the AHP in the Environment of Inaccurate Expert Evaluations. In Proceedings of the Selected Issues in Experimental Economics; Nermend, K., Łatuszyńska, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 227–243. [Google Scholar]

- Guitouni, A.; Martel, J.-M. Tentative Guidelines to Help Choosing an Appropriate MCDA Method. Eur. J. Oper. Res. 1998, 109, 501–521. [Google Scholar] [CrossRef]

- Ziemba, P.; Becker, J. Analysis of the Digital Divide Using Fuzzy Forecasting. Symmetry 2019, 11, 166. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Garg, H. Algorithm for Multiple Attribute Decision-Making with Interactive Archimedean Norm Operations under Pythagorean Fuzzy Uncertainty. Int. J. Comput. Intell. Syst. 2020, 14, 503–527. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Wang, J.; Li, J.; Li, L. Extended TODIM-PROMETHEE II Method with Hesitant Probabilistic Information for Solving Potential Risk Evaluation Problems of Water Resource Carrying Capacity. Expert Syst. 2021, 38, e12681. [Google Scholar] [CrossRef]

- Samanlioglu, F.; Ayağ, Z. Concept Selection with Hesitant Fuzzy ANP-PROMETHEE II. J. Ind. Prod. Eng. 2021, 38, 547–560. [Google Scholar] [CrossRef]

| Research Goal | MCDA Method | Approach to Uncertainty | Reference |

|---|---|---|---|

| Choosing a comprehensive ERP system with a defined selection framework | AHP | Group assessment | [6] |

| Choosing the right ERP system for the textile industry | Fuzzy AHP | Triangular fuzzy numbers | [7] |

| Choosing the right ERP system to meet the company’s requirements | ANP, CI, MACBETH | Fuzzy measures integrated in CI | [8] |

| Determining the importance of the criteria for ERP system selection | Likert scale, Arithmetic mean | - | [9] |

| Investigate ERP maintenance risk factors | AHP | - | [10] |

| Measuring the company’s readiness to implement an ERP system | Fuzzy ANP | Triangular fuzzy numbers | [11] |

| ERP sandtable simulation evaluation | AHP | - | [12] |

| Identify feasible customization choices for the ERP implementing | AHP | - | [13] |

| Evaluation and selection of the most appropriate SCA tool in logistics | HFL AHP, HFL MULTIMOORA, HFL VIKOR | Hesitant fuzzy linguistic term sets | [14] |

| Choosing the best IOIS alternative in an electronic supply chain | AHP, TOPSIS | - | [15] |

| Help supply chain managers with improved decision making for closed loop SCM | AHP | - | [16] |

| Analyzing the big data on operational factors of the SCM | Fuzzy ANP, TOPSIS | Triangular fuzzy numbers, Sensitivity analysis | [17] |

| Evaluating CRM partner selection | IF-DEMATEL, IF-ANP | Group assessment, Intuitionistic fuzzy sets | [18] |

| CRM performance evaluation | ANP | Sensitivity analysis | [19] |

| Choosing the right CMMS to meet the needs of the organization | AHP | - | [20] |

| Choosing the optimal SHMS system | DEMATEL, ANP, ZOGP | - | [21] |

| Criterion | Group of Criteria | Reference |

|---|---|---|

| Total costs/Cost | SSF/IF/SRC | [6,7,8,9] |

| Implementation time/Implementation | SSF/IF/SRC | [6,7,8,9] |

| Functionality | SSF/SC/SRC | [6,7,8,9] |

| User friendliness | SSF/SC | [6,7] |

| Flexibility/Ease in customizing the system (Flexibility)/Ease of customization | SSF/SC/CRC | [6,7,8,9] |

| Reliability/System reliability | SSF/SC/SRC | [6,7,8,9] |

| Reputation/Vendor reputation | VF/VC/VRC | [6,7,8] |

| Technical capability/R&D capability/Technical aspects | VF/VC/SRC | [6,7,8,9] |

| Service/After sales service (Consultancy services)/Support and service | VF/VC/VRC | [6,7,8,9] |

| Better fit with company’s business processes | SC | [7] |

| Ability for upgrade in-house | SC | [7] |

| Compatibility with other systems/Compatibility | SC/SRC | [7,8,9] |

| Terms and period of guarantee | VC | [7] |

| Vision | VRC | [8,9] |

| Market position/Market position of the vendor | VRC | [8,9] |

| Domain knowledge/Domain knowledge of the vendor | VRC | [8,9] |

| Methodology of software | VRC | [8,9] |

| Better fit with organizational structure | CRC | [8,9] |

| Fit with parent/allied organizational system | CRC | [8,9] |

| Cross module integration | CRC | [8,9] |

| References of the vendor | [9] | |

| Consultancy | [9] |

| Criterion | Name | Functionality in the Criterion | Reference |

|---|---|---|---|

| C1 | SCM functions | ||

| C1.1 | Distribution | links between plants, wholesalers and customers; replenishment planning in related entities and across the network; supply chain service; bar codes; possibility to use GS1 | [14,32,34,35] |

| C1.2 | Distribution networks | managing contacts with SRM suppliers; cooperation with CRM customers; transport management; renovation economy; quality control; advanced APS planning and scheduling | [14,15,32] |

| C1.3 | Trade | support for POS points of sale; handling returns; handling of returnable packaging; handling sales and settlement procedures in accordance with Polish tax regulations; technical service as well as warranty and post-warranty service of products; use of bar codes; use of RFID | [14,15,32,35] |

| C1.4 | International company service | multilingualism; multi-currency; a uniform labelling system for goods | [4,6] |

| C1.5 | Customer relationship management | own database; access via own website; planning, supervision and evaluation of marketing campaigns; collection of marketing data; collecting data in a database about customers, potential customers and markets; correspondence service; issuing commercial documentation | [32] |

| C2 | Internet and communication | ||

| C2.1 | Use of the Internet and electronic commerce | own website; B2B and B2C cooperation | [4,6] |

| C2.2 | Electronic information exchange | Polish version; foreign language version; access to and application of Internet techniques; use of the XML format | [4,6,14,33] |

| C2.3 | Service processing model | remote work; compiling software from components from different SOA suppliers; work with software made available in the ASP mode; IT service by an external unit—SAAS; Cloud Computing | [6,14] |

| C3 | Versatility | ||

| C3.1 | Categories of supported enterprises | small, medium, large | [6,8,9] |

| C3.2 | Support for the specific requirements of various industry categories | heavy; automotive—final production; automotive—manufacturing and delivery of components; electromechanical; production of building and ceramic material; precise; electronic; food; chemical; pharmaceutical; light; furniture; other | [6,8,9] |

| C4 | Personalization and polonization | ||

| C4.1 | Personalization | CASE; program modification; workflow; adaptation to GS1 requirements; personalization of screens; automation of data import to the system; other | [9,13] |

| C4.2 | Polonization | documentation; assistance; screens and printouts; instructions and implementation procedures | [9,13] |

| Group | Group Weight | Criterion | Local Weight | Global Weight | Preference Direction | Preference Function | Indifference Threshold | Preference Threshold | Max Value |

|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.55 | C1.1 | 0.3 | 0.165 | Maximum | Usual/ V-shape/ V-shape with indifference | 1 | 2 | 5 |

| C1.2 | 0.3 | 0.165 | 1 | 3 | 6 | ||||

| C1.3 | 0.2 | 0.11 | 1 | 3 | 7 | ||||

| C1.4 | 0.1 | 0.055 | 0 | 1 | 3 | ||||

| C1.5 | 0.1 | 0.055 | 1 | 3 | 8 | ||||

| C2 | 0.25 | C2.1 | 0.3 | 0.075 | 0 | 1 | 2 | ||

| C2.2 | 0.3 | 0.075 | 1 | 2 | 4 | ||||

| C2.3 | 0.4 | 0.1 | 1 | 2 | 5 | ||||

| C3 | 0.1 | C3.1 | 0.3 | 0.03 | 0 | 1 | 3 | ||

| C3.2 | 0.7 | 0.07 | 2 | 4 | 13 | ||||

| C4 | 0.1 | C4.1 | 0.6 | 0.06 | 1 | 3 | 7 | ||

| C4.2 | 0.4 | 0.04 | 1 | 2 | 4 |

| Criterion | Comarch ERP XL | Epicor ERP 10 | Infor M3 | JD Edwards EnterpriseOne | Microsoft Dynamics 365 Business Central Essentials | Oracle E-Business Suite | SAP Business One |

|---|---|---|---|---|---|---|---|

| C1.1 | 3 | 4 | 3 | 5 | 5 | 5 | 5 |

| C1.2 | 5 | 6 | 6 | 6 | 4 | 6 | 6 |

| C1.3 | 6 | 5 | 5 | 6 | 6 | 7 | 7 |

| C1.4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| C1.5 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| C2.1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| C2.2 | 4 | 4 | 4 | 4 | 2 | 4 | 4 |

| C2.3 | 4 | 5 | 3 | 2 | 2 | 5 | 3 |

| C3.1 | 3 | 2 | 3 | 3 | 2 | 3 | 2 |

| C3.2 | 10 | 10 | 6 | 13 | 13 | 12 | 12 |

| C4.1 | 4 | 3 | 5 | 5 | 4 | 6 | 6 |

| C4.2 | 4 | 2 | 2 | 4 | 4 | 3 | 4 |

| Alternative | True Criterion | V-Shape Criterion | V-Shape with Indifference Criterion | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rank | Rank | Rank | ||||||||||

| A1 | 0.200 | 0.432 | −0.232 | 6 | 0.131 | 0.248 | −0.117 | 5 | 0.086 | 0.132 | −0.046 | 5 |

| A2 | 0.218 | 0.362 | −0.144 | 4 | 0.154 | 0.217 | −0.063 | 4 | 0.105 | 0.107 | −0.002 | 4 |

| A3 | 0.146 | 0.403 | −0.257 | 7 | 0.085 | 0.315 | −0.230 | 7 | 0.046 | 0.258 | −0.212 | 7 |

| A4 | 0.310 | 0.140 | 0.170 | 3 | 0.201 | 0.086 | 0.115 | 3 | 0.138 | 0.050 | 0.088 | 3 |

| A5 | 0.208 | 0.420 | −0.213 | 5 | 0.136 | 0.295 | −0.159 | 6 | 0.092 | 0.224 | −0.132 | 6 |

| A6 | 0.438 | 0.050 | 0.388 | 1 | 0.302 | 0.019 | 0.282 | 1 | 0.213 | 0.000 | 0.213 | 1 |

| A7 | 0.380 | 0.093 | 0.287 | 2 | 0.238 | 0.068 | 0.171 | 2 | 0.145 | 0.053 | 0.091 | 2 |

| Alternative | Priority | Rank |

|---|---|---|

| A1 | 0.1352 | 5 |

| A2 | 0.143 | 4 |

| A3 | 0.1308 | 6 |

| A4 | 0.1467 | 3 |

| A5 | 0.129 | 7 |

| A6 | 0.1627 | 1 |

| A7 | 0.1527 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziemba, P.; Gago, I. Uncertainty of Preferences in the Assessment of Supply Chain Management Systems Using the PROMETHEE Method. Symmetry 2022, 14, 1043. https://doi.org/10.3390/sym14051043

Ziemba P, Gago I. Uncertainty of Preferences in the Assessment of Supply Chain Management Systems Using the PROMETHEE Method. Symmetry. 2022; 14(5):1043. https://doi.org/10.3390/sym14051043

Chicago/Turabian StyleZiemba, Paweł, and Izabela Gago. 2022. "Uncertainty of Preferences in the Assessment of Supply Chain Management Systems Using the PROMETHEE Method" Symmetry 14, no. 5: 1043. https://doi.org/10.3390/sym14051043

APA StyleZiemba, P., & Gago, I. (2022). Uncertainty of Preferences in the Assessment of Supply Chain Management Systems Using the PROMETHEE Method. Symmetry, 14(5), 1043. https://doi.org/10.3390/sym14051043