Heat Flow Characteristics of Ferrofluid in Magnetic Field Patterns for Electric Vehicle Power Electronics Cooling

Abstract

:1. Introduction

2. Experimental Method

2.1. Problem Conceptualization

2.2. Experimental Set-Up Description

2.3. Experimental Procedure and Uncertainty Analysis

3. Results & Discussion

4. Conclusions

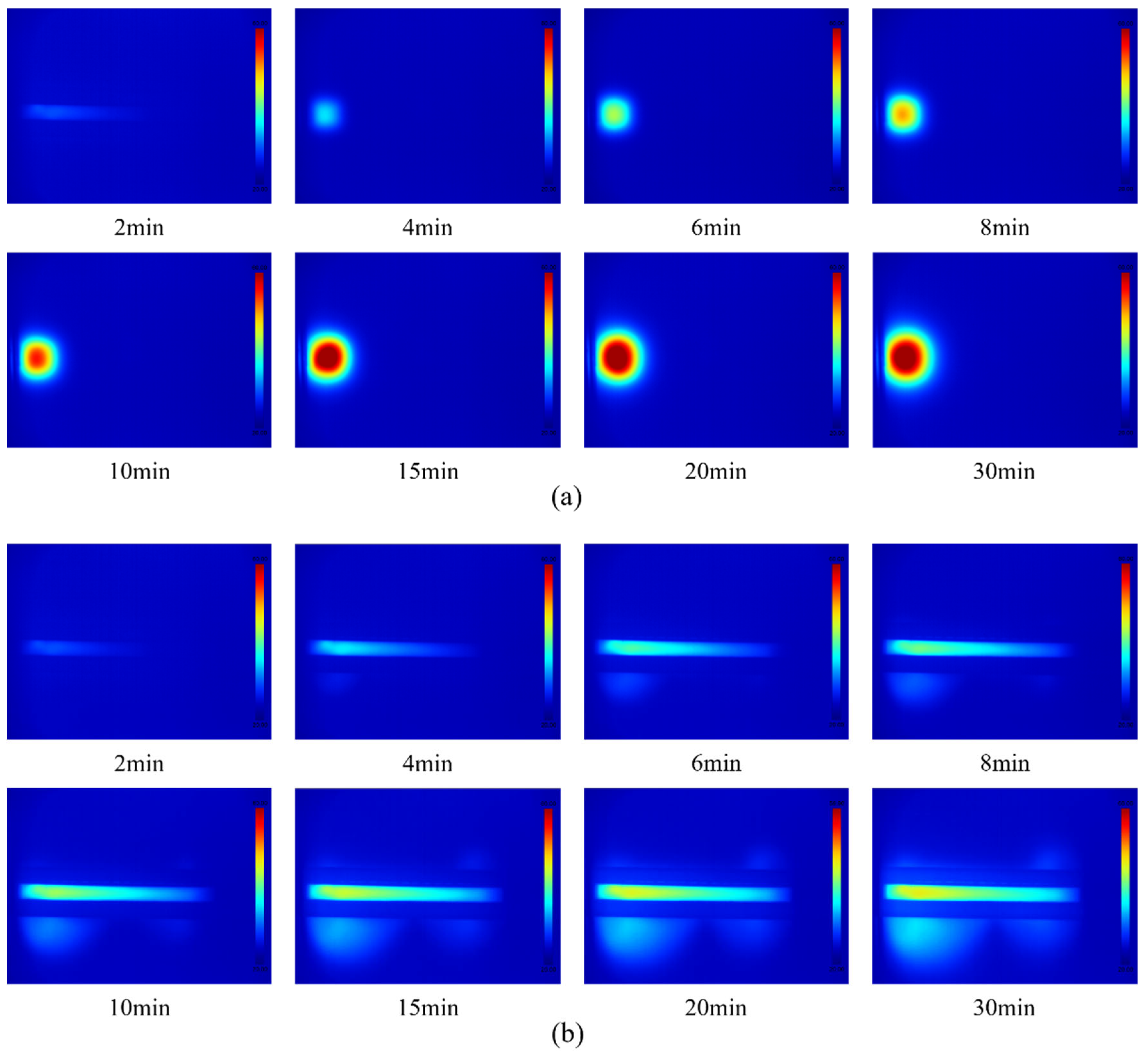

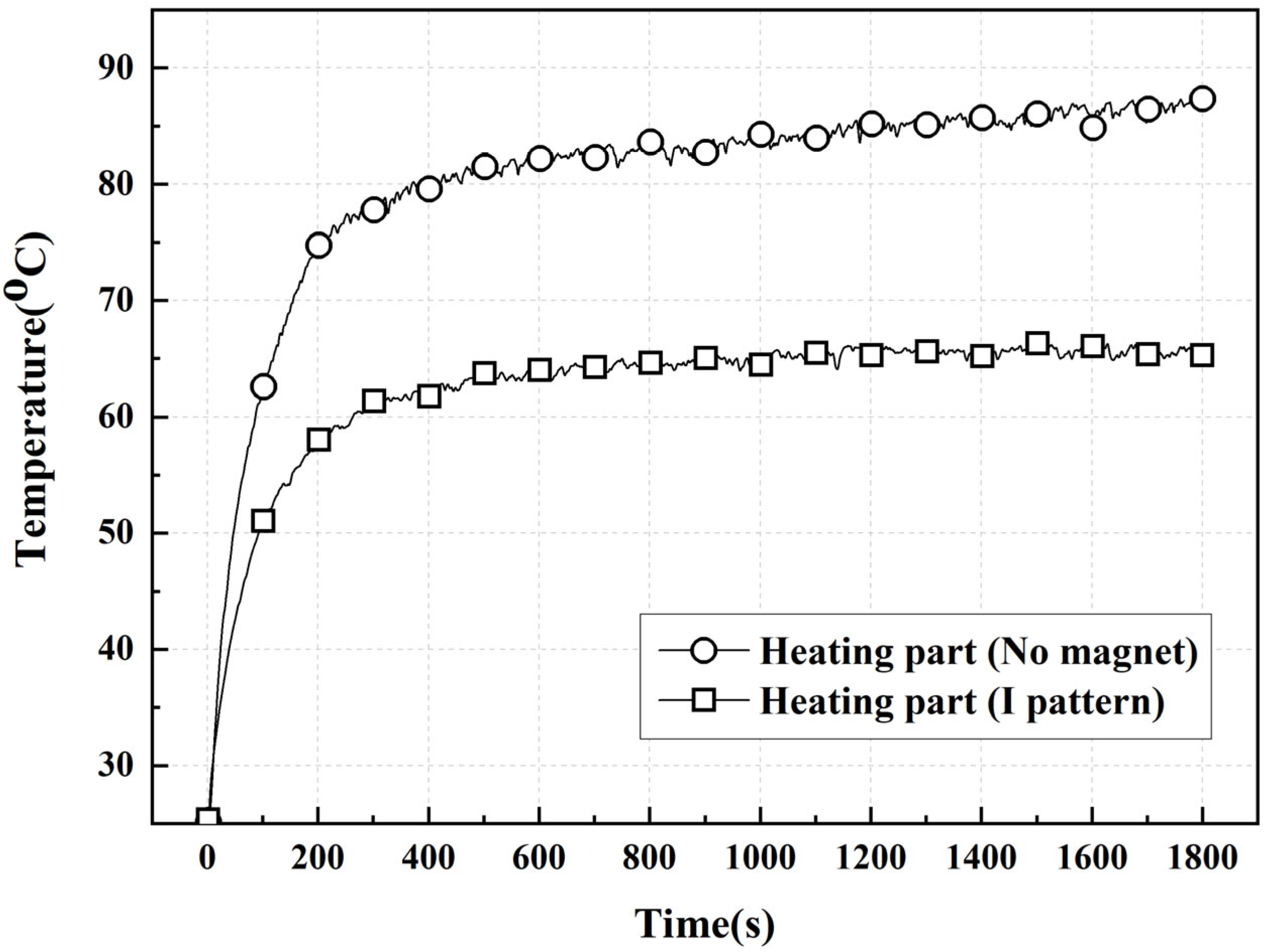

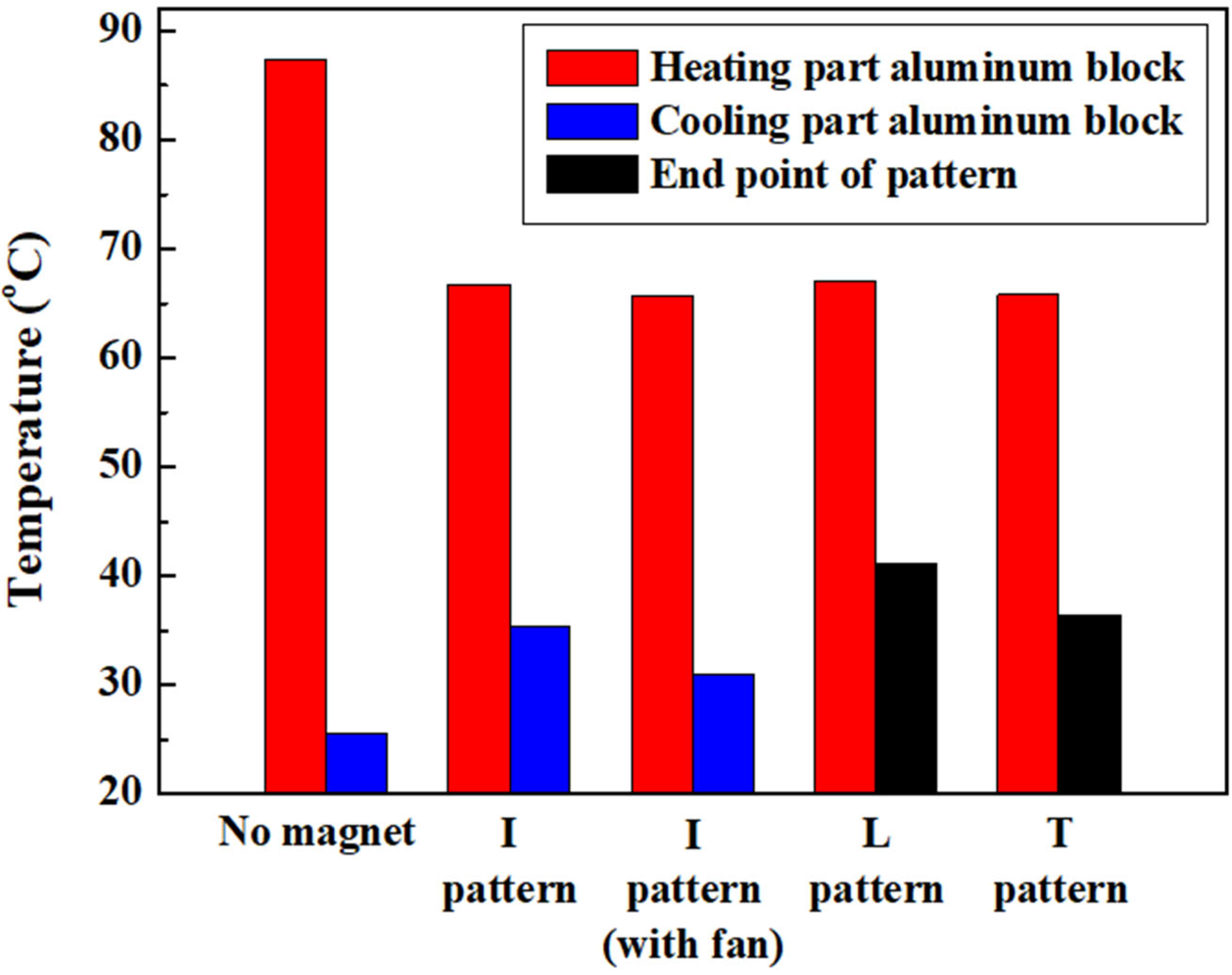

- The temperatures of heating and cooling blocks are evaluated as 87.4 °C and 25.6 °C, respectively, in the case of the no-magnet experiment. This indicates that the heat is not dissipated within ferrofluid, and it gets accumulated near the heating block due to the absence of thermomagnetic convection;

- In the case of the I magnetic field pattern, the heat flows from the heating block to the cooling block along the path of the magnetic field pattern. The thermomagnetic convection of ferrofluid drives the heat in the presence of the magnetic field and the heat dissipation rate increases as time passes;

- The temperatures of the heating and cooling blocks are measured as 66.7 °C and 35.3 °C for the I magnetic field pattern without a cooling fan and as 65.3 °C and 30.9 °C for the I magnetic field pattern with a cooling fan;

- When the fan is used with cooling block in the case of the I magnetic field pattern, the temperature of the heating block lowers by 22.1 °C compared to the heating block temperature in the case of no magnet. Furthermore, the heating and cooling blocks’ temperatures are lower by 1.4 °C and 4.4 °C, respectively, for the cooling block with a fan compared to that without a fan, which indicates that the thermomagnetic convection is sensitive to the temperature difference;

- The heat from the heating block flows to one side’s right-angle corner in the case of the L magnetic field pattern and flows symmetrically to both sides’ right-angle corners in the case of the T magnetic field pattern. In both magnetic field patterns, the heat dissipates along the respective paths of the magnetic field patterns;

- The temperatures of the heating block and the endpoint of the pattern are measured as 67.1 °C and 41.1 °C, respectively, in the case of the L magnetic field pattern and 65.8 °C and 36.4 °C, respectively, in the case of the T magnetic field pattern. In the case of the T magnetic field pattern, the temperatures of the heating block and the endpoint of the pattern are lower by 1.3 °C and 4.7 °C, respectively, compared to the L magnetic field pattern. This indicates a superior heat dissipation performance in the case of the T magnetic field pattern;

- The direction and path of heat flow could be controlled using the magnetization properties of ferrofluid by enabling thermomagnetic convection using various magnetic field patterns. This concept and results database could be referred to as the guidelines to design a ferrofluid-based cooling system with heat dissipation direction control characteristics. This system could be used in electric vehicles to dissipate the heat from high-flux-density power electronics devices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bahiraei, M.; Hangi, M. Flow and heat transfer characteristics of magnetic nanofluids: A review. J. Magn. Magn. Mater. 2015, 374, 125–138. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Mirlohi, A.; Nazari, M.A.; Ghasempour, R. A review of thermal conductivity of various nanofluids. J. Mol. Liq. 2018, 265, 181–188. [Google Scholar] [CrossRef]

- Jang, S.P. Thermal conductivities of nanofluids. Trans. Korean Soc. Mech. Eng. B 2004, 28, 968–975. [Google Scholar] [CrossRef]

- Ali, H.M.; Babar, H.; Shah, T.R.; Sajid, M.U.; Qasim, M.A.; Javed, S. Preparation Techniques of TiO2 Nanofluids and Challenges: A Review. Appl. Sci. 2018, 8, 587. [Google Scholar] [CrossRef] [Green Version]

- Patrizi, G.; Catelani, M.; Ciani, L.; Bartolini, A.; Corti, F.; Grasso, F.; Reatti, A. Electrical Characterization Under Harsh Environment of DC–DC Converters Used in Diagnostic Systems. IEEE Trans. Instrum. Meas. 2021, 71, 1–11. [Google Scholar] [CrossRef]

- Johnson, R.; Evans, J.; Jacobsen, P.; Thompson, J.; Christopher, M. The Changing Automotive Environment: High-Temperature Electronics. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 164–176. [Google Scholar] [CrossRef]

- Andresen, M.; Ma, K.; Buticchi, G.; Falck, J.; Blaabjerg, F.; Liserre, M. Junction Temperature Control for More Reliable Power Electronics. IEEE Trans. Power Electron. 2017, 33, 765–776. [Google Scholar] [CrossRef] [Green Version]

- Garud, K.; Lee, M.-Y. Numerical Investigations on Heat Transfer Characteristics of Single Particle and Hybrid Nanofluids in Uniformly Heated Tube. Symmetry 2021, 13, 876. [Google Scholar] [CrossRef]

- Garud, K.; Hwang, S.-G.; Lim, T.-K.; Kim, N.; Lee, M.-Y. First and Second Law Thermodynamic Analyses of Hybrid Nanofluid with Different Particle Shapes in a Microplate Heat Exchanger. Symmetry 2021, 13, 1466. [Google Scholar] [CrossRef]

- Ghadiri, M.; Sardarabadi, M.; Passandideh-Fard, M.; Moghadam, A.J. Experimental investigation of a PVT system performance using nano ferrofluids. Energy Convers. Manag. 2015, 103, 468–476. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Turkyilmazoglu, M. A New Theoretical Approach of Wall Transpiration in the Cavity Flow of the Ferrofluids. Micromachines 2019, 10, 373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aswal, V.K.; Goyal, P.S. Characterization of a temperature-sensitive ferrofluid. Phys. Rev. B 1997, 55, 5585. [Google Scholar]

- Raj, K.; Moskowitz, R. Commercial applications of ferrofluids. J. Magn. Magn. Mater. 1990, 85, 233–245. [Google Scholar] [CrossRef]

- Lian, W.; Xuan, Y.; Li, Q. Characterization of miniature automatic energy transport devices based on the thermomagnetic effect. Energy Convers. Manag. 2009, 50, 35–42. [Google Scholar] [CrossRef]

- Xuan, Y.; Lian, W. Electronic cooling using an automatic energy transport device based on thermomagnetic effect. Appl. Therm. Eng. 2011, 31, 1487–1494. [Google Scholar] [CrossRef]

- Hejazian, M.; Nguyen, N.-T. Magnetofluidics for manipulation of convective heat transfer. Int. Commun. Heat Mass Transf. 2017, 81, 149–154. [Google Scholar] [CrossRef] [Green Version]

- Koji, F.; Hideaki, Y.; Masahiro, I. A mini heat transport device based on thermo-sensitive magnetic fluid. Nanoscale Microscale Thermophys. Eng. 2007, 11, 201–210. [Google Scholar]

- Seo, J.-H.; Lee, M.-Y. Illuminance and heat transfer characteristics of high power LED cooling system with heat sink filled with ferrofluid. Appl. Therm. Eng. 2018, 143, 438–449. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Iwamoto, Y. Energy transport in cooling device by ferrofluid. J. Magn. Magn. Mater. 2017, 431, 229–236. [Google Scholar] [CrossRef]

- Pattanaik, M.; Cheekati, S.; Varma, V.; Ramanujan, R. A novel magnetic cooling device for long distance heat transfer. Appl. Therm. Eng. 2022, 201, 117777. [Google Scholar] [CrossRef]

- I3-System. TE–V1. Available online: http://www.i3-thermalexpert.com/ (accessed on 21 March 2022).

- SCIPIA. CM9 10 × 10 mm 2~38 V Mini MCH Ceramic Heater Module Heater Plate. Available online: http://scipia.com (accessed on 15 March 2022).

- Lutron Electronic. Wide Range, General Purpose AC/DC Magnetic Meter Model: MG-3002. Available online: https://www.lutroninstruments.eu/ (accessed on 15 March 2022).

- EMAGNET. Round Neodymium Magnet. Available online: http://emagnet.co.kr/ (accessed on 15 March 2022).

- Kim, D.W.; Mitamura, Y. Characteristics of the Sealing Pressure of a Ferrofluid Shaft Seal for Intra-Cardiac Axial Flow Blood Pumps. Trans. Korean Inst. Electr. Eng. D 2002, 51, 477–482. [Google Scholar]

- Seo, J.-H.; Garud, K.S.; Lee, M.-Y. Grey relational based Taguchi analysis on thermal and electrical performances of thermoelectric generator system with inclined fins hot heat exchanger. Appl. Therm. Eng. 2021, 184, 116279. [Google Scholar] [CrossRef]

- Bahiraei, M.; Hangi, M.; Rahbari, A. A two-phase simulation of convective heat transfer characteristics of water–Fe3O4 ferrofluid in a square channel under the effect of permanent magnet. Appl. Therm. Eng. 2019, 147, 991–997. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Kobori, I.; Uehata, Y.; Shimada, K. Natural convection of ferrofluid in a rectangular box. J. Magn. Magn. Mater. 1999, 201, 264–267. [Google Scholar] [CrossRef]

| Part (Length × Width × Thickness) (mm) | Dimensions |

|---|---|

| Acrylic plate | 200 × 200 × 10 |

| Ferrofluid injection space inside acrylic plate | 180 × 180 × 1.8 |

| Ceramic heater | 10 × 10 × 1.2 |

| Aluminum block (outside) | 20 × 20 × 3 |

| Aluminum block (inside) | 10 × 10 × 5 |

| Cooling fan | 40 × 40 × 10 |

| Items | Conditions |

|---|---|

| Cooling fan | KF0410B1MS-R (JAMICON Co., New Taipei City, Taiwan) |

| Data logger | GL840, GL820 (GRAPHTEC Co., Yokohama, Japan) |

| DC power supply | K-6333A (EXSO Co. Ltd., Busan, Korea) |

| Magnetic field meter | MG-3002 (LUTRON Co., Coopersburg, PA, USA) |

| Thermal imaging camera | TE-V1 (I3-system, Inc., Daejeon, Korea) |

| Thermocouple | T-type (Accuracy ±0.1 °C) |

| Properties | Conditions |

|---|---|

| Specific gravity (at 25 °C) | 1.388 |

| Viscosity (at 25 °C) | 10 mPa·s |

| Surface tension (at 25 °C) | 26 ± 2 dyne |

| Saturation magnetization | 47.5 ± 3 mT |

| Boiling point (at 760 mmHg) | 150~250 °C |

| Operating temperature range | −20~120 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, S.-G.; Garud, K.S.; Seo, J.-H.; Lee, M.-Y. Heat Flow Characteristics of Ferrofluid in Magnetic Field Patterns for Electric Vehicle Power Electronics Cooling. Symmetry 2022, 14, 1063. https://doi.org/10.3390/sym14051063

Hwang S-G, Garud KS, Seo J-H, Lee M-Y. Heat Flow Characteristics of Ferrofluid in Magnetic Field Patterns for Electric Vehicle Power Electronics Cooling. Symmetry. 2022; 14(5):1063. https://doi.org/10.3390/sym14051063

Chicago/Turabian StyleHwang, Seong-Guk, Kunal Sandip Garud, Jae-Hyeong Seo, and Moo-Yeon Lee. 2022. "Heat Flow Characteristics of Ferrofluid in Magnetic Field Patterns for Electric Vehicle Power Electronics Cooling" Symmetry 14, no. 5: 1063. https://doi.org/10.3390/sym14051063

APA StyleHwang, S.-G., Garud, K. S., Seo, J.-H., & Lee, M.-Y. (2022). Heat Flow Characteristics of Ferrofluid in Magnetic Field Patterns for Electric Vehicle Power Electronics Cooling. Symmetry, 14(5), 1063. https://doi.org/10.3390/sym14051063