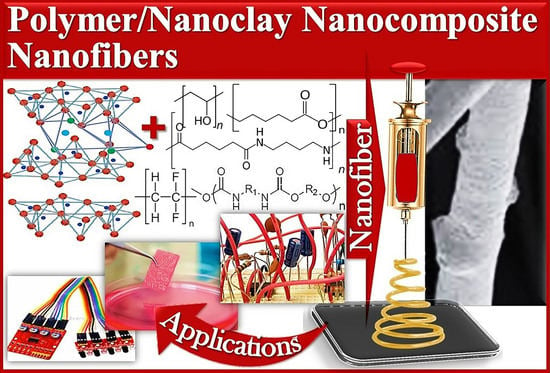

Nanoclay-Reinforced Nanocomposite Nanofibers—Fundamentals and State-of-the-Art Developments

Abstract

1. Introduction

2. Nanoclay

3. Polymer and Nanocomposite Nanofiber

- The distance between the spinneret and the collector influences fiber diameter and morphology [64]. The optimum distance is important to avoid bead formation and to form solid round fibers.

- The feed rate affects polymer solution delivery speed [65]. Solution feed rate defines the nanofiber diameter and morphology.

- The voltage between the needle and collector (metal) is significant to form thin polymer jets and minimize the surface tension [66]. A very low electric field cannot cause jet elongation to form uniform nanofibers.

- The pressure of pumping a polymer solution or melt from a spinneret also affects the nanofiber diameter and morphology [67].

4. Polymer/Nanoclay Nanocomposite Nanofiber

4.1. Poly(Vinylidene Fluoride)/Nanoclay Nanofiber

4.2. Poly(Vinyl Alcohol)/Nanoclay Nanofiber

4.3. Nylon/Nanoclay Nanofiber

4.4. Polycaprolactone/Nanoclay Nanofiber

4.5. Polyurethane/Nanoclay Nanofiber

4.6. Poly(Lactic Acid)/Nanoclay Nanofiber

5. Significance of Polymer/Nanoclay Nanocomposite Nanofiber

5.1. Sensors

5.2. Packaging

5.3. Tissue Engineering and Wound Healing

6. Future Prospects

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kausar, A. Up-to-date notions of polystyrene nanocomposite nanofibers. Mater. Res. Innov. 2022, 26, 113–125. [Google Scholar] [CrossRef]

- Wang, D.; Meng, Y.; Tang, A.; Yang, H. Dehydroxylation of Kaolinite Tunes Metal Oxide—Nanoclay Interactions for Enhancing Antibacterial Activity. Minerals 2022, 12, 1097. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Maaza, M.; Eisa, M. State-of-the-Art Nanoclay Reinforcement in Green Polymeric Nanocomposite: From Design to New Opportunities. Minerals 2022, 12, 1495. [Google Scholar] [CrossRef]

- Pinto, G.M.; Cremonezzi, J.M.; Ribeiro, H.; Andrade, R.J.; Demarquette, N.R.; Fechine, G.J. From two-dimensional materials to polymer nanocomposites with emerging multifunctional applications: A critical review. Polym. Compos. 2023, 44, 1438–1470. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A review of the synthesis and applications of polymer—Nanoclay composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Al-Dhahebi, A.M.; Ling, J.; Krishnan, S.G.; Yousefzadeh, M.; Elumalai, N.K.; Saheed, M.S.M.; Ramakrishna, S.; Jose, R. Electrospinning research and products: The road and the way forward. Appl. Phys. Rev. 2022, 9, 011319. [Google Scholar] [CrossRef]

- Song, W.; Tang, Y.; Qian, C.; Kim, B.J.; Liao, Y.; Yu, D.-G. Electrospinning spinneret: A bridge between the visible world and the invisible nanostructures. Innovation 2023, 4, 100381. [Google Scholar] [CrossRef]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M.E.; Tan, L. A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro-Centrifugal Spinning. Macromol. Mater. Eng. 2023, 308, 2200502. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, X.; Shen, Y.; Dong, K.; Shen, L.; Alzalab, A.A.A. Research progress, models and simulation of electrospinning technology: A review. J. Mater. Sci. 2021, 57, 58–104. [Google Scholar] [CrossRef]

- Barghamadi, M.; Ghoreishy, M.H.R.; Karrabi, M.; Mohammadian-Gezaz, S. Modeling of nonlinear hyper-viscoelastic and stress softening behaviors of acrylonitrile butadiene rubber/polyvinyl chloride nanocomposites reinforced by nanoclay and graphene. Polym. Compos. 2021, 42, 583–596. [Google Scholar] [CrossRef]

- Wang, P.; Lv, H.; Cao, X.; Liu, Y.; Yu, D.-G. Recent progress of the preparation and application of electrospun porous nanofibers. Polymers 2023, 15, 921. [Google Scholar] [CrossRef] [PubMed]

- Padil, V.V.; Kumar, K.A.; Murugesan, S.; Torres-Mendieta, R.; Wacławek, S.; Cheong, J.Y.; Černík, M.; Varma, R.S. Sustainable and safer nanoclay composites for multifaceted applications. Green Chem. 2022, 24, 3081–3114. [Google Scholar] [CrossRef]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Tullio, S.; Chalcraft, D. Converting natural nanoclay into modified nanoclay augments the toxic effect of natural nanoclay on aquatic invertebrates. Ecotoxicol. Environ. Saf. 2020, 197, 110602. [Google Scholar] [CrossRef]

- Galimberti, M. Rubber-Clay Nanocomposites: Science, Technology, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Mousavi, M.; Fini, E.H.; Hung, A.M. Underlying molecular interactions between sodium montmorillonite clay and acidic bitumen. J. Phys. Chem. C 2019, 123, 15513–15522. [Google Scholar] [CrossRef]

- Li, A.; Wang, A.-Q.; Chen, J.-M. Preparation and Properties of Poly (acrylic acid-potassium acrylate)/Attapulgite Superabsorbent Composite. J. Funct. Polym. 2004, 17, 200–206. [Google Scholar]

- Liu, M.; Fakhrullin, R.; Novikov, A.; Panchal, A.; Lvov, Y. Tubule nanoclay-organic heterostructures for biomedical applications. Macromol. Biosci. 2019, 19, 1800419. [Google Scholar] [CrossRef]

- Srithammaraj, K. Electrical Property-Investigation of Porous Clay Heterostructures Derived from Naturally-Occurring Clay Minerals for Smart Packaging. Ph.D. Dissertation, Chulalongkorn Univiversity, Bangkok, Thailand, 2017. [Google Scholar]

- Mazloomi, F.; Jalali, M. Effects of vermiculite, nanoclay and zeolite on ammonium transport through saturated sandy loam soil: Column experiments and modeling approaches. Catena 2019, 176, 170–180. [Google Scholar] [CrossRef]

- Wypych, F.; Bergaya, F.; Schoonheydt, R.A. From Polymers to Clay Polymer Nanocomposites’ Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2018; pp. 331–359. [Google Scholar]

- Shunmugasamy, V.C.; Xiang, C.; Gupta, N. Clay/polymer nanocomposites: Processing, properties, and applications. In Hybrid and Hierarchical Composite Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 161–200. [Google Scholar]

- Abdul Hanan, U.; Abu Hassan, S.; Uzir Wahit, M.; Binoj, J.S.; Mansingh, B.B.; Goh, K.L. Experimentation, optimization, and predictive analysis of compressive behavior of montmorillonite nano-clay/unsaturated polyester composites. Polym. Compos. 2023, 44, 241–251. [Google Scholar] [CrossRef]

- Nejat, T.; Naghdi, R.; Nadali, E.; Asgharzadeh Avajeghi, P.; Jafari, R. Effects of nanoclay cloisite 20A and alkali treatments on structure-property relationships of bagasse/recycled polypropylene nanocomposites. J. Thermoplast. Compos. Mater. 2023, 08927057231170802. [Google Scholar] [CrossRef]

- Ngcobo, S.; Silwana, B.; Maqhashu, K.; Matoetoe, M.C. Bentonite Nanoclay Optoelectrochemical Property Improvement through Bimetallic Silver and Gold Nanoparticles. J. Nanotechnol. 2022, 2022, 3693938. [Google Scholar] [CrossRef]

- Albayrak Hacioglu, O.; Tasdelen, M.A. Synergistic effect of organically modified sepiolite clay in intumescent flame retardant polyolefin elastomer-based cable outer sheath compounds. Iran. Polym. J. 2023, 32, 93–102. [Google Scholar] [CrossRef]

- Jabeen, A.; Bhatti, H.N.; Khan, A. Micro and Nano Clay-Biopolymer Composites for Drug Delivery. In Advanced Applications of Micro and Nano Clay II: Synthetic Polymer Composites; Materials Research Forum LLC.: Millersville, PA, USA, 2022; Volume 129, pp. 24–52. [Google Scholar]

- Ang, M.B.M.Y.; Deang, A.B.G.; Chiao, Y.-H.; Aquino, R.R.; Millare, J.C.; Huang, S.-H.; Tsai, H.-A.; Lee, K.-R. Integrating nanoclay intercalated with interlayers of cationic surfactant into thin-film nanocomposite nanofiltration membranes to improve performance and antifouling property. Sep. Purif. Technol. 2022, 285, 120360. [Google Scholar] [CrossRef]

- Merah, N.; Ashraf, F.; Shaukat, M.M. Mechanical and Moisture Barrier Properties of Epoxy–Nanoclay and Hybrid Epoxy–Nanoclay Glass Fibre Composites: A Review. Polymers 2022, 14, 1620. [Google Scholar] [CrossRef]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A. Hybridization of MMT/lignocellulosic fiber reinforced polymer nanocomposites for structural applications: A review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Abulyazied, D.E.; Ene, A. An investigative study on the progress of nanoclay-reinforced polymers: Preparation, properties, and applications: A review. Polymers 2021, 13, 4401. [Google Scholar] [CrossRef]

- Albdiry, M.; Yousif, B.; Ku, H.; Lau, K. A critical review on the manufacturing processes in relation to the properties of nanoclay/polymer composites. J. Compos. Mater. 2013, 47, 1093–1115. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Ming, L.Y.; Yong, H.C.; Tahir, M.F.M. Clay-Based Materials in Geopolymer Technology’ Cement Based Materials; IntechOpen: London, UK, 2018. [Google Scholar]

- Misaelides, P. Clay Minerals and Zeolites for Radioactive Waste Immobilization and Containment: A Concise Verview’ Modified Clay and Zeolite Nanocomposite Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 243–274. [Google Scholar]

- Kausar, A. A review of fundamental principles and applications of polymer nanocomposites filled with both nanoclay and nano-sized carbon allotropes–graphene and carbon nanotubes. J. Plast. Film. Sheeting 2020, 36, 209–228. [Google Scholar] [CrossRef]

- Kausar, A. Flame retardant potential of clay nanoparticles. In Clay Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 169–184. [Google Scholar]

- Kausar, A. Review on polymer/halloysite nanotube nanocomposite. Polym. Plast. Technol. Eng. 2018, 57, 548–564. [Google Scholar] [CrossRef]

- Xu, X.; Lv, H.; Zhang, M.; Wang, M.; Zhou, Y.; Liu, Y.; Yu, D.-G. Recent progress in electrospun nanofibers and their applications in heavy metal wastewater treatment. Front. Chem. Sci. Eng. 2023, 17, 249–275. [Google Scholar] [CrossRef]

- Maliszewska, I.; Czapka, T. Electrospun Polymer Nanofibers with Antimicrobial Activity. Polymers 2022, 14, 1661. [Google Scholar] [CrossRef]

- Zupančič, Š. Core-shell nanofibers as drug-delivery systems. Acta Pharm. 2019, 69, 131–153. [Google Scholar] [CrossRef]

- Mukheja, Y.; Kaur, J.; Pathania, K.; Sah, S.P.; Salunke, D.B.; Sangamwar, A.T.; Pawar, S.V. Recent advances in pharmaceutical and biotechnological applications of lignin-based materials. Int. J. Biol. Macromol. 2023, 241, 124601. [Google Scholar] [CrossRef]

- Shinde, S.S.; Kher, J.A. A review on polyaniline and its noble metal composites. Int. J. Innovative Res. Sci. Eng. Technol. 2014, 3, 16570–16576. [Google Scholar] [CrossRef]

- Nemati, S.; Kim, S.-J.; Shin, Y.M.; Shin, H. Current progress in application of polymeric nanofibers to tissue engineering. Nano Converg. 2019, 6, 36. [Google Scholar] [CrossRef]

- Zhao, G.; Shi, L.; Yang, G.; Zhuang, X.; Cheng, B. 3D fibrous aerogels from 1D polymer nanofibers for energy and environmental applications. J. Mater. Chem. A 2023, 11, 512–547. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, S.; Wu, W.; Xiao, G.; Sundarrajan, S.; Ramakrishna, S. Electrospun transparent nanofibers as a next generation face filtration media: A review. Biomater. Adv. 2023, 149, 213390. [Google Scholar] [CrossRef] [PubMed]

- Mittal, V. Synthesis Techniques for Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Kausar, A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review. Polym. Plast. Technol. Mater. 2020, 59, 895–909. [Google Scholar] [CrossRef]

- Sreekumar, P.; Al-Harthi, M.A.; De, S. Reinforcement of starch/polyvinyl alcohol blend using nano-titanium dioxide. J. Compos. Mater. 2012, 46, 3181–3187. [Google Scholar] [CrossRef]

- Rathnam, V.; Kichu, A.; Dutta, N.; Maji, T.K.; Devi, N. Influence of organically modified nanoclay and TiO2 nanopowder on the properties of Azadirachta indica wood flour-reinforced high-density polyethylene, low-density polyethylene, polypropylene, and polyvinyl chloride nanocomposite. J. Thermoplast. Compos. Mater. 2022, 35, 1468–1487. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kameoka, J. Amperometric cholesterol biosensor using layer-by-layer adsorption technique onto electrospun polyaniline nanofibers. J. Ind. Eng. Chem. 2012, 18, 193–197. [Google Scholar] [CrossRef]

- Kellenberger, A.; Plesu, N.; Mihali, M.T.-L.; Vaszilcsin, N. Synthesis of polyaniline nanostructures by electrochemical deposition on niobium. Polymer 2013, 54, 3166–3174. [Google Scholar] [CrossRef]

- Patil, P.T.; Anwane, R.S.; Kondawar, S.B. Development of electrospun polyaniline/ZnO composite nanofibers for LPG sensing. Procedia Mater. Sci. 2015, 10, 195–204. [Google Scholar] [CrossRef]

- Kayaci, F.; Ozgit-Akgun, C.; Donmez, I.; Biyikli, N.; Uyar, T. Polymer—Inorganic core—Shell nanofibers by electrospinning and atomic layer deposition: Flexible nylon–ZnO core–shell nanofiber mats and their photocatalytic activity. ACS Appl. Mater. Interfaces 2012, 4, 6185–6194. [Google Scholar] [CrossRef]

- Arjmandi, S.K.; Khademzadeh Yeganeh, J.; Zare, Y.; Rhee, K.Y. Development of Kovacs model for electrical conductivity of carbon nanofiber—Polymer systems. Sci. Rep. 2023, 13, 7. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.K.Y.; Chen, N.; Peng, S.; Li, L.; Tian, L.; Thakor, N.; Ramakrishna, S. Polymer-based composites by electrospinning: Preparation & functionalization with nanocarbons. Prog. Polym. Sci. 2018, 86, 40–84. [Google Scholar]

- Fajardo-Diaz, J.L.; Morelos-Gomez, A.; Cruz-Silva, R.; Ishii, K.; Yasuike, T.; Kawakatsu, T.; Yamanaka, A.; Tejima, S.; Izu, K.; Saito, S. Low-pressure reverse osmosis membrane made of cellulose nanofiber and carbon nanotube polyamide nano-nanocomposite for high purity water production. Chem. Eng. J. 2022, 448, 137359. [Google Scholar] [CrossRef]

- Amer Flayeh, A.; Jawad Kadhim, H. Enhancing the physical properties of polystyrene nanofibers by adding multiwall carbon nanotubes and natural dye. Fuller. Nanotub. Carbon Nanostructures 2022, 30, 1090–1096. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, C.; Zhang, Y.; Strong, V.; Tang, J.; Li, X.-G.; Kalantar-Zadeh, K.; Hoek, E.M.; Wang, K.L.; Kaner, R.B. Carbon nanotube/polyaniline composite nanofibers: Facile synthesis and chemosensors. Nano Lett. 2011, 11, 954–959. [Google Scholar] [CrossRef]

- Cooley, J.F. Improved methods of and apparatus for electrically separating the relatively volatile liquid component from the component of relatively fixed substances of composite fluids. UK Pat. 1900, 6385, 19. [Google Scholar]

- Malgras, V.; Ji, Q.; Kamachi, Y.; Mori, T.; Shieh, F.-K.; Wu, K.C.-W.; Ariga, K.; Yamauchi, Y. Templated synthesis for nanoarchitectured porous materials. Bull. Chem. Soc. Jpn. 2015, 88, 1171–1200. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y. Centrifugal spinning: An alternative approach to fabricate nanofibers at high speed and low cost. Polym. Rev. 2014, 54, 677–701. [Google Scholar] [CrossRef]

- Zhang, Z.-M.; Duan, Y.-S.; Xu, Q.; Zhang, B. A review on nanofiber fabrication with the effect of high-speed centrifugal force field. J. Eng. Fibers Fabr. 2019, 14, 1558925019867517. [Google Scholar] [CrossRef]

- Ma, B.; Xie, J.; Jiang, J.; Shuler, F.D.; Bartlett, D.E. Rational design of nanofiber scaffolds for orthopedic tissue repair and regeneration. Nanomedicine 2013, 8, 1459–1481. [Google Scholar] [CrossRef]

- Meyer, M. Processing of collagen based biomaterials and the resulting materials properties. Biomed. Eng. 2019, 18, 1–74. [Google Scholar]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, J.; Li, J.; Li, D.; Xiao, C.; Xiao, H.; Yang, H.; Zhuang, X.; Chen, X. Electrospun polymer biomaterials. Prog. Polym. Sci. 2019, 90, 1–34. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Sundaray, B.; Choi, A.; Park, Y.W. Highly conducting electrospun polyaniline-polyethylene oxide nanofibrous membranes filled with single-walled carbon nanotubes. Synth. Met. 2010, 160, 984–988. [Google Scholar] [CrossRef]

- Zhou, H.; Green, T.B.; Joo, Y.L. The thermal effects on electrospinning of polylactic acid melts. Polymer 2006, 47, 7497–7505. [Google Scholar] [CrossRef]

- Tsuji, H.; Nakano, M.; Hashimoto, M.; Takashima, K.; Katsura, S.; Mizuno, A. Electrospinning of poly (lactic acid) stereocomplex nanofibers. Biomacromolecules 2006, 7, 3316–3320. [Google Scholar] [CrossRef]

- Guo, Y.; Ghobeira, R.; Aliakbarshirazi, S.; Morent, R.; De Geyter, N. Polylactic Acid/Polyaniline Nanofibers Subjected to Pre-and Post-Electrospinning Plasma Treatments for Refined Scaffold-Based Nerve Tissue Engineering Applications. Polymers 2023, 15, 72. [Google Scholar] [CrossRef]

- Di Cristo, F.; Valentino, A.; De Luca, I.; Peluso, G.; Bonadies, I.; Di Salle, A.; Calarco, A. Polylactic Acid/Poly (vinylpyrrolidone) Co-Electrospun Fibrous Membrane as a Tunable Quercetin Delivery Platform for Diabetic Wounds. Pharmaceutics 2023, 15, 805. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Eisa, M.; Maaza, M.; Khan, H. Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions. Nanomanufacturing 2023, 3, 1–19. [Google Scholar] [CrossRef]

- Flayeh, A.A.; Kadhim, H.J. The effect of multiwall carbon nanotube on the physical properties of polystyrene nanofibers using electrospinning technique. In The Effect of Multiwall Carbon Nanotube on the Physical Properties of Polystyrene Nanofibers Using Electrospinning Technique; AIP Publishing LLC: Melville, NY, USA, 2022. [Google Scholar]

- Snari, R.M.; Bayazeed, A.; Ibarhiam, S.F.; Alnoman, R.B.; Attar, R.; Abumelha, H.M.; El-Metwaly, N.M. Solution blowing spinning of polylactate/polyvinyl alcohol/ZnO nanocomposite toward green and sustainable preparation of wound dressing nanofibrous films. Microsc. Res. Tech. 2022, 85, 3860–3870. [Google Scholar] [CrossRef] [PubMed]

- Costa, R.G.; Brichi, G.S.; Ribeiro, C.; Mattoso, L.H. Nanocomposite fibers of poly (lactic acid)/titanium dioxide prepared by solution blow spinning. Polym. Bull. 2016, 73, 2973–2985. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Zhu, W.; Xu, Z.; Zhang, A.; Dong, G.; Zhao, G. Ultra-light, super-insulating, and strong polystyrene/carbon nanofiber nanocomposite foams fabricated by microcellular foaming. Eur. Polym. J. 2022, 173, 111261. [Google Scholar] [CrossRef]

- Martins, D.; Scagion, V.P.; Schneider, R.; Lemos, A.C.C.; Oliveira, J.; Correa, D.S. Biodegradable polymer nanofibers applied in slow release systems for agri-food applications. In Polymers for Agri-Food Applications; Springer: Berlin/Heidelberg, Germany, 2019; pp. 291–316. [Google Scholar]

- Shan, W.; Du, J.; Yang, K.; Ren, T.; Wan, D.; Pu, H. Superhydrophobic and superoleophilic polystyrene/carbon nanotubes foam for oil/water separation. J. Environ. Chem. Eng. 2021, 9, 106038. [Google Scholar] [CrossRef]

- Wang, N.; Chen, Y.; Ren, J.; Huang, X.; Chen, X.; Li, G.; Liu, D. Electrically conductive polyaniline/polyimide microfiber membrane prepared via a combination of solution blowing and subsequent in situ polymerization growth. J. Polym. Res. 2017, 24, 42. [Google Scholar] [CrossRef]

- Ikegame, M.; Tajima, K.; Aida, T. Template synthesis of polypyrrole nanofibers insulated within one-dimensional silicate channels: Hexagonal versus lamellar for recombination of polarons into bipolarons. Angew. Chem. Int. Ed. 2003, 42, 2154–2157. [Google Scholar] [CrossRef]

- Huang, J. Syntheses and applications of conducting polymer polyaniline nanofibers. Pure Appl. Chem. 2006, 78, 15–27. [Google Scholar] [CrossRef]

- Tao, S.L.; Desai, T.A. Aligned arrays of biodegradable poly (ϵ-caprolactone) nanowires and nanofibers by template synthesis. Nano Lett. 2007, 7, 1463–1468. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Liu, J.; Lee, L.A.; Bruckman, M.A.; Zhao, D.; Koley, G.; Wang, Q. Biological templated synthesis of water-soluble conductive polymeric nanowires. Nano Lett. 2007, 7, 3729–3733. [Google Scholar] [CrossRef] [PubMed]

- Baek, N.; Kim, Y.T.; Marcy, J.E.; Duncan, S.E.; O’Keefe, S.F. Physical properties of nanocomposite polylactic acid films prepared with oleic acid modified titanium dioxide. Food Packag. Shelf Life 2018, 17, 30–38. [Google Scholar] [CrossRef]

- Melone, L.; Altomare, L.; Alfieri, I.; Lorenzi, A.; De Nardo, L.; Punta, C. Ceramic aerogels from TEMPO-oxidized cellulose nanofibre templates: Synthesis, characterization, and photocatalytic properties. J. Photochem. Photobiol. A Chem. 2013, 261, 53–60. [Google Scholar] [CrossRef]

- Riaz, U.; Ahmad, S.; Ashraf, S. Pseudo template synthesis of poly (1-naphthylamine): Effect of environment on nanostructured morphology. J. Nanoparticle Res. 2008, 10, 1209–1214. [Google Scholar] [CrossRef]

- Costa, L.; Al-Hashimi, M.; Heeney, M.; Terekhov, A.; Rajput, D.; Hofmeister, W.; Verma, A. Template-synthesis of conjugated Poly (3-Hexylselenophene)(P3HS) nanofibers using femtosecond laser machined fused silica templates. MRS Adv. 2017, 2, 2957–2960. [Google Scholar] [CrossRef]

- Shah, A.A.; Cho, Y.H.; Nam, S.-E.; Park, A.; Park, Y.-I.; Park, H. High performance thin-film nanocomposite forward osmosis membrane based on PVDF/bentonite nanofiber support. J. Ind. Eng. Chem. 2020, 86, 90–99. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Soria, R.B.; Volodine, A.; Van der Bruggen, B. Aramid nanofiber and modified ZIF-8 constructed porous nanocomposite membrane for organic solvent nanofiltration. J. Membr. Sci. 2020, 603, 118002. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, T.; He, S.; Xiao, H.; Dai, H.; Yuan, B.; Chen, X.; Yang, X. Flame-retardant polyvinyl alcohol/cellulose nanofibers hybrid carbon aerogel by freeze drying with ultra-low phosphorus. Appl. Surf. Sci. 2019, 497, 143775. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.-Y.; Cordie, T.; Salick, M.; Peng, X.-F.; Turng, L.-S. Fabrication of porous poly (ε-caprolactone) scaffolds containing chitosan nanofibers by combining extrusion foaming, leaching, and freeze-drying methods. Ind. Eng. Chem. Res. 2014, 53, 17909–17918. [Google Scholar] [CrossRef]

- Lee, K.-Y.; Blaker, J.J.; Murakami, R.; Heng, J.Y.; Bismarck, A. Phase behavior of medium and high internal phase water-in-oil emulsions stabilized solely by hydrophobized bacterial cellulose nanofibrils. Langmuir 2014, 30, 452–460. [Google Scholar] [CrossRef] [PubMed]

- Qian, L.; Zhang, H. Green synthesis of chitosan-based nanofibers and their applications. Green Chem. 2010, 12, 1207–1214. [Google Scholar] [CrossRef]

- Ngadiman, N.H.A.; Yusof, N.M.; Idris, A.; Fallahiarezoudar, E.; Kurniawan, D. Novel processing technique to produce three dimensional polyvinyl alcohol/maghemite nanofiber scaffold suitable for hard tissues. Polymers 2018, 10, 353. [Google Scholar] [CrossRef]

- Khoramgah, M.S.; Ranjbari, J.; Abbaszadeh, H.-A.; Mirakabad, F.S.T.; Hatami, S.; Hosseinzadeh, S.; Ghanbarian, H. Freeze-dried multiscale porous nanofibrous three dimensional scaffolds for bone regenerations. BioImpacts 2020, 10, 73–85. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Si, Y.; Yu, J.; Ding, B. Electrospun porous engineered nanofiber materials: A versatile medium for energy and environmental applications. Chem. Eng. J. 2023, 456, 140989. [Google Scholar] [CrossRef]

- Babu, A.; Aazem, I.; Walden, R.; Bairagi, S.; Mulvihill, D.M.; Pillai, S.C. Electrospun nanofiber based TENGs for wearable electronics and self-powered sensing. Chem. Eng. J. 2023, 452, 139060. [Google Scholar] [CrossRef]

- Mohammadpourfazeli, S.; Arash, S.; Ansari, A.; Yang, S.; Mallick, K.; Bagherzadeh, R. Future prospects and recent developments of polyvinylidene fluoride (PVDF) piezoelectric polymer; fabrication methods, structure, and electro-mechanical properties. RSC Adv. 2023, 13, 370–387. [Google Scholar] [CrossRef]

- Nivedhitha, D.M.; Jeyanthi, S. Polyvinylidene fluoride, an advanced futuristic smart polymer material: A comprehensive review. Polym. Adv. Technol. 2023, 34, 474–505. [Google Scholar] [CrossRef]

- Yogarathinam, L.T.; Ismail, A.F.; Arthanareeswaran, G.; Bin Azali, M.A.; Bin Ramli, M.K.N.; Rushdan, A. Impact of Nanoclays on Polyvinylidene Fluoride Mixed Matrix Membranes for the Efficient Treatment of Oily Wastewater. Micro Nanosyst. 2023, 15, 35–42. [Google Scholar]

- Gaur, A.; Shukla, R.; Kumar, B.; Pal, A.; Chatterji, S.; Ranjan, R.; Maiti, P. Processing and nanoclay induced piezoelectricity in poly (vinylidene fluoride-co-hexafluoro propylene) nanohybrid for device application. Polymer 2016, 97, 362–369. [Google Scholar] [CrossRef]

- Yu, L.; Cebe, P. Crystal polymorphism in electrospun composite nanofibers of poly (vinylidene fluoride) with nanoclay. Polymer 2009, 50, 2133–2141. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Wang, J.; Zhang, Q.; Chen, F.; Deng, H.; Wang, K.; Fu, Q. Cooperative effect of shear and nanoclay on the formation of polar phase in poly (vinylidene fluoride) and the resultant properties. Polymer 2011, 52, 4970–4978. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Li, Y.; Xu, J.-T.; Fan, Z.-Q. Cooperative effect of electrospinning and nanoclay on formation of polar crystalline phases in poly (vinylidene fluoride). ACS Appl. Mater. Interfaces 2010, 2, 1759–1768. [Google Scholar] [CrossRef]

- Tiwari, S.; Gaur, A.; Kumar, C.; Maiti, P. Enhanced piezoelectric response in nanoclay induced electrospun PVDF nanofibers for energy harvesting. Energy 2019, 171, 485–492. [Google Scholar] [CrossRef]

- Aslam, M.; Kalyar, M.A.; Raza, Z.A. Polyvinyl alcohol: A review of research status and use of polyvinyl alcohol based nanocomposites. Polym. Eng. Sci. 2018, 58, 2119–2132. [Google Scholar] [CrossRef]

- Park, J.-C.; Ito, T.; Kim, K.-O.; Kim, K.-W.; Kim, B.-S.; Khil, M.-S.; Kim, H.-Y.; Kim, I.-S. Electrospun poly (vinyl alcohol) nanofibers: Effects of degree of hydrolysis and enhanced water stability. Polym. J. 2010, 42, 273–276. [Google Scholar] [CrossRef]

- Pandey, K.; Dwivedi, M.M. Spectroscopic Study of Poly Vinyl Alcohol Film Prepared in Different Polar Solvents. In Spectroscopic Study of Poly Vinyl Alcohol Film Prepared in Different Polar Solvents; Wiley Online Library: New York, NY, USA, 2023; p. 2100440. [Google Scholar]

- Tian, H.; Yuan, L.; Wang, J.; Wu, H.; Wang, H.; Xiang, A.; Ashok, B.; Rajulu, A.V. Electrospinning of polyvinyl alcohol into crosslinked nanofibers: An approach to fabricate functional adsorbent for heavy metals. J. Hazard. Mater. 2019, 378, 120751. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, H.W.; Chae, D.K.; Oh, W.; Yun, J.D.; Deng, Y.; Yeum, J.H. Electrospinning and characterization of poly (vinyl alcohol)/chitosan oligosaccharide/clay nanocomposite nanofibers in aqueous solutions. Colloid Polym. Sci. 2009, 287, 943–950. [Google Scholar] [CrossRef]

- Elhami, M.; Habibi, S. A Study on morphology of Poly (vinyl alcohol)-organoclay nanocomposite nanofibers. J. Sci. Technol. Compos. 2018, 5, 325–330. [Google Scholar]

- Elhami, M.; Habibi, S. A study on UV-protection property of poly (vinyl alcohol)-montmorillonite composite nanofibers. J. Vinyl Addit. Technol. 2021, 27, 89–96. [Google Scholar] [CrossRef]

- Sharma, B.; Jain, P.; Purwar, R. Preparation and characterization of poly (vinyl alcohol)/modified clay electrospun nanocomposite nanofibrous mats for microbial protection. J. Text. Inst. 2019, 110, 1624–1634. [Google Scholar] [CrossRef]

- Dilmani, S.A.; Koç, S.; Çakır, D.; Gümüşderelioğlu, M. Organomodified nanoclay with boron compounds is improving structural and antibacterial properties of nanofibrous matrices. Eur. J. Pharm. Biopharm. 2023, 184, 125–138. [Google Scholar] [CrossRef] [PubMed]

- Ilaslan, K.; Tornuk, F. Characterization of Silver Ions-Doped Organomodified Nanoclays. Arab. J. Sci. Eng. 2023, 48, 327–340. [Google Scholar] [CrossRef]

- Subramaniam, R.; Eswaran, A.; Sivasubramanian, G.; Gurusamy, A. Synthesis and characterization techniques for clay-based polymer nanocomposites and their evaluation of antibacterial, anticancer, and anti-inflammatory activities. Emergent Mater. 2023, 6, 261–269. [Google Scholar] [CrossRef]

- Hu, H.; Xu, Q.; Sun, L.; Zhu, R.; Gao, T.; He, Y.; Ma, B.; Yu, J.; Wang, X. Rapid Hydrolysis of Waste and Scrap PA6 Textiles to ε-Caprolactam. ACS Appl. Polym. Mater. 2023, 5, 751–763. [Google Scholar] [CrossRef]

- Zargham, S.; Bazgir, S.; Tavakoli, A.; Rashidi, A.S.; Damerchely, R. The effect of flow rate on morphology and deposition area of electrospun nylon 6 nanofiber. J. Eng. Fibers Fabr. 2012, 7, 155892501200700414. [Google Scholar] [CrossRef]

- Li, L.; Bellan, L.M.; Craighead, H.G.; Frey, M.W. Formation and properties of nylon-6 and nylon-6/montmorillonite composite nanofibers. Polymer 2006, 47, 6208–6217. [Google Scholar] [CrossRef]

- Saeed, K.; Park, S.Y. Effect of nanoclay on the thermal, mechanical, and crystallization behavior of nanofiber webs of nylon-6. Polym. Compos. 2012, 33, 192–195. [Google Scholar] [CrossRef]

- Wu, H.; Krifa, M.; Koo, J.H. Flame retardant polyamide 6/nanoclay/intumescent nanocomposite fibers through electrospinning. Text. Res. J. 2014, 84, 1106–1118. [Google Scholar] [CrossRef]

- Agarwal, A.; Raheja, A.; Natarajan, T.; Chandra, T. Effect of electrospun montmorillonite-nylon 6 nanofibrous membrane coated packaging on potato chips and bread. Innov. Food Sci. Emerg. Technol. 2014, 26, 424–430. [Google Scholar] [CrossRef]

- Rafiee, R.; Shahzadi, R. Predicting mechanical properties of nanoclay/polymer composites using stochastic approach. Compos. Part B Eng. 2018, 152, 31–42. [Google Scholar] [CrossRef]

- Diedkova, K.; Pogrebnjak, A.D.; Kyrylenko, S.; Smyrnova, K.; Buranich, V.V.; Horodek, P.; Zukowski, P.; Koltunowicz, T.N.; Galaszkiewicz, P.; Makashina, K. Polycaprolactone–MXene Nanofibrous Scaffolds for Tissue Engineering. ACS Appl. Mater. Interfaces 2023, 15, 14033–14047. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Bartnikowski, M.; Dargaville, T.R.; Ivanovski, S.; Hutmacher, D.W. Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment. Prog. Polym. Sci. 2019, 96, 1–20. [Google Scholar] [CrossRef]

- Irandoost, M.; Pezeshki-Modaress, M.; Javanbakht, V. Removal of lead from aqueous solution with nanofibrous nanocomposite of polycaprolactone adsorbent modified by nanoclay and nanozeolite. J. Water Process Eng. 2019, 32, 100981. [Google Scholar] [CrossRef]

- Devina Merin, D.; Anith Jose, R.; Arulananth, T.; Allwyn Sundarraj, A.; Inbamalar, T.; Getnet Meharie, M. Nanoclay-Incorporated Polycaprolactone Matrix via Electrospinning Techniques-Enriched Spectroscopic Responses. J. Nanomater. 2023, 2023, 1194158. [Google Scholar] [CrossRef]

- Zhou, Y.; Mahurubin, S.; Sooriyaarachchi, D.; Tan, G.Z. The effect of nanoclays on nanofiber density gradient in 3D scaffolds fabricated by divergence electrospinning. Procedia Manuf. 2019, 34, 110–117. [Google Scholar] [CrossRef]

- Ahmadi, S.; Shafiei, S.S.; Sabouni, F. Electrospun Nanofibrous Scaffolds of Polycaprolactone/Gelatin Reinforced with Layered Double Hydroxide Nanoclay for Nerve Tissue Engineering Applications. ACS Omega 2022, 7, 28351–28360. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, H.; Hu, J.; Chen, S.; Yeung, L. Preparation of polyurethane nanofibers by electrospinning. J. Appl. Polym. Sci. 2008, 109, 406–411. [Google Scholar] [CrossRef]

- Yeganegi, M.; Kandel, R.A.; Santerre, J.P. Characterization of a biodegradable electrospun polyurethane nanofiber scaffold: Mechanical properties and cytotoxicity. Acta Biomater. 2010, 6, 3847–3855. [Google Scholar] [CrossRef]

- Sambaer, W.; Zatloukal, M.; Kimmer, D. 3D modeling of filtration process via polyurethane nanofiber based nonwoven filters prepared by electrospinning process. Chem. Eng. Sci. 2011, 66, 613–623. [Google Scholar] [CrossRef]

- Viscusi, G.; Lamberti, E.; D’Amico, F.; Tammaro, L.; Vigliotta, G.; Gorrasi, G. Design and characterization of polyurethane based electrospun systems modified with transition metals oxides for protective clothing applications. Appl. Surf. Sci. 2023, 617, 156563. [Google Scholar] [CrossRef]

- Saha, K.; Butola, B.S.; Joshi, M. Drug-loaded polyurethane/clay nanocomposite nanofibers for topical drug-delivery application. J. Appl. Polym. Sci. 2014, 131, 40230. [Google Scholar] [CrossRef]

- Bahrambeygi, H.; Sabetzadeh, N.; Rabbi, A.; Nasouri, K.; Shoushtari, A.M.; Babaei, M.R. Nanofibers (PU and PAN) and nanoparticles (Nanoclay and MWNTs) simultaneous effects on polyurethane foam sound absorption. J. Polym. Res. 2013, 20, 72. [Google Scholar] [CrossRef]

- Singh, S.; Kumar Paswan, K.; Kumar, A.; Gupta, V.; Sonker, M.; Ashhar Khan, M.; Kumar, A.; Shreyash, N. Recent Advancements in Polyurethane-based Tissue Engineering. ACS Appl. Bio Mater. 2023, 6, 327–348. [Google Scholar] [CrossRef]

- Salah, L.S.; Ouslimani, N.; Danlée, Y.; Beltrán, F.R.; Huynen, I.; de la Orden, M.U. Investigation of mechanical recycling effect on electromagnetic properties of polylactic acid (PLA)–Nanoclay nanocomposites: Towards a valorization of recycled PLA nanocomposites. Compos. Part C Open Access 2023, 10, 100339. [Google Scholar] [CrossRef]

- Tsuji, H. Poly (lactic acid). In Bio-Based Plastics: Materials and Applications; Wiley Online Library: New York, NY, USA, 2013; pp. 171–239. [Google Scholar]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable polylactic acid (PLA)-based sustainable engineered blends and biocomposites: Recent developments, challenges, and opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Mehmood, A.; Raina, N.; Phakeenuya, V.; Wonganu, B.; Cheenkachorn, K. The current status and market trend of polylactic acid as biopolymer: Awareness and needs for sustainable development. Mater. Today Proc. 2023, 72, 3049–3055. [Google Scholar] [CrossRef]

- Ilyas, R.; Zuhri, M.; Aisyah, H.; Asyraf, M.; Hassan, S.; Zainudin, E.; Sapuan, S.; Sharma, S.; Bangar, S.; Jumaidin, R. Natural fiber-reinforced polylactic acid, polylactic acid blends and their composites for advanced applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef]

- Fattahi, F.; Khoddami, A.; Avinc, O. Poly (Lactic Acid) nanofibres as drug delivery systems: Opportunities and challenges. Nanomed. Res. J. 2019, 4, 130–140. [Google Scholar]

- Hardiansyah, A.; Tanadi, H.; Yang, M.-C.; Liu, T.-Y. Electrospinning and antibacterial activity of chitosan-blended poly (lactic acid) nanofibers. J. Polym. Res. 2015, 22, 59. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Bikiaris, D.N.; Ait Hocine, N. Effect of rigid nanoparticles and preparation techniques on the performances of poly (lactic acid) nanocomposites: A review. Polym. Adv. Technol. 2021, 32, 444–460. [Google Scholar] [CrossRef]

- Valapa, R.B.; Pugazhenthi, G.; Katiyar, V. Effect of graphene content on the properties of poly (lactic acid) nanocomposites. RSC Adv. 2015, 5, 28410–28423. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Imran, M.; Wahit, M.U. Toughening of polylactic acid nanocomposites: A short review. Polym. Plast. Technol. Eng. 2012, 51, 175–192. [Google Scholar] [CrossRef]

- Picard, E.; Espuche, E.; Fulchiron, R. Effect of an organo-modified montmorillonite on PLA crystallization and gas barrier properties. Appl. Clay Sci. 2011, 53, 58–65. [Google Scholar] [CrossRef]

- Lewitus, D.; McCarthy, S.; Ophir, A.; Kenig, S. The effect of nanoclays on the properties of PLLA-modified polymers part 1: Mechanical and thermal properties. J. Polym. Environ. 2006, 14, 171–177. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Okamoto, M.; Ueda, K. New polylactide-layered silicate nanocomposites. 2. Concurrent improvements of material properties, biodegradability and melt rheology. Polymer 2003, 44, 857–866. [Google Scholar]

- Mayekar, P.C.; Castro-Aguirre, E.; Auras, R.; Selke, S.; Narayan, R. Effect of nano-clay and surfactant on the biodegradation of poly (lactic acid) films. Polymers 2020, 12, 311. [Google Scholar] [CrossRef] [PubMed]

- Pavón, E.; Martín-Rodríguez, R.; Perdigón, A.C.; Alba, M.D. New trends in nanoclay-modified sensors. Inorganics 2021, 9, 43. [Google Scholar] [CrossRef]

- Lal, G.; Tiwari, D. Investigation of nanoclay doped polymeric composites on piezoelectric Quartz Crystal Microbalance (QCM) sensor. Sens. Actuators B Chem. 2018, 262, 64–69. [Google Scholar] [CrossRef]

- Pirsa, S. Biodegradable film based on pectin/Nano-clay/methylene blue: Structural and physical properties and sensing ability for measurement of vitamin C. Int. J. Biol. Macromol. 2020, 163, 666–675. [Google Scholar] [CrossRef] [PubMed]

- López-Cabrera, H.; Figueroa-López, U.; Taylor, A.; Guevara-Morales, A. Dynamic Fracture Resistance under Plane Strain Conditions of High-Density Polyethylene Nanoclay Composites. Polymers 2023, 15, 813. [Google Scholar] [CrossRef]

- Yan, J.; Liu, M.; Jeong, Y.G.; Kang, W.; Li, L.; Zhao, Y.; Deng, N.; Cheng, B.; Yang, G. Performance enhancements in poly (vinylidene fluoride)-based piezoelectric nanogenerators for efficient energy harvesting. Nano Energy 2019, 56, 662–692. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Kang, W.; Liu, X.; Wang, Q. Current advances and future perspectives of additive manufacturing for functional polymeric materials and devices. SusMat 2021, 1, 127–147. [Google Scholar] [CrossRef]

- Lai, C.Y.; Groth, A.; Gray, S.; Duke, M. Enhanced abrasion resistant PVDF/nanoclay hollow fibre composite membranes for water treatment. J. Membr. Sci. 2014, 449, 146–157. [Google Scholar] [CrossRef]

- Hwang, H.-Y.; Deuk-Ju, K.; Hyung-Jun, K.; Young-Taik, H.; Sang-Yong, N. Effect of nanoclay on properties of porous PVdF membranes. Trans. Nonferrous Met. Soc. China 2011, 21, s141–s147. [Google Scholar] [CrossRef]

- Lu, L.; Ding, W.; Liu, J.; Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 2020, 78, 105251. [Google Scholar] [CrossRef]

- Xin, Y.; Qi, X.; Tian, H.; Guo, C.; Li, X.; Lin, J.; Wang, C. Full-fiber piezoelectric sensor by straight PVDF/nanoclay nanofibers. Mater. Lett. 2016, 164, 136–139. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Asim, M. Nanocomposites with Nanofibers and Fillers from Renewable Resources’ Green Composites for Automotive Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 145–170. [Google Scholar]

- Kausar, A. A review of high performance polymer nanocomposites for packaging applications in electronics and food industries. J. Plast. Film. Sheeting 2020, 36, 94–112. [Google Scholar] [CrossRef]

- Bratovčić, A.; Odobašić, A.; Ćatić, S.; Šestan, I. Application of polymer nanocomposite materials in food packaging. Croat. J. Food Sci. Technol. 2015, 7, 86–94. [Google Scholar] [CrossRef]

- Nath, D.; Santhosh, R.; Pal, K.; Sarkar, P. Nanoclay-based active food packaging systems: A review. Food Packag. Shelf Life 2022, 31, 100803. [Google Scholar] [CrossRef]

- Idumah, C.I.; Hassan, A.; Ihuoma, D.E. Recently emerging trends in polymer nanocomposites packaging materials. Polym. Plast. Technol. Mater. 2019, 58, 1054–1109. [Google Scholar] [CrossRef]

- Lasenko, I.; Sanchaniya, J.V.; Kanukuntla, S.P.; Ladani, Y.; Viluma-Gudmona, A.; Kononova, O.; Lusis, V.; Tipans, I.; Selga, T. The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers. Polymers 2023, 15, 673. [Google Scholar] [CrossRef]

- Harrison, R.H.; St-Pierre, J.-P.; Stevens, M.M. Tissue engineering and regenerative medicine: A year in review. Tissue Eng. Part B Rev. 2014, 20, 1–16. [Google Scholar] [CrossRef]

- Chyzy, A.; Plonska-Brzezinska, M.E. Hydrogel properties and their impact on regenerative medicine and tissue engineering. Molecules 2020, 25, 5795. [Google Scholar] [CrossRef]

- Saini, G.; Segaran, N.; Mayer, J.L.; Saini, A.; Albadawi, H.; Oklu, R. Applications of 3D bioprinting in tissue engineering and regenerative medicine. J. Clin. Med. 2021, 10, 4966. [Google Scholar] [CrossRef]

- Rahmati, M.; Mills, D.K.; Urbanska, A.M.; Saeb, M.R.; Venugopal, J.R.; Ramakrishna, S.; Mozafari, M. Electrospinning for tissue engineering applications. Prog. Mater. Sci. 2021, 117, 100721. [Google Scholar] [CrossRef]

- Gao, X.; Han, S.; Zhang, R.; Liu, G.; Wu, J. Progress in electrospun composite nanofibers: Composition, performance and applications for tissue engineering. J. Mater. Chem. B 2019, 7, 7075–7089. [Google Scholar] [CrossRef] [PubMed]

- Nouri, M.; Mokhtari, J.; Rostamloo, M. Electrospun poly (ɛ-caprolactone)/nanoclay nanofibrous mats for tissue engineering. Fibers Polym. 2013, 14, 957–964. [Google Scholar] [CrossRef]

- Koosha, M.; Mirzadeh, H.; Shokrgozar, M.A.; Farokhi, M. Nanoclay-reinforced electrospun chitosan/PVA nanocomposite nanofibers for biomedical applications. RSC Adv. 2015, 5, 10479–10487. [Google Scholar] [CrossRef]

- Ghasemi Hamidabadi, H.; Rezvani, Z.; Nazm Bojnordi, M.; Shirinzadeh, H.; Seifalian, A.M.; Joghataei, M.T.; Razaghpour, M.; Alibakhshi, A.; Yazdanpanah, A.; Salimi, M. Chitosan-intercalated montmorillonite/poly (vinyl alcohol) nanofibers as a platform to guide neuronlike differentiation of human dental pulp stem cells. ACS Appl. Mater. Interfaces 2017, 9, 11392–11404. [Google Scholar] [CrossRef]

- Hakimi, F.; Jafari, H.; Hashemikia, S.; Shabani, S.; Ramazani, A. Chitosan-polyethylene oxide/clay-alginate nanofiber hydrogel scaffold for bone tissue engineering: Preparation, physical characterization, and biomimetic mineralization. Int. J. Biol. Macromol. 2023, 233, 123453. [Google Scholar] [CrossRef] [PubMed]

- Golafshan, N.; Rezahasani, R.; Esfahani, M.T.; Kharaziha, M.; Khorasani, S. Nanohybrid hydrogels of laponite: PVA-Alginate as a potential wound healing material. Carbohydr. Polym. 2017, 176, 392–401. [Google Scholar] [CrossRef] [PubMed]

- Venkataprasanna, K.; Prakash, J.; Vignesh, S.; Bharath, G.; Venkatesan, M.; Banat, F.; Sahabudeen, S.; Ramachandran, S.; Venkatasubbu, G.D. Fabrication of Chitosan/PVA/GO/CuO patch for potential wound healing application. Int. J. Biol. Macromol. 2020, 143, 744–762. [Google Scholar] [CrossRef]

- Baghaie, S.; Khorasani, M.T.; Zarrabi, A.; Moshtaghian, J. Wound healing properties of PVA/starch/chitosan hydrogel membranes with nano Zinc oxide as antibacterial wound dressing material. J. Biomater. Sci. Polym. Ed. 2017, 28, 2220–2241. [Google Scholar] [CrossRef]

- Heydary, H.A.; Karamian, E.; Poorazizi, E.; Khandan, A.; Heydaripour, J. A novel nano-fiber of Iranian gum tragacanth-polyvinyl alcohol/nanoclay composite for wound healing applications. Procedia Mater. Sci. 2015, 11, 176–182. [Google Scholar] [CrossRef]

| Methods | Nanofiber Diameter | Effecting Parameters | Production/Injection Rate | Voltage | Industrialization | Formation of Aligned Nanofibers | Polymer/Composite Fiber Formed | Ref. |

|---|---|---|---|---|---|---|---|---|

| Electrospinning | 40 nm–2 μm | Viscosity; voltage; distance; solution feed rate | 5 μL/min | 10–40 kV | Yes | Yes | Polystyrene; polyamide; polyaniline; poly(lactic acid); poly(lactic acid)/polyaniline; poly(lactic acid)/poly(vinylpyrrolidone); polystyrene/graphene; polystyrene/carbon nanotube | [51,52,53,56,57,58,69,70,71,72,73,74] |

| Solution blowing | 40 nm–several μm | Voltage; viscosity; nozzle geometry; solution feed Rate | 20 μL/min | No | Yes | Yes | Polystyrene/carbon nanotube; polyamide/carbon nanotube; polyaniline/carbon nanotube; polyaniline/carbon nanotube nanofiber; polyaniline/titania; nylon 6,6/zinc oxide; poly(vinyl fluoride)/bentonite/ poly(vinyl alcohol); polyaniline/polyimide | [75,76,77,78,79,80] |

| Template synthesis | 40 nm–200 nm | Template shape; template pore size | - | ~30 V | No | Yes | Poly (lactic acid); poly(vinyl alcohol); poly(lactic acid)/titanium dioxide; poly(vinyl alcohol)/zinc oxide; poly (1-naphthylamine); cellulose nanofiber; polypyrrole nanofibers; poly(ϵ-caprolactone) nanowires; poly (3-Hexylselenophene) | [81,82,83,84,85,86,87,88] |

| Phase inversion/freeze drying | 50 nm–1 μm | Polymer concentration; solvent properties; freezing rate; | - | No | No | Yes | Polyaniline; polypyrrole; polypyrrole/silica; poly (ε-caprolactone); poly(vinyl alcohol)/maghemite; cellulose nanofibrils; chitosan; polytetrafluoroethylene | [89,90,91,92,93,94,95,96] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H. Nanoclay-Reinforced Nanocomposite Nanofibers—Fundamentals and State-of-the-Art Developments. Minerals 2023, 13, 817. https://doi.org/10.3390/min13060817

Kausar A, Ahmad I, Aldaghri O, Ibnaouf KH, Eisa MH. Nanoclay-Reinforced Nanocomposite Nanofibers—Fundamentals and State-of-the-Art Developments. Minerals. 2023; 13(6):817. https://doi.org/10.3390/min13060817

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, O. Aldaghri, Khalid H. Ibnaouf, and M. H. Eisa. 2023. "Nanoclay-Reinforced Nanocomposite Nanofibers—Fundamentals and State-of-the-Art Developments" Minerals 13, no. 6: 817. https://doi.org/10.3390/min13060817

APA StyleKausar, A., Ahmad, I., Aldaghri, O., Ibnaouf, K. H., & Eisa, M. H. (2023). Nanoclay-Reinforced Nanocomposite Nanofibers—Fundamentals and State-of-the-Art Developments. Minerals, 13(6), 817. https://doi.org/10.3390/min13060817