The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines

Abstract

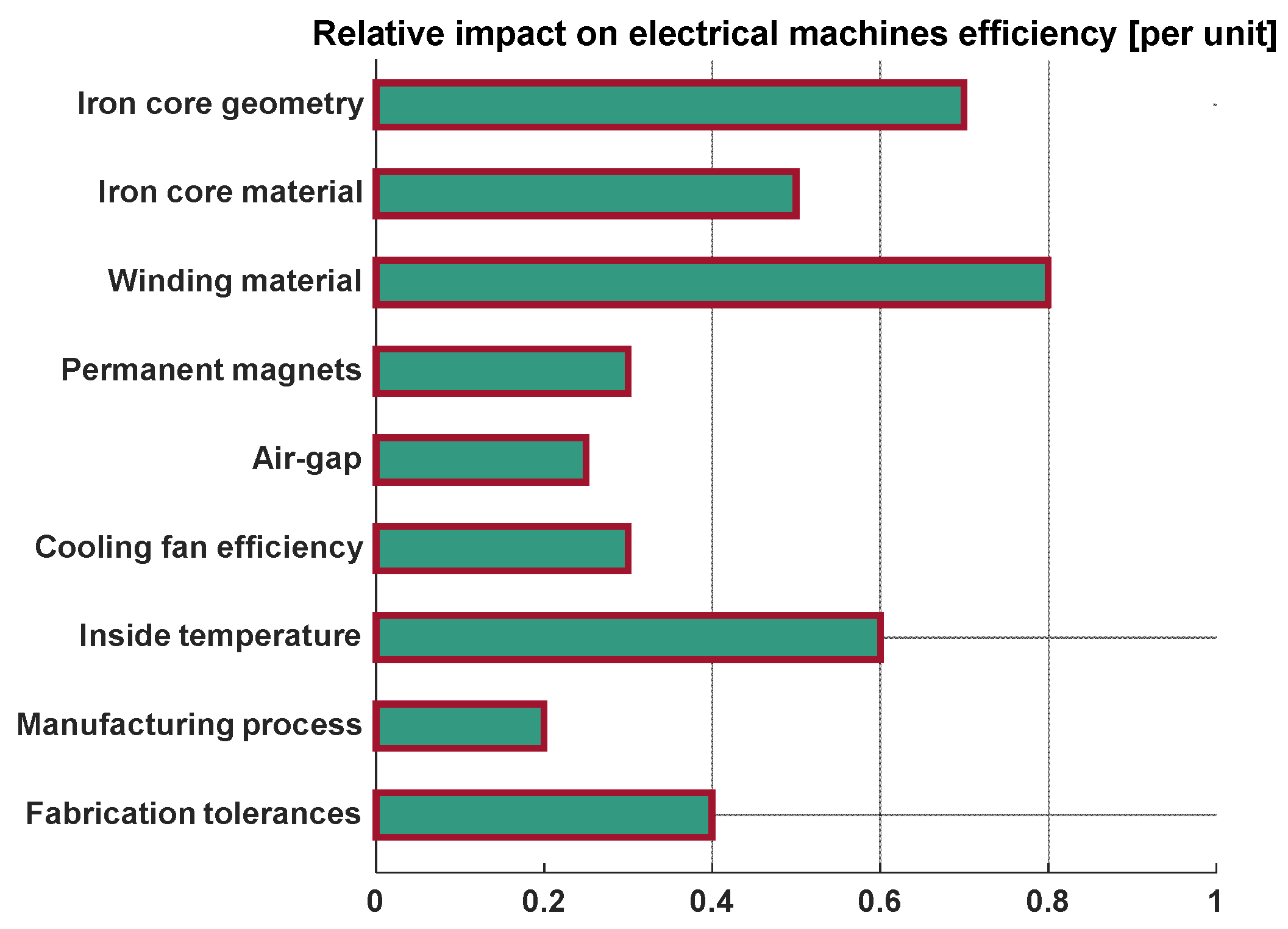

:1. Introduction

2. Additive Manufacturing Technologies

3. Materials for 3D Printing of Electrical Machines

3.1. Soft Magnetic Materials

3.2. Hard Magnetic Materials

3.3. Conducting Materials

3.4. Insulator Materials

3.5. Materials for Thermal Management

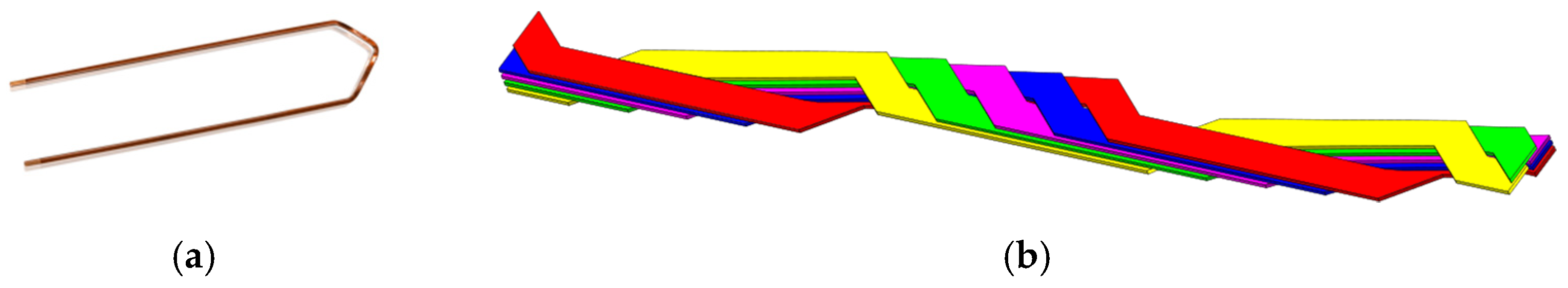

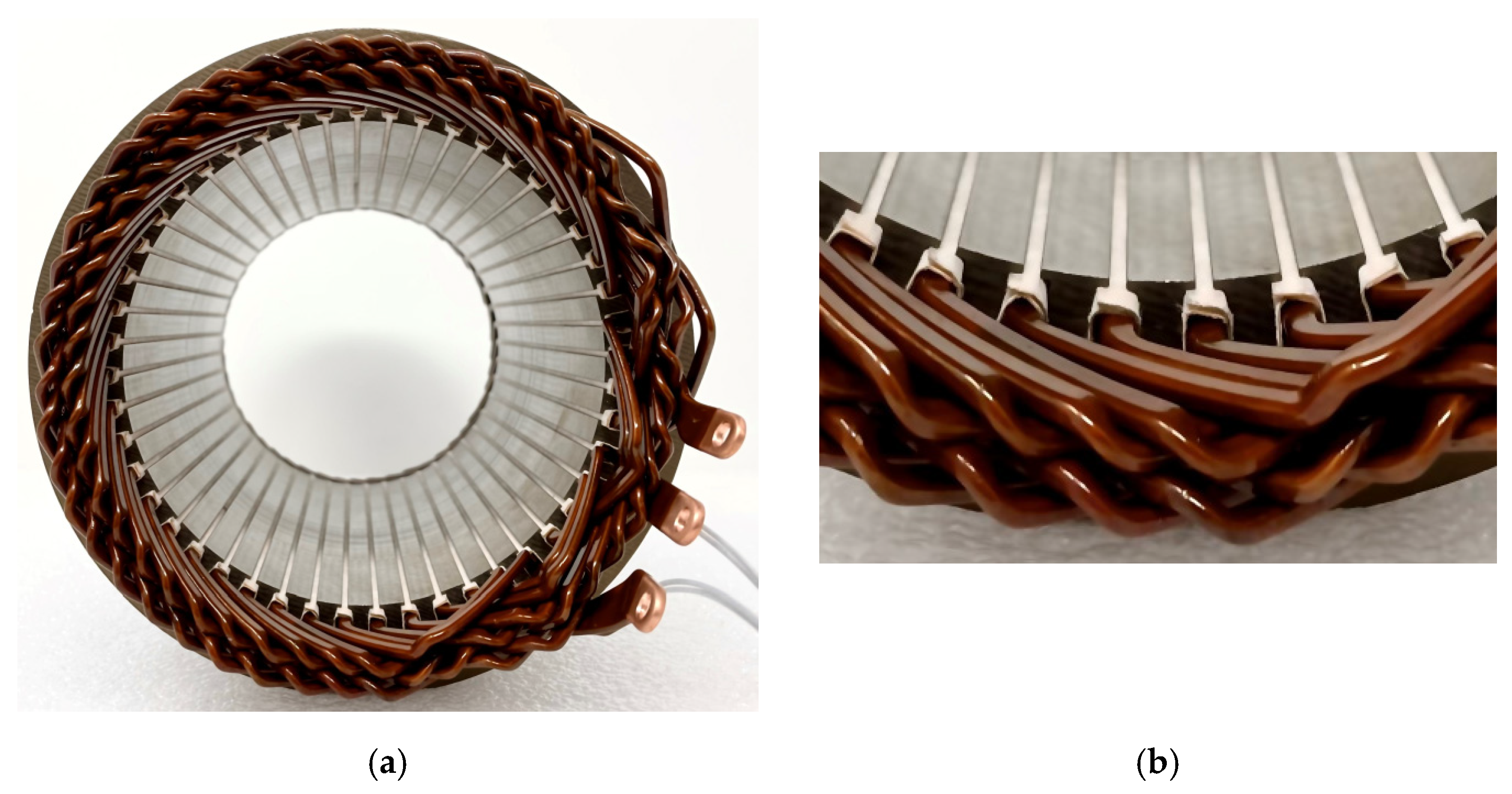

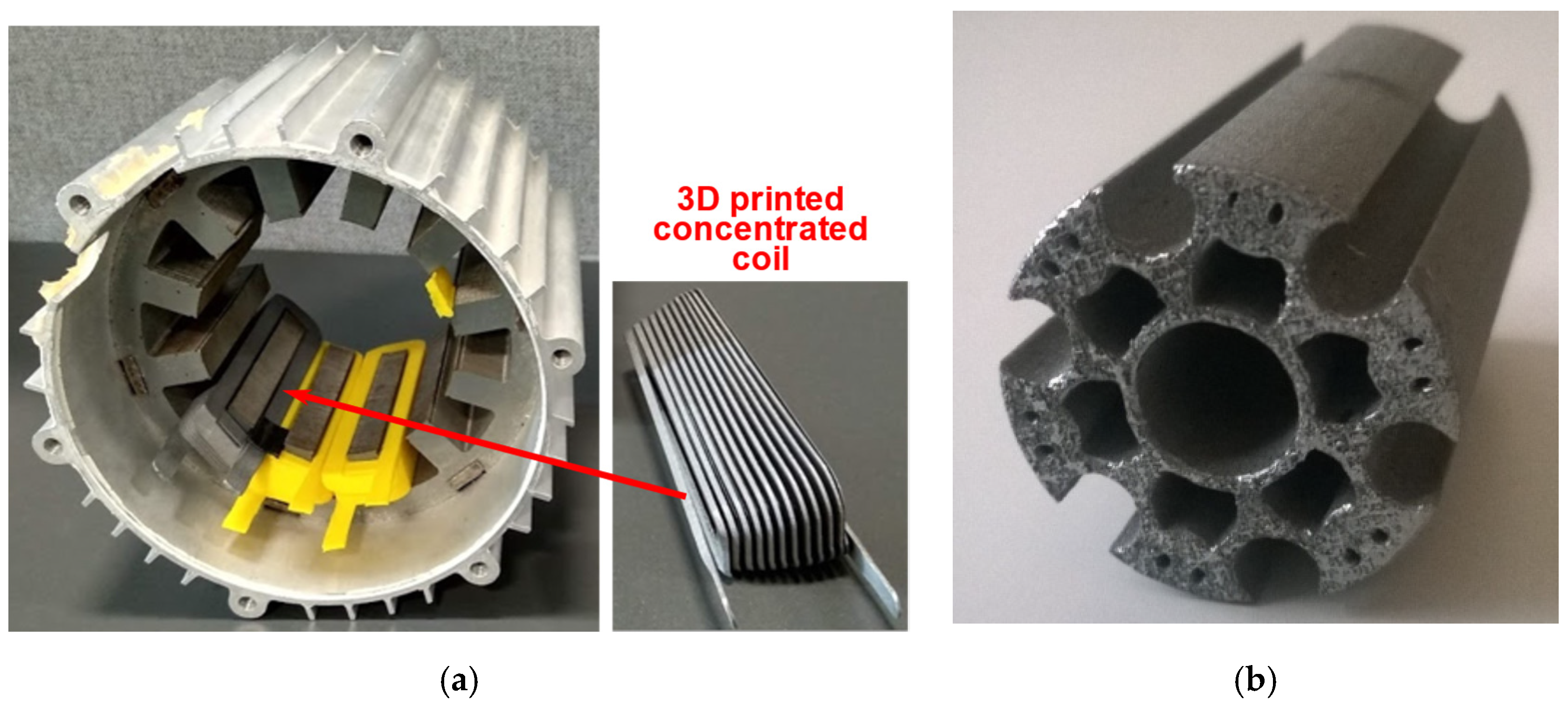

4. 3D Printing of Windings

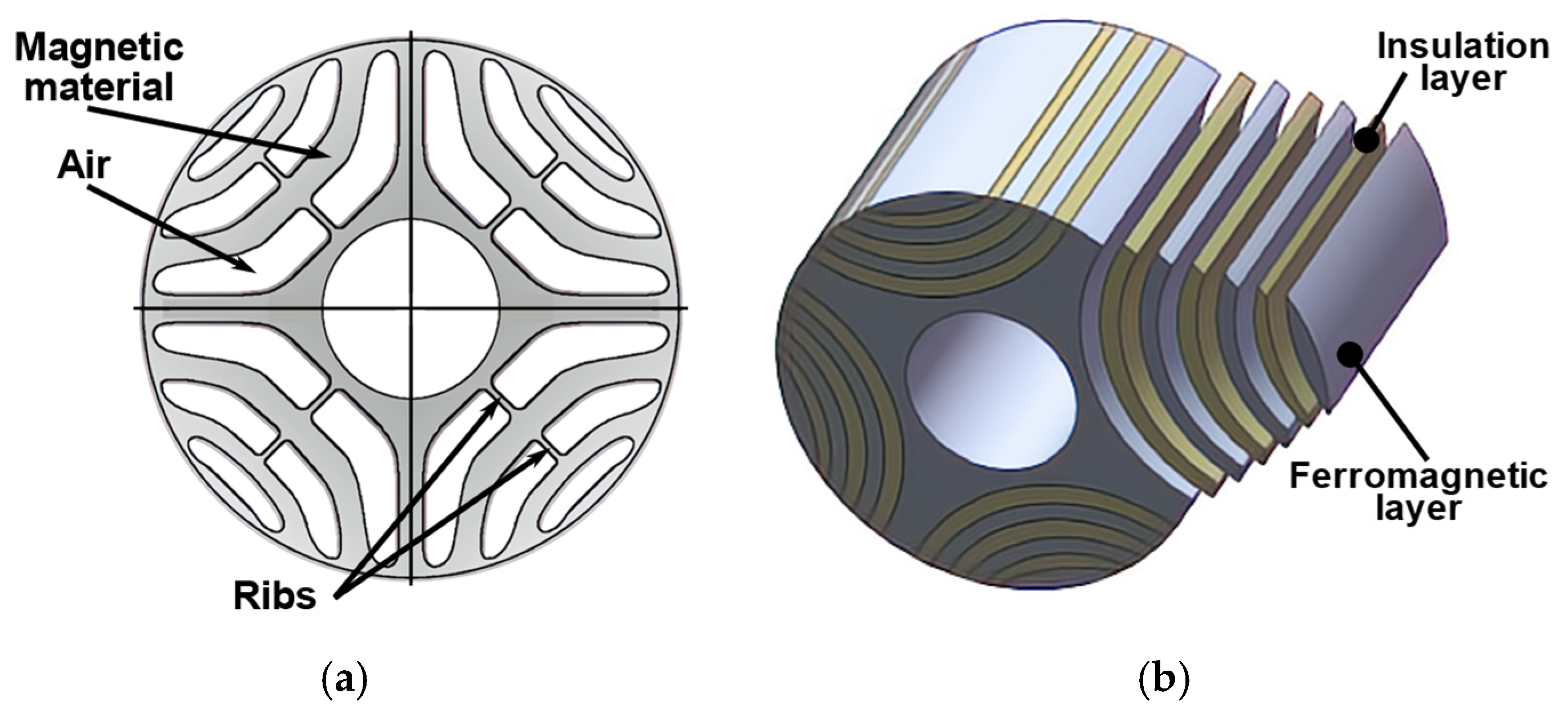

5. Additive Manufacturing of the Iron Cores

6. Additive Manufacturing of the Cooling Systems

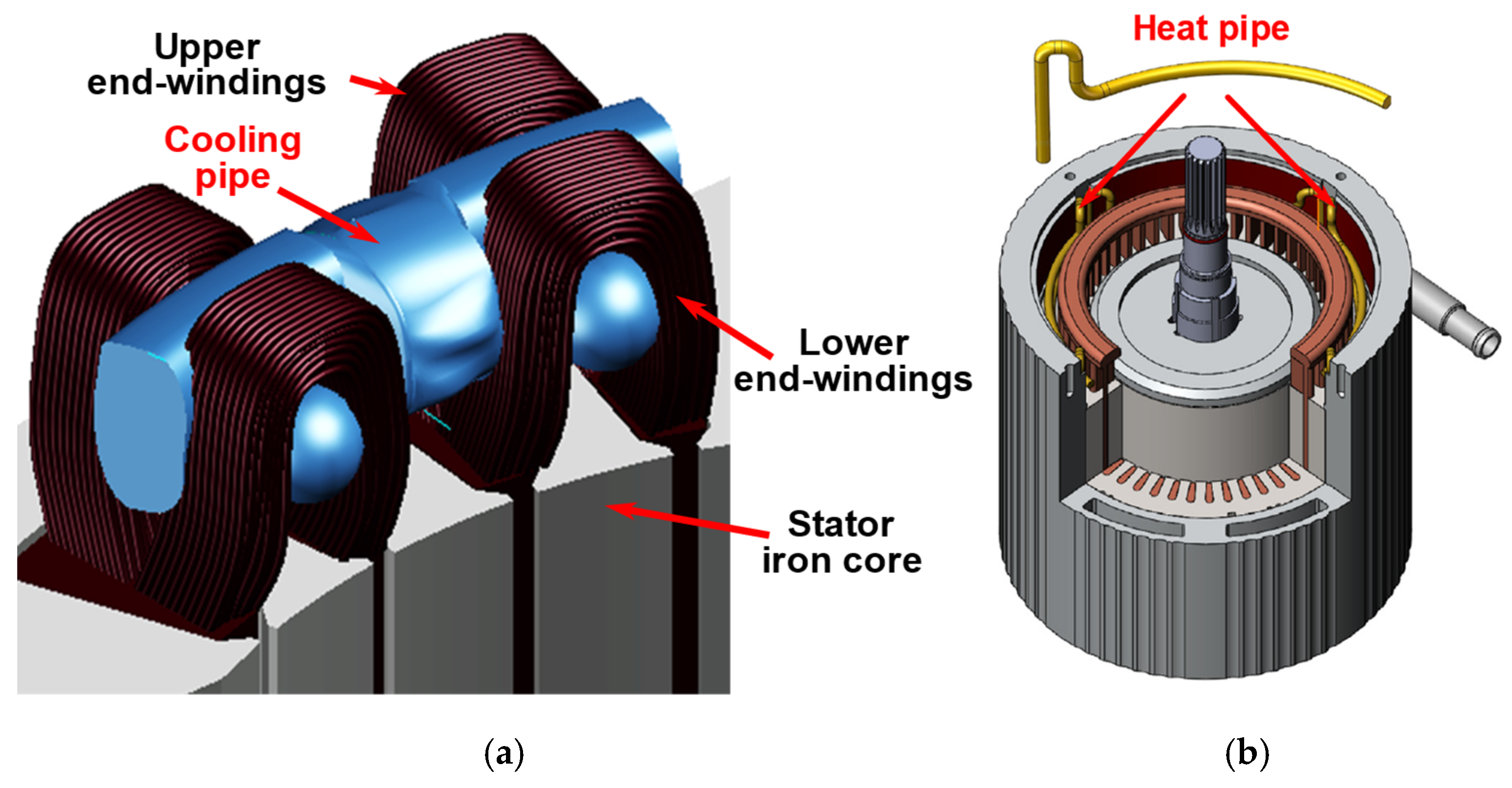

6.1. Hollow Winding Conductors

6.2. Direct Cooling of the Windings

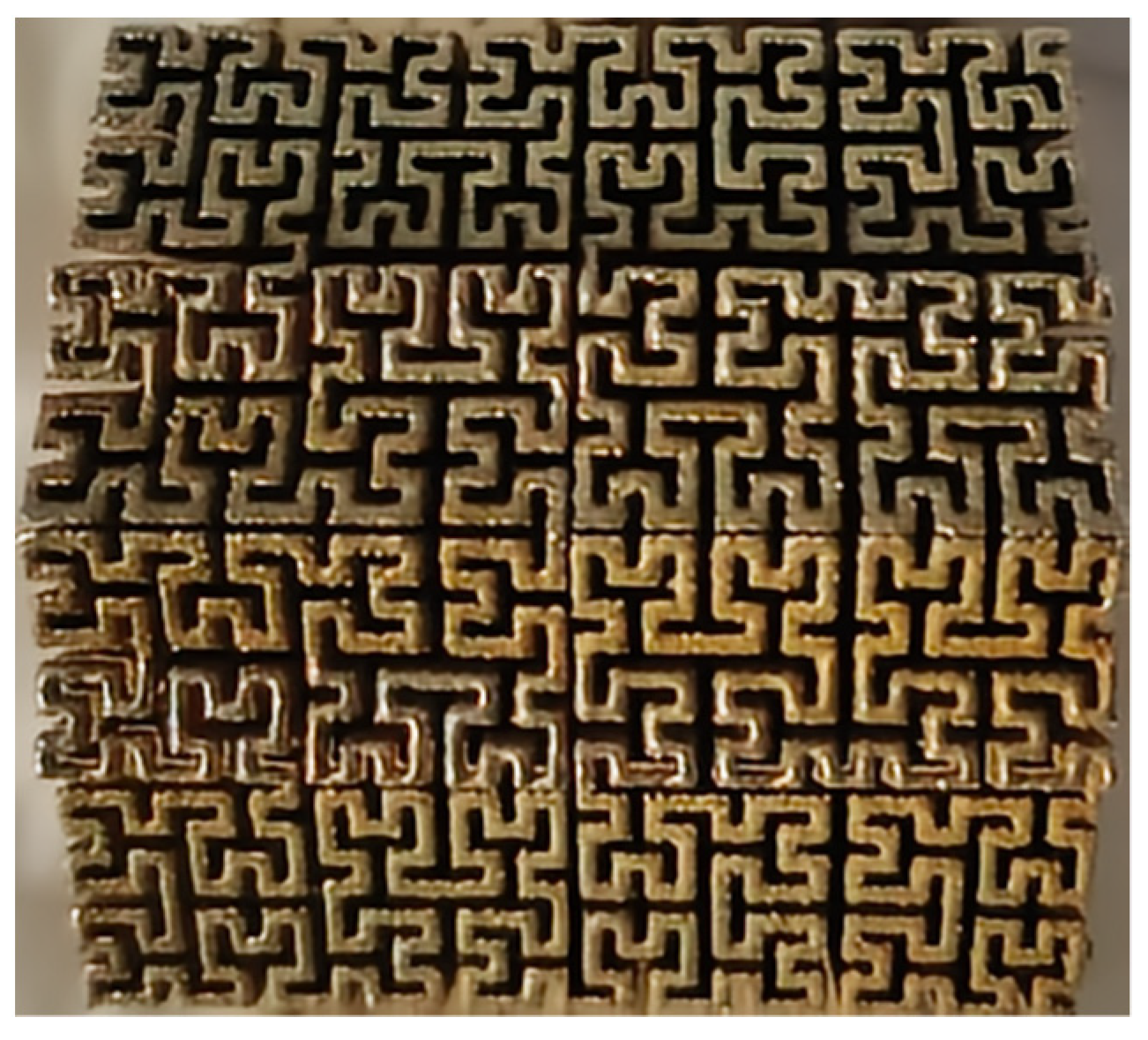

6.3. Cooling the Iron Core

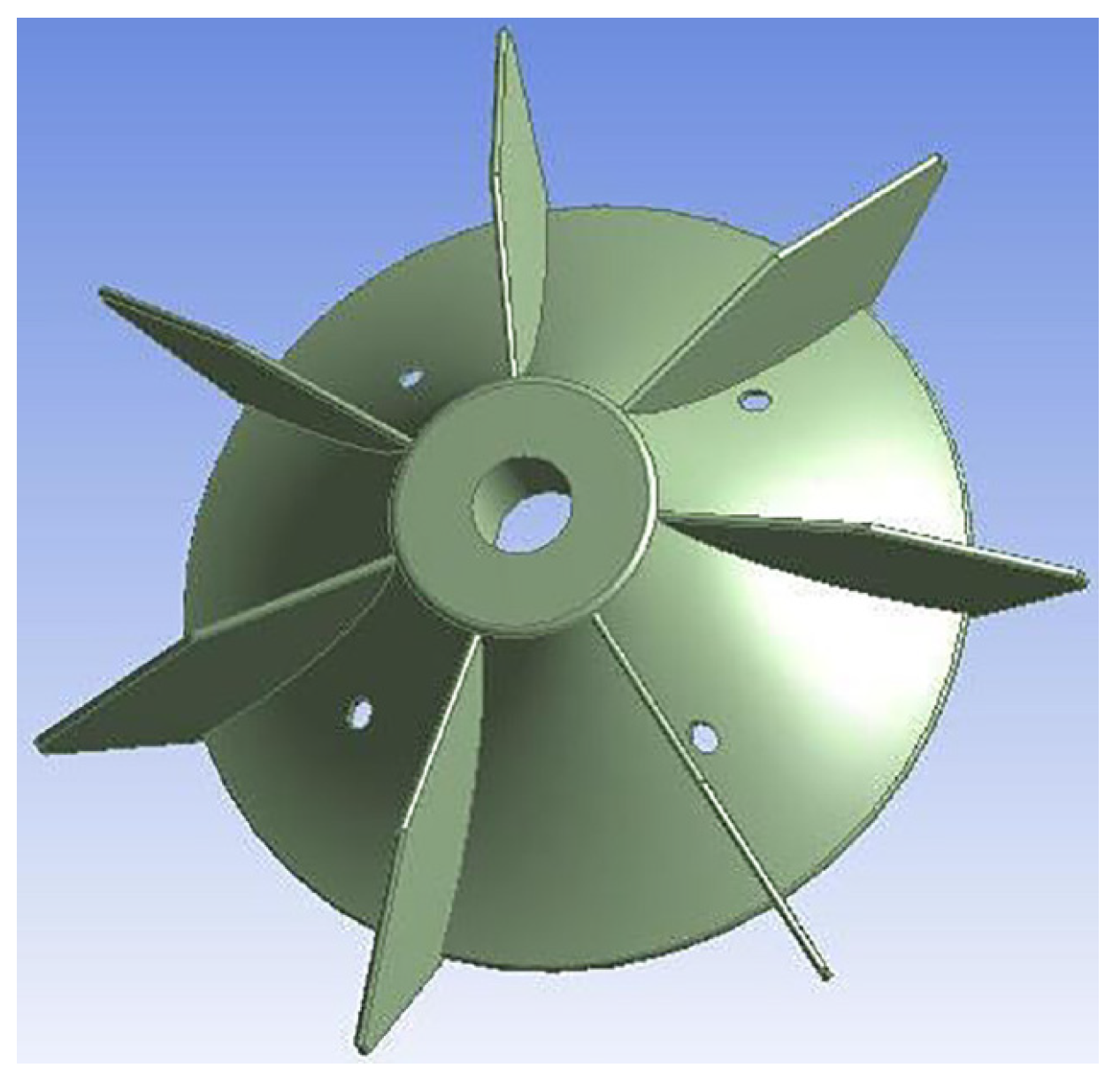

6.4. The Housing and the Cooling Fan

7. Representative and Potential Examples of Using 3D Printing in the Fabrication of Electric Machines

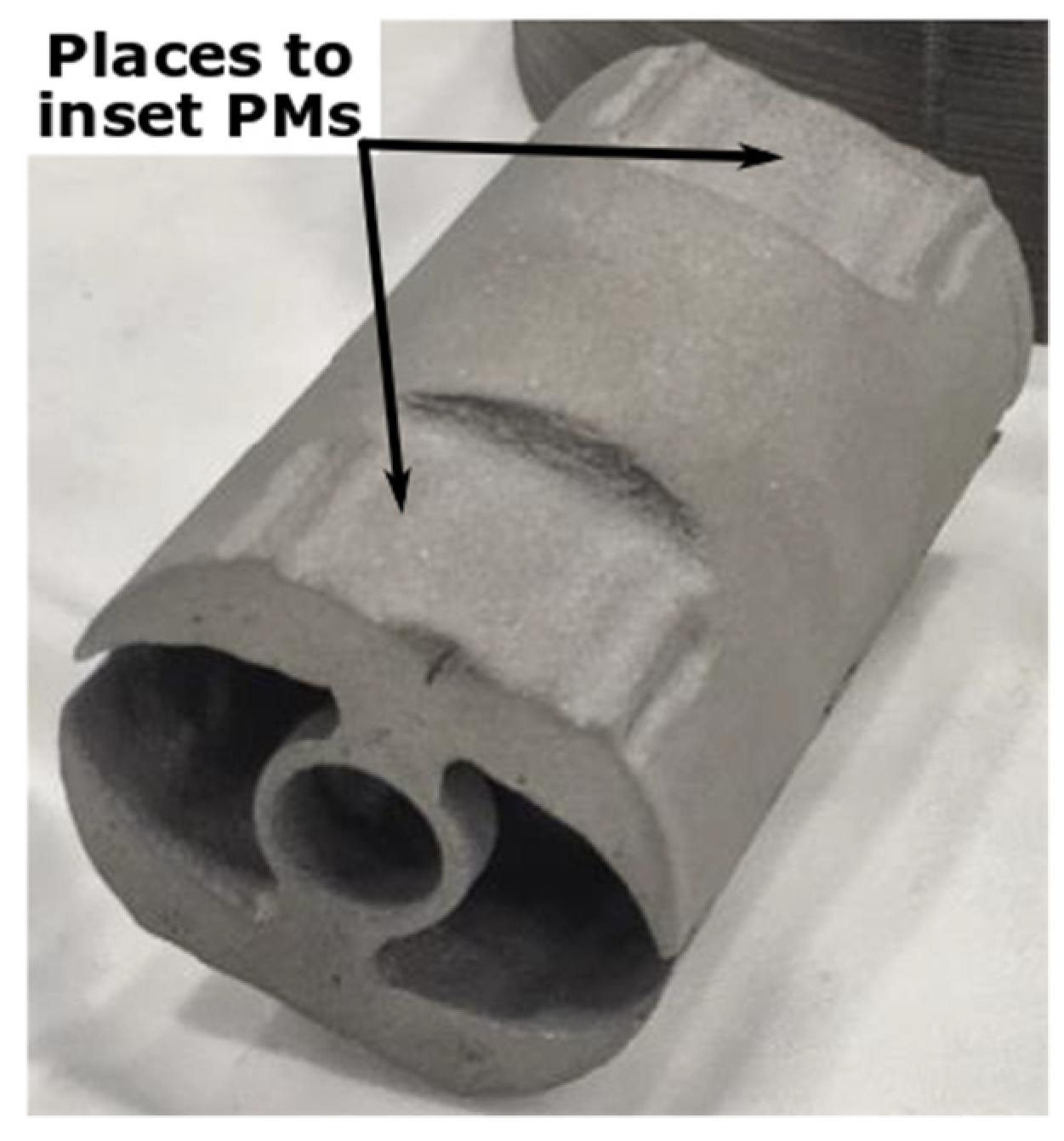

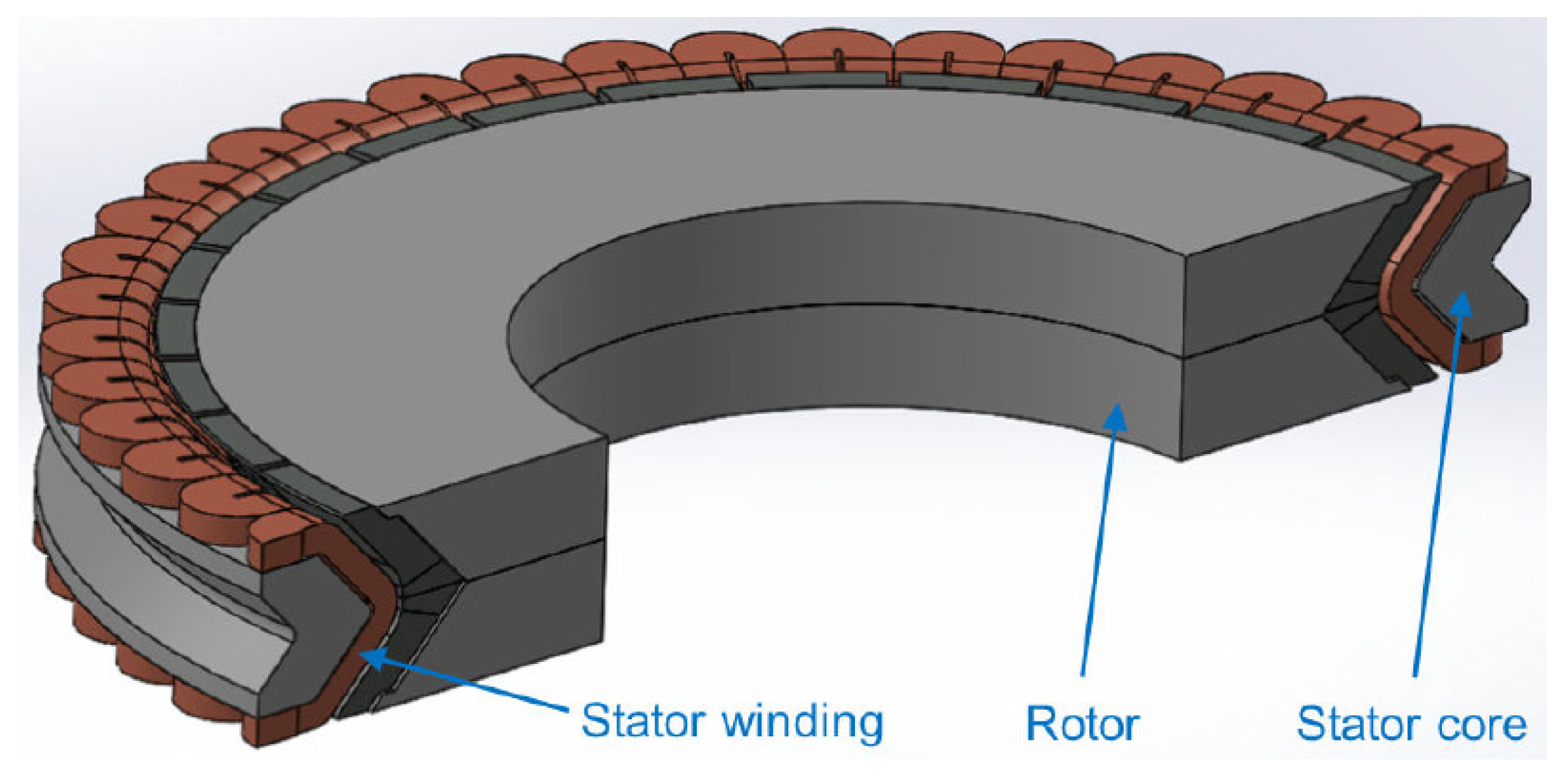

7.1. Permanent Magnet Synchronous Machines

7.2. Induction Machines

7.3. Synchronous Reluctance Machines

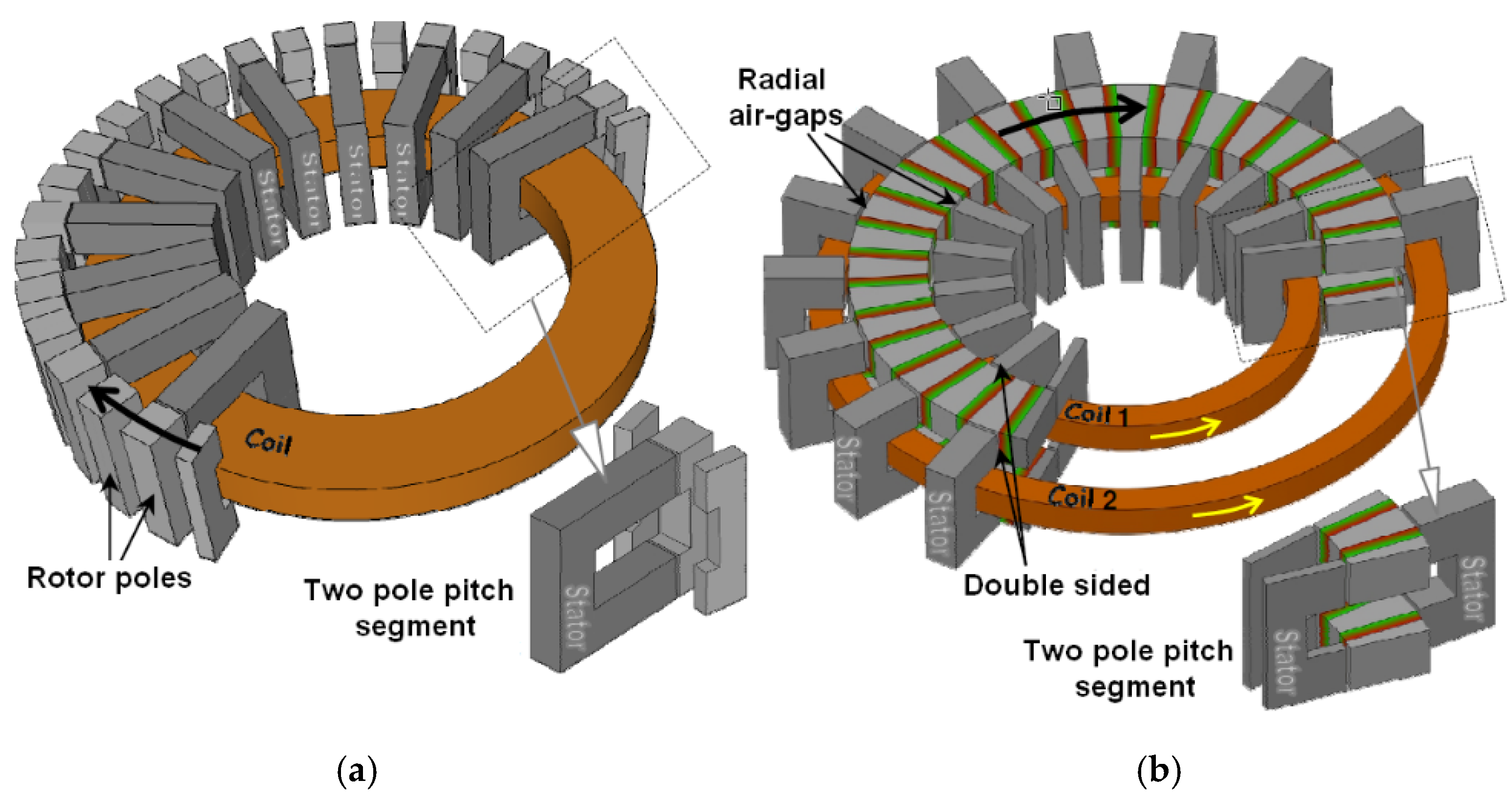

7.4. Switched Reluctance Machines

7.5. Construction of Special Electrical Machines

8. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Electric Motor Market Report 2021–2030: Development of High Power-to-Weight Ratio Electric Motors Gaining Momentum. Available online: https://www.globenewswire.com/news-release/2021/12/20/2355052/28124/en/Global-Electric-Motor-Market-Report-2021-2030-Development-of-High-Power-to-Weight-Ratio-Electric-Motors-Gaining-Momentum.html (accessed on 27 January 2022).

- Cheng, M.; Chan, C. General Requirement of Traction Motor Drives. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D.E., Kobayashi, T., Vaughan, N.D., Eds.; Wiley: Chichester, UK, 2014; pp. 1–18. [Google Scholar]

- Dorrell, D.G. A review of the methods for improving the efficiency of drive motors to meet IE4 efficiency standards. J. Power Electron. 2014, 14, 842–851. [Google Scholar] [CrossRef] [Green Version]

- Cantwell, J.; Hayashi, T. Paradigm Shift in Technologies and Innovation Systems; Springer Nature: Singapore, 2019. [Google Scholar]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1–4, 64–76. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Tarraste, M.; Vaimann, T.; Rassõlkin, A.; Asad, B.; Shams Ghahfarokhi, P. AC magnetic loss reduction of SLM processed Fe-Si for additive manufacturing of electrical machines. Energies 2021, 14, 1241. [Google Scholar] [CrossRef]

- ISO/ASTM 52900-15; Additive manufacturing—General principles—Terminology. ASTM International: West Conshohockeas, PA, USA, 2015.

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353, aaf2093. [Google Scholar] [CrossRef] [PubMed]

- Razavykia, A.; Brusa, E.; Delprete, C.; Yavari, R. An overview of additive manufacturing technologies—A review to technical synthesis in numerical study of selective laser melting. Materials 2020, 13, 3895. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassõlkin, A.; Belahcen, A. Electrical resistivity of additively manufactured silicon steel for electrical machine fabrication. In Proceedings of the Electric Power Quality and Supply Reliability Conference (PQ 2019) & Symposium on Electrical Engineering and Mechatronics (SEEM 2019), Kärdla, Estonia, 12–15 June 2019. [Google Scholar] [CrossRef] [Green Version]

- Pfaff, A.; Jäcklein, M.; Hoschke, K.; Wickert, M. Designed materials by additive manufacturing—Impact of exposure strategies and parameters on material characteristics of AlSi10Mg processed by laser beam melting. Metals 2018, 8, 491. [Google Scholar] [CrossRef] [Green Version]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Multi-material selective laser melting of Fe/Al-12Si components. Manuf. Lett. 2017, 11, 8–11. [Google Scholar] [CrossRef]

- Kocsis, B.; Fekete, I.; Varga, L. Metallographic and magnetic analysis of direct laser sintered soft magnetic composites. J. Magn. Magn. Mater. 2020, 501, 166425. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef] [Green Version]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting—Selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Jiménez, A.; Bidare, P.; Hassanin, H.; Tarlochan, F.; Dimov, S.; Essa, K. Powder-based laser hybrid additive manufacturing of metals: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 63–96. [Google Scholar] [CrossRef]

- Pham, T.; Kwon, P.; Foster, S. Additive manufacturing and topology optimization of magnetic materials for electrical machines—A review. Energies 2021, 14, 283. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Naseer, M.U.; Kallaste, A.; Asad, B.; Vaimann, T.; Rassãlkin, A. A review on additive manufacturing possibilities of electrical machines. Energies 2021, 14, 1940. [Google Scholar] [CrossRef]

- Sarap, M.; Kallaste, A.; Ghahfarokhi, P.S.; Tiismus, H.; Vaimann, T. Determining the thermal conductivity of additively manufactured metal specimens. In Proceedings of the 29th International Workshop on Electric Drives: Advances in Power Electronics for Electric Drives (IWED 2022), Moscow, Russia, 26–29 January 2022. [Google Scholar]

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M.P. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

- Plotkowski, A.; Carver, K.; List, F.; Pries, J.; Li, Z.; Rossy, A.M.; Leonard, D. Design and performance of an additively manufactured high-Si transformer core. Mater. Des. 2020, 194, 108894. [Google Scholar] [CrossRef]

- Stornelli, G.; Faba, A.; Di Schino, A.; Folgarait, P.; Ridolfi, M.R.; Cardelli, E.; Montanari, R. Properties of additively manufactured electric steel powder cores with increased Si content. Materials 2021, 14, 1489. [Google Scholar] [CrossRef] [PubMed]

- Mikler, C.; Chaudhary, V.; Borkar, T.; Soni, V.; Jaeger, D.; Chen, X.; Contieri, R.; Ramanujan, R.; Banerjee, R. Laser additive manufacturing of magnetic materials. JOM 2017, 69, 532–543. [Google Scholar] [CrossRef] [Green Version]

- Schönrath, H.; Spasova, M.; Kilian, S.; Meckenstock, R.; Witt, G.; Sehrt, J.; Farle, M. Additive manufacturing of soft magnetic permalloy from Fe and Ni powders: Control of magnetic anisotropy. J. Magn. Magn. Mater. 2019, 478, 274–278. [Google Scholar] [CrossRef]

- Ding, C.; Liu, L.; Mei, Y.; Ngo, K.D.; Lu, G.-Q. Magnetic paste as feedstock for additive manufacturing of power magnetics. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC 2018), San Antonio, TX, USA, 4–8 March 2018; pp. 615–618. [Google Scholar] [CrossRef]

- Metsä-Kortelainen, S.; Lindroos, T.; Savolainen, M.; Jokinen, A.; Revuelta, A.; Pasanen, A.; Ruusuvuori, K.; Pippuri, J. Manufacturing of topology optimized soft magnetic core through 3D printing. In Proceedings of the NAFEMS Exploring the Design Freedom of Additive Manufacturing through Simulation, Helsinki, Finland, 22–23 November 2016. [Google Scholar]

- Schmool, D.; Markó, D. Magnetism in Solids: Hysteresis. In Reference Module in Materials Science and Materials Engineering; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Chaudhary, V.; Mantri, S.A.; Ramanujan, R.V.; Banerjee, R. Additive manufacturing of magnetic materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Szabó, L.; Viorel, I.A.; Iancu, V.; Popa, D.C. Soft magnetic composites used in transverse flux machines. Oradea Univ. Ann. Electrotech. Fascicle 2004, 134–141. [Google Scholar]

- Pham, T.Q.; Do, T.T.; Kwon, P.; Foster, S.N. Additive manufacturing of high performance ferromagnetic materials. In Proceedings of the Energy Conversion Congress and Exposition (ECCE 2018), Portland, OR, USA, 23–27 September 2018; pp. 4303–4308. [Google Scholar] [CrossRef]

- Pyo, H.-J.; Jeong, J.W.; Yu, J.; Lee, S.G.; Kim, W.-H. Design of 3D-printed hybrid axial-flux motor using 3D-printed SMC core. IEEE Trans. Appl. Supercond. 2020, 30, 5202004. [Google Scholar] [CrossRef]

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive manufacturing of soft magnetic materials and components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Benack, N.C.; Wang, T.; Matthews, K.; Taheri, M.L. Additive manufacturing methods for soft magnetic composites (SMCs). Microsc. Microanal. 2018, 24, 1066–1067. [Google Scholar] [CrossRef] [Green Version]

- Kong, F.; Chang, C.; Inoue, A.; Shalaan, E.; Al-Marzouki, F. Fe-based amorphous soft magnetic alloys with high saturation magnetization and good bending ductility. J. Alloy. Compd. 2014, 615, 163–166. [Google Scholar] [CrossRef]

- Enomoto, Y.; Tokoi, H.; Imagawa, T.; Suzuki, T.; Obata, T.; Souma, K. Amorphous motor with IE5 efficiency class. Hitachi Rev. 2015, 64, 480–487. [Google Scholar]

- Cepoi, R.D.; Jaşcău, F.F.; Szabó, L. Current trends in energy efficient electrical machines. J. Electr. Electron. Eng. 2017, 10, 13–18. [Google Scholar]

- Nam, Y.G.; Koo, B.; Chang, M.S.; Yang, S.; Yu, J.; Park, Y.H.; Jeong, J.W. Selective laser melting vitrification of amorphous soft magnetic alloys with help of double-scanning-induced compositional homogeneity. Mater. Lett. 2020, 261, 127068. [Google Scholar] [CrossRef]

- Zou, Y.; Qiu, Z.; Tan, C.; Wu, Y.; Li, K.; Zeng, D. Microstructure and mechanical properties of Fe-based bulk metallic glass composites fabricated by selective laser melting. J. Non-Cryst. Solids 2020, 538, 120046. [Google Scholar] [CrossRef]

- Ozden, M.G.; Morley, N.A. Laser additive manufacturing of Fe-based magnetic amorphous alloys. Magnetochemistry 2021, 7, 20. [Google Scholar] [CrossRef]

- Treadgold, T. Nickel Soars and Could Keep Flying as Demand Rises and Supply Falls. Available online: https://www.forbes.com/sites/timtreadgold/2021/01/14/nickel-soars-and-could-keep-flying-as-demand-rises-and-supply-falls/?sh=7fe1e74675ba (accessed on 1 March 2022).

- Permalloy 80. Available online: https://www.espimetals.com/index.php/technical-data/175-Permalloy%2080 (accessed on 22 April 2021).

- Somaloy® 3P Material Data; Höganäs: 2018. Available online: https://www.hoganas.com/globalassets/download-media/sharepoint/brochures-and-datasheets---all-documents/somaloy-3p_material-data_june_2018_2273hog.pdf (accessed on 1 March 2022).

- Metals, H. Nanocrystalline Soft Magnetic Material FINEMET®; Hitachi Metals: 2018. Available online: https://elnamagnetics.com/wp-content/uploads/catalogs/Finemet/FINEMET%20Materials%20(HL-FM10-D).pdf (accessed on 1 March 2022).

- Wu, F.; El-Refaie, A.M. Towards fully additively-manufactured permanent magnet synchronous machines: Opportunities and challenges. In Proceedings of the International Electric Machines & Drives Conference (IEMDC 2019), San Diego, CA, USA, 12–15 May 2019; pp. 2225–2232. [Google Scholar] [CrossRef] [Green Version]

- El-Refaie, A. Role of advanced materials in electrical machines. CES Trans. Electr. Mach. Syst. 2019, 3, 124–132. [Google Scholar] [CrossRef]

- Yan, Y. Design Methodology and Materials for Additive Manufacturing of Magnetic Components. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2017. [Google Scholar]

- Li, Z.; Yao, K.; Li, D.; Ni, X.; Lu, Z. Core loss analysis of Finemet type nanocrystalline alloy ribbon with different thickness. Prog. Nat. Sci. Mater. Int. 2017, 27, 588–592. [Google Scholar] [CrossRef]

- Nonaka, T.; Zeze, S.; Makino, S.; Ohto, M. Research on motor with nanocrystalline soft magnetic alloy stator cores. Electr. Eng. Jpn. 2020, 211, 55–62. [Google Scholar] [CrossRef]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Processes 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Volegov, A.; Andreev, S.; Selezneva, N.; Ryzhikhin, I.; Kudrevatykh, N.; Mädler, L.; Okulov, I. Additive manufacturing of heavy rare earth free high-coercivity permanent magnets. Acta Mater. 2020, 188, 733–739. [Google Scholar] [CrossRef]

- Wu, J.; Aboulkhair, N.T.; Degano, M.; Ashcroft, I.; Hague, R.J. Process-structure-property relationships in laser powder bed fusion of permanent magnetic Nd-Fe-B. Mater. Des. 2021, 209, 109992. [Google Scholar] [CrossRef]

- Marfoli, A.; Dinardo, M.; Degano, M.; Gerada, C.; Jara, W. Squirrel cage induction motor: A design-based comparison between aluminium and copper cages. IEEE Open J. Ind. Appl. 2021, 2, 110–120. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A review on additive manufacturing of pure copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Copper CuCrZr Datasheet; 3T Additive Manufacturing: Newbury, UK, 2021.

- Wrobel, R.; Mecrow, B. A comprehensive review of additive manufacturing in construction of electrical machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef] [Green Version]

- Cabrini, M.; Calignano, F.; Fino, P.; Lorenzi, S.; Lorusso, M.; Manfredi, D.; Testa, C.; Pastore, T. Corrosion behavior of heat-treated AlSi10Mg manufactured by laser powder bed fusion. Materials 2018, 11, 1051. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wohlers, C.; Juris, P.; Kabelac, S.; Ponick, B. Design and direct liquid cooling of tooth-coil windings. Electr. Eng. 2018, 100, 2299–2308. [Google Scholar] [CrossRef]

- Bonaccorso, F.; Colombo, L.; Yu, G.; Stoller, M.; Tozzini, V.; Ferrari, A.C.; Ruoff, R.S.; Pellegrini, V. Graphene, related two-dimensional crystals, and hybrid systems for energy conversion and storage. Science 2015, 347, 1246501. [Google Scholar] [CrossRef] [PubMed]

- Szabó, L.; Szabó, G.S.; Szabó, R. Usage of Graphene in Power Systems. A Survey. In Proceedings of the 11th International Conference on Electrical Power Drive Systems (ICEPDS 2020), Saint-Petersburg, Russia, 4–7 October 2020. [Google Scholar] [CrossRef]

- Rallabandi, V.; Taran, N.; Ionel, D.M.; Eastham, J.F. On the feasibility of carbon nanotube windings for electrical machines—Case study for a coreless axial flux motor. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE 2016), Milwaukee, WI, USA, 18–22 September 2016. [Google Scholar] [CrossRef]

- Ramesh, P.; Lenin, N. High power density electrical machines for electric vehicles—Comprehensive review based on material technology. IEEE Trans. Magn. 2019, 55, 0900121. [Google Scholar] [CrossRef]

- Subramaniam, C.; Yamada, T.; Kobashi, K.; Sekiguchi, A.; Futaba, D.N.; Yumura, M.; Hata, K. One hundred fold increase in current carrying capacity in a carbon nanotube–copper composite. Nat. Commun. 2013, 4, 2202. [Google Scholar] [CrossRef] [Green Version]

- Podsiadły, B.; Matuszewski, P.; Skalski, A.; Słoma, M. Carbon Nanotube-Based Composite Filaments for 3D Printing of Structural and Conductive Elements. Appl. Sci. 2021, 11, 1272. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Advanced APTIV™ Film Electrical Insulation for Cost-Effective, High Power Density E-Motors; Victrex Plc: Thornton-Cleveleys, UK, 2017.

- Szabó, L. Additive manufacturing of cooling systems used in power electronics. A brief survey. In Proceedings of the 29th International Workshop on Electric Drives: Advances in Power Electronics for Electric Drives (IWED 2022), Moscow, Russia, 26–29 January 2022; p. 32. [Google Scholar]

- Chung, D.D.L. Materials for thermal conduction. Appl. Therm. Eng. 2001, 21, 1593–1605. [Google Scholar] [CrossRef]

- Tommasi, A.; Maillol, N.; Bertinetti, A.; Penchev, P.; Bajolet, J.; Gili, F.; Pullini, D.; Mataix, D.B. Influence of surface preparation and heat treatment on mechanical behavior of hybrid aluminum parts manufactured by a combination of laser powder bed fusion and conventional manufacturing processes. Metals 2021, 11, 522. [Google Scholar] [CrossRef]

- Nafis, B.M.; Whitt, R.; Iradukunda, A.-C.; Huitink, D. Additive manufacturing for enhancing thermal dissipation in heat sink implementation: A review. Heat Transf. Eng. 2021, 42, 967–984. [Google Scholar] [CrossRef]

- Nawrot, W.; Malecha, K. Additive manufacturing revolution in ceramic microsystems. Microelectron. Int. 2020, 37, 79–85. [Google Scholar] [CrossRef]

- Silva, C.K.A.; Alves, A.K. Graphene Application. In Technological Applications of Nanomaterials; Kopp Alves, A., Ed.; Springer: Cham, Switzerland, 2022; pp. 195–206. [Google Scholar]

- Wang, N.; Liu, Y.; Ye, L.; Li, J. Highly thermal conductive and light-weight graphene-based heatsink. In Proceedings of the 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC 2019), Pisa, Italy, 16–19 September 2019. [Google Scholar] [CrossRef]

- Fu, Y.; Hansson, J.; Liu, Y.; Chen, S.; Zehri, A.; Samani, M.K.; Wang, N.; Ni, Y.; Zhang, Y.; Zhang, Z.-B. Graphene related materials for thermal management. 2D Materials 2019, 7, 12001. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Kumar, S.; Batish, A. Metal matrix composites for thermal management: A review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 132–157. [Google Scholar] [CrossRef]

- Baig, M.M.A.; Hassan, S.F.; Saheb, N.; Patel, F. Metal matrix composite in heat sink application: Reinforcement, processing, and properties. Materials 2021, 14, 6257. [Google Scholar] [CrossRef]

- Chawla, K.K. Carbon Fiber/Carbon Matrix Composites. In Composite Materials; Chawla, K.K., Ed.; Springer: Cham, Switzerland, 2019; pp. 297–311. [Google Scholar]

- Windhorst, T.; Blount, G. Carbon-carbon composites: A summary of recent developments and applications. Mater. Des. 1997, 18, 11–15. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Xu, Z.; Nai, M.L.S.; Lu, S.; Ten, J.S.; Wei, J. Binder jetting additive manufacturing of high porosity 316L stainless steel metal foams. Materials 2020, 13, 3744. [Google Scholar] [CrossRef] [PubMed]

- Wawrzyniak, B.I.; Tangudu, J. Design Analysis of High Power Density Additively Manufactured Induction Motor; 0148-7191; SAE Technical Paper no. 2016-01-2063; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Liu, M.; Li, Y.; Ding, H.; Sarlioglu, B. Thermal management and cooling of windings in electrical machines for electric vehicle and traction application. In Proceedings of the Transportation Electrification Conference and Expo (ITEC 2017), Chicago, IL, USA, 22–24 June 2017; pp. 668–673. [Google Scholar] [CrossRef]

- Zhao, K.; Luo, J. Performance comparison and analysis of different rotor structures of vehicle permanent magnet synchronous flat wire motor. Machines 2022, 10, 212. [Google Scholar] [CrossRef]

- Silbernagel, C. Investigation of the Design, Manufacture and Testing of Additively Manufactured Coils for Electric Motor Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2019. [Google Scholar]

- Lorenz, F.; Rudolph, J.; Wemer, R. Design of 3D printed high performance windings for switched reluctance machines. In Proceedings of the 23rd International Conference on Electrical Machines (ICEM 2018), Alexandroupoli, Greece, 3–6 September 2018; pp. 2451–2457. [Google Scholar] [CrossRef]

- Simpson, N.; North, D.J.; Collins, S.M.; Mellor, P.H. Additive manufacturing of shaped profile windings for minimal AC loss in electrical machines. IEEE Trans. Ind. Appl. 2020, 56, 2510–2519. [Google Scholar] [CrossRef] [Green Version]

- Use-Case: Racing Engine. Available online: https://www.additive-drives.de/en/project/racing-engine/ (accessed on 19 December 2021).

- Jung, J.; Helm, A.; Liebold, J. Improved efficiency of electric drives with additively manufactured roebel bar windings. MTZ Worldw. 2021, 82, 54–58. [Google Scholar] [CrossRef]

- Ghahfarokhi, P.S.; Podgornovs, A.; Cardoso, A.J.M.; Kallaste, A.; Belahcen, A.; Vaimann, T. AC losses analysis approaches for electric vehicle motors with hairpin winding configuration. In Proceedings of the 47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021. [Google Scholar] [CrossRef]

- Hairpin Winding. Available online: https://www.bihler.de/files/bihler/images/branchen/e-mobilitaet/bihler-hairpin-elektromobilitaet.png (accessed on 11 February 2022).

- Vervecken, L. Assebled Roebel Cable. Available online: https://commons.wikimedia.org/wiki/Category:Roebel_bars#/media/File:Roebel_assembled_coated_conductor_cable_(RACC).svg (accessed on 21 February 2022).

- Venturini, G.; Volpe, G.; Villani, M.; Popescu, M. Investigation of cooling solutions for hairpin winding in traction application. In Proceedings of the 24th International Conference on Electrical Machines (ICEM 2020), Online, 23–26 August 2020; pp. 1573–1578. [Google Scholar] [CrossRef]

- Rivière, N.; Volpe, G.; Villani, M.; Fabri, G.; Di Leonardo, L.; Popescu, M. Design analysis of a high speed copper rotor induction motor for a traction application. In Proceedings of the International Electric Machines & Drives Conference (IEMDC 2019), San Diego, CA, USA, 12–15 May 2019; pp. 1024–1031. [Google Scholar] [CrossRef] [Green Version]

- Xue, S. Maximising E-Machine Efficiency with Hairpin Windings; Motor Design: Wrexham, UK, 2021. [Google Scholar]

- Sher, D. Additive Drives Introduces Highly Efficient 3D Printed Windings for Electric Motors; 3D Printing Media Network (3dpbm): Farnham, UK, 2020. [Google Scholar]

- Use-Case: E-Traction Motor. Available online: https://www.additive-drives.de/en/project/e-traction-motor/ (accessed on 5 December 2021).

- Al-Ani, M. Plug-In Winding for Electrical Machine and Electromagnetic Devices; Fluxmakers: Nottinghamshire, UK, 2019. [Google Scholar]

- Fleischer, J.; Haag, S.; Hofmann, J. Quo Vadis Winding Technology? A study on the State of the Art and Research on Future Trends in Automotive Engineering; Institute of Production Science, Karlsruhe Institute of Technology: Karlsruhe, Germany, 2017. [Google Scholar]

- Reinap, A. Direct Cooled Laminated Windings—Radially Displaced Laminated Winding Segments; Technical report; LUTEDX/(TEIE-7261); Lund University: Lund, Sweden, 2015. [Google Scholar]

- Högmark, C.; Andersson, R.; Reinap, A.; Alaküla, M. Electrical machines with laminated winding for hybrid vehicle applications. In Proceedings of the International Electric Drives Production Conference (EDPC 2012), Nuremberg, Germany, 15–18 October 2012. [Google Scholar] [CrossRef]

- Gmyrek, Z.; Cavagnino, A. Influence of punching, welding, and clamping on magnetic cores of fractional kilowatt motors. IEEE Trans. Ind. Appl. 2018, 54, 4123–4132. [Google Scholar] [CrossRef]

- Peng, H.; Guimbretière, F.; McCann, J.; Hudson, S. A 3D printer for interactive electromagnetic devices. In Proceedings of the 29th Annual Symposium on User Interface Software and Technology (UIST 2016), Tokyo, Japan, 16–19 October 2016; pp. 553–562. [Google Scholar] [CrossRef]

- Elaskri, A.; Ellery, A. 3D printed electric motors as a step towards self-replicating machines. In Proceedings of the International Symposium Artificial Intelligence Robotics & Automation in Space (i-SAIRAS 2020), Online, 19–23 October 2020. [Google Scholar]

- Ferrara, M.; Rinaldi, M.; Pigliaru, L.; Cecchini, F.; Nanni, F. Investigating the use of 3D printed soft magnetic PEEK-based composite for space compliant electrical motors. J. Appl. Polym. Sci. 2022, 139, 52150. [Google Scholar] [CrossRef]

- Stornelli, G.; Folgarait, P.; Ridolfi, M.R.; Corapi, D.; Repitsch, C.; Pietro, O.D.; Schino, A.D. Feasibility study of ferromagnetic cores fabrication by additive manufacturing process. Mater. Proc. 2021, 3, 28. [Google Scholar] [CrossRef]

- Zhang, Y.; Poli, L.; Garratt, E.; Foster, S.; Roch, A. Utilizing fused filament fabrication for printing iron cores for electrical devices. 3D Print. Addit. Manuf. 2020, 7, 279–287. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.; Wang, L.; Muizelaar, R. Selective laser melting of soft magnetic alloys for automotive applications. In Proceedings of the Joint Special Interest Group meeting between euspen and ASPE Advancing Precision in Additive Manufacturing, Nantes, France, 12 September 2019. [Google Scholar]

- Gnanaraj, S.D.; Gundabattini, E.; Singh, R.R. Materials for lightweight electric motors–a review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 906, 12020. [Google Scholar] [CrossRef]

- Gai, Y.; Kimiabeigi, M.; Chong, Y.C.; Widmer, J.D.; Deng, X.; Popescu, M.; Goss, J.; Staton, D.A.; Steven, A. Cooling of automotive traction motors: Schemes, examples, and computation methods—A review. IEEE Trans. Ind. Electron. 2018, 66, 1681–1692. [Google Scholar] [CrossRef] [Green Version]

- Vialva, T. TRUMPF Introduces Precious Metal and Copper 3D Printing Powered by Green Laser; 3D Printing Industry: Hong Kong, China, 2018. [Google Scholar]

- Lindh, P.M.; Petrov, I.; Semken, R.S.; Niemelä, M.; Pyrhönen, J.J.; Aarniovuori, L.; Vaimann, T.; Kallaste, A. Direct liquid cooling in low-power electrical machines: Proof-of-concept. IEEE Trans. Energy Convers. 2016, 31, 1257–1266. [Google Scholar] [CrossRef]

- Reinap, A.; Andersson, M.; Márquez-Fernández, F.J.; Abrahamsson, P.; Alaküla, M. Performance estimation of a traction machine with direct cooled hairpin winding. In Proceedings of the Transportation Electrification Conference and Expo (ITEC 2019), Detroit, MI, USA, 19–21 June 2019. [Google Scholar] [CrossRef]

- Bräuer, P.; Lindner, M.; Studnitzky, T.; Kieback, B.; Rudolph, J.; Werner, R.; Krause, G. 3D Screen Printing technology-Opportunities to use revolutionary materials and machine designs. In Proceedings of the 2nd International Electric Drives Production Conference (EDPC 2012), Nuremberg, Germany, 15–18 October 2012. [Google Scholar] [CrossRef]

- Lindh, P.; Petrov, I.; Jaatinen-Värri, A.; Grönman, A.; Martinez-Iturralde, M.; Satrústegui, M.; Pyrhönen, J. Direct liquid cooling method verified with an axial-flux permanent-magnet traction machine prototype. IEEE Trans. Ind. Electron. 2017, 64, 6086–6095. [Google Scholar] [CrossRef]

- Orosz, T.; Rassõlkin, A.; Kallaste, A.; Arsénio, P.; Pánek, D.; Kaska, J.; Karban, P. Robust design optimization and emerging technologies for electrical machines: Challenges and open problems. Appl. Sci. 2020, 10, 6653. [Google Scholar] [CrossRef]

- Thermally Conductive Polymer Materials for 3D Printing. Available online: https://3dprinting.com/3d-printing-use-cases/thermally-conductive-polymer-materials/ (accessed on 29 November 2021).

- Diana, M.; Colussi, J.; La Ganga, A.; Guglielmi, P. An innovative slot cooling for integrated electric drives. In Proceedings of the Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD 2019), Athens, Greece, 22–23 April 2019; pp. 191–196. [Google Scholar] [CrossRef]

- High Thermal Conductivity 3D Printing Materials and Parts; TCPoly: Atlanta, GA, USA, 2019.

- Xu, Y.; Wang, X.; Zhou, J.; Song, B.; Jiang, Z.; Lee, E.M.; Huberman, S.; Gleason, K.K.; Chen, G. Molecular engineered conjugated polymer with high thermal conductivity. Sci. Adv. 2018, 4, eaar3031. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Madonna, V.; Giangrande, P.; Walker, A.; Galea, M. On the effects of advanced end-winding cooling on the design and performance of electrical machines. In Proceedings of the 23rd International Conference on Electrical Machines (ICEM 2018), Alexandroupoli, Greece, 3–6 September 2018; pp. 311–317. [Google Scholar] [CrossRef]

- Fang, G.; Yuan, W.; Yan, Z.; Sun, Y.; Tang, Y. Thermal management integrated with three-dimensional heat pipes for air-cooled permanent magnet synchronous motor. Appl. Therm. Eng. 2019, 152, 594–604. [Google Scholar] [CrossRef]

- Schiefer, M.; Doppelbauer, M. Indirect slot cooling for high-power-density machines with concentrated winding. In Proceedings of the International Electric Machines & Drives Conference (IEMDC 2015), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1820–1825. [Google Scholar] [CrossRef]

- Huang, J.; Naini, S.S.; Miller, R.; Rizzo, D.; Sebeck, K.; Shurin, S.; Wagner, J. A hybrid electric vehicle motor cooling system—design, model, and control. IEEE Trans. Veh. Technol. 2019, 68, 4467–4478. [Google Scholar] [CrossRef]

- Vansompel, H.; Sergeant, P. Extended end-winding cooling insert for high power density electric machines with concentrated windings. IEEE Trans. Energy Convers. 2019, 35, 948–955. [Google Scholar] [CrossRef]

- Galea, M.; Gerada, C.; Raminosoa, T.; Wheeler, P. A thermal improvement technique for the phase windings of electrical machines. IEEE Trans. Ind. Appl. 2011, 48, 79–87. [Google Scholar] [CrossRef]

- Acquaviva, A.; Skoog, S.; Thiringer, T. Design and verification of in-slot oil-cooled tooth coil winding PM machine for traction application. IEEE Trans. Ind. Electron. 2020, 68, 3719–3727. [Google Scholar] [CrossRef]

- Gundabattini, E.; Mystkowski, A.; Idzkowski, A.; Solomon, D.G. Thermal mapping of a high-speed electric motor used for traction applications and analysis of various cooling methods—A review. Energies 2021, 14, 1472. [Google Scholar] [CrossRef]

- Geng, W.; Zhu, T.; Li, Q.; Zhang, Z. Windings indirect liquid cooling method for a compact outer-rotor PM starter/generator with concentrated windings. IEEE Trans. Energy Convers. 2021, 36, 3282–3293. [Google Scholar] [CrossRef]

- Yin, H.; Huang, S.; Li, H. Study on the influence of internal water cooling system on the loss of permanent magnet synchronous motor. AIP Conf. Proc. 2018, 1971, 040043. [Google Scholar] [CrossRef]

- Wrobel, R.; Hussein, A. Design considerations of heat guides fabricated using additive manufacturing for enhanced heat transfer in electrical machines. In Proceedings of the Energy Conversion Congress and Exposition (ECCE 2018), Portland, OR, USA, 23–27 September 2018; pp. 6506–6513. [Google Scholar] [CrossRef] [Green Version]

- Acquaviva, A.; Skoog, S.; Grunditz, E.; Thiringer, T. Electromagnetic and calorimetric validation of a direct oil cooled tooth coil winding PM machine for traction application. Energies 2020, 13, 3339. [Google Scholar] [CrossRef]

- Szabó, L. Survey on applying 3D printing in manufacturing the cooling systems of electrical machines. In Proceedings of the International Conference on Automation, Quality and Testing, Robotics (AQTR 2022), Cluj-Napoca, Romania, 21–22 May 2022. in print. [Google Scholar]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of windings in electric machines via 3-D printed heat exchanger. IEEE Trans. Ind. Appl. 2020, 56, 4718–4726. [Google Scholar] [CrossRef]

- Semidey, S.A.; Mayor, J.R. Experimentation of an electric machine technology demonstrator incorporating direct winding heat exchangers. IEEE Trans. Ind. Electron. 2014, 61, 5771–5778. [Google Scholar] [CrossRef]

- Panse, S.S.; Ekkad, S.V. Forced convection cooling of additively manufactured single and double layer enhanced microchannels. Int. J. Heat Mass Transf. 2021, 168, 120881. [Google Scholar] [CrossRef]

- Carriero, A.; Locatelli, M.; Ramakrishnan, K.; Mastinu, G.; Gobbi, M. A Review of the State of the Art of Electric Traction Motors Cooling Techniques; 0148-7191; SAE Technical Paper no. 2018-01-0057; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Nollau, A.; Gerling, D. A flux barrier cooling for traction motors in hybrid drives. In Proceedings of the International Electric Machines & Drives Conference (IEMDC 2015), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 1103–1108. [Google Scholar] [CrossRef]

- Wrobel, R.; Scholes, B.; Hussein, A.; Law, R.; Mustaffar, A.; Reay, D. A metal additively manufactured (MAM) heat exchanger for electric motor thermal control on a high-altitude solar aircraft—Experimental characterisation. Therm. Sci. Eng. Prog. 2020, 19, 100629. [Google Scholar] [CrossRef]

- Amelia, H. Porsche Present 40% Lighter 3D Printed Electric Drive Housing. Available online: https://www.3dnatives.com/en/porsche-present-3d-printed-electric-drive-housing-261220204/ (accessed on 30 September 2021).

- Porsche Electric Traction Drive System Housing. Available online: https://www.tuningblog.eu/en/wp-content/uploads/2020/12/E-Antrieb-Gehaeuse-3D-Drucker-Porsche-2.jpg; https://www.tuningblog.eu/en/wp-content/uploads/2020/12/E-Antrieb-Gehaeuse-3D-Drucker-Porsche-4.jpg (accessed on 30 September 2021).

- Galloni, E.; Parisi, P.; Marignetti, F.; Volpe, G. CFD analyses of a radial fan for electric motor cooling. Therm. Sci. Eng. Prog. 2018, 8, 470–476. [Google Scholar] [CrossRef]

- De Santiago, J.; Bernhoff, H.; Ekergård, B.; Eriksson, S.; Ferhatovic, S.; Waters, R.; Leijon, M. Electrical motor drivelines in commercial all-electric vehicles: A review. IEEE Trans. Veh. Technol. 2011, 61, 475–484. [Google Scholar] [CrossRef] [Green Version]

- Candelo-Zuluaga, C.; Espinosa, A.G.; Riba, J.-R.; Tubert, P. PMSM design for achieving a target torque-speed-efficiency map. IEEE Trans. Veh. Technol. 2020, 69, 14448–14457. [Google Scholar] [CrossRef]

- Zhao, X.; Kou, B.; Huang, C.; Zhang, L. Optimization design and performance analysis of a reverse-salient permanent magnet synchronous motor. Machines 2022, 10, 204. [Google Scholar] [CrossRef]

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive manufacturing of a lightweight rotor for a permanent magnet synchronous machine. In Proceedings of the International Electric Drives Production Conference (EDPC 2016), Nuremberg, Germany, 30 November–1 December 2016; pp. 41–45. [Google Scholar] [CrossRef]

- Garibaldi, M. Laser Additive Manufacturing of Soft Magnetic Cores for Rotating Electrical Machinery: Materials Development and Part Design. Ph.D. thesis, University of Nottingham, Nottingham, UK, 2018. [Google Scholar]

- Bailey, P. Light work. Electr. Hybrid Veh. Technol. Int. 2020, 24–26. [Google Scholar]

- Młot, A.; Łukaniszyn, M. Analysis of axial flux motor performance for traction motor applications. COMPEL-Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 1306–1322. [Google Scholar] [CrossRef]

- Singh, S.; Pillay, P. Sinusoidal shaped surface permanent magnet motor using cold spray additive manufacturing. In Proceedings of the Energy Conversion Congress and Exposition (ECCE 2020), Detroit, MI, USA, 11–15 October 2020; pp. 2089–2094. [Google Scholar] [CrossRef]

- Demir, U. Improvement of the power to weight ratio for an induction traction motor using design of experiment on neural network. Electr. Eng. 2021, 103, 2267–2284. [Google Scholar] [CrossRef]

- Chinthavali, M. Additive manufacturing technology for power electronics applications. In Proceedings of the Applied Power Electronics Conference and Exposition (APEC 2016), Long Beach, CA, USA, 20–24 March 2016. [Google Scholar]

- Bianchi, N.; Bolognani, S.; Carraro, E.; Castiello, M.; Fornasiero, E. Electric vehicle traction based on synchronous reluctance motors. IEEE Trans. Ind. Appl. 2016, 52, 4762–4769. [Google Scholar] [CrossRef]

- Uberti, F.; Frosini, L.; Szabó, L. An optimization procedure for a synchronous reluctance machine with fluid shaped flux barriers. In Proceedings of the 24th International Conference on Electrical Machines (ICEM 2020), Online, 23–26 August 2020; pp. 389–395. [Google Scholar] [CrossRef]

- Uberti, F.; Frosini, L.; Szabó, L. A new design procedure for rotor laminations of synchronous reluctance machines with fluid shaped barriers. Electronics 2022, 11, 134. [Google Scholar] [CrossRef]

- Ibrahim, M.; Bernier, F.; Lamarre, J.-M. Design of a PM-assisted synchronous reluctance motor utilizing additive manufacturing of magnetic materials. In Proceedings of the Conversion Congress and Exposition (ECCE 2019), Baltimore, MD, USA, 29 September–3 October 2019; pp. 1663–1668. [Google Scholar] [CrossRef]

- Freeman, F.S.; Lincoln, A.; Sharp, J.; Lambourne, A.; Todd, I. Exploiting thermal strain to achieve an in-situ magnetically graded material. Mater. Des. 2019, 161, 14–21. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Jhong, K.J.; Cheng, C.-W.; Huang, P.-W.; Tsai, M.-C.; Lee, W.-H. Metal 3D printing of synchronous reluctance motor. In Proceedings of the International Conference on Industrial Technology (ICIT 2016), Taipei, Taiwan, 14–17 March 2016; pp. 1125–1128. [Google Scholar] [CrossRef]

- Ban, B.; Stipetic, S. Absolutely feasible synchronous reluctance machine rotor barrier topologies with minimal parametric complexity. Machines 2022, 10, 206. [Google Scholar] [CrossRef]

- Reddy, P.B.; El-Refaie, A.M.; Zou, M.; Pan, D.; Alexander, J.P.; Tapadia, N.; Grace, K.; Huh, K.-K.; Johnson, F. Performance testing and analysis of synchronous reluctance motor utilizing dual-phase magnetic material. IEEE Trans. Ind. Appl. 2018, 54, 2193–2201. [Google Scholar] [CrossRef] [Green Version]

- RotorVagatiSynRM. Available online: https://upload.wikimedia.org/wikipedia/commons/c/c2/RotorVagatiSynRM.png (accessed on 10 February 2022).

- Cai, S.; Shen, J.; Hao, H.; Jin, M. Design methods of transversally laminated synchronous reluctance machines. CES Trans. Electr. Mach. Syst. 2017, 1, 164–173. [Google Scholar] [CrossRef]

- Pyrhönen, J.; Jokinen, T.; Hrabovcová, V.; Niemelä, H. Design of Rotating Electrical Machines; John Wiley and Sons: Chichester, UK, 2008. [Google Scholar]

- Abramenko, V.; Petrov, I.; Nerg, J.; Pyrhönen, J. Synchronous reluctance motors with an axially laminated anisotropic rotor as an alternative in high-speed applications. IEEE Access 2020, 8, 29149–29158. [Google Scholar] [CrossRef]

- Son, I.; Lukman, G.F.; Shah, M.H.; Jeong, K.-I.; Ahn, J.-W. Design considerations and selection of cost-effective switched reluctance drive for radiator cooling fans. Electronics 2021, 10, 917. [Google Scholar] [CrossRef]

- Dúbravka, P.; Rafajdus, P.; Makyš, P.; Szabó, L. Control of switched reluctance motor by current profiling under normal and open phase operating condition. IET Electr. Power Appl. 2017, 11, 548–556. [Google Scholar] [CrossRef]

- Lee, J.; Seo, J.H.; Kikuchi, N. Topology optimization of switched reluctance motors for the desired torque profile. Struct. Multidiscip. Optim. 2010, 42, 783–796. [Google Scholar] [CrossRef]

- Tseng, G.-M.; Jhong, K.-J.; Tsai, M.-C.; Huang, P.-W.; Lee, W.-H. Application of additive manufacturing for low torque ripple of 6/4 switched reluctance motor. In Proceedings of the 19th International Conference on Electrical Machines and Systems (ICEMS 2016), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Szabó, L. A survey on modular variable reluctance generators for small wind turbines. IEEE Trans. Ind. Appl. 2019, 55, 2548–2557. [Google Scholar] [CrossRef]

- Wan, Z.; Ahmed, A.; Husain, I.; Muljadi, E. A novel transverse flux machine for vehicle traction aplications. In Proceedings of the Power & Energy Society General Meeting, Denver, CO, USA, 26–30 July 2015. [Google Scholar] [CrossRef]

- Drabek, T.; Kapustka, P.; Lerch, T.; Skwarczyński, J. A novel approach to transverse flux machine construction. Energies 2021, 14, 7690. [Google Scholar] [CrossRef]

- Szabó, L. Novel variable reluctance generators used in small wind turbines. The modular approach. In Proceedings of the 19th International Carpathian Control Conference (ICCC 2018), Szilvásvárad, Hungary, 28–31 May 2018. [Google Scholar] [CrossRef]

- Baserrah, S. Theoretical and Experimental Investigations of a Permanent Magnet Excited Transverse Flux Machine with a Segmented Stator for In-Wheel Motor Applications. Ph.D. Thesis, University of Bremen, Bremen, Germany, 2014. [Google Scholar]

- Hosek, M.; Krishnasamy, J.; Sah, S.; Bashaw, T. Spray-formed hybrid-field electric motor. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar] [CrossRef]

- Lamarre, J.-M.; Bernier, F. Permanent magnets produced by cold spray additive manufacturing for electric engines. J. Therm. Spray Technol. 2019, 28, 1709–1717. [Google Scholar] [CrossRef]

- Szabó, L. Modular switched reluctance machines to be used in automotive applications. In Proceedings of the SRM Drives an Alternative for E-traction Workshop, Vilanova i la Geltrú, Spain, 2 February 2018. [Google Scholar]

- Kallaste, A.; Vaimann, T.; Rassãlkin, A. Additive design possibilities of electrical machines. In Proceedings of the 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON 2018), Riga, Latvia, 12–13 November 2018. [Google Scholar] [CrossRef]

- Garcia Gonzalez, A.; Wang, D.; Dubus, J.-M.; Rasmussen, P.O. Design and experimental investigation of a hybrid rotor permanent magnet modular machine with 3D flux paths accounting for recyclability of permanent magnet material. Energies 2020, 13, 1342. [Google Scholar] [CrossRef] [Green Version]

- European Commission. A New Circular Economy Action Plan—For a Cleaner and More Competitive Europe; Commission to the European Parliament: Bruegel, Belgium, 2020. [Google Scholar]

- Claeys, G.; Tagliapietra, S.; Zachmann, G. How to Make the European Green Deal Work; Bruegel: Brussels, Belgium, 2019. [Google Scholar]

- Aguilera, E.; Ramos, J.; Espalin, D.; Cedillos, F.; Muse, D.; Wicker, R.; MacDonald, E. 3D printing of electro mechanical systems. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013; pp. 950–961. [Google Scholar]

- Petrick, I.J.; Simpson, T.W. 3D printing disrupts manufacturing: How economies of one create new rules of competition. Res.-Technol. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

| Soft Magnetic Material | Iron Core Losses@50 Hz, 1 T | Saturation Flux Density | Magnetic Permeability | Resistivity |

|---|---|---|---|---|

| Non-oriented electrical steel (M330-50A) | 2 | 4 | 2 | 3 |

| Fe-Si alloy (6.5% Si) | 3 | 4 | 4 | 3 |

| Fe-Ni alloy (Permalloy) | 4 | 2 | 4 | 3 |

| Fe-Co alloy (Hiperco) | 3 | 5 | 3 | 3 |

| SMC (Somaloy 700) | 1 | 3 | 1 | 5 |

| Amorphous iron (MetalGlass) | 4 | 4 | 4 | 4 |

| Nanocrystalline iron (FINEMET) | 5 | 3 | 5 | 4 |

.

.| EM | Iron Core | PM | Winding | Cooling System | Mean Score |

|---|---|---|---|---|---|

| Low-power IM | 2 | – | 1 | 2 | 1.66 |

| High-power IM | 1 | – | 2 | 3 | 2 |

| Low-Power PMSM | 2 | 3 | 1 | 2 | 2 |

| High-power PMSM | 1 | 2 | 2 | 3 | 2 |

| SyncRel | 3 | 3 | 2 | 2 | 2.5 |

| SRM | 2 | – | 3 | 4 | 3 |

| TFM | 5 | 3 | 3 | 2 | 3.25 |

| Special EMs | 5 | 4 | 4 | 4 | 4.25 |

.

.Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabó, L.; Fodor, D. The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines. Machines 2022, 10, 330. https://doi.org/10.3390/machines10050330

Szabó L, Fodor D. The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines. Machines. 2022; 10(5):330. https://doi.org/10.3390/machines10050330

Chicago/Turabian StyleSzabó, Loránd, and Dénes Fodor. 2022. "The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines" Machines 10, no. 5: 330. https://doi.org/10.3390/machines10050330

APA StyleSzabó, L., & Fodor, D. (2022). The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines. Machines, 10(5), 330. https://doi.org/10.3390/machines10050330