Equilibrium Analysis and Simulation Calculation of Four-Star Type Crank Linkage Mechanism

Abstract

1. Introduction

2. Research on Dynamic Balancing Method of Crank Linkage Mechanism

2.1. Balance of Inertial Forces

2.1.1. Full Balance of Inertial Forces

Balanced Mass Method

Symmetrical Layout Method

2.1.2. Partial Balance of Inertial Forces

Balanced Mass Method

Balance of Mechanism Method

Approximate Symmetrical Layout Method

2.2. Comparison of Balancing Methods

3. Calculation Method of Multibody Dynamics

3.1. Kinetic Equations

3.2. Equation Solution

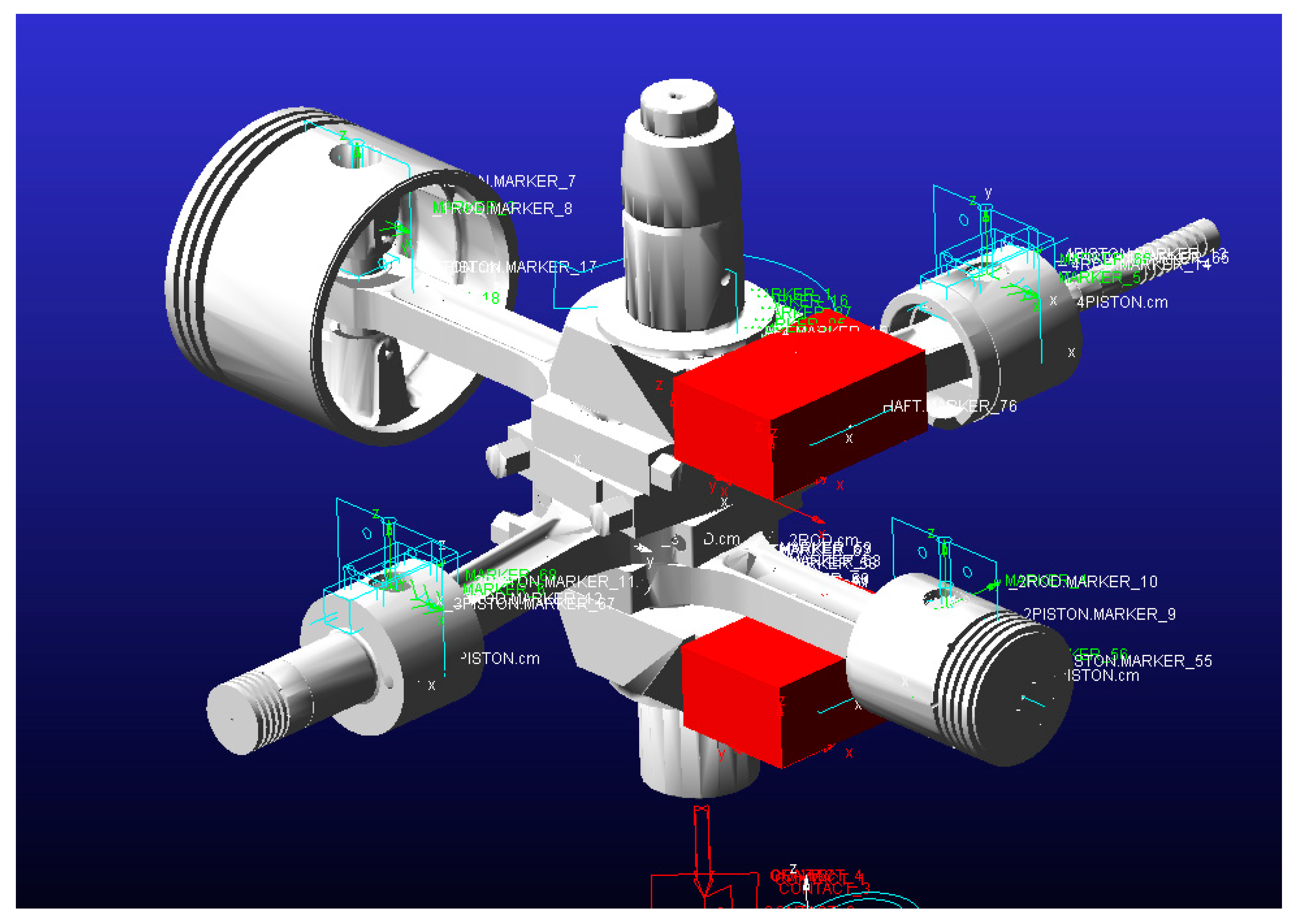

4. Balance Study of Four-Star Type Crank Linkage

4.1. Motion Relationship of Crank Linkage

4.2. Dynamic Balancing of Crank Linkage Mechanism

4.2.1. Design for Dynamic Balancing

4.2.2. Determination of Balanced Mass

4.3. The Effect of Mass Asymmetry on the Force of Crankshaft Rotating Pair

5. Two New Types of Crank Linkage Structure Forms

5.1. Optimization of Inertia Forces

5.2. Comparison of Dynamic Characteristics in Different Working Conditions

5.3. Optimization of the Moment of Inertia

6. Conclusions

- (1)

- Fully balanced inertia force is better than partially balanced inertia force in terms of a balancing effect. However, it will greatly increase the complexity of the crank linkage. In engineering practice, the stable and reliable partial balancing method of inertia force, with a simple structure and low cost, is more widely used.

- (2)

- The parametric design of ADAMS software is more efficient and can get the best quality quickly. After the balance quality optimization, the first-order inertia force is effectively balanced, and the third-order inertia force becomes the main influencing factor of the dynamic balance of the four-star type crank linkage. However, the actual air compressor crank linkage mechanism will also be influenced by friction, misalignment, clearance, and other factors.

- (3)

- Piston masses larger or smaller than symmetrical masses will increase the crankshaft forces, and the effect of larger than symmetrical masses is more pronounced. The asymmetric piston mass mainly affects the first-order inertia force, while it will excite the second-order inertia force. It has almost no effect on the third-order inertia force.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pradhan, D.; Ganguly, K.; Swain, B.; Roy, H. Optimal kinematic synthesis of 6 bar rack and pinion Ackerman steering linkage. J. Automob. Eng. 2021, 235, 1660–1669. [Google Scholar] [CrossRef]

- Hyeong, J.; Jongryun, R.; Choi, C. Design of an efficient swing mechanism for electric swing beds. Trans. Korean Soc. Mech. Eng. A 2022, 46, 923–930. [Google Scholar] [CrossRef]

- Kim, S.H.; Cho, C. Transformation of static balancer from truss to linkage. J. Mech. Sci. Technol. 2016, 30, 2093–2104. [Google Scholar] [CrossRef]

- Berkof, R.S.; Lowen, G.G. A new method for completely force balancing simple linkages. J. Eng. Ind. 1969, 91, 21–26. [Google Scholar] [CrossRef]

- Bagci, C. Complete shaking force shaking moment balancing of link mechanisms using balancing idler loops. J. Adv. Mech. Des. Syst. 1982, 104, 482–493. [Google Scholar] [CrossRef]

- Arakelian, V.; Briot, S. Simultaneous inertia force/moment balancing and torque compensation of slider-crank mechanisms. Mech. Res. Commun. 2010, 37, 265–269. [Google Scholar] [CrossRef]

- Lee, T.W.; Cheng, C. Optimum balancing of combined shaking force, shaking moment, and torque fluctuation in high-speed linkages. J. Mech. Transm. Autom. Des. 1984, 106, 242–251. [Google Scholar] [CrossRef]

- Kochev, I.S. General method for active balancing of combined shanking moment and torque fluctuation in planar linkages. Mech. Mach. Theory 1998, 25, 679–687. [Google Scholar] [CrossRef]

- Zhou, S.; Shi, J. Optimal one-plane active balancing of rigid tutor during acceleration. J. Sound Vib. 2002, 249, 196–205. [Google Scholar] [CrossRef]

- Zheng, E.; Zhu, R.; Zhu, S.; Lu, X. A study on dynamics of flexible multi-link mechanism including joints with clearance and lubrication for ultra-precision presses. Nonlinear Dyn. 2016, 83, 137–159. [Google Scholar] [CrossRef]

- Zhao, J.S.; Wei, S.T.; Ji, J.J. Kinematics of a planar slider-crank linkage in screw form. J. Mech. Eng. Sci. 2021, 236, 1588–1597. [Google Scholar] [CrossRef]

- Yoon, D.; Choi, Y.J. Underactuated Finger Mechanism Using Contractible Slider-Cranks and Stackable Four-Bar Linkages. IEEE-ASME Trans. Mechatron. 2017, 22, 2046–2057. [Google Scholar] [CrossRef]

- Reza, A.; Moslehi, M. Optimal synthesis of an adjustable six-bar path generator mechanism using a cuckoo optimization algorithm. J. Mech. Mater. Struct. 2022, 17, 149–167. [Google Scholar] [CrossRef]

- Chen, L.P.; Zhang, Y.Q. Mechanical System Dynamics Analysis and ADAMS Application Course; Tsinghua University Press: Beijing, China, 2005; Volume I, pp. 21–74. [Google Scholar]

- Albaghdadi, A.M.; Baharom, M.B.; Sulaiman, S.A. Tri-planar balancing optimization of a double crank-rocker mechanism for shaking forces and shaking moments reduction. Proc. Est. Acad. Sci. 2021, 70, 286–296. [Google Scholar] [CrossRef]

- Zheng, E.; Wang, T.; Guo, J.; Zhu, Y.; Lin, X.; Wang, Y.; Kang, M. Dynamic modeling and error analysis of planar flexible multilink mechanism with clearance and spindle-bearing structure. Mech. Mach. Theory 2019, 131, 234–260. [Google Scholar] [CrossRef]

| I3 | SI1 | SI2 | |

|---|---|---|---|

| Stability of solution | Common | Good | Good |

| Speed of solution | Fast | Common | Common |

| Accuracy of solution | High accuracy in displacement | High accuracy in displacement, velocity, and acceleration | High accuracy in displacement, velocity, and acceleration |

| Name of Parameter | Value of Parameter | Name of Parameter | Value of Parameter |

|---|---|---|---|

| Collision stiffness | The coefficient of kinetic friction is | ||

| Contact force index e | 1.5 | The coefficient of static friction is | |

| Damping coefficient C | The speed of dynamic friction is | ||

| Penetration depth | The speed of static friction is |

| Mass (kg) | Moment of Inertia Ixx (kg·m2) | Moment of Inertia Iyy (kg·m2) | Moment of Inertia Izz (kg·m2) |

|---|---|---|---|

| 3.8 | 0.548 | 0.474 | 0.367 |

| 3.9 | 0.563 | 0.487 | 0.376 |

| 4.0 | 0.577 | 0.499 | 0.386 |

| 4.1 | 0.591 | 0.511 | 0.396 |

| 4.2 | 0.606 | 0.524 | 0.405 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, K.; Hu, J.; Lou, J. Equilibrium Analysis and Simulation Calculation of Four-Star Type Crank Linkage Mechanism. Machines 2023, 11, 735. https://doi.org/10.3390/machines11070735

Chai K, Hu J, Lou J. Equilibrium Analysis and Simulation Calculation of Four-Star Type Crank Linkage Mechanism. Machines. 2023; 11(7):735. https://doi.org/10.3390/machines11070735

Chicago/Turabian StyleChai, Kai, Junbo Hu, and Jingjun Lou. 2023. "Equilibrium Analysis and Simulation Calculation of Four-Star Type Crank Linkage Mechanism" Machines 11, no. 7: 735. https://doi.org/10.3390/machines11070735

APA StyleChai, K., Hu, J., & Lou, J. (2023). Equilibrium Analysis and Simulation Calculation of Four-Star Type Crank Linkage Mechanism. Machines, 11(7), 735. https://doi.org/10.3390/machines11070735