Rheological and Frictional Properties of Lithium Complex Grease with Graphene Additives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Processing and Sample Preparation

2.2. Experimental Procedure

3. Results

3.1. Effect of FLG on the Microstructure of LCG

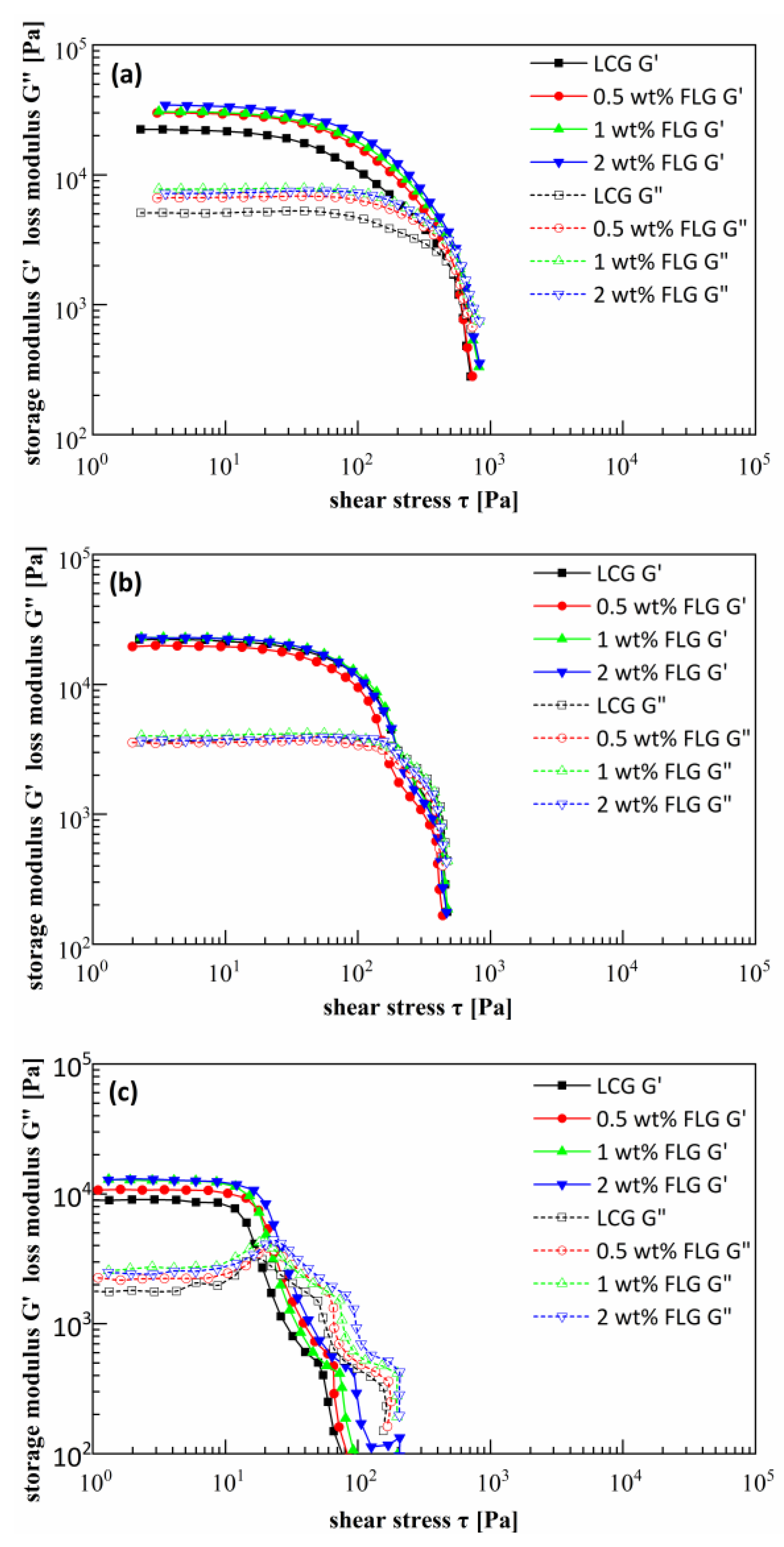

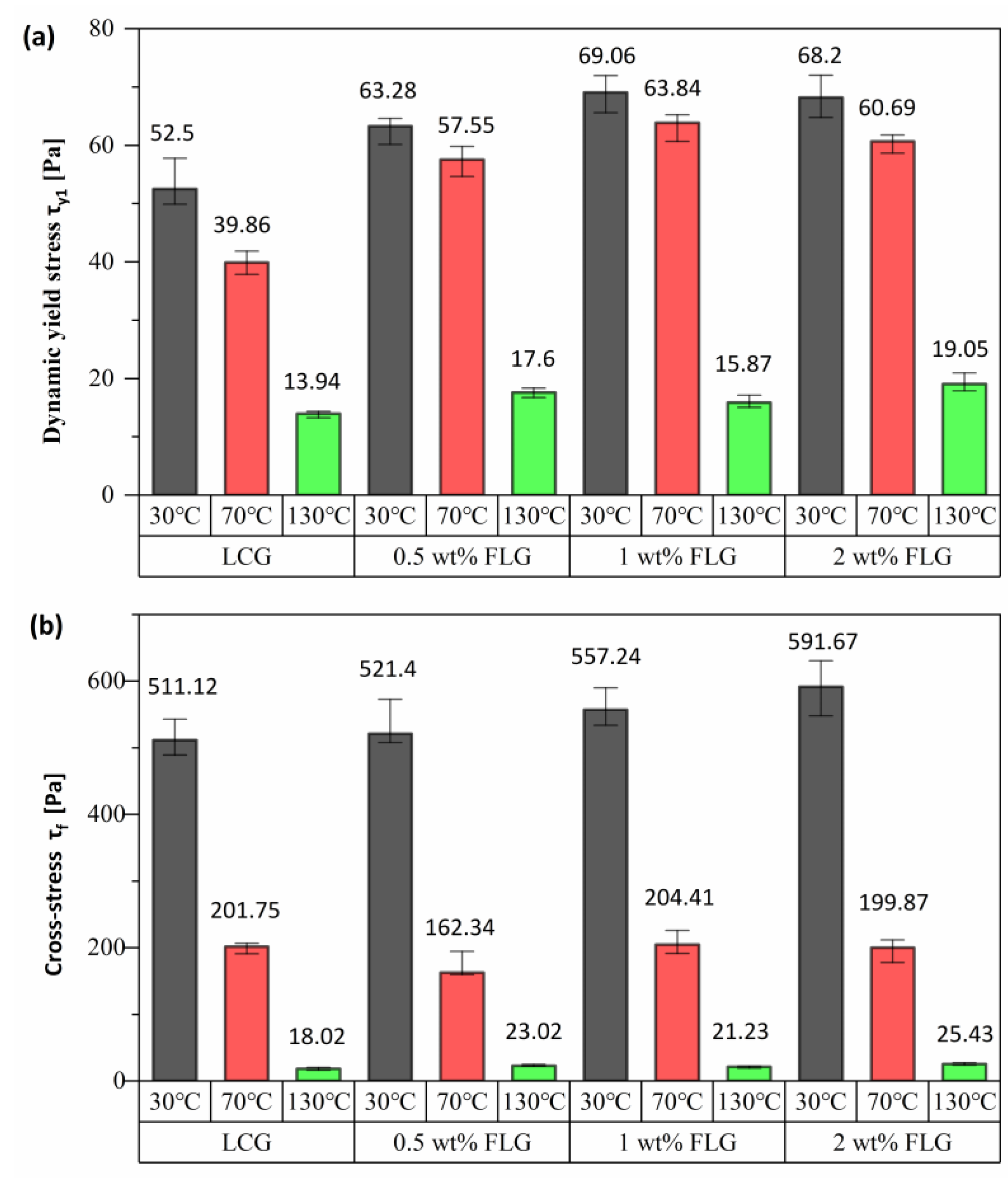

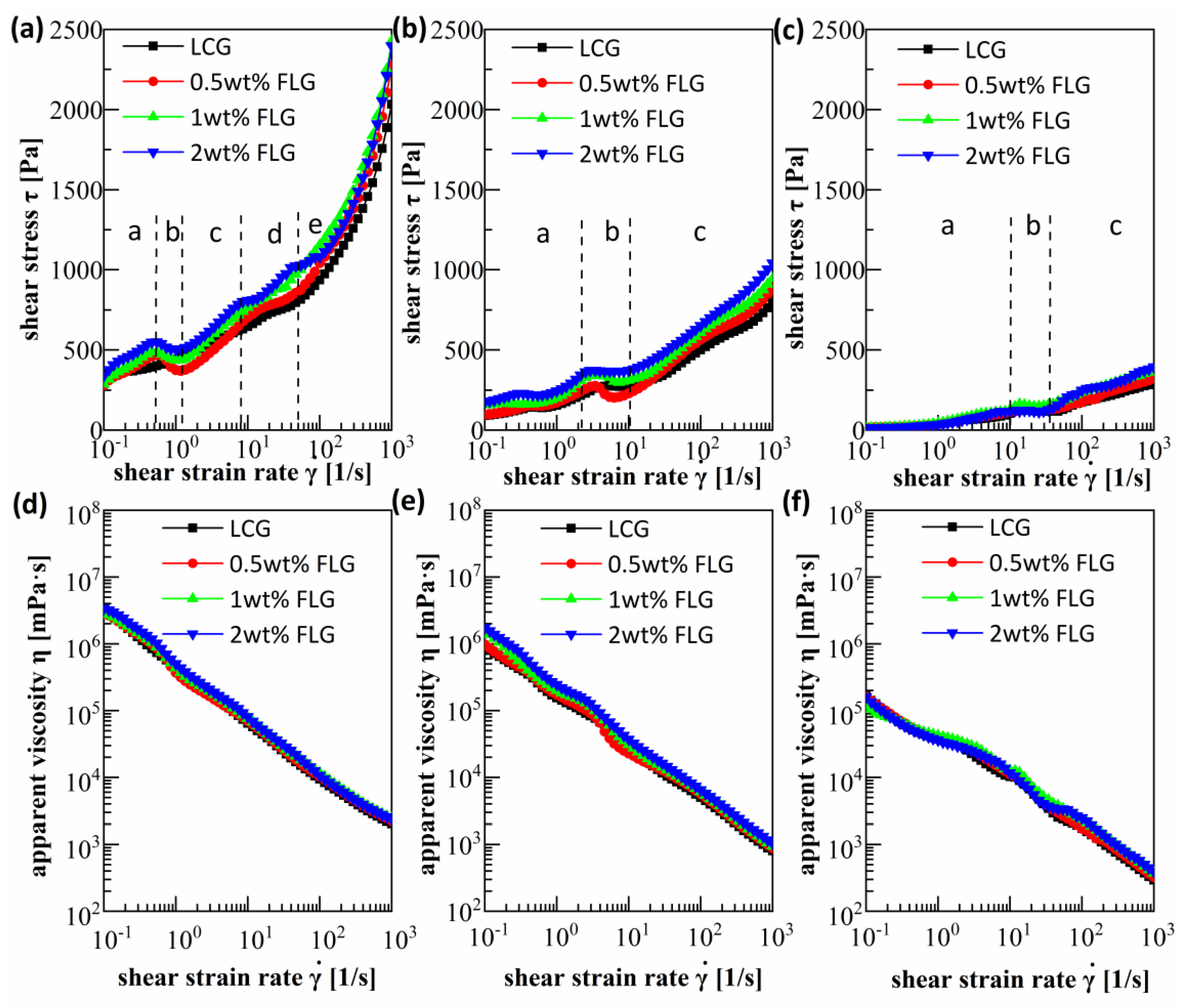

3.2. Effect of FLG on the Viscoelasticity of LCG

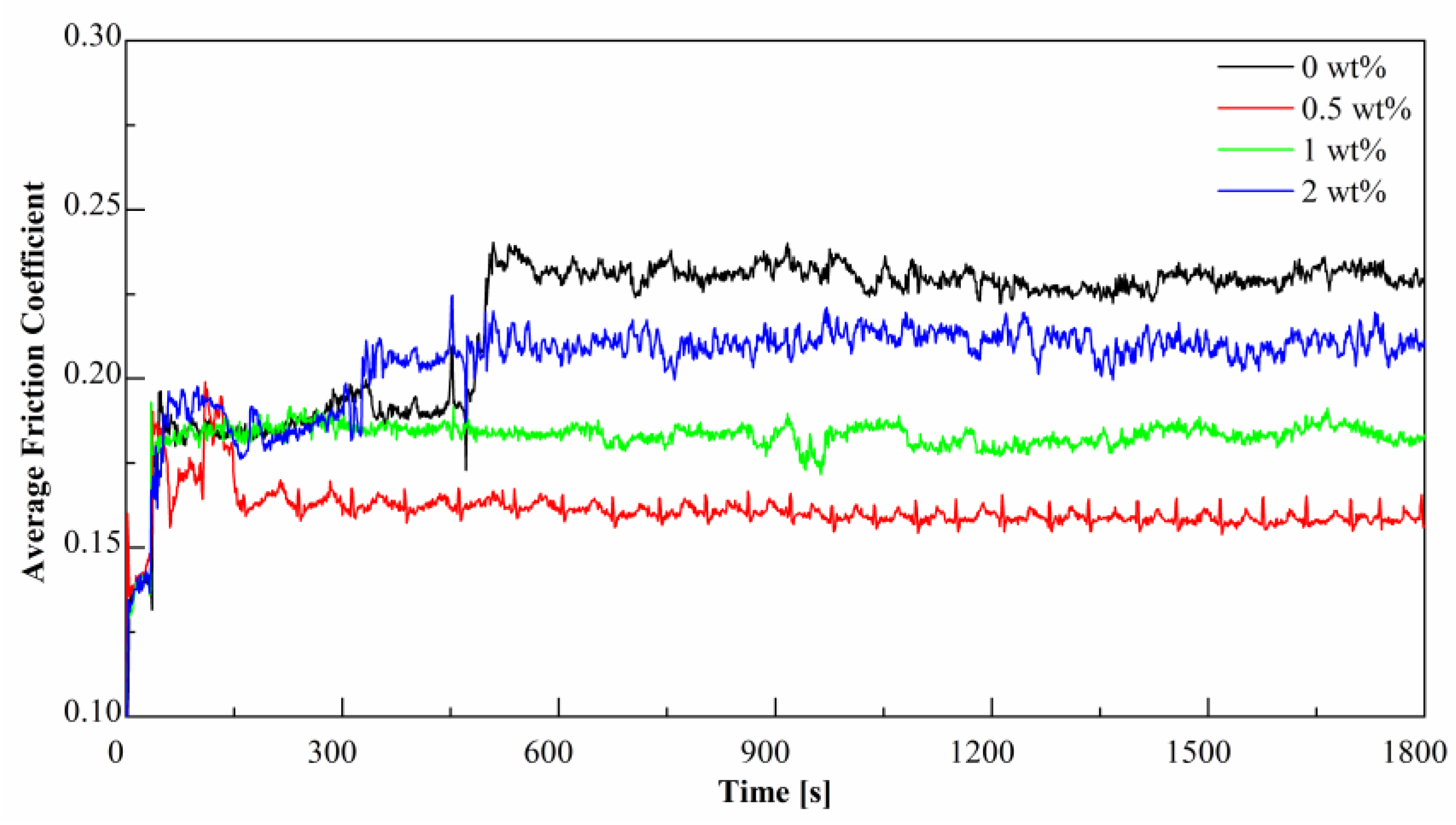

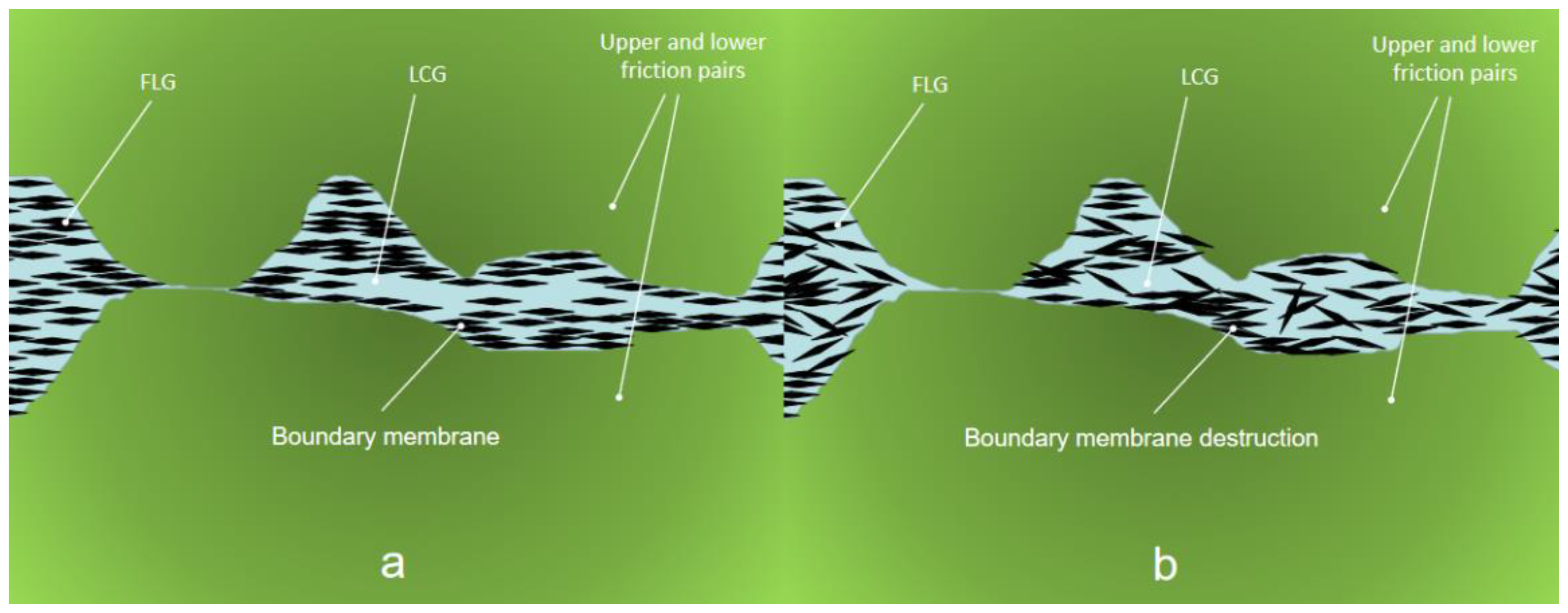

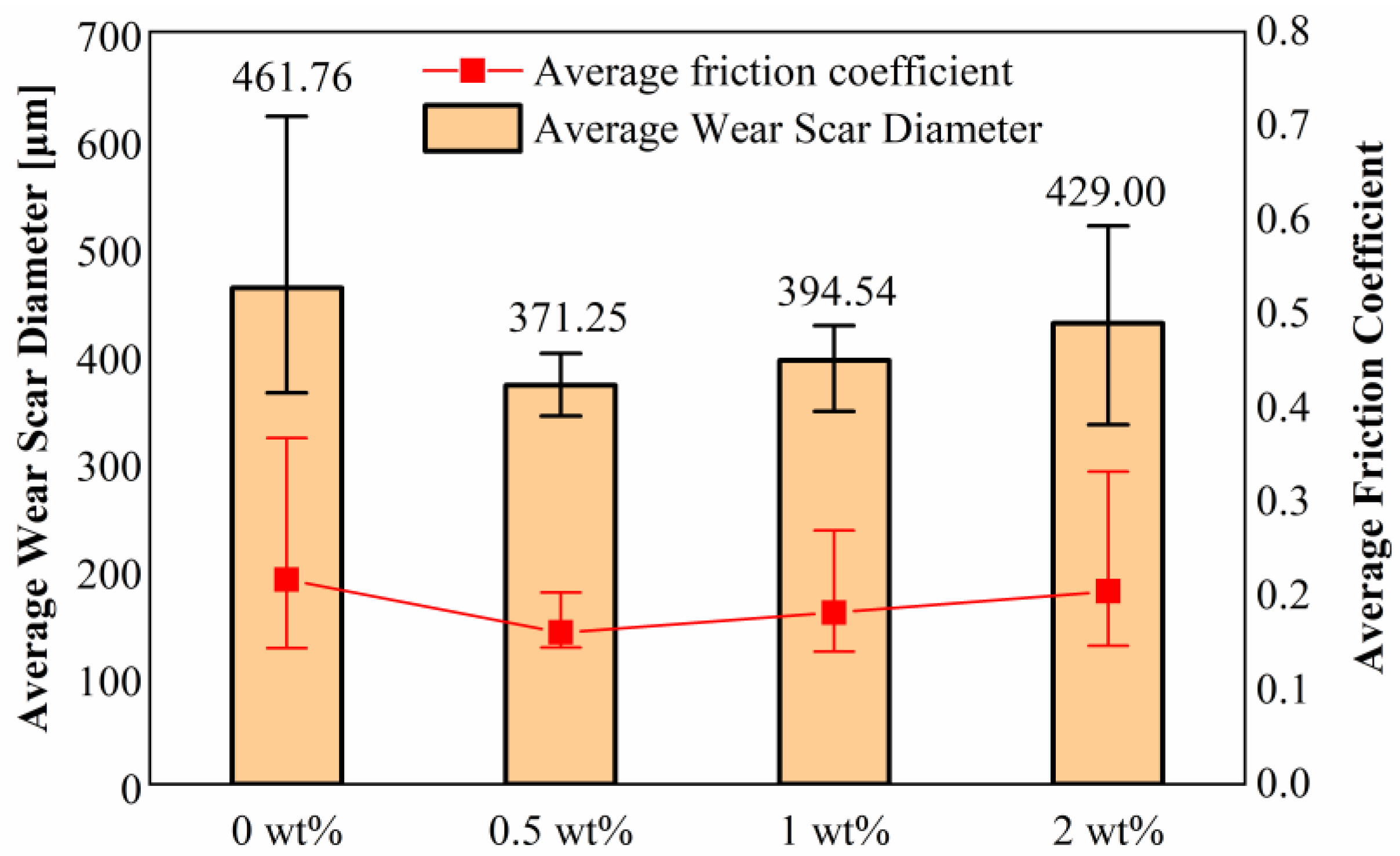

3.3. Effect of FLG on the Friction and Wear of LCG

4. Conclusions

- The addition of FLG makes the fiber microstructure of the LCG more compact, resulting in greater structural strength, yield strength, apparent viscosity, storage modulus, and loss modulus of the LCG.

- FLG can enhance the viscoelasticity of the LCG, and the increase in temperature will reduce the viscoelasticity of the LCG, and has a greater impact on the viscosity. Adding an appropriate amount of FLG can offset the effect of temperature on the elasticity and viscosity of the LCG, which means that FLG additives can improve the viscosity–temperature performance of the grease and the performance of the elastic deformation with temperature changes. Among the temperatures selected in this article, 70 °C is more suitable for FLG to play a role.

- An appropriate amount of FLG can make the boundary film more stable, can withstand long-term friction without failure, and reduce wear. When the FLG content is too high, FLG can fully cover the friction surface, however, it is easy to polymerize during the friction process, which makes the FLG change continuously in the two states of disordered polymerization and ordered arrangement, resulting in the instability of the boundary film and affecting the friction effect. Under the working conditions of this paper, the grease with FLG content of 0.5 wt% is the grease with the best friction and wear performance among the four greases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| FLG | few-layer graphene |

| COF | friction coefficient |

| LCG | lithium complex grease |

| WSD | wear scar diameter |

| SEM | scanning electron microscope |

References

- Ma, S.; Zhang, X.; Yan, K.; Zhu, Y.; Hong, J. A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision. Lubricants. 2022, 10, 9. [Google Scholar] [CrossRef]

- Zhang, E.; Li, W.; Zhao, G.; Wang, Z.; Wang, X. A Study on Microstructure, Friction and Rheology of Four Lithium Greases Formulated with Four Different Base Oils. Tribol. Lett. 2021, 69, 98. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Li, H.; Zhu, M.; Xia, Y.; Wang, J. Probing the effect of thickener on tribological properties of lubricating greases. Tribol. Int. 2018, 118, 128–139. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Exploration of Talc nanoparticles to enhance the performance of Lithium grease. Tribol. Int. 2021, 162, 107107. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Performance properties of lithium greases with PTFE particles as additive: Controlling parameter- size or shape? Tribol. Int. 2020, 148, 106302. [Google Scholar] [CrossRef]

- Huang, X.; Zhi, C.; Lin, Y.; Bao, H.; Wu, G.; Jiang, P.; Mai, Y.W. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R-Rep. 2020, 142, 100577. [Google Scholar] [CrossRef]

- Wu, W.; Chen, R.; Yang, Z.; He, Z.; Zhou, Y.; Lv, F. Corrosion resistance of 45 carbon steel enhanced by laser graphene-based coating. Diam. Relat. Mat. 2021, 116, 108370. [Google Scholar] [CrossRef]

- Mao, J.; Chen, G.; Zhao, J.; He, Y.; Luo, J. An investigation on the tribological behaviors of steel/copper and steel/steel friction pairs via lubrication with a graphene additive. Friction 2021, 9, 228–238. [Google Scholar] [CrossRef] [Green Version]

- Niu, M.; Qu, J.; Gu, L. Synthesis of titanium complex grease and effects of graphene on its tribological properties. Tribol. Int. 2019, 140, 105815. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; He, Y.; Jiang, M.; Gu, K. Tribological characteristics of graphene as grease additive under different contact forms. Tribol. Int. 2018, 127, 457–469. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; Li, Y.; Gao, T.; Dou, Z.; Mao, J.; Wang, H.; He, Y.; Li, S.; Luo, J. Superhigh-exfoliation graphene with a unique two-dimensional (2D) microstructure for lubrication application. Appl. Surf. Sci. 2020, 513, 145608. [Google Scholar] [CrossRef]

- Curà, F.; Mura, A.; Adamo, F. Experimental investigation about tribological performance of grapheme-nanoplatelets as additive for lubricants. Procedia Struct. Integr. 2018, 12, 44–51. [Google Scholar] [CrossRef]

- Zheng, D.; Cai, Z.; Shen, M.; Li, Z.; Zhu, M. Investigation of the tribology behaviour of the graphene nanosheets as oil additives on textured alloy cast iron surface. Appl. Surf. Sci. 2016, 387, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Gu, L.; Jian, R. Lubrication mechanism of graphene nanoplates as oil additives for ceramics/steel sliding components. Ceram. Int. 2021, 47, 16935–16942. [Google Scholar] [CrossRef]

- Radhika, P.; Sobhan, C.B.; Chakravorti, S. Improved tribological behavior of lubricating oil dispersed with hybrid nanoparticles of functionalized carbon spheres and graphene nano platelets. Appl. Surf. Sci. 2021, 540, 148402. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, G.; Xie, G. Ultralow concentration of graphene oxide nanosheets as oil-based lubricant additives. Appl. Surf. Sci. 2019, 498, 143683. [Google Scholar] [CrossRef]

- Ouyang, T.; Shen, Y.; Lei, W.; Xu, X.; Liang, L.; Waqar, H.S.; Lin, B.; Tian, Z.; Shen, P. Reduced friction and wear enabled by arc-discharge method-prepared 3D graphene as oil additive under variable loads and speeds. Wear 2020, 462, 203495. [Google Scholar] [CrossRef]

- Mohamed, A.; Tirth, V.; Kamel, B.M. Tribological characterization and rheology of hybrid calcium grease with graphene nanosheets and multi-walled carbon nanotubes as additives. J. Mater. Res. Technol. 2020, 9, 6178–6185. [Google Scholar] [CrossRef]

- Li, Z.; He, Q.; Du, S.; Zhang, Y. Effect of few layer graphene additive on the tribological properties of lithium grease. Lubr. Sci. 2020, 32, 333–343. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, A.; Yin, H. Preparation of graphite nanosheets in different solvents by sand milling and their enhancement on tribological properties of lithium-based grease. Chin. J. Chem. Eng. 2020, 28, 1177–1186. [Google Scholar] [CrossRef]

- Ouyang, T.; Shen, Y.; Yang, R.; Liang, L.; Liang, H.; Lin, B.; Tian, Z.; Shen, P. 3D hierarchical porous graphene nanosheets as an efficient grease additive to reduce wear and friction under heavy-load conditions. Tribol. Int. 2020, 144, 106118. [Google Scholar] [CrossRef]

- Aziev, R.; Savilov, S.; Kupreenko, S.; Ivanov, A.; Stolbov, D.; Usol'tseva, N.; Lunin, V. Graphene nanoflakes as effective dopant to Li-based greases. Funct. Mater. Lett. 2020, 9, 2040006. [Google Scholar] [CrossRef]

- Lin, B.; Rustamov, I.; Zhang, L.; Luo, J.Q.; Wan, X. Graphene-Reinforced Lithium Grease for Antifriction and Antiwear. ACS Appl. Nano Mater. 2020, 3, 10508–10521. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, J.; Chen, G.; He, Y.; Huang, Y.; Luo, J. In situ synthesis of Mn3O4/graphene nanocomposite and its application as a lubrication additive at high temperatures. Appl. Surf. Sci. 2021, 546, 149019. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Qiao, D.; Feng, D.; Wang, H.; Meng, W. The Influence of Graphene Oxide on the Tribological Properties of Lithium-based Grease. Sur. Tech. 2021, 50, 70–78. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, C.; Peng, Y.; Shi, Y.; Zhang, Y. Fretting tribological behaviors of steel wires under lubricating grease with compound additives of graphene and graphite. Wear 2020, 454, 203333. [Google Scholar] [CrossRef]

- Cheng, Z.; Kong, Y.; Fan, L.; Liu, Z. Ultrasound-assisted Li+/Na+ co-intercalated exfoliation of graphite into few-layer graphene. Ultrason. Sonochem. 2020, 66, 105108. [Google Scholar] [CrossRef]

- Pan, J.; Cheng, Y.; Qian, M.; Zhou, B. Thermal-rheological properties and variation mechanisms of lithium lubricating grease. Chem. Ind. Eng. Progress 2018, 37, 1509–1515. [Google Scholar] [CrossRef]

| LCG | 0.5 wt% FLG | 1 wt% FLG | 2 wt% FLG | ||||

|---|---|---|---|---|---|---|---|

| T [°C] | τy2 [Pa] | τy2 [Pa] | growth rate [%] | τy2 [Pa] | growth rate [%] | τy2 [Pa] | growth rate [%] |

| 30 | 594.13 | 726.32 | 22.25 | 740.76 | 24.68 | 801.65 | 34.93 |

| 70 | 269.52 | 275.53 | 2.23 | 342.48 | 27.07 | 372.26 | 38.12 |

| 130 | 116.02 | 139.02 | 19.82 | 159.94 | 37.86 | 123.05 | 6.06 |

| LCG | 0.5 wt% FLG | 1 wt% FLG | 2 wt% FLG | |||

|---|---|---|---|---|---|---|

| COF [1] | COF [1] | Reduction Rate [%] | COF [1] | Reduction Rate [%] | COF [1] | Reduction Rate [%] |

| 0.218 | 0.161 | 52.05 | 0.183 | 16.06 | 0.205 | 5.96 |

| LCG | 0.5 wt% FLG | 1 wt% FLG | 2 wt% FLG | |||

|---|---|---|---|---|---|---|

| WSD [μm] | WSD [μm] | Reduction Rate [%] | WSD [μm] | Reduction Rate [%] | WSD [μm] | Reduction Rate [%] |

| 461.76 | 371.25 | 19.60 | 394.54 | 14.56 | 429.00 | 7.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Gao, X.; Lin, J.; Zhang, P. Rheological and Frictional Properties of Lithium Complex Grease with Graphene Additives. Lubricants 2022, 10, 57. https://doi.org/10.3390/lubricants10040057

Wang Y, Gao X, Lin J, Zhang P. Rheological and Frictional Properties of Lithium Complex Grease with Graphene Additives. Lubricants. 2022; 10(4):57. https://doi.org/10.3390/lubricants10040057

Chicago/Turabian StyleWang, Yanshuang, Xudong Gao, Jianghai Lin, and Pu Zhang. 2022. "Rheological and Frictional Properties of Lithium Complex Grease with Graphene Additives" Lubricants 10, no. 4: 57. https://doi.org/10.3390/lubricants10040057

APA StyleWang, Y., Gao, X., Lin, J., & Zhang, P. (2022). Rheological and Frictional Properties of Lithium Complex Grease with Graphene Additives. Lubricants, 10(4), 57. https://doi.org/10.3390/lubricants10040057