Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

2.2. Synthesis of MXene (Ti3C2)

2.3. Preparation of MoS2-Ti3C2 Hybrid Nanoparticle

2.4. Synthesis of Amine-Functionalized MoS2-Ti3C2 Hybrid Nanoparticle

2.5. Characterizations

3. Results and Discussion

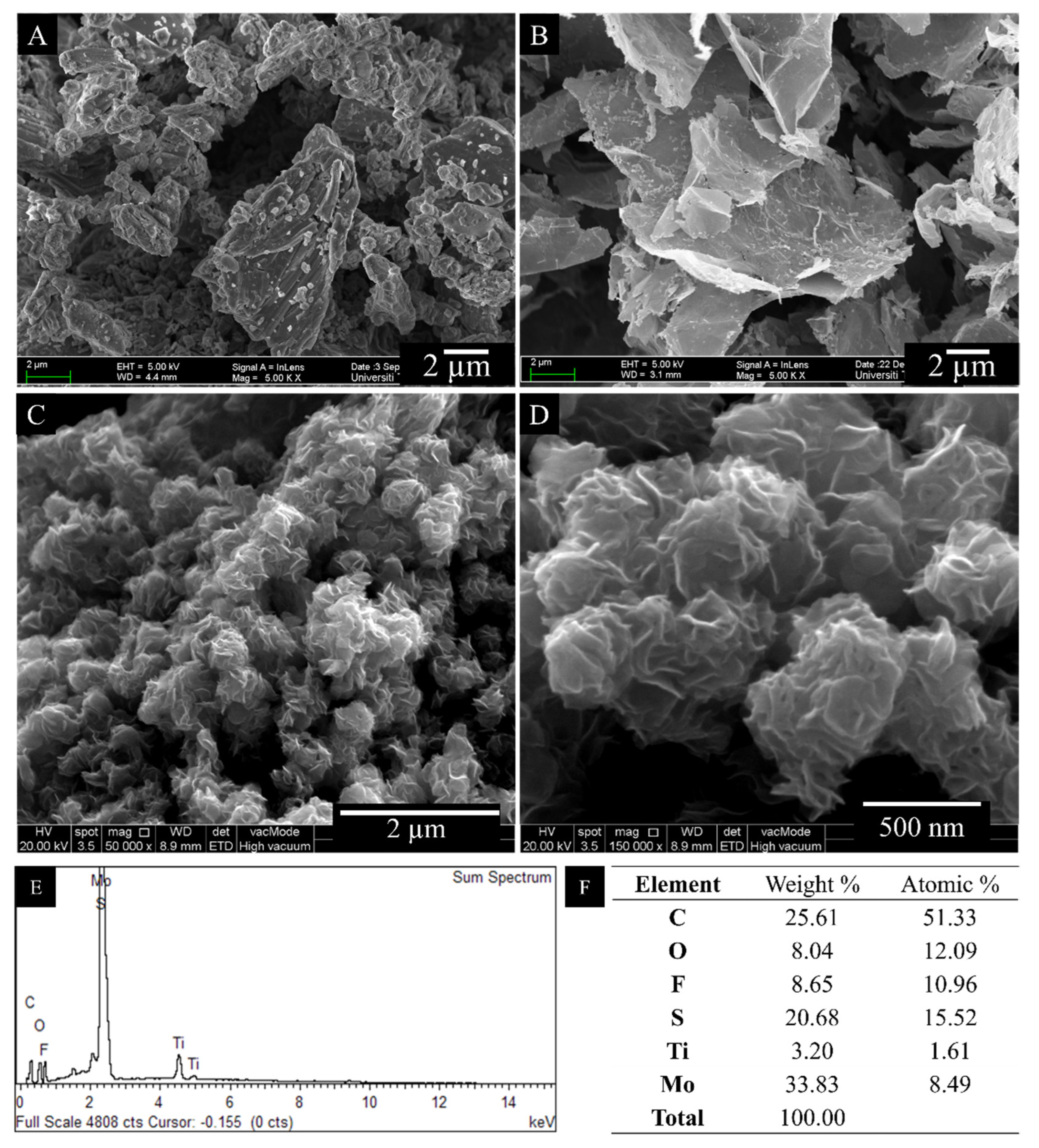

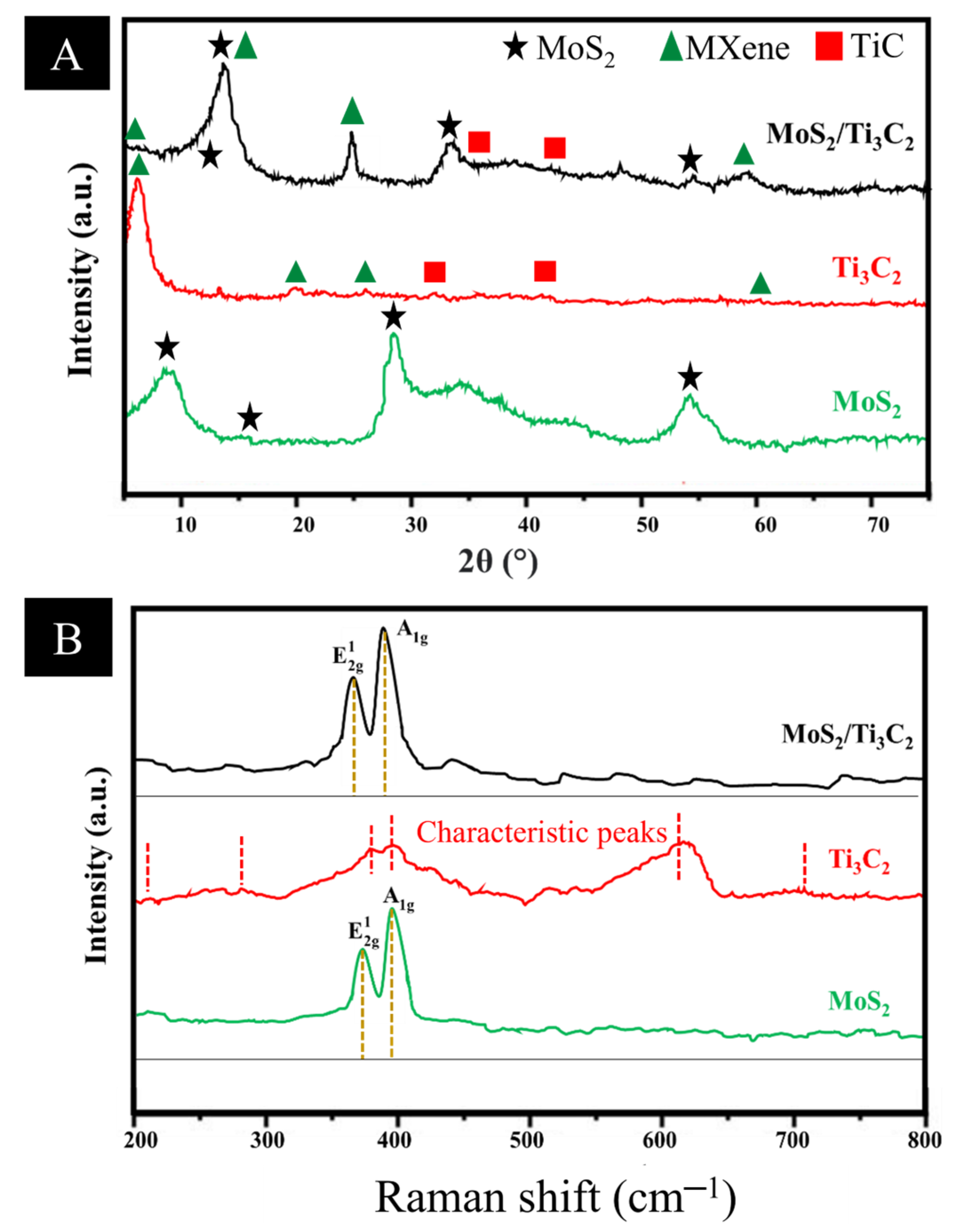

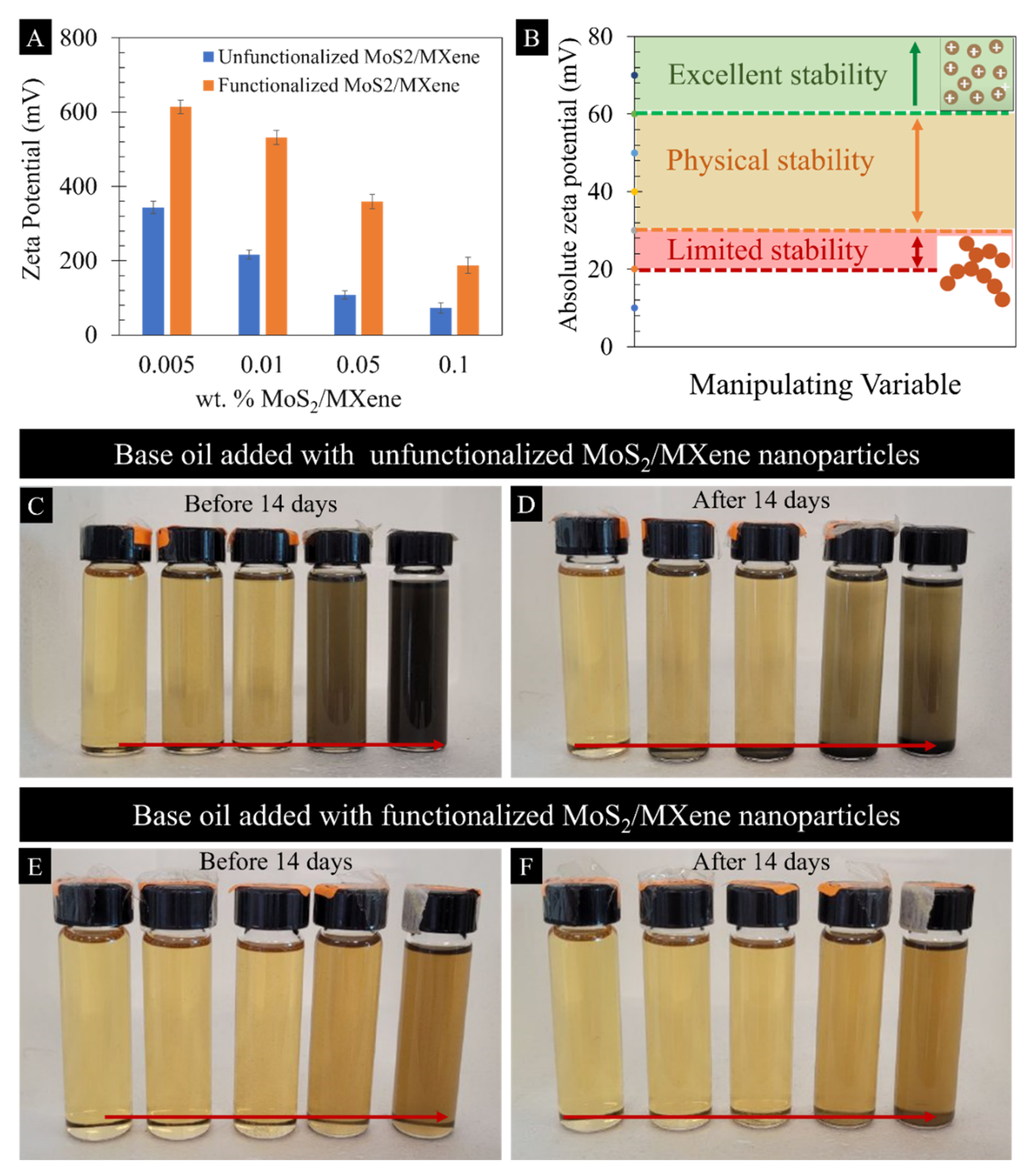

3.1. Morphology and Characterization

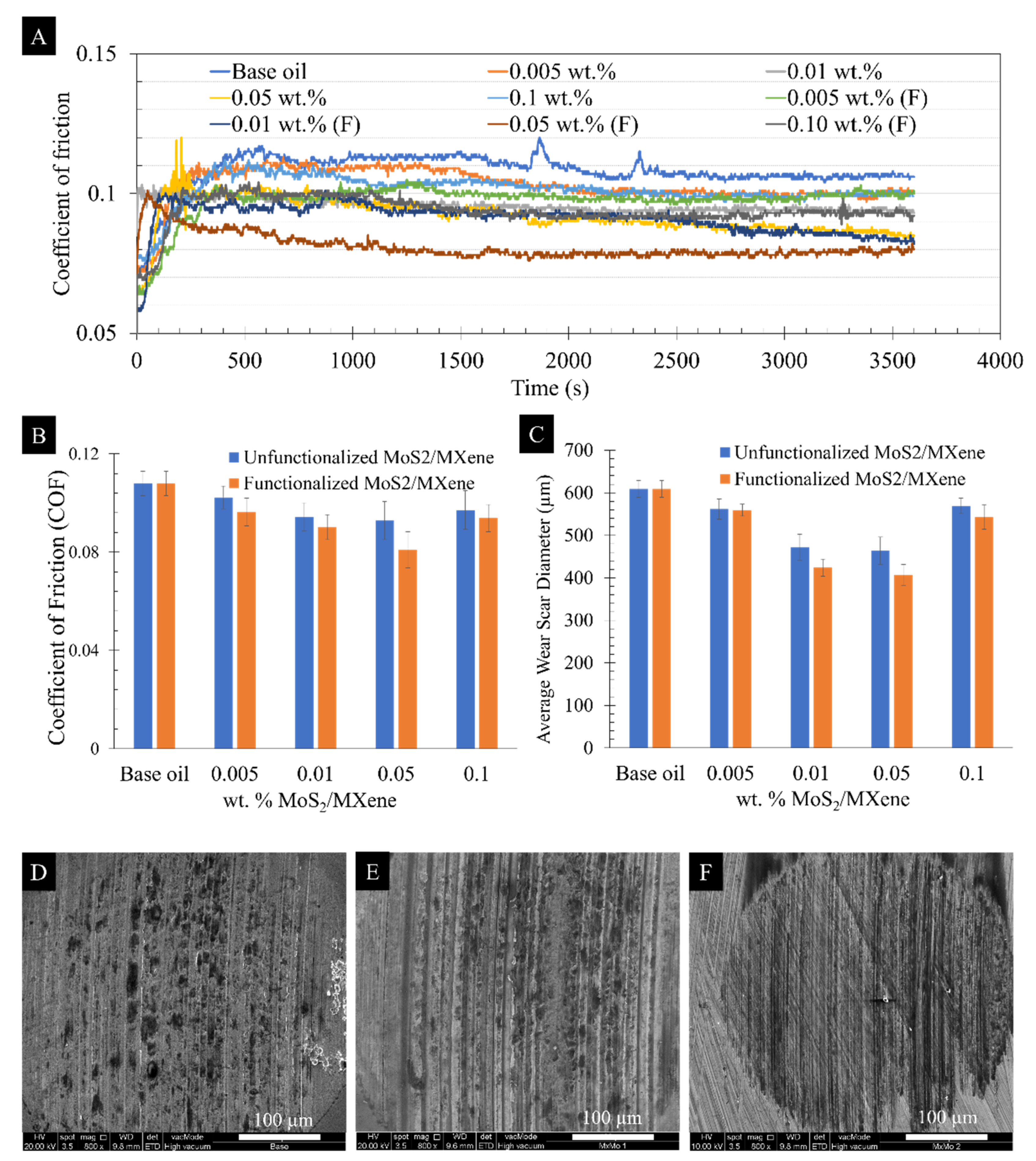

3.2. Tribological Behaviour

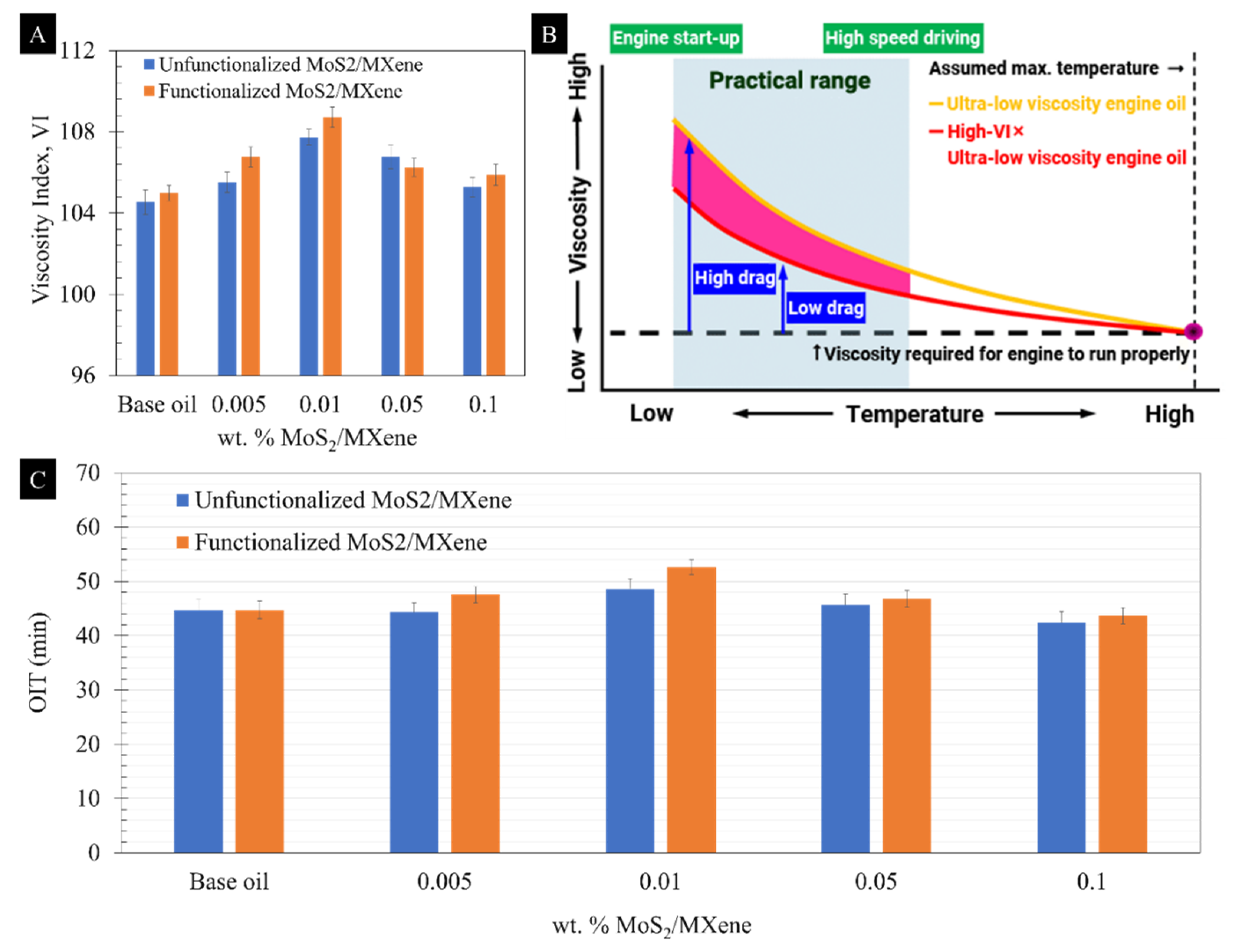

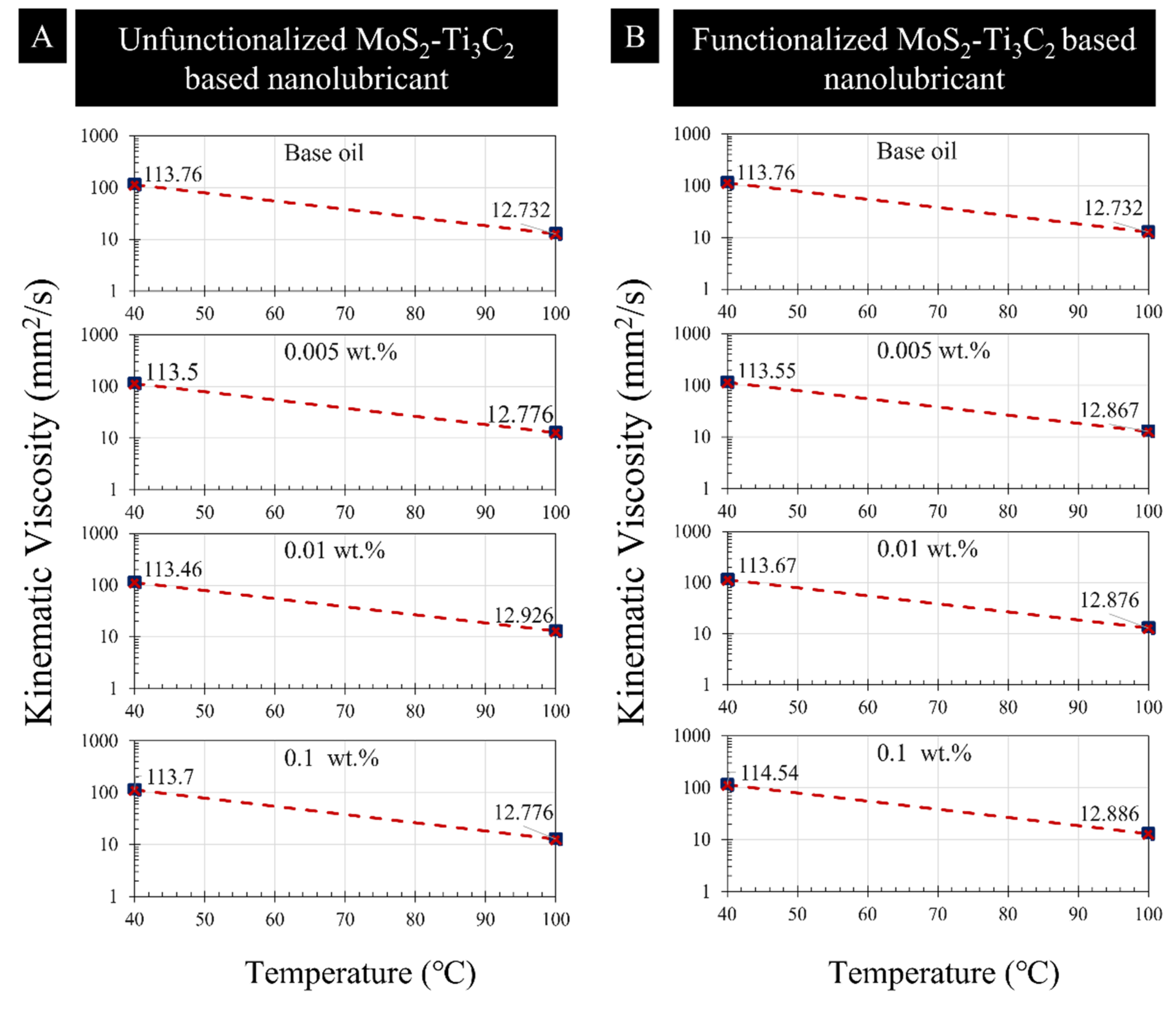

3.3. Viscosity Behaviour and Oxidative Induction Time (OIT)

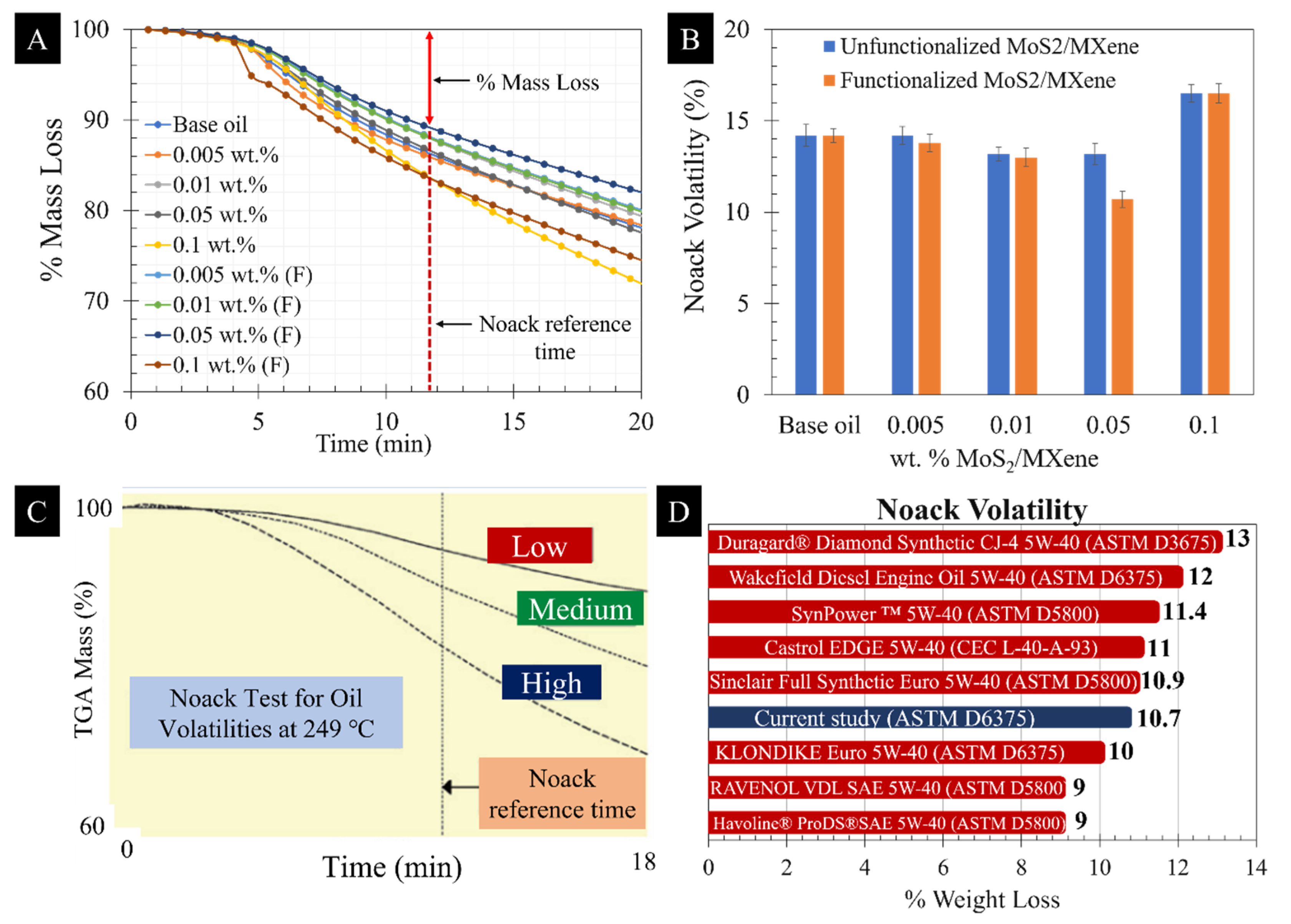

3.4. Noack Volatility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, M.; Xianjun, H.; Abdelkareem, M.; Gulzar, M.; Elsheikh, A. Novel approach of the graphene nanolubricant for energy saving via anti-friction/wear in automobile engines. Tribol. Int. 2018, 124, 209–229. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Ali, M.; Xianjun, H.; Turkson, R.; Peng, Z.; Chen, X. Enhancing the thermophysical properties and tribological behaviour of engine oils using nano-lubricant additives. RSC Adv. 2016, 6, 77913–77924. [Google Scholar] [CrossRef]

- Yu, R.; Liu, J.; Zhou, Y. Experimental study on tribological property of MoS2 nanoparticle in castor oil. J. Tribol. 2019, 141, 3–7. [Google Scholar] [CrossRef]

- Ali, M.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Li, W.; Zheng, S.; Cao, B.; Ma, S. Friction and wear properties of ZrO2/SiO2 composite nanoparticles. J. Nanoparticle Res. 2011, 13, 2129–2137. [Google Scholar] [CrossRef]

- Rasheed, A.; Khalid, M.; Nor, A.B.M.; Wong, W.; Duolikun, T.; Natu, V.; Barsoum, M.; Leo, B.; Zaharin, H.; Ghazali, M. MXene-graphene hybrid nanoflakes as friction modifiers for outboard engine oil. IOP Conf. Ser. Mater. Sci. Eng. 2020, 834, 012039. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.; Barsoum, M.; Gogotsi, Y. 25th anniversary article: MXenes: A new family of two-dimensional materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef] [PubMed]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gogotsi, Y.; Huang, Q. MXenes: Two-Dimensional Building Blocks for Future Materials and Devices. ACS Nano 2021, 15, 5775–5780. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Zhang, L.; Li, H.; Fan, X.; Zhu, M. Towards high-performance additive of Ti3C2/graphene hybrid with a novel wrapping structure in epoxy coating. Carbon 2020, 157, 217–233. [Google Scholar] [CrossRef]

- Nguyen, H.; Chung, K. Assessment of tribological properties of ti3c2 as a water-based lubricant additive. Materials 2020, 13, 5545. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Ashton, M.; Ostadhossein, A.; Van Duin, A.; Hennig, R.; Sinnott, S. Computational study of low interlayer friction in Tin+1Cn (n = 1, 2, and 3) MXene. ACS Appl. Mater. Interfaces 2017, 9, 34467–34479. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Dong, S.; Ye, Z.; Wei, Y. Synthesis and tribological property of Ti3C2TX nanosheets. J. Mater. Sci. 2017, 52, 2200–2209. [Google Scholar] [CrossRef]

- Gao, J.; Du, C.-F.; Zhang, T.; Zhang, X.; Ye, Q.; Liu, S.; Liu, W. Dialkyl Dithiophosphate-Functionalized Ti3C2TX MXene Nanosheets as Effective Lubricant Additives for Antiwear and Friction Reduction. ACS Appl. Nano Mater. 2021, 4, 11080–11087. [Google Scholar] [CrossRef]

- Vazirisereshk, M.; Martini, A.; Strubbe, D.; Baykara, M. Solid lubrication with MoS2: A review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef] [Green Version]

- Serles, P.; Gaber, K.; Pajovic, S.; Colas, G.; Filleter, T. High Temperature Microtribological Studies of MoS2 Lubrication for Low Earth Orbit. Lubricants 2020, 8, 49. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Shahabuddin, S.; Anwar, A.; Sridewi, N. Tribological analysis of advanced microwave synthesized Molybdenum disulfide (MoS2) as anti-friction additives in diesel engine oil for military vehicles. Mater. Today Proc. 2022, 62, 7243–7247. [Google Scholar] [CrossRef]

- Gradt, T.; Schneider, T. Tribological performance of MoS2 coatings in various environments. Lubricants 2016, 4, 32. [Google Scholar] [CrossRef] [Green Version]

- Numan, A.; Rafique, S.; Khalid, M.; Zaharin, H.A.; Radwan, A.; Mokri, N.A.; Ching, O.P.; Walvekar, R. Microwave-assisted rapid MAX phase etching and delamination: A paradigm shift in MXene synthesis. Mater. Chem. Phys. 2022, 288, 126429. [Google Scholar] [CrossRef]

- Nagarajan, T.; Khalid, M.; Sridewi, N.; Jagadish, P.; Shahabuddin, S.; Muthoosamy, K.; Walvekar, R. Tribological, oxidation and thermal conductivity studies of microwave synthesized molybdenum disulfide (MoS2) nanoparticles as nano-additives in diesel based engine oil. Sci. Rep. 2022, 12, 14108. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lv, X.; Sun, X.; Yang, C.; Zheng, Y.; Yang, L.; Li, S.; Tao, X. Edge-oriented, high-percentage 1T′-phase MoS2 nanosheets stabilize Ti3C2 MXene for efficient electrocatalytic hydrogen evolution. Appl. Catal. B Environ. 2021, 284, 119708. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Li, H.; Lin, S.; Ding, W.; Zhu, X.; Sheng, Z.; Wang, H.; Zhu, X.; Sun, Y. 2D/2D 1T-MoS2/Ti3C2 MXene Heterostructure with Excellent Supercapacitor Performance. Adv. Funct. Mater. 2020, 30, 0190302. [Google Scholar] [CrossRef]

- Wang, H.; Ma, H. The electromagnetic and microwave absorbing properties of MoS2 modified Ti3C2Tx nanocomposites. J. Mater. Sci. Mater. Electron. 2019, 30, 15250–15256. [Google Scholar] [CrossRef]

- Wei, S.; Fu, Y.; Liu, M.; Yue, H.; Park, S.; Lee, Y.; Li, H.; Yao, F. Dual-phase MoS2/MXene/CNT ternary nanohybrids for efficient electrocatalytic hydrogen evolution, Npj 2D. Mater. Appl. 2022, 6, 25. [Google Scholar] [CrossRef]

- Liu, Y.; He, Y.; Vargun, E.; Plachy, T.; Saha, P.; Cheng, Q. 3D Porous Ti3C2 MXene/NiCo-MOF Composites for Enhanced Lithium Storage. Nanomaterials 2020, 10, 10040695. [Google Scholar] [CrossRef] [Green Version]

- Mao, X.; Zou, Y.; Xu, F.; Sun, L.; Chu, H.; Zhang, H.; Zhang, J.; Xiang, C. Three-Dimensional Self-Supporting Ti3C2 with MoS2 and Cu2O Nanocrystals for High-Performance Flexible Supercapacitors. ACS Appl. Mater. Interfaces 2021, 13, 22664–22675. [Google Scholar] [CrossRef]

- Radhika, P.; Sobhan, C.; Chakravorti, S. Improved tribological behavior of lubricating oil dispersed with hybrid nanoparticles of functionalized carbon spheres and graphene nano platelets. Appl. Surf. Sci. 2021, 540, 148402. [Google Scholar] [CrossRef]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of graphene in poly(lactic) acid by 3D printing to develop creep and wear-resistant hierarchical nanocomposites. Polym. Compos. 2018, 39, 3877–3888. [Google Scholar] [CrossRef]

- Feng, P.; Ren, Y.; Li, Y.; He, J.; Zhao, Z.; Ma, X.; Fan, X.; Zhu, M. Synergistic lubrication of few-layer Ti3C2Tx/MoS2 heterojunction as a lubricant additive. Friction 2022, 10, 2018–2032. [Google Scholar] [CrossRef]

- Mukherjee, S. Preparation and Stability of Nanofluids—A Review. IOSR J. Mech. Civ. Eng. 2013, 9, 63–69. [Google Scholar] [CrossRef]

- Zainon, S.; Azmi, W. Recent progress on stability and thermo-physical properties of mono and hybrid towards green nanofluids. Micromachines 2021, 12, 12020176. [Google Scholar] [CrossRef] [PubMed]

- Salameh, T.; Kumar, P.; Sayed, E.; Abdelkareem, M.; Rezk, H.; Olabi, A. Fuzzy modeling and particle swarm optimization of Al2O3/SiO2 nanofluid. Int. J. Thermofluids 2021, 10, 100084. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Priest, M.; Green, J. ZDDP and MoDTC interactions and their effect on tribological performance—Tribofilm characteristics and its evolution. Tribol. Lett. 2006, 24, 243–256. [Google Scholar] [CrossRef]

- Thornley, A.; Wang, Y.; Wang, C.; Chen, J.; Huang, H.; Liu, H.; Neville, A.; Morina, A. Optimizing the Mo concentration in low viscosity fully formulated oils. Tribol. Int. 2022, 168, 107437. [Google Scholar] [CrossRef]

- ENEOS Corporation. Development of Next Generation Engine Oils. Lubricants (n.d.). Available online: https://www.eneos.co.jp/english/company/rd/intro/lubricants/hairyo.html (accessed on 14 December 2022).

- Shah, R.; Hope, K.; Aragon, N. Fuel economy considerations: Effect of lube oils and their volatility. Lube Magazine, November 2020; pp. 1–4. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markandan, K.; Nagarajan, T.; Walvekar, R.; Chaudhary, V.; Khalid, M. Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil. Lubricants 2023, 11, 47. https://doi.org/10.3390/lubricants11020047

Markandan K, Nagarajan T, Walvekar R, Chaudhary V, Khalid M. Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil. Lubricants. 2023; 11(2):47. https://doi.org/10.3390/lubricants11020047

Chicago/Turabian StyleMarkandan, Kalaimani, Thachnatharen Nagarajan, Rashmi Walvekar, Vishal Chaudhary, and Mohammad Khalid. 2023. "Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil" Lubricants 11, no. 2: 47. https://doi.org/10.3390/lubricants11020047

APA StyleMarkandan, K., Nagarajan, T., Walvekar, R., Chaudhary, V., & Khalid, M. (2023). Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil. Lubricants, 11(2), 47. https://doi.org/10.3390/lubricants11020047