Measurement for Lubricant Distribution in an Angular Contact Ball Bearing and Its Influence Investigation

Abstract

1. Introduction

2. Measurement for Lubricant Distribution in an Angular Contact Ball Bearing

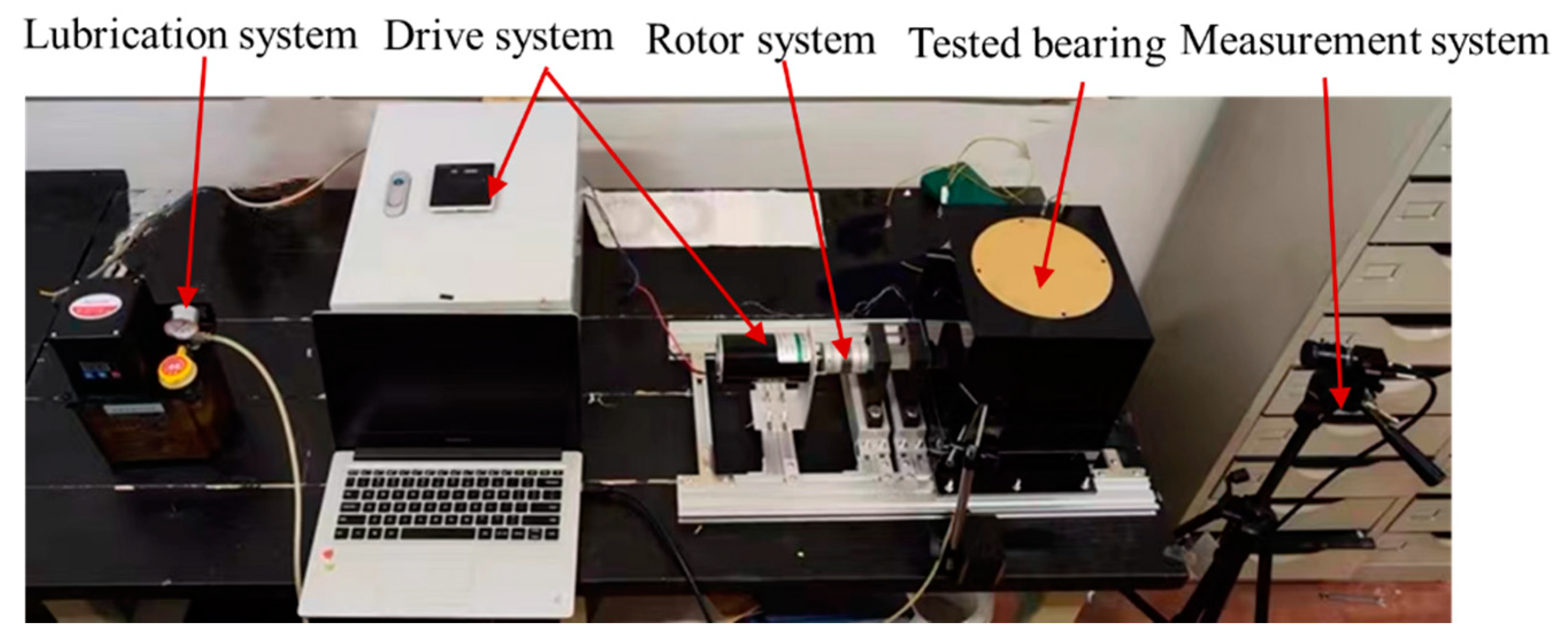

2.1. Test Rig

2.2. Tested Bearing

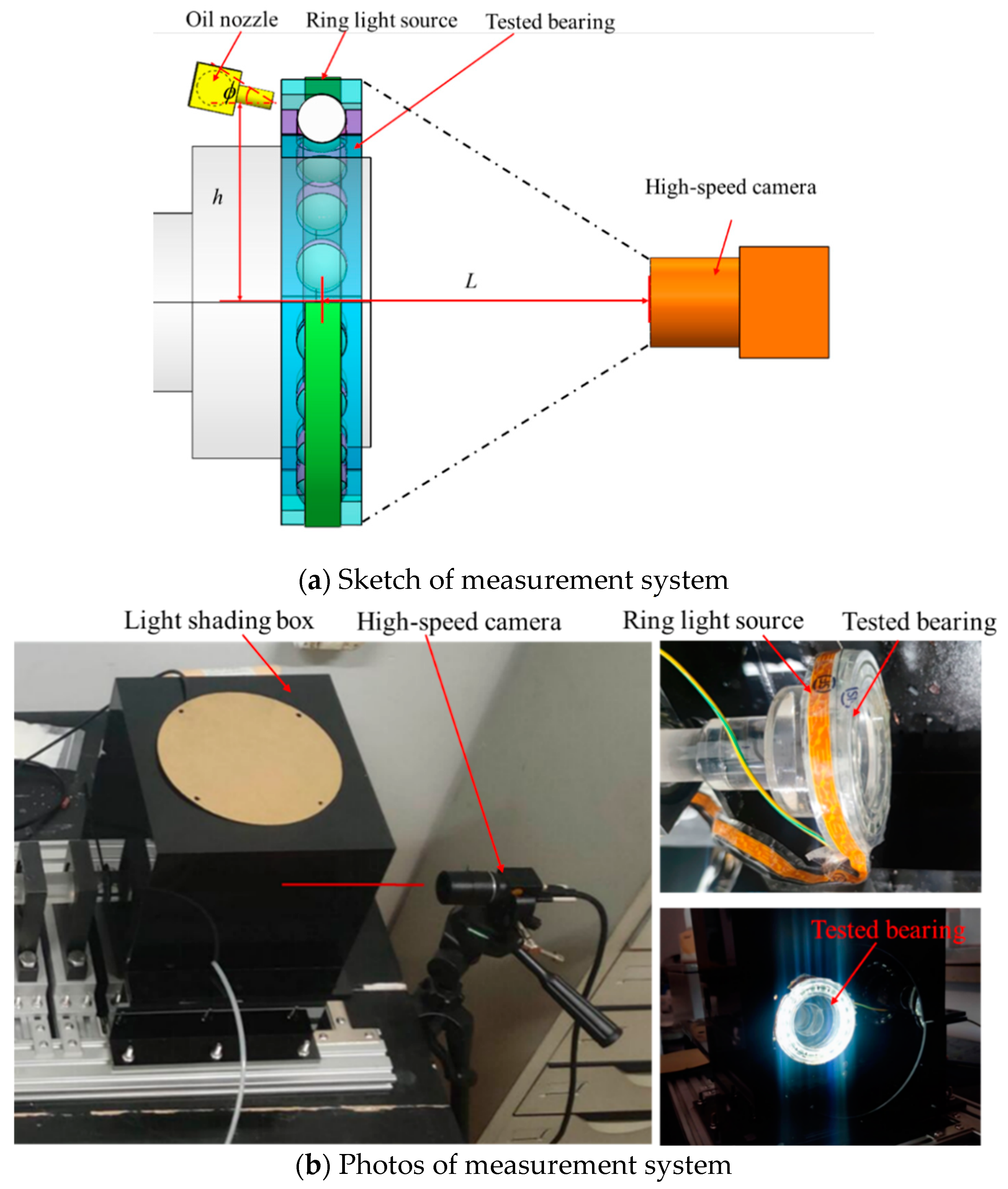

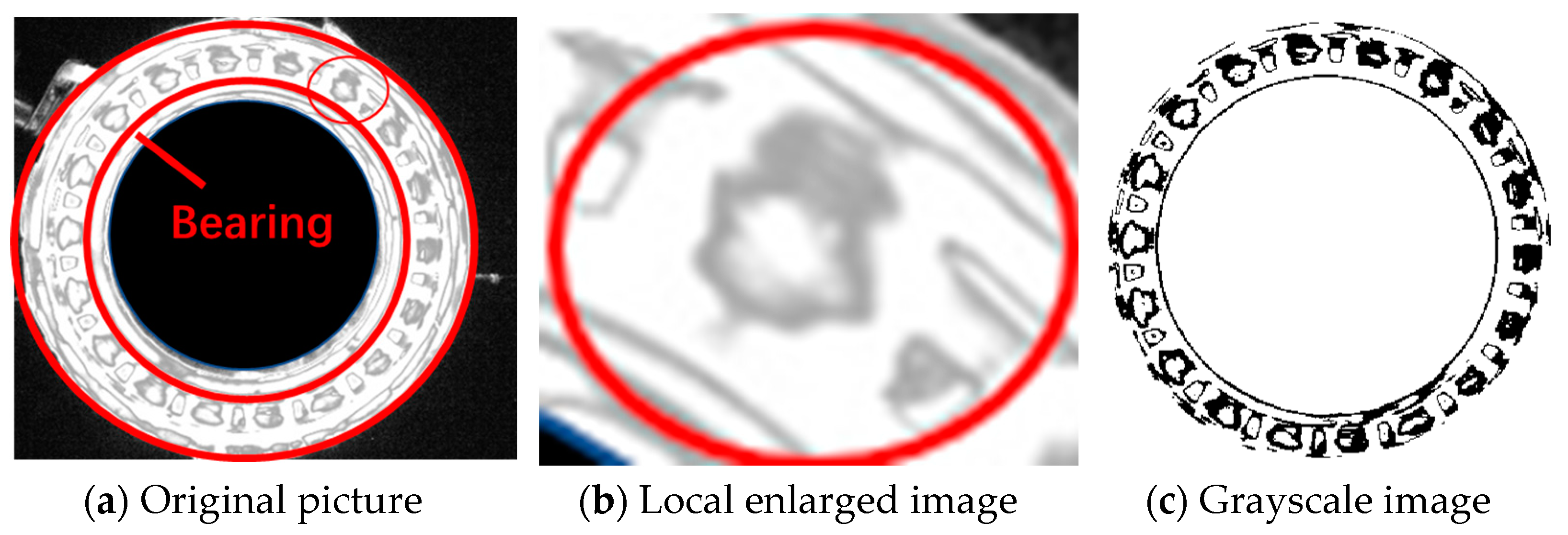

2.3. Measurement for Lubricant Distribution

3. Influence of Lubrication Conditions on Lubricant Distribution

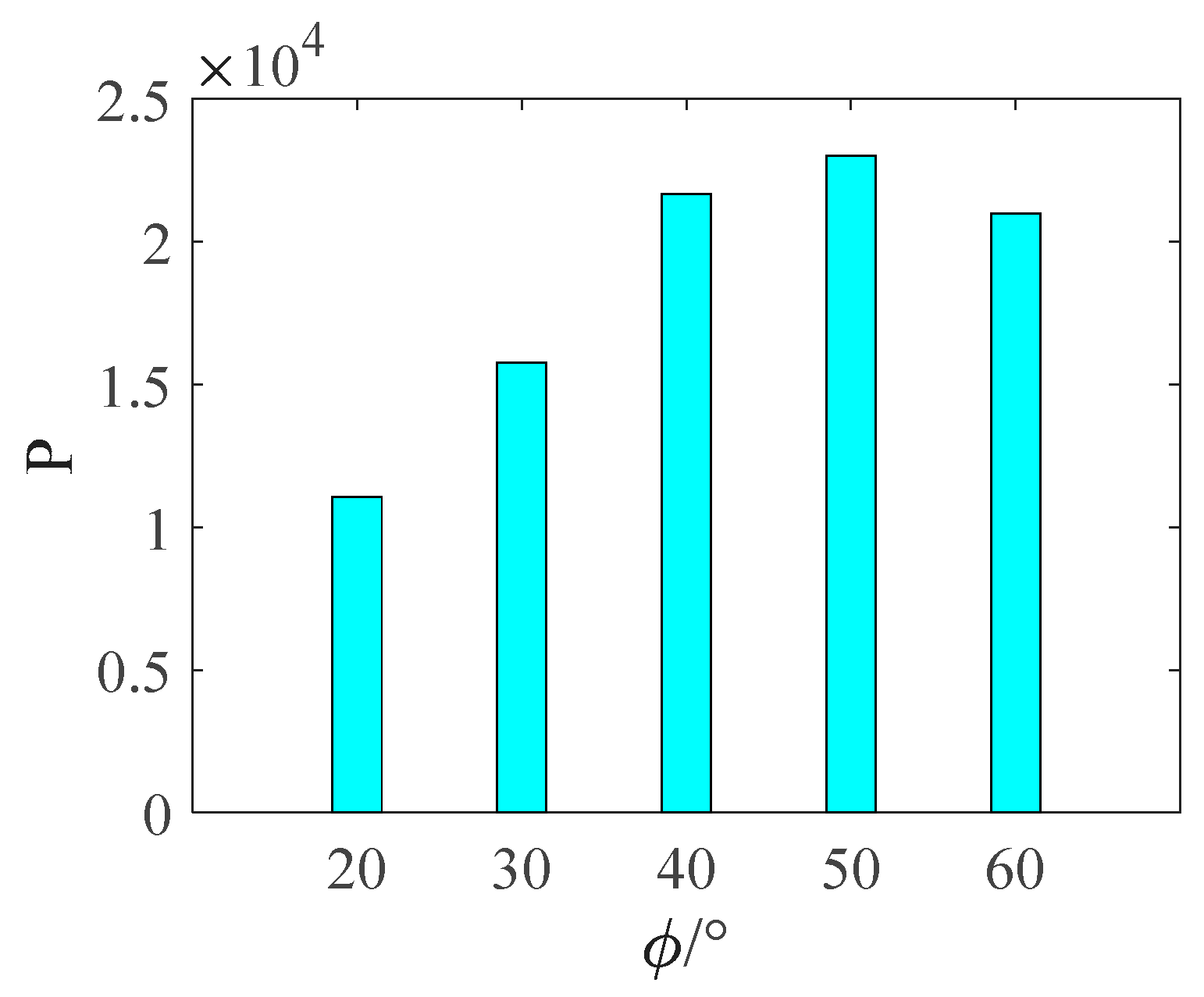

3.1. Influence of Oil Jet Nozzle Angle on Lubricant Distribution

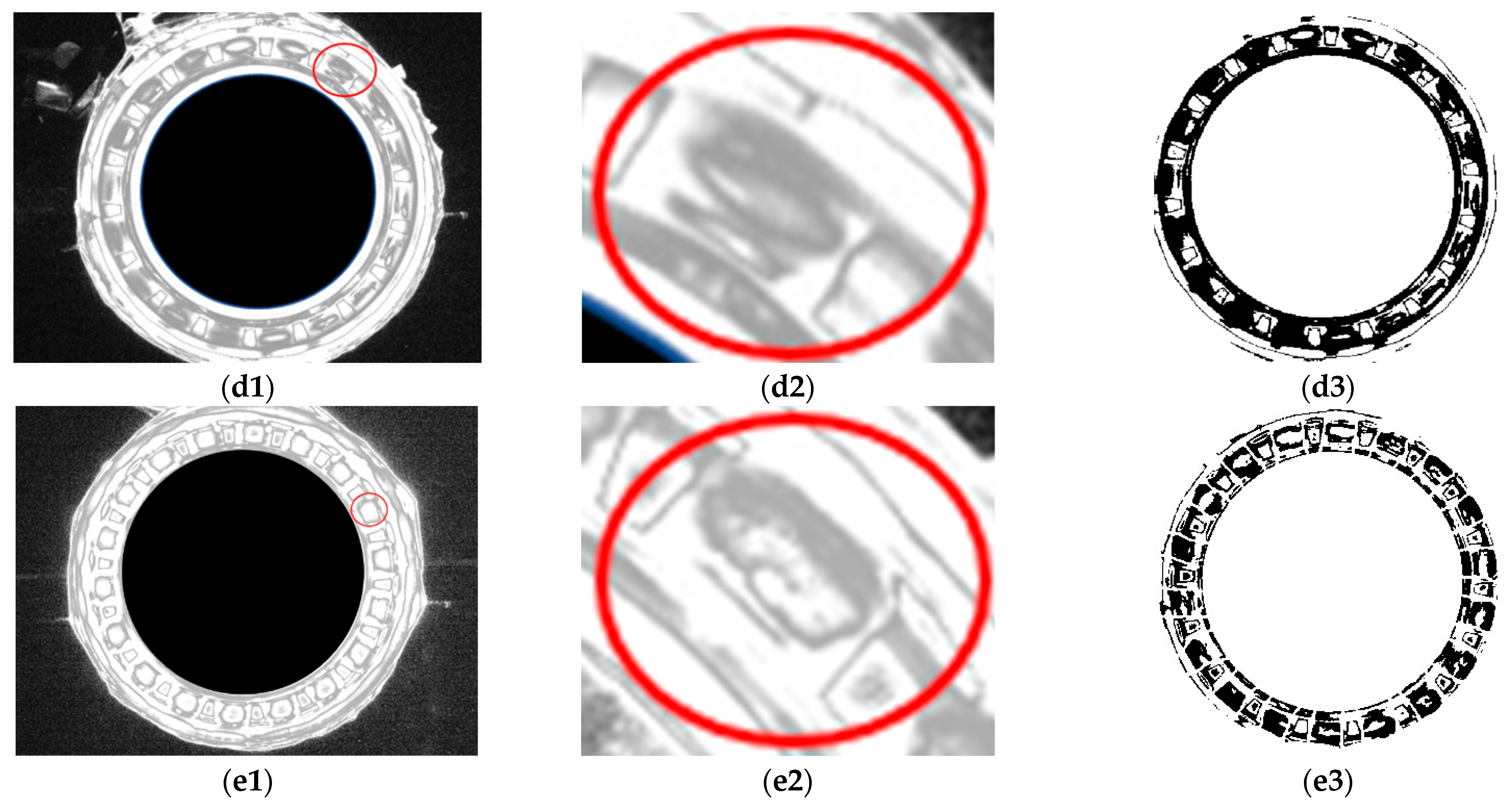

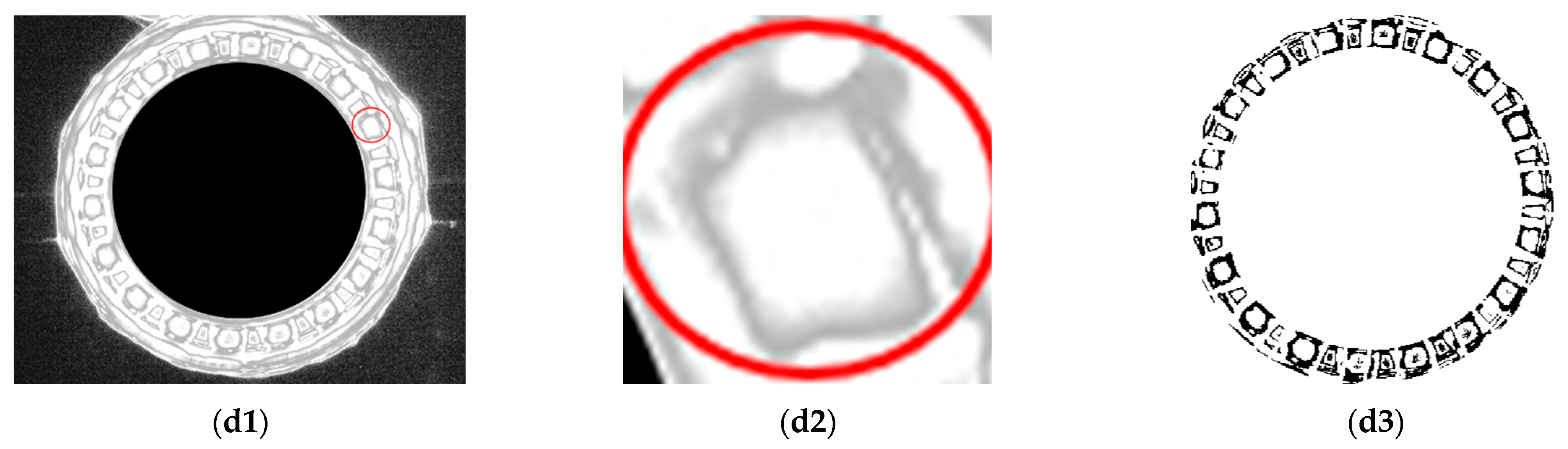

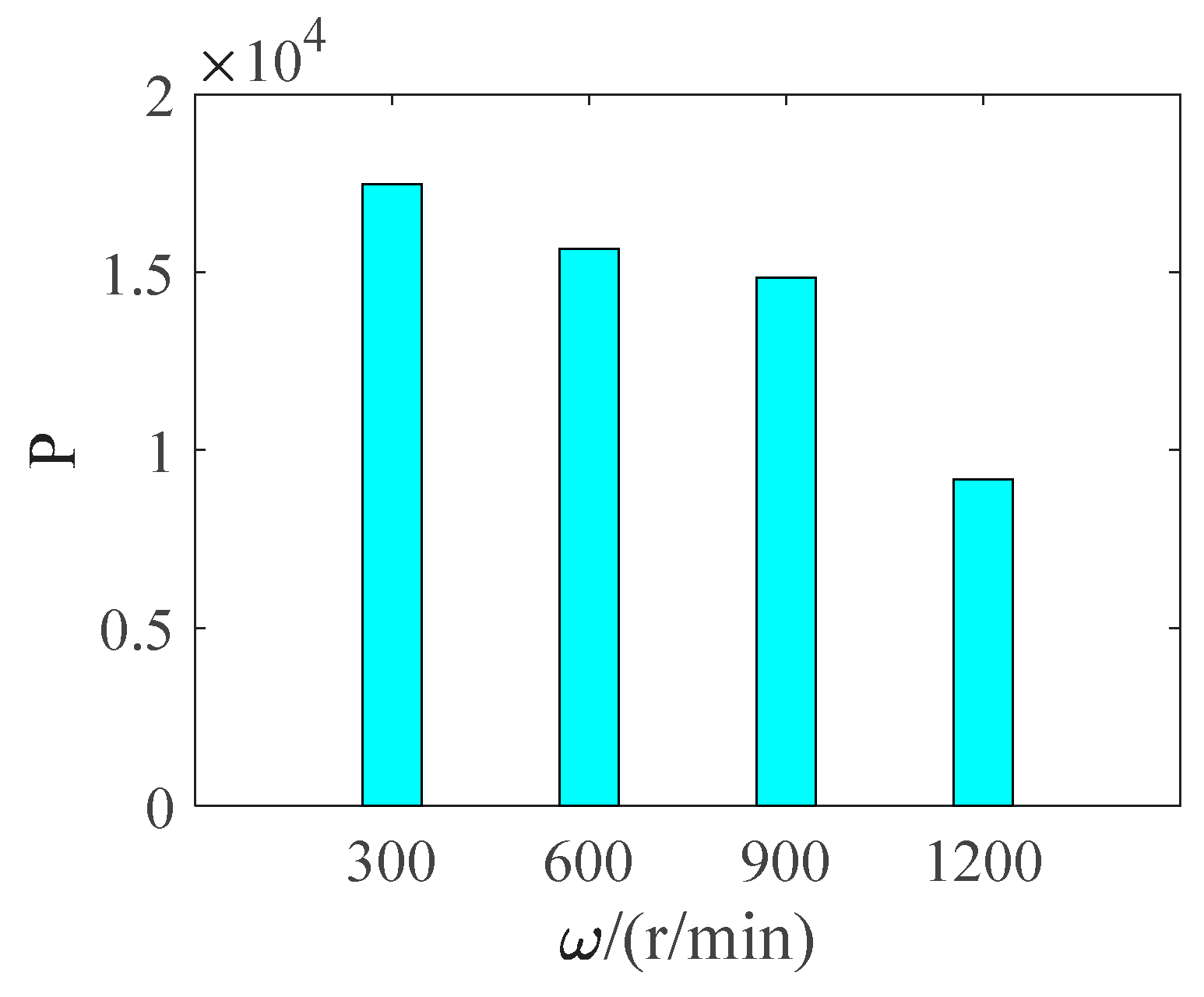

3.2. Influence of Operating Speed on Lubricant Distribution

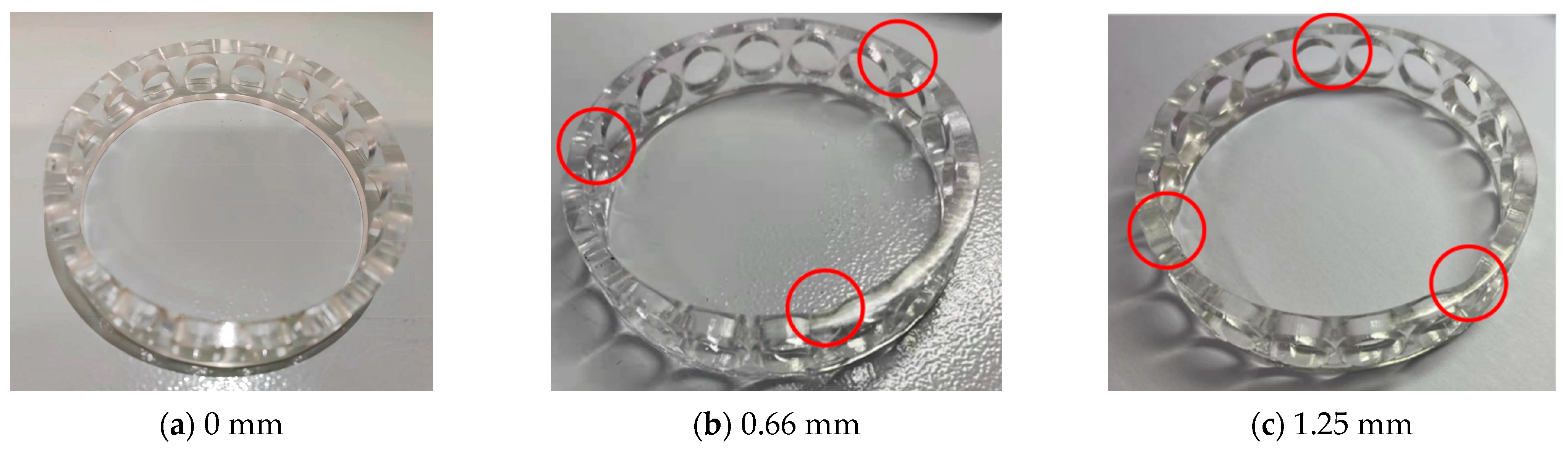

4. Influence of Cage Structure on Lubricant Distribution

5. Conclusions

- (1)

- The observation of lubricant distribution based on a specially designed test rig was proposed, and pixel numbers of the lubricant can be calculated to quantitatively characterize the oil volume in a bearing.

- (2)

- The lubricant distribution is affected by the oil jet nozzle angle, operating speed, and cage structure. The lubricant distributed among balls and the cage pocket in bearings gradually increased with the increase in the nozzle angle, but decreased with the rising operating speed. The optimal nozzle angle available for lubrication needs to be given sufficient consideration.

- (3)

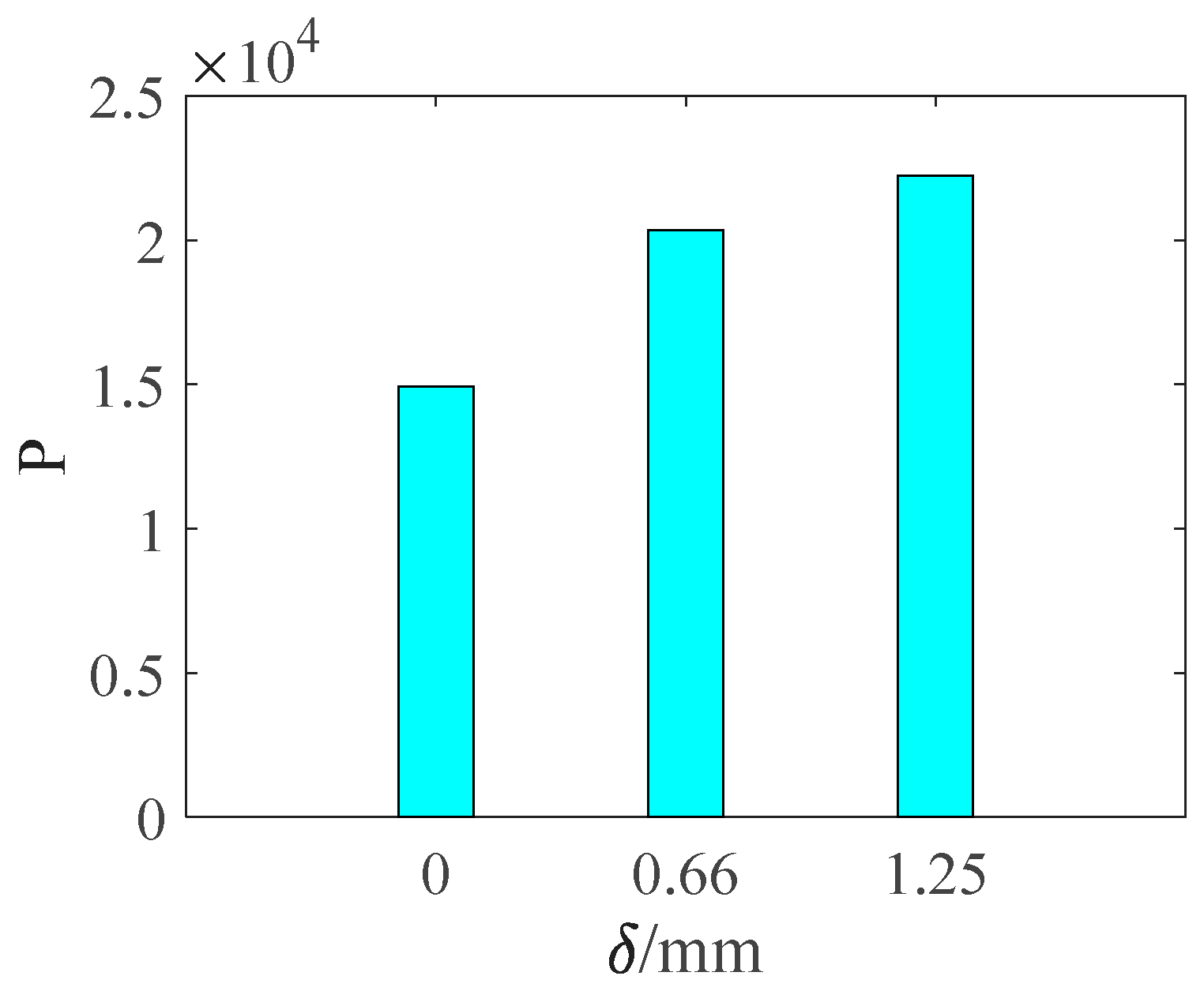

- The structure of cage grooves can significantly affect the lubricant distribution inside the bearing. The increase in the depth of cage grooves caused an increase in lubrication capacity in the bearing. With the increased depth of cage grooves, the oil volume in the bearing cavity keeps increasing, which is more favorable for the lubricant distribution in bearings. Therefore, the structural design of cage grooves has important significance for improving bearing lubrication.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, W.; Nelias, D.; Li, K.; Liu, Z.; Lyu, Y. A multiphase computational study of oil distribution inside roller bearings with under-race lubrication. Tribol. Int. 2019, 140, 105862. [Google Scholar] [CrossRef]

- Jiang, L.; Lyu, Y.; Gao, W.; Zhu, P.; Liu, Z. Numerical investigation of the oil–air distribution inside ball bearings with under-race lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 499–513. [Google Scholar] [CrossRef]

- Yunlong, W.; Wenzhong, W.; Yulong, L.; Ziqiang, Z. Lubrication and thermal failure mechanism analysis in high-speed angular contact ball bearing. J. Tribol. 2018, 140, 031503. [Google Scholar] [CrossRef]

- Russell, T.; Sadeghi, F. The Effects of Lubricant Starvation on Ball Bearing Cage Pocket Friction. Tribol. Int. 2022, 173, 107630. [Google Scholar] [CrossRef]

- Zhirkin, Y.V.; Puzik, E.; Sultanov, N. Design of heavy-duty bearings with oil–air lubrication. Russ. Eng. Res. 2016, 36, 1001–1003. [Google Scholar] [CrossRef]

- Ge, L.; Wang, C.; Yan, K.; Zhu, Y.; Hong, J. Design of groove structures for bearing lubrication enhancement based on the flow mechanism analysis. Tribol. Int. 2021, 158, 106950. [Google Scholar] [CrossRef]

- Wen, B.; Wang, M.; Zhang, X.; Zhai, J.; Sun, W. Experimental Investigation of Clearance Influences on Cage Motion and Wear in Ball Bearings. Appl. Sci. 2021, 11, 11848. [Google Scholar] [CrossRef]

- Damiens, B.; Lubrecht, A.; Cann, P. Influence of cage clearance on bearing lubrication©. Tribol. Trans. 2004, 47, 2–6. [Google Scholar] [CrossRef]

- Liu, J.; Ni, H.; Zhou, R.; Li, X.; Xing, Q.; Pan, G. A simulation analysis of ball bearing lubrication characteristics considering the cage clearance. J. Tribol. 2023, 145, 044301. [Google Scholar] [CrossRef]

- Oh, I.-S.; Kim, D.; Hong, S.-W.; Kim, K. Three-dimensional air flow patterns within a rotating ball bearing. Adv. Sci. Lett. 2013, 19, 2180–2183. [Google Scholar] [CrossRef]

- Yan, K.; Wang, Y.; Zhu, Y.; Hong, J.; Zhai, Q. Investigation on heat dissipation characteristic of ball bearing cage and inside cavity at ultra high rotation speed. Tribol. Int. 2016, 93, 470–481. [Google Scholar] [CrossRef]

- Yan, B.; Dong, L.; Yan, K.; Chen, F.; Zhu, Y.; Wang, D. Effects of oil-air lubrication methods on the internal fluid flow and heat dissipation of high-speed ball bearings. Mech. Syst. Signal Process. 2021, 151, 107409. [Google Scholar] [CrossRef]

- Liu, J.; Ni, H.; Xu, Z.; Pan, G. A simulation analysis for lubricating characteristics of an oil-jet lubricated ball bearing. Simul. Model. Pract. Theory 2021, 113, 102371. [Google Scholar] [CrossRef]

- Peterson, W.; Russell, T.; Sadeghi, F.; Berhan, M.T. Experimental and analytical investigation of fluid drag losses in rolling element bearings. Tribol. Int. 2021, 161, 107106. [Google Scholar] [CrossRef]

- Peterson, W.; Russell, T.; Sadeghi, F.; Berhan, M.T.; Stacke, L.-E.; Ståhl, J. A CFD investigation of lubricant flow in deep groove ball bearings. Tribol. Int. 2021, 154, 106735. [Google Scholar] [CrossRef]

- Wu, W.; Hu, C.; Hu, J.; Yuan, S. Jet cooling for rolling bearings: Flow visualization and temperature distribution. Appl. Therm. Eng. 2016, 105, 217–224. [Google Scholar] [CrossRef]

- Wu, W.; Hu, J.; Yuan, S.; Hu, C. Numerical and experimental investigation of the stratified air-oil flow inside ball bearings. Int. J. Heat Mass Transf. 2016, 103, 619–626. [Google Scholar] [CrossRef]

- Hu, J.; Wu, W.; Wu, M.; Yuan, S. Numerical investigation of the air–oil two-phase flow inside an oil-jet lubricated ball bearing. Int. J. Heat Mass Transf. 2014, 68, 85–93. [Google Scholar] [CrossRef]

- Ma, F.; Jiang, F.; Qi, A. Simulation of hydrodynamic lubrication between cage pockets and rollers in cylindrical roller bearings. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 2551–2560. [Google Scholar] [CrossRef]

- Wu, C.-H.; Kung, Y.-T. A parametric study on oil/air lubrication of a high-speed spindle. Precis. Eng. 2005, 29, 162–167. [Google Scholar] [CrossRef]

- Aidarinis, J.; Missirlis, D.; Yakinthos, K.; Goulas, A. CFD modeling and LDA measurements for the air-flow in an aero engine front bearing chamber. J. Eng. Gas Turbines Power 2011, 133, 082504. [Google Scholar] [CrossRef]

- Chen, H.; Liang, H.; Wang, W.; Zhang, S. Investigation on the oil transfer behaviors and the air-oil interfacial flow patterns in a ball bearing under different capillary conditions. Friction 2023, 11, 228–245. [Google Scholar] [CrossRef]

- Sánchez-González, R.; North, S.W. Nitric oxide laser-induced fluorescence imaging methods and their application to study high-speed flows. In Frontiers and Advances in Molecular Spectroscopy; Elsevier: Amsterdam, The Netherlands, 2018; pp. 599–630. [Google Scholar]

- Meinhart, C.D.; Wereley, S.T.; Santiago, J.G. PIV measurements of a microchannel flow. Exp. Fluids 1999, 27, 414–419. [Google Scholar] [CrossRef]

- Mastrone, M.N.; Hartono, E.A.; Chernoray, V.; Concli, F. Oil distribution and churning losses of gearboxes: Experimental and numerical analysis. Tribol. Int. 2020, 151, 106496. [Google Scholar] [CrossRef]

- Maccioni, L.; Chernoray, V.G.; Bohnert, C.; Concli, F. Particle Image Velocimetry measurements inside a tapered roller bearing with an outer ring made of sapphire: Design and operation of an innovative test rig. Tribol. Int. 2022, 165, 107313. [Google Scholar] [CrossRef]

- Maccioni, L.; Chernoray, V.G.; Mastrone, M.N.; Bohnert, C.; Concli, F. Study of the impact of aeration on the lubricant behavior in a tapered roller bearing: Innovative numerical modelling and validation via particle image velocimetry. Tribol. Int. 2022, 165, 107301. [Google Scholar] [CrossRef]

- Arya, U.; Peterson, W.; Sadeghi, F.; Meinel, A.; Grillenberger, H. Investigation of oil flow in a ball bearing using Bubble Image Velocimetry and CFD modeling. Tribol. Int. 2023, 177, 107968. [Google Scholar] [CrossRef]

- Chen, H.; Wang, W.; Liang, H.; Ge, X. Observation of the oil flow in a ball bearing with a novel experiment method and simulation. Tribol. Int. 2022, 174, 107731. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, Y.; Wang, W. Influence of the cage on the migration and distribution of lubricating oil inside a ball bearing. Friction 2022, 10, 1035–1045. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

| Item | Symbol | Unit | Value |

|---|---|---|---|

| Diameter of inner ring | d | mm | 65 |

| Diameter of outer ring | D | mm | 100 |

| Groove curvature coefficient of inner ring | 0.515 | ||

| Groove curvature coefficient of outer ring | 0.525 | ||

| Diameter of ball | Dw | mm | 11 |

| Number of balls | Z | No. | 18 |

| Contact angle | α | ° | 15 |

| Width of ring | B | mm | 18 |

| Cases | Oil Jet Nozzle Angles (°) | Height of the Injection Point (mm) | Operation Speed (r/min) | Test Results |

|---|---|---|---|---|

| Case 1 | 20 | 44.7 | 400 | Figure 6(a1–a3) |

| Case 2 | 30 | 44.7 | 400 | Figure 6(b1–b3) |

| Case 3 | 40 | 44.7 | 400 | Figure 6(c1–c3) |

| Case 4 | 50 | 44.7 | 400 | Figure 6(d1–d3) |

| Case 5 | 60 | 44.7 | 400 | Figure 6(e1–e3) |

| Cases | Oil Jet Nozzle Angles (°) | Height of the Injection Point (mm) | Operating Speed (r/min) | Test Results |

|---|---|---|---|---|

| Case 1 | 20 | 44.7 | 300 | Figure 8(a1–a3) |

| Case 2 | 20 | 44.7 | 600 | Figure 8(b1–b3) |

| Case 3 | 20 | 44.7 | 900 | Figure 8(c1–c3) |

| Case 4 | 20 | 44.7 | 1200 | Figure 8(d1–d3) |

| Cases | Radius and Depth of Groove (mm) | Oil Jet Nozzle Angles (°) | Height of the Injection Point (mm) | Operating Speed (r/min) | Test Results |

|---|---|---|---|---|---|

| Case 1 | 0, 0 | 0 | 37.2 | 1000 | Figure 12(a1–a3) |

| Case 2 | 4.5, 0.66 | 0 | 37.2 | 1000 | Figure 12(b1–b3) |

| Case 3 | 4.5, 1.25 | 0 | 37.2 | 1000 | Figure 12(c1–c3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, B.; Li, Y.; Wang, M.; Yang, Y. Measurement for Lubricant Distribution in an Angular Contact Ball Bearing and Its Influence Investigation. Lubricants 2023, 11, 63. https://doi.org/10.3390/lubricants11020063

Wen B, Li Y, Wang M, Yang Y. Measurement for Lubricant Distribution in an Angular Contact Ball Bearing and Its Influence Investigation. Lubricants. 2023; 11(2):63. https://doi.org/10.3390/lubricants11020063

Chicago/Turabian StyleWen, Baogang, Yemin Li, Meiling Wang, and Yang Yang. 2023. "Measurement for Lubricant Distribution in an Angular Contact Ball Bearing and Its Influence Investigation" Lubricants 11, no. 2: 63. https://doi.org/10.3390/lubricants11020063

APA StyleWen, B., Li, Y., Wang, M., & Yang, Y. (2023). Measurement for Lubricant Distribution in an Angular Contact Ball Bearing and Its Influence Investigation. Lubricants, 11(2), 63. https://doi.org/10.3390/lubricants11020063