Susceptibility of Environmentally Friendly Sheep Wool Insulation Panels to the Common Clothes Moth Tineola bisselliella in Laboratory Assays

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Insecticidal Preparations

2.2. Resistance Bioassays

2.3. Concentration-Response Bioassays

2.4. Statistical Analyses

3. Results

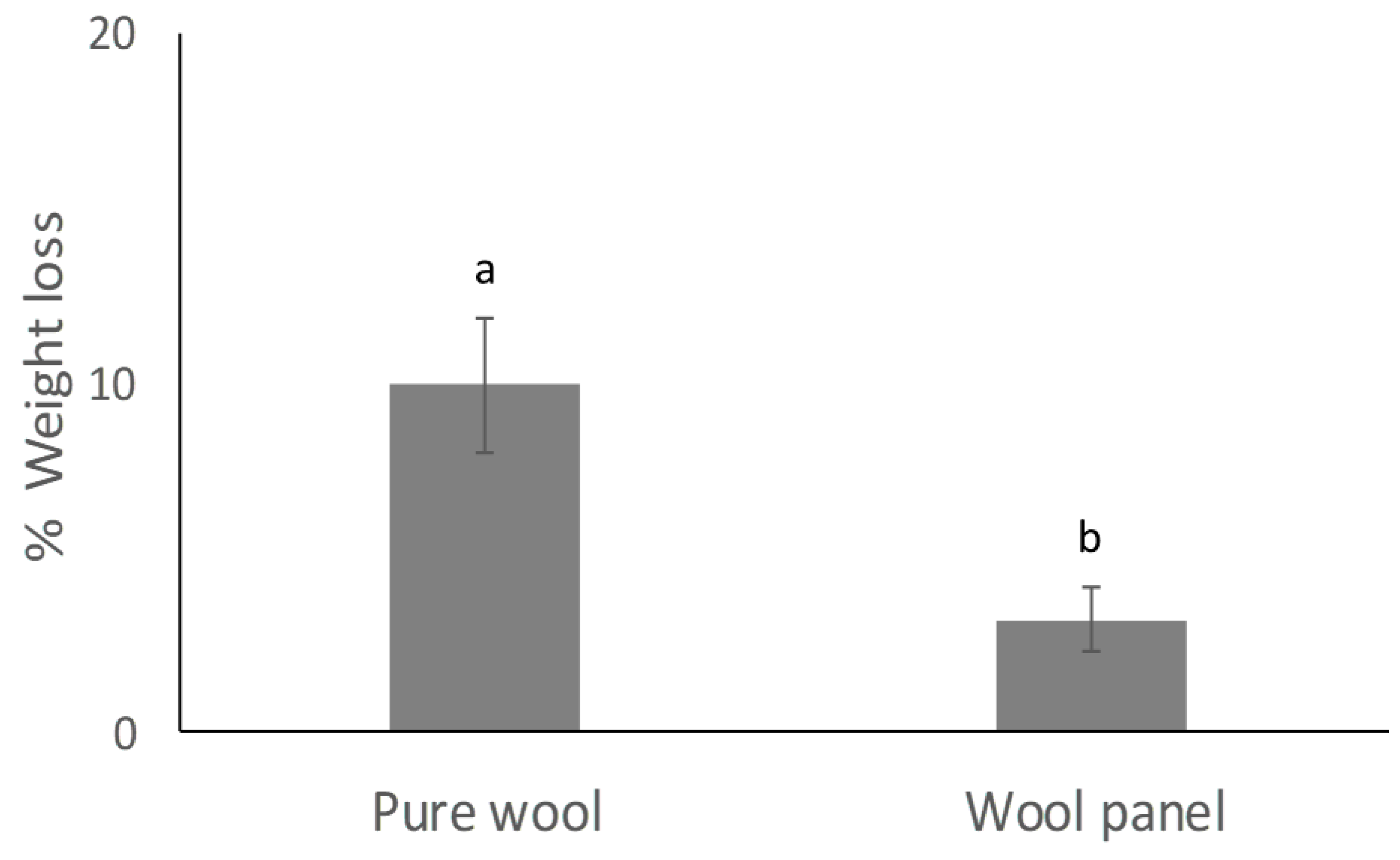

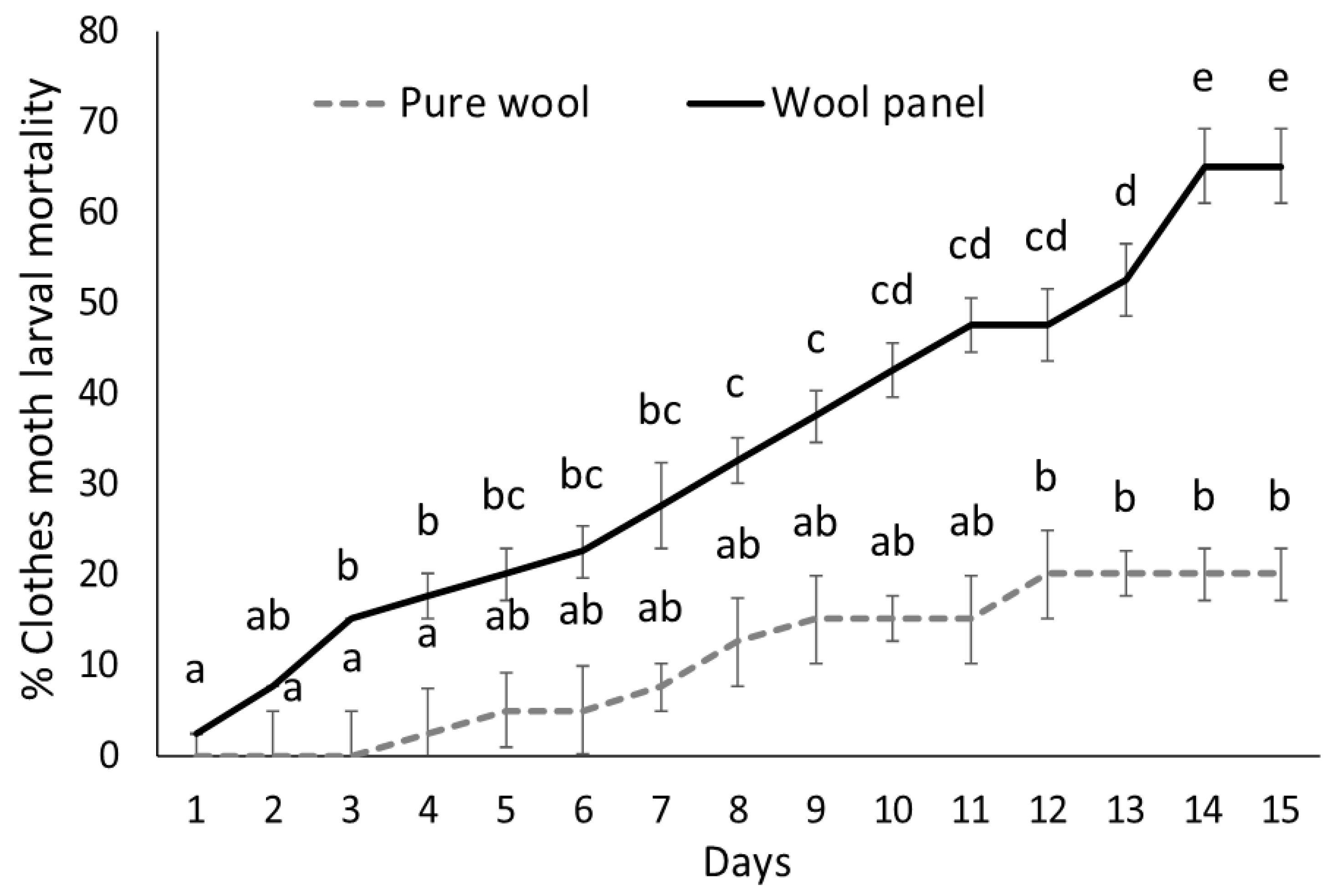

3.1. Resistance Bioassays

3.2. Concentration-Response Bioassays

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sust. Energ. Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Pennacchio, R.; Savio, L.; Bosia, D.; Thiebat, F.; Piccablotto, G.; Patrucco, A.; Fantucci, S. Fitness: Sheep-wool and Hemp Sustainable Insulation Panels. Energy Procedia 2017, 111, 287–297. [Google Scholar] [CrossRef]

- Ward, C.W. Resolution of proteases in the keratinolytic larvae of the webbing clothes moth. Aust. J. Biol. Sci. 1975, 28, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Cox, P.D.; Pinniger, D.B. Biology, behaviour and environmentally sustainable control of Tineola bisselliella (Hummel) (Lepidoptera: Tineidae). J. Stored Prod. Res. 2007, 43, 2–32. [Google Scholar] [CrossRef]

- Pinniger, D.B.; Harmon, J.D. Pest management, prevention and control. In Care and Conservation of Natural History Collections; Carter, D., Walker, A.K., Eds.; Butterworth Heinemann: Oxford, UK, 1999; pp. 152–176. [Google Scholar]

- Trematerra, P.; Fontana, F. Monitoring of webbing clothes moth, Tineola bisselliella, by sex pheromone. Anzeiger für Schädlingskunde Pflanzenschutz Umweltschutz 1996, 69, 119–121. [Google Scholar] [CrossRef]

- Zimmermann, O.; Scholler, M.; Prozell, S. Investigations on the biological control of Tineola bisselliella with Trichogramma species (Hymenoptera: Trichogrammatidae). In Proceedings of the Eighth International Working Conference on Stored Product Protection, York, UK, 22–26 July 2002; Credland, P.F., Armitage, D.M., Bell, C.H., Cogan, P.M., Highley, E., Eds.; CAB International: Wallingford, UK, 2003; pp. 319–321. [Google Scholar]

- Brokerhof, A.W.; Jonathan Banks, H.; Morton, R. A model for time-temperature-mortality relationships for eggs of the webbing clothes moth, Tineola bisselliella (Lepidoptera: Tineidae), exposed to cold. J. Stored Prod. Res. 1992, 28, 269–277. [Google Scholar] [CrossRef]

- Bernard, C.E.; Harrass, M.C.; Manning, M.J. Boric Acid and Inorganic Borate Pesticides. In Hayes’ Handbook of Pesticide Toxicology; Krieger, R.I., Krieger, W.C., Eds.; Academic Press: Riverside, CA, USA, 2010; pp. 2033–2053. [Google Scholar]

- Farfán-García, E.D.; Castillo-Mendieta, N.T.; Ciprés-Flores, F.J.; Padilla-Martínez, I.I.; Trujillo-Ferrara, J.G.; Soriano-Ursúa, M.A. Current data regarding the structure-toxicity relationship of boron-containing compounds. Toxicol. Lett. 2018, 258, 115–125. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization (ISO). Textiles—Determination of Resistance to Certain Insect Pests; SO Standard No. 3998; International Organization for Standardization (ISO): Geneve, Switzerland, 1977; Available online: https://www.iso.org/obp/ui/#iso:std:iso:3998:en (accessed on 24 January 2019).

- SAS Institute. SAS/STAT 9.1: User’s Guide; SAS Publishers: Hojai, India, 2004. [Google Scholar]

- Braulio-Gonzalo, M.; Bovea, M.D. Environmental and cost performance of building’s envelope insulation materials to reduce energy demand: Thickness optimisation. Energy Build. 2019, 150, 527–545. [Google Scholar] [CrossRef]

- Vasile, V.; Petcu, C.; Meitą, V.; Zaharia, M.C. Innovative Thermal Insulation Products for a Circular Economy. IOP Conf. Ser. Earth. Environ. Sci. 2019, 290, 012037. [Google Scholar] [CrossRef]

- Trematerra, P.; Pinniger, D. Museum Pests—Cultural Heritage Pests. In Recent Advances in Stored Product Protection; Athanassiou, G.C., Arthur, F.H., Eds.; Springer: Berlin, Germany, 2018; pp. 229–260. [Google Scholar]

- Moretti, E.; Belloni, E.; Agosti, F. Innovative mineral fiber insulation panels for buildings: Thermal and acoustic characterization. Appl. Energy 2016, 169, 421–432. [Google Scholar] [CrossRef]

- See, A.S.; Salleh, A.B.; Bakar, F.A.; Yusof, N.A.; Abdulamir, A.S.; Heng, L.Y. Risk and health effect of boric acid. Am. J. Appl. Sci. 2010, 7, 620–627. [Google Scholar] [CrossRef]

- Larkin, G.M.; Merrick, P.; Gnatowski, M.J.; Laks, P.E. In-process protection of wood composites: An industry perspective. ACS Symp. Ser. Am. Chem. Soc. 2008, 982, 458–469. [Google Scholar]

- Lloyd, J.D. Borates and Their Biological Applications. In International Research Group on Wood Preservation; IRG/WP 98-30178; IRG Secretariat: Stockholm, Sweden, 1998. [Google Scholar]

- Lloyd, J.D.; Dickinson, D.J.; Murphy, R.J. The Probable Mechanisms of Action of Boric Acid and Borates as Wood Preservatives. In International Research Group on Wood Preservation; IRG/WP/1450—IRG; Secretariat: Stockholm, Sweden, 1990. [Google Scholar]

- Tokoro, M.; Su, N. Wood protection by surface treatment of two borate preservatives, TIMBOR and BORA-CARE, for the formosan subterranean termite and eastern subterrean termite. In International Research Group on Wood Preservation; IRG/WP 93-10044; IRG Secretariat: Stockholm, Sweden, 1993. [Google Scholar]

- Gentz, M.C.; Grace, J.K. A Review of Boron Toxicity in Insects with an Emphasis on Termites. J. Agric. Urban Entomol. 2006, 23, 201–207. [Google Scholar]

- Salman, S.; Pétrissans, A.; Thévenon, M.F.; Dumarçay, S.; Perrin, D.; Pollier, B.; Gérardin, P. Development of new wood treatments combining boron impregnation and thermo modification: Effect of additives on boron leachability. Eur. J. Wood Wood Prod. 2014, 72, 355–365. [Google Scholar] [CrossRef]

- Butterwick, L.; Oude, N.; Raymond, K. Safety assessment of boron in aquatic and terrestrial environments. Ecotox. Environ. Safe. 1989, 17, 339–371. [Google Scholar] [CrossRef]

- Schoderboeck, L.; Mühlegger, S.; Losert, A.; Gausterer, C.; Hornek, R. Effects assessment: Boron compounds in the aquatic environment. Chemosphere 2011, 82, 483–487. [Google Scholar] [CrossRef] [PubMed]

- Dubey, N.K.; Srivastava, B.; Kumar, A. Current Status of Plant Products as Botanical Pesticides instorage pest management. J. Biopest. 2018, 1, 182–186. [Google Scholar]

- Bouchikhi Tani, Z.; Khelil, M.A.; Hassani, F. Fight against the bruche bean Acanthoscelides obtectus (coleoptera: Bruchidae) and the mite Tineola bisselliella (lepidoptera, tineidae) by the essential oils extracted from Rosmarinus officinalis. Biosci. Biotechnol. Res. Asia 2008, 5, 651–656. [Google Scholar]

- Vega, F.E.; Kaya, H.K. Insect Pathology, 2nd ed.; Elsevier: London, UK, 2012; p. 504. [Google Scholar]

- Rai, M.; Ingle, A. Role of nanotechnology in agriculture with special reference to management of insect pests. Appl. Microbiol. Biotechnol. 2012, 94, 287–293. [Google Scholar] [CrossRef]

- Sunderland, M.R.; McNeil, S.J. Protecting wool carpets from beetle and moth larvae with nanocidal titanium dioxide desiccant. Clean Technol. Environ. 2017, 19, 1205–1213. [Google Scholar] [CrossRef]

| Grade | Superficial Attack | Grade | Deep Attack |

|---|---|---|---|

| 1 | no attack | A | no holes |

| 2 | slight attack | B | partially damaged fibers |

| 3 | moderate attack | C | small and sparse holes |

| 4 | strong attack | D | large and deep holes |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiu, L.; Floris, I. Susceptibility of Environmentally Friendly Sheep Wool Insulation Panels to the Common Clothes Moth Tineola bisselliella in Laboratory Assays. Insects 2019, 10, 379. https://doi.org/10.3390/insects10110379

Ruiu L, Floris I. Susceptibility of Environmentally Friendly Sheep Wool Insulation Panels to the Common Clothes Moth Tineola bisselliella in Laboratory Assays. Insects. 2019; 10(11):379. https://doi.org/10.3390/insects10110379

Chicago/Turabian StyleRuiu, Luca, and Ignazio Floris. 2019. "Susceptibility of Environmentally Friendly Sheep Wool Insulation Panels to the Common Clothes Moth Tineola bisselliella in Laboratory Assays" Insects 10, no. 11: 379. https://doi.org/10.3390/insects10110379

APA StyleRuiu, L., & Floris, I. (2019). Susceptibility of Environmentally Friendly Sheep Wool Insulation Panels to the Common Clothes Moth Tineola bisselliella in Laboratory Assays. Insects, 10(11), 379. https://doi.org/10.3390/insects10110379