Study of Microstructure and Properties of Aluminum/Steel Inertia Radial Friction Welding

Abstract

:1. Introduction

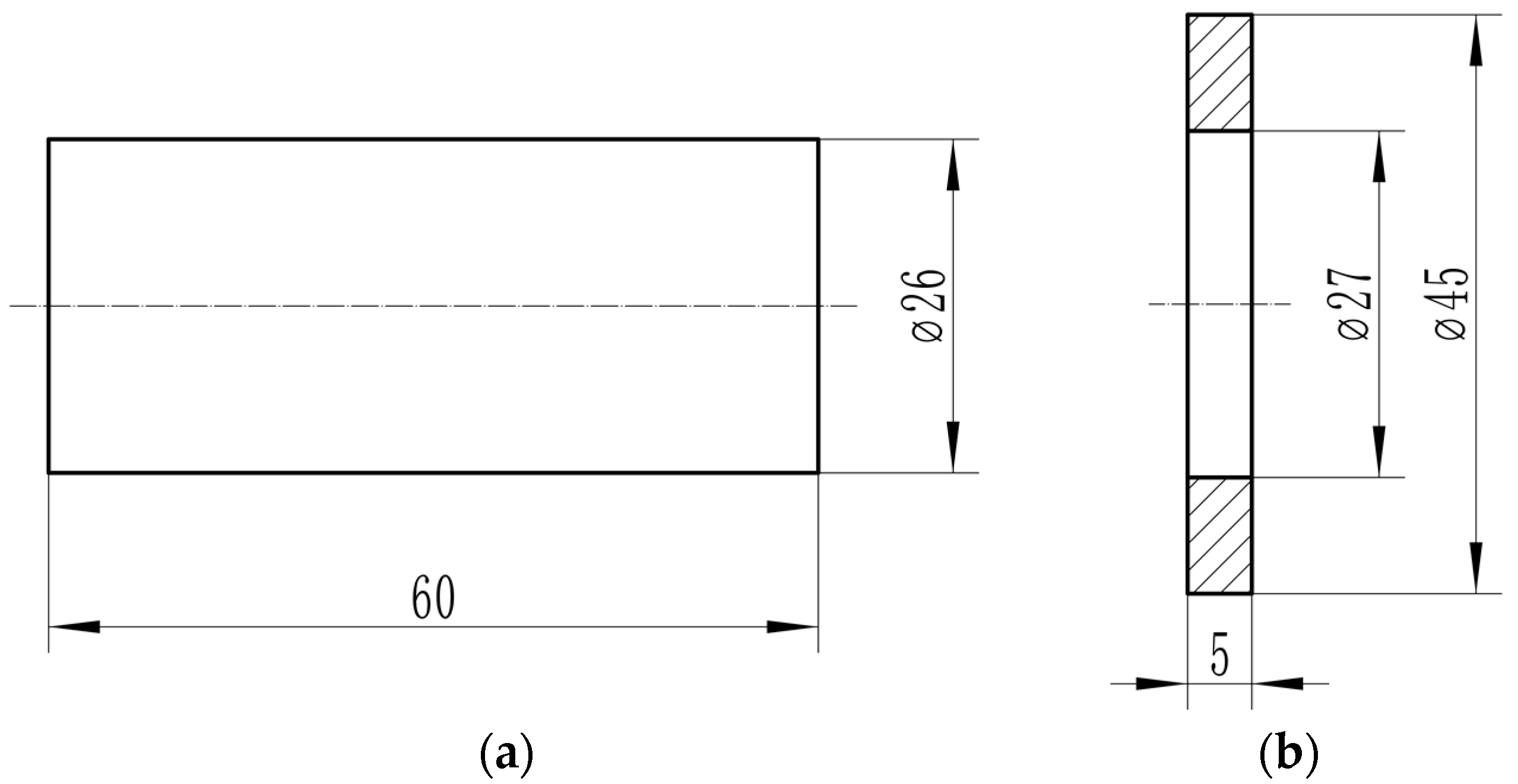

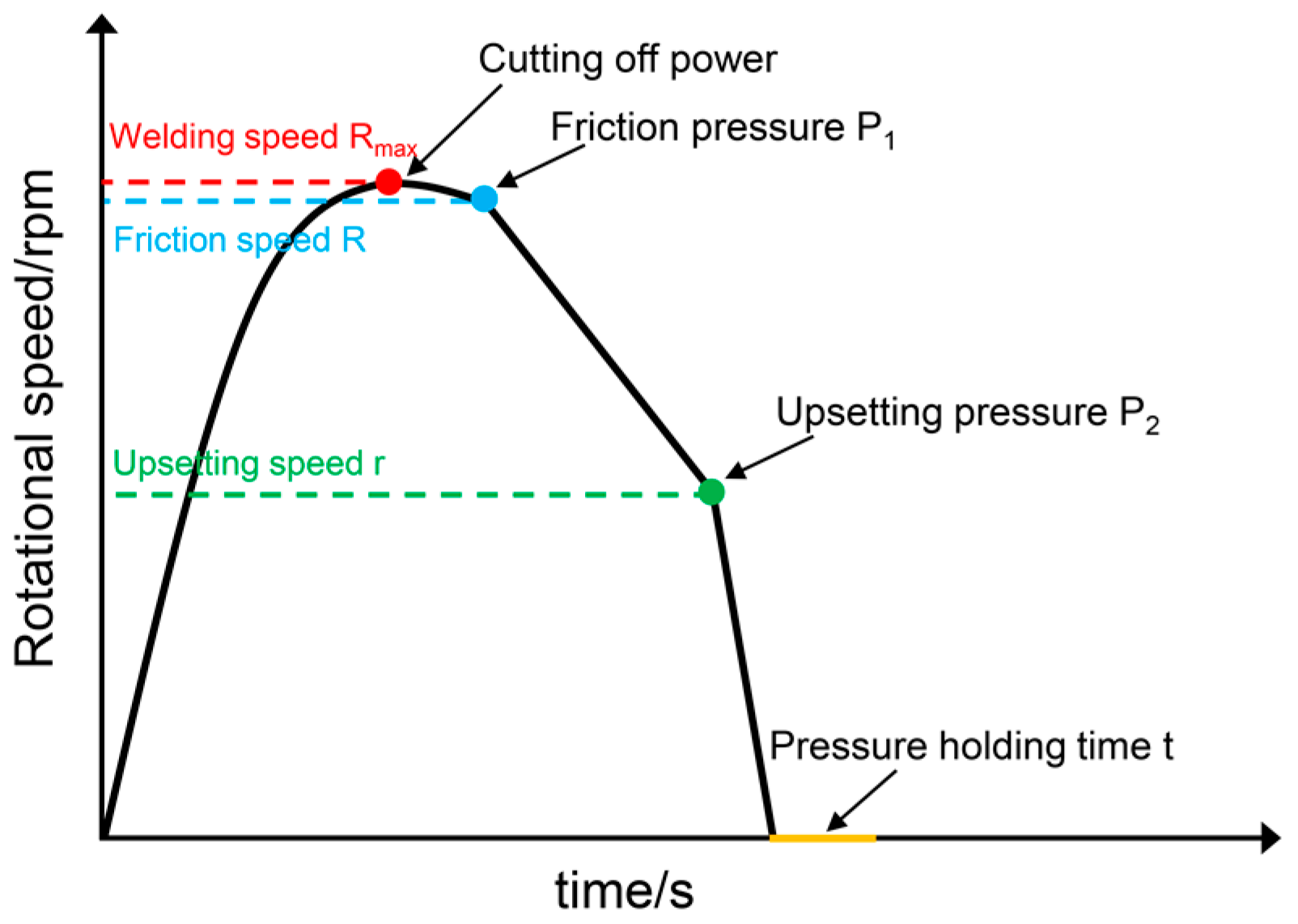

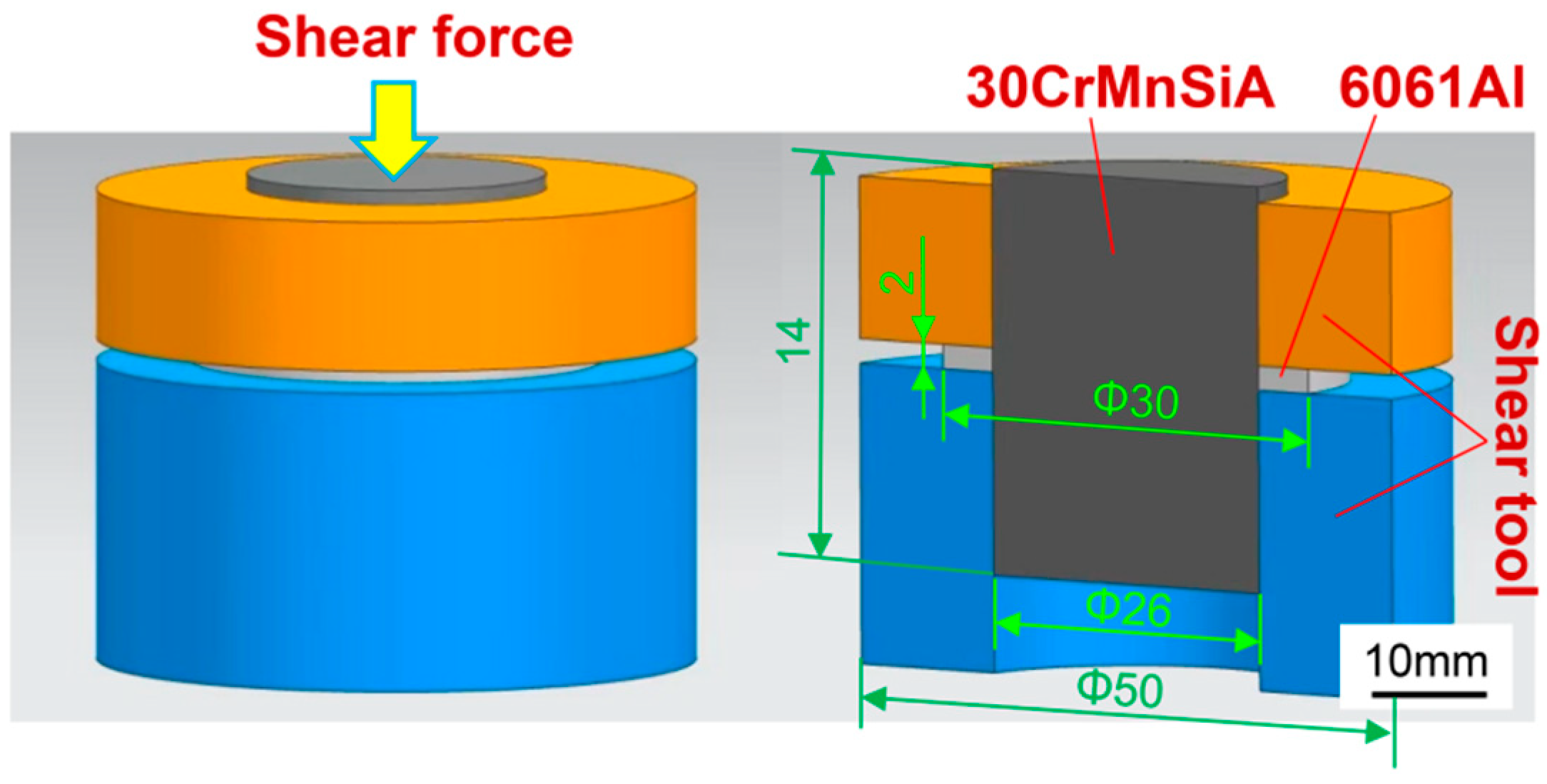

2. Materials and Methods

3. Results

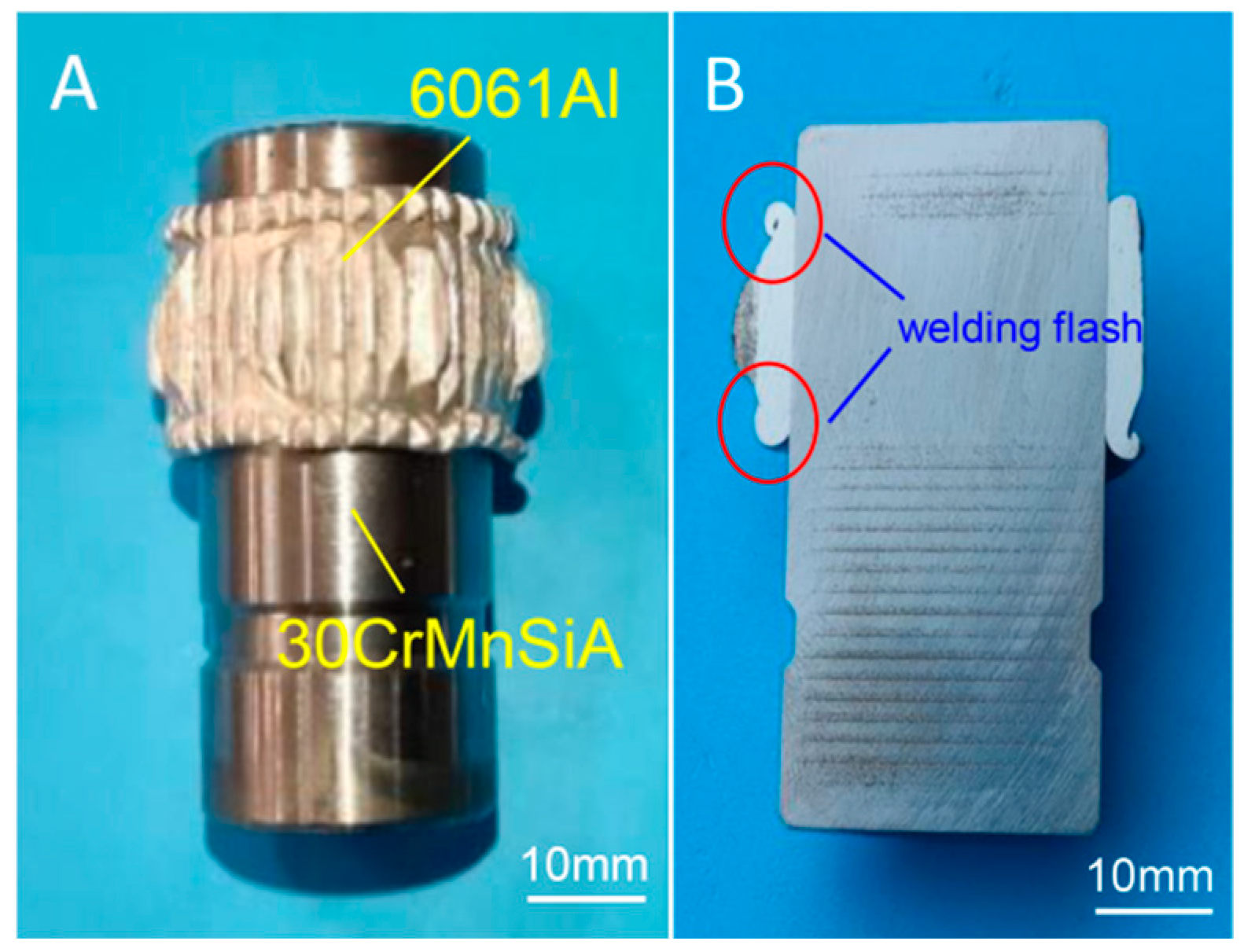

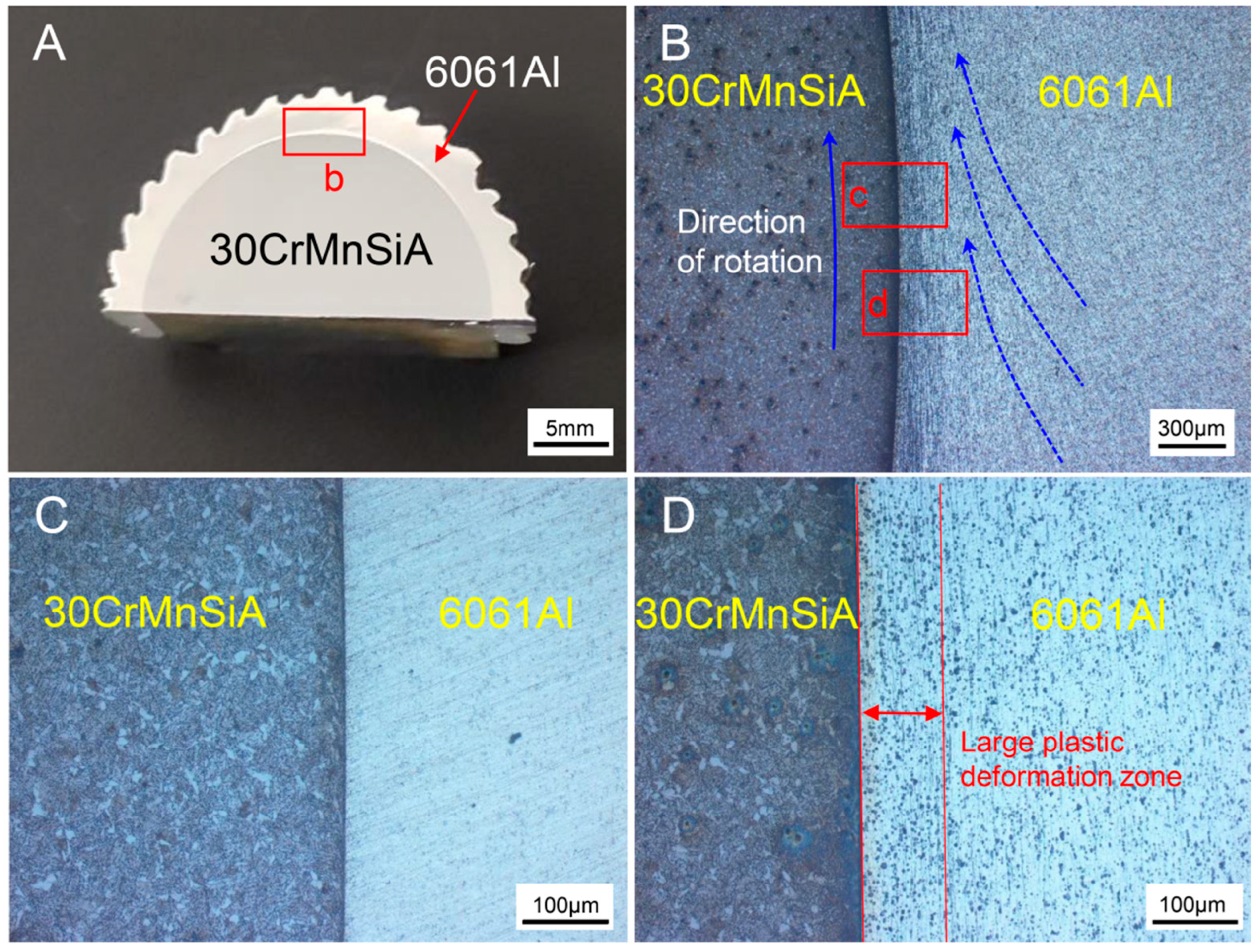

3.1. Macromorphology

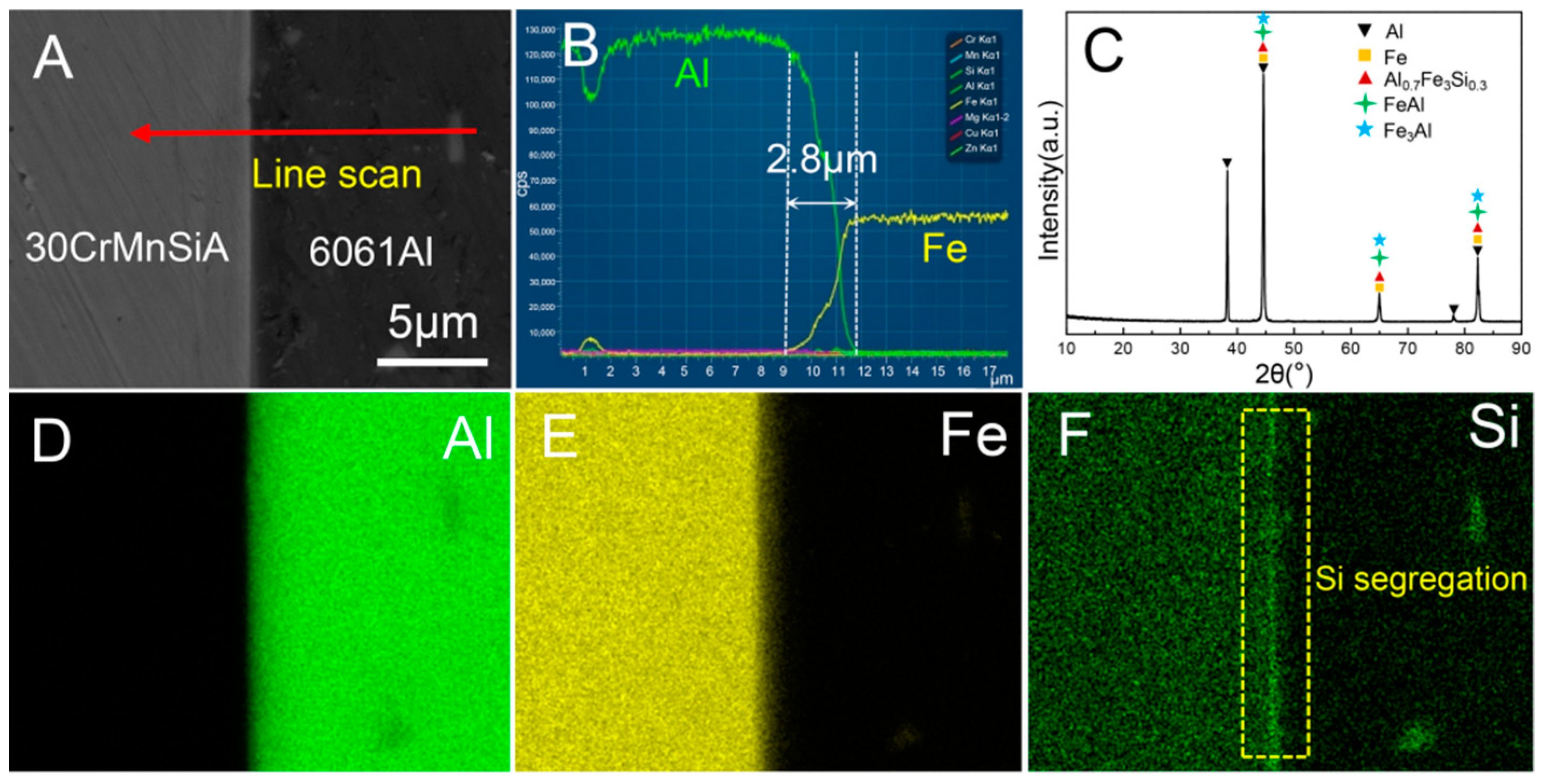

3.2. Microstructure

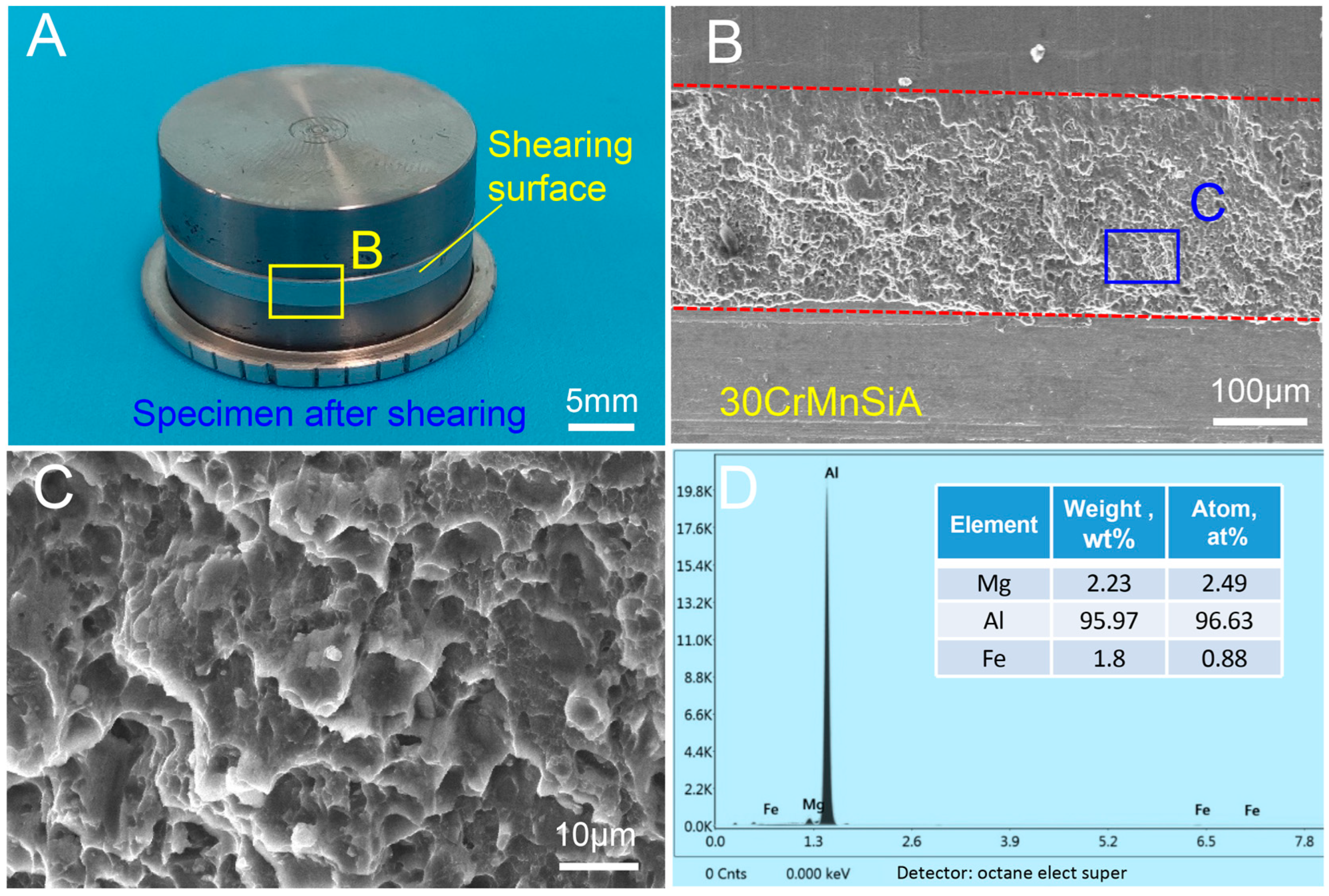

3.3. Shear Strength

- σmax—maximum shear strength

- σmin—minimum shear strength

3.4. Fracture Morphology

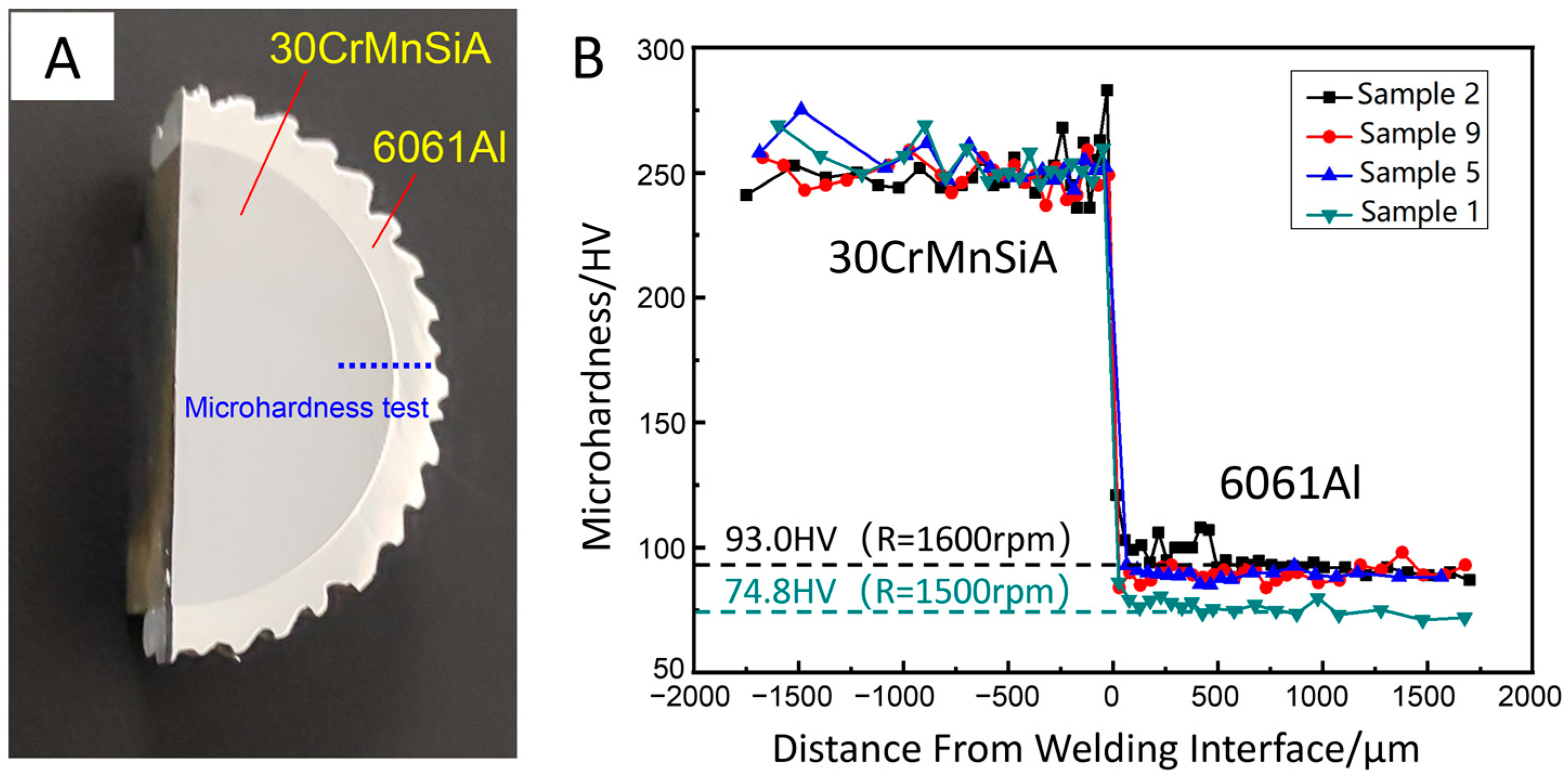

3.5. Microhardness

4. Discussion

5. Conclusions

- (1)

- In this work, the optimal welding parameters of 6061-T6 aluminum alloy/30CrMnSiA steel IRFW are for sample 5: friction speed R = 1600 rpm, friction pressure P1 = 2.5 MPa, and upsetting pressure P2 = 7 MPa. The average shear strength of the joint reaches a maximum of 176 MPa, which is 87.1% of the shear strength of the 6061-T6 aluminum alloy base metal, and the shear fraction is a typical ductile fracture; Aluminum/steel joints have good adhesion, and can be used in the surface modification of steel structures, and aluminum/steel rotary lightweight structures, etc.

- (2)

- When friction speed, friction pressure and upsetting pressure are single variables, the average shear strength fluctuation coefficients of the aluminum/steel joints are 16.9%, 9.3%, and 13.9%, respectively. Compared to friction pressure and upsetting pressure, the friction speed affects aluminum/steel joint mechanical properties more significantly, and an appropriate reduction in friction speed is beneficial to improve the aluminum/steel joint bonding strength.

- (3)

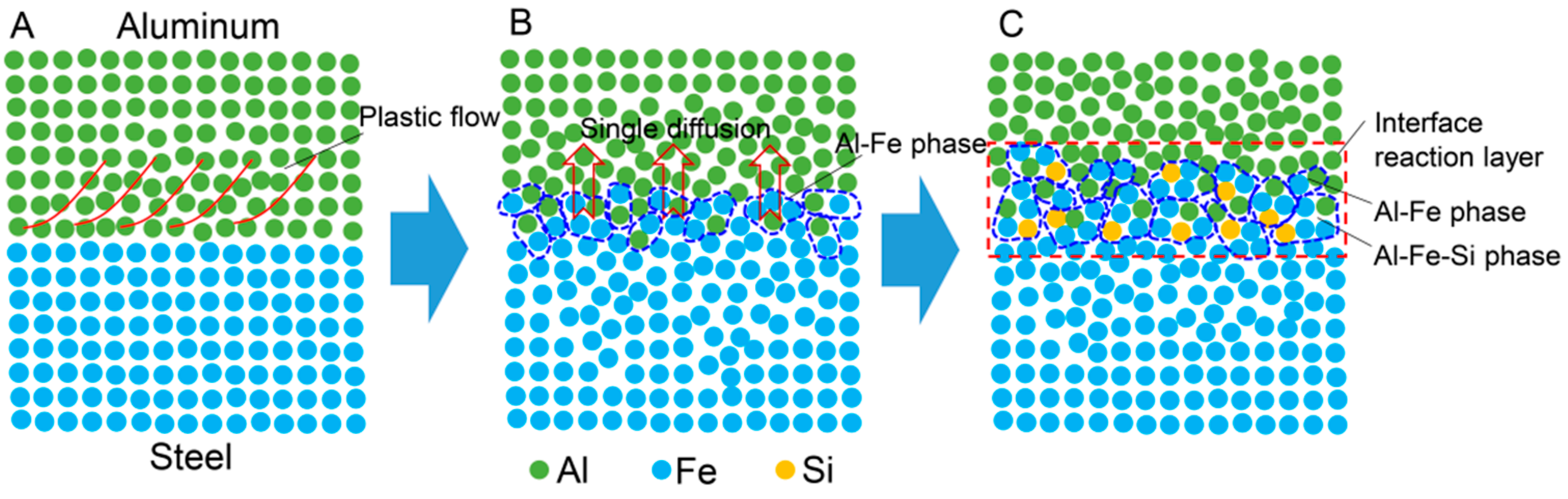

- Si element aggregates at the aluminum/steel interface and exists in the form of Al−Fe−Si phase, which may inhibit the formation and growth of a Al−Fe IMCs. Finally, a micron ultrathin interface reaction layer, composed of Al0.7Fe3Si0.3, FeAl, and Fe3Al phases, is formed at the aluminum/steel welding interface.

- (4)

- In this study, the size and phase structure of the IMCs layer in aluminum/steel joints have not been accurately measured, and the next step is to carry out relevant research to further clarify the mechanism of Si element in the formation and growth of Al−Fe intermetallic compounds, which is of great significance to optimize the phase structure of joints and improve joint performance. In addition, the feasibility of IRFW of other dissimilar metals, such as aluminum/titanium and aluminum/copper, shall be verified through experiments, which will lay a theoretical foundation for the development and application of IRFW technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.K.; He, J.; Yu, X.Q.; Li, C.L.; Fan, D. The study of mechanical strength for fusion-brazed butt joint between aluminum alloy and galvanized steel by arc-assisted laser welding. J. Manuf. Process. 2017, 25, 126–133. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Zhang, J.; Lu, W.; Taub, A.; Sun, K. Alloy amorphization through nanoscale shear localization at Al−Fe interface. Mater. Today Phys. 2020, 15, 100252. [Google Scholar] [CrossRef]

- Zhu, R.C.; Zhao, Y.H.; Wang, H.; Qin, G.L.; Liu, S.G.; Zhang, L.D. Research status of rotary friction welding of aluminum/steel dissimilar metals. Weld Joi. 2020, 12, 1–10. [Google Scholar] [CrossRef]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Ma, H.; Qin, G.L.; Geng, P.H.; Li, F.; Fu, B.L.; Meng, X.M. Microstructure characterization and properties of carbon steel to stainless steel dissimilar metal joint made by friction welding. Mater. Des. 2015, 86, 587–597. [Google Scholar] [CrossRef]

- Qin, G.L.; Ma, H.; Geng, P.H.; Zhou, J.; Qi, X.B. Continuous-drive friction welding of 45 steel to 304 stainless steel. Trans. Chin. Weld Inst. 2015, 36, 1–4. [Google Scholar]

- Ma, H.; Qin, G.L.; Geng, P.H.; Wang, S.L.; Zhang, D. Microstructural characterisation and corrosion behaviour of aluminium alloy/steel hybrid structure produced by friction welding. J. Manuf. Process. 2021, 61, 349–356. [Google Scholar] [CrossRef]

- Qin, G.L.; Ma, H.; Wang, S.L.; Zhao, Y.H.; Zhu, R.C. Microstructure and properties of friction welded joint of aluminum alloy to alloy steel. Trans. Chin. Weld Inst. 2021, 7, 1–8. [Google Scholar]

- Kimura, M.; Kusaka, M.; Kaizu, K.; Nakata, K.; Nagatsuka, K. Friction welding technique and joint properties of thin-walled pipe friction-welded joint between type 6063 aluminum alloy and AISI 304 austenitic stainless steel. Int. J. Adv. Manuf. Tech. 2016, 82, 489–499. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.X. Friction welding of AA6061 to AISI 316L steel: Characteristic analysis and novel design equipment. Int. J. Adv. Manuf. Tech. 2018, 95, 4117–4128. [Google Scholar] [CrossRef]

- Fukumoto, S.; Tsubakino, H.; Okita, K.; Aritoshi, M.; Tomita, T. Friction welding process of 5052 aluminium alloy to 304 stainless steel. Mater. Sci. Tech-Lond. 1999, 15, 1080–1086. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Wang, S.W.; Luo, D.C.; Shi, W.C.; Liu, X.; Cui, G.S.; Chen, B.Y.; Xin, Z.; Rui, Z.Y. Influence of Process Parameters on Structure of Aluminum/Steel Rotary Friction Welding Joints. Nonferr. Met. Eng. 2022, 2, 8–13. [Google Scholar]

- Love, G.; Shewmon, P.G. Self-diffusivity of silver in twist boundaries. Acta Metall. 1963, 11, 899–906. [Google Scholar] [CrossRef]

- Nagarkar, M.D.; Carpenter, S.H. An investigation of atomic diffusion at the interface of explosion welded Cu-Ni couples. Mat. Sci. Eng. 1975, 20, 251–260. [Google Scholar] [CrossRef]

- Palanivel, S.; Arora, A.; Doherty, K.J.; Mishra, R.S. A framework for shear driven dissolution of thermally stable particles during friction stir welding and processing. Mater. Sci. Eng. A 2016, 678, 308–314. [Google Scholar] [CrossRef]

- Dong, H.G.; Hu, W.J.; Duan, Y.P.; Wang, X.D.; Dong, C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J. Mater. Process. Tech. 2012, 212, 458–464. [Google Scholar] [CrossRef]

- Yin, F.C.; Zhao, M.X.; Liu, Y.X.; Han, W.; Li, Z. Effect of Si on growth kinetics of intermetallic compounds during reaction between solid iron and molten aluminum. Trans. Nonferr. Met. Soc. 2013, 23, 556–561. [Google Scholar] [CrossRef]

- Yokoyama, T.; Ogawa, K. Impact tensile properties of 6061 aluminium alloy to SUS 304 stainless steel friction-welded butt joints. Weld Int. 2003, 17, 514–523. [Google Scholar] [CrossRef]

- Du, S.G.; Fu, L.; Liu, X.W. Fea coupled with thermo-mechanical effect on friction welding. Chin. J. Mech. Eng. 2002, 38, 77–82. [Google Scholar] [CrossRef]

- Yılmaz, M.; Çöl, M.; Acet, M. Interface properties of aluminum/steel friction-welded components. Mater. Charact. 2002, 49, 421–429. [Google Scholar] [CrossRef]

- Watanabe, M.; Feng, K.; Nakamura, Y.; Kumai, S. Growth Manner of Intermetallic Compound Layer Produced at Welding Interface of Friction Stir Spot Welded Aluminum/Steel Lap Joint. Mater. Trans. 2011, 52, 953–959. [Google Scholar] [CrossRef] [Green Version]

- Pérez, F.J.; Hierro, M.P.; Trilleros, J.A.; Carpintero, M.C.; Sánchez, L.; Bolívar, F.J. Aluminum and aluminum/silicon coatings on ferritic steels by CVD-FBR technology. Mater. Chem. Phys. 2006, 97, 50–58. [Google Scholar] [CrossRef]

- Mehrer, H.; Stolica, N.; Stolwijk, N.A. Diffusion in solid metals and alloys figures for 2. Phys. Metall. 1990, 15, 535–668. [Google Scholar]

- Kimura, M.; Suzuki, K.; Kusaka, M.; Kaizu, K. Effect of friction welding condition on joining phenomena and mechanical properties of friction welded joint between 6063 aluminium alloy and AISI 304 stainless steel. J. Manuf. Process. 2017, 26, 178–187. [Google Scholar] [CrossRef]

| Base Metal | Chemical Composition (wt.%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Al | C | Mn | Si | Cr | Ni | Cu | Mg | Zn | Ti | |

| 30CrMnSiA | Bal | — | 0.28~0.35 | 0.80~1.10 | 0.90~1.20 | 0.80~1.10 | ≤0.40 | — | — | — | — |

| 6061-T6 | 0.70 | Bal | — | 0.15 | 0.40~0.8 | 0.04~0.35 | — | 0.15~0.40 | 0.8~1.2 | 0.25 | 0.15 |

| Number | Friction Speed R (rpm) | Friction Pressure P1 (MPa) | Upsetting Pressure P2 (MPa) |

|---|---|---|---|

| 1 | 1500 | 2 | 7 |

| 2 | 1600 | 2 | 7 |

| 3 | 1700 | 2 | 7 |

| 4 | 1600 | 1.5 | 7 |

| 5 | 1600 | 2.5 | 7 |

| 6 | 1600 | 3 | 7 |

| 7 | 1600 | 2 | 3 |

| 8 | 1600 | 2 | 5 |

| 9 | 1600 | 2 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Liu, Z.; Chen, D.; Mo, F.; Fu, Y.; Dai, Y.; Wu, X.; Cong, D. Study of Microstructure and Properties of Aluminum/Steel Inertia Radial Friction Welding. Metals 2022, 12, 2023. https://doi.org/10.3390/met12122023

Li Z, Liu Z, Chen D, Mo F, Fu Y, Dai Y, Wu X, Cong D. Study of Microstructure and Properties of Aluminum/Steel Inertia Radial Friction Welding. Metals. 2022; 12(12):2023. https://doi.org/10.3390/met12122023

Chicago/Turabian StyleLi, Zhongsheng, Zhengtao Liu, Dajun Chen, Fei Mo, Yangfan Fu, Ye Dai, Xia Wu, and Dalong Cong. 2022. "Study of Microstructure and Properties of Aluminum/Steel Inertia Radial Friction Welding" Metals 12, no. 12: 2023. https://doi.org/10.3390/met12122023

APA StyleLi, Z., Liu, Z., Chen, D., Mo, F., Fu, Y., Dai, Y., Wu, X., & Cong, D. (2022). Study of Microstructure and Properties of Aluminum/Steel Inertia Radial Friction Welding. Metals, 12(12), 2023. https://doi.org/10.3390/met12122023