On the Measurability and Predictability of HAZ Softening in GMAW of Automotive DP980 Steel

Abstract

:1. Introduction

2. Materials and Experimental Details

2.1. Materials

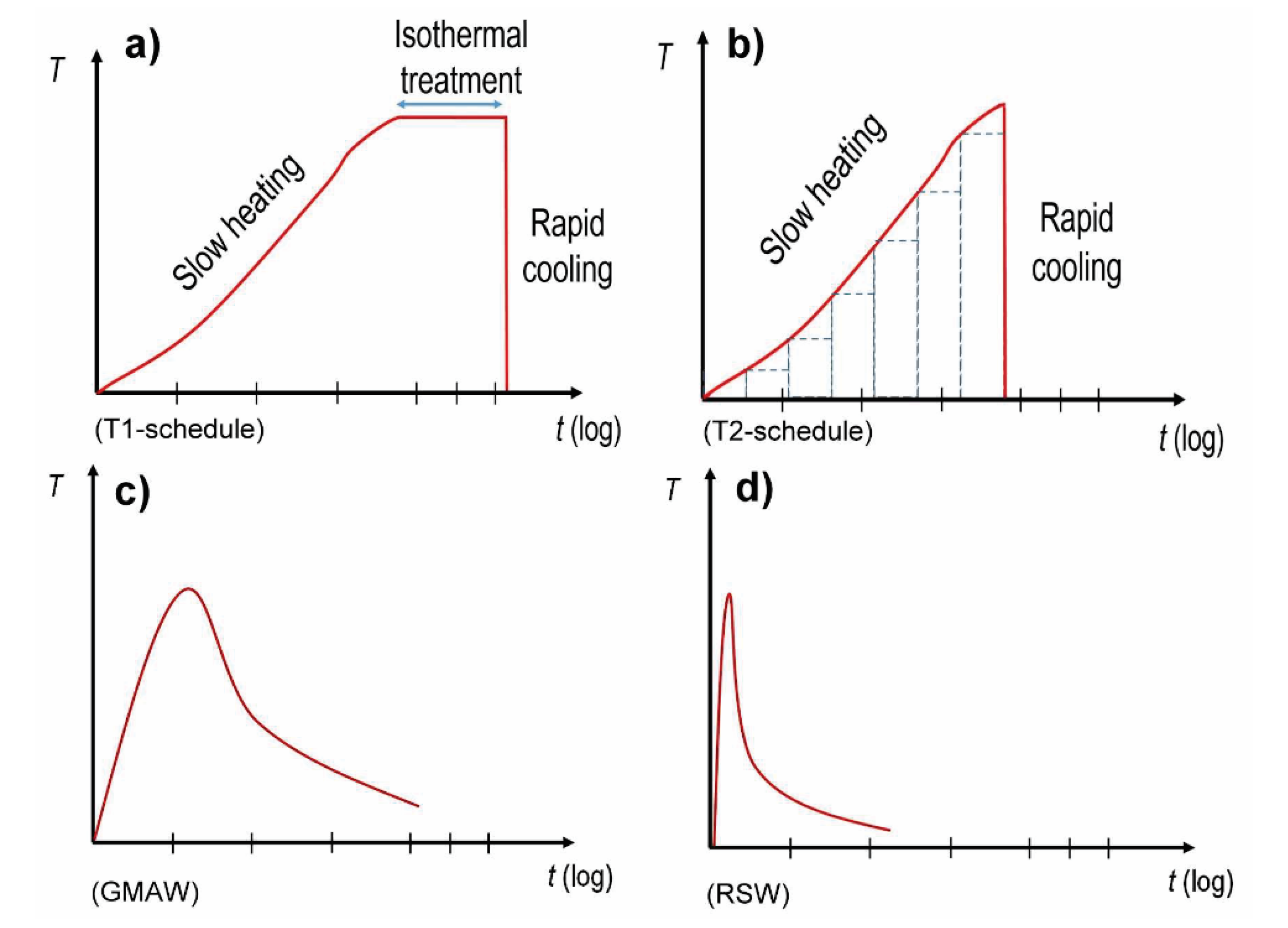

2.2. Tempering Treatments

2.3. Welding Procedure

2.4. Microstructure Characterization

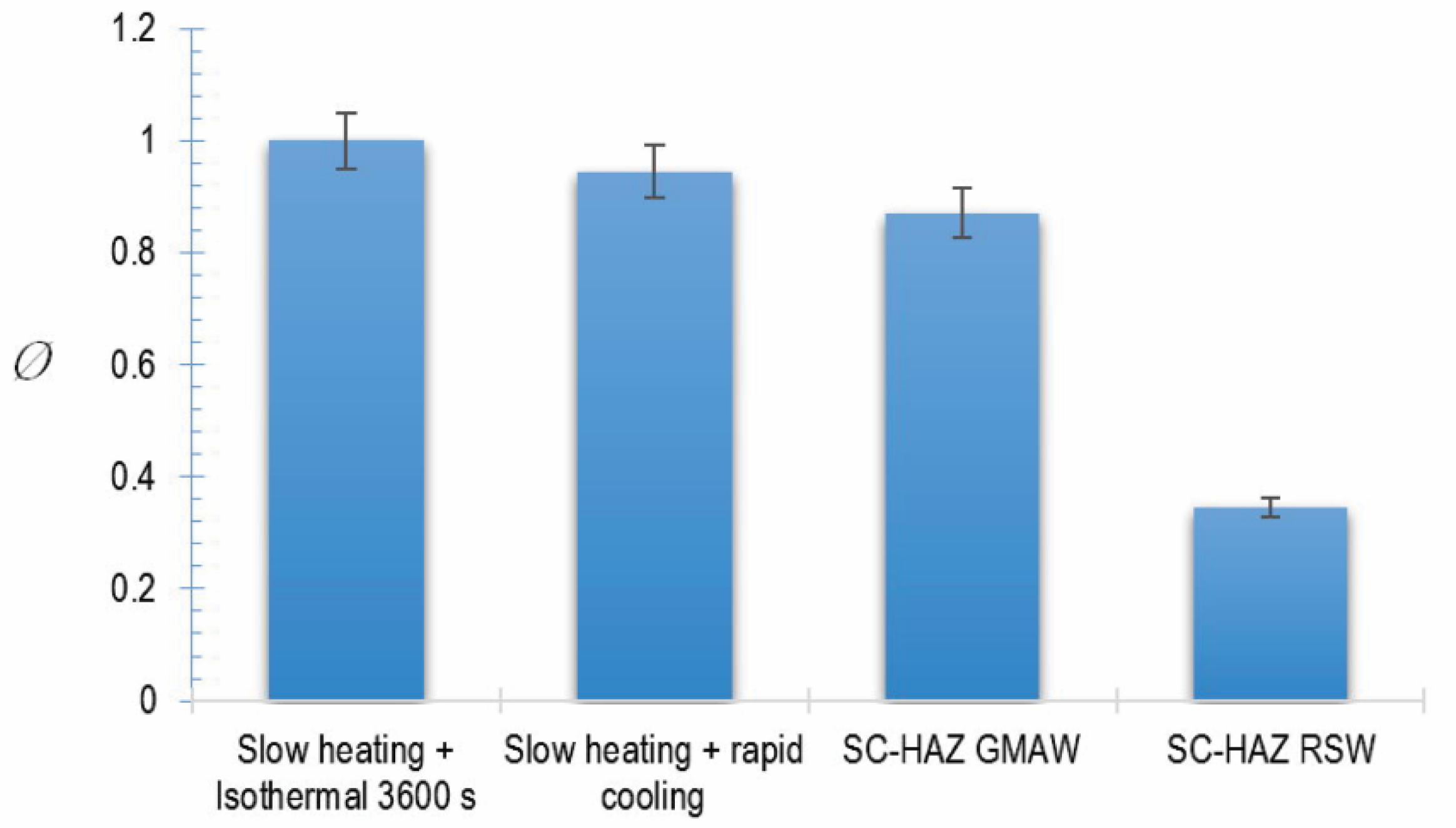

2.5. Softening Analysis Method

3. Results and Discussion

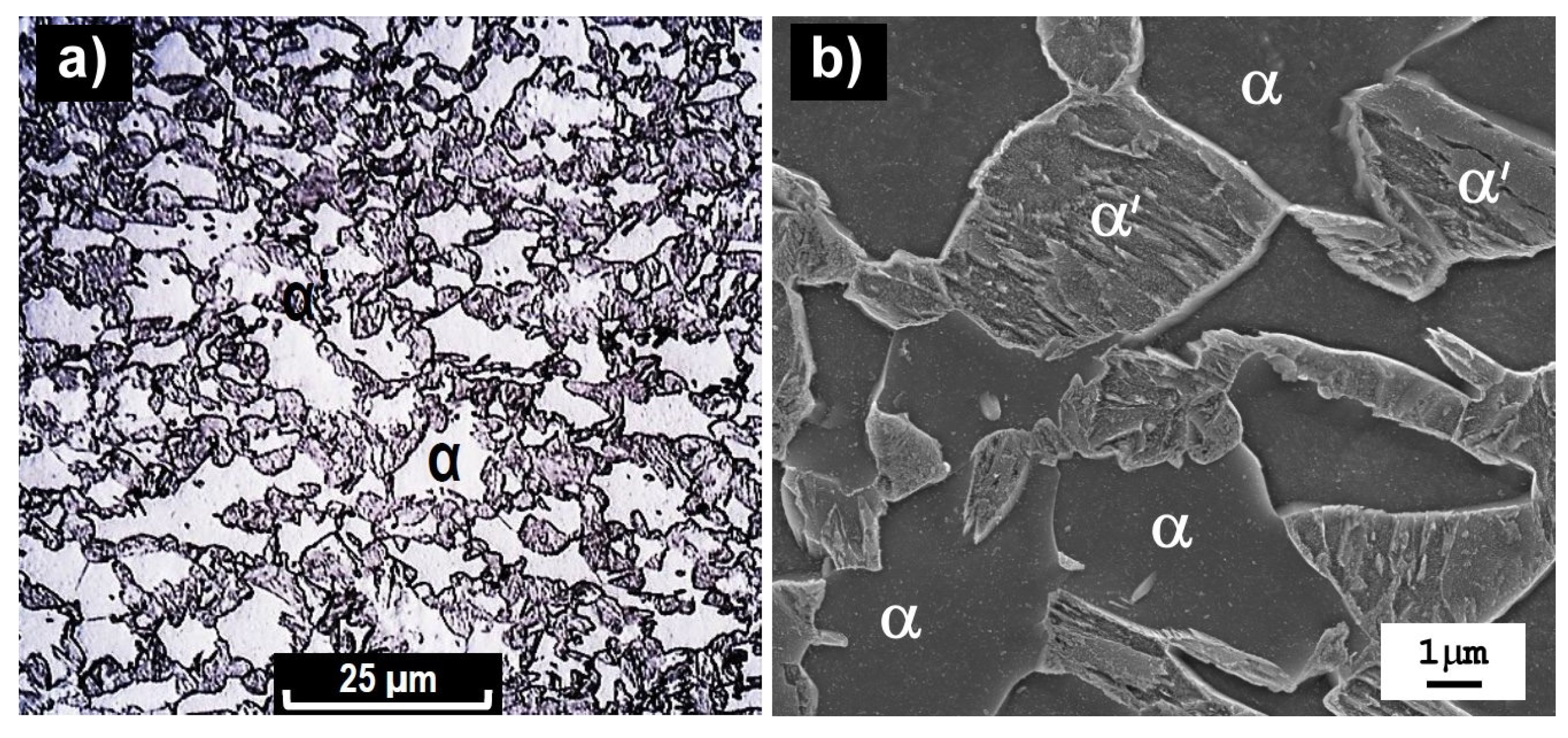

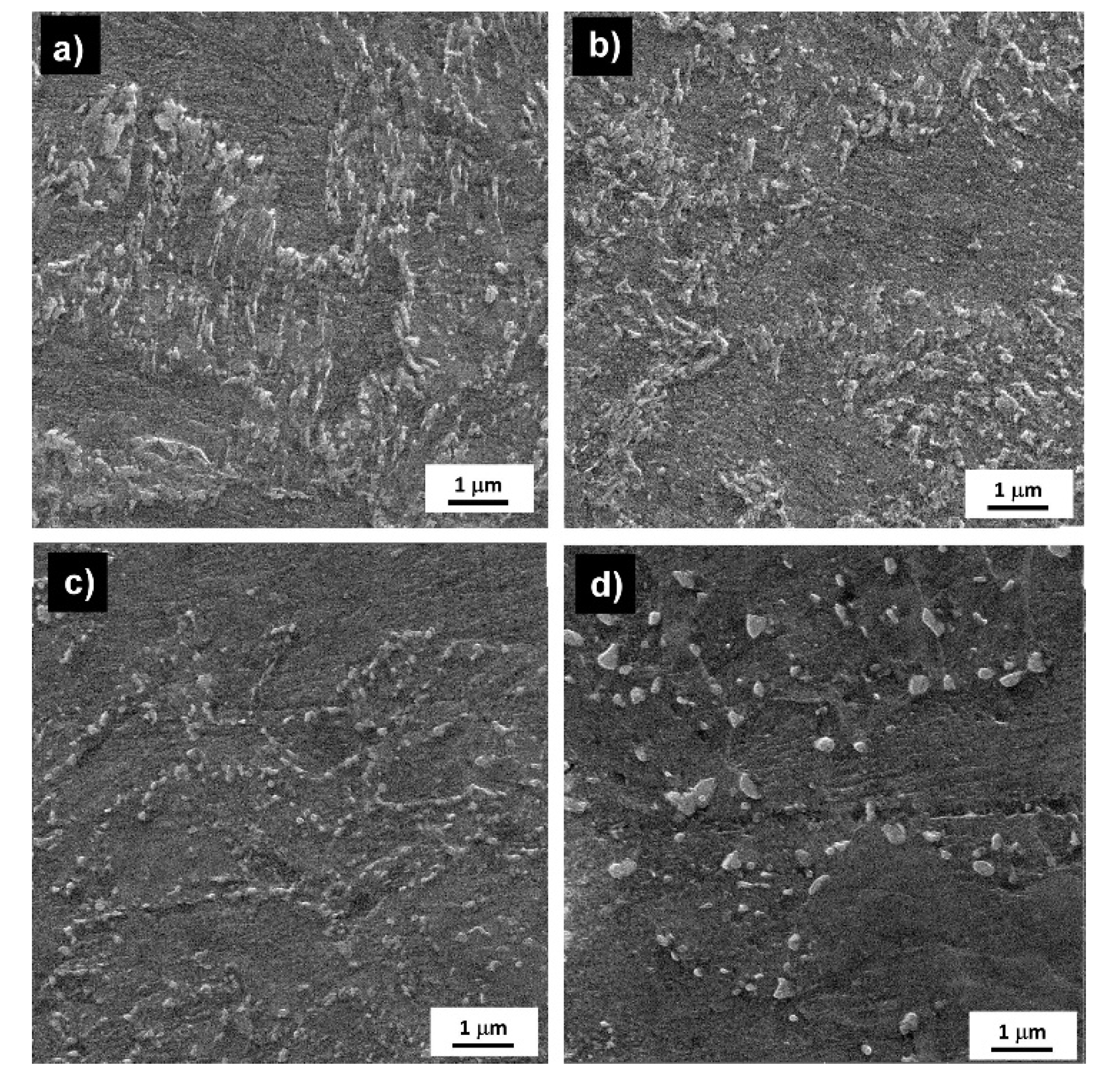

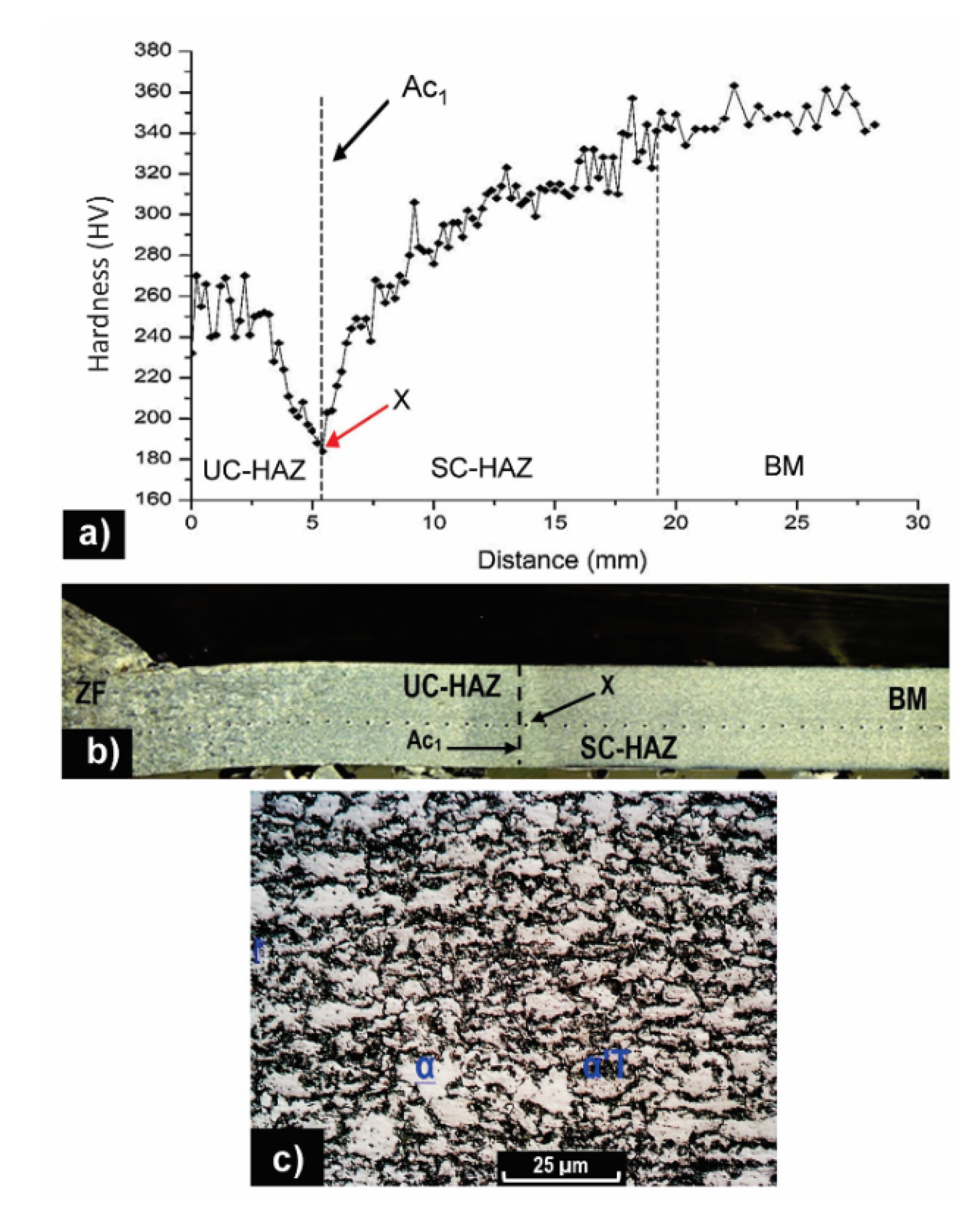

3.1. Microstructure and Hardness

3.2. HAZ-Softening Prediction in GMAW of DP980 Steel

4. Conclusions

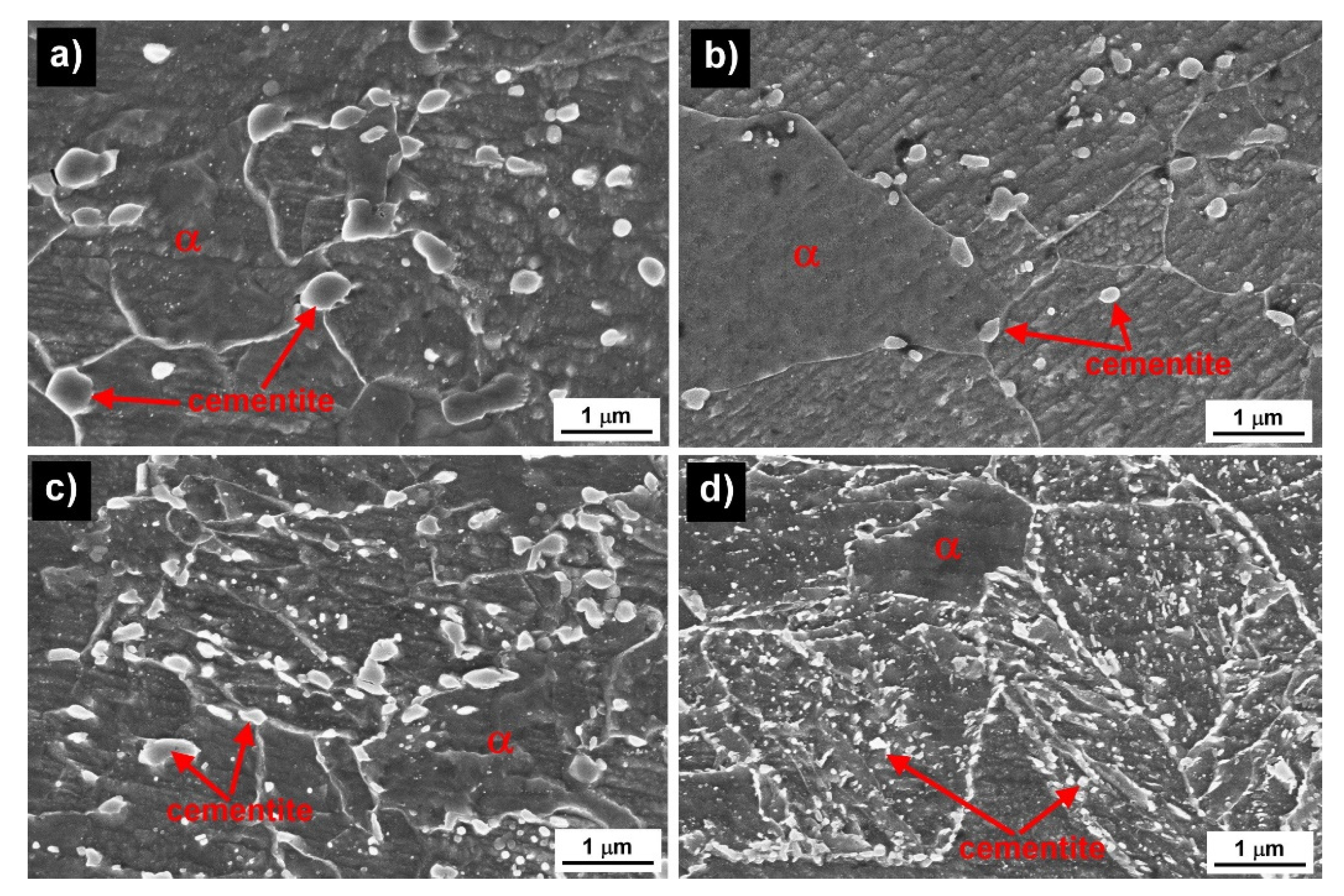

- Tempered martensite islands in the SC-HAZ of GMAW DP980 steel containing coarse cementite carbides of approximately 147 ± 23 nm in diameter resulted in large softening with a drop in hardness of 157 HV, and the advanced stage of carbide growth is the result of the high heat input from the arc welding process. On the contrary, the average carbide size at the SC-HAZ of DP980 upon RSW resulted in 62 ± 11 nm with a drop in hardness of 60 HV, clearly influenced by the rapid thermal cycle.

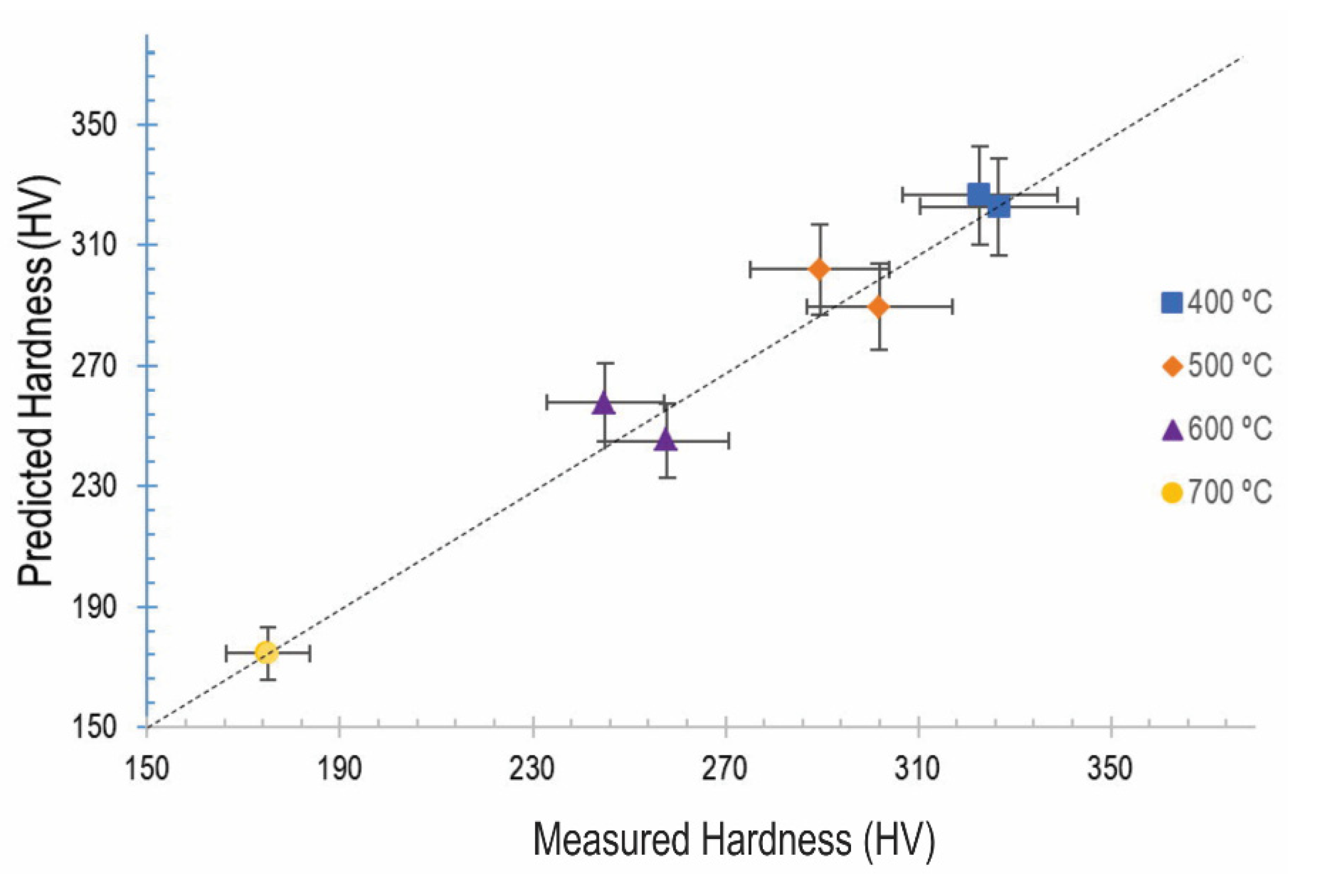

- The rate of softening was quantified by measuring the progression between furnace heat treatment with and without an isothermal hold at various temperatures. The predicted hardness was in good agreement with the measured hardness, in the range 400~700 °C.

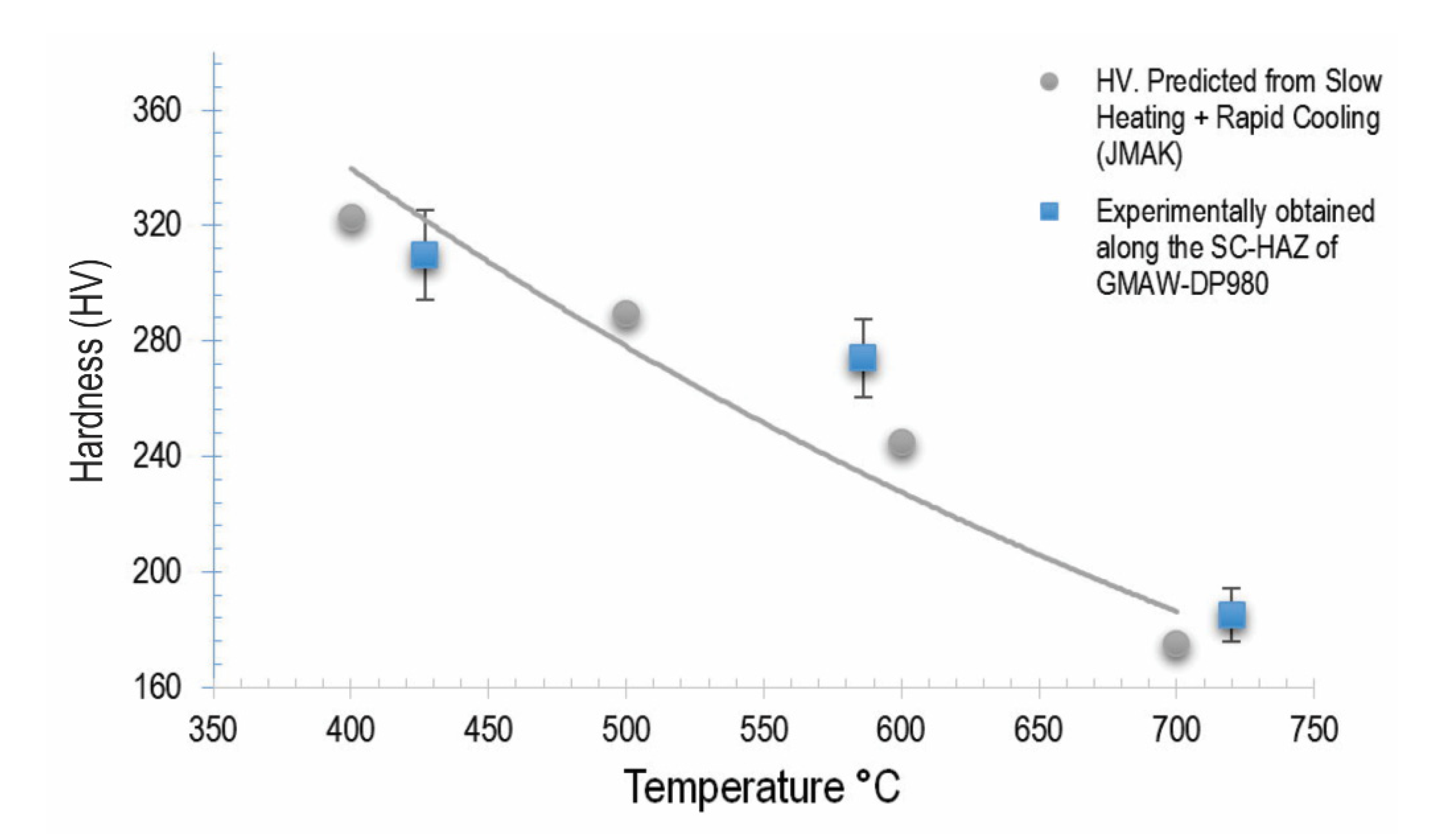

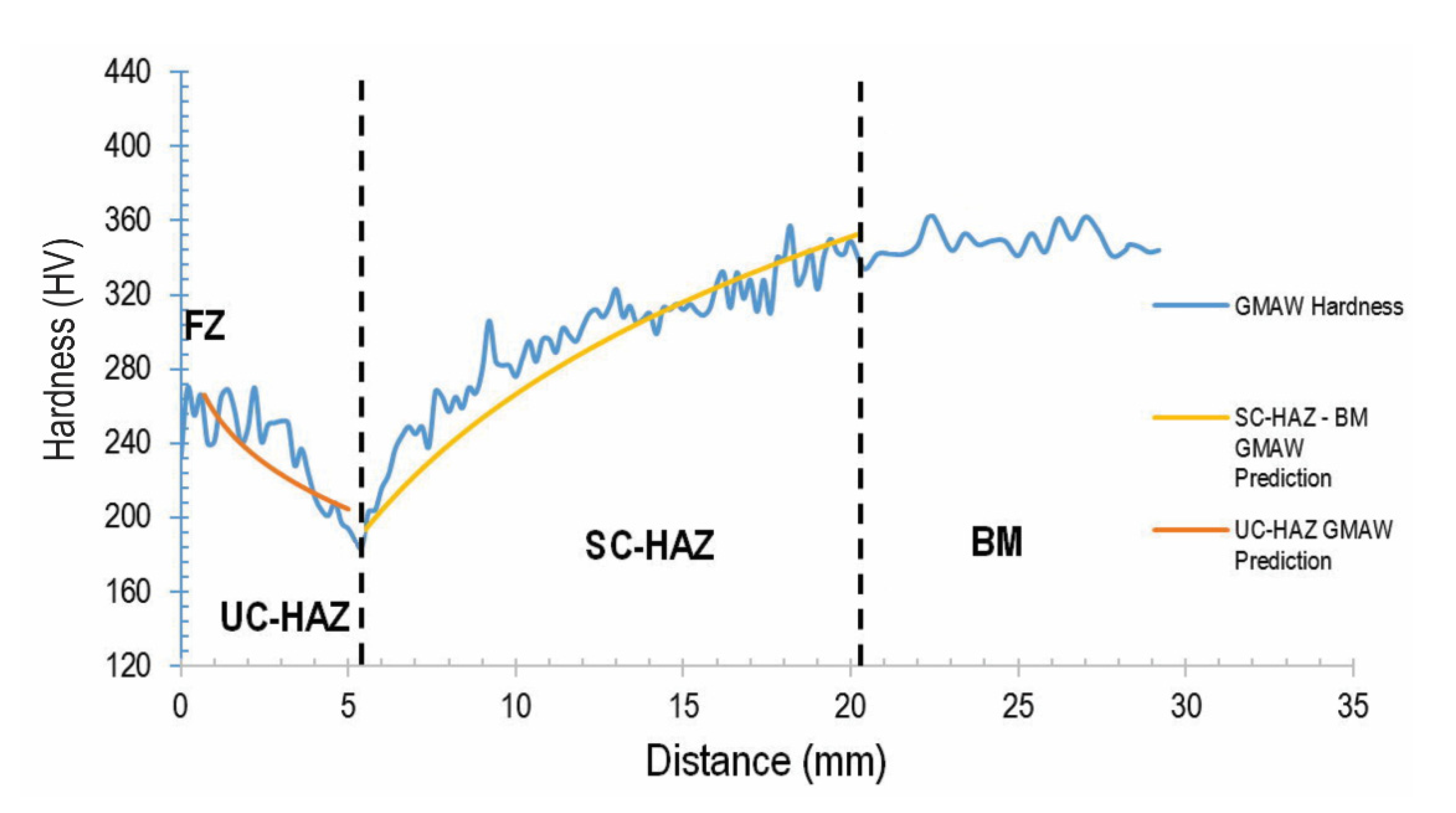

- By using an equivalent isothermal temperature approach, softening kinetic data from furnace heat treatments were used to estimate the hardness profile in gas metal arc welding, thus resulting in reasonable correspondence.

- The JAMK equation and Yurioka´s model were successfully used to predict the hardness profile along the heat-affected zone (both sub-critical and upper critical zones) of the gas metal arc welding of DP980 steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keeler, S. Advanced High-Strength Steels Application Guidelines. Availabe online: https://www.worldautosteel.org/projects/advanced-high-strength-steel-application-guidelines/ (accessed on 17 May 2022).

- Ghosh, P.; Gupta, P.; Avtar, R.; Jha, B. Weldability of intercritical annealed dual-phase steel with the resistance spot welding process. Weld. J. 1991, 70, 7. [Google Scholar]

- Marya, M.; Wang, K.; Hector, L.; Gayden, X. Tensile-Shear Forces and Fracture Modes in Single and Multiple Weld Specimens in Dual-Phase Steels. J. Manuf. Sci. Eng.-Trans. Asme 2006, 128, 287–298. [Google Scholar] [CrossRef]

- Baltazar Hernandez, V.H.; Panda, S.K.; Okita, Y.; Zhou, N.Y. A study on heat affected zone softening in resistance spot welded dual phase steel by nanoindentation. J. Mater. Sci. 2009, 45, 1638–1647. [Google Scholar] [CrossRef]

- Hernandez, B.V.H.; Kuntz, M.L.; Khan, M.I.; Zhou, Y. Influence of microstructure and weld size on the mechanical behaviour of dissimilar AHSS resistance spot welds. Sci. Technol. Weld. Join. 2013, 13, 769–776. [Google Scholar] [CrossRef]

- Khan, M.I.; Kuntz, M.L.; Zhou, Y. Effects of weld microstructure on static and impact performance of resistance spot welded joints in advanced high strength steels. Sci. Technol. Weld. Join. 2013, 13, 294–304. [Google Scholar] [CrossRef]

- Saha, D.C.; Westerbaan, D.; Nayak, S.S.; Biro, E.; Gerlich, A.P.; Zhou, Y. Microstructure-properties correlation in fiber laser welding of dual-phase and HSLA steels. Mater. Sci. Eng. A 2014, 607, 445–453. [Google Scholar] [CrossRef]

- Westerbaan, D.; Parkes, D.; Chen, D.; Biro, E.; Goodwin, F.; Zhou, Y.; Nayak, S.S. Effects of concavity on tensile and fatigue properties in fibre laser welding of automotive steels. Sci. Technol. Weld. Join. 2013, 19, 60–68. [Google Scholar] [CrossRef]

- Li, J.; Nayak, S.S.; Biro, E.; Panda, S.K.; Goodwin, F.; Zhou, Y. Effects of weld line position and geometry on the formability of laser welded high strength low alloy and dual-phase steel blanks. Mater. Des. 2013, 52, 757–766. [Google Scholar] [CrossRef]

- Xu, W.; Westerbaan, D.; Nayak, S.S.; Chen, D.L.; Goodwin, F.; Biro, E.; Zhou, Y. Microstructure and fatigue performance of single and multiple linear fiber laser welded DP980 dual-phase steel. Mater. Sci. Eng. A 2012, 553, 51–58. [Google Scholar] [CrossRef]

- Xia, M.; Biro, E.; Tian, Z.; Zhou, Y.N. Effects of Heat Input and Martensite on HAZ Softening in Laser Welding of Dual Phase Steels. ISIJ Int. 2008, 48, 809–814. [Google Scholar] [CrossRef] [Green Version]

- Prijanovič, U.; Prijanovič Tonkovič, M.; Trdan, U.; Pleterski, M.; Jezeršek, M.; Klobčar, D. Remote Fibre Laser Welding of Advanced High Strength Martensitic Steel. Metals 2020, 10, 533. [Google Scholar] [CrossRef]

- Burns, T.J. Weldability of a Dual-Phase Sheet Steel by the Gas Metal Arc Welding Process; UWSpace: Waterloo, ON, Canada, 2010. [Google Scholar]

- Kapustka, N.; Conrardy, C.; Babu, S.; Albright, C. Effect of GMAW Process and Material Conditions on DP 780 and TRIP 780 Welds. Weld. J. 2008, 87, 135s–148s. [Google Scholar]

- Elliot Biro, C.J.; Lyttle, K. Correlation between Failure Location and Tensile Strength of AHSS GMAW Lap Joint. In Proceedings of the Sheet Metal Welding Conference XIII. Livonia, MI, USA, 14–16 May 2008. [Google Scholar]

- Conrardy, N.K.; Albright, C.E. Effect of material and GMAW process conditions on AHSS welds. In Proceedings of the Sheet Metal Welding Conference XII, Livonia, MI, USA, 9–12 May 2006. [Google Scholar]

- Biro, A.L. Welded Properties of Various DP600 Chemistries. In Proceedings of the Sheet Metal Welding Conference XI, Sterling Heights, MI, USA, 11–14 May 2006. [Google Scholar]

- Shome, M.; Tumuluru, M. Introduction to welding and joining of advanced high-strength steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Woodhead Plublishing: Sawston, UK, 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Duchet, M.; Haouas, J.; Gibeau, E.; Pechenot, F.; Honecker, C.; Munier, R.; Weber, B. Improvement of the fatigue strength of welds for lightweight chassis application made of Advanced High Strength Steels. Procedia Struct. Integr. 2019, 19, 585–594. [Google Scholar] [CrossRef]

- Baltazar-Hernández, V.H.; López-Baltazar, E.A.; Alvarado-Hernández, F.; Gómez-Jiménez, S.; Ruiz-Mondragón, J.J.; Biro, E.; Zhou, N. Surface Residual Stress Analysis in GMAW and LBW of the Dissimilar TRIP-DP Steels Joint: An Experimental Approach. Metals 2022, 12, 880. [Google Scholar] [CrossRef]

- John, M.; Kumar, A.; Bhat, U. AHSS welding using undermatching filler wires and process advantages with P-GMAW. Mater. Today Proc. 2022, 49, 1312–1318. [Google Scholar] [CrossRef]

- Baltazar Hernandez, V.H.; Panda, S.K.; Kuntz, M.L.; Zhou, Y. Nanoindentation and microstructure analysis of resistance spot welded dual phase steel. Mater. Lett. 2010, 64, 207–210. [Google Scholar] [CrossRef]

- Nayak, S.S.; Baltazar-Hernandez, V.; Zhou, Y. Effect of Chemistry on Nonisothermal Tempering and Softening of Dual-Phase Steels. Metall. Mater. Trans. A 2011, 42, 3242–3248. [Google Scholar] [CrossRef]

- Gould, J.; Khurana, S.P.; Li, T. Predictions of Microstructures When Welding Automotive Advanced High-Strength Steels—A Combination of Thermal and Microstructural Modeling can be Used to Estimate Performance of Welds in Advanced High-Strength Steels. Weld. J. 2006, 85, 111S–116S. [Google Scholar]

- Vignier, S.; Biro, E.; Hervé, M. Predicting the hardness profile across resistance spot welds in martensitic steels. Weld. World 2014, 58, 297–305. [Google Scholar] [CrossRef]

- Biro, E.; McDermid, J.; Vignier, S.; Zhou, Y. Decoupling of the softening processes during rapid tempering of a martensitic steel. Mater. Sci. Eng. A 2014, 615, 395–404. [Google Scholar] [CrossRef]

- Biro, E.; Vignier, S.; Kaczynski, C.; McDermid, J.; Lucas, E.; Embury, J.; Zhou, N. Predicting Transient Softening in the Sub-Critical Heat-Affected Zone of Dual-Phase and Martensitic Steel Welds. ISIJ Int. 2013, 53, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Biro, E.; McDermid, J.; Embury, J.; Zhou, Y. Softening Kinetics in the Subcritical Heat-Affected Zone of Dual-Phase Steel Welds. Metall. Mater. Trans. A 2010, 41, 2348–2356. [Google Scholar] [CrossRef]

- E. Biro, A.L. Tensile properties of Gleeble simulated HAZ from various dual-phase steels. In Proceedings of the Sheet Metal Welding Conference XII. In Proceedings of the Sheet Metal Welding Conference XII, Livonia, MI, USA, 9–12 May 2006. [Google Scholar]

- Martínez-González, C.J.; López-Ibarra, A.; Haro-Rodriguez, S.; Baltazar-Hernandez, V.H.; Nayak, S.S.; Zhou, Y. Effects of holding time on haz-softening in resistance spot welded dp980 steels–Erratum. MRS Online Proc. Libr. Arch. 2013, 1485, 1. [Google Scholar] [CrossRef] [Green Version]

- RWMA. Resistance Welding Manual, 4th ed.; American Welding Society (AWS): Miami, FL, USA, 2003. [Google Scholar]

- American Welding Society. Recommended Practices for Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials; American Welding Society: Miami, FL, USA, 1997. [Google Scholar]

- Yurioka, Y.O.M.; Kasuya, T.; Cotton, H.J.U. Prediction of HAZ hardness of transformable steels. Met. Constr. 1987, 19, 217R–223R. [Google Scholar]

| Material | C | Mn | Si | Cu | Ni | Cr | Mo | Nb | V | Al | CEy | TAc1 (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DP980 | 0.15 | 1.50 | 0.31 | 0.02 | 0.01 | 0.02 | 0.006 | 0.02 | 0.003 | 0.047 | 0.391 | 716 |

| Material | YS (MPa) | UTS (MPa) | Elongation (%) | HV |

|---|---|---|---|---|

| DP980 | 674 | 1074 | 11 | 342 |

| GMAW-Parameter | Current (A) | Voltage (V) | Shield Gas | Gas Flow (L/min) | Travel Speed (mm/s) |

| 55 | 16.5 | 75% CO2 + 25% Ar | 18 | 1.8 | |

| RSW-Parameter | Welding Current (kA) | Force (kN) | Squeeze Time Cycles (s−1) | Welding Time Cycles (s−1) | Holding Time Cycles (s−1) |

| 9 | 4.5 | 25 | 20 | 10 |

| Temperature (°C) | Slow Heating + Isothermally Treated for 3600 s | Slow Heating + Rapid Cooling |

|---|---|---|

| 400 | 274 ± 13 | 327 ± 15 |

| 500 | 233 ± 9 | 302 ± 13 |

| 600 | 207 ± 3 | 258 ± 9 |

| 700 | 166 ± 6 | 175 ± 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-González, C.J.; López-Baltazar, E.A.; Alvarado-Hernández, F.; Baltazar-Hernández, V.H.; Saha, D.C.; Biro, E.; Zhou, N. On the Measurability and Predictability of HAZ Softening in GMAW of Automotive DP980 Steel. Metals 2022, 12, 1009. https://doi.org/10.3390/met12061009

Martínez-González CJ, López-Baltazar EA, Alvarado-Hernández F, Baltazar-Hernández VH, Saha DC, Biro E, Zhou N. On the Measurability and Predictability of HAZ Softening in GMAW of Automotive DP980 Steel. Metals. 2022; 12(6):1009. https://doi.org/10.3390/met12061009

Chicago/Turabian StyleMartínez-González, Cecilio J., Enrique A. López-Baltazar, Francisco Alvarado-Hernández, Víctor H. Baltazar-Hernández, Dulal C. Saha, Elliot Biro, and Norman Zhou. 2022. "On the Measurability and Predictability of HAZ Softening in GMAW of Automotive DP980 Steel" Metals 12, no. 6: 1009. https://doi.org/10.3390/met12061009