The Study of Hardness Evolution during the Tempering Process of 38MnB5Nb Ultra-High-Strength Hot Stamping Steel: Experimental Analysis and Constitutive Models

Abstract

:1. Introduction

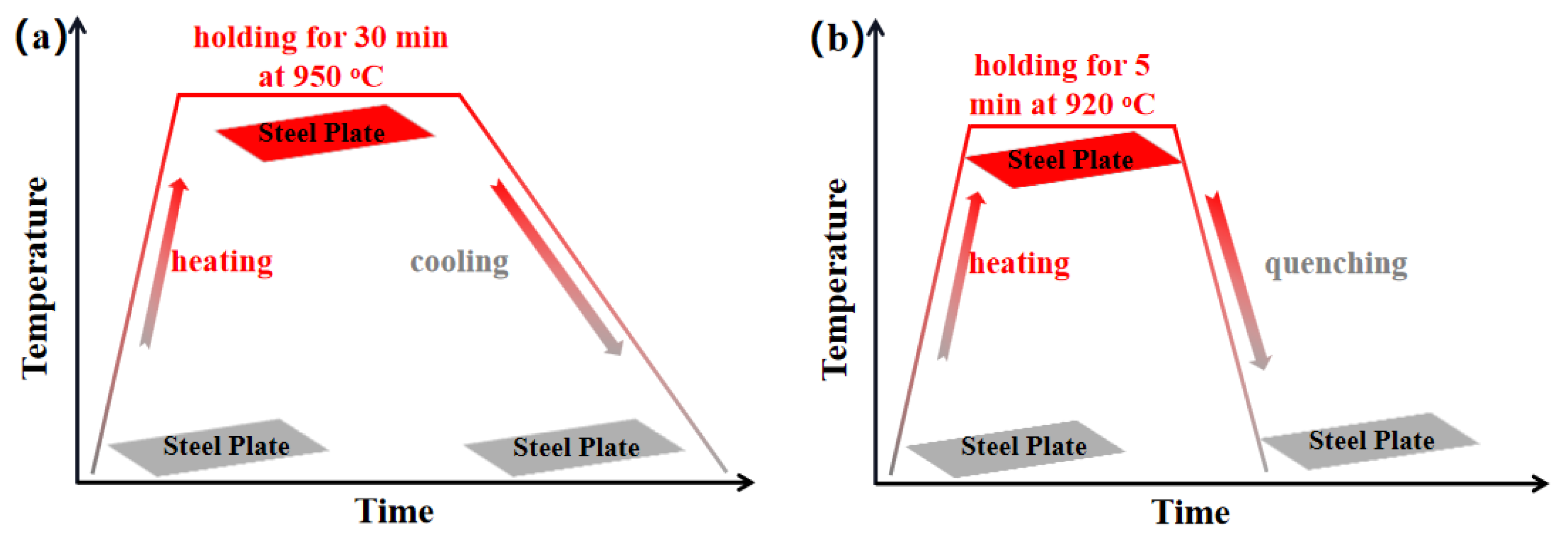

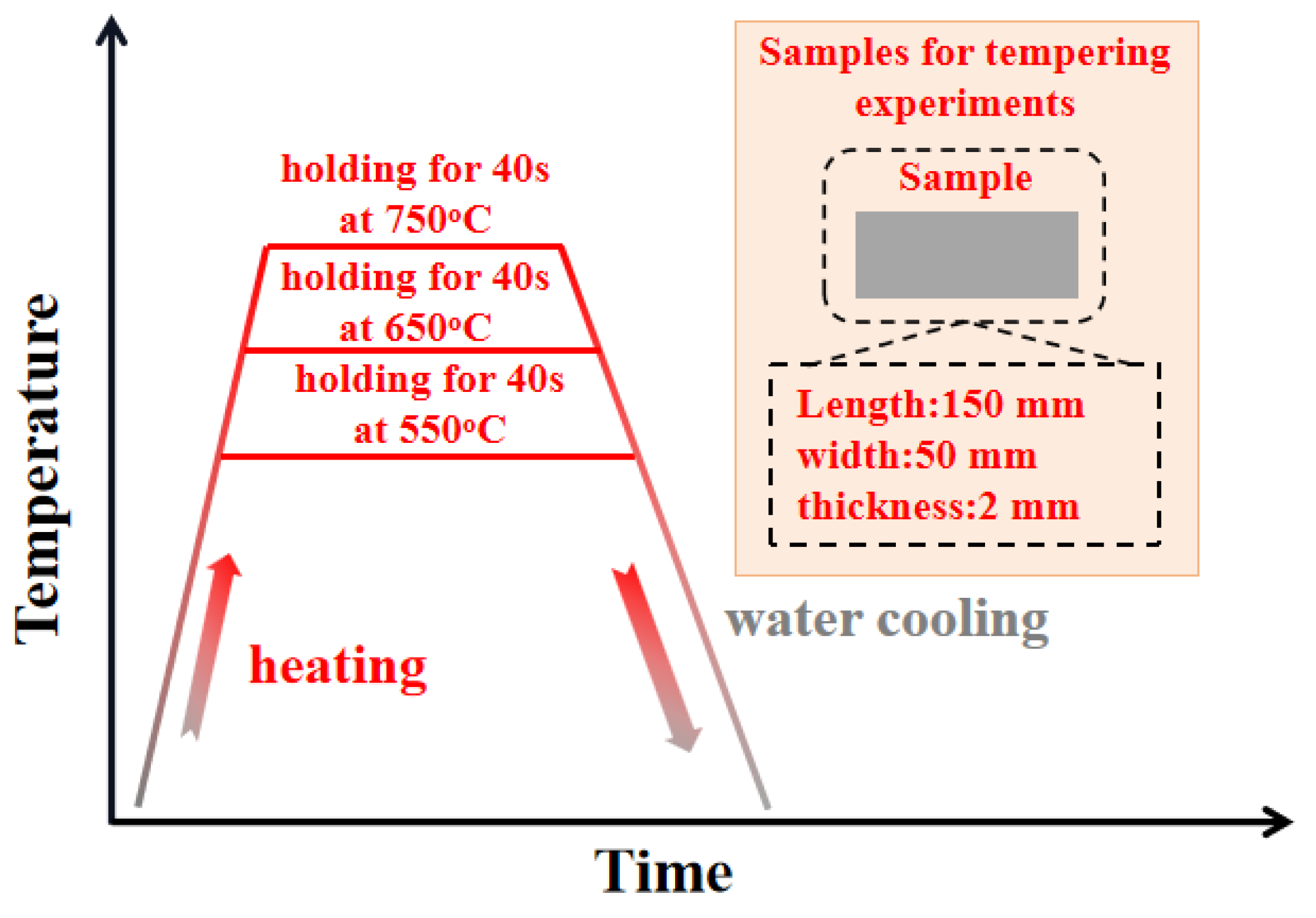

2. Methods

3. Results and Discussions

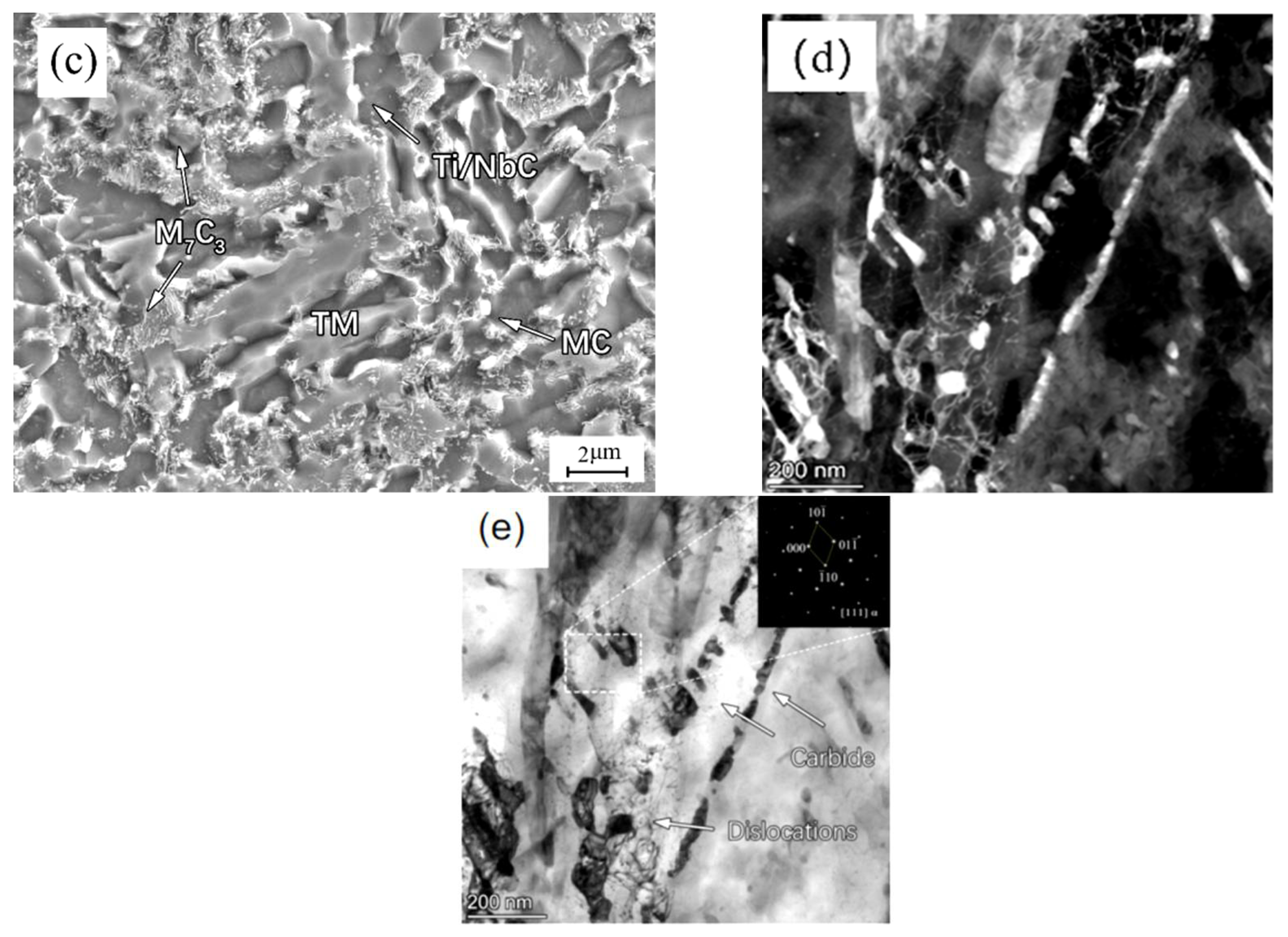

3.1. The Hardness Evolution during Tempering

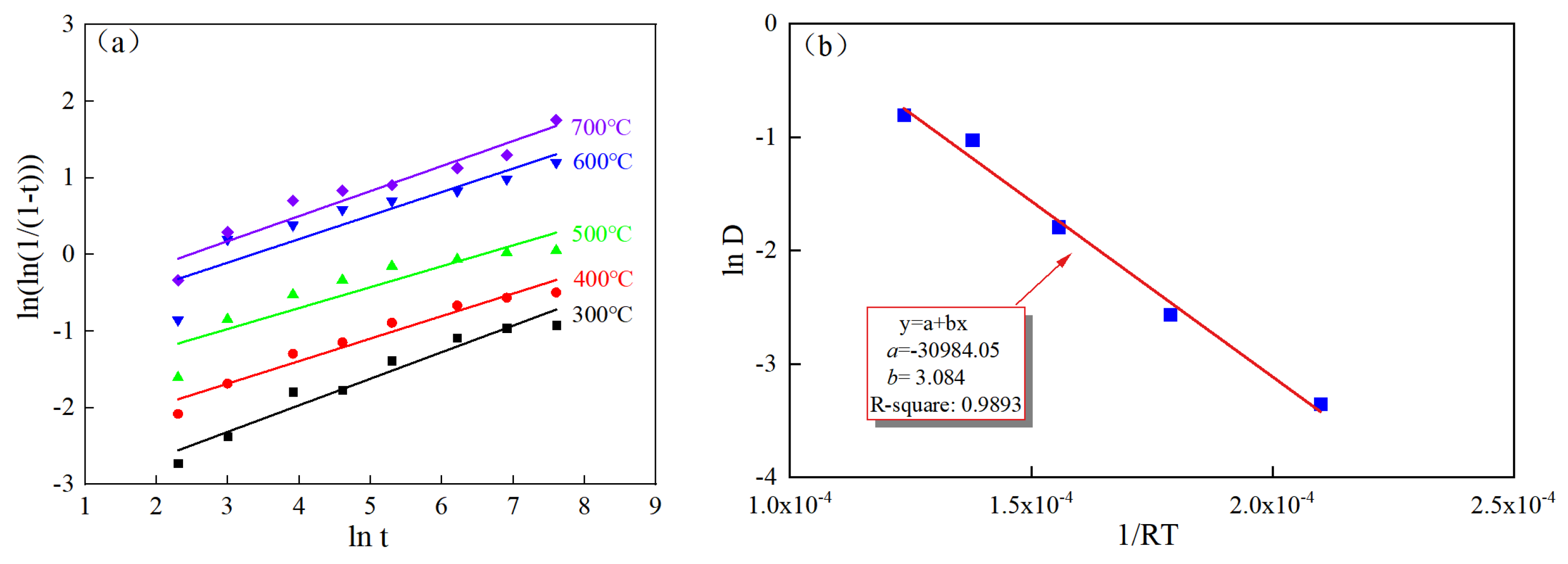

3.2. The Construction of Tempering Model

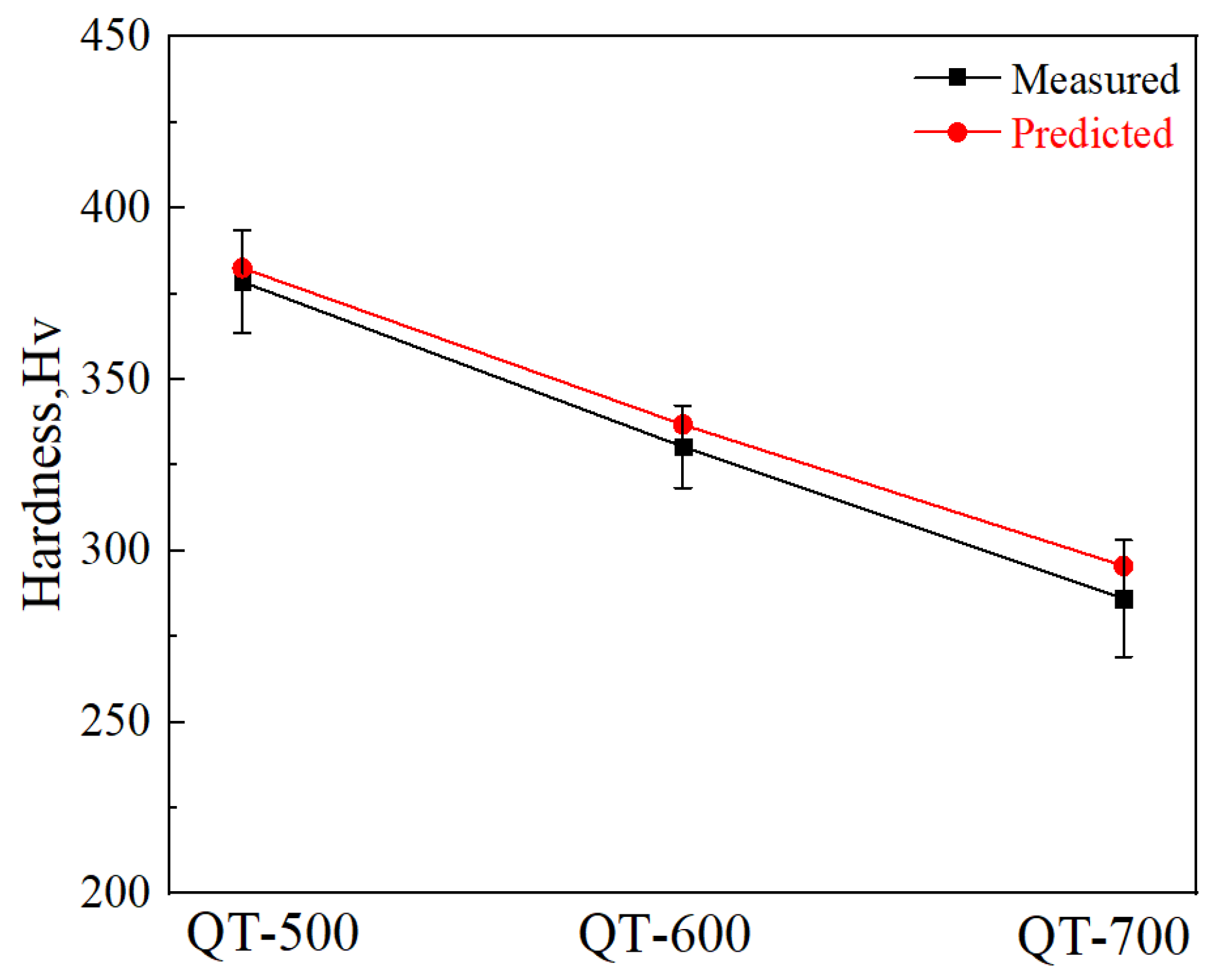

3.3. Application of the Tempering Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Zhao, L.; Lu, S.; Lin, Z.; Wen, T.; Chen, Z. Progress and Perspective of Ultra-High-Strength Martensitic Steels for Automobile. Metals 2022, 12, 2184. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced Lightweight Materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, X.; Zhu, P.; Wang, W. Lightweight Design of Automobile Component using High Strength Steel Based on Dent Resistance. Mater. Des. 2006, 27, 64–68. [Google Scholar] [CrossRef]

- Romain, P.; David, L.; Eric, P. Use of Multi-scale Approach for Vehicle Weight Reduction Study. Procedia Eng. 2023, 66, 403–414. [Google Scholar]

- Huang, W.; Gu, H.; Liu, Q.; Si, T. Suppression of Hydrogen-induced Damage in 22MnB5 Hot Stamping Steel by Microalloying. Mater. Chem. Phys. 2020, 256, 123729. [Google Scholar] [CrossRef]

- Zhang, J.; Ji, L.; Bao, D.; Feng, Y.; Li, S.; Weng, Y. Gigacycle Fatigue Behavior of 1800 MPa Grade High Strength Spring Steel for Automobile Lightweight. J. Iron Steel Res. Int. 2014, 21, 614–618. [Google Scholar] [CrossRef]

- Masoud, A.; Amy, B.; Jimi, T.; Chandra, V.; Omar, F.; Mohini, S. Prediction of Greenhouse Gas Emissions Reductions Via Machine Learning Algorithms: Toward an Artificial Intelligence-based Life Cycle Assessment for Automotive Lightweighting. Sustain. Mater. Technol. 2022, 31, e00370. [Google Scholar]

- Gupta, M.; Singhal, V. Review on Materials for Making Lightweight Vehicles. Mater. Today Proc. 2022, 56, 868–872. [Google Scholar] [CrossRef]

- Hultgren, g.; Boåsen, M.; Narström, T.; Barsoum, Z. Fracture Toughness Assessment of Surface Cracks in Slender Ultra-high-strength Steel Plates. Eng. Fract. Mech. 2023, 289, 109458. [Google Scholar] [CrossRef]

- Li, K.; Yang, T.; Gong, N.; Wu, J.; Wu, X.; Zhang, D.; Murr, L. Additive Manufacturing of Ultra-high Strength Steels: A Review. J. Alloys Compd. 2023, 965, 171390. [Google Scholar] [CrossRef]

- Song, C.; Zhang, Z.; Wu, W.; Wang, H.; Sun, Z.; Yang, Y.; He, W.; Xu, J.; Xia, Y.; Yin, W.; et al. Effect of Si on the Dislocation Date within Martensite of Ultra-high Strength Hot-rolled Medium Mn Steel with Good Ductility. Mater. Sci. Eng. A 2023, 869, 144825. [Google Scholar] [CrossRef]

- Quan, G.; Zhan, Z.; Zhang, L.; Wu, D.; Luo, G.; Xia, Y. A Study on the Multi-phase Transformation Kinetics of Ultra-high-strength Steel and Application in Thermal-Mechanical-Phase Coupling Simulation of Hot Stamping Process. Mater. Sci. Eng. A 2016, 673, 24–338. [Google Scholar] [CrossRef]

- Mor, K.; Okuda, Y. Tailor Die Quenching in Hot Stamping for Producing Ultra-high strength Steel Formed Parts Having Strength Distribution. CIRP Ann. 2010, 59, 291–294. [Google Scholar] [CrossRef]

- Liu, S.; Long, M.; Zhang, S.; Zhao, Y.; Zhao, J.; Feng, Y.; Chen, D.; Ma, M. Study on the Prediction of Tensile Strength and Phase Transition for Ultra-high Strength Hot Stamping Steel. J. Mater. Res. Technol. 2020, 9, 14244–14253. [Google Scholar] [CrossRef]

- Liang, J.; Lu, H.; Zhang, L.; Li, F.; Gao, R.; Liu, K.; Pan, H.; Teng, H.; Li, X.; Guo, A.; et al. A 2000 MPa Grade Nb Bearing Hot Stamping Steel with Ultra-high Yield Strength. Mater. Sci. Eng. A 2020, 9, 14244–14253. [Google Scholar] [CrossRef]

- Thawin, H.; Johannes, B.; Alexander, H.; Markus, B.; Marion, M. A Unified Model for Isothermal and Non-isothermal Phase Transformation in Hot Stamping of 22MnB5 Steel. J. Mater. Process. Technol. 2023, 313, 117856. [Google Scholar]

- Çavuşoğlu, O.; Çavuşoğlu, O.; Yılmazoğlu, A.; Üzel, U.; Güral, A. Microstructural Features and Mechanical Properties of 22MnB5 Hot Stamping Steel in Different Heat Treatment Conditions. J. Mater. Res. Technol. 2020, 9, 10901–10908. [Google Scholar] [CrossRef]

- Min, J.; Lin, J.; Min, Y. Effect of Thermo-mechanical Process on the Microstructure and Secondary-deformation Behavior of 22MnB5 Steels. J. Mater. Process. Technol. 2013, 213, 818–825. [Google Scholar] [CrossRef]

- Berglund, D. Hot Stamped Components with Tailored Properties-Simulation and Validation of Product Performance. Steel Grips 2010, 8, 41–44. [Google Scholar]

- Cantergiani, E.; Fillon, A.; Lawrence, B.; Sauvage, X.; Perez, M.; Scott, C.; Weck, A. Tailoring the mechanical properties of steel sheets using FeC films and diffusion annealing. Mater. Sci. Eng. A 2016, 657, 291–2298. [Google Scholar] [CrossRef]

- Tang, B.; Li, Q.; Wang, Q.; Guo, N.; Meng, X.; Shi, Y.; Su, H.; Lin, L. A Novel Micromechanical-Based Secant Method to Predict the Elastoplastic Constitutive Relation of a Tailor-tempered 22MnB5 Sheet. Mater. Today Commun. 2022, 31, 103236. [Google Scholar] [CrossRef]

- Bao, L.; Wang, B.; You, X.; Li, H.; Gu, Y.; Liu, W. Numerical and Experimental Research on Localized Induction Heating Process for Hot Stamping Steel Sheets. Int. J. Heat Mass Transf. 2020, 151, 119422. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, D.; Qin, Z.; Chu, X.; Liu, J.; Zhao, Z. A Novel Hot Stamping Steel with Superior Mechanical Properties and Antioxidant Properties. J. Mater. Res. Technol. 2022, 21, 1944–1959. [Google Scholar] [CrossRef]

- Song, R.; Pottore, N.S. Martensitic Steels with 1700–2200 MPa Tensile Strength. Patent EP2785888B1, 8 October 2014. [Google Scholar]

- Jo, M.C.; Yoo, J.; Kim, S.; Kim, S.; Oh, J.; Bian, J.; Sohn, S.S.; Lee, S. Effects of Nb and Mo alloying on resistance to hydrogen embrittlement in 1.9 GPa-grade hot-stamping steels. Mater. Sci. Eng. A 2020, 789, 139656. [Google Scholar] [CrossRef]

- Lin, L.; Li, B.; Zhu, G.M.; Kang, Y.-L.; Liu, R.-D. Effects of Nb on the Microstructure and Mechanical Properties of 38MnB5 Steel. Int. J. Miner. Metall. Mater. 2018, 25, 1181–1190. [Google Scholar] [CrossRef]

- Luo, P.; Li, X.; Zhang, W.; Liang, X.; Tan, Z.; Wang, D.; Jiang, C.; Hou, J.; Sun, L. The Study of Phase Transformation Behaviors for 38MnB5Nb Ultra High-Strength Steel by CCT Curves and TTT Curves. Metals 2023, 13, 190. [Google Scholar] [CrossRef]

- Liang, X.; Li, X.; Wang, D.; Lin, X.; Luo, P.; Tan, Z.; Song, Y.; Tian, Y.; Hou, J.; Jiang, C.; et al. Numerical and Experimental Study on Hot Forming by Partition Cooling of 38MnB5Nb. Metals 2022, 12, 839. [Google Scholar] [CrossRef]

- Shi, L.; Ran, X.; Zhai, Y.; Pan, Y.; Zhang, S.; Cheng, X.; Tang, B.; Wang, H. Influence of Isothermal Tempering on Microstructures and Hydrogen-environmentally Embrittlement Susceptibility of Laser Additively Manufactured Ultra-high Strength AerMet100 Steel. Mater. Sci. Eng. A 2023, 876, 145167. [Google Scholar] [CrossRef]

- Zhang, Z.; Delagnes, D.; Bernhart, G. Microstructure Evolution of Hot-work Tool Steels During Tempering and Definition of a Kinetic Law Based on Hardness Measurements. Mater. Sci. Eng. A 2004, 380, 222–230. [Google Scholar] [CrossRef]

- Johnson, W.; Mehl, R. Reaction Kinetics in Processes of Nucleation and Growth. Trans. Am. Inst. Min. Metall. Eng. 1939, 135, 416–442. [Google Scholar]

| Steel | C | Si | Mn | Cr | B | Nb | Fe |

|---|---|---|---|---|---|---|---|

| 38MnB5Nb | 0.36 | 0.24 | 1.39 | 0.19 | 0.005 | 0.05 | Bal. |

| Parameters | Tempering Temperature, °C | Average | ||||

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | 700 | ||

| 0.347 | 0.294 | 0.273 | 0.307 | 0.327 | 0.308 | |

| −0.805 | −1.026 | −1.790 | −2.566 | −3.355 | - | |

| Samples | Rm (MPa) | Rp0.2 (MPa) | TEL (%) | PSE (GPa%) |

|---|---|---|---|---|

| Q-30 | 1986 | 1476 | 6.8 | 13.5 |

| QT-500 | 1252 | 880 | 15.8 | 19.8 |

| QT-600 | 1116 | 772 | 16.8 | 18.7 |

| QT-700 | 987 | 642 | 18.8 | 18.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, P.; Li, X.; Zhang, W.; Tan, Z.; Zhang, M.; Wang, K.; Hou, P.; Liu, J.; Liang, X. The Study of Hardness Evolution during the Tempering Process of 38MnB5Nb Ultra-High-Strength Hot Stamping Steel: Experimental Analysis and Constitutive Models. Metals 2023, 13, 1642. https://doi.org/10.3390/met13101642

Luo P, Li X, Zhang W, Tan Z, Zhang M, Wang K, Hou P, Liu J, Liang X. The Study of Hardness Evolution during the Tempering Process of 38MnB5Nb Ultra-High-Strength Hot Stamping Steel: Experimental Analysis and Constitutive Models. Metals. 2023; 13(10):1642. https://doi.org/10.3390/met13101642

Chicago/Turabian StyleLuo, Ping, Xianjun Li, Wenliang Zhang, Zhunli Tan, Minghao Zhang, Kaize Wang, Pengdi Hou, Junjie Liu, and Xiao Liang. 2023. "The Study of Hardness Evolution during the Tempering Process of 38MnB5Nb Ultra-High-Strength Hot Stamping Steel: Experimental Analysis and Constitutive Models" Metals 13, no. 10: 1642. https://doi.org/10.3390/met13101642

APA StyleLuo, P., Li, X., Zhang, W., Tan, Z., Zhang, M., Wang, K., Hou, P., Liu, J., & Liang, X. (2023). The Study of Hardness Evolution during the Tempering Process of 38MnB5Nb Ultra-High-Strength Hot Stamping Steel: Experimental Analysis and Constitutive Models. Metals, 13(10), 1642. https://doi.org/10.3390/met13101642