Microstructure and Magnetism of Heavily Helium-Ion Irradiated Epitaxial Iron Films

Abstract

:1. Introduction

2. Experimental Procedures

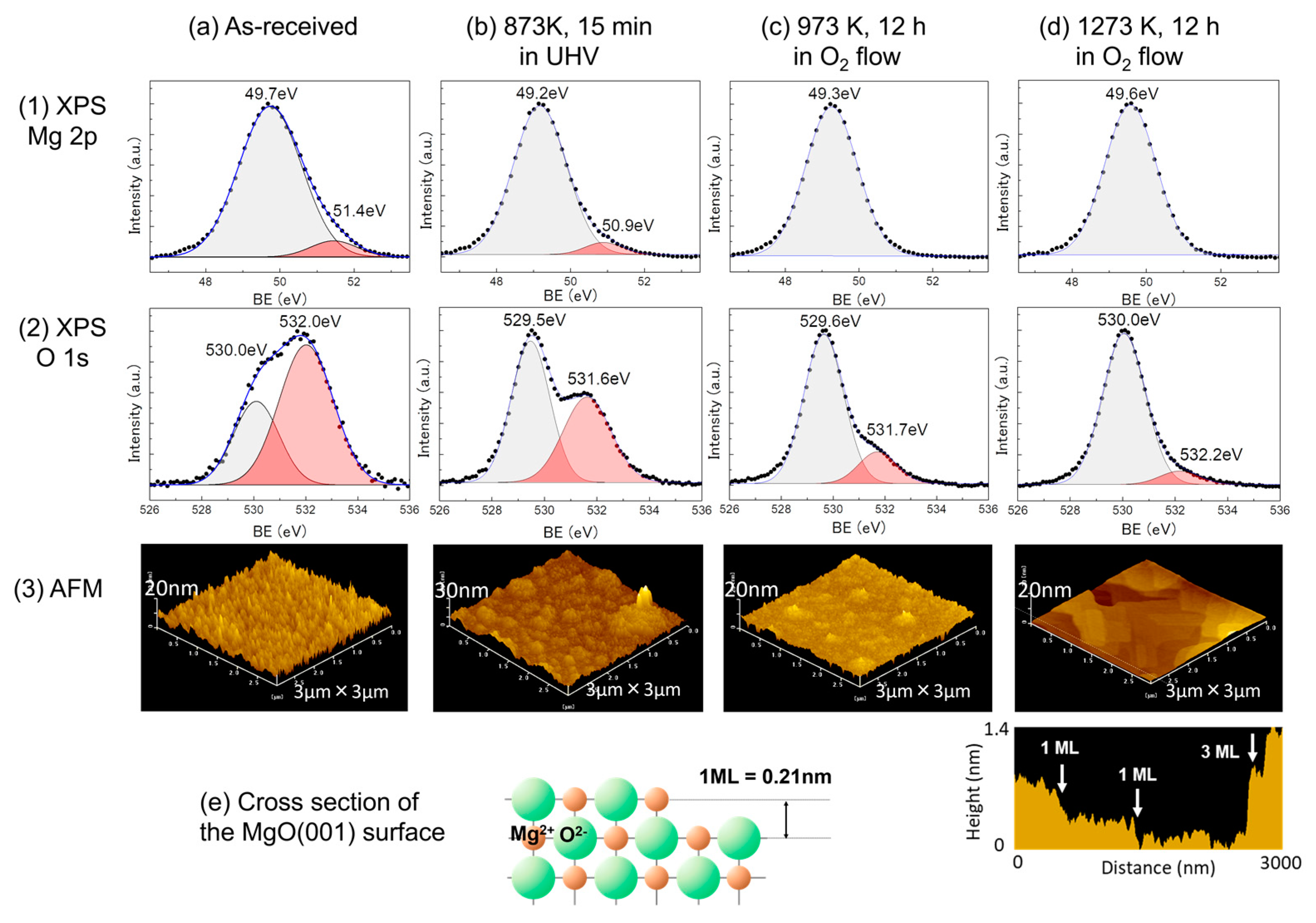

2.1. Specimen Preparation

2.2. Characterization of Microstructure and Magnetism

3. Results

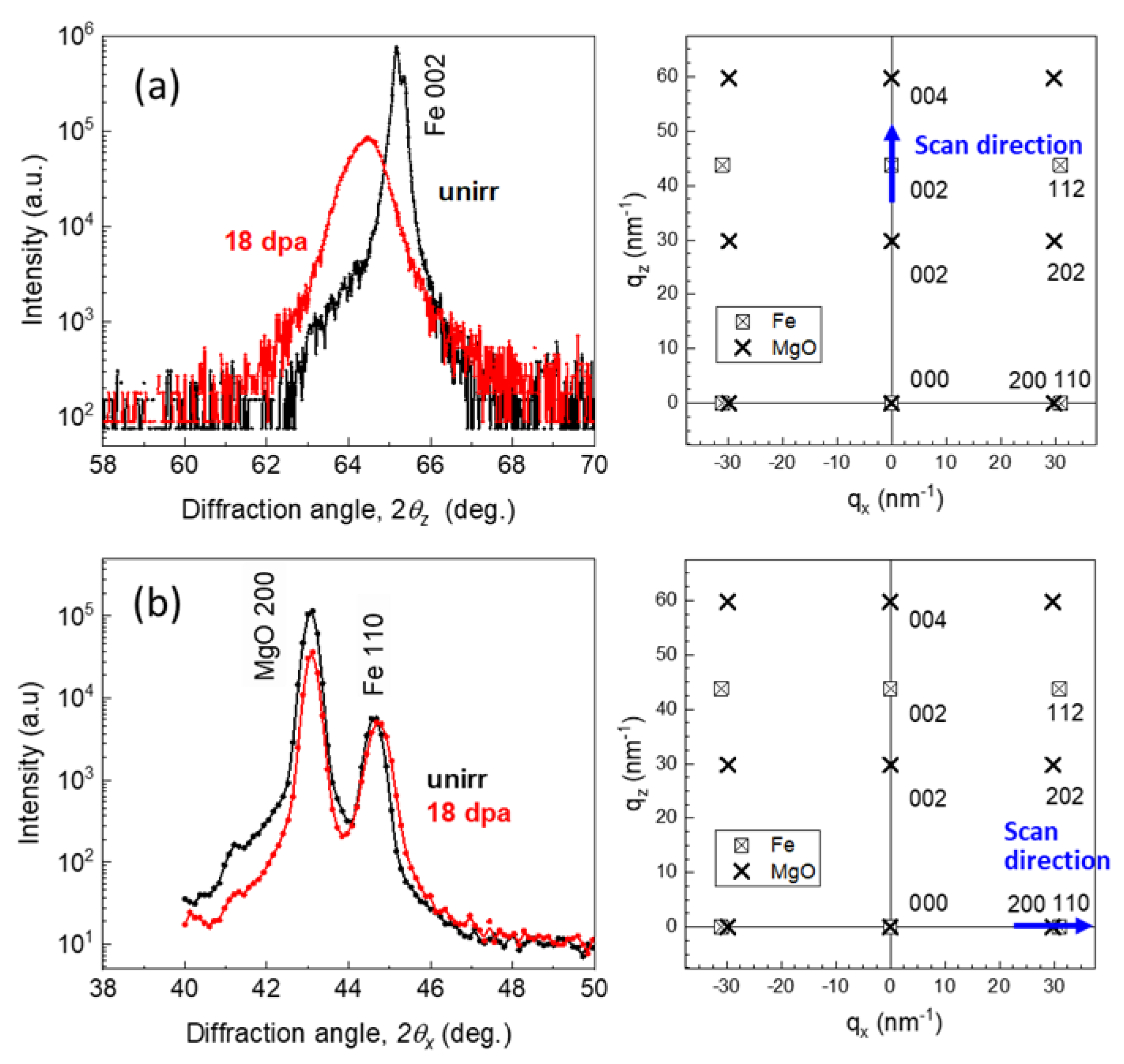

3.1. Epitaxial Structure and Lattice Expansion

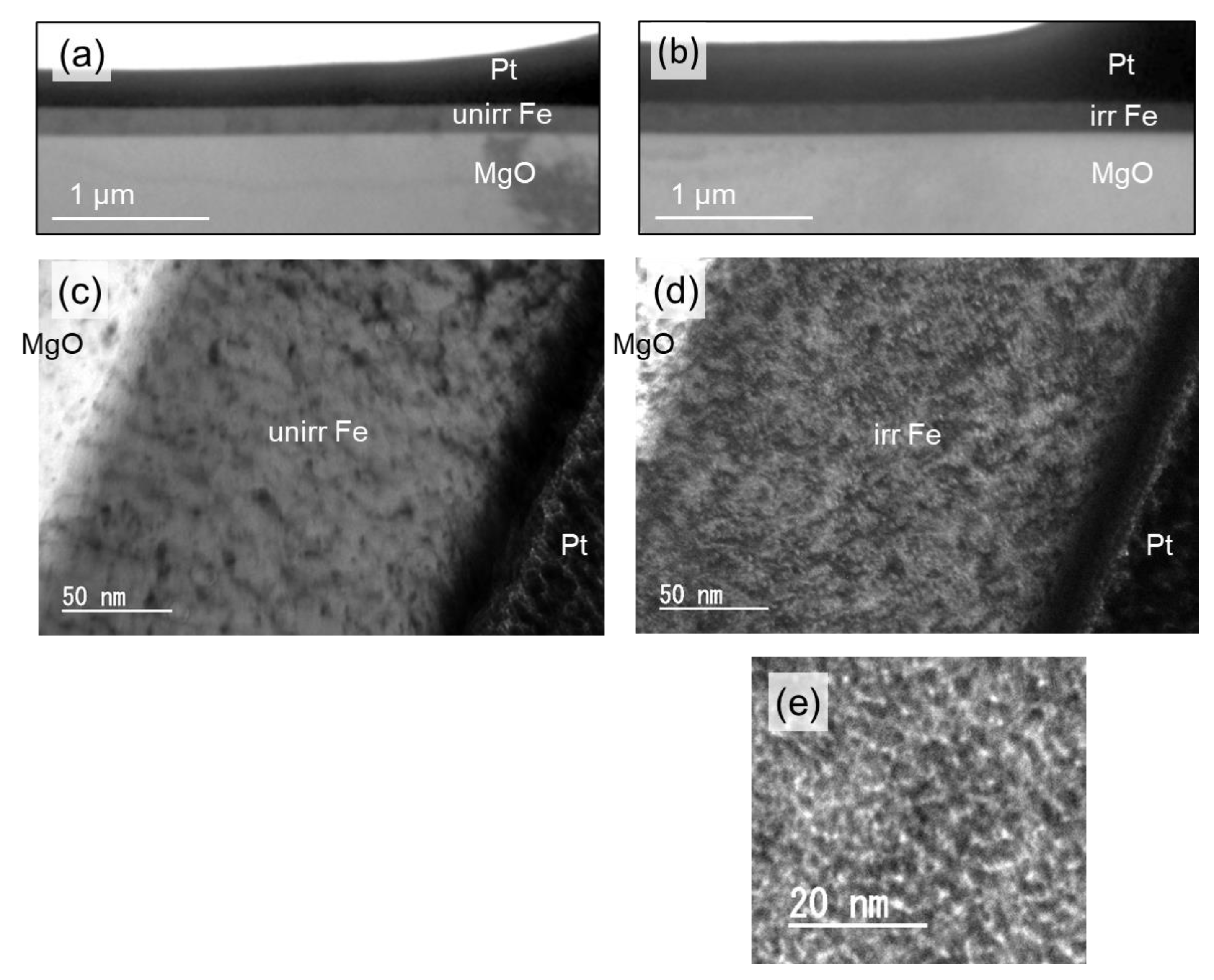

3.2. Formation of Cavities

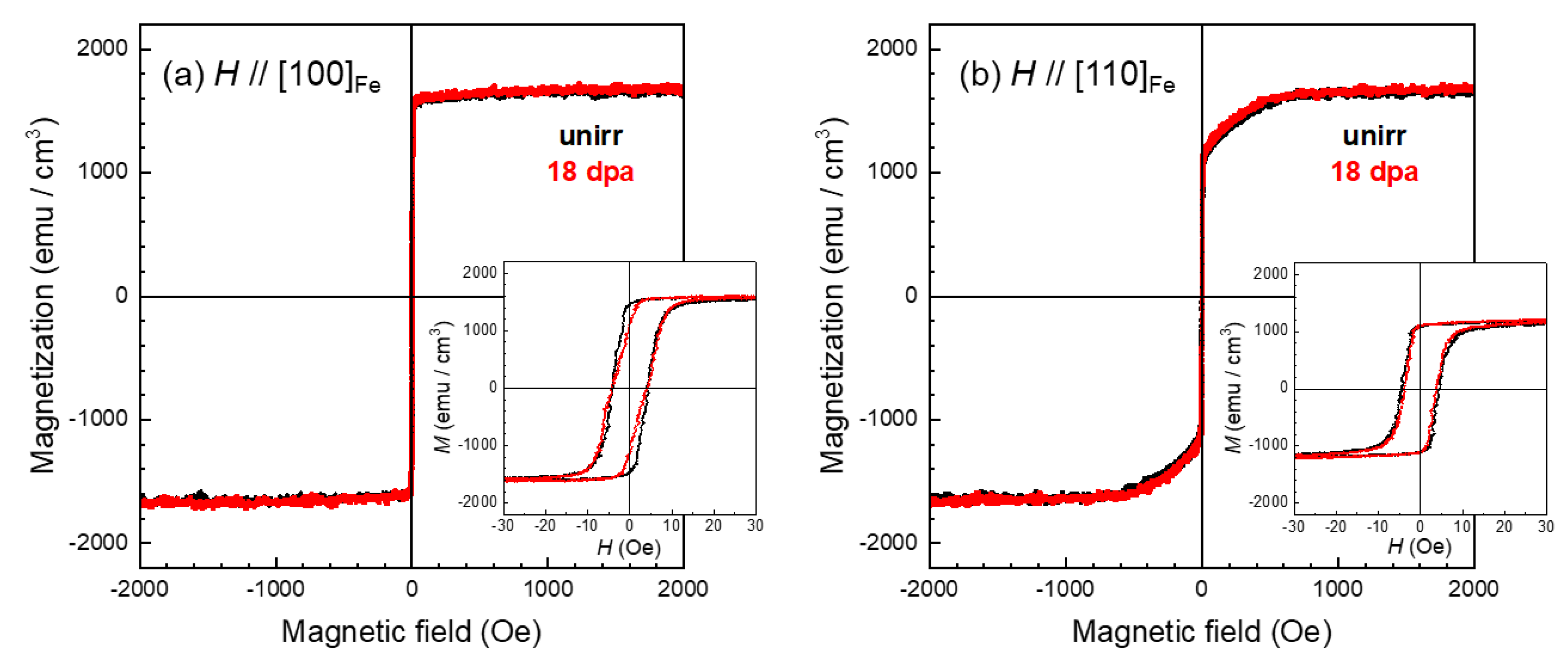

3.3. Irradiation Effects on Magnetization Curves

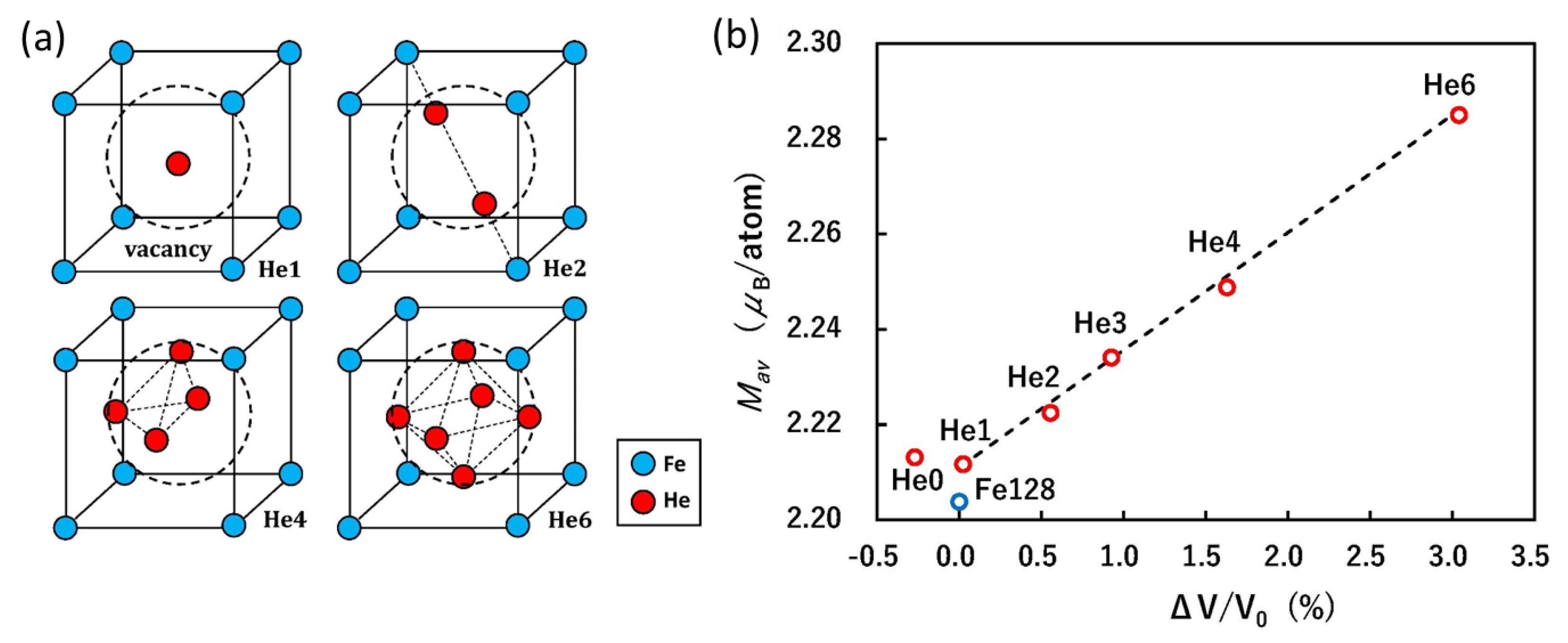

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cabet, C.; Dalle, F.; Gaganidze, E.; Henry, J.; Tanigawa, H. Ferritic-martensitic steels for fission and fusion applications. J. Nucl. Mater. 2019, 523, 510–537. [Google Scholar]

- Hirose, T.; Nozawa, T.; Stoller, R.E.; Hamaguchi, D.; Sakasegawa, H.; Tanigawa, H.; Tanigawa, H.; Enoeda, M.; Katoh, Y.; Snead, L.L. Physical properties of F82H for fusion blanket design. Fusion Eng. Des. 2014, 89, 1595–1599. [Google Scholar] [CrossRef]

- Gaganidze, E.; Gillemot, F.; Szenthe, I.; Gorley, M.; Rieth, M.; Diegele, E. Development of EUROFER97 database and material property handbook. Fusion Eng. Des. 2018, 135, 9–14. [Google Scholar]

- Roccella, R.; Boccaccini, L.V.; Meyder, R.; Raff, S.; Roccella, M. Assessment of EM loads on the EU HCPB TBM during plasma disruption and normal operating scenario including the ferromagnetic effect. Fusion Eng. Des. 2008, 83, 1212–1216. [Google Scholar]

- Maione, I.A.; Roccella, M.; Hernández, F.A.; Lucca, F. Update of electromagnetic loads on HCPB breeding blanked for DEMO 2017 configuration. Fusion Eng. Des. 2020, 156, 111604. [Google Scholar] [CrossRef]

- Guan, W.; Gwon, H.; Tanigawa, H.; Hirose, T.; Kawamura, Y. Electromagnetic analysis of cylindrical WCCB TBM. Fusion Eng. Des. 2020, 155, 111719. [Google Scholar]

- Knaster, J.; Moeslang, A.; Muroga, T. Materials research for fusion. Nat. Phys. 2016, 12, 424–434. [Google Scholar]

- Abromeit, C. Aspects of simulation of neutron damage by ion irradiation. J. Nucl. Mater. 1994, 216, 78–96. [Google Scholar]

- Kamada, Y.; Watanabe, H.; Mitani, S.; Echigoya, J.; Mohapatra, J.N.; Kikuchi, H.; Kobayashi, S.; Takanashi, K. Magnetic properties of on irradiated epitaxial Fe films. J. Phys. Conf. Ser. 2011, 266, 012035. [Google Scholar]

- Papamihail, K.; Mergia, K.; Ott, F.; Serruys, Y.; Speliotis, T.; Apostolopoulos, G.; Messoloras, S. Magnetic effects induced by self-ion irradiation of Fe films. Phys. Rev. B 2016, 93, 100404(R). [Google Scholar]

- Papamihail, K.; Mergia, K.; Ott, F.; Serruys, Y.; Speliotis, T.; Apostolopoulos, G.; Messoloras, S. Fe+ ion irradiation induced changes in structural and magnetic properties of iron films. Nucl. Mater. Energy 2016, 9, 459–464. [Google Scholar] [CrossRef]

- Mergia, K.; Tsompopoulou, E.O.; Dellis, S.; Marrows, C.H.; Michelakaki, I.; Kinane, C.; Caruana, A.; Langridge, S.; Douvalis, A.P.; Cabet, C.; et al. Phase stability of Fe-5at%Cr and Fe-10at%Cr films under Fe+ ion irradiation. J. Phys. Condens. Matter. 2020, 32, 185702. [Google Scholar] [CrossRef] [PubMed]

- Pantousa, S.; Mergia, K.; Ionescu, A.; Manios, E.; Dellis, S.; Kinane, C.; Langridge, S.; Caruana, A.; Kentsch, U.; Messoloras, S. Fe+ ion irradiation effects in Fe-10at%Cr films irradiated at 300 °C. Nucl. Mater. Energy 2022, 30, 101147. [Google Scholar]

- Chimi, Y.; Ishikawa, N.; Iwase, A.; Ono, F. Modification of magnetic properties in Fe-Ni alloy thin films induced by energetic ion irradiation. Nucl. Instrum. Methods Phys. Res. 2007, 257, 388–391. [Google Scholar] [CrossRef]

- Kamada, Y.; Oyake, T.; Murakami, T.; Kobayashi, S.; Shimizu, K.; Watanabe, H. Ion Irradiation Effects on the Crystal Structure and Magnetic Properties of Iron-Nickel Binary Alloys. IEEE Trans. Mag. 2023, 59, 2001505. [Google Scholar] [CrossRef]

- Scheunert, G.; Heinonen, O.; Hardeman, R.; Lapicki, A.; Gubbins, M.; Bowman, R.M. A review of high magnetic moment thin films for microscale and nanotechnology applications. Appl. Phys. Rev. 2016, 3, 011301. [Google Scholar]

- Chen, C.-W. Magnetism and Metallurgy of Soft Magnetic Materials; Dober Publications, Inc.: Mineola, NY, USA, 1986; p. 98. [Google Scholar]

- Yamamoto, T.; Wu, Y.; Odette, G.R.; Yabuuchi, K.; Kondo, S.; Kimura, A. A dual ion irradiation study of helium-dpa interactions on cavity evolution in tempered martensitic steels and nanostructured ferritic alloys. J. Nucl. Mater. 2014, 449, 190–199. [Google Scholar]

- Aswal, D.K.; Muthe, K.P.; Tawde, S.; Chodhury, S.; Bagkar, N.; Singh, A.; Gupta, S.K.; Yakhami, J.V. XPS and AFM investigations of annealing induced modifications of MgO single crystals. J. Cryst. Growth 2002, 236, 661–666. [Google Scholar]

- Zama, H.; Ishii, Y.; Yamamoto, H.; Morishita, T. Atomically Flat MgO Single-Crystal Surface Prepared by Oxygen Thermal Annealing. Jpn. J. Appl. Phys. 2001, 40, L465–L467. [Google Scholar]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Miyamoto, M.; Nishijima, D.; Baldwin, M.J.; Doerner, R.P.; Ueda, Y.; Yasunaga, K.; Yoshida, N.; Ono, K. Microscopic damage of tungsten exposed to deuterium-helium mixture plasma in PISCES and its impacts on retention property. J. Nucl. Mater. 2011, 415, S567–S660. [Google Scholar] [CrossRef]

- O’Handley, R.C. Modern Magnetic Materials Principles and Applications; John Wiley & Sons, Inc.: New York, NY, USA, 2000; pp. 99, 180. [Google Scholar]

- Takahashi, S.; Kikuchi, H.; Ara, K.; Ebine, N.; Kamada, Y.; Kobayashi, S.; Suzuki, M. In situ magnetic measurements under neutron radiation in Fe metal and low carbon steel. J. Appl. Phys. 2006, 100, 023902. [Google Scholar]

- Kamada, Y.; Mohapatra, J.N.; Kikuchi, H.; Kobayashi, S.; Murakami, T.; Watanabe, H. Neutron Irradiation Effects on Mechanical and Magnetic Properties of Pre-deformed Iron-based Model Alloys. J. Magn. Soc. Jpn. 2013, 37, 147–150. [Google Scholar] [CrossRef]

- Schlömann, E. Properties of Magnetic Materials with a Nonuniform Saturation Magnetization. I. General Theory and Calculation of the Static Magnetization. J. Appl. Phys. 1967, 38, 5027–5034. [Google Scholar]

- Moruzzi, V.L.; Marcus, P.M.; Schwarz, K.; Mohn, P. Ferromagnetic phases of bcc and fcc Fe, Co, and Ni. Phys. Rev. B 1986, 34, 1784–1791. [Google Scholar] [CrossRef]

- Herper, H.C.; Hoffmann, E.; Entel, P. Ab initio full-potential study of the structural and magnetic phase stability of iron. Phys. Rev. B 1999, 60, 3839–3848. [Google Scholar]

- Lee, D.; Hong, S. Correlation between Structures and Magnetism in Iron: Ferromagnetism and Antiferromagnetism. J. Magn. 2007, 12, 68–71. [Google Scholar] [CrossRef]

- Kresse, G.; Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 1993, 48, 13115–13118. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar]

- Ohsawa, K.; Eguchi, K.; Watanabe, H.; Yamaguchi, M.; Yagi, M. Configuration and binding energy of multiple hydrogen atoms trapped in monovacancy in bcc transition metals. Phys. Rev. B 2012, 85, 094102. [Google Scholar]

| Out-of-Plane | In-Plane | Atomic Volume | ||||

|---|---|---|---|---|---|---|

| d002 (nm) | Δd/dunirr ×100 (%) | d110 (nm) | Δd/dunirr ×100 (%) | V (nm3) | ΔV/Vunirr ×100 (%) | |

| unirr | 0.14303 | −−− | 0.20308 | −−− | 0.011798 | −−− |

| 18 dpa | 0.14451 | 1.04 | 0.20263 | −0.22 | 0.011867 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamada, Y.; Umeyama, D.; Oyake, T.; Murakami, T.; Shimizu, K.; Fujisaki, S.; Yoshimoto, N.; Ohsawa, K.; Watanabe, H. Microstructure and Magnetism of Heavily Helium-Ion Irradiated Epitaxial Iron Films. Metals 2023, 13, 1905. https://doi.org/10.3390/met13111905

Kamada Y, Umeyama D, Oyake T, Murakami T, Shimizu K, Fujisaki S, Yoshimoto N, Ohsawa K, Watanabe H. Microstructure and Magnetism of Heavily Helium-Ion Irradiated Epitaxial Iron Films. Metals. 2023; 13(11):1905. https://doi.org/10.3390/met13111905

Chicago/Turabian StyleKamada, Yasuhiro, Daiki Umeyama, Tomoki Oyake, Takeshi Murakami, Kazuyuki Shimizu, Satomi Fujisaki, Noriyuki Yoshimoto, Kazuhito Ohsawa, and Hideo Watanabe. 2023. "Microstructure and Magnetism of Heavily Helium-Ion Irradiated Epitaxial Iron Films" Metals 13, no. 11: 1905. https://doi.org/10.3390/met13111905

APA StyleKamada, Y., Umeyama, D., Oyake, T., Murakami, T., Shimizu, K., Fujisaki, S., Yoshimoto, N., Ohsawa, K., & Watanabe, H. (2023). Microstructure and Magnetism of Heavily Helium-Ion Irradiated Epitaxial Iron Films. Metals, 13(11), 1905. https://doi.org/10.3390/met13111905