Microstructure Evolution and Effect on Deuterium Retention in TiC- and ZrC-Doped Tungsten under He+ Ion Irradiation

Abstract

1. Introduction

2. Experimental Procedure

2.1. Samples

2.2. He+ Irradiation at 600 °C

2.3. Deuterium Retention Analysis by TDS

3. Results

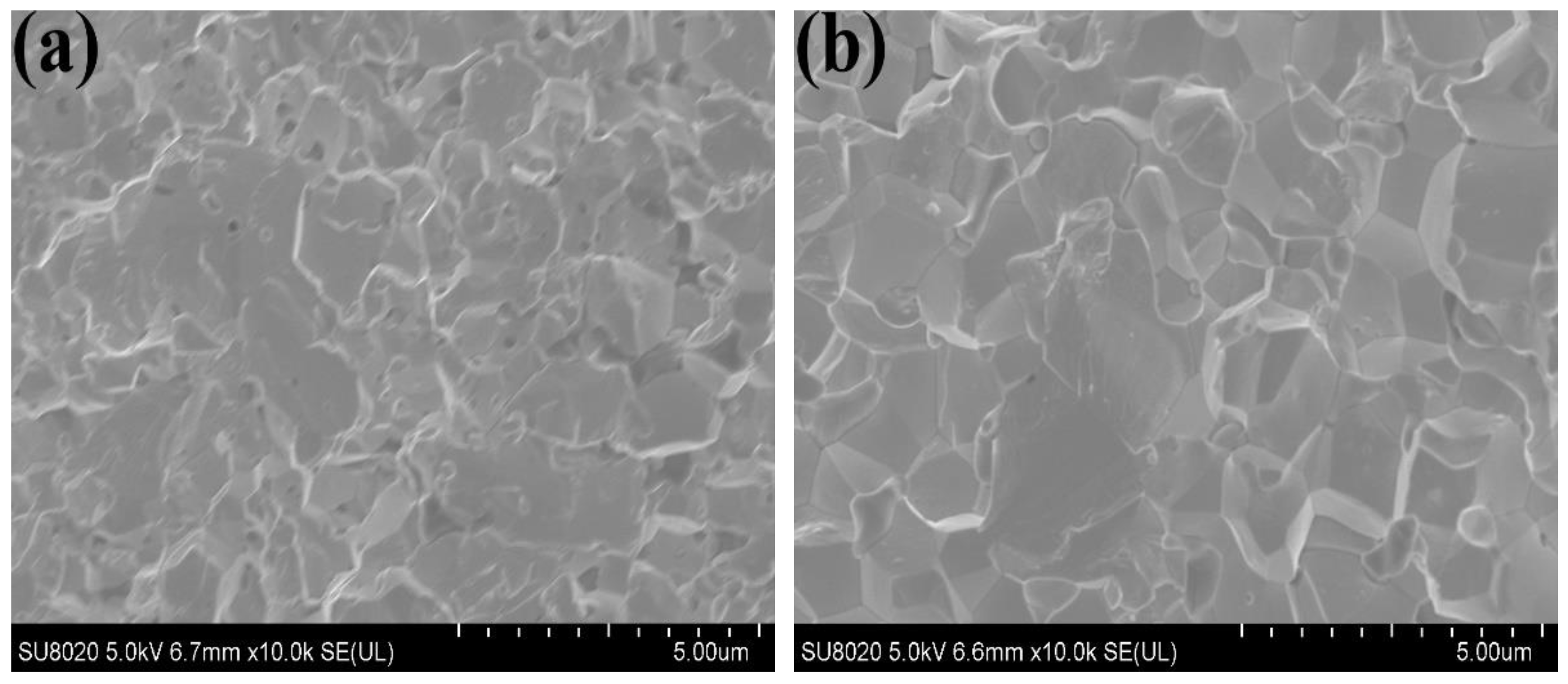

3.1. Synthesized Doped W Powders and SPS Sintered Samples

3.2. Microstructural Evolution under 5 keV He+ Irradiation

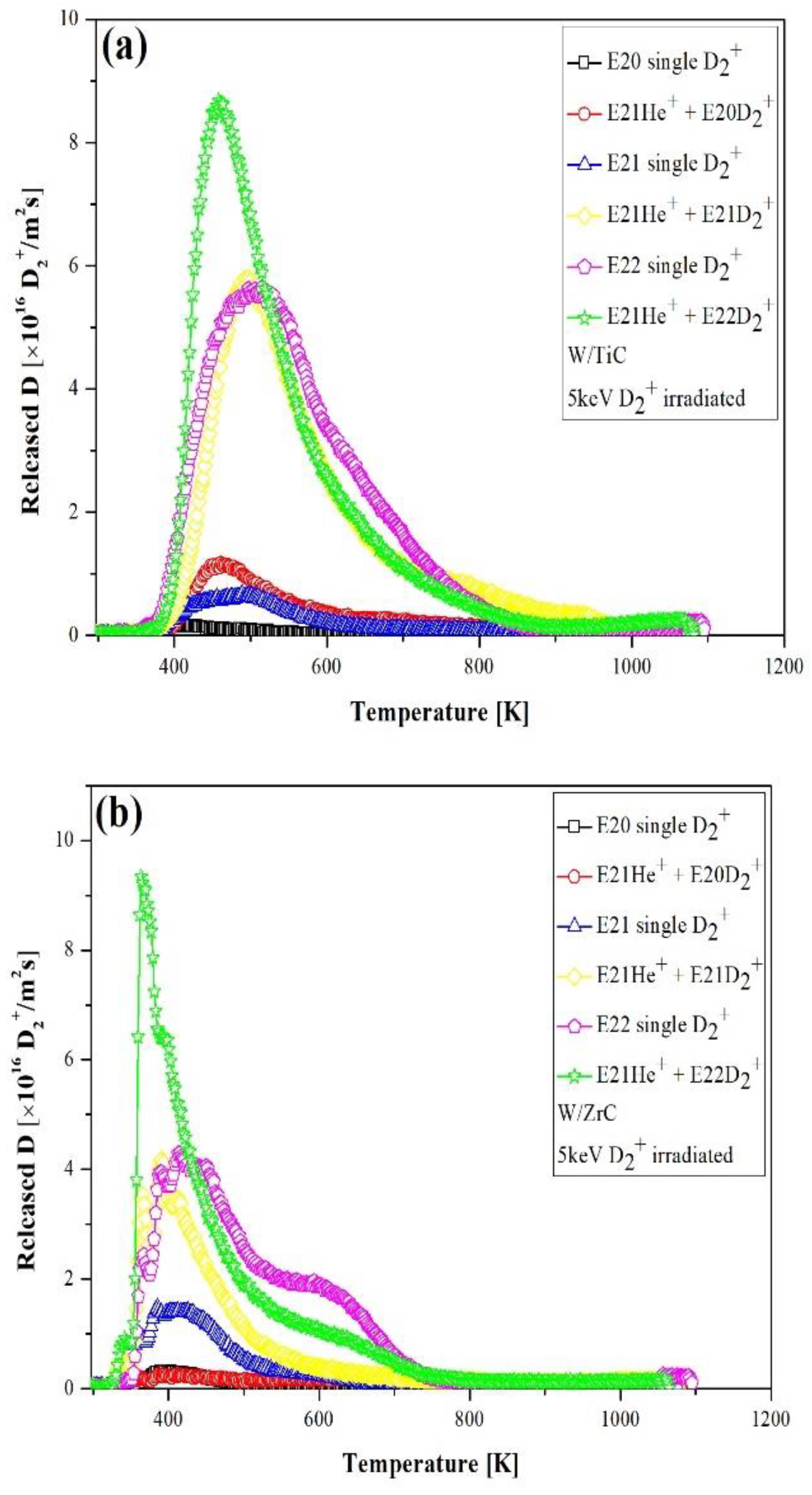

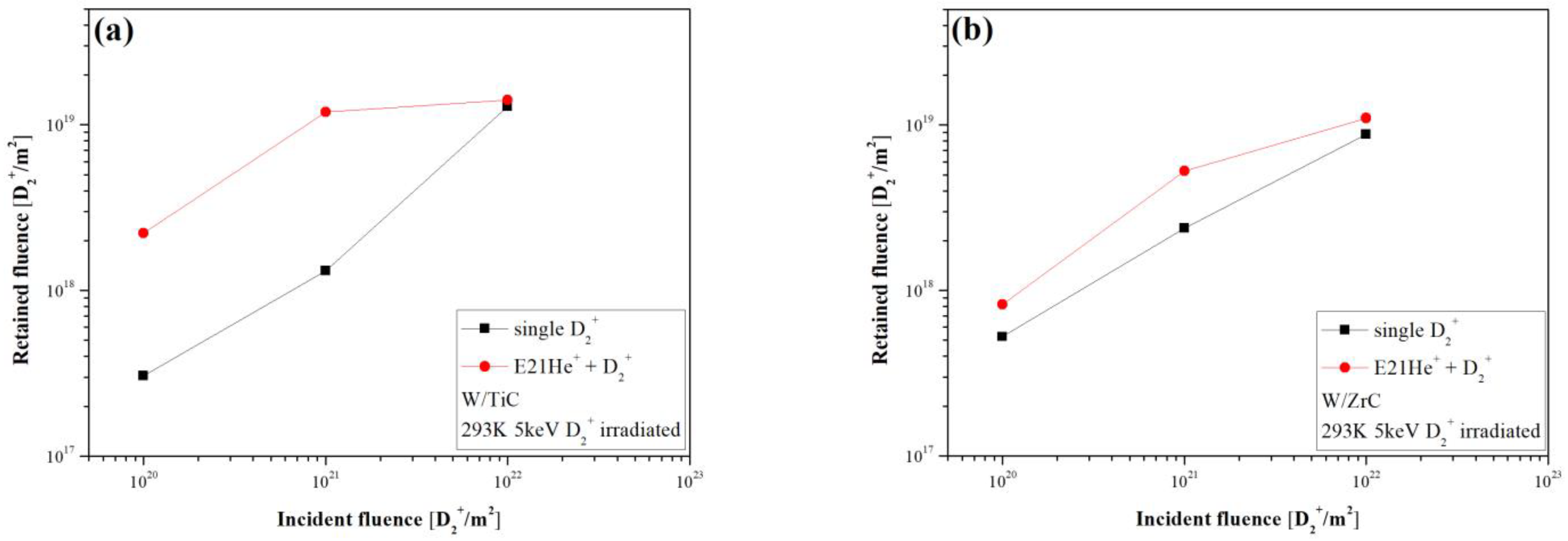

3.3. TDS Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sandoval, L.; Perez, D.; Uberuaga, B.P.; Voter, A.F. Formation of helium-bubble networks in tungsten. Acta Mater. 2018, 159, 46–50. [Google Scholar] [CrossRef]

- El-Atwani, O.; Esquivel, E.; Efe, M.; Aydogan, E.; Wang, Y.Q.; Martinez, E.; Maloy, S.A. Loop and void damage during heavy ion irradiation on nanocrystalline and coarse grained tungsten: Microstructure, effect of dpa rate, temperature, and grain size. Acta Mater. 2018, 149, 206–219. [Google Scholar] [CrossRef]

- Frolov, T.; Zhu, Q.; Oppelstrup, T.; Marian, J.; Rudd, R.E. Structures and transitions in bcc tungsten grain boundaries and their role in the absorption of point defects. Acta Mater. 2018, 159, 123–134. [Google Scholar] [CrossRef]

- Qin, W.J.; Ren, F.; Doerner, R.P.; Wei, G.; Lv, Y.W.; Chang, S.; Tang, M.; Deng, H.Q.; Jiang, C.Z.; Wang, Y.Q. Nanochannel structures in W enhance radiation tolerance. Acta Mater. 2018, 153, 147–155. [Google Scholar] [CrossRef]

- El-Atwani, O.; Gonderman, S.; Efe, M.; De Temmerman, G.; Morgan, T.; Bystrov, K.; Klenosky, D.; Qiu, T.; Allain, J.P. Ultrafine tungsten as a plasma-facing component in fusion devices: Effect of high flux, high fluence low energy helium irradiation. Nucl. Fusion 2014, 54, 083013. [Google Scholar] [CrossRef]

- Zhao, M.; Jacob, W.; Manhard, A.; Gao, L.; Balden, M.; von Toussaint, U.; Zhou, Z. Deuterium implantation into Y2O3-doped and pure tungsten: Deuterium retention and blistering behavior. J. Nucl. Mater. 2017, 487, 75–83. [Google Scholar] [CrossRef]

- Xia, M.; Yan, Q.Z.; Guo, H.Y.; Zhu, L.X.; Ge, C.C. Bulk tungsten with uniformly dispersed La2O3 nanoparticles sintered from co-precipitated La2O3/W nanoparticles. J. Nucl. Mater. 2013, 434, 85–89. [Google Scholar] [CrossRef]

- Xia, M.; Yan, Q.Z.; Xu, L.; Zhu, L.X.; Guo, H.Y.; Ge, C.C. Synthesis of TiC/W core–shell nanoparticles by precipitate-coating process. J. Nucl. Mater. 2012, 430, 216–220. [Google Scholar] [CrossRef]

- Ding, H.L.; Xie, Z.M.; Fang, Q.F.; Zhang, T.; Cheng, Z.J.; Zhuang, Z.; Wang, X.P.; Liu, C.S. Determination of the DBTT of nanoscale ZrC doped W alloys through amplitude-dependent internal friction technique. Mat. Sci. Eng. A 2018, 716, 268–273. [Google Scholar] [CrossRef]

- Wang, Y.K.; Miao, S.; Xie, Z.M.; Liu, R.; Zhang, T.; Fang, Q.F.; Hao, T.; Wang, X.P.; Liu, C.S.; Liu, X.; et al. Thermal stability and mechanical properties of HfC dispersion strengthened W alloys as plasma-facing components in fusion devices. J. Nucl. Mater. 2017, 492, 260–268. [Google Scholar] [CrossRef]

- Tanabe, T. Review of hydrogen retention in tungsten. Phys. Scr. 2014, T159, 014044. [Google Scholar] [CrossRef]

- Arkhipov, I.I.; Kanashenko, S.L.; Sharapov, V.M.; Zalavutdinov, R.K.; Gorodetsky, A.E. Deuterium trapping in ion-damaged tungsten single crystal. J. Nucl. Mater. 2007, 363–365, 1168–1172. [Google Scholar] [CrossRef]

- Iwakiri, H.; Yasunaga, K.; Morishita, K.; Yoshida, N. Microstructure evolution in tungsten during low-energy helium ion irradiation. J. Nucl. Mater. 2000, 283–287, 1134–1138. [Google Scholar] [CrossRef]

- Iwakiri, H.; Morishita, K.; Yoshida, N. Effects of helium bombardment on the deuterium behavior in tungsten. J. Nucl. Mater. 2002, 307–311, 135–138. [Google Scholar] [CrossRef]

- Yi, X.; Jenkins, M.L.; Kirk, M.A.; Zhou, Z.; Roberts, S.G. In-situ TEM studies of 150 keV W+ ion irradiated W and W-alloys: Damage production and microstructural evolution. Acta Mater. 2016, 112, 105–120. [Google Scholar] [CrossRef]

- Xu, Q.; Ding, X.Y.; Luo, L.M.; Miyamoto, M.; Tokitani, M.; Zhang, J.; Wu, Y.C. D2 retention and microstructural evolution during He irradiation in candidate plasma facing material W–La2O3 alloy. J. Nucl. Mater. 2017, 496, 227–233. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Čížek, J.; Lorinčík, J.; Karlík, M.; Callisti, M.; Čech, J.; Havránek, V.; Li, B.; Krsjak, V.; et al. Characterizing heavy ions-irradiated Zr/Nb: Structure and mechanical properties. Mater. Design. 2022, 219, 110732. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Callisti, M.; Vronka, M.; Karlik, M.; Duchon, J.; Čech, J.; Havránek, V.; Polcar, T. Revealing nanoscale strain mechanisms in ion-irradiated multilayers. Acta Mater. 2022, 229, 117807. [Google Scholar] [CrossRef]

- Watanabe, H.; Futagami, N.; Naitou, S.; Yoshida, N. Microstructure and thermal desorption of deuterium in heavy-ion-irradiated pure tungsten. J. Nucl. Mater. 2014, 455, 51–55. [Google Scholar] [CrossRef]

- Roth, J.; Schmid, K. Hydrogen in tungsten as plasma-facing material. Phys. Scr. 2011, T159, 014031. [Google Scholar] [CrossRef]

- Zibrov, M.; Mayer, M.; Markina, E.; Sugiyama, K.; Betzenbichler, M.; Kurishita, H.; Gasparyan, Y.; Ogorodnikova, O.V.; Manhard, A.; Pisarev, A. Deuterium retention in TiC and TaC doped tungsten under low-energy ion irradiation. Phys. Scr. 2014, T159, 14050. [Google Scholar] [CrossRef]

- Lee, H.T.; Haasz, A.A.; Davis, J.W.; Macaulay-Newcombe, R.G.; Whyte, D.G.; Wright, G.M. Hydrogen and helium trapping in tungsten under simultaneous irradiations. J. Nucl. Mater. 2007, 363–365, 898–903. [Google Scholar] [CrossRef]

- Ogorodnikova, O.V.; Roth, J.; Mayer, M. Deuterium retention in tungsten in dependence of the surface conditions. J. Nucl. Mater. 2003, 313–316, 469–477. [Google Scholar] [CrossRef]

- Tian, Z.; Davis, J.W.; Haasz, A.A. Deuterium retention in tungsten at fluences of up to 1026 D+/m2 using D+ ion beams. J. Nucl. Mater. 2010, 399, 101–107. [Google Scholar] [CrossRef]

- Oya, M.; Lee, H.T.; Ohtsuka, Y.; Ueda, Y.; Kurishita, H.; Oyaidzu, M.; Yamanishi, T. Deuterium retention in various toughened, fine-grained recrystallized tungsten materials under different irradiation conditions. Phys. Scripta 2014, T159, 014048. [Google Scholar] [CrossRef]

- Zibrov, M.; Bystrov, K.; Mayer, M.; Morgan, T.W.; Kurishita, H. The high-flux effect on deuterium retention in TiC and TaC doped tungsten at high temperatures. J. Nucl. Mater. 2017, 494, 211–218. [Google Scholar] [CrossRef]

| Sample | Relative Density (%) | Grain Size (μm) | HV200g | Thermal Conductivity at RT (W/m·K) |

|---|---|---|---|---|

| W-1wt%TiC | 98.6 | 3 | 471 | 127 |

| W-1wt%ZrC | 97.2 | 3 | 427 | 110 |

| Sample | Loop-Number Volume Density (Loops/m3) | Mean Dislocation Loop Diameter (nm) |

|---|---|---|

| W-1wt%TiC | 4.1 × 1023 | 2.1 |

| W-1wt%ZrC | 3.0 × 1022 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Fang, J.; Xu, Q.; Zhang, P.; Zhang, H.; Luo, L.; Wu, Y.; Yao, J. Microstructure Evolution and Effect on Deuterium Retention in TiC- and ZrC-Doped Tungsten under He+ Ion Irradiation. Metals 2023, 13, 783. https://doi.org/10.3390/met13040783

Ding X, Fang J, Xu Q, Zhang P, Zhang H, Luo L, Wu Y, Yao J. Microstructure Evolution and Effect on Deuterium Retention in TiC- and ZrC-Doped Tungsten under He+ Ion Irradiation. Metals. 2023; 13(4):783. https://doi.org/10.3390/met13040783

Chicago/Turabian StyleDing, Xiaoyu, Jiahui Fang, Qiu Xu, Panpan Zhang, Haojie Zhang, Laima Luo, Yucheng Wu, and Jianhua Yao. 2023. "Microstructure Evolution and Effect on Deuterium Retention in TiC- and ZrC-Doped Tungsten under He+ Ion Irradiation" Metals 13, no. 4: 783. https://doi.org/10.3390/met13040783

APA StyleDing, X., Fang, J., Xu, Q., Zhang, P., Zhang, H., Luo, L., Wu, Y., & Yao, J. (2023). Microstructure Evolution and Effect on Deuterium Retention in TiC- and ZrC-Doped Tungsten under He+ Ion Irradiation. Metals, 13(4), 783. https://doi.org/10.3390/met13040783