Abstract

The evolution of MC-type primary carbonitrides (M=V, Ti, Mo; C=C, N) in terms of morphology, quantity, size and composition was systematically investigated in commercial H13 die steels with different Ti and N contents during thermal holding at 1250 °C for 5 h to 15 h. Results showed that the mean size and quantity of carbonitrides in the four samples had decreased during thermal holding. However, the mean size and quantity of MC carbonitrides had increased with increasing Ti contents when held at 1250 °C while the addition of N increased the quantity but decreased the sizes of the stable MC carbonitrides. It was concluded that the compact carbonitrides could be decomposed and changed into a fishnet structure when held at 1250 °C, especially in samples #1 and #2 containing lower Ti and N contents. The decomposition mechanism was illustrated considering the changes in Ti and Fe elements in carbonitrides. On the basis of the thermodynamic model, the thermal stability of (Tix,V1−x)(Cy,N1−y), with a larger x value, in samples #3 and #4 containing more Ti and N contents was generally higher than those in samples #1 and #2. To control the Ti-containing MC carbonitrides, the low Ti and N contents and high holding temperature should be taken into consideration.

1. Introduction

AISI H13, a hot-work die steel, is widely used in die casting, extrusion, and hot forging, where H13 inevitably suffers from mechanical stress and thermal shock [1]. Large primary carbonitrides are precipitated for interdendritic segregation during the solidification process [2,3]. Extensive research has been conducted, showing that alloying elements such as Ti [2], Nb [3], and Mg [4], and rare-earth metals [5,6,7], could affect the precipitation and characteristics of carbonitrides in H13, in addition to the cooling rate and axial static magnetic field during the solidification process [8,9]. There are mainly two kinds of MC precipitates in H13, including V-rich and Ti-containing carbonitrides [2,10,11]. The precipitation temperature of Ti-containing MC precipitates can be significantly enhanced by increasing the concentration of Ti in H13. Those precipitates can also act as the heterogeneous core of V-rich MC carbonitrides and influence the characteristics of MC carbonitrides in commercial H13 [2,10]. The quantities and sizes of precipitates increase as the Ti content increases from 0.011 wt% to 0.036 wt% in lab-scale H13 steel [10].

It has been well known that the formation of small Ti-containing precipitates could refine the structure by pinning the boundary against grain coarsening and acting as nucleation sites of ferrite [12,13]. Many reports have shown that the mechanical properties and thermal fatigue life of hot-work die steels are directly influenced by the fine nano-sized precipitates [14,15], of which the characteristics could be improved through heat treatments [16,17,18]. Nevertheless, the large and stable primary precipitates would severely deteriorate the toughness of H13 steel [2,19] and have an adverse effect on the precipitation of fine nano-sized precipitates [20] and performance of the steel. As a main type of primary carbonitrides in H13 steel, the large Ti-containing MC carbonitride with sharp corners and high hardness is much more stable than the V-rich MC carbonitride at a high temperature [5,21,22]. The MC primary carbonitrides are considered to be controlled by Ti contents [2,10,11] and the cooling process during solidification [9]. Nevertheless, prohibiting the precipitation of carbonitrides may be quite difficult concerning the industrial practices involving H13 steel. Homogenization treatment is an effective way widely used to alleviate and eliminate the segregation and primary carbonitrides in H13 [5,14,15,21]. As reported previously [22], the carbonitrides undergo shrinking, passivation, fragmentation, and dissolution during isothermal holding from 1150 °C to 1230 °C. Thus, the sizes and quantities of precipitates are remarkably declined, and the composition is progressively changed after holding from 1150 °C to 1250 °C [21,22].

The primary carbides in H13 steel can be broken and partially dissolved in a matrix after hot forging between 950 °C and 1050 °C [23], but there are still many V-rich MC-type primary carbides larger than 20 um. Thermodynamic shows that V-rich carbides are completely dissolved while the Ti-V-rich ones are still stable when held at 1250 °C in H13 [5]. The 3D morphology of primary carbides shows no evident changes when held at 1150 °C and 1200 °C, while obvious dissolution occurs at 1250 °C and the morphology changes from dendritic to flake-type with an increasing holding temperature [5,24]. There still exists a certain quantity of V-rich MC carbides, even held for 20 h at 1200 °C [25], and no carbonitrides remain after 6 h when held at 1250 °C in lab-scale H13 ingots [26]. Hence, we are convinced that the evolution and thermal stability of primary carbides in H13 are influenced by holding temperature and time [24,25]. Additionally, research shows that Si can inhibit the diffusion of C and affect the characteristics and evolution of nano-sized carbides, thus improving the thermal stability of hot-work die steel [27]. By decreasing the thermal stability of large MC precipitates during thermal exposure, the stress-rupture life of alloys can be improved [28]. For H13 die steel, it is expected that decreasing the thermal stability of primary carbonitrides will contribute to reducing the large primary carbonitrides and enhancing the toughness [2,19] and service life of H13 steel.

Recently, researchers have been interested in the influences of different Ti contents on the characteristics of carbonitrides in H13 [2,10,11]. Some studies have been carried out on the evolution of MC precipitates [14,15,19] in H13 at high temperature. However, there are still no reports on the influence of Ti on the evolution of primary carbonitrides during isothermal holding in H13. And this is critical for improving primary carbonitrides and determining the properties of H13 steel. In this paper, the effects of Ti and N contents in H13 on the characteristic evolution and thermal stability of Ti-containing MC carbonitrides held at 1250 °C are clarified in detail, based on the investigations of optical microscope, electron microprobe analyzer, and thermodynamic analyses. The results herein provide relevant information for further controlling the carbonitrides in H13 during homogenization.

2. Materials and Methods

The samples with different Ti and N contents were obtained from the industrial H13 steels, produced via the EAF (electric arc furnace)-LF (ladle furnace)-VD (vacuum degassing)-IC (ingot casting)-ESR (electroslag remelting) process followed by a hot forging and annealing process. The molten steel tapped from EAF was refined through LF treatment, and deoxidizing agent and ferroalloy were added to control the element contents. After slagging off, the liquid steel was treated in VD process under pressure smaller than 67 Pa for more than 15 min to reduce the gas contents and then was poured into the mold with argon protective atmosphere. The casting ingot was subsequently refined using ESR to reduce the segregation and non-metallic inclusion. Finally, the steel was forged at between 1180 °C and 1230 °C with forging ratio 10 and then annealed at 880 °C. The main chemical composition was detected using an NCS LabSpark-1000 spark-optical emission spectrometer. NCS Plasma-1000 inductively coupled plasma-atomic emission spectrometry (ICP–AES) was utilized to determine the soluble Ti content. The inert gas-fusion thermal conductivity method was employed for the testing of the total nitrogen content using an NCS ONH-3000 gas analyzer. The compositions of the four commercial H13 samples marked #1, #2, #3, and #4 were measured and are listed in Table 1. It is clear that there are different Ti contents among samples #1, #2, and #4 and different N contents between samples #2 and #3.

Table 1.

Chemical composition of commercial H13 steel samples, wt.%.

The samples with dimensions of 30 mm × 30 mm × 20 mm were taken from the centers of the steels with severe carbonitride segregation [2]. Then, the samples were heated in the electric resistance furnace at a heating rate of 300 °C/h. And samples #1, #3, and #4 were held at 1250 °C for 5 h, 10 h, and 15 h while sample #2 was held at 1250 °C for 10 h and 15 h followed by oil cooling immediately. Then, the samples were cut using a wire-electrode cutting machine and ground using a grinding wheel to avoid the negative effects of the oxidation layer and decarbonization layer for micro-observations. Subsequently, the samples with dimensions of 15 mm × 15 mm × 10 mm were ground using SiC paper, mechanically polished with diamond paste, and etched via 5 pct volume fraction nital. The morphology, quantities, and sizes of primary carbonitrides were determined using an Olympus GX51 optical microscope (OM; Olympus Corporation, Tokyo, Japan). A JXA-8530F field-emission electron microprobe analyzer (EMPA; Japan Electron Optics Ltd., Tokyo, Japan) in combination with the wavelength dispersive spectrometer (WDS) was utilized to analyze the alloying elemental distribution and characteristics of primary carbonitrides.

3. Results

3.1. Morphology Evolution of Carbonitrides during Holding at 1250 °C

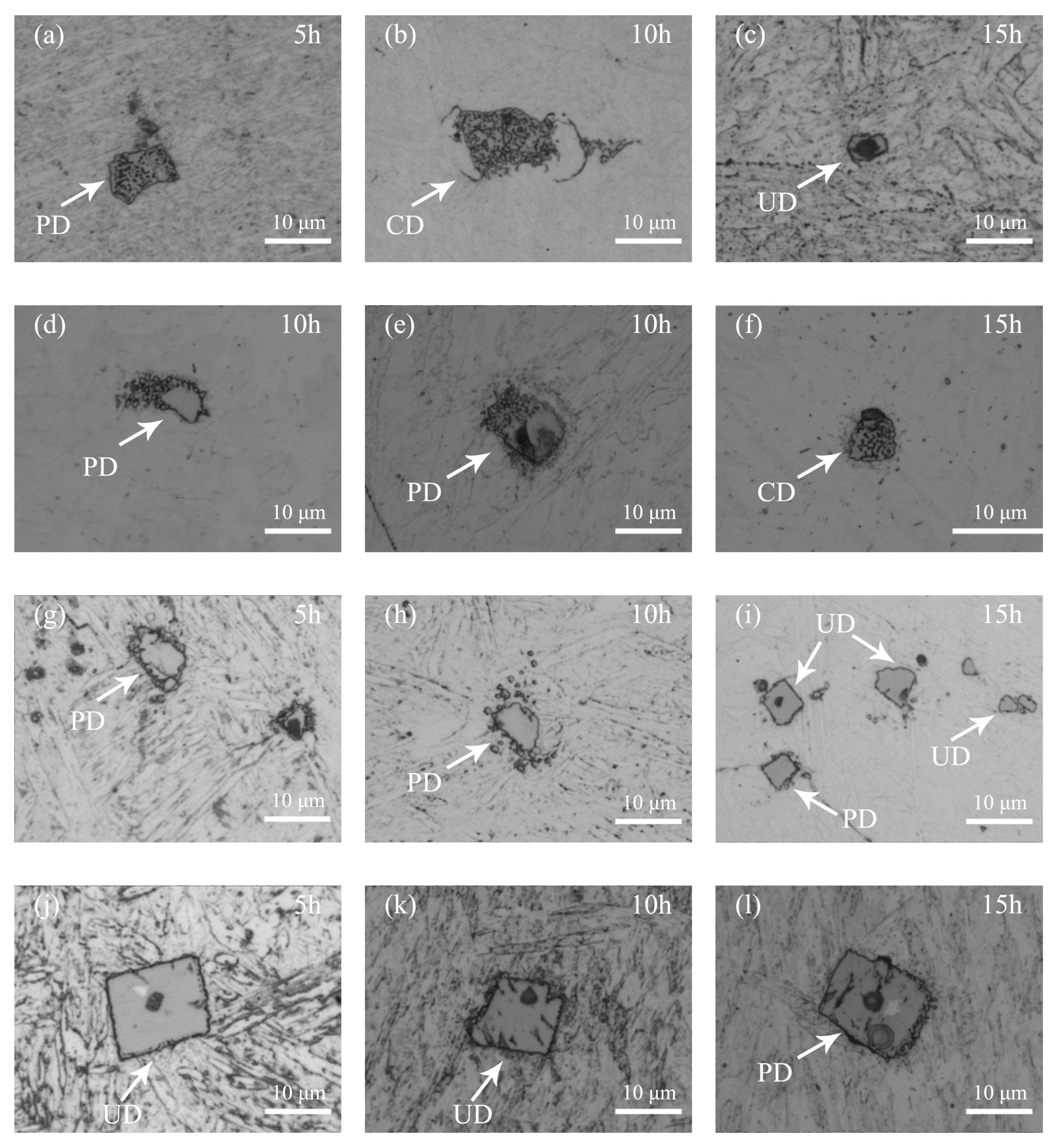

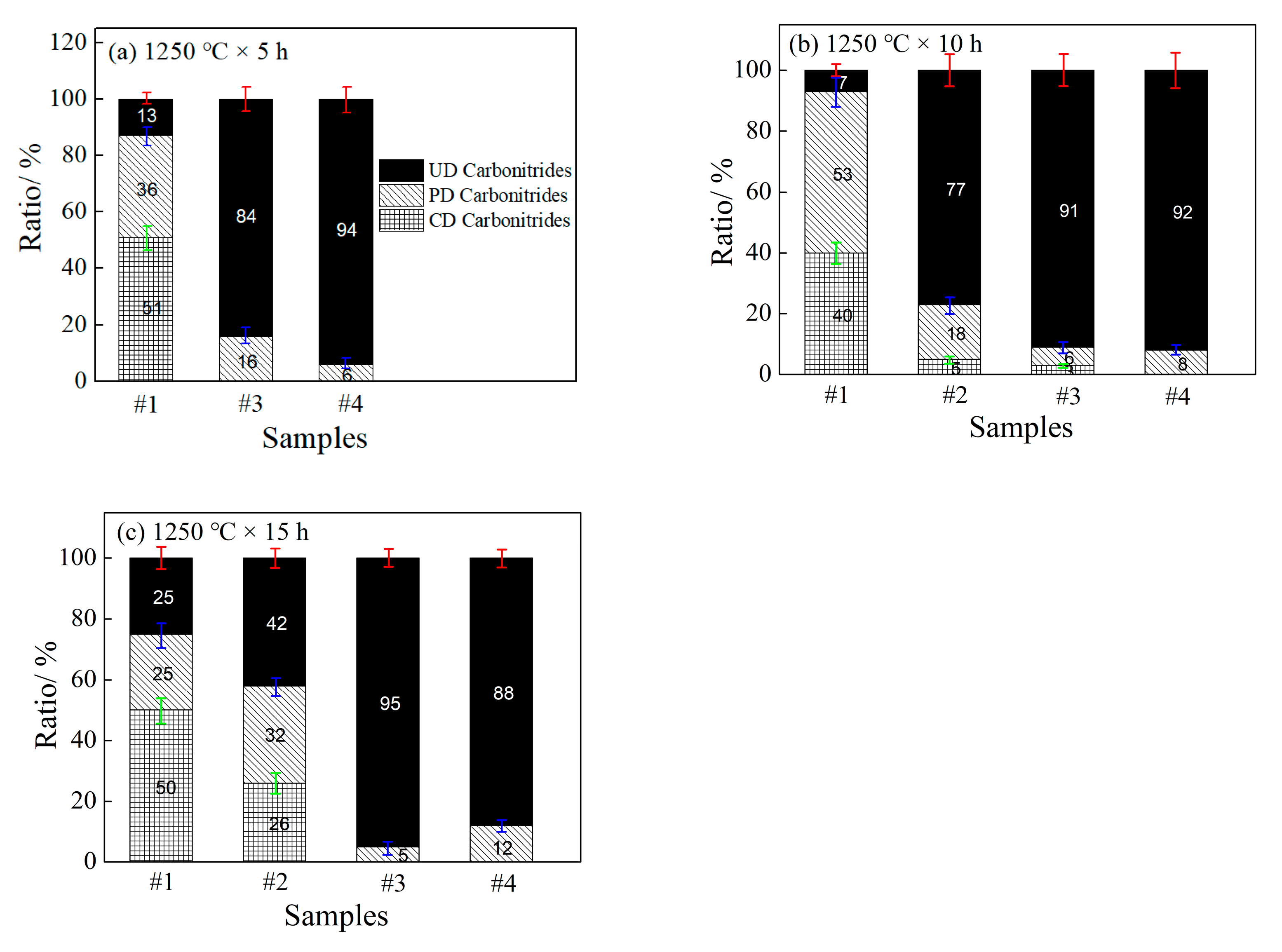

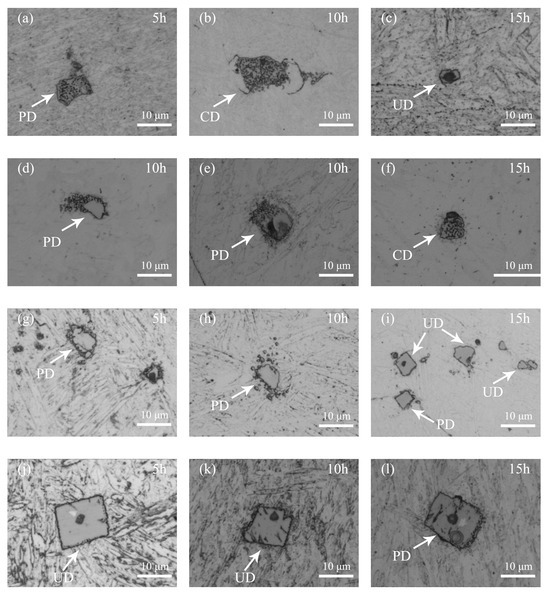

There are many large and compact carbonitrides in H13 steels, which could be influenced by Ti content [2]. A proportion of carbonitrides in the samples had gradually decomposed [21,29] at 1250 °C, as shown in Figure 1. Based on the morphology evolution, the carbonitrides holding at 1250 °C were roughly classified into three categories: undecomposed carbonitrides in Figure 1c,i–k, partly decomposed carbonitrides in Figure 1a,d–e,g–h,l, and completely decomposed carbonitrides like the fishnet in Figure 1b,f. These were marked as ‘UD’ (undecomposed and retaining the completely compact blocky carbonitrides without small particles generated around them), ‘PD’ (partly decomposed carbonitrides with small particles generated and retaining compact carbonitrides larger than 3 μm), and ‘CD’ (completely decomposed into small particles without compact blocky carbonitrides larger than 3 μm), respectively. The carbonitrides of different categories when held at 1250 °C are quantitatively counted in Figure 2, according to the carbonitride morphology observed using OM in an area of 4.7 mm2.

Figure 1.

Morphology of MC primary carbonitrides in samples when held at 1250 °C: (a–c) in sample #1, (d–f) in sample #2, (g–i) in sample #3, and (j–l) in sample #4.

Figure 2.

Ratios of the three kinds of carbonitrides held at 1250 °C in samples.

The evolution of primary carbonitrides holding at 1250 °C in H13 can be expressed as follows: (1) being firstly jagged and initially decomposed at the edge in Figure 1g,l; (2) being gradually decomposed inward like the fishnet in Figure 1a,e; (3) being granulated with small particles, as generated in Figure 1b,d; and (4) being finally dissolved. As shown in Figure 1a,b,d–f, the compact carbonitrides in original H13 steels progressively evolve into the fishnet structure from the edge to the center after holding at 1250 °C.

It has been reported that the long strips (Vx,Mo1−x)(Cy,N1−y) are completely dissolved in the matrix due to the relatively low equilibrium temperature, and only (Tix,V1−x)(Cy,N1−y) strips are retained, as described in previous research [21]. In sample #1, the carbonitrides decomposed notably, as in Figure 1a, and 87% of MC carbonitrides decomposed when held for 5 h, as shown in Figure 2a. And Figure 2a shows that the ‘CD’ carbonitrides in Figure 1b account for 53%, with the ‘UD’ ones accounting for only 7% when held for 10 h. There were still 25% of ‘UD’ carbonitrides, shown in Figure 1c, when holding for 15 h. The decrease in total number in Figure 3 may be responsible for the increased ratio of ‘UD’ carbonitrides holding for 15 h compared with that holding for 10 h.

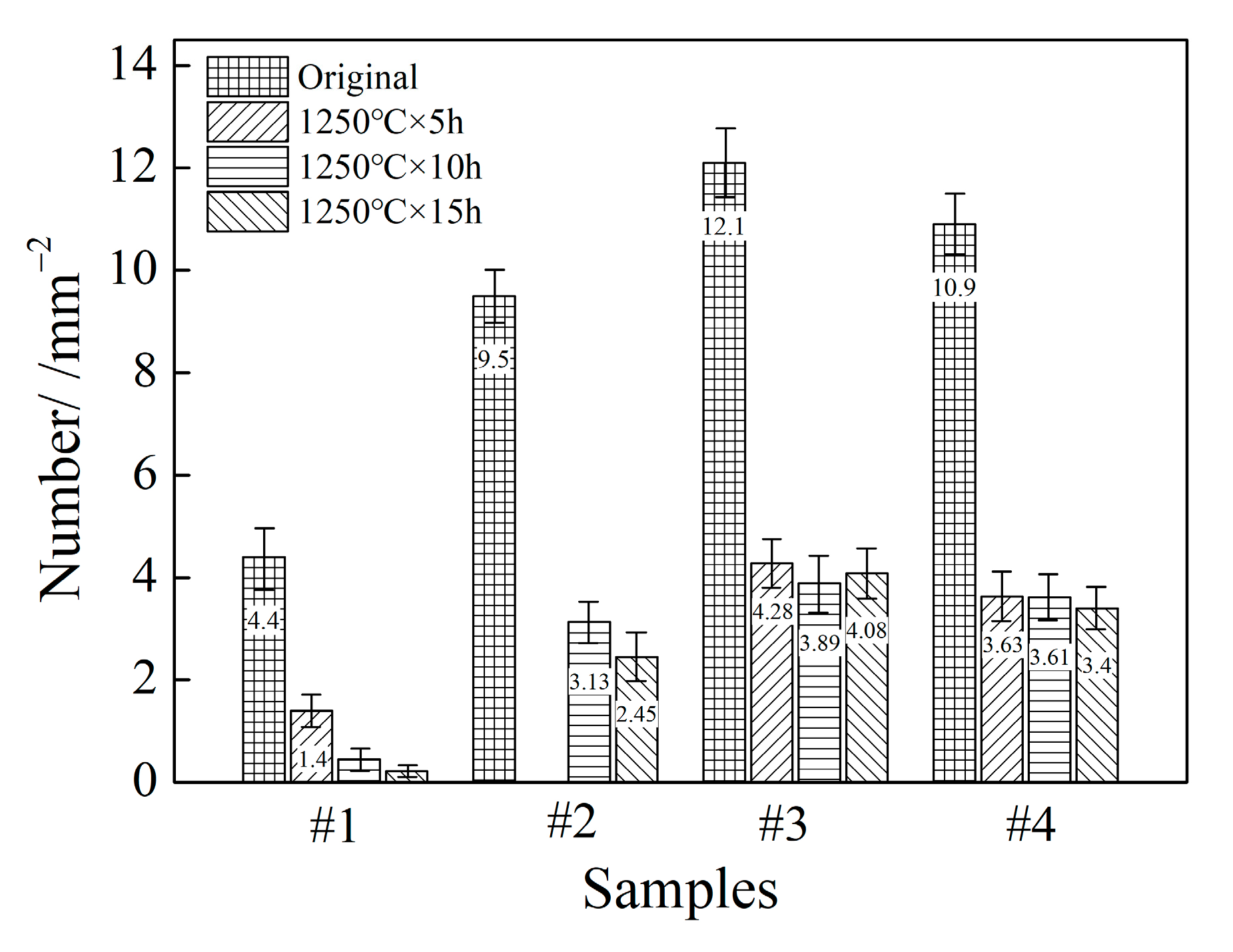

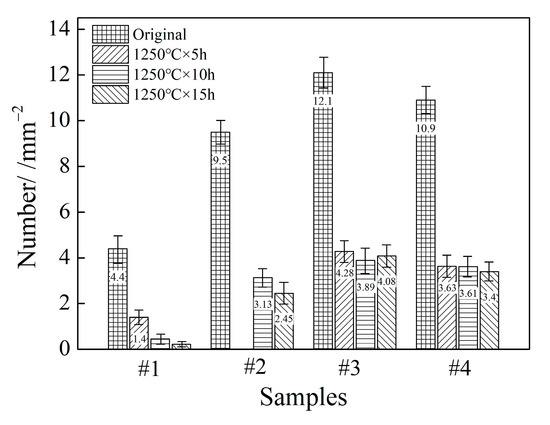

Figure 3.

The variation in number of carbonitrides in the samples held at 1250 °C.

There was a lower decomposition trend observed in sample #2 compared with that in sample #1. The ‘UD’ carbonitrides constituted 77% of the total quantity, even holding at 1250 °C for 10 h in sample #2, and the ‘PD’ carbonitrides shown in Figure 1d only accounted for 18% in terms of their number. When holding for 15 h, the number fractions of ‘PD’ carbonitrides and ‘CD’ carbonitrides just increased to 32% and 26%, respectively.

Figure 1g–i demonstrate that the decomposition tendency persistently declined as the N content increased in sample #3, which contained almost the same Ti content as sample #2. Only some small particles are observed at the original edges of carbonitrides in Figure 1g,h. Statistical results show that fewer than 10% of carbonitrides decomposed when holding for 10 h, nearly one-third of the percentage in sample #2, as shown in Figure 2b. When holding for 15 h, the ‘UD’ carbonitrides accounted for 95%, as shown in Figure 2c, indicating that more N content improved the thermal stability of carbonitrides at 1250 °C compared with that in sample #2.

It is considered that the decomposition of the carbonitrides in sample #4 was really difficult as only the edge became jagged without inner decomposition, as shown in Figure 1j–l. The ratio of ‘UD’ carbonitrides was up to 88% even after holding for 15 h. And it seems that the morphology of the carbonitrides holding at 1250 °C changed inconspicuously in sample #4 with the most Ti content in steel.

The decomposition of carbonitrides becomes difficult in H13 as the Ti and N contents increase and more carbonitrides are retained.

3.2. Change in Quantities of Carbonitrides during Holding at 1250 °C

The quantities of carbonitrides in the original four samples were determined through deep etching, as shown in our previous research [2]. And the selected total area, 4.9 mm2, in magnification ×50 using OM, is applied for the statistical number of carbonitrides. Statistical results show that the average quantities in the four original samples were 4.4/mm2 [2], 9.5/mm2 [2], 12.1/mm2, and 10.9/mm2. The quantities of the carbonitrides were analyzed using OM with a total area of about 4.7 mm2, in magnification ×200, to observe the small size and small quantities of decomposed carbonitrides when held at 1250 °C. After holding for 5 h at 1250 °C, the quantities of the carbonitrides, as shown in Figure 3, evidently decreased to 1.4/mm2, 4.28/mm2, and 3.63/mm2 in samples #1, #3, and #4, respectively. Clearly, the quantities of carbonitrides continuously decreased in samples #1 and #2 after holding for 10 h and 15 h, but the changes were not obvious in samples #3 and #4. The quantities of carbonitrides decreased by 95%, 74%, 66%, and 69% in the four samples when held for 15 h compared with those in the original samples. There still existed many carbonitrides even holding for 15 h in sample #3, with the largest product of Ti and N content, while the fewest carbonitrides were in sample #1 with the smallest product. The quantities of carbonitrides are directly related to the original Ti and N contents in H13 when held at 1250 °C, that is, fewer carbonitrides during thermal holding can remain with both lower Ti and N contents.

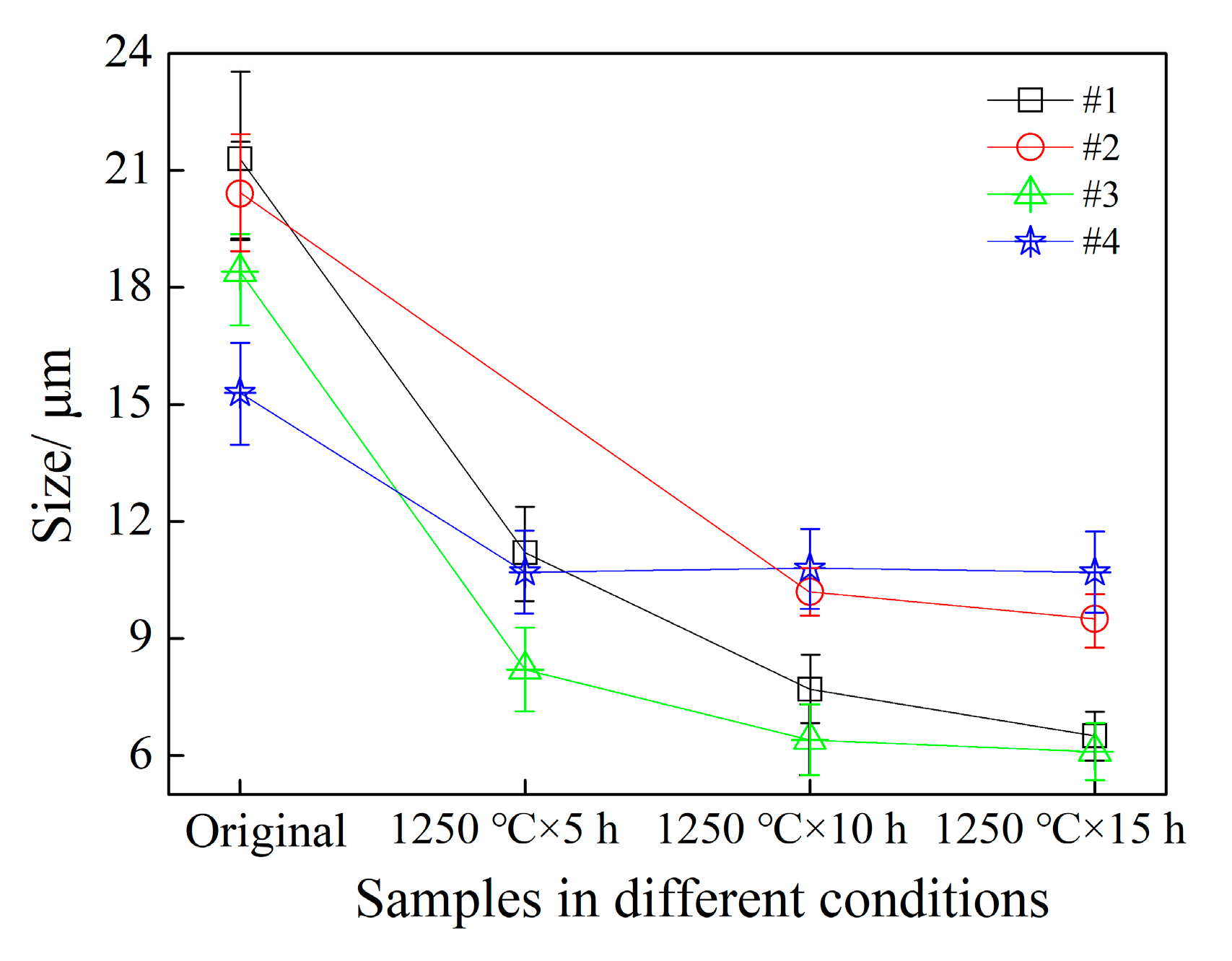

3.3. Changes in Size of Carbonitrides during Holding at 1250 °C

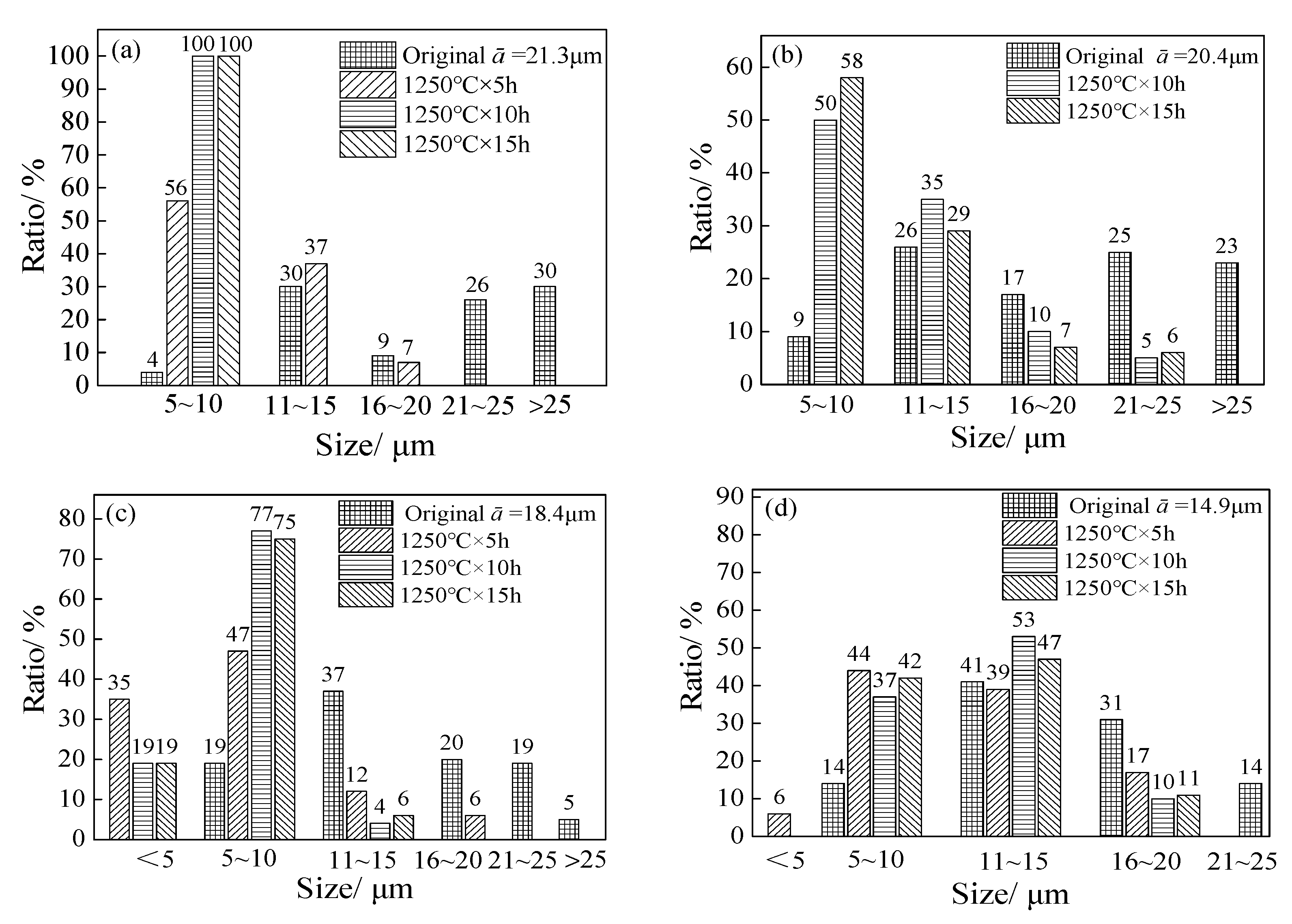

As expected, the sizes of carbonitrides decreased after holding at 1250 °C because the carbonitrides gradually decomposed and dissolved into the matrix. Statistical results show that the mean sizes were 11.2 μm after holding at 1250 °C for 5 h and 6.5 μm for 15 h, as shown in Figure 4a, having significantly decreased from the original size of 21.3 μm in sample #1 [21]. Figure 4b shows that the average size of carbonitrides in the original sample #2 was 20.4 μm and then decreased to 10.2 μm after holding at 1250 °C for 10 h. Meanwhile, the number fraction of carbonitrides larger than 20 μm decreased to 5% from 48% in the original sample #2, which mainly comprised the long strip (Vx,Mo1−x)(Cy,N1−y) with the theoretically decomposed temperature [21] being far less than 1250 °C. After holding for 15 h, the mean size reduced further to 9.3 μm, with 58% of carbonitrides being smaller than 10 μm.

Figure 4.

Change in size of carbonitrides holding at 1250 °C: samples (a) #1 [21], (b) #2, (c) #3 [29], and (d) #4.

According to statistics, the mean sizes of carbonitrides in original samples #3 and #4 were 18.4 μm and 14.9 μm, respectively. The strip carbonitrides larger than 20 μm in the two samples dissolved into steel when held at 1250 °C for 5 h [21,29], and the mean sizes declined to 8.2 μm and 10.7 μm, respectively, as shown in Figure 4c,d. More than 90% of carbonitrides in sample #3 and 42% of carbonitrides in sample #4 were smaller than 10 μm after holding for 15 h, and their mean sizes changed indistinctively to 6.1 μm and 10.6 μm, respectively. It is speculated that the decomposition of (Tix,V1−x)(Cy,N1−y) in sample #4 was not preferable due to the mean size of carbonitrides having changed little when held at 1250 °C for more than 10 h.

3.4. Change in Composition of Carbonitrides during Holding at 1250 °C

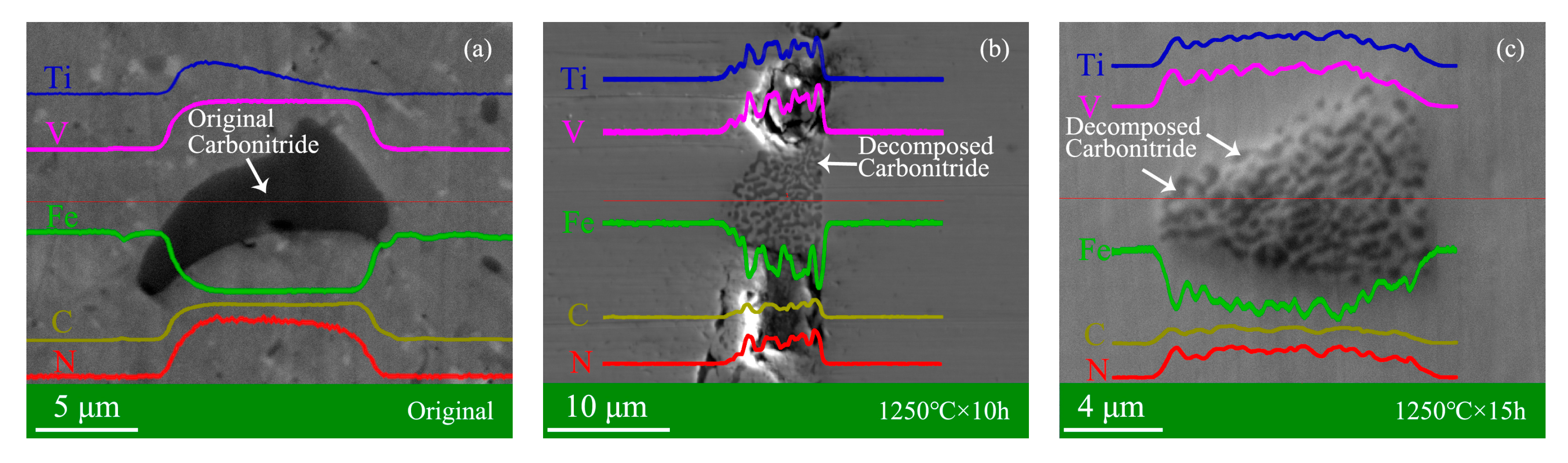

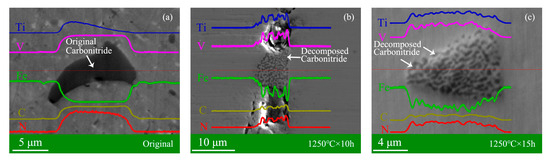

It has been reported that the composition of carbonitrides has significant effects on the balance decomposition temperature [21] and that the constituent of (Tix,V1−x)(Cy,N1−y) can be affected by the Ti content [2]. The composition evolution of carbonitrides in sample #1 has been characterized in our former work [21]. It is expected that the strip MC carbonitrides, (Vx,Mo1−x)(Cy,N1−y), would be completely undiscovered when held at 1250 °C for 5 h in samples #2 to #4, in agreement with our previous research [21]. The typical compositions of (Tix,V1−x)(Cy,N1−y) in the other three samples holding at 1250 °C are shown below in Figure 5.

Figure 5.

The composition of carbonitrides in the samples held at 1250 °C: (a–c) sample #2; (d–f) sample #3 [29]; (g,h) sample #4.

There were mainly square (Tix,V1−x)(Cy,N1−y) with x 0.26−0.57 and y 0.09−0.32 and having less than 4 wt % Fe in original sample #2. Figure 5a shows an irregular carbonitride expressed as (Ti0.03,V0.97)(C0.60,N0.40) with high Ti content in the center. When held for 10 h, some carbonitrides in Figure 5b decomposed and changed into fishnet structures comprising small particles approximately 0.1−1 μm in size. The chemical compositions of the fine decomposed carbonitrides were 15−25 wt% Ti, 15−45 wt% V, 0.6−2.4 wt% C, 8−16 wt% N, and 18−35 wt% Fe, respectively. There were great differences in the Ti and V contents between the decomposed carbonitrides and original carbonitrides. The formula of the decomposed carbonitrides can be expressed as (Ti0.27,V0.38,Fe0.35)(C0.12,N0.88) in Figure 5b and (Ti0.27,V0.28,Fe0.45)(C0.06,N0.94) in Figure 5c, based on the determination via EMPA.

For original sample #3, the carbonitride expressed as (Ti0.56,V0.44)(C0.06,N0.94) with an oxide core in the center is shown in Figure 5d [29]. There was less than 5 wt% Fe in the original carbonitrides such as (Ti0.37,V0.63)(C0.08,N0.92) in Figure 5e and (Ti0.43,V0.57)(C0.04,N0.96) in Figure 5f [29]. Only a few carbonitrides became edge-jagged and decomposed during holding at 1250 °C in sample #3. In case of the fine decomposed carbonitrides in Figure 5e,f, there was more than 24 wt% Fe in the decomposed carbonitrides, which can be expressed as (Ti0.13,V0.49,Fe0.45)(C0.18,N0.82) and (Ti0.20,V0.48,Fe0.32)(C0.06,N0.94), respectively. However, most of the (Tix,V1−x)(Cy,N1−y) in sample #3 was not likely to decompose as previously mentioned in Figure 2. Through determination via EMPA, the x value in (Tix,V1−x)(Cy,N1−y) ranged mainly between 0.41 and 0.57 but the y value was generally smaller than 0.10.

Sample #4 exhibited the highest Ti content (0.0127 wt%) of the four samples, and it may be beneficial for the precipitation of (Tix,V1−x)(Cy,N1−y) and increasing the x value [2]. According to the determination via EMPA, the x value ranged mainly from 0.50 to 0.70. Figure 5g shows an original carbonitride expressed as (Ti0.67,V0.33)(C0.10,N0.90), in which the contents of Ti and Fe are 44 wt% and 3 wt%, respectively. After holding at 1250 °C, only a relatively small proportion of carbonitrides were decomposed, as shown in Figure 2. A ‘UD’ carbonitride is shown in Figure 5h after holding for 10 h, and it is expressed as (Ti0.72,V0.28)(C0.09,N0.91) with 45 wt% Ti and less than 4 wt% Fe. The composition of most of the (Tix,V1−x)(Cy,N1−y) changed indistinctively in sample #4.

On the basis of EMPA analysis, the elements in the decomposed carbonitrides, especially Ti and Fe, changed significantly during thermal holding. It is concluded that more Fe was contained in the decomposed carbonitrides compared with the original carbonitrides, and the diffusion of Fe to the carbonitrides from the matrix is critical for the decomposition of carbonitrides.

4. Discussion

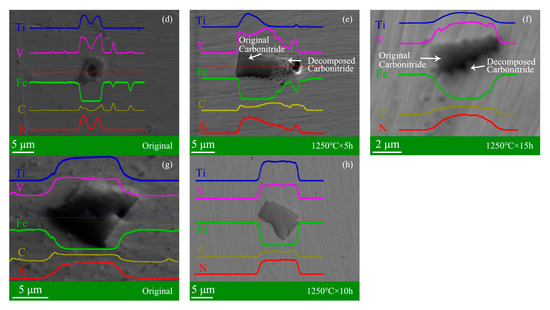

4.1. Difference in Carbonitride Composition Holding at 1250 °C

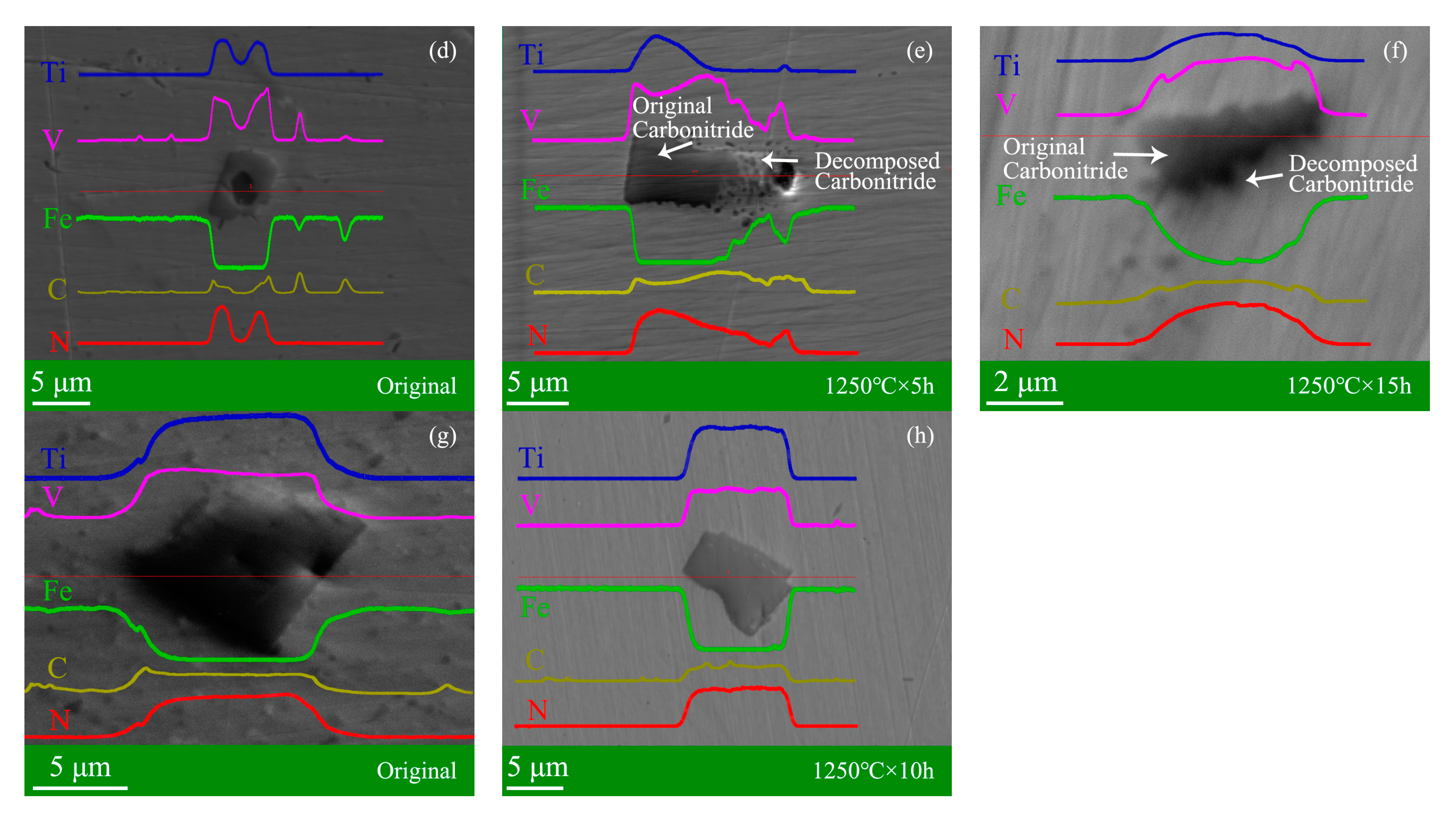

On the basis of EMPA determination, the x values and y values calculated in the original (Tix,V1−x)(Cy,N1−y) of the four samples were 0.04−0.54 and 0.15−0.69, 0.26−0.57 and 0.09−0.32, 0.25−0.57 and 0.06−0.31, and 0.50−0.70 and 0.05−0.15. The y value is decreased and the x value is increased with an increase in the Ti content in H13 steels [2], as shown in Figure 6.

Figure 6.

Relationship between x value and y value in (Tix,V1−x)(Cy,N1−y).

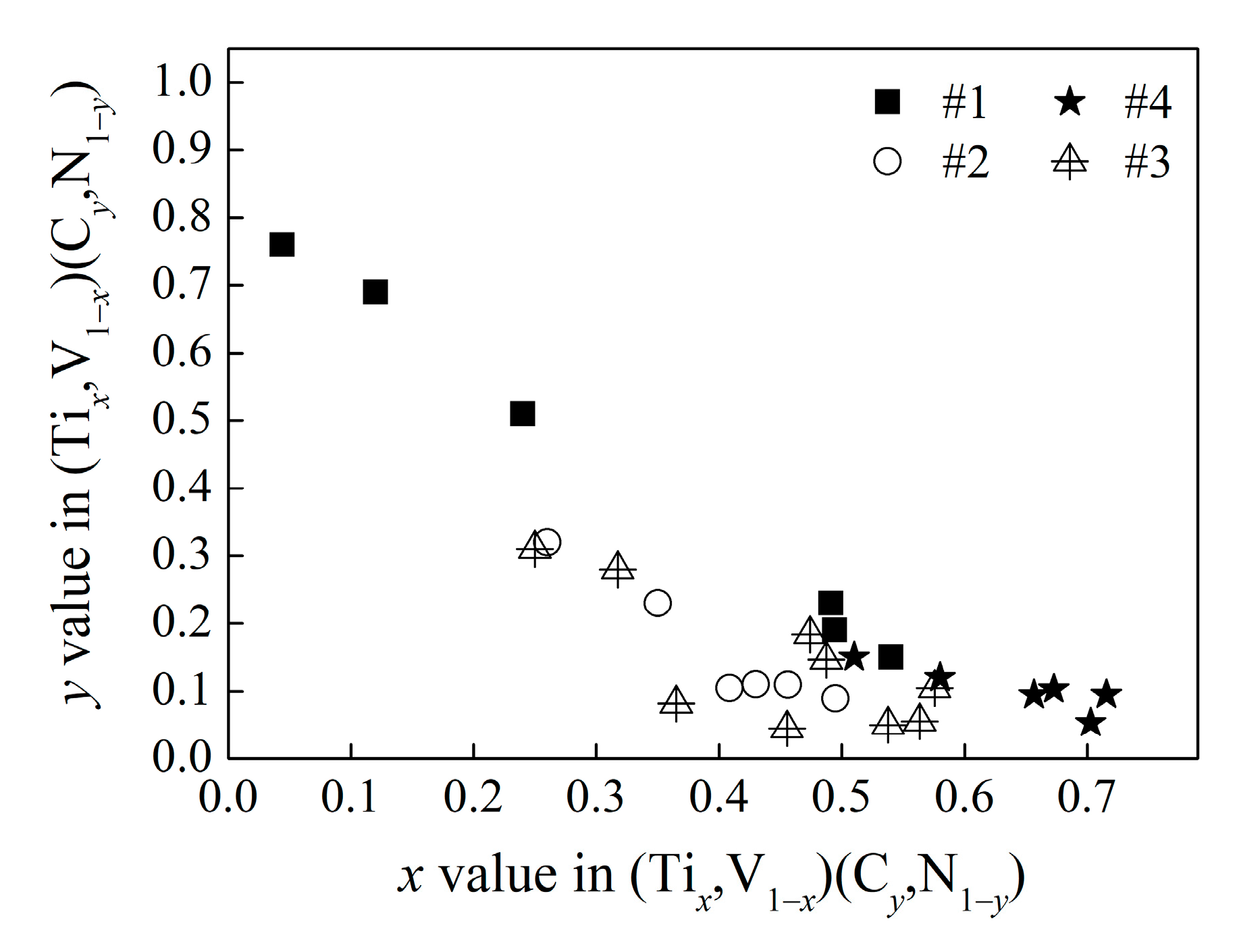

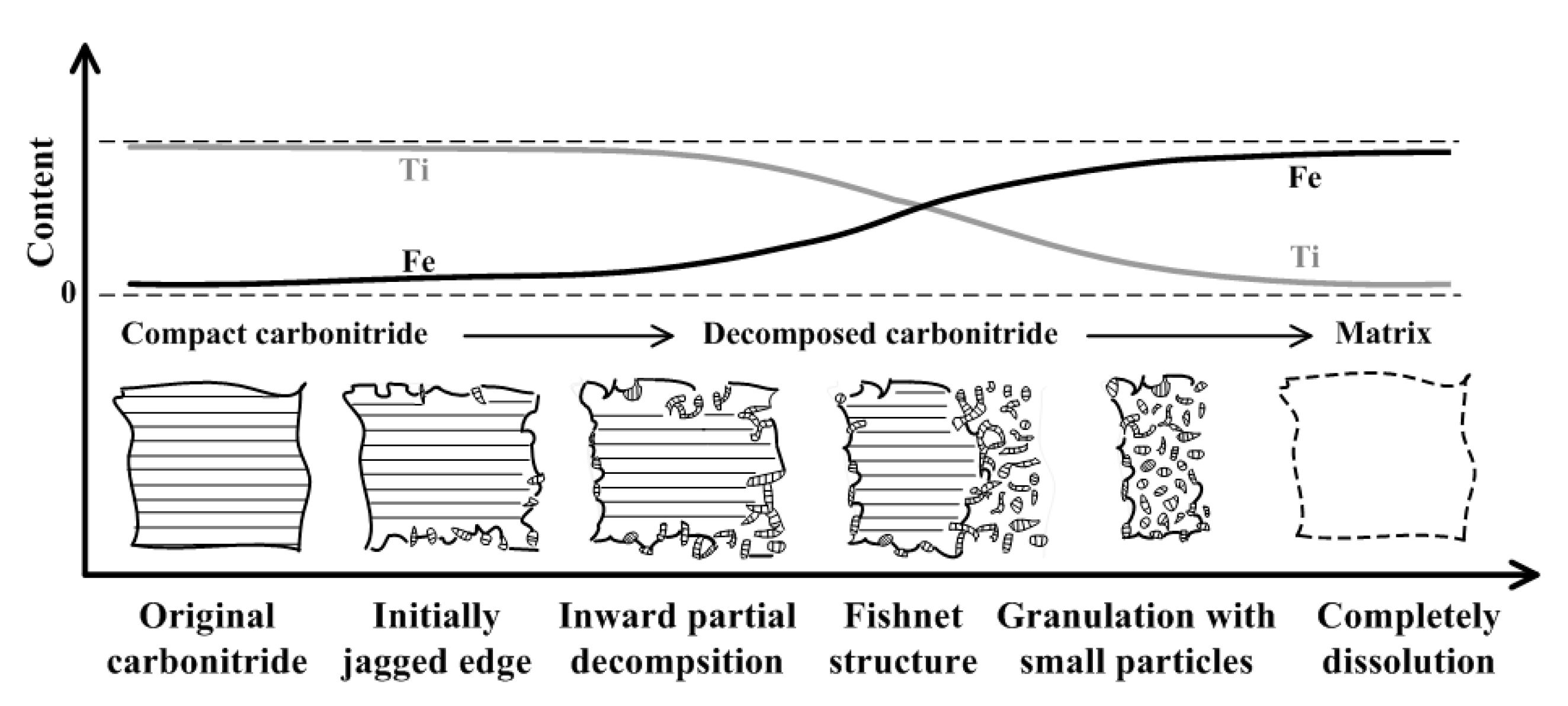

The constituent evolution of (Tix,V1−x)(Cy,N1−y) during holding at 1250 °C is shown in Figure 7. It is explicit that the Fe content in Ti-containing MC carbonitrides increases, while Ti and V decrease gradually, when (Tix,V1−x)(Cy,N1−y) decomposes at 1250 °C. The mole fraction of Fe in the Ti-containing MC carbonitrides, i.e., xFe = nFe/(nTi + nV + nFe), was less than 0.05 in the original (Tix,V1−x)(Cy,N1−y). However, xFe was generally larger than 0.25 when the carbonitrides decomposed in samples #1 and #2, as shown in Figure 7. The decomposition mechanism of the carbonitride is demonstrated by the schematic diagram in Figure 8. It shows that (Tix,V1−x)(Cy,N1−y) will be progressively transformed into (Tix,Vz,Fe1−x−z)(Cy,N1−y) during the thermal holding, especially when the fishnet structure is generated. It is definite that Fe will diffuse to (Tix,V1−x)(Cy,N1−y) from the matrix when the carbonitrides decompose at an elevated temperature, but Ti in carbonitrides is released and decreases.

Figure 7.

Elements in Ti-containing carbonitrides in samples.

Figure 8.

Evolution mechanism of carbonitrides during thermal holding.

However, only a small number of carbonitrides with xFe lager than 0.25 were found in sample #3 during holding at 1250 °C. In the case of sample #4, there was no obvious difference in the Fe content in carbonitrides between the original sample and heated samples, even holding for 15 h. As a result, the decomposition of (Tix,V1−x)(Cy,N1−y) was inconspicuous in sample #4, so the ‘UD’ carbonitrides are predominant in Figure 2. The low Fe content in carbonitrides means that it is difficult to decompose for the Ti-containing MC carbonitrides.

4.2. Effect of Ti and N on Thermal Stability of Ti-Containing MC Carbonitrides

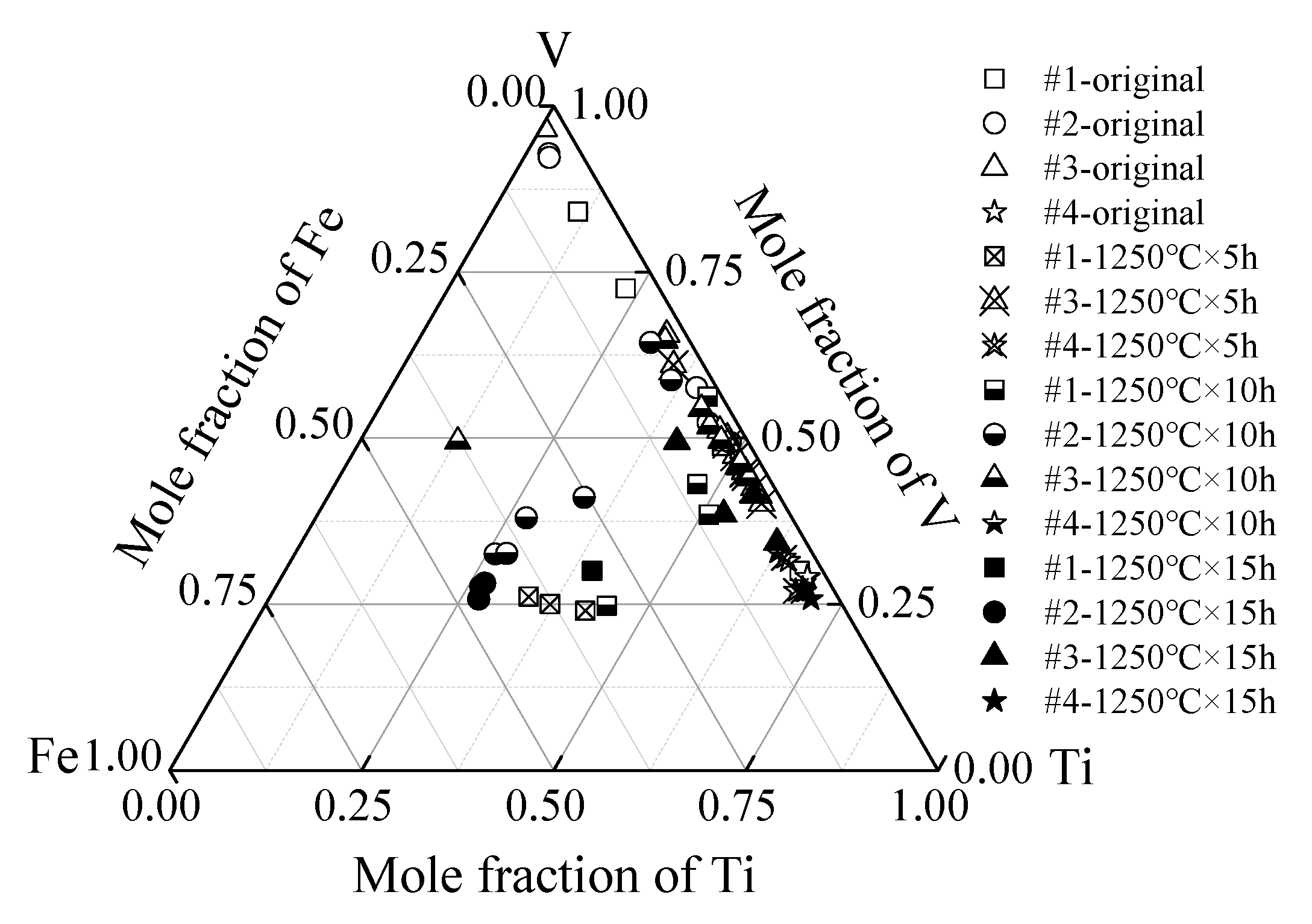

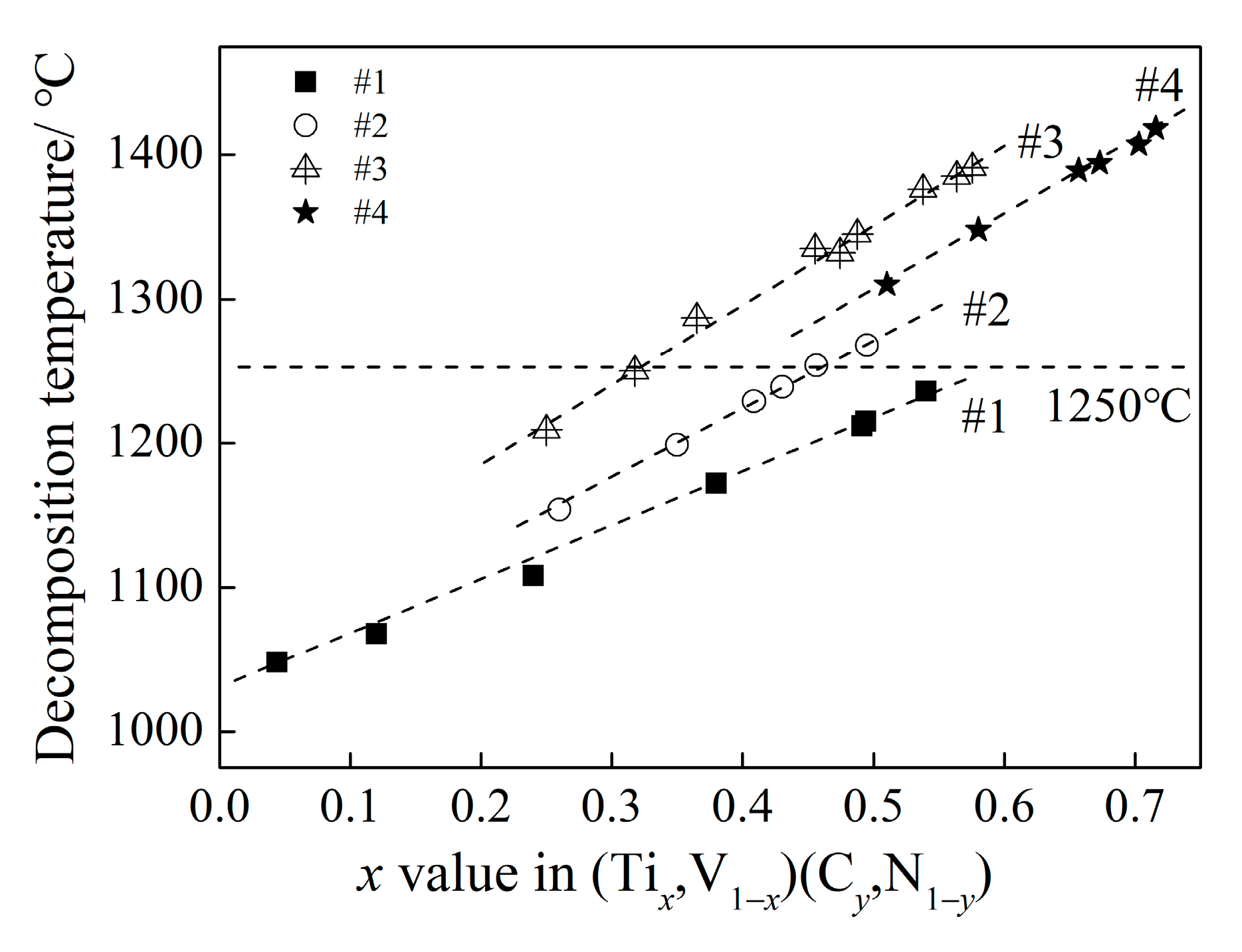

Many studies have confirmed that primary carbonitrides can be decomposed at high temperatures [21,22,24,25,26]. The two-sublattice-solution model illustrated by Equations (1)–(6) can be applied to calculate the equilibrium decomposition temperature of (Tix,V1−x)(Cy,N1−y) [21].

The different decomposition temperatures of (Tix,V1−x)(Cy,N1−y) in the four samples were calculated. As seen in the four dot lines in Figure 9, a higher Ti content definitively results in a higher balance decomposition temperature of (Tix,V1−x)(Cy,N1−y), and the values were 1048−1236 °C, 1154−1268 °C, 1209−1391 °C, and 1310−1418 °C in the four samples as the x value in (Tix,V1−x)(Cy,N1−y) changed. It is valid that the x value in (Tix,V1−x)(Cy,N1−y) had a positive relationship with the Ti contents [2] in H13. Meanwhile, the large x value enhanced the decomposed temperature and thermal stability of (Tix,V1−x)(Cy,N1−y). As a result, (Tix,V1−x)(Cy,N1−y) with small x values in samples #1 and #2 could be easily decomposed when holding at 1250 °C, as shown in Figure 5b,c. But the (Tix,V1−x)(Cy,N1−y) in Figure 5h was difficult to decompose in sample #4, with the most Ti, because the theoretical decomposition temperature was higher than the heated temperature. The theoretical calculation fits well with the experimental results.

Figure 9.

Effect of the constituents of (Tix,V1−x)(Cy,N1−y) on the decomposition temperature.

Adding the content of N will subtly change the constituent and improve the thermal stability of (Tix,V1−x)(Cy,N1−y). This can be legitimately clarified by comparing the x value and balance decomposition temperature of the carbonitrides in samples #2 and #3, as shown in Figure 6 and Figure 9. This comparison shows that the decomposed temperature of (Tix,V1−x)(Cy,N1−y) in sample #3 was much higher than that in sample #2. Therefore, there were much more undecomposed carbonitrides in sample #3 when holding at 1250 °C in Figure 2. The increase in N content in H13 shows a similar influence on the decomposition of (Tix,V1−x)(Cy,N1−y) to that of the Ti content mentioned above. Therefore, the high Ti and N contents would be disadvantageous for reducing the harmful Ti-containing MC carbonitrides in H13 when held at 1250 °C. To control the stable Ti-containing MC carbonitrides, much lower Ti and N contents in H13 and a higher holding temperature should be taken into consideration.

4.3. Effects of Ti and N Contents on the Characteristic Evolution of Carbonitrides Holding at 1250 °C

Sample #1 contained the lowest Ti and N contents of the four samples, and most of the carbonitrides were prone to decomposition. Therefore, the size apparently decreased after holding at 1250 °C in Figure 10. Increasing the Ti content in sample #2 resulted in an increase in the thermal stability of (Tix,V1−x)(Cy,N1−y), as shown in Figure 9, and there were more undecomposed carbonitrides when held at 1250 °C in Figure 2. Theoretical analysis illustrates that the decomposition temperatures of most carbonitrides were lower than 1250 °C, as shown in Figure 9, and holding for longer time may have been favorable for the decomposition of the remained carbonitrides in samples #1 and #2. Meanwhile, the change in size was inconspicuous when holding for more than 10 h in samples #3 and #4 compared with that in samples #1 and #2, as shown in Figure 10.

Figure 10.

Mean sizes of carbonitrides in the samples under different conditions.

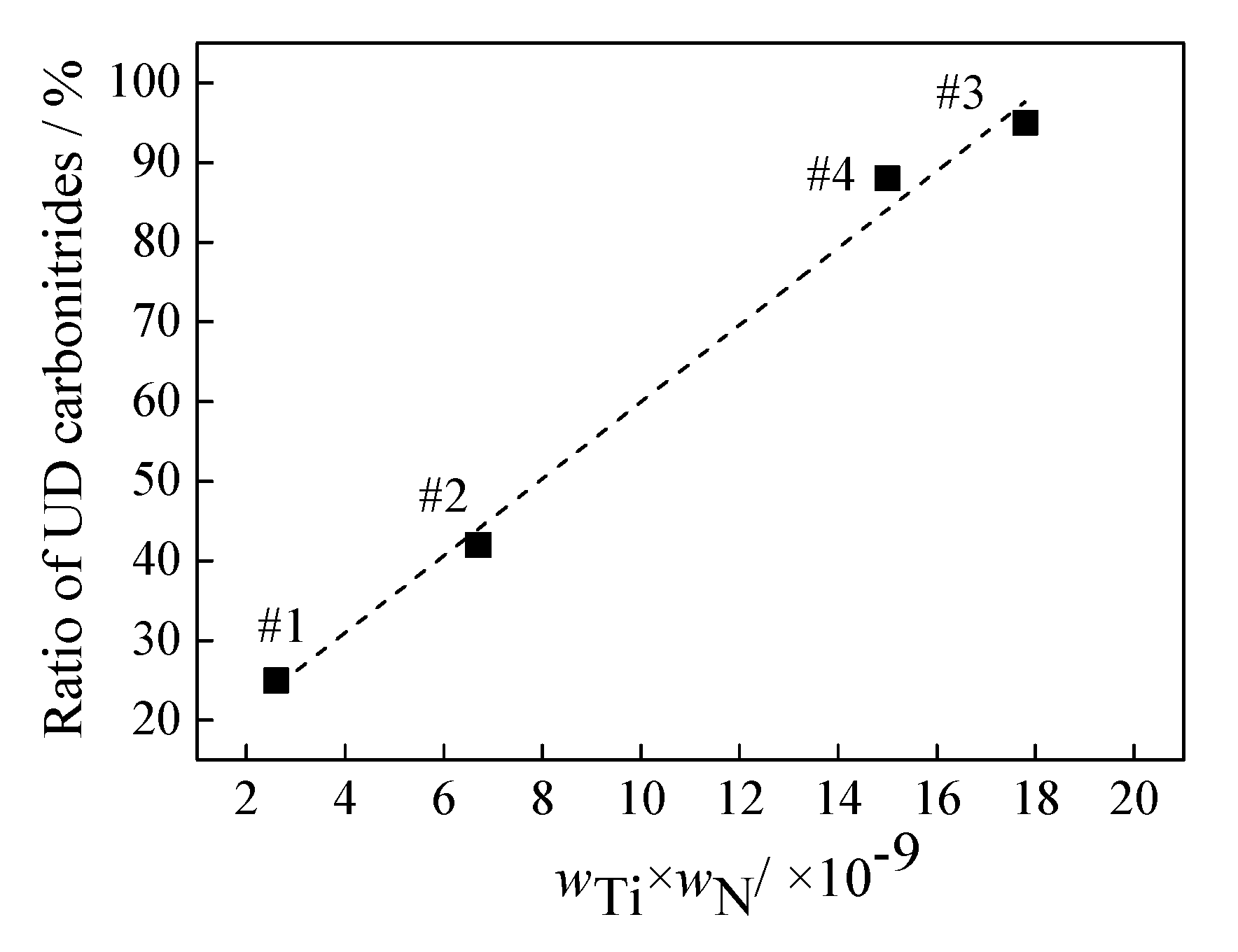

Sample #4 contained the most Ti and exhibited the highest decomposition temperature of (Tix,V1−x)(Cy,N1−y) in the four samples. It has been confirmed that (Tix,V1−x)(Cy,N1−y) with an x value larger than 0.40 cannot be decomposed at 1250 °C, and a higher holding temperature should have been considered to accelerate the decomposition of carbonitrides in sample #4. It is reasonable to deem that increasing Ti would prevent the decomposition of Ti-containing MC carbonitrides, and this may deteriorate the control of carbonitrides in H13. Consequently, there were more undecomposed carbonitrides in sample #4 after holding for 15 h, as shown in Figure 11, compared with samples #1 and #2.

Figure 11.

Relationship between the ratio of undecomposed carbonitrides holding at 1250 °C for 15 h and the product of Ti and N in the samples.

It is of interest that the mean size of the carbonitrides in sample #3 was minimum while the carbonitrides in sample #4 had the maximum size after holding for 15 h. Though the increase in N content is good for the size refinement of carbonitrides, the highest quantities of carbonitrides were in sample #3, as shown in Figure 3. Meanwhile, a high content of N will suppress the decomposition of (Tix,V1−x)(Cy,N1−y) because the x value in (Tix,V1−x)(Cy,N1−y) is also enhanced and thus improves the stability of carbonitrides at a high temperature. It was confirmed that the product of Ti and N contents, wTi × wN, is proportional to the ratio of undecomposed (Tix,V1−x)(Cy,N1−y) when held for 15 h, as shown in Figure 11. The quantities of ‘UD’ carbonitrides were 0.06/mm2, 1.03/mm2, 3.88/mm2, and 2.99/mm2 in samples #1 to #4, calculated from the ratio in Figure 2 and quantity in Figure 3, respectively. Therefore, comprehensive effects of N content on carbonitrides should be taken into consideration in nitrogen micro-alloyed hot-work die steel [30,31], for the small sizes but large quantities of MC primary carbonitrides may affect the performance.

In conclusion, the results suggest that thermal holding at 1250 °C did not effectively reduce the sizes and quantities of Ti-containing MC carbonitrides in samples #3 and #4, even holding for more than 10 h. Decreasing both the Ti and N contents should be beneficial for the decomposition of Ti-containing MC carbonitrides when held at an elevated temperature. To control the carbonitrides in H13 with higher Ti and N contents during homogenization, having a higher holding temperature would have probably been more meaningful. The prolongation of the holding time may be ineffective. The effects of temperature and the diffusion of Fe on the decomposition of the carbonitrides in Ti-containing die steel will also be investigated in future work.

5. Conclusions

The evolution of MC carbonitrides in H13 steels holding at 1250 °C with different Ti and N contents was characterized, including features such as the morphology, quantity, size, and composition. The effects of Ti and N contents on the thermal stability of MC carbonitrides were elucidated based on the thermodynamics.

- The quantities of carbonitrides decreased by 95%, 74%, 66%, and 69% after holding for 15 h at 1250 °C in the four samples, and the mean sizes decreased to 6.5 μm, 9.3 μm, 6.1 μm, and 10.6 μm, respectively. The addition of Ti resulted in an increase in size and quantity in carbonitrides during holding at 1250 °C while the high N content in sample #3 increased the quantities but decreased the sizes of carbonitrides. It was beneficial for the carbonitrides to decompose in samples #1 and #2 with low Ti and N contents. The product of Ti and N was proportional to the number fraction of the undecomposed carbonitrides held for 15 h.

- After holding at 1250 °C, only the Ti-containing MC-type carbonitrides, (Tix,V1−x)(Cy,N1−y), remained and progressively evolved into the fishnet structure from the compacted block, and this was accompanied with the edges being jagged and granulated with small particles. Results showed that the Fe content in the Ti-containing MC carbonitrides had increased while the Ti content had decreased during the decomposition. It was deemed that the xFe value being larger than 0.25 in the carbonitrides in samples #1 and #2 was beneficial for the Ti-containing MC carbonitrides to decompose when held at 1250 °C compared with xFe being generally smaller than 0.05 in samples #3 and #4.

- On the basis of thermodynamic analysis, the increase in the x value in (Tix,V1−x)(Cy,N1−y) and the decomposed temperature of (Tix,V1−x)(Cy,N1−y) in samples #3 and #4 were ascribed to the increases in Ti and N contents. As a result, the decreases in both sizes and quantities of carbonitrides in samples #3 and #4 were not effective when these samples were held for more than 10 h at 1250 °C. To control MC carbonitrides, a high holding temperature is much more preferable than a long holding time, in addition to having both low Ti and N contents in steel.

Author Contributions

Conceptualization, X.S. and S.G.; methodology, X.S. and Q.Z.; software, G.S.; validation, X.S., S.G. and G.S.; formal analysis, S.Z.; investigation, W.S.; resources, S.G; data curation, X.S. and W.S.; writing—original draft preparation, X.S. and S.Z.; writing—review and editing, X.S. and G.S.; visualization, X.S.; supervision, S.G; project administration, Q.Z.; funding acquisition, X.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Hebei Natural Science Foundation (Grant No. E2020402067) and State Key Laboratory of Advanced Metallurgy (Grant No. KF21-08) and S&T Program of Hebei (Grant No. 216Z1007G).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would express their sincere thanks to Tianjin CISRI-HARDER Materials & Technology Co., Ltd., and AVIC Shangda Superalloy Materials Co., Ltd., for providing the raw material and some of the experiment tests.

Conflicts of Interest

Authors Shengyong Gao and Qingyuan Zhong were employed by the company AVIC Shangda Superalloy Materials Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Oliveira, A.; Lima, L.; Felipe, B.; Bolfarini, C.; Coelho, R.; Gargarella, P. Effect of microstructure and defect formation on the bending properties of additive manufactured H13 tool steel. J. Mater. Res. Technol. 2021, 15, 3598–3609. [Google Scholar] [CrossRef]

- Sun, X.; Guo, H.; Song, G.; Xu, D.; Wang, F.; Zhang, J. Effect of Ti content on the characteristics of MC-type primary carbonitrides in H13 steel. Metall. Mater. Trans. B 2022, 53, 895–901. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, G.; Chen, L.; Zhang, Y.; Yan, Q. Generating mechanism of large heterogeneous carbonitrides with multiple layers in H13+Nb bar. Steel Res. Int. 2017, 88, 1600119. [Google Scholar] [CrossRef]

- He, B.; Li, J.; Shi, C.; Wang, H. Effect of Mg addition on carbides in H13 steel during electroslag remelting process. Metall. Res. Technol. 2018, 115, 501. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, G.; Li, S.; Dai, W. Distribution characteristics and thermal stability of primary carbide in cast Ce-H13 steel. ISIJ Int. 2020, 60, 267–275. [Google Scholar] [CrossRef]

- Chen, R.; Wang, Z.; Qi, L.; Zhong, L.; Guan, R.; He, J.; Hu, X. The carbides, tensile properties, and work-hardening behavior of annealed H13 die steels with varied yttrium contents. Mater. Sci. Eng. A 2021, 806, 140856. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Liu, Y.; Wang, F.; Wang, Q. Cerium addition effect on modification of inclusions, primary carbides and microstructure refinement of H13 die steel. ISIJ Int. 2021, 61, 1850–1859. [Google Scholar] [CrossRef]

- Ma, C.; Xia, Z.; Guo, Y.; Liu, W.; Zhao, X.; Li, Q.; Qi, W.; Zhong, Y. Carbides refinement and mechanical properties improvement of H13 die steel by magnetic—Controlled electroslag remelting. J. Mater. Res. Technol. 2022, 19, 3272–3286. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Liu, Y.; Cao, Y.; Wang, F.; Wang, Q. Investigation of primary carbides in a commercial sized electroslag remelting ingot of H13 steel. Metals 2019, 9, 1247. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, G.; Zhu, M. Effect of Ti content on the behavior of primary carbides in H13 ingots. Metals 2020, 10, 837. [Google Scholar] [CrossRef]

- Ji, F.; Xu, R.; Gao, Y.; Tian, Q.; Wang, L.; Xiao, Z.; Yin, F. Effect of Ti and rare earth on microsegregation and large-sized precipitates of H13 steel. J. Iron Steel Res. Int. 2021, 28, 1591–1604. [Google Scholar] [CrossRef]

- Tomita, Y.; Saito, N.; Tsuzuki, T.; Tokunagai, Y.; Okamoto, K. Improvement in HAZ toughness of steel by TiN-MnS addition. ISIJ Int. 1994, 34, 829–835. [Google Scholar] [CrossRef]

- Lee, M.; Park, J. Synergistic effect of nitrogen and refractory material on TiN formation and equiaxed grain structure of ferritic stainless steel. Metall. Mater. Trans. B 2018, 49, 877–893. [Google Scholar] [CrossRef]

- Li, L.; Wu, X. Effect of carbides on the thermal stability of Cr3 and Cr5 die-casting die steels. J. Mater. Eng. Perform. 2023, 32, 4483–4499. [Google Scholar] [CrossRef]

- Korade, D.; Ramana, K.; Jagtap, K. Effect of carbide density on fatigue limit of H21 die steel. J. Mater. Eng. Perform. 2020, 29, 230–241. [Google Scholar] [CrossRef]

- Zhu, J.; Lin, G.; Zhang, Z.; Xie, J. The martensitic crystallography and strengthening mechanisms of ultra-high strength rare earth H13 steel. Mater. Sci. Eng. A 2020, 797, 140139. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, M.; Yue, J.; Guo, H.; Li, J.; Bu, H.; Li, M.; Li, S. A Novel heat treatment strategy based on quenching and carbides preprecipitation and subsequent critical quenching to improve the thermal fatigue performance of AISI H13 tool steel. Steel Res. Int. 2023, 94, 220083. [Google Scholar] [CrossRef]

- Shinde, T. Influence of carbide particle size on the wear performance of cryogenically treated H13 die steel. Surf. Eng. 2021, 37, 1206–1214. [Google Scholar] [CrossRef]

- Wang, M.; Ma, D.; Liu, Z.; Zhou, J.; Chi, H.; Dai, J. Effect of Nb on segregation, primary carbides and toughness of H13 steel. Acta. Metall. Sin. 2014, 50, 285–293. (In Chinese) [Google Scholar]

- Park, J.; Ajmal, M.; Priestner, R. Tensile properties of simulated thin slab cast and direct rolled low-carbon steel microalloyed with Nb, V and Ti. ISIJ Int. 2000, 40, 380–385. [Google Scholar] [CrossRef]

- Sun, X.; Wang, F.; Chen, X.; Mao, M.; Guo, H. Study on decomposition of primary carbonitrides in H13 steel under high temperature. Chin. J. Eng. 2017, 39, 721–730. (In Chinese) [Google Scholar]

- Han, Y.; Li, C.; He, S.; Gao, C.; Chen, S.; Li, E. Effect of Homogenisation temperature on the microstructure and microhardness of as-cast H13 steel. Met. Mater. Int. 2021, 28, 755–769. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Wang, L.; Li, L. Study on carbide in forged and annealed H13 hot work die steel. High Temp. Mater. Process. 2015, 34, 593–598. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, G.; Li, S.; Dai, W. Precipitation mechanism and thermal stability of primary carbide in Ce microalloyed H13 steel. Acta Metall. Sin. 2019, 52, 1487–1494. (In Chinese) [Google Scholar]

- Han, Y.; Li, C.; Ren, J.; Qiu, C.; Zhang, Y.; Wang, J. Dendrite segregation changes in high temperature homogenization process of as-cast H13 steel. ISIJ Int. 2019, 59, 1893–1900. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, G.; Meng, X.; Huang, Y. Thermal stability of primary elongated V-rich carbonitrides in H13 tool steel. Metall. Res. Technol. 2017, 114, 206. [Google Scholar] [CrossRef]

- Li, L.; Cai, Z.; Wu, X. Effect of silicon on thermal stability of 4Cr3Mo2V hot-work die steel. Metals 2023, 13, 100. [Google Scholar] [CrossRef]

- Sun, W.; Qin, X.; Guo, J.; Lou, L.; Zhou, L. Thermal stability of primary MC carbide and its influence on the performance of cast Ni-base superalloys. Mater. Des. 2015, 69, 81–88. [Google Scholar] [CrossRef]

- Sun, X.; Guo, H.; Guo, J.; Wang, F.; Xu, D.; Song, G.; Wang, S. Characteristics and stability of oxide + carbonitride in H13 steel at 1250 °C. J. Iron Steel Res. Int. 2024, 31, 134–142. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Huo, J. Mechanism of improvement on strength and toughness of H13 die steel by nitrogen. Mater. Sci. Eng. A 2015, 640, 16–23. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Feng, H.; Jiao, W.; Zhu, H.; Zhang, S.; Jiang, Z. A novel high nitrogen hot-work die steel 3Cr5Mo2SiVN achieving excellent hardness-strength-toughness balance. Mater. Charact. 2023, 203, 113154. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).