Simulation Models in a Fluidity Test of the Al-Si Alloy

Abstract

:1. Introduction

- Alloy properties, including viscosity, surface tension, density, and thermal conductivity.

- The metal’s temperature at the time of casting.

- The design of the inlet system through which the metal enters the mold.

- Mold properties, such as thermal conductivity, density, and the coefficient of friction between the melted metal and the mold walls.

- The configuration of the casting as it solidifies.

- Environmental conditions, including ambient temperature, pressure, and geoclimatic factors.

2. Materials and Methods

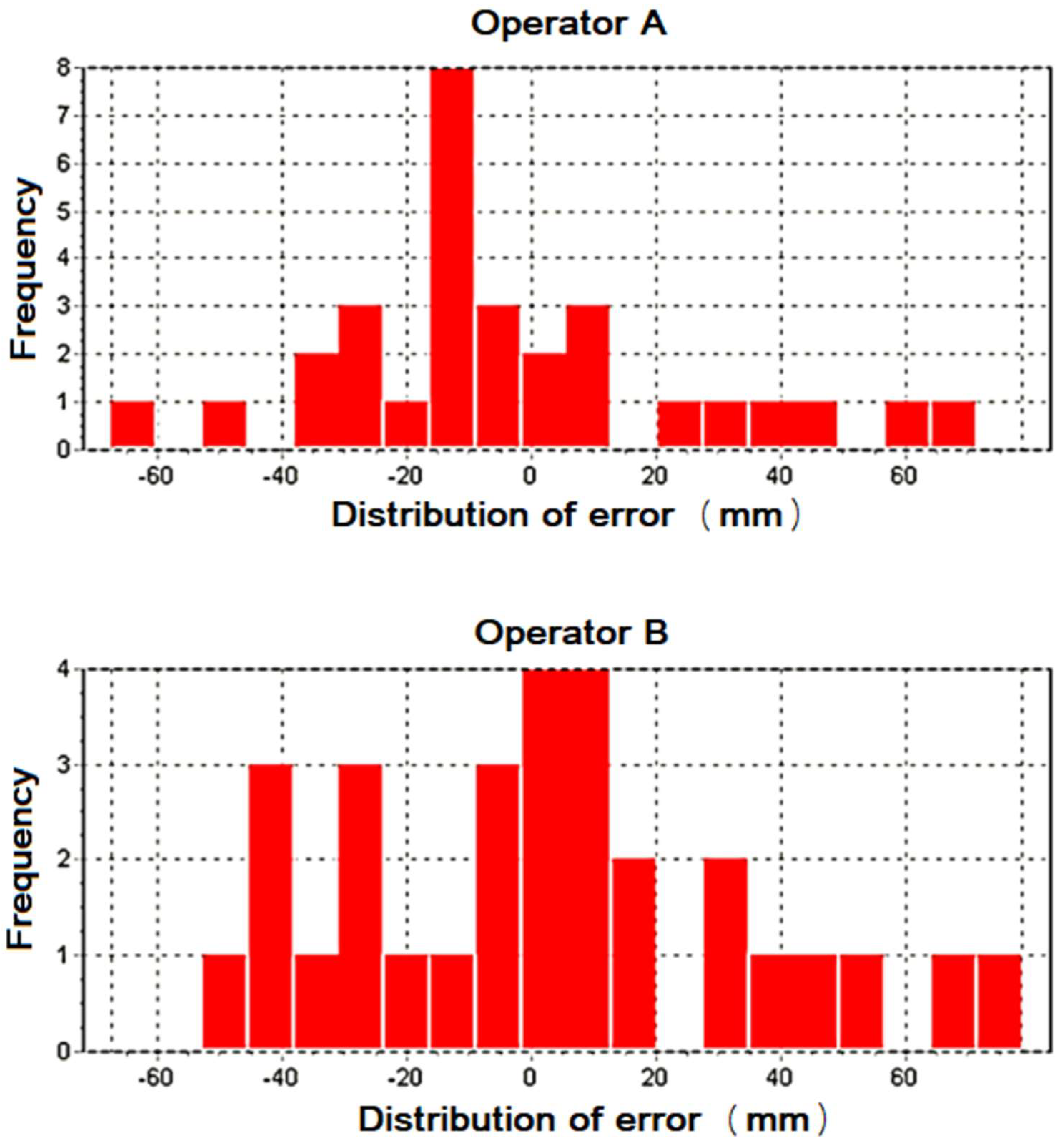

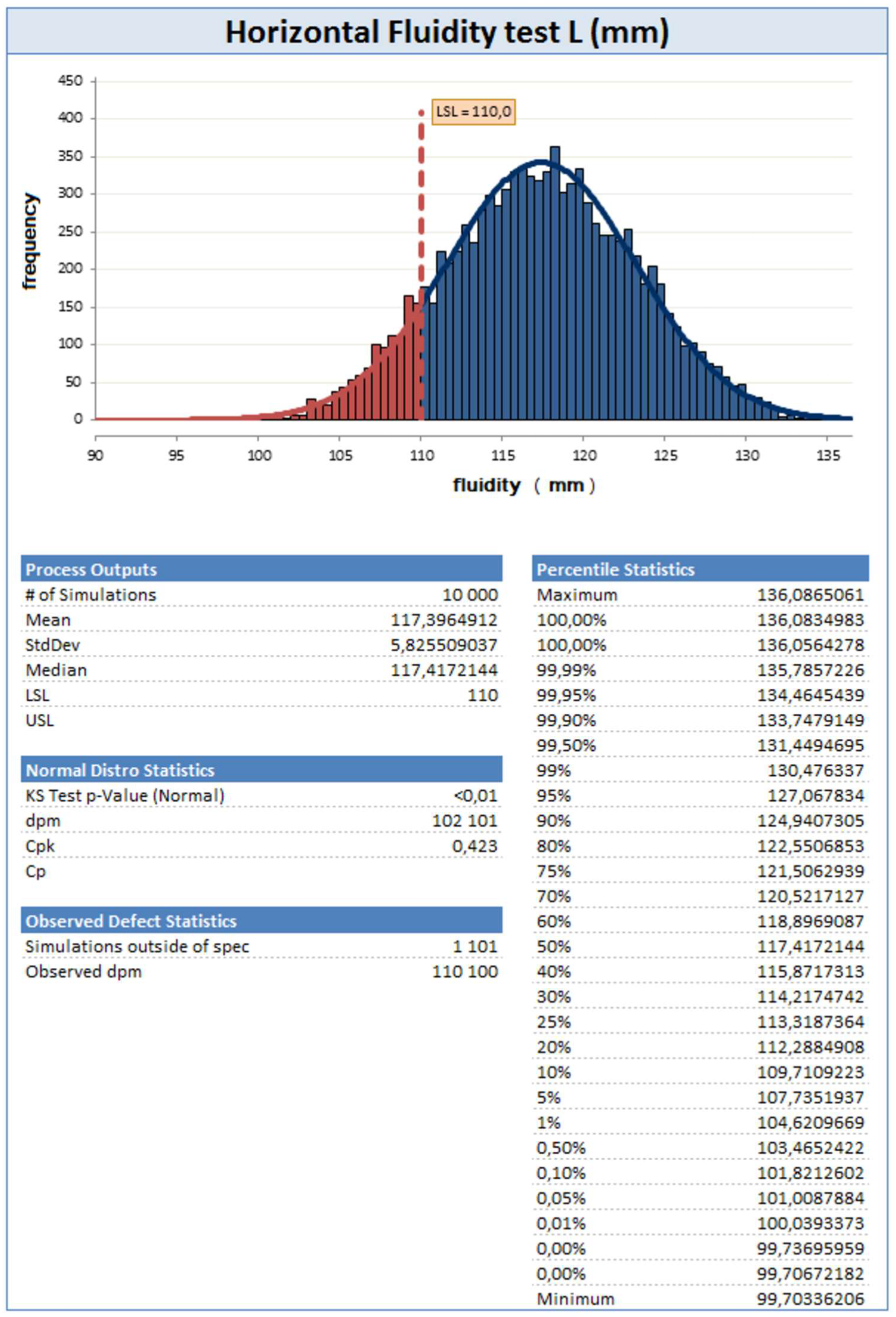

The Evaluation of the Capability of Measurement by the “Horizontal” Mold

3. Results

velocity (g·s−1) + 1.3862 × temperature of pre-heated mold (°C)

velocity (g·s−1) + 0.1125 × temperature of pre-heated mold (°C)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mikulecký, I.; Nemečková, A.; Palenčár, R. Základný Kurz Metrológie, 1st ed.; Úřad pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví (ÚNMZ) ve Spolupráci s Českým Metrologickým Institutem, Českou Metrologickou Společností a Českým Kalibračním Sdružením: Bratislava, Slovakia, 1998; p. 20. (In Slovak) [Google Scholar]

- Puškár, M.; Bigoš, P.; Kelemen, M.; Markulik, Š.; Puškárová, P. Method for accurate measurement of output ignition curves for combustion engines. Measurement 2013, 46, 1379–1384. [Google Scholar] [CrossRef]

- Zuo, H.; Li, J.; Zhu, L.; Cheng, D.; Chang, D. Identification Fluidity Method to Determine Suitability of Weathered and River Sand for Constructions Purposes. Coatings 2023, 13, 327. [Google Scholar] [CrossRef]

- ISO 9000:2015; Quality Management Systems—Fundamentals and Vocabulary. International Organization for Standardization ISO: Geneva, Switzerland, 2015.

- Kotus, M.; Holota, T.; Pauliček, T.; Petrík, M.; Sklenár, M. Quality and Reliability of Manufacturing Process in Automation of Die-Casting. Adv. Mater. Res. 2013, 801, 103–107. [Google Scholar] [CrossRef]

- Automotive Industry Action Group. Measurement Systems Analysis: Reference Manual, 4th ed.; Chrysler Group: Auburn Hills, MI, USA, 2010; ISBN 978-1-60534-211-5. [Google Scholar]

- Betteley, G. Using Statistics in Industry: Quality Improvement through Total Process Control; The Manufacturing Practitioner Series; Prentice Hall: New York, NY, USA, 1994; ISBN 978-0-13-457862-0. [Google Scholar]

- ISO 10012; Measurement Management Systems—Requirements for Measurement Processes and Measuring Equipment. ISO: Geneva, Switzerland, 2003.

- Blaško, P.; Šolc, M.; Petrík, J.; Girmanová, L.; Blašková, A. Application of the FMEA Tool in an Accredited Testing Laboratory in the Context of the ISO/IEC 17025:2017 Standard. Standards 2023, 3, 57–69. [Google Scholar] [CrossRef]

- Markulik, S.; Nagyova, A.; Turisova, R.; Villinsky, T. Improving Quality in the Process of Hot Rolling of Steel Sheets. Appl. Sci. 2021, 11, 5451. [Google Scholar] [CrossRef]

- ISO 10017:2021; Quality Management—Guidance on Statistical Techniques for ISO 9001:2015. International Organization for Standardization ISO: Geneva, Switzerland, 2015.

- Vilčko, J.; Slovák, S. Zlievárenská Technológia, 1st ed.; Alfa: Bratislava, Slovakia; SNTL: Prague, Czech Republic, 1987; pp. 24–28. (In Slovak) [Google Scholar]

- Heine, R.W.; Loper, C.R.; Rosenthal, P.C. Principles of Metal Casting; Indian Edition; McGraw-Hill Education: New Delhi, India, 2017; ISBN 978-0-07-099348-8. [Google Scholar]

- Elbel, T.; Havlíček, F. Hospodárné konstruování odlitků. Slévárenství 2007, 4, 1–8. (In Czech) [Google Scholar]

- STN 42 0483; Skúška Zabiehavosti Ocele na Odliatky. SUTN: Bratislava, Slovakia, 1965. (In Slovak)

- Malkovský, J. Slévárenství Neželezných Kovů, 1st ed.; Alfa: Bratislava, Slovakia, 1970. (In Czech) [Google Scholar]

- Grigerová, T.; Lukáč, I.; Kořený, R. Zlievarenstvo Neželezných Kovov, 1st ed.; Alfa: Bratislava, Slovakia; SNTL: Prague, Czech Republic, 1988; p. 421. (In Slovak) [Google Scholar]

- Wang, L.; Makhlouf, M.; Apelian, D. Aluminium Die Casting Alloys: Alloy Composition, Microstructure and Properties-Performance Relationships. Int. Mater. Rev. 1995, 40, 221–238. [Google Scholar] [CrossRef]

- IATF 16949; Quality Management System Requirements for Automotive Production and Relevant Service Parts Organizations. International Organization for Standardization ISO: Geneva, Switzerland, 2016.

- Futáš, P.; Petrík, J.; Pribulová, A. The Analysis of AL-SI Alloys Fluidity Test In Computer Simulation. In Proceedings of the 14th SGEM GeoConference on Informatics, Geoinformatics and Remote Sensing, Albena, Bulgaria, 17–26 June 2014. [Google Scholar] [CrossRef]

- Futáš, P.; Petrík, J.; Pribulová, A.; Bartošová, M. Fluidity Test of Al-Si Alloy Using by Computer Simulation. KEM 2014, 635, 45–50. [Google Scholar] [CrossRef]

- STN ISO/TS 16 949:2002; Quality management systems—Particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations. ISO: Geneva, Switzerland, 2002.

- Meloun, M.; Militký, J. Kompendium Statistického Zpracování Dat: Metody a Řešené Úlohy Včetně CD; Vyd. 1; Academia: Prague, Czech Republic, 2002; ISBN 978-80-200-1008-7. (In Czech) [Google Scholar]

- Aakre, A. Statistical Functions and Tools in Microsoft Excel. Trondheim, 2004.

- McDonald, J.H. Handbook of Biological Statistics, 3rd ed.; Sparky House Publishing: Baltimore, MD, USA, 2014; p. 1. [Google Scholar]

- Qi, X.; Ma, Y.; Liu, S.; Nie, X.; Zhang, T.; Wu, Y.; Peng, W.; Hu, G. Modelling the Impact of Graphene Coating of Different Thicknesses on Polyimide Substrate on the Secondary Electron Yield. Coatings 2024, 14, 13. [Google Scholar] [CrossRef]

- Sienkowski, S. Estimation of Random Variable Distribution Parameters by the Monte Carlo Method. Metrol. Meas. Syst. 2013, 20, 249–262. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; Ju, H.; Li, X.; Qu, Y.; Yu, J. Prediction Model of Aluminized Coating Thicknesses Based on Monte Carlo Simulation by X-ray Fluorescence. Coatings 2022, 12, 764. [Google Scholar] [CrossRef]

- Raychaudhuri, S. Introduction to Monte Carlo Simulation. Available online: http://www.informs-sim.org/wsc08papers/012.pdf (accessed on 26 March 2023).

- Baršič, Z.; Runje, B.; Alar, V.; Baršič, G. Confirmation of the measurement uncertainty estimation. In Proceedings of the 18th IMEKO World Congres—Metrology for a Sustainable Development, Rio de Janeiro, Brazil, 17–22 September 2006. [Google Scholar]

- Knežo, D. O Metóde Monte Carlo a Možnostiach jej Aplikácií. Transf. Inovácií 2012, 24, 178–181. Available online: https://www.sjf.tuke.sk/transferinovacii/pages/archiv/transfer/24-2012/pdf/178-181.pdf (accessed on 22 July 2021). (In Slovak).

- Ravi, B. Casting Simulation and Optimalisation: Benefits, Bottlenecks, and Best Practices. Indian Foundry J. 2008, 54, 1–12. [Google Scholar]

- Campbell, R.A.; Dan Harding, J. The Fluidity of Molten Metals, Training in Aluminium Application Technologies. Fluidity Molten Met. Train. Alum. Appl. Technol. 1994, 3205, 2–4. [Google Scholar]

- Di Sabatino, M.; Arnberg, L.; Bonollo, F. Simulation of fluidity in Al-Si alloys. Metall. Sci. Technol. 2005, 23, 3–10. [Google Scholar]

- Bang, H.-S.; Kwon, H.-I.; Chung, S.-B.; Kim, D.-U.; Kim, M.-S. Experimental Investigation and Numerical Simulation of the Fluidity of A356 Aluminum Alloy. Metals 2022, 12, 1986. [Google Scholar] [CrossRef]

- Jiang, J.; Yan, J.; Liu, Y.; Hu, G.; Wang, Y.; Ding, C.; Zou, D. Numerical Simulation and Experimental Validation of Squeeze Casting of AlSi9Mg Aluminum Alloy Component with a Large Size. Materials 2022, 15, 4334. [Google Scholar] [CrossRef] [PubMed]

| Temperature of the melt (°C) | operator | 600 | 650 | 670 | 680 | 700 | 720 | 750 | 760 | 780 | 830 | |

| Uncertainty Uc (°C) | A | 3.00 | 3.00 | 3.13 | 2.93 | 3.00 | 3.43 | 3.09 | 3.31 | 3.31 | 3.11 | |

| B | 3.14 | 3.02 | 3.43 | 2.94 | 3.54 | 3.29 | 4.17 | 3.09 | 3.25 | 3.11 | ||

| Pouring velocity (g s−1) | “horizontal” mold | A | 102 | 93 | 93 | 98 | 101 | 101 | 91 | 93 | 99 | 98 |

| B | 111 | 98 | 98 | 123 | 108 | 96 | 92 | 121 | 109 | 108 | ||

| “vertical” mold | A | 89 | 91 | 91 | 98 | 90 | 96 | 91 | 93 | 99 | 98 | |

| B | 111 | 121 | 121 | 123 | 129 | 96 | 92 | 121 | 131 | 108 | ||

| Temperature of the mold (°C) | “horizontal” mold | A | 121 | 122 | 121 | 118 | 118 | 120 | 120 | 122 | 125 | 129 |

| B | 111 | 122 | 121 | 118 | 121 | 118 | 118 | 120 | 120 | 129 | ||

| “vertical” mold | A | 120 | 120 | 112 | 121 | 120 | 120 | 120 | 122 | 125 | 129 | |

| B | 112 | 122 | 121 | 125 | 127 | 130 | 130 | 129 | 128 | 129 | ||

| Operators | T (°C) | 600 | 650 | 670 | 680 | 700 | 720 | 750 | 760 | 780 | 830 |

| A | L (mm) | 25.2 | 47.3 | 54.7 | 93.1 | 73.0 | 147.0 | 152.7 | 155.3 | 165.0 | 174.7 |

| Yz (mm) | 3.4 | 4.52 | 3.78 | 6.08 | 5.87 | 9.09 | 9.92 | 9.92 | 10.56 | 10.65 | |

| B | L (mm) | 44.5 | 76.0 | 75.3 | 77.0 | 112.0 | 93.7 | 130.0 | 145.7 | 131.3 | 258.0 |

| Yz (mm) | 3.96 | 6.42 | 6.37 | 7.15 | 10.39 | 8.79 | 9.99 | 9.99 | 10.95 | 6.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šolc, M.; Blaško, P.; Petrík, J.; Girmanová, L.; Blašková, A.; Małysa, T.; Furman, J.; Socha, V. Simulation Models in a Fluidity Test of the Al-Si Alloy. Metals 2024, 14, 456. https://doi.org/10.3390/met14040456

Šolc M, Blaško P, Petrík J, Girmanová L, Blašková A, Małysa T, Furman J, Socha V. Simulation Models in a Fluidity Test of the Al-Si Alloy. Metals. 2024; 14(4):456. https://doi.org/10.3390/met14040456

Chicago/Turabian StyleŠolc, Marek, Peter Blaško, Jozef Petrík, Lenka Girmanová, Andrea Blašková, Tomasz Małysa, Joanna Furman, and Vladimír Socha. 2024. "Simulation Models in a Fluidity Test of the Al-Si Alloy" Metals 14, no. 4: 456. https://doi.org/10.3390/met14040456