Abstract

Against the backdrop of climate policy goals and the EU’s aim for a resource-efficient economy, the foundry industry must rethink product range, energy consumption, and production technologies. Light metal casting, which is performed through processes like gravity die casting and high-pressure die casting, requires effective thermal management, which is crucial for optimising mould filling, solidification, cycle times, and part quality. Against this background, this study presents the development and characterisation of a cooling system that completely dispenses with energy-intensive heating/cooling devices. The system is based on a mask shape combined with internal spray cooling. This paper shows the simulation workflow for developing the mould mask and the design of the cooling system and compares the performance with conventional temperature control using channels. In the tests, an 82% higher cooling rate was achieved with Cool-Spray than with conventional temperature control, which was approx. 2.5 mm below the cavity surface. In addition to the more dynamic temperature control, the potential for process control was utilised, and the component quality of the test part was significantly improved compared to conventional temperature control.

1. Introduction

Against the background of climate policy goals and the European Union’s aim to transform into a society with a modern, resource-efficient, and competitive economy, transformations in mobility and consistent advancement of industrial manufacturing are essential []. The decarbonisation pursued at all levels, rising energy costs, and the shift in mobility are forcing the foundry industry to rethink its product range, energy consumption and efficiency, as well as production technologies.

The casting of light metals primarily takes place in highly automated production processes such as gravity die casting and high-pressure die casting. Within seconds to minutes, complex, near-net-shape parts with high functional integration and lightweight potential can be produced. Thermal management plays a crucial role in the processes and influences mould filling, solidification, cycle times and part quality []. Furthermore, mould tempering has been identified in various studies [,,] as one of the most important factors affecting mould life. The case study of a foundry on the cause and effect of casting defects by Bharambe [] emphasises mould tempering as a common cause of casting defects and an important element in increasing the efficiency of foundries.

Tempering of permanent moulds is largely carried out using fluid-based systems, which differ primarily in the design of the cooling areas and tempering media used. In principle, the processes can be divided into conventionally drilled and additively generated channels, mask moulds, special solutions such as quills and jet coolers, and external spray applications. The primary media used are water, heat transfer oils, compressed air and separating agent/water mixtures, as well as CO2 and other media on an experimental level and in niche processes [,,,].

To improve the cooling effect in permanent moulds, additively manufactured solutions, in particular, have increased in recent years. Anand goes so far as to cite in his study [] conformal cooling as the missing link in the die-casting industry to solve the problems of casting quality, scrap rate and mould life. He mentions that designing conformal cooling channels in complicated structural shapes is still a challenge and emphasises the increasing relevance of numerical simulation techniques in the design phase.

In [], a conformal cooling channel mould was manufactured from Inconel-625 using the DMLS method. They reduced the cycle time by 28% with a conformal cooling channel in gravity die casting and reduced the average grain size of the castings by 13.5%. The study by [] shows that printed mould inserts are not just a matter of laboratory-scale implementation, but are also suitable for production. They demonstrate the industrial feasibility of 3D printed inserts for the mass-produced MQ200GA transmission housing at Škoda Auto a.s., which produced over 43,000 cast parts.

An additive approach for the targeted adjustment of local heat transfer by means of static mixers in cooling channels is given in []. They show that in direct comparison with a channel without a static mixer, the heat transfer can be adapted in principle and increased by up to 33%. Another approach to improving the local cooling effect of die-cast moulds is given in []. There, linings made of pure copper are used in the cooling channels using an explosive expansion bonding process. This application improved the cooling rate by 12%.

The most widely used method for the temperature control of permanent moulds is still generally based on a complex network of interconnected drilled channels in which a heat transfer medium circulates. As the flow temperature of the medium is generally kept constant over the course of a cycle, this is also referred to as stationary temperature control. Heat is transferred between the mould and the temperature control medium via forced convection. The circulation, heating, and cooling of the medium is usually carried out by so-called TCU—thermal control units and corresponding distribution units.

The significant disadvantage of this type of tempering is the high inertia and low efficiency due to the high thermal mass of the mould, the mere convective heat transfer in the mould, and the large number of heat transfers and transports. Each process is associated with a degree of efficiency and losses. Conventional temperature control units require a pump for circulation, heating elements for heating, and a separate internal circuit for cooling the medium.

This article focuses on the characterisation of a new type of cooling system called Cool-Spray, which was developed at the University of Kassel Department of Foundry Technology. The first description of this principle can be found in the patent specification [] and was first investigated by Reiche [].

The Cool-Spray cooling system is based on a permanent mould designed as a mask, which can be produced using conventional milling without additive manufacturing. This means that the system is not as constrained in terms of design space as additively manufactured parts, and the cost is not as high. Mask moulds are another approach to close-contour temperature control. By maximising the surface area between the cooling area and the mould, the heat transfer can be significantly increased. One way of implementing such a mould structure is given in []. The composite mask mould consists of a base body and a contouring mask, which are connected to each other by support geometries and form a cooling cavity into which a temperature control medium is fed. The design of the flow conditions in these moulds is no longer based on guidelines and reference works but rather on flow simulations due to the high degree of individuality. The challenge of this design is the targeted setting of the flow and the limited controllability of the mould temperature [].

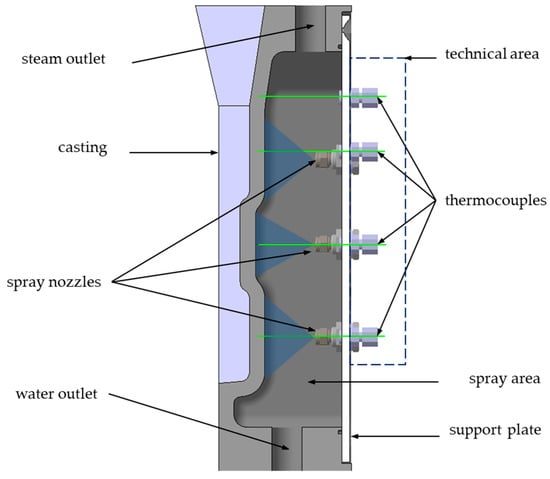

This is where the Cool-Spray cooling system takes up the theme. Essentially, the system differs from other mask tools primarily in the type and structure of the cooling system see Figure 1. Instead of a cooling area through which the medium flows, the mask is divided into two areas separated by a support plate: the spray area and the technical area. The back of the mould is sprayed with water through nozzles in the spray area and cooled by the complete or partial evaporation of a cooling medium. There are two reasons for incomplete evaporation. Firstly, the wall temperature; as soon as the wall temperature locally falls below 100 °C, evaporation no longer takes place. Secondly, droplets from the spray jet bounce off the wall. The additional thermocouples allow the temperatures to be recorded directly in the mould wall and thus enable process monitoring. The combination of the individually positioned nozzles and the local temperature recording thus enables dynamic temperature control in real-time in line with demand. Service water at a pressure of 5 bar and approx. 20 °C is used as the medium. The vaporised water escapes into the environment via the steam outlet, while the water that drifts downwards can be returned to the system via the water outlet. The main concept also includes heat recovery; however, this is not part of this study. A component for heating is not integrated into the current state of the art and restricts its application to the manufacturing processes for cast parts, in which more heat has to be dissipated than supplied. Heating before the start of production is carried out using a gas burner.

Figure 1.

Concept and components of the Cool-Spray cooling system.

In his work, Reiche [] demonstrates the potential of cooling in a basic test rig without a melt in addition to achievable HTC and derives the optimum spray parameters (pressure, frequency and duty cycle) for pulsed spray cooling. Based on this, a transfer to the mould and die-casting applications is shown. Further applications for series moulds at Volkswagen AG [] are based on this. The current lack of knowledge is the quantitative description of the performance and the direct comparison between the conventional temperature control and the Cool-Spray cooling system. This is where this study begins to address this issue.

A double mould is developed with the help of which both systems can be investigated for one casting under the same boundary conditions. The systems are analysed and compared with regard to their tempering and reaction behaviour, temperature change rates and the ability to influence the quality of the casting.

2. Theoretical Background and Methods for Describing Spray Cooling

2.1. Influencing Factors on the Heat Transfer of a Spray Cooling

The heat dissipation and efficiency of spray cooling are highly dependent on the selected spray parameters and the respective boundary conditions. The state of the literature presented here refers to publications that deal with water and air-water mixtures as the medium and is focused on the influencing variables in the context of this investigation. In addition, reference is made here to the work of Reiche [], which contains a very broad and comprehensive compilation of investigations into spray cooling with various media and a focus on achievable heat flux densities and heat transfer coefficients.

The influence of temperature on heat transfer is primarily determined by the boiling regime during pool boiling. The basis for this is provided by Nukiyama []. Studies on spray cooling, such as those by Kim [], show significantly higher heat transfer coefficients than in pure pool boiling. One possible explanation is provided by Yang [], who cites the increasing number of nucleation sites for the formation of bubbles as the film thickness decreases. Yang also states that gases are dissolved in the impinging droplets, which are dissolved when they enter the liquid film. The released gases, in turn, act as nucleation sites for further bubble formation (secondary nucleation sites).

Increasing the inlet pressure leads to a reduction in the size of the droplets, an increase in the droplet velocity and an increase in the jet angle [,]. Aamir et al. [] investigated the influence of pressure on the cooling rate using a stainless-steel substrate and wall superheat from 0 K to 800 K. They show that the cooling rate increases with increasing pressure. They show that an increase in pressure is accompanied by an increase in heat transfer up to a critical pressure, after which the cooling rates drop again. Cooling rates on the surface at wall temperatures between 300 °C and 500 °C of 150 K/s (300 °C, 12 bar) and 300 K/s (500 °C, 16 bar) were determined [].

Another side effect of increasing the pressure when using the same nozzle is the increase in the volume flow and the impingement density. As a rule, an increase in the heat flow density can be observed with an increase in the impingement density [,]. The experimental setup by Liu et al. [], in which cooling during mould spraying in die casting is simulated, shows an application-oriented example of the present work. A test specimen made of hot-work tool steel 1.2344 was heated up to 350 °C and subjected to a water-air mixture. For both media, an increase in the pressure at a constant pressure of the other medium first leads to an increase and then a decrease in the heat flux density. The reason for this is the interaction of the changed volume flows, droplet diameters and droplet velocities [].

The study presented above by Aamir et al. [] shows that the increased heat transfer during film boiling due to the pressure increase is due to better penetration of the vapour layer by smaller, faster droplets. The heat transfer from the substrate to the droplets requires a certain dwell time for the droplets on the surface. Droplet velocities that are too high reduce the necessary dwell time and cause the droplets to bounce off, resulting in inefficient heat transfer. The determined velocities at the nozzle opening are given as 20 m/s to 60 m/s []. In contrast, Todorov [] considers significantly lower droplet velocities when spraying cooling sheets made of a nickel-based alloy above the Leidenfrost temperature in the range from 300 °C to 600 °C. At 3.8 m/s, heat transfer coefficients of 175 W/m2K to 200 W/m2K were achieved and at velocities up to 6.7 m/s between 70 W/m2K and 100 W/2K higher HTC. The Sauter diameter is specified as 63 µm to 66 µm [].

The efficiency of spray cooling can be improved by an intermittent spray jet, especially in the bubble boiling area. In his work, Reiche [] compares the cooling curves of intermittent spray cooling with those of conventional spray cooling using a single-material nozzle and a copper disc as the substrate. The HTC determined at a set pressure of 4 bar is approx. 11 kW/m2K for continuous spray cooling in the bubble boiling range and approx. 8.3 kW/m2K for intermittent cooling with a duty cycle of 20% and a frequency of 5 Hz, using 80% less media. In the area of film boiling, both cooling systems have approx. 2/3 lower HTC [].

Several publications [,,,] have also cited the surface structure of the substrate as another significant factor influencing heat transfer. However, this is not a variable parameter in the present experiments.

The literature shows that the factors influencing spray cooling are widely dispersed. There is consensus that it is particularly the impingement density and droplet velocity, as well as the droplet size, that influence heat transfer.

2.2. Characterisation of the Spray Flow

To describe a spray flow, the volume flow rates and the mass flow rates related to the sprayed surface are used as volume flow density and mass flow density , also termed the impingement density:

Due to the stochastic size distribution of the droplets, it is useful to describe the droplet size using the Sauter diameter . The Sauter diameter is the diameter of a droplet whose volume-to-surface ratio corresponds to that of all the droplets. The equation for determining the Sauter diameter is defined in DIN ISO 9276-2 []:

If the orifice diameter of the nozzle , the density of the gaseous environment , the pressure loss across the nozzle , the dynamic viscosity and surface tension σ of the sprayed liquid are known, the Sauter diameter can be determined according to the relationship shown by Estes and Mudawar []:

In the present Cool-Spray system, the impingement density, nozzle exit velocity, droplet velocity and volume flow are directly proportional to each other, see Figure 2. The volume flow of the nozzles depends on the pressure of the medium, which is the spray parameter that can be adjusted in the Cool-Spray system and is varied in this study.

Figure 2.

The impact density and droplet velocity, as well as the Sauter diameter as a criterion of the droplet size, are each related to the relative pressure in the Cool-Spray system.

2.3. Temperature Change Rates

Temperature change rates are used in this study as a descriptive measure to describe the dynamics and response behaviour of the process control. The rates of temperature change are determined by forming the difference quotient from the successive time-temperature pairs and according to Equation (4). Due to the scatter of the determined change rates, a smoothing by the moving average of 15 readings corresponds to a time interval of 0.3 s.

3. Development of a Masked Mould with Internal Spray Cooling

3.1. Conception of the Experiment Mould and Design of the Casting

The concept is based on a test setup with a mask mould and a conventional mould, Figure 3. This double mould enables the simultaneous casting of two sample components, each with its own casting system. With the selected design, the same casting conditions, such as melt temperature, melt quantity, casting speed and impurities, can be guaranteed. To achieve a high degree of thermal decoupling of the two cooling systems, mould inserts are provided on both sides, in which the casting pool is housed and supplies the respective casting systems evenly with melt. The segments have air gaps between them on all contact surfaces. Exceptions are the surfaces between the segments and the mould inserts in the melt contact area.

Figure 3.

Concept of the double mould with symmetrical casting (3). The movable and fixed sides are each provided with a conventionally tempered segment (1) and a Cool-Spray segment (2). The mould insert with the pouring basin (4) is in the top centre between the two segments.

In order to develop the double mould, which can be used to investigate both systems for casting under the same boundary conditions, the test specimen is first defined and the casting system is designed.

The symmetrical specimen shown in Figure 4 is based on a three-stage plate with varying wall thicknesses, which enables the most homogeneous heat input possible in individual areas. The aim is to exclude geometry-related disturbances by choosing a simple geometry and to ensure a safe, stable, and, above all, reproducible process. By positioning the thinnest step in the centre of the plate, the challenge of feeding difficulty is specifically introduced. The entire casting with the gating system is designed completely symmetrically so that the mould segments for conventional cooling and Cool-Spray have their own casting systems and are only connected via the pouring basin.

Figure 4.

Structure of the casting, including casting system and dimensions. The entire casting is symmetrical.

To minimise the negative influences of the casting process on the tests, it is essential to design a suitable casting system. The design of the system is based on the calculation principles for casting and gating technology according to Nielsen [] and taking into account the filling system design fundamentals of [].

The pouring basin (1) is the reservoir at the top of the gating system, into which the molten metal is first poured. It helps to stabilise the metal flow and retain impurities. The sprue (2) is the vertical channel and an important part of the gating system that regulates the pressure and, together with the choke (3), the speed of the metal flow. This is followed by the riser (4), which is used to supply the gates (5). It is designed in such a way that the melt is distributed over the entire test specimen, which ensures low turbulence and the provision of hot melt in each segment of the plate. The plate consists of a bottom (6), middle (7) and top (8) section plus a feeder (9) above.

3.2. Design of the Cooling Systems

To ensure an efficient comparison process, conventional temperature control is designed according to the current state of the art. The setting of an effective and homogeneous cooling effect is realised on the basis of the guidelines formulated by Erlenkämper [] and Brunhuber [] and the investigations by Lange-Robben []. In these guidelines, the canal diameter, the distance between the canals and the distance to the cavity are related to each other.

The starting point for the design of cooling channels is the distance between the cooling channel and cavity. This corresponds to the wall thickness of the moulded mask of the Cool-Spray system. From the studies by Reiche [] and Haban [], a mask wall thickness of 15 mm is recommended. For a mask wall thickness of 15 mm, conventional cooling results in a channel diameter of 10 mm, a distance between the channels of 3 × Ø (30 mm) and a distance to the cavity of 2 × Ø (20 mm). All dimensions are based on the centre of the channel.

The design is more complex for Cool-Spray. Firstly, an offset with the specified wall thickness is generated from the casting geometry, which is then smoothed. Starting from this initial version, a simulation workflow is used to iteratively approximate the final design to ensure the structural integrity of the mould

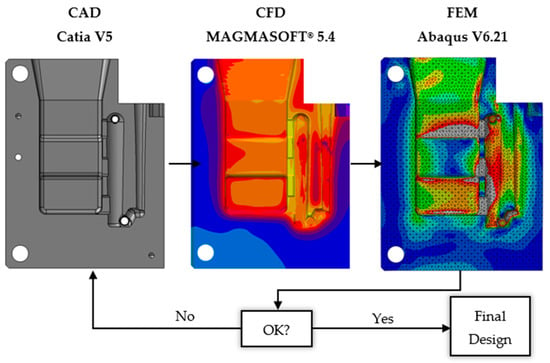

3.3. Simulation Workflow

The workflow for developing the segments of the mask moulds for Cool-Spray in Figure 5 is as follows. The designs are constructed in Catia V5 and simulated iteratively using the casting process simulation software MAGMASOFT® 5.4 and the temperature fields are passed on to the strength calculation in Abaqus V6.21. In the strength calculation, the mechanical boundary conditions are applied and the stress and strain states are determined. The time step 13 s after mould filling is calculated here as the worst-case step, and a limit value for the fatigue strength of 800 MPa is defined. The determination of the fatigue strength is carried out analogous to Reiche [] using the tables and diagrams according to Nogowizin [], taking into account a safety coefficient against fatigue fracture. After checking whether the design meets the requirements, a new iteration or the final design is created.

Figure 5.

Schematic of the workflow for developing the segments of the mask moulds for Cool-Spray tempering.

3.4. Integration of Spraying and Measuring Technology

Once the final design of the mask moulds has been determined, the spray areas are defined by positioning and selecting the nozzles. The spray areas are separated based on the sample geometry and the casting system, whereby the largest possible coverage of the mould masks must be achieved. The distance between the spray nozzles and the mould mask on the fixed mould half is between 32 and 38 mm. The resulting distribution and overlap of the spray cones are shown in Figure 6.

Figure 6.

Visualisation and separation of the spraying areas of the two mould masks. The areas are divided into the plate segment top (red), plate segment centre (yellow), plate segment bottom (green), feeder (white), and casting system (blue). The coloured, numbered circles indicate the positions of the spray nozzles (blue), jacket thermocouples (yellow), and weld-on thermocouples (purple).

The most important measured variable of the system is the temperature. Type K thermocouples are provided in all four segments of the mould at different depths below the specimen section and at one depth in the sprue and feeder area to record the temperatures over a large area. In the centre below the three plates, holes are drilled in each segment on a bolt circle diameter of 8 mm with 2.5 mm spacing from 2.5 to 10 mm starting from the cavity.

4. Experimental Setup and Test Procedure

The test setup for carrying out the gravity die-casting tests is shown in Figure 7. The double mould is mounted on an Auber GK 3 gravity die-casting machine. The aluminium melt AlSi9Cu3 is supplied by a Nabertherm resistance furnace type KF80/12. Two Robamat Thermocast 5212 thermal control units, using Transtherm 617 heat transfer oil, control the temperature of the conventional side and the casting inserts with the pouring basins. This configuration enables four independent circuits with up to 350 °C.

Figure 7.

Experimental setup with mould casting machine and clamped mould as the central element. The flows of the electrical signals are marked in green, the melt in red, the Cool-Spray media in blue and the heat transfer oil in grey.

The Cool-Spray system consists of a valve cabinet, which is supplied with non-tempered process water. The solenoid switching valves and, therefore, the nozzles in the mould are controlled via a control cabinet, which also contains all the necessary hardware for the measurement and control technology. The CompactDAQ hardware system and the LabVIEW software 2018 SP1 from NI form the basis for the measurement and control technology and are controlled via a separate measurement computer. The pressure and volumetric flow in the valve cabinet and the temperatures in the mould are recorded as described in the previous chapter. The water evaporating during the cool spray is emitted into the environment, and the drifting water is collected with a burette, measured, and fed into a reservoir. This system is an open cooling water system to keep the boundary conditions the same for each experiment. There have been further investigations with closed circuits, but these are not part of this study.

To run the test, the mould is first coated with conductive graphite coating and preheated to casting temperature. This is performed in 50 °C steps to the respective target temperature for the conventional side and to approx. 150 °C for the cool spray side using a gas burner. Then the first casts are then made with a pouring temperature of 680 °C until a quasi-steady state is reached and once this has been reached, the actual test casts are made with the corresponding repetitions. The preliminary tests to determine the stable process window indicate that conventional temperature control needs to be set 50 °C lower than the Cool-Spray system to achieve the same surface temperature. A detailed analysis of the tempering behaviour is given in the following chapter. The individual process steps and the durations are shown in Table 1. This results in a cycle time of .

Table 1.

Sequence of the process steps with the corresponding duration and description of the execution. The maximum deviations that can occur are specified. The total deviation is less than the sum of the individual deviations, as these partially cancel each other out.

Table 2 shows the parameters of the two cooling systems. Conventional temperature control conveys the temperature control medium continuously through the channels at a pressure of 5 bar and a flow rate of approx. 16–17 L/min. The temperature is controlled via a temperature sensor in the return flow of the heating/cooling unit.

Table 2.

Standard parameters of the temperature control of the reference test. The set temperature and pressure are varied as part of the tests.

With Cool-Spray, on the contrary, the temperature is controlled directly via a thermocouple in the mould wall at a distance of 5.0 mm from the cavity. As soon as the set temperature of 250 °C is exceeded at this thermocouple, cooling starts in the form of pulsed spray cooling until the target temperature is reached. The standard spray parameters determined by Reiche [] are used by Cool-Spray. The primary purpose of pulsing the spray parameters is to avoid the Leidenfrost effect and to allow alternation of cooling by evaporation and removal of vapour by convection. Somasundaram and Tay [], as well as Reiche [], also describe increased spray efficiency by pulsing.

5. Results and Discussion

5.1. Analysis of the Tempering and Reaction Behaviour of the Mould

The reference test is analysed below to describe and compare the characteristics of the conventional and Cool-Spray temperature control system. Figure 8 shows the temperature curves at the thermocouples TC 1x (Cool-Spray) and TC 7x (conventional) measuring points in the fixed mould half, centred in the upper plate segment, for a representative casting cycle in the quasi-stationary state.

Figure 8.

Temperature curves at the measuring points TC 1x (Cool-Spray) and TC 7x (conventional) in the fixed mould half, in the centre of the upper plate segment, for a representative casting cycle in quasi-stationary state. The two temperature control systems differ fundamentally in their tempering characteristics.

The two temperature control systems differ fundamentally in their tempering characteristics. The temperatures of the conventional cooling system follow uniform and steady curves. They rise steadily up to a peak, e.g., of 402 °C at TC 71 close to the cavity, and then fall steadily again. The maximum amplitude at a measuring point within a cycle is 174 °C at the TC 71 close to the cavity, while the maximum difference in the wall between the TC 71 and TC 74 measuring points is 76 °C. After component removal at approx. 63 s, a further increasing temperature drop follows. The temperature level of 250 °C is reached after 74 s. The heating and cooling process from 250 °C takes 68 s.

The temperature curves of the Cool-Spray side, on the other hand, show a strongly oscillating curve, which is characterised by the oscillation around the setpoint value of 250 °C on the controlling TC 12. The maximum amplitudes occur at TC 13 2.5 mm below the cooling side or 7.5 mm away from the cavity and decrease in both directions. The maximum temperature below the cavity at TC 11 is 321 °C, which is 81 °C less than with conventional temperature control, while the temperature delta at TC 11 is a maximum of 84 °C. Compared to conventional temperature control, however, the gradient that forms within the mould wall from TC 11 to TC 14 is many times higher than with conventional cooling at a maximum of 233 °C. The targeted temperature level for the next casting of 250 °C can be reached after just 39 s. After this main cooling phase, only isolated cooling pulses occur, and the temperatures homogenise until the next casting.

The Cool-Spray system is characterised by the aforementioned oscillating temperature curve during the main cooling phase of 7 to approx. 39 s. The temperatures at the regulating TC 12 oscillate around the set point (250 °C) between 230 and 260 °C with a period duration of approx. 4 s. This behaviour also occurs on the TC 13 facing the cooling side at the same time with a significantly higher amplitude of approx. 92 °C between 114 and 206 °C and the same period duration. In the work by Reiche [], the basic behaviour of Cool-Spray is considered in a single depth on the basis of the regulating TC (distance 7.5 mm from cavity) and is consistent with the results of this work.

The TC 14 welded to the spray side shows a less regular behaviour between 100 and 150 °C for the most part. The evaporation limit of 100 °C for water is only partially undercut and can be interpreted as an indication of the type of heat dissipation. Although two-phase heat dissipation can be assumed at temperatures above 100 °C, it occurs in a single phase at temperatures below 100 °C, which results in an increase in drift water and a reduction in cooling efficiency.

The curves, especially near the spray side, show that the oscillating behaviour does not result from pulsing by duty cycle and frequency, but rather from exceeding and falling below the set point. Pulsing by means of the spray parameters primarily serves to avoid the Leidenfrost effect and is intended to enable an alternation of cooling by evaporation and removal of vapour by convection.

While conventional cooling involves static temperature control with high inertia, the Cool-Spray system shows a direct reaction to the cooling pulses. Using the example of the cooling pulse at TC 14 after 7.4 s, the reaction at TC 13 takes place after just 7.5 s, at TC 12 after 7.9 s, and at TC 11 close to the cavity after 8.8 s. This enables direct intervention during a cycle and, thus, dynamic mould temperature control in the form of time- or temperature-dependent control variants. These are analysed in more detail in Section 5.3, in the extended process control for influencing component quality.

5.2. Temperature Change Rates

Temperature change rates are a descriptive comparison feature for the performance of different temperature control systems. While heating in the steady state is primarily achieved by the heat energy introduced by the melt, preheating of the mould can be achieved by heat transfer media in conventional temperature control and by means of a gas burner for cool spray. Rapid transfer of the energy released during the solidification and cooling of the casting is essential for productive and economical process control.

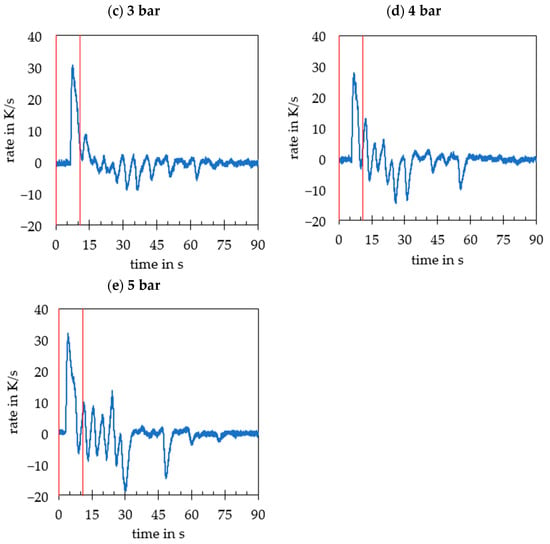

5.2.1. Temperature Change Rates as a Function of Pressure for Cool-Spray

In contrast to conventional cooling systems, there is no specific information in the literature on cooling rates and how they can be influenced by the Cool-Spray system. The literature research in Section 2.1 shows that the factors influencing spray cooling are widely dispersed. There is agreement that it is primarily the impingement density and droplet velocity, as well as the droplet size, that influences heat transfer. In the present Cool-Spray system, the impingement density and nozzle outlet velocity or droplet velocity as well as the volume flow are directly proportional to each other. The volume flow of the nozzles depends on the pressure of the medium, which is the spray parameter that can be adjusted in the Cool-Spray system, and it is analysed in more detail below.

The test parameters correspond to those of the reference test. The relative pressure to the environment is varied from 1 to 5 bar. Figure 9 shows the temperature change rates of a casting cycle calculated according to Equation (4) from Section 2.2, for different pressures. The measuring point is TC 11, close to the cavity on the upper plate of the fixed mould half. The pouring is marked in red.

Figure 9.

Course of temperature change rates of Cool-Spray under varying pressure over a representative casting cycle. The measuring point is the TC 11 close to the cavity on the upper plate of the fixed mould half. Mould filling in red. There is a significant relationship between the cooling rates and pressure.

The rate of the temperature change can be divided into three phases. The first phase during mould filling up to approx. 10 s is characterised by a strong increase in the heating rate until a maximum mould temperature is reached and the onset of cooling reaches the area close to the cavity. The second range, from 10 to 60 s, is characterised by a dynamic alternation of heating and cooling at pressures of 2 to 5 bar. These oscillating curves of the temperature change rates result from intermittent cooling caused by the cyclical falling below the set temperature. The highest cooling rates occur in this range. In the third range from approx. 60 s, the rates of temperature change oscillate close to zero until the start of the next cycle.

The curve at a relative pressure of 1 bar differs from that in the second phase. The rates initially remain in the positive range and decrease steadily until about 70 s before the characteristic oscillation occurs. Cooling occurs at the TC 11 close to the cavity from about 30 s. During the test, a few castings broke off during the transition from the pouring basin to the drop runner, which can be attributed to an excessively high mould temperature due to insufficient cooling performance.

5.2.2. Analysis of the Cooling Performance

The correlation between the set pressure and the influence on the cooling behaviour is analysed using two characteristic values: the maximum cooling rate achieved and the time of initial cooling. For this purpose, Figure 10 shows the values averaged from three successive casts in a quasi-stationary state.

Figure 10.

Averaged, maximum cooling rates and time of occurrence of the first cooling as a function of the pressure on the fixed side, upper plate on the thermocouple close to the cavity. A significant increase in the cooling effect can be observed by increasing the pressure, particularly from 4 bar.

Figure 10 clearly shows the influence of increasing pressure. In general, an increase in pressure leads to an increase in the cooling rates close to the cavity and a shift in the initial time of cooling to an earlier point. While at 1 to 3 bar, the maximum cooling rates are between—8.3 and 9.4 K/s, the further increase in pressure from 3 to 4.5 bar leads to a strong increase in the cooling effect, which continues to a lesser extent when the pressure is increased to 5 bar.

The times of initial cooling also show the greatest difference in the reduction in time when the pressure is increased from 3 to 4 bar. To achieve a strong cooling effect, a pressure of at least 4 bar is recommended for process control. A further increase can result in stronger cooling, but the extent to which this leads to increasing drift and thus to poorer local, demand-oriented cooling must be considered.

The results of the test series on the dependence of the cooling rate on the spray pressure confirm the influence of the factors described in Section 2.1. It can be assumed that, on the one hand, the increasing pressure increases the flow rate and thus the impingement density, and, on the other hand, the droplet velocity increases, which leads to better penetration of the vapour layer in the boiling ranges of film and transition boiling.

High cooling rates not only enable more dynamic temperature control and shorter cycle times in the casting process, but also greater economic efficiency. In addition, there is a direct correlation between the cooling rate or local solidification time in the casting and the secondary dendrite arm spacing, which in turn determines the fineness of the microstructure. See also the basic investigation using Differential Thermal Analysis DTA by Ronté [], the investigation for sandcasting by Radhakrishna [], the analyses by Pavlovic [] for gravity die casting, and the work from Cho [] for high-pressure die casting.

5.2.3. Comparison with Conventional Cooling

The following procedure has been chosen to categorise the performance of the Cool-Spray cooling system and compare it with conventional temperature control. The starting point is a test rig and test procedure developed by the Austrian Foundry Institute ÖGI to determine the cooling rates of various cooling standards, media, and systems, which is published in [,,]. A test specimen made of hot-work tool steel 1.2343 was heated to 350 °C using integrated heating cartridges and cooled by switching on the internal cooling with a media temperature of 30 °C. The cooling rates were calculated from the recorded cooling curves by averaging the first five seconds.

This test procedure is adapted to our own tests. The mould was heated to 350 °C in a casting series; the temperatures homogenised to approx. 325 °C and cooled to a target value of 50 °C with a spray parameter pressure of 4 bar, frequency of 5 Hz, and duty cycle of 20%, in accordance with the reference test. Figure 11 shows the average cooling rates of the first five seconds at the upper position of the movable side (wall thickness 15 mm) at different depths and compares them with the results of the ÖGI.

Figure 11.

Comparison of the cooling rates determined when using spray cooling in Cool-Spray (a) and conventional temperature control (b) from ÖGI publications [,].

The results show that the cooling rates that can be achieved using Cool-Spray are significantly higher than those achieved using conventional temperature control. For the distance from cooling to thermocouple of 2.0 mm, respectively, 2.5 mm, the cooling rates achieved with Cool-Spray are around 63% higher than with conventional temperature control with water and around 148% higher than with oil temperature control. For a distance of 7.5 mm respectively, 8 mm, cooling rates 103% higher than with water temperature control and 235% higher than with oil temperature control can be achieved.

There is no exact comparability between the conventional temperature control of this study and that of the ÖGI. This is mainly due to the possibility of directly switching the temperature control on and off, for which a bypass system and expansion tank are required. A modification of the test procedure has, therefore, been carried out. The test for conventional cooling is based on the test described above for Cool-Spray (starting temperature for cooling 325 °C). In the test, the temperature of the conventionally cooled side of the mould is set to the maximum value of approx. 330 °C, then the set point is set to 50 °C, and the maximum cooling rates are determined. The cooling rates of conventional cooling averaged over a series of tests are shown in Figure 12. The values for the cool spray are also plotted for comparison.

Figure 12.

Cooling rates depending on the distance of the cavity for conventional cooling in comparison to the Cool-Spray system.

Using conventional cooling, cooling rates of up to −2.8 K/s can be achieved on the thermocouple close to the cavity (2.5 mm). In comparison, an 82% higher cooling rate of −5.1 K/s was achieved at the same distance using Cool-Spray. This ratio increases with increasing distance from the cavity or proximity to the cooling area. This ratio increases with increasing distance from the cavity or proximity to the cooling area.

In addition to the clear differences in height, the inverse course of the maximum values is also conspicuous. This is mainly due to the different dynamics of the temperature control systems. As explained in Section 5.1, using Figure 8, conventional cooling is characterised by a continuous process with a single oscillation within a cycle. This is due to the high inertia of the full mould and the single-phase heat supply through the pipe flow.

In contrast, the cool spray is characterised by strong oscillations within a cycle with significantly higher amplitudes due to the lower thermal mass and the high proportion of evaporation in the heat removal.

5.3. Influenceability of Component Quality

This section shows options for temperature control with the aim of influencing component quality. The variables for temperature control are the target temperatures of the individual spray areas for both the conventional temperature control and Cool-Spray. In addition, the real-time controllable opening of the nozzles and the agile reaction behaviour of Cool-Spray enable the setting of individual start times and, thus, a further variable that can be used instead of the target temperature or in combination with it.

The volume deficits or porosity occurring in the casting are selected as the target criteria, and attempts are made to reduce them by means of controlled solidification. According to the BDG guideline P203, shrinkage-induced porosity and gas porosity occur together. The latter cannot be directly influenced by tempering, but is indirectly increased by shrinkage [].

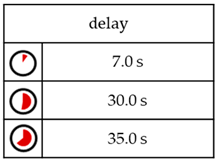

Table 3 presents an overview of the test series. For temperature control, the casting was divided into four areas, which are provided with separate target temperatures depending on the test series and, in the case of Cool-Spray, with additional start times. The nozzles of the casting system are assigned to the area at the corresponding height, depending on their position. This ensures comparability with conventional temperature controls whose channels also run horizontally. The output is the reference test with a homogeneous target temperature described in the previous chapter. For both Cool-Spray and conventional temperature control, a series of tests with a gradient is carried out in addition to the reference test to set a directional solidification vertically upwards to the feeder. For Cool-Spray, an additional series of tests is carried out using a combination of delay and gradient. The tempering start times were determined iteratively on the basis of the casting process simulations and solidification simulation.

Table 3.

Overview of the test series for the influencesof component quality.

The temperature curves of the representative casting cycles of the Cool-Spray on the thermocouples near the cavity of the test part on the moving side are shown in Figure 13. The temperature curve in (a) shows the Cool-Spray reference test. This results in almost homogeneous surface temperatures over the cycle. Only in the centre segment does an earlier temperature drop to the target value occur due to the smaller wall thickness of the casting and the associated lower heat input. In comparison, the characteristics of the set temperature gradient can be clearly recognised in (b). This is reduced during the mould filling process but is restored immediately after completion. It can be assumed that the gradient maintained during solidification enables directional solidification, and thus, a reduction in volume deficits. It should be noted that the gradient is also present during mould filling and, therefore, results in different flow conditions in the individual plate segments. The combination of the gradient and delayed start of cooling in (c) leads to higher heating in the upper areas and to the formation of a significantly higher gradient towards the lower plate, which favours the replenishment of this plate. After approx. 33 s, and after completion of solidification in the lower area, a gradient forms between the middle and upper plates, which also has a positive effect on the replenishment of the middle plate.

Figure 13.

Temperature curves on the thermocouple close to the cavity with Cool-Spray.

The temperature curves of the reference test for conventional temperature control in Figure 14a have an amplitude that is approx. 50 K greater compared to Cool-Spray in Figure 13a. The upper plate has slightly higher temperatures. The set gradient in (b) is formed, but with a greater delay and smaller difference compared to Cool-Spray. It can, therefore, be assumed that the effect on the reduction of the volume deficits is positive, but less so than with Cool-Spray.

Figure 14.

Temperature curves on the thermocouple close to the cavity with conventional cooling.

The volume deficits are analysed using computed tomography and Volume Graphics STUDIO MAX in accordance with BDG guideline P 203 []. The voxel size is defined as 0.2 mm, and the analysis is limited to macroporosity (Ø > 0.5 mm). The three plate segments are defined as the reference volume. Figure 15 shows the volume deficits of the test series averaged over the three samples.

Figure 15.

Comparison of volume deficits over the entire plate of the two temperature control systems.

The reference sample exhibits the greatest porosity with both conventional tempering and cool spray. The setting of a gradient leads to a significant reduction in defects in both systems. The best results can be achieved with a combination of delay and temperature gradient using Cool-Spray. In this study, significantly fewer defects were achieved everywhere with Cool-Spray than with conventional temperature control, which can be attributed to two points. Firstly, the higher dynamics of Cool-Spray allow a more targeted response to the feeding problem in the middle area, resulting in different heat inputs into the mould. Secondly, the drifting water from the upper areas of the mould results in additional cooling of the areas below and thus favours the formation of a gradient.

The series of tests that influence the component quality show the clear advantages of Cool-Spray over conventional temperature control. The greater agility and additional control options are reflected in the temperature curves in the mould and in the reduction of volume deficits. In addition to setting gradients via the target temperatures of individual areas, time-controlled cooling offers an additional degree of freedom for targeted temperature control, thus improving the quality of the cast part.

6. Conclusions

This study introduces and characterises the Cool-Spray cooling system for permanent moulds, demonstrating significant advances over conventional temperature control systems. The Cool-Spray system exhibits a fundamentally different and more dynamic temperature control behaviour, as evidenced by the high volatility of the temperature curves and an 82% higher cooling rate near the cavity surface than that of conventional cooling.

This enhanced cooling performance leads to more dynamic temperature control, more direct process control, and significantly improved component quality. Compared to the Cool-Spray reference test, the more direct process control halved the volume deficits and reduced them by 62.5% compared to the best result with conventional temperature control.

Overall, the Cool-Spray cooling system represents a major advance in thermal management for die casting, as it completely eliminates the need for energy-intensive TCUs. Its introduction could lead to wider changes in the industry and promote more sustainable and efficient production processes. The results of this study provide a compelling case for the adoption of advanced cooling technologies in the foundry industry and pave the way for future innovations and improvements in thermal management.

Author Contributions

Conceptualisation, A.H., M.F. and S.F.K.; methodology, A.H. and M.F.; software, D.N.R.; validation, A.H. and D.N.R.; simulation, A.H.; investigation, A.H. and D.N.R.; writing—original draft preparation, A.H.; writing—review and editing, S.F.K.; supervision, M.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, and further enquiries can be directed to the corresponding author.

Conflicts of Interest

Author Danny Noah Rohde was employed by the company Volkswagen AG-Division of Components Manufacturing, 34225 Baunatal, Germany. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- The European Parliament and the Council of the European Union. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’); European Parliament: Brüssel, Belgium, 2021. [Google Scholar]

- Nogowizin, B. Theorie und Praxis des Druckguss; Schiele & Schön: Berlin, Germany, 2011; pp. 643–644. [Google Scholar]

- Liu, M.; Sang, B.; Hao, C.; Chen, G.; Yan, J. Thermal fatigue life prediction method for die casting mold steel based on the cooling cycle. J. Mater. Process. Technol. 2023, 321, 118131. [Google Scholar] [CrossRef]

- Majerník, J.; Podaril, M.; Majernikova, M. Evaluation of High Pressure Die Casting Mold Temperature Relations Depending on the Location of the Tempering Channels. Arch. Foundry Eng. 2024, 24, 115–120. [Google Scholar] [CrossRef]

- Piekło, J.; Garbacz-Klempka, A.; Burbelko, A. The Numerical Fatigue Life Analysis of a Conformal HPDC Mould Core Additively Manufactured from Maraging Steel. Materials 2023, 16, 365. [Google Scholar] [CrossRef]

- Bharambe, C.; Jaybhaye, M.D.; Dalmiya, A.; Daund, C.; Shinde, D. Analyzing casting defects in high-pressure die casting industrial case study. Mater. Today Proc. 2023, 72, 1079–1083. [Google Scholar] [CrossRef]

- Brunhuber, E. Praxis der Druckgußfertigung, 4th ed.; Schiele & Schön: Berlin, Germany, 1991; pp. 11+30+367–384+408. ISBN 3-7949-0535-0. [Google Scholar]

- Glück, J.; Schilling, A. Efficiency and Agility of a Liquid CO2 Cooling System for Molten Metal Systems—Case Study. Therm. Eng. 2021, 28, 101485. [Google Scholar] [CrossRef]

- Nogowizin, B. Konstruktion und Fertigung der Druckgießformen; Schiele & Schön: Berlin, Germany, 2019; ISBN 978-3-7949-0893-6. [Google Scholar]

- Tucan, K.; Gschwandtner, R.; Hofer, P. Vergleich der Wirkung von Lokalen Temperiermaßnahmen in Druckgießformen. Giesserei-Rundschau 2012, 59, 8. [Google Scholar]

- Anand, A.; Nagarajan, D.; El Mansori, M.; Sivarupan, T. Integration of Additive Fabrication with High-Pressure Die Casting for Quality Structural Castings of Aluminium Alloys; Optimising Energy Consumption. Trans. Indian Inst. Met. 2023, 76, 347–379. [Google Scholar] [CrossRef]

- Kurtulus, K.; Bolatturk, A.; Coskun, A.; Gürel, B. An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels. Appl. Therm. Eng. 2021, 194, 117105. [Google Scholar] [CrossRef]

- Andronov, V.; Pitrmuc, Z.; Zajíc, J. Conformal cooling as a support tool for eliminating local defects in high-pressure die casting series production. Prog. Addit. Manuf. 2024, 1–19. [Google Scholar] [CrossRef]

- Sode, M.; Kahlert, M.; Arold, T.; Fros, A.; Vollmer, M. Tailoring flow behavior and heat transfer in tempering channels for high-pressure die casting—Analysis of potentials of commercial static mixers and prospects of additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 125, 5463–5477. [Google Scholar] [CrossRef]

- Shin, S.; Lee, S.; Kim, D.; Lee, B. Enhanced cooling channel efficiency of high-pressure die-casting molds with pure copper linings in cooling channels via explosive bonding. J. Mater. Process. Technol. 2021, 297, 117235. [Google Scholar] [CrossRef]

- Reiche, L.; Nölke, O.; Fehlbier, M. Gussform. Patent DE 10 2014 001 563 B4, 20 August 2015. [Google Scholar]

- Reiche, L. Entwicklung einer Geregelten und Energieeffizienten Werkzeugtemperierung im Dauerformguss unter Einsatz einer Sprühkühlung mit Wärmerückgewinnung. Ph.D. Thesis, Universität Kassel, Kassel, Germany, 2019. [Google Scholar] [CrossRef]

- Findeisen, S. Zykluszeitreduzierung beim Druckgießen durch Mehrteiligen Werkzeugaufbau. Ph.D. Thesis, Technische Universität Bergakademie Freiberg, Freiberg, Germany, 2015; pp. 19–23. [Google Scholar]

- Haban, A.; Fehlbier, M.; Reiche, L. Umsetzung einer Gepulsten Verdampfungskühlung für Druckgusswerkzeuge im Serienprozess. In Gießen von Fahrwerks- und Karosseriekomponenten; VDI-Berichte: Bad Gögging, Germany, 2020; p. 131. ISBN 978-3-18-092367-3. [Google Scholar]

- Nukiyama, S. The Maximum and Minimum Values of the Heat Q Transmitted from Metal to Boiling Water under Atmospheric Pressure. J. Jpn. Soc. Mech. Eng. 1934, 37, 367–374. [Google Scholar] [CrossRef]

- Kim, J. Spray Cooling Heat Transfer: The State of the Art. Int. J. Heat Fluid Flow 2007, 28, 753–767. [Google Scholar] [CrossRef]

- Yang, J.; Chow, L.; Pais, M. Nucleate Boiling Heat Transfer in Spray Cooling. J. Heat Transf. 1996, 118, 668–671. [Google Scholar] [CrossRef]

- Aamir, M.; Qiang, L. Ultra Fast Spray Cooling and Critical Droplet Diameter Estimation from Cooling Rate. J. Power Energy Eng. 2014, 2, 259–270. [Google Scholar] [CrossRef]

- Somasundaram, S.; Tay, A. Comparative Study of Intermittent Spray Cooling in Single and Two Phase Regimes. Int. J. Therm. Sci. 2013, 74, 174–182. [Google Scholar] [CrossRef]

- Estes, K.; Mudawar, I. Correlation of Sauter Mean Diameter and Critical Heat Flux for Spray Cooling of Small Surfaces. Int. J. Heat Mass Transf. 1995, 38, 2985–2996. [Google Scholar] [CrossRef]

- Martínez-Galván, E.; Ramos, J. Film Thickness and Heat Transfer Measurements in a Spray Cooling System with R134a. J. Electron. Packag. 2011, 133, 1. [Google Scholar] [CrossRef]

- Liu, G.; Morsi, Y.; Clayton, B. Characterisation of the Spray Cooling Heat Transfer Involved in a High Pressure Die Casting Process. Int. J. Therm. Sci. 2000, 39, 582–591. [Google Scholar] [CrossRef]

- Todorov, T. Wärmeübergang bei der Sprühkühlung unter Berücksichtigung der Sprühstrahlparameter. Ph.D. Thesis, Otto-von-Guericke-Universität, Magdeburg, Germany, 2009; pp. 6+126. [Google Scholar]

- Aamir, M.; Qiang, L. Transient Heat Transfer Performance of Stainless Steel Structured Surfaces Combined with Air-Water Spray Evaporative Cooling at High Temperature Scenarios. Appl. Therm. Eng. 2017, 115, 418–434. [Google Scholar] [CrossRef]

- Hsieh, C.; Yao, S. Evaporative Heat Transfer Characteristics of a Water Spray on Micro-Structured Silicon Surfaces. Int. J. Heat Mass Transf. 2006, 49, 962–974. [Google Scholar] [CrossRef]

- Wengler, C. Einfluss des Heizwandmaterials auf den Wärmeübergang beim Blasensieden. Ph.D. Thesis, Universität Kassel, Kassel, Germany, 2018. [Google Scholar]

- Winter, M. Heat Transfer Mechanisms during Spray Cooling of Electronic Devices. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2015. [Google Scholar]

- Deutsches Institut für Normung. DIN ISO 9276-2-Darstellung der Ergebnisse von Partikelgrößenanalysen–Teil 2: Berechnung von Mittleren Partikelgrößen/-Durchmessern und Momenten aus Partikelgrößenverteilungen; Beuth Verlag GmbH: Berlin, Germany, 2018; pp. 3–16. [Google Scholar]

- Nielsen, F. Gieß- und Anschnitttechnik—Grundlagen und Anwendung einer Methode; Gießereiverlag: Düsseldorf, Germany, 1993; pp. 2–37. [Google Scholar]

- Campbell, J. Complete Casting Handbook; Elsevier: Oxford, UK, 2015; pp. 741–852. [Google Scholar] [CrossRef]

- Erlenkämper, E. Der Beitrag des Spritzgießwerkzeuges zur Zykluszeit. Der Stahlformenbauer 2001, 18, 28–34. [Google Scholar]

- Lange-Robben, R. Beeinflussung des Wärmehaushalts metallischer Dauerformen. Ph.D. Thesis, Universität Hannover, Hannover, Germany, 2006; pp. 7–18. [Google Scholar]

- Ronté, V.; RoÓlSz, A. The Effect of Cooling Rate and Composition on the Secondary Dendrite Arm Spacing during Solidification. Part I: Al-Cu-Si Alloys. Int. J. Cast Met. Res. 2001, 13, 337–342. [Google Scholar] [CrossRef]

- Radhakrishna, K.; Seshan, S. Dendrite Arm Spacing and Mechanical Properties of Aluminium Alloy Castings. Cast Met. 1989, 2, 34–38. [Google Scholar] [CrossRef]

- Pavlovic-Krstic, J.; Bähr, R.; Krstic, G.; Putic, S. The Effect of Mould Temperature and Cooling Conditions on the Size of Secondary Dendrite Arm Spacing in Al-7Si-3Cu Alloy. Assoc. Metall. Eng. Serbia 2009, 15, 105–113. [Google Scholar]

- Cho, J.; Kim, C.; Choi, S.; Kang, C. The Relationship between Dendrite Arm Spacing and Cooling Rate of Al-Si Casting Alloys in High Pressure Die Casting. In Proceedings of the ICAA13 Pittsburgh, Pittsburgh, PA, USA, 3–7 June 2012; Weiland, H., Rollett, A.D., Cassada, W.A., Eds.; Springer: Cham, Switzerland, 2012. [Google Scholar] [CrossRef]

- Gössl, W. Untersuchung zur Kühlwirkung in Druckgussformen. Master’s Thesis, Montanuniversität Leoben, Leoben, Austria, 2011. [Google Scholar]

- Reichen, P.; Schwarz, M.; Altheimer, M. Characterizing the Cooling Capacity of Pulsed Air/Water Cooling in Die Casting Molds. In Proceedings of the Euroguss, Nuremberg, Germany, 16–18 January 2018. [Google Scholar]

- Bundesverband der Deutschen Gießerei-Industrie. Porositätsanalyse und -beurteilung mittels industrieller Röntgen-Computertomographie (CT). In Technical guideline P 203; BDG: Düsseldorf, Germany, 2019; Available online: https://www.guss.de/fileadmin/user_upload/richtlinien/bdg-richtlinie_p_203.pdf (accessed on 22 August 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).