A Study on Powder Metallurgy Process for x Electric Vehicle Stator Core

Abstract

:1. Introduction

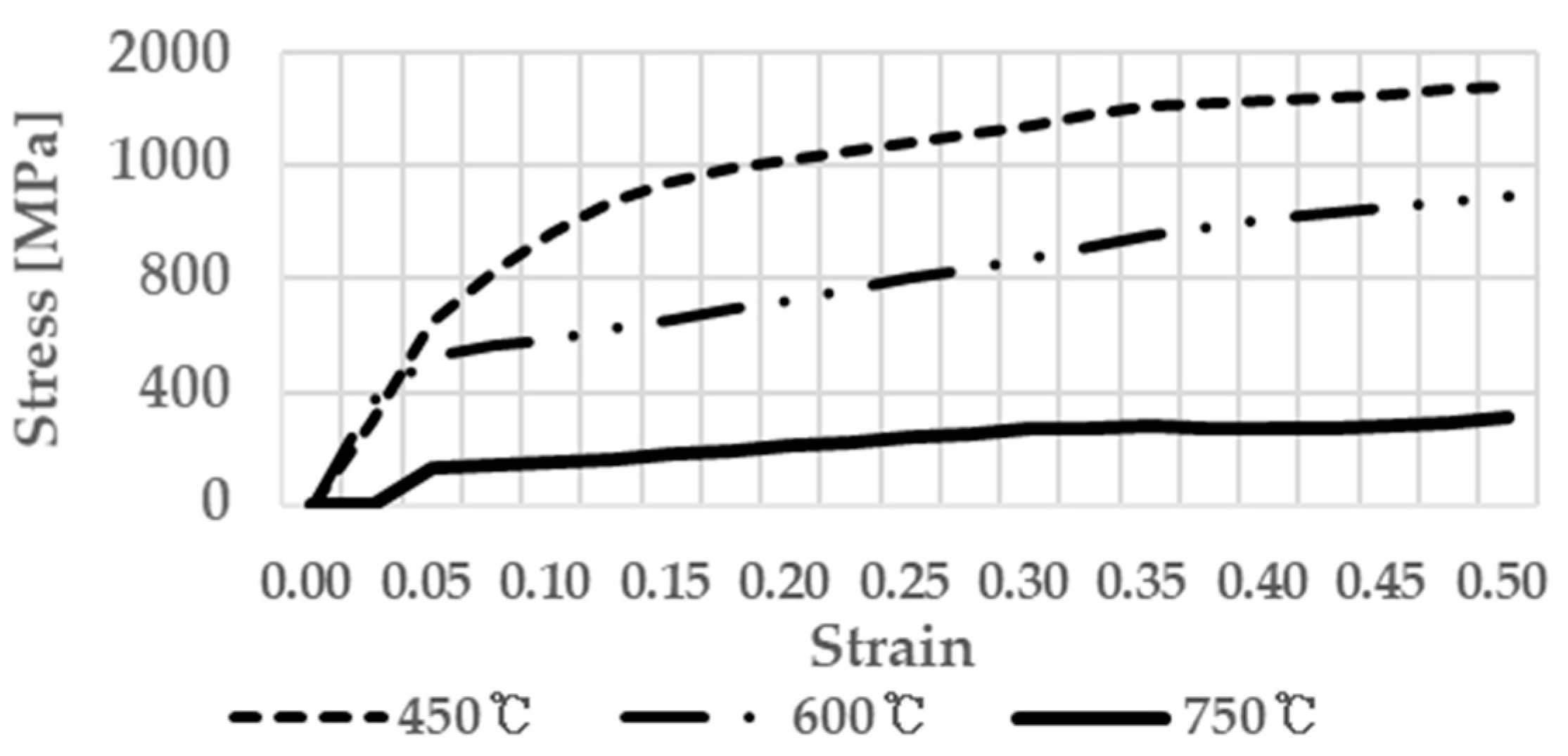

2. Theoretical Background

2.1. Powder Metallurgy and Key Factors

2.2. Yield Conditions for Porous Materials

2.3. Taguchi Method

3. Material Properties

4. Simulation

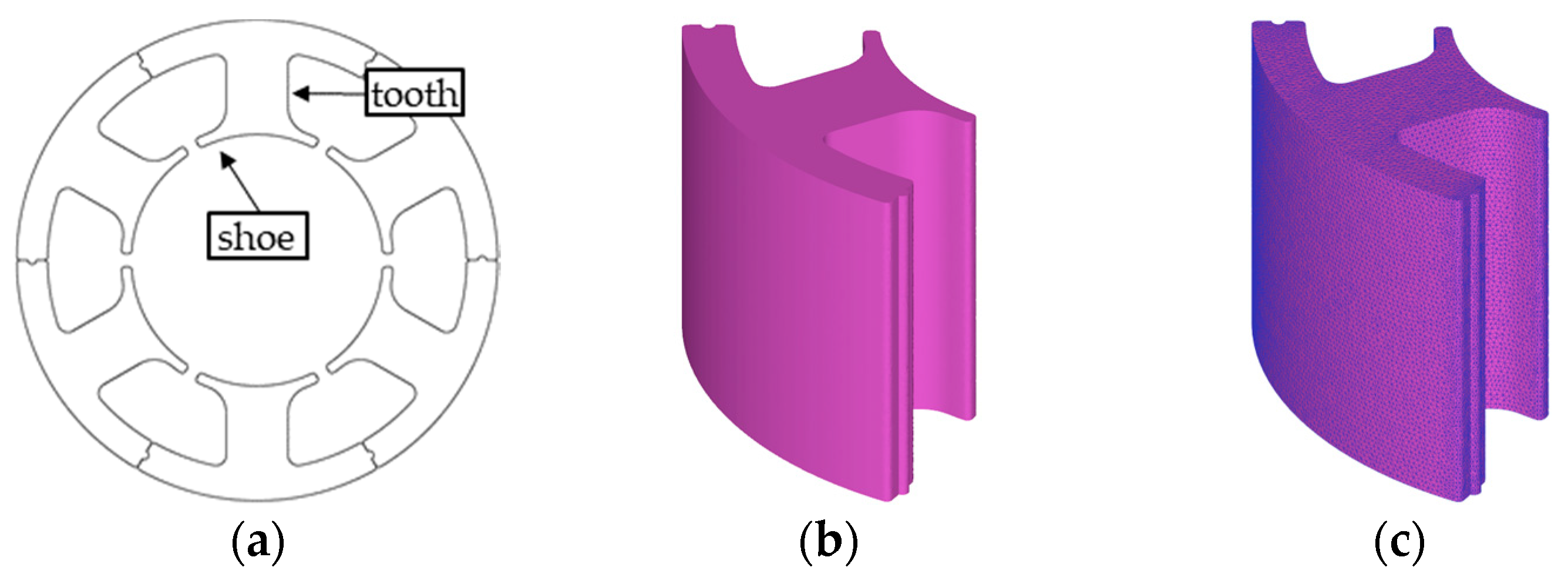

4.1. Shape of Stator Core

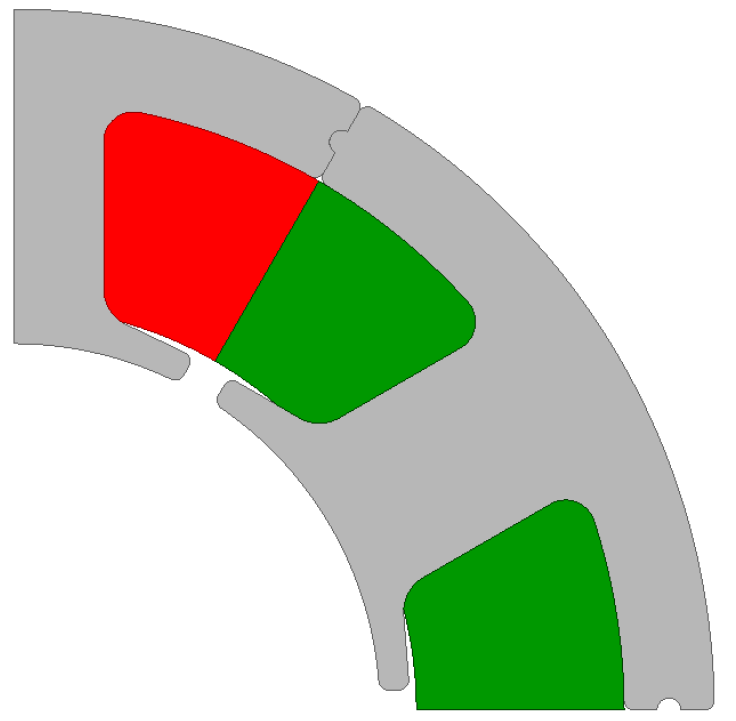

4.2. PM Analysis Model

4.3. DOE Parameters and Level Settings

4.4. Motor Performance Analysis

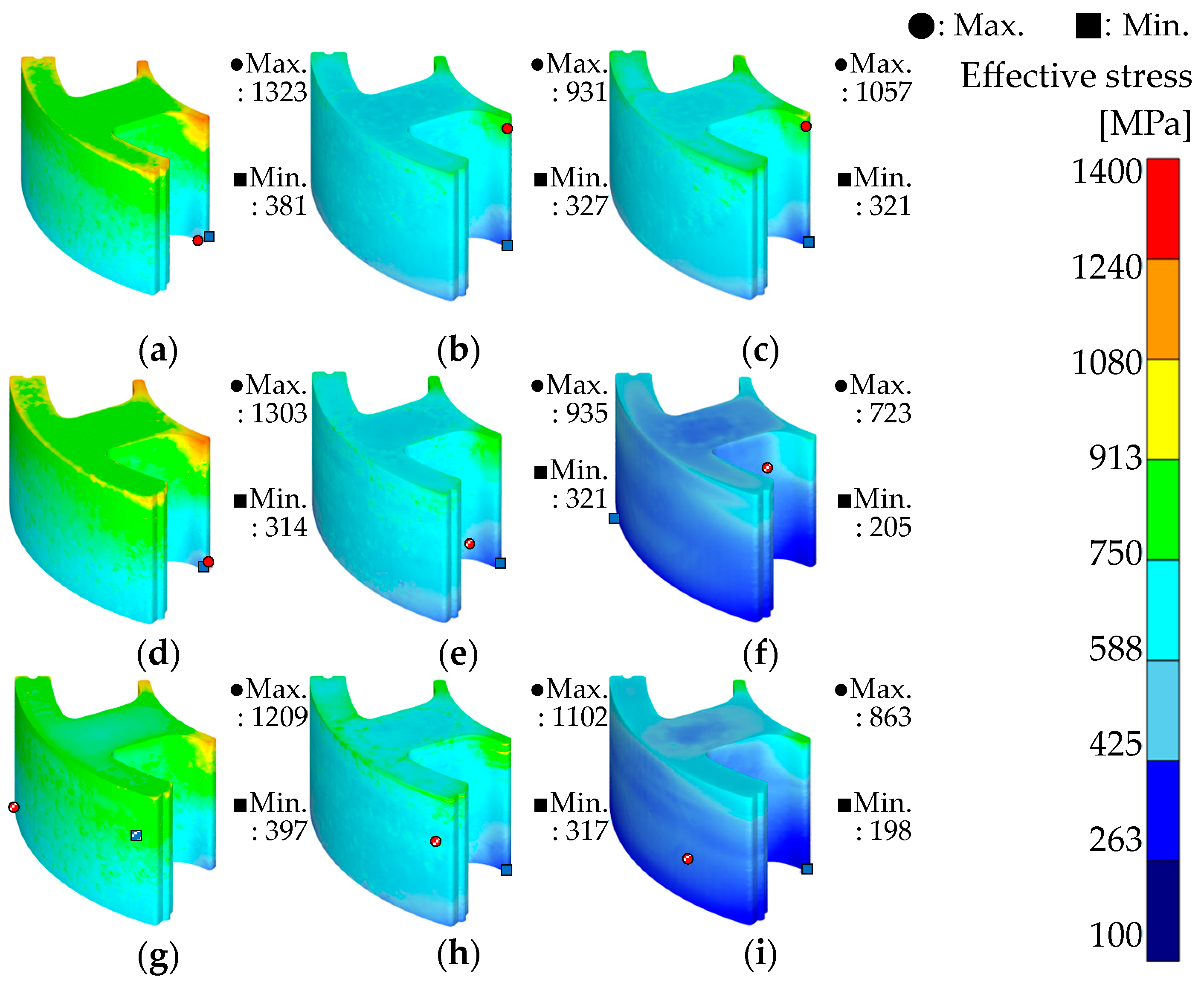

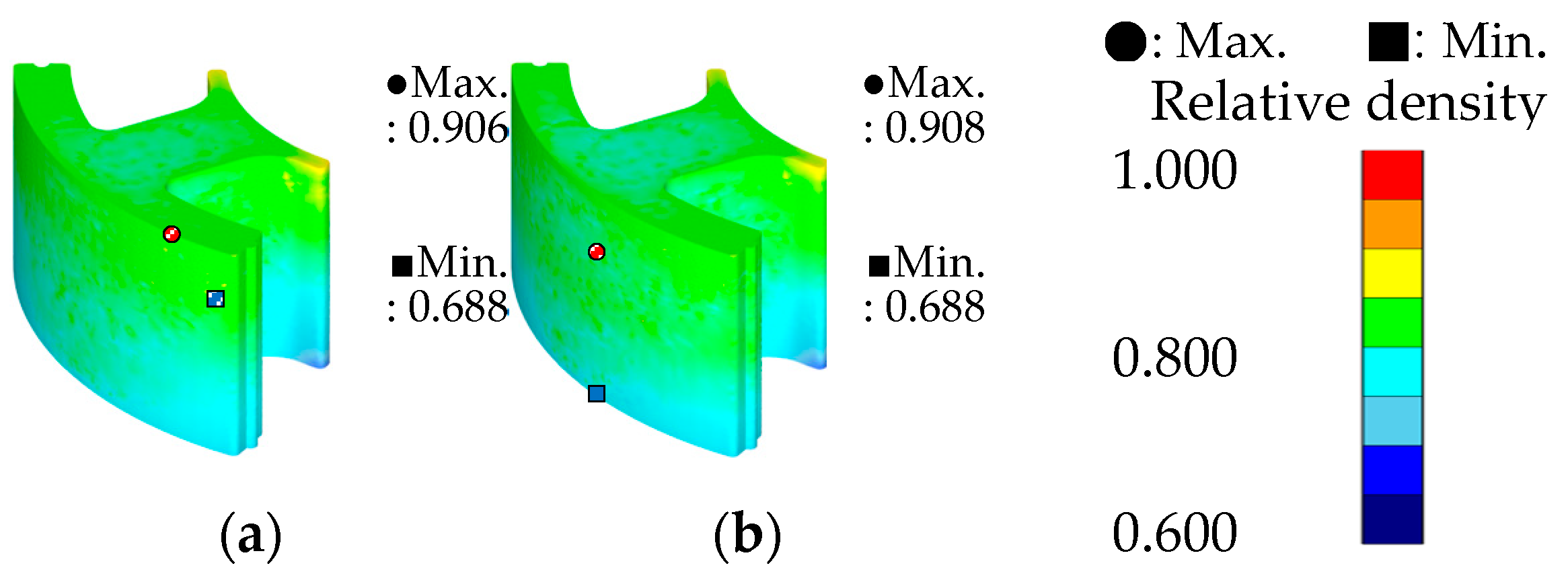

5. Simulation Results

5.1. DOE Results

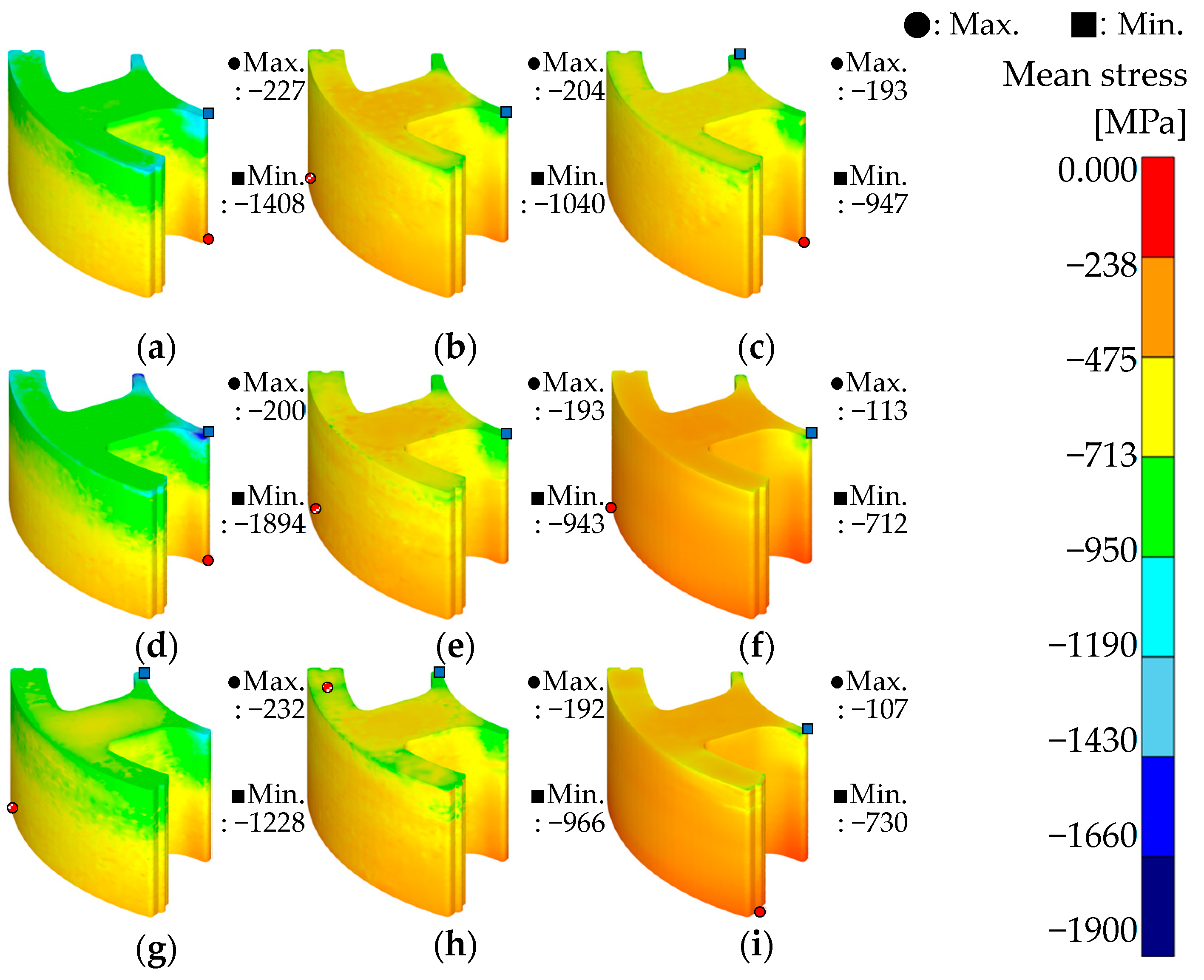

5.2. DOE Analysis

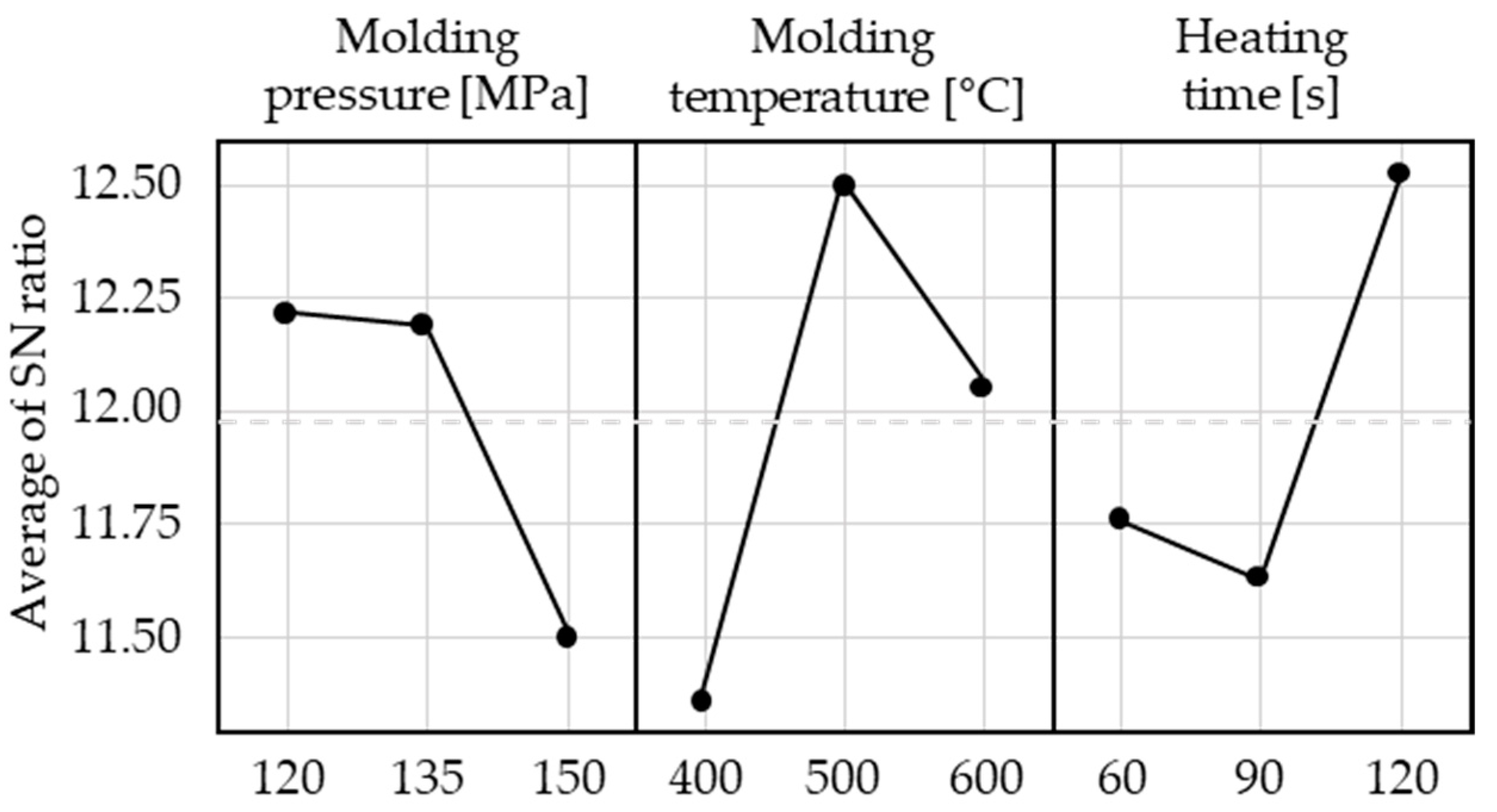

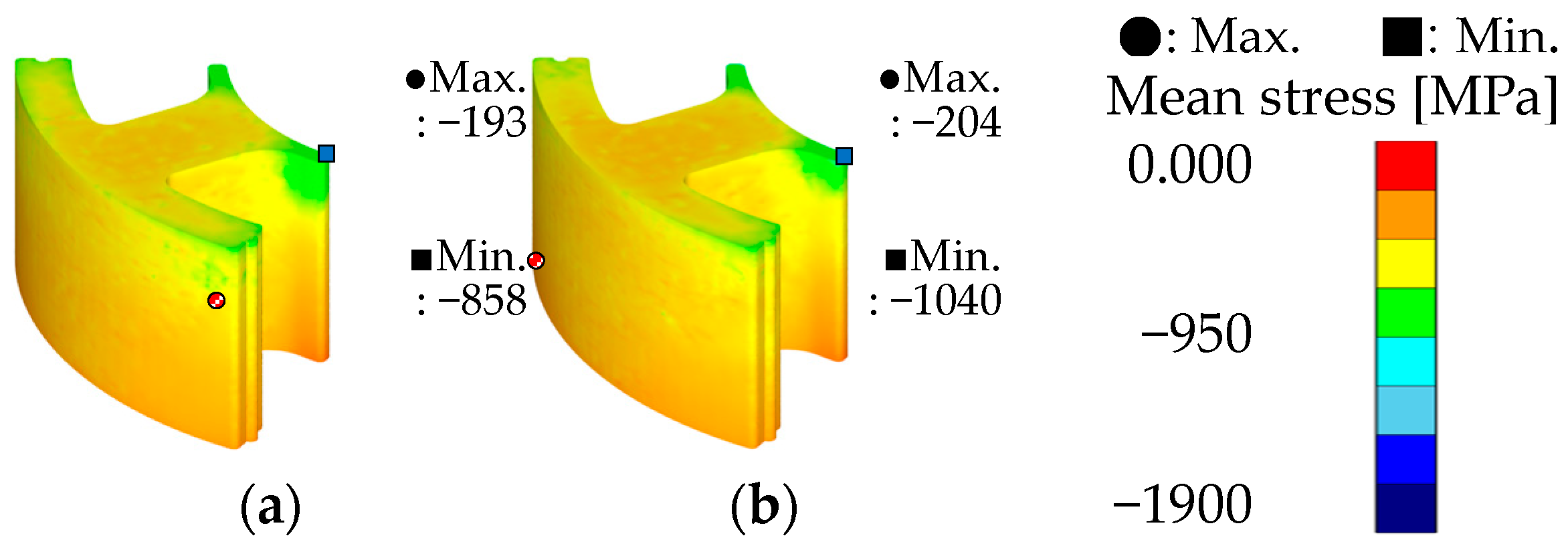

5.3. Verification of Proposed Optimal Process Conditions

5.4. Motor Analysis

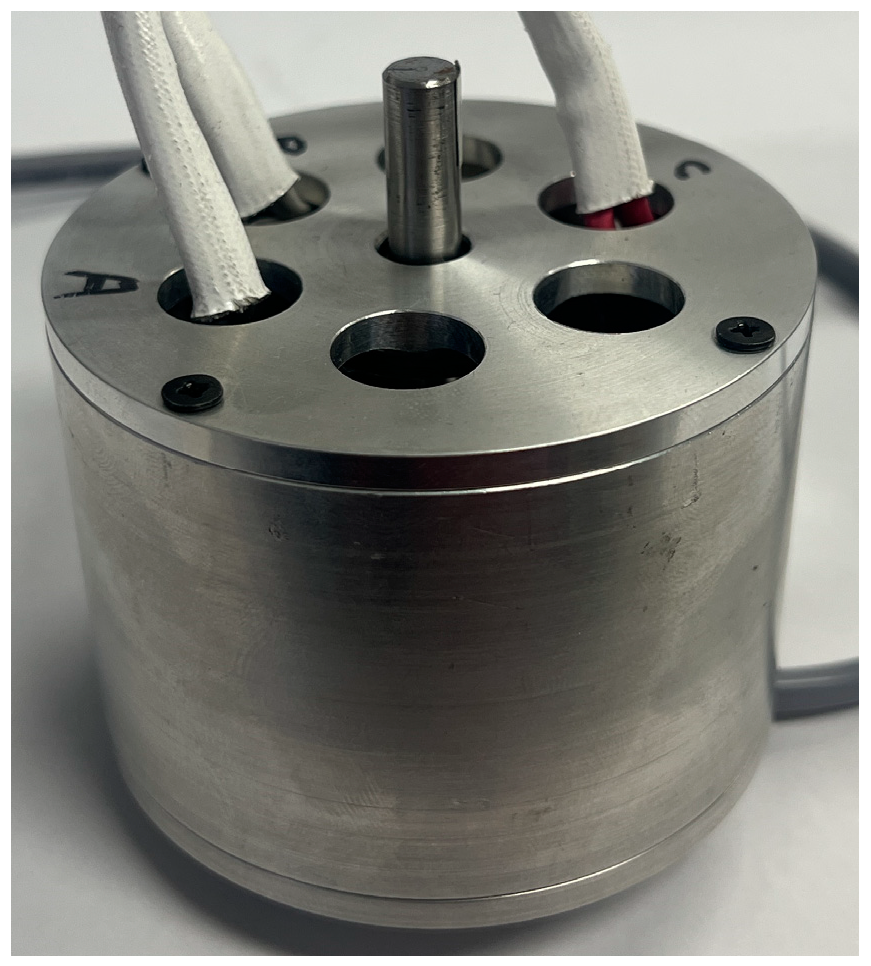

6. Experimental Verification

6.1. Mechanical Property

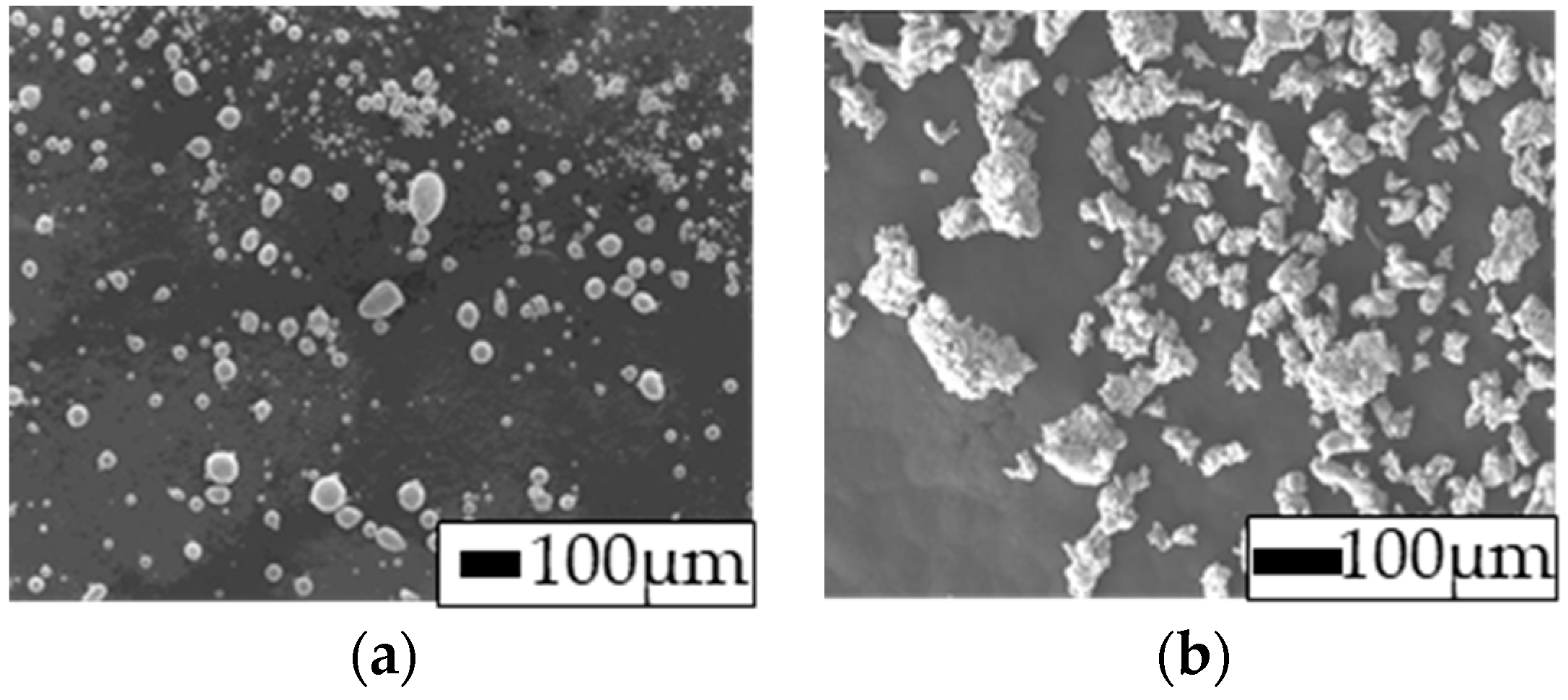

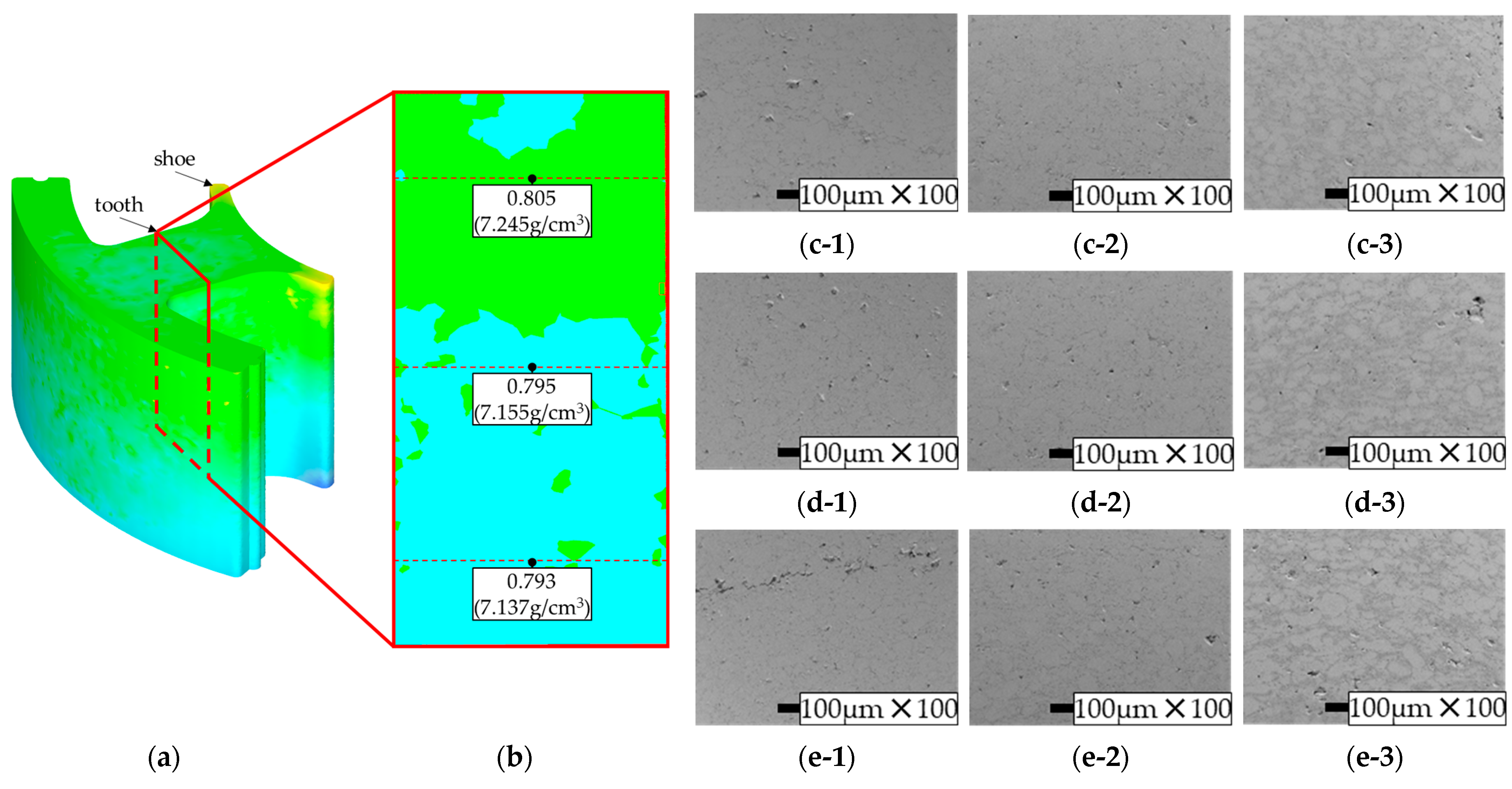

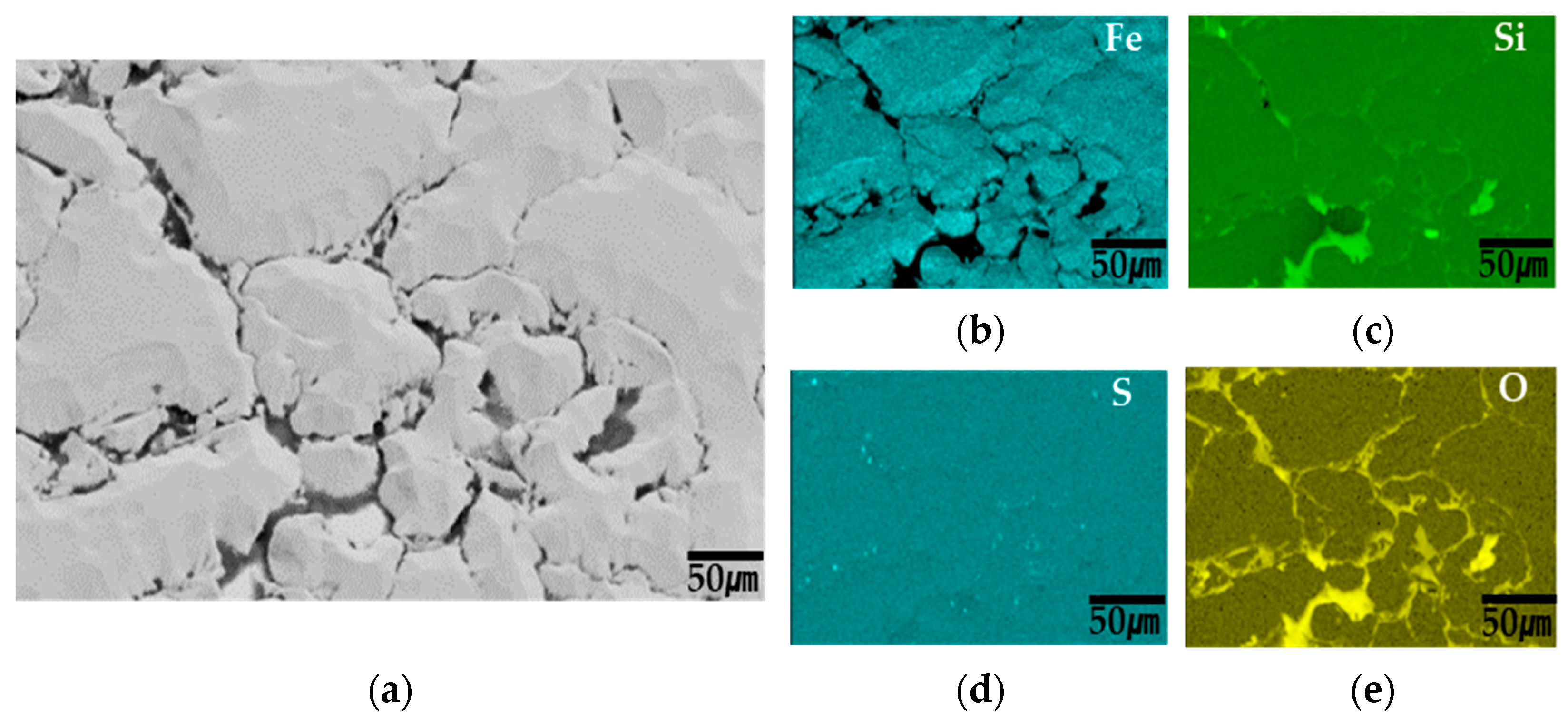

6.2. Microstructure Evaluation

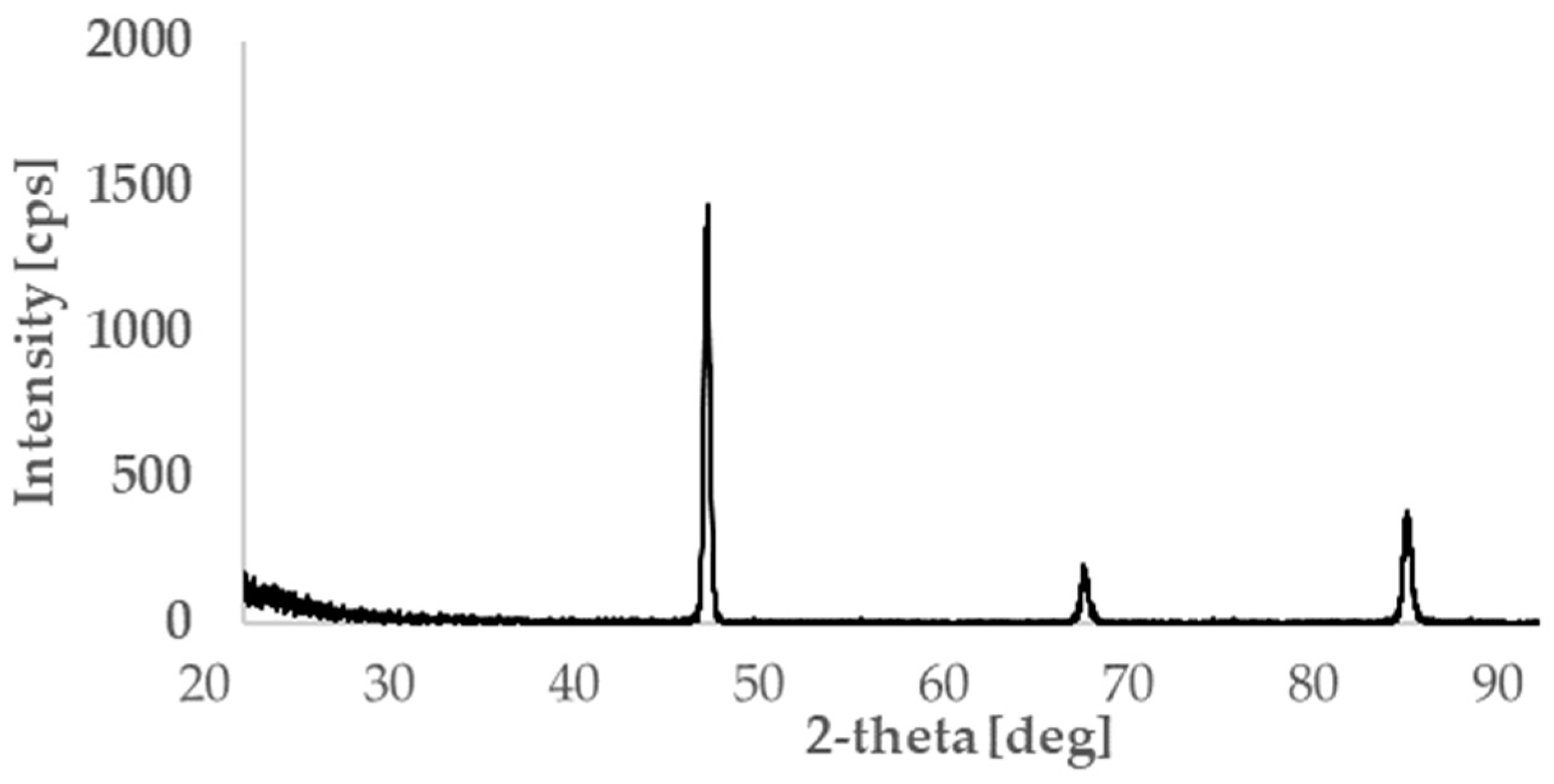

6.3. Electrical Property

7. Discussion and Conclusions

- The Taguchi method was used to select the optimal process conditions for molding the Fe-6.5 wt.%Si powder, and the difference between the maximum and minimum relative densities of the final molded body was set as the characteristic value. In addition, the molding pressure, molding temperature, and temperature rise time, which affect formability, were selected as the control factors.

- Based on powder metallurgy analysis using the Taguchi method, the optimal process conditions were found to be a molding pressure of 120 MPa, a molding temperature of 500 °C, and a temperature rise time of 120 s. Under these conditions, the average relative density was 0.799, and the difference between the maximum and minimum relative densities was 0.218. Additionally, the average effective stress and average mean stress were 578.69 MPa and −441.04 MPa, respectively.

- Core loss, saturation flux density, and bulk conductivity were measured, and motor performance analysis was performed. As a result, the average torque was 150.237 mN·m at 10,000 rpm.

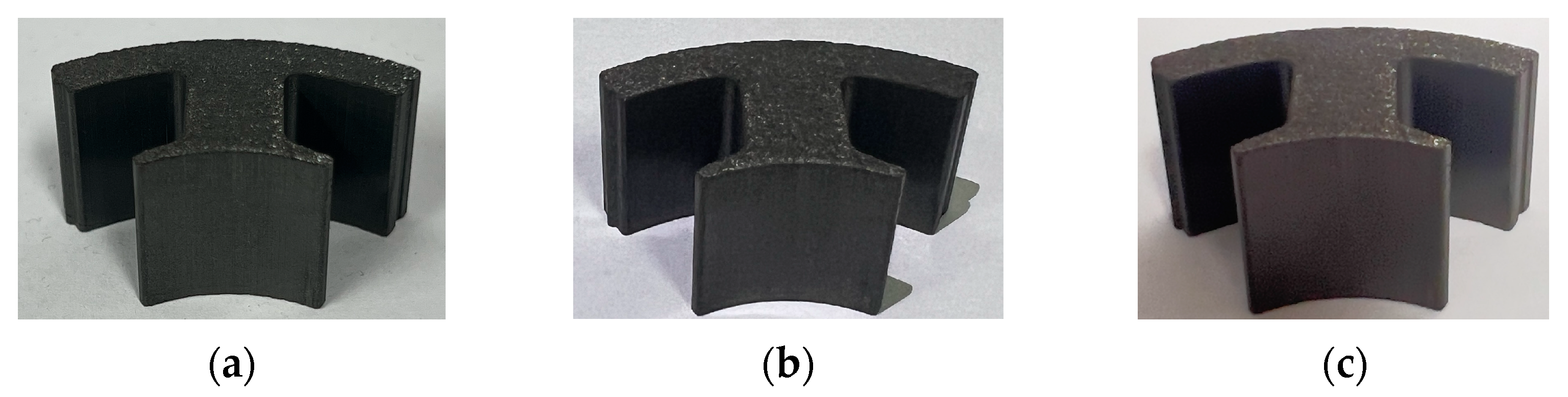

- To validate the optimal process conditions, three prototype stator cores were manufactured, and the densities obtained from the powder metallurgy simulation were compared with those of the prototypes. To analyze the trend of internal density, SEM was analyzed by dividing the 15, 9, and 3 mm sections from the bottom into the top, middle, and bottom. The powder metallurgy analysis showed that the density decreased from the top to the middle to the bottom; this trend was consistent with the SEM analysis.

- XRD tests were performed to confirm the phase information of the stator core, and EDS and EBSD tests were performed to quantitatively characterize the crystal phase and particle distribution. As a result of the test, it was confirmed that the peak value was the same as the peak value of ɑ-Fe, and it had a BCC crystal structure.

- A test motor was manufactured using SMCs stator core, and performance tests were conducted. As a result, the torque was found to be 150.156 mN·m at 10,107.5 rpm. In addition, the reliability of the analysis can be verified, as the error rate between the analysis and test results was 0.05%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jansson, P. Soft Magnetic Composite Materials Applied to Electric Motors. EPE J. 2004, 14, 38–42. [Google Scholar] [CrossRef]

- Hasegawa, R. Present status of amorphous soft magnetic alloys. J. Magn. Magn. Mater. 2000, 215, 240–245. [Google Scholar] [CrossRef]

- Pošković, E.; Carosio, F.; Franchini, F.; Ferraris, L. Innovative SMC Insulation Technique Applied to Axial Flux Machine Prototypes. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022. [Google Scholar]

- Tsunata, R.; Takemoto, M.; Ogasawara, S.; Saito, T.; Ueno, T. SMC development guidelines for axial flux PM machines employing coreless rotor structure for enhancing efficiency based on experimental results. IEEE Trans. Ind. Appl. 2022, 58, 3470–3485. [Google Scholar] [CrossRef]

- Chengcheng, L.; Youhua, W.; Gang, L.; Youguang, G.; Jianguo, Z. Performance analysis of a new radial-axial flux machine with SMC cores and ferrite magnets. AIP Adv. 2017, 7, 056603. [Google Scholar]

- Boll, R. Soft Magnetic Materials; Siemens AK and Heyden and Son Ltd.: Philadelphia, PA, USA, 1979. [Google Scholar]

- Shokrollahi, H.; Janghorban, K. Different annealing treatments for improvement of magnetic and electrical properties of soft magnetic composites. J. Magn. Magn. Mater. 2007, 317, 61–67. [Google Scholar] [CrossRef]

- Enescu, E.; Lungu, P.; Marinescu, S.; Dragoi, P. The effect of processing conditions on magnetic and electric properties of composite materials used in nonconventional magnetic circuits. J. Optoelectron. Adv. Mater. 2006, 8, 745–748. [Google Scholar]

- Lagutkin, S.; Achelis, L.; Sheikhaliev, S.; Uhlenwinkel, V.; Srivastava, V. Atomization process for metal powder. Mater. Sci. Eng. A 2004, 383, 1–6. [Google Scholar] [CrossRef]

- Sunday, K.J.; Darling, K.A.; Hanejko, F.G.; Anasori, B.; Liu, Y.C.; Taheri, M.L. Al2O3 “self-coated” iron powder composites via mechanical milling. J. Alloys Compd. 2015, 65, 61–68. [Google Scholar] [CrossRef]

- Kim, H.R.; Jang, M.S.; Nam, Y.G.; Kim, Y.S.; Yang, S.S.; Kim, Y.J.; Jeong, J.W. Enhanced permeability of Fe-based amorphous powder cores realized through selective incorporation of carbonyl iron powders at inter-particle voids. Metals 2021, 11, 1220. [Google Scholar] [CrossRef]

- Dudrová, E.; Kabátová, M.; Hvizdoš, P.; Oriňáková, R. Sintered composite materials on the basis of Fe/FePO4-coated powders. Surf. Interface Anal. 2015, 47, 350–356. [Google Scholar] [CrossRef]

- Rausch, T.; Beiss, P.; Broeckmann, C.; Lindlohr, S.; Weber, R. Application of quantitative image analysis of graphite structures for the fatigue strength estimation of cast iron materials. Procedia Eng. 2010, 2, 1283–1290. [Google Scholar] [CrossRef]

- Jeandin, M.; Rupp, S.; Massol, J.; Bienvenu, Y. Structural study and image analysis of rapidly cooled supersolidus-sintered Astroloy. Mater. Sci. Eng. 1986, 77, 139–147. [Google Scholar] [CrossRef]

- Bidulská, J.; Kvačkaj, T.; Kočiško, R.; Bidulský, R.; Grande, M.A. Effect of ECAP on the dimensional and morphological characteristics of high performance aluminium PM alloy. Mater. Sci. Forum 2011, 667, 535–540. [Google Scholar] [CrossRef]

- Vander Voort, G.F. (Ed.) Metallography and microstructures; ASM International Materials Park: Novelty, OH, USA, 2004. [Google Scholar]

- Exner, H.E.; Arzt, E. Sintering Processes. In Sintering Key Papers; Springer: Berlin/Heidelberg, Germany, 1990; pp. 157–184. [Google Scholar]

- Bidulská, J.; Bidulský, R.; Petroušek, P.; Fedoriková, A.; Katreničová, I.; Pokorný, I. Porosity behaviour of insulated iron powder compounds. Acta Phys. Pol. A 2017, 131, 1384–1386. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S. Study on compressibility according to mixing ratio and milling time of Fe-6.5 wt.% Si. Materials 2024, 17, 1723. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of advanced manufactured titanium implants—A review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy Science; Metal Powder Industries Federation: Princeton, NJ, USA, 1994. [Google Scholar]

- Reed, J.S. Principles of Ceramics Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1995. [Google Scholar]

- Shima, S.; Oyane, M. Plasticity theory for porous metals. Int. J. Mech. Sci. 1976, 18, 285–291. [Google Scholar] [CrossRef]

- Karna, S.K.; Sahai, R. An overview on Taguchi method. Int. J. Eng. Math. Sci. 2012, 1, 11–18. [Google Scholar]

- Tsui, K.L. An overview of Taguchi method and newly developed statistical methods for robust design. Iie Trans. 1992, 24, 44–57. [Google Scholar] [CrossRef]

- Lee, S.L.; Lee, S.B. A study on mPPO development and injection molding process for lightweight stack enclosure of FCEV. Polymers 2023, 15, 1303. [Google Scholar] [CrossRef]

- Kraft, T.; Riedel, H. Numerical simulation of solid state sintering; model and application. J. Eur. Ceram. Soc. 2004, 24, 345–361. [Google Scholar] [CrossRef]

| Temperature [°C] | Coefficient of Thermal Expansion |

|---|---|

| 100 | 1.13 |

| 200 | 1.19 |

| 300 | 1.26 |

| 400 | 1.31 |

| 500 | 1.35 |

| 600 | 1.42 |

| 700 | 1.47 |

| Temperature [°C] | Thermal Diffusivity [mm2/s] | Specific Heat [J/gK] | Thermal Conductivity [W/mK] |

|---|---|---|---|

| 25 | 4.20 | 0.45 | 14.2 |

| 100 | 4.34 | 0.54 | 17.6 |

| 200 | 4.50 | 0.57 | 19.0 |

| 300 | 4.59 | 0.58 | 20.0 |

| 400 | 4.60 | 0.60 | 20.6 |

| 500 | 4.51 | 0.64 | 21.6 |

| 600 | 4.21 | 0.91 | 28.6 |

| 700 | 3.76 | 1.07 | 30.2 |

| Jmax [T] | Frequency [Hz] | ||

|---|---|---|---|

| 250 | 500 | 1000 | |

| 0.01 | 0.019 W/kg | 0.038 W/kg | 0.076 W/kg |

| 0.05 | 0.095 W/kg | 0.189 W/kg | 0.378 W/kg |

| 0.1 | 0.189 W/kg | 0.378 W/kg | 0.756 W/kg |

| Definition | Ms [emu/g] | Saturation Flux Density [T] |

|---|---|---|

| Sample 1 | 188.28 | 1.72 |

| Sample 2 | 190.84 | 1.74 |

| Average | 189.56 | 1.73 |

| Definition | Bulk Conductivity [S/m] |

|---|---|

| Sample 1 | 0.44 |

| Sample 2 | 0.55 |

| Average | 0.495 |

| Factor | Description | Level | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| A | Molding pressure [MPa] | 120 | 135 | 150 |

| B | Molding Temperature [°C] | 400 | 500 | 600 |

| C | Heating time [s] | 60 | 90 | 120 |

| Simulation No. | A | B | C |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 |

| 3 | 1 | 3 | 3 |

| 4 | 2 | 1 | 2 |

| 5 | 2 | 2 | 3 |

| 6 | 2 | 3 | 1 |

| 7 | 3 | 1 | 3 |

| 8 | 3 | 2 | 1 |

| 9 | 3 | 3 | 2 |

| Definition | Unit | Value |

|---|---|---|

| Pole/Slot | - | 4/12 |

| Outer diameter/ Inner (Stator) | mm | 70/36.6 |

| Outer diameter/ Inner (Rotor) | mm | 32/10 |

| Length | mm | 49.45 |

| Case | Average Relative Density (Absolute Density) | Max.–Min. Relative Density (Absolute Density) | Average Effective Stress [MPa] | Average Mean Stress [MPa] |

|---|---|---|---|---|

| 1 | 0.800 (7.200 g/cm3) | 0.278 (2.502 g/cm3) | 753.39 | −580.64 |

| 2 | 0.798 (7.182 g/cm3) | 0.220 (1.980 g/cm3) | 575.75 | −435.62 |

| 3 | 0.799 (7.191 g/cm3) | 0.240 (2.160 g/cm3) | 580.00 | −437.99 |

| 4 | 0.800 (7.200 g/cm3) | 0.289 (2.601 g/cm3) | 748.70 | −579.10 |

| 5 | 0.798 (7.182 g/cm3) | 0.224 (2.016 g/cm3) | 572.10 | −432.60 |

| 6 | 0.800 (7.200 g/cm3) | 0.229 (2.061 g/cm3) | 408.30 | −314.72 |

| 7 | 0.797 (7.173 g/cm3) | 0.246 (2.214 g/cm3) | 738.29 | −557.22 |

| 8 | 0.799 (7.191 g/cm3) | 0.270 (2.430 g/cm3) | 557.72 | −433.19 |

| 9 | 0.802 (7.218 g/cm3) | 0.283 (2.547 g/cm3) | 410.59 | −317.03 |

| Case | Max.–Min. Relative Density | SNR |

|---|---|---|

| 1 | 0.278 | 11.119 |

| 2 | 0.220 | 13.152 |

| 3 | 0.240 | 12.396 |

| 4 | 0.289 | 10.782 |

| 5 | 0.224 | 12.995 |

| 6 | 0.229 | 12.803 |

| 7 | 0.246 | 12.181 |

| 8 | 0.270 | 11.373 |

| 9 | 0.283 | 10.964 |

| Description | Molding Pressure [MPa] | Molding Temperature [°C] | Heating Time [s] | |

|---|---|---|---|---|

| Level | 1 | 12.22 | 11.36 | 11.77 |

| 2 | 12.19 | 12.51 | 11.63 | |

| 3 | 11.51 | 12.05 | 12.52 | |

| Delta | 0.72 | 1.15 | 0.89 | |

| Rank | 3 | 1 | 2 | |

| Simulation Case | Max.–Min. Relative Density | Relative Density | Effective Stress [MPa] | Mean Stress [MPa] |

|---|---|---|---|---|

| Optimal process conditions | 0.218 | 0.799 | 578.69 | −441.04 |

| Case 2 | 0.220 | 0.798 | 757.75 | −435.62 |

| Definition | Torque [mN·m] |

|---|---|

| Analysis (@10,000 rpm) | 150.237 |

| Experiment (@10,107.5 rpm) | 150.156 |

| Error rate | 0.05% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Lee, S. A Study on Powder Metallurgy Process for x Electric Vehicle Stator Core. Metals 2024, 14, 858. https://doi.org/10.3390/met14080858

Kim J, Lee S. A Study on Powder Metallurgy Process for x Electric Vehicle Stator Core. Metals. 2024; 14(8):858. https://doi.org/10.3390/met14080858

Chicago/Turabian StyleKim, Jaemin, and Seonbong Lee. 2024. "A Study on Powder Metallurgy Process for x Electric Vehicle Stator Core" Metals 14, no. 8: 858. https://doi.org/10.3390/met14080858

APA StyleKim, J., & Lee, S. (2024). A Study on Powder Metallurgy Process for x Electric Vehicle Stator Core. Metals, 14(8), 858. https://doi.org/10.3390/met14080858