Effect of Annealing Temperature on Microstructure and Magnetocaloric Properties of Gd-Based Metallic Microfibers

Abstract

:1. Introduction

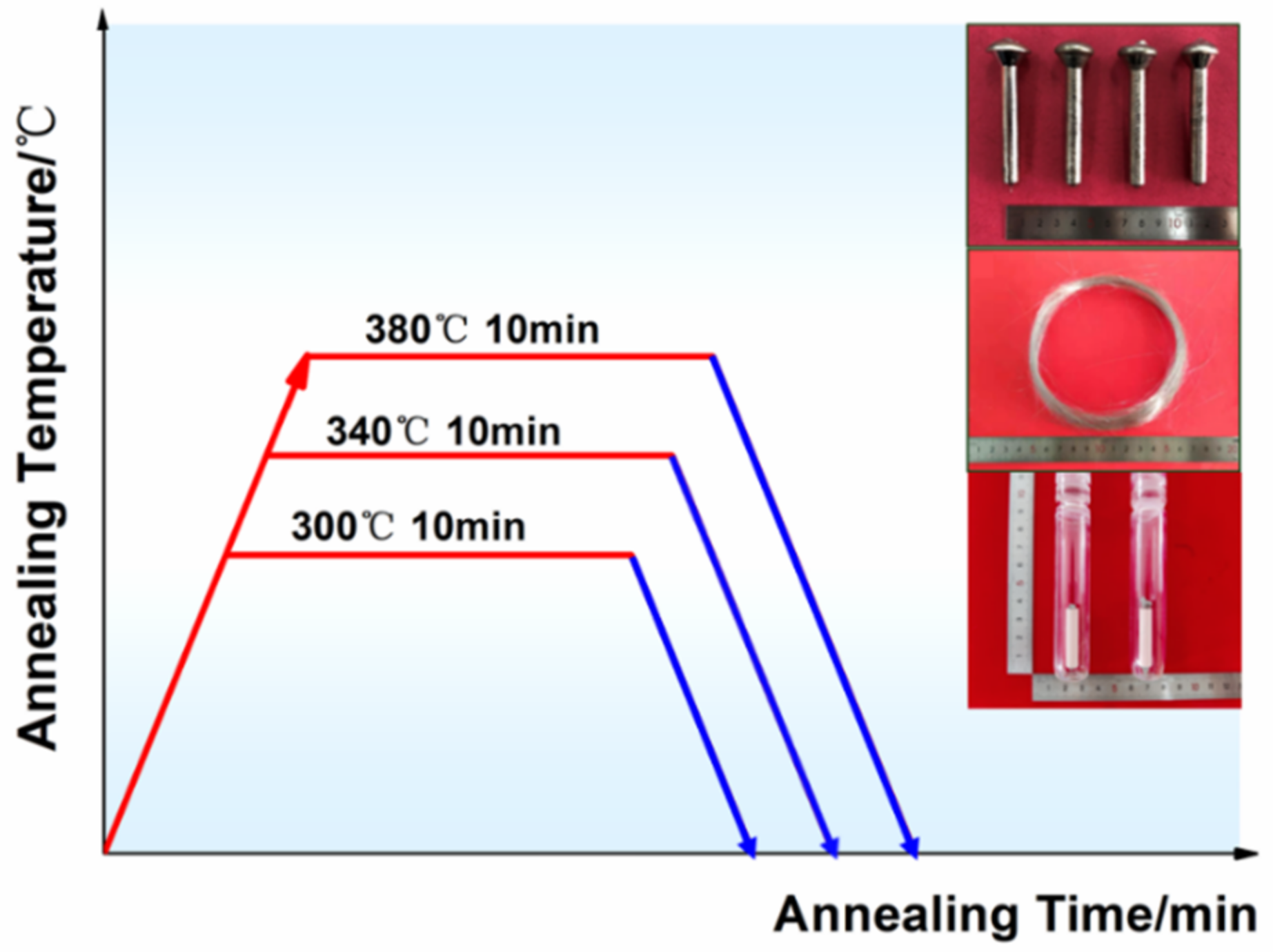

2. Materials and Methods

3. Results and Discussion

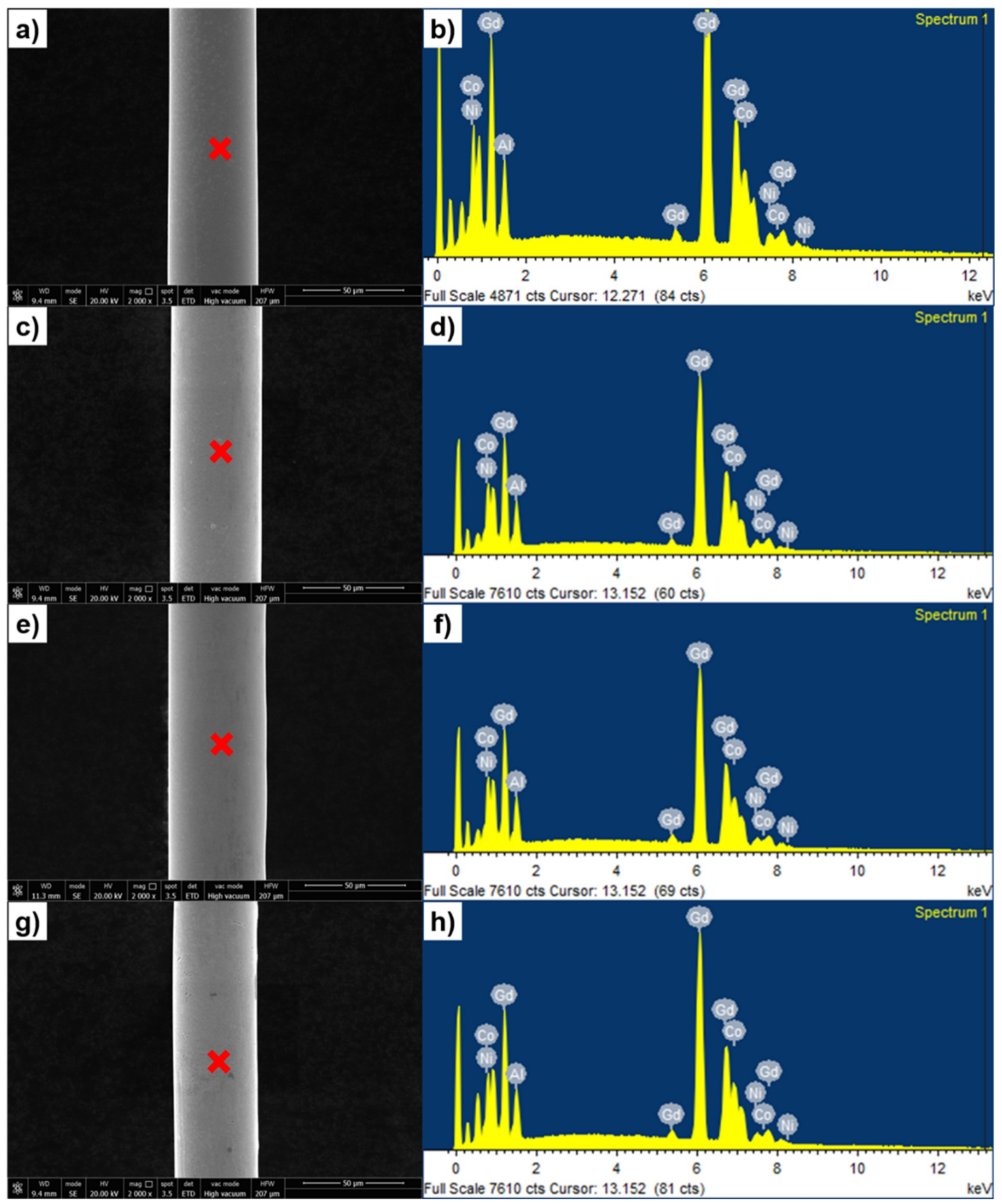

3.1. Structural Analysis of Gd-Based Metallic Microfibers

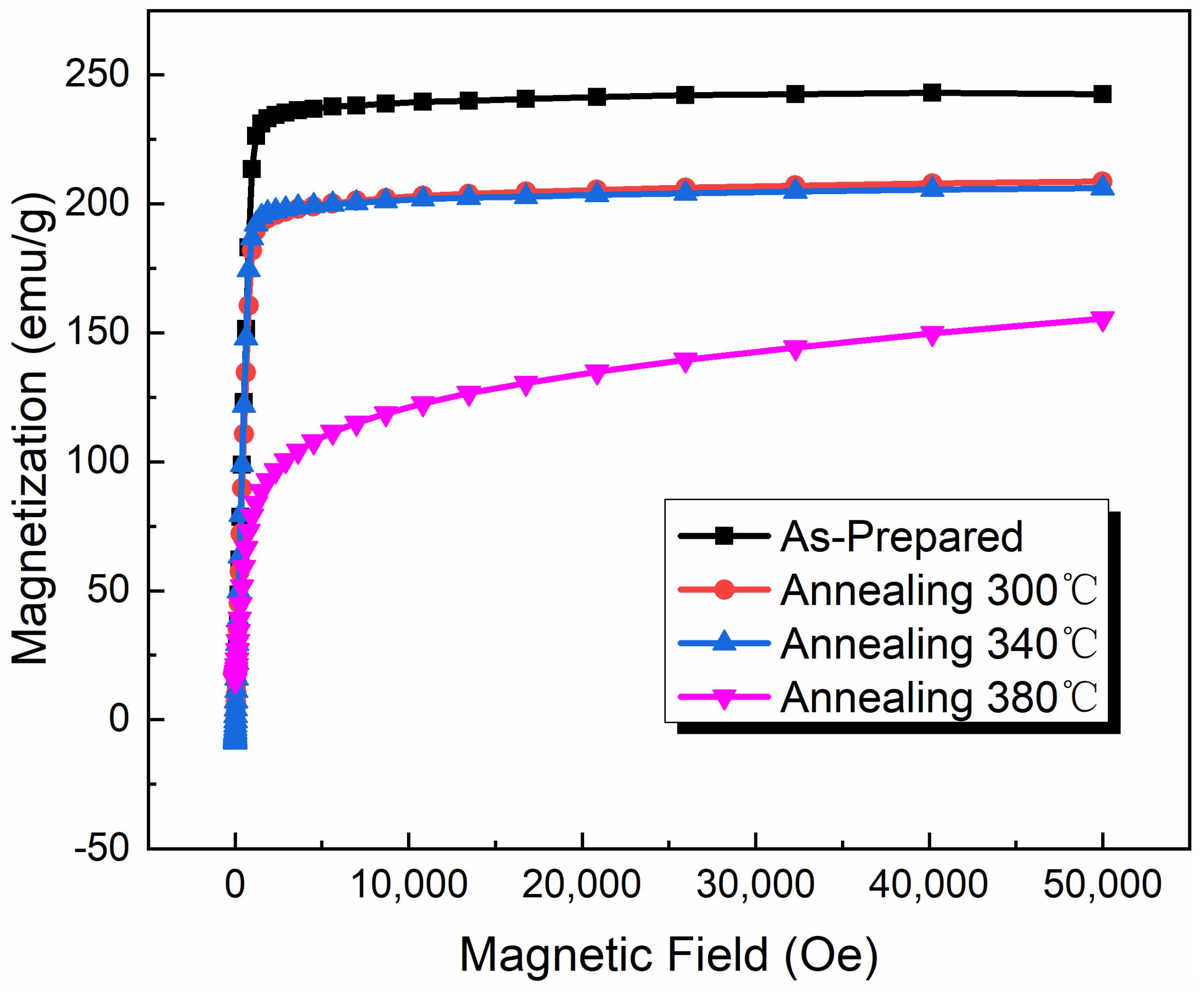

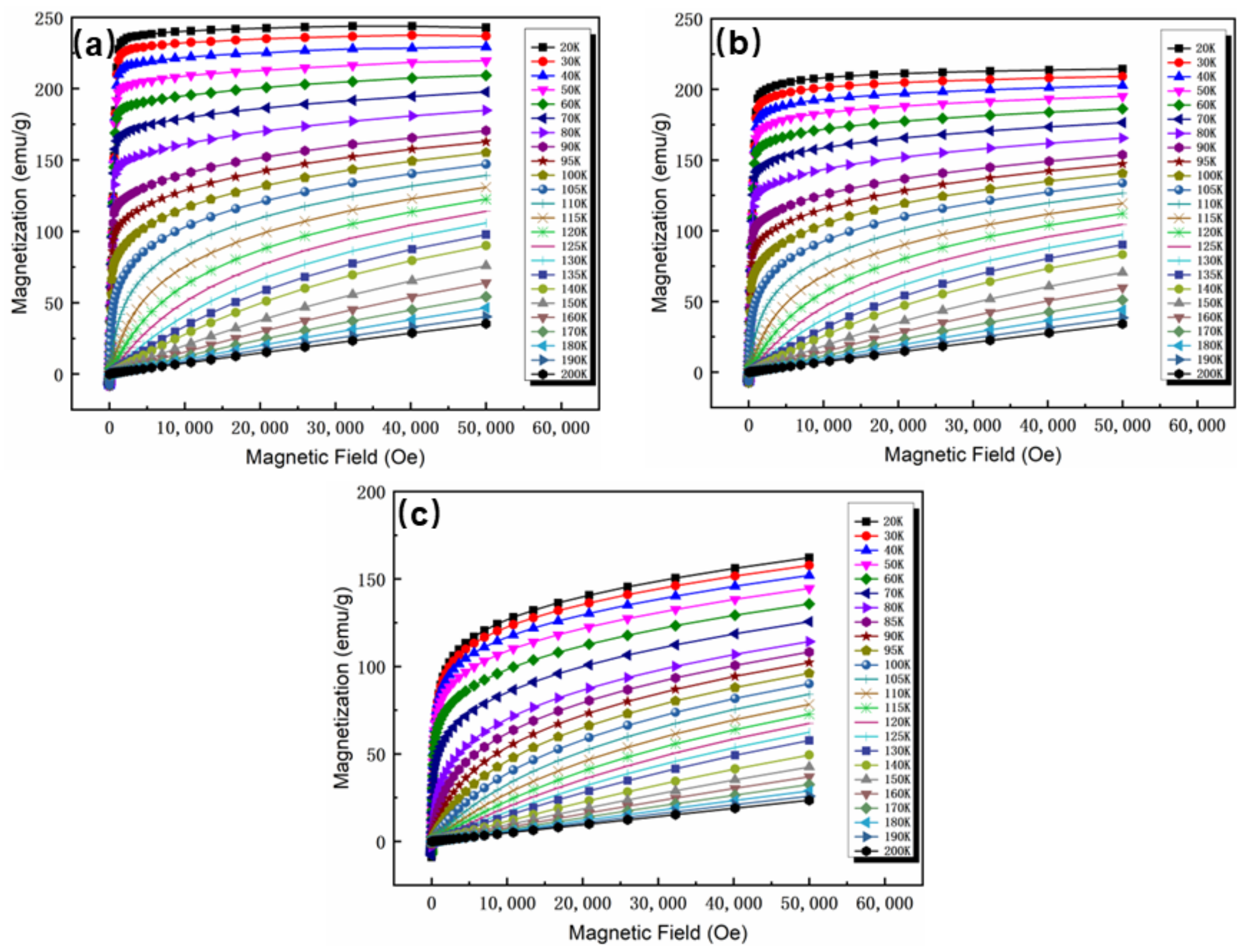

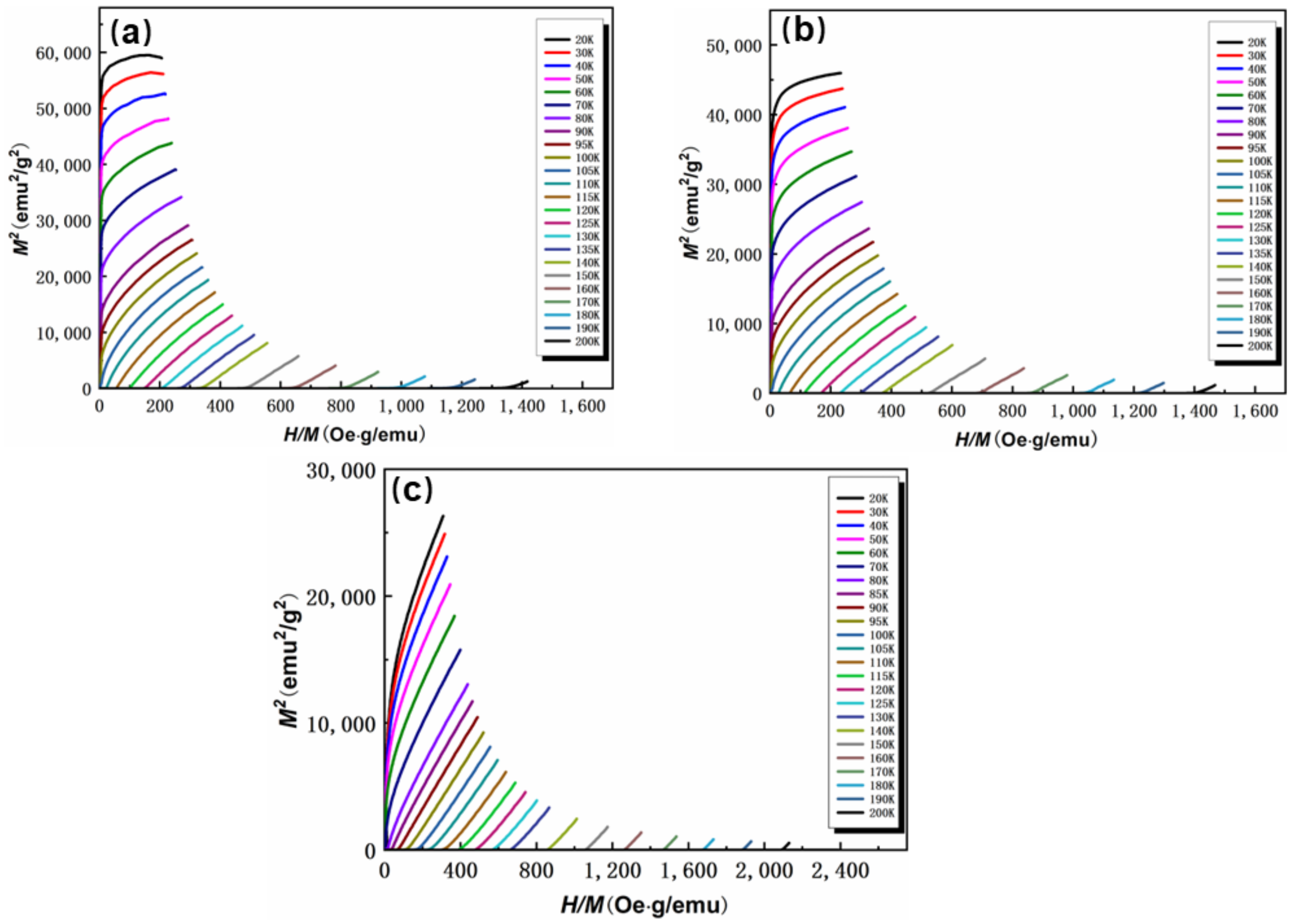

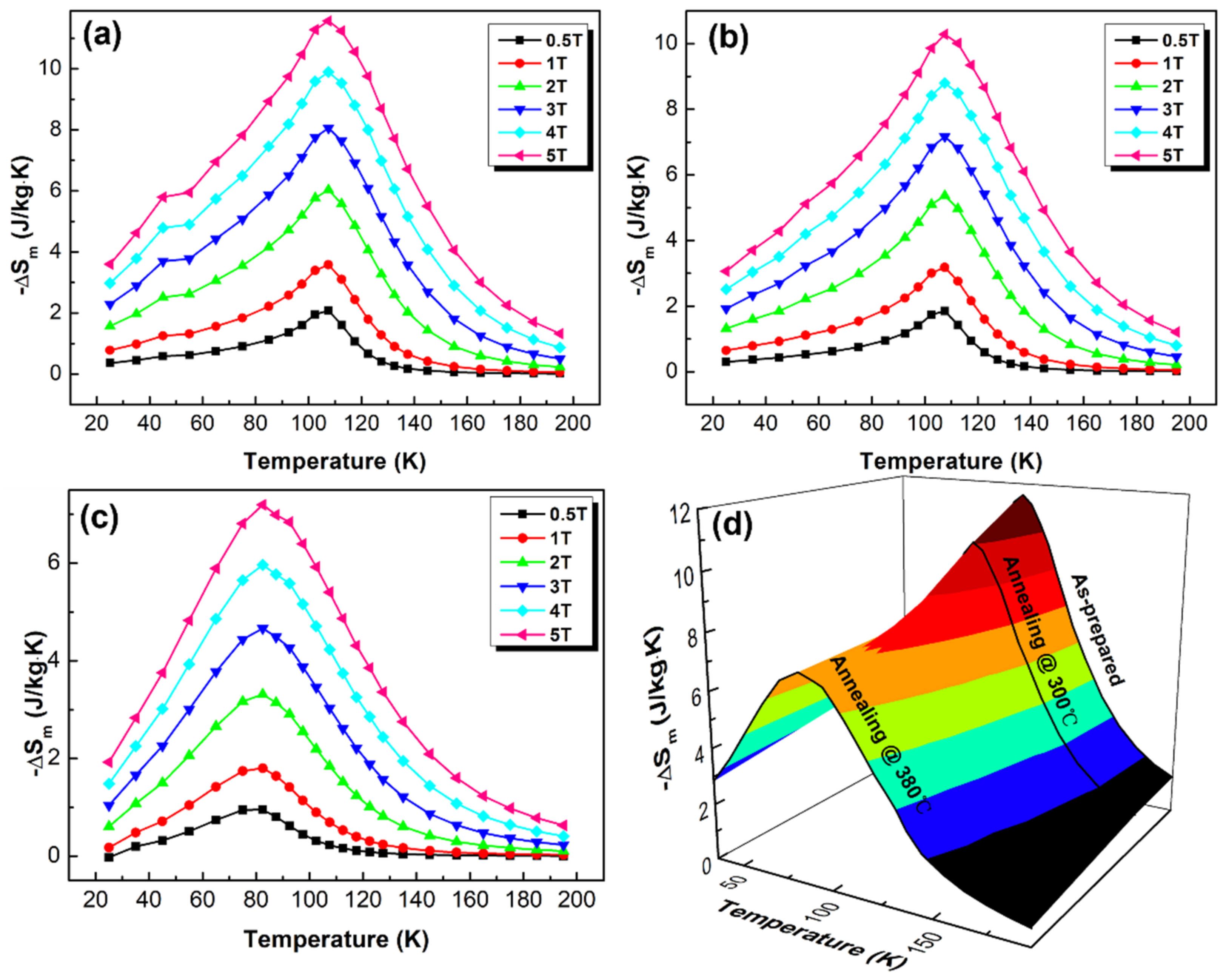

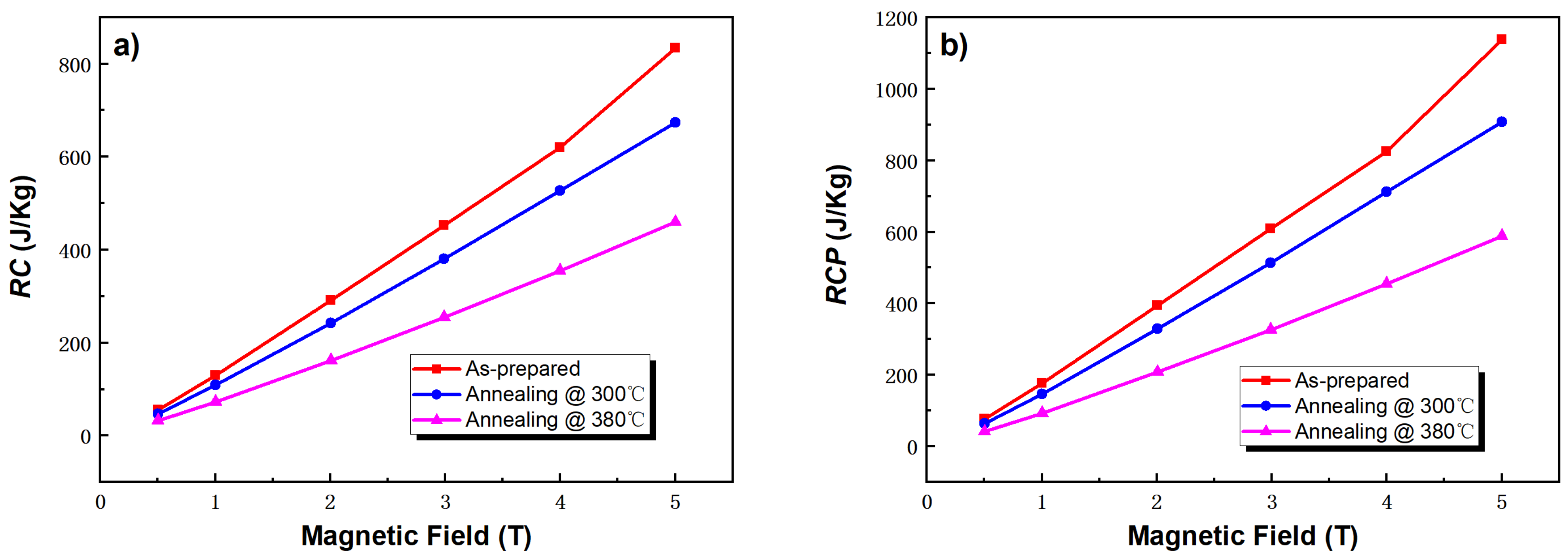

3.2. Magnetic Property Analysis of Gd-Based Metallic Microfibers

3.3. Mechanism Analysis of Annealing Gd-Based Metallic Microfibers

4. Conclusions

- Gd-based metallic microfibers have a favorable thermal stability and glass-forming ability. The local atoms in the microfibers are arranged in an orderly manner and the ordered micro-regions are formed after annealing @ 380 °C.

- The Mr, Hc, and μm of the Gd-based metallic microfibers increase with the rising of the annealing temperature, which reached 17.83 emu/g, 125.12 Oe, and 0.58, respectively at the annealing temperature of 380 °C. The −ΔSmmax, RC, and RCP for the microfibers annealed at 380 °C are 7.20 J/kg K, 459.4 J/kg, and 588.7 J/kg, respectively, at the Hex of 5 T.

- After annealing @ 380 °C, the local atoms in the metallic microfibers are rearranged to generate ordered micro-regions of atomic clusters, which will hinder the movement of the domain wall and the rotation of the magnetic moment during the magnetization process, thereby affecting the synergy of the magnetic moment under the external magnetic field. Simultaneously, the magnetic entropy value of the microfibers decreases with the formation of the locally ordered micro-regions, which ultimately affects the magnetocaloric properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, L.; Shen, H.X.; Bao, Y.; Yin, H.; Jiang, S.D.; Huang, Y.J.; Guo, S.; Gao, S.Y.; Xing, D.W.; Li, Z.; et al. Magnetocaloric effect of melt-extracted high-entropy Gd19Tb19Er18Fe19Al25 amorphous microwires. J. Magn. Magn. Mater. 2020, 507, 166856. [Google Scholar] [CrossRef]

- Shao, L.L.; Xue, L.; Luo, Q.; Wang, Q.Q.; Shen, B.L. The role of Co/Al ratio in glass-forming GdCoAl magnetocaloric metallic glasses. Materialia 2019, 7, 100419. [Google Scholar] [CrossRef]

- Gandara, L.A.B.; Zubiate, L.V.; Flores, D.M.C.; Galindo, J.T.E.; Ornelas, C.; Ramos, M. Tuning magnetic entropy change and relative cooling power in La0.7Ca0.23Sr0.07MnO3 electrospun nanofibers. Nanomaterials 2020, 10, 435. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Han, K.; Gao, M.; Zhang, Y.; Xu, W.; Huo, J.T.; Zhang, C.J.; Song, L.J.; Wang, J.Q. Magnetocaloric properties of melt-extracted Gd-Co-Al amorphous/crystalline composite fiber. Metals 2022, 12, 1367. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; González-Legarreta, L.; Ipatov, M.; Zhukov, A. Stress-induced magnetic anisotropy enabling engineering of magnetic softness of Fe-rich amorphous microwires. J. Magn. Magn. Mater. 2020, 510, 166939. [Google Scholar] [CrossRef]

- Gudoshnikov, S.A.; Odintsov, V.I.; Liubimov, B.Y.; Menshov, S.A.; Churukanova, M.N.; Kaloshkin, S.D.; Elmanov, G.N. Method for evaluating the temperature of amorphous ferromagnetic microwires under Joule heating. Measurement 2021, 182, 109783. [Google Scholar] [CrossRef]

- Xue, L.; Luo, Q.; Shao, L.L.; Shen, B.L. Magnetocaloric difference between ribbon and bulk shape of Gd-based metallic glasses. J. Magn. Magn. Mater. 2020, 497, 166015. [Google Scholar] [CrossRef]

- Yin, H.B.; Huang, Y.J.; Bao, Y.; Jiang, S.D.; Xue, P.; Jiang, S.S.; Wang, H.; Qin, F.X.; Li, Z.; Sun, S.C.; et al. Comparable magnetocaloric properties of melt-extracted Gd36Tb20Co20Al24 metallic glass microwires. J. Alloys Compd. 2020, 815, 150983. [Google Scholar] [CrossRef]

- Gudoshnikov, S.A.; Odintsov, V.I.; Liubimov, B.Y.; Menshov, S.A.; Popova, A.V.; Tarasov, V.P. Correlation of electrical and magnetic properties of Co-rich amorphous ferromagnetic microwires after DC Joule heating treatment. J. Alloys Compd. 2020, 845, 156220. [Google Scholar] [CrossRef]

- Hou, L.; Xiang, X.Y.; Huang, Y.; Zhang, B.; Jiang, C.; Chen, S.S.; Li, W.H. Influences of oxygen on the magnetocaloric properties of a Fe-based amorphous alloy. Appl. Phys. A 2021, 127, 501. [Google Scholar] [CrossRef]

- Tishin, A.M.; Spichkin, Y.I. Recent progress in magnetocaloric effect: Mechanisms and potential applications. Int. J. Refrig. 2014, 37, 223–229. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Qin, S.J.; Ye, X.B.; Liu, Z.H.; Guo, Y.J.; Cui, H.Z.; Ge, J.Y.; Long, Y.W.; Zeng, Y.J. Large magnetic entropy change in weberite type oxides Gd3MO7 (M = Nb, Sb, and Ta). Sci. China Phys. Mech. 2022, 65, 247011. [Google Scholar] [CrossRef]

- Zhai, Y.Q.; Chen, W.P.; Evangelisti, M.; Fu, Z.; Zheng, Y.Z. Gd-based molecular coolants: Aggregating for better magnetocaloric effect. Aggregate 2024, e520. [Google Scholar] [CrossRef]

- Wang, L.; Ouyang, Z.; Li, Z.; Cao, J.; Xia, Z. Large magnetocaloric effect in Gd2Si2O7 and plateau-like magnetic entropy change in Dy2Si2O7. J. Alloys Compd. 2023, 969, 172402. [Google Scholar] [CrossRef]

- Manchón-Gordón, A.F.; Blázquez, J.S.; Kowalczyk, M.; Ipus, J.J.; Kulik, T.; Conde, C.F. Effect of thermal treatments below devitrification temperature on the magnetic and magnetocaloric properties in mechanically alloyed Fe70Zr30 powders. J. Non-Cryst. Solids 2023, 609, 122267. [Google Scholar] [CrossRef]

- Manchón-Gordón, A.F.; López-Martín, R.; Vidal-Crespo, A.; Ipus, J.J.; Blázquez, J.S.; Conde, C.F.; Conde, A. Distribution of transition temperatures in magnetic transformations: Sources, effects and procedures to extract information from experimental data. Metals 2020, 10, 226. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Tang, Q.; Wang, F.C.; Zhang, H.Y.; Zhou, Y.X.; Xia, A.; Li, H.L.; Chen, S.S.; Li, W.H. Tailorable magnetocaloric effect by Fe substitution in Gd-(Co, Fe) amorphous alloy. Intermetallics 2019, 111, 106500. [Google Scholar] [CrossRef]

- Tang, B.Z.; Huang, L.W.; Song, M.N.; Ding, D.; Wang, X.; Xia, L. Compositional dependence of magnetic and magnetocaloric properties of the Gd-Ni binary amorphous alloys. J. Non-Cryst. Solids 2019, 522, 119589. [Google Scholar] [CrossRef]

- Wang, X.; Tang, B.Z.; Wang, Q.; Yu, P.; Ding, D.; Xia, L. Co50Gd48-xFe2Nix amorphous alloys with high adiabatic temperature rise near the hot end of a domestic magnetic refrigerator. J. Non-Cryst. Solids 2020, 544, 120146. [Google Scholar] [CrossRef]

- Anatoly, G.K.; Sergey, P.P.; Roman, D.M.; Alexey, V.L.; Aleksey, S.V.; Vasilii, S.G.; Mari, Y.Y. Large magnetic entropy change in GdRuSi optimal for magnetocaloric liquefaction of nitrogen. Metals 2023, 13, 290. [Google Scholar] [CrossRef]

- Duc, N.T.M.; Shen, H.X.; Thiabgoh, O.; Huong, N.T.; Sun, J.F.; Phan, M.H. Melt-extracted Gd73.5Si13B13.5/GdB6 ferromagnetic/antiferromagnetic microwires with excellent magnetocaloric properties. J. Alloys Compd. 2020, 818, 153333. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.Z.; Yu, P.; Xia, L.; Ding, D. Large magnetic entropy change and adiabatic temperature rise of a ternary Gd34Ni33Al33 metallic glass. J. Rare Earths 2021, 39, 998. [Google Scholar] [CrossRef]

- Uporova, S.; Bykova, V.; Uporova, N. Magnetocaloric effect in Gd60Al25(NiCo)15 bulk metallic glass. J. Non-Cryst. Solids 2019, 521, 119506. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Effect of alloying on the giant magnetocaloric effect of Gd5 (Si2Ge2). J. Magn. Magn. Mater. 1997, 167, L179–L184. [Google Scholar] [CrossRef]

- Elham, S.; Baran, S.; Yonghui, Z.; Piotr, B.; Jürgen, E. Fabrication of stainless-steel microfibers with amorphous-nanosized microstructure with enhanced mechanical properties. Sci. Rep. 2022, 12, 10784. [Google Scholar] [CrossRef]

- Zhukova, V.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Churyukanova, M.; Zhukov, A. Effect of stress annealing on magnetic properties and GMI effect of Co-rich and Fe-rich microwires. J. Alloys Compd. 2017, 707, 189–194. [Google Scholar] [CrossRef]

- Amirabadizadeh, A.; Mardani, R.; Ghanaatshoar, M. The effect of current frequency and magnetic field direction in alternative current-field annealing on the GMI and magnetic properties of Co-based wires. J. Alloys Compd. 2016, 661, 501–507. [Google Scholar] [CrossRef]

- Corte-León, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Gonzalez, J.; Zhukov, A. Engineering of magnetic properties of Co-rich microwires by joule heating. Intermetallics 2019, 105, 92–98. [Google Scholar] [CrossRef]

- Gonzalez-Legarreta, L.; Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Route of magnetoimpedance and domain walls dynamics optimization in Co-based microwires. J. Alloys Compd. 2020, 830, 154576. [Google Scholar] [CrossRef]

- Pan, L.; Ali, A.; Wang, Y.F.; Zheng, Z.M.; Lv, Y.F. Characterization of effects of heat treated anodized film on the properties of hygrothermally aged AA5083-based fiber-metal laminates. Compos. Struct. 2017, 167, 112–122. [Google Scholar] [CrossRef]

- Gao, G.E.; Li, H.X.; Jiao, Z.B.; Wu, Y.; Chen, Y.H.; Yu, T.; Lu, Z.P. Effects of nanocrystal formation on the soft magnetic properties of Fe-based bulk metallic glasses. Appl. Phys. Lett. 2011, 99, 5. [Google Scholar] [CrossRef]

- Zhang, R.C.; Qian, M.F.; Waske, A.; Shen, H.X.; Zhang, X.X. Investigating the microstructure and magnetic properties of La-Fe-Si microwires during fabrication and heat treatment process. J. Alloys Compd. 2019, 794, 153–162. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, W.H. Magnetocaloric effect in rare earth-based bulk metallic glasses. J. Alloys Compd. 2010, 495, 209–216. [Google Scholar] [CrossRef]

- Yao, Y.Y.; Li, Z.; Liu, J.S.; Zhang, M.W.; Zhang, Y.; Wang, F.; Liu, R.; Shen, H.X. Effect of Ni alloying on the microstructure and magnetocaloric properties of Gd-based metallic microfibers. J. Alloys Compd. 2023, 961, 170979. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Ouyang, J.T.; Ding, D.; Li, H.L.; Wang, J.G.; Li, W.H. Influence of Fe substitution on thermal stability and magnetocaloric effect of Gd60Co40-xFex amorphous alloy. J. Alloys Compd. 2018, 769, 186–192. [Google Scholar] [CrossRef]

- Phan, M.H.; Yu, S.C. Review of the magnetocaloric effect in manganite materials. J. Magn. Magn. Mater. 2007, 308, 325–340. [Google Scholar] [CrossRef]

- Xue, L.; Shao, L.L.; Luo, Q.; Shen, B.L. Gd25RE25Co25Al25 (RE = Tb, Dy and Ho) high-entropy glassy alloys with distinct spin-glass behavior and good magnetocaloric effect. J. Alloys Compd. 2019, 790, 633–639. [Google Scholar] [CrossRef]

- Xue, L.; Li, J.; Yang, W.M.; Yuan, C.C.; Shen, B.L. Effect of Fe substitution on magnetocaloric effects and glass-forming ability in Gd-based metallic glasses. Intermetallics 2018, 93, 67–71. [Google Scholar] [CrossRef]

- Liu, J.S.; Wang, Q.X.; Wu, M.J.; Zhang, Y.; Shen, H.X.; Ma, W. Improving the refrigeration capacity of Gd-rich wires through Fe-doping. J. Alloys Compd. 2017, 711, 71–76. [Google Scholar] [CrossRef]

| Parameter | Tg (°C) | Tx1 (°C) | Tx2 (°C) | ΔT (°C) | −∆H (J·g−1) |

|---|---|---|---|---|---|

| As-Prepared | 303 | 346 | 487 | 44 | 30.5 |

| Compositions | −ΔSmmax (J/kg·K) | RC (J/kg) | RCP (J/kg) | Refs. |

|---|---|---|---|---|

| Gd57Al19Co19Ni5 | 11.57 | 1138.16 | 834.14 | This work |

| Gd70Co10Al20 | 6.36 | 538 | - | [4] |

| Gd36Tb20Co20Al24 | 12.36 | 417 | - | [8] |

| Gd3SbO7 | 3.54 | - | - | [12] |

| Gd70Co30 | 5.13 | - | 277 | [17] |

| Gd70Co20Fe10 | 2.78 | - | 353 | [17] |

| Gd71Ni29 | - | 804.3 | - | [19] |

| Gd73.5Si13B13.5 | 6.4 | 790 | 885 | [21] |

| Gd34Ni33Al33 | 11.06 | - | - | [22] |

| Gd60Al25(NiCo)15 | 6.31 | - | 890 | [23] |

| Gd55Co15Al24Si1Fe5 | 7.26 | 857 | - | [33] |

| Gd60Al20Co20 | 10.12 | 698.28 | 936.19 | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yu, S.; Zhang, M.; Li, Z.; Cui, Y. Effect of Annealing Temperature on Microstructure and Magnetocaloric Properties of Gd-Based Metallic Microfibers. Metals 2024, 14, 874. https://doi.org/10.3390/met14080874

Liu J, Yu S, Zhang M, Li Z, Cui Y. Effect of Annealing Temperature on Microstructure and Magnetocaloric Properties of Gd-Based Metallic Microfibers. Metals. 2024; 14(8):874. https://doi.org/10.3390/met14080874

Chicago/Turabian StyleLiu, Jingshun, Shiyang Yu, Mingwei Zhang, Ze Li, and Yaqiang Cui. 2024. "Effect of Annealing Temperature on Microstructure and Magnetocaloric Properties of Gd-Based Metallic Microfibers" Metals 14, no. 8: 874. https://doi.org/10.3390/met14080874