Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures

Abstract

:1. Introduction

2. Materials and Methods

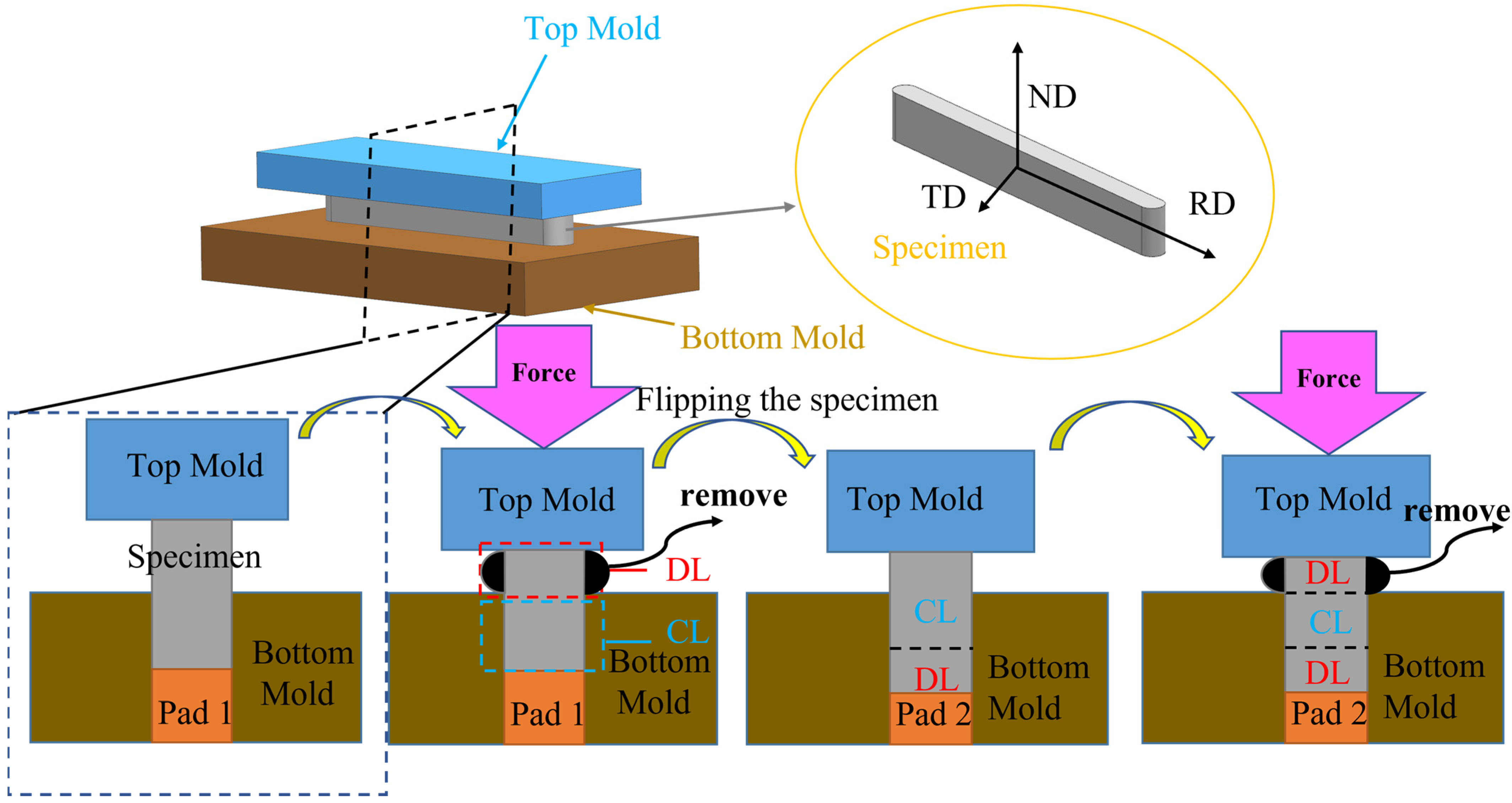

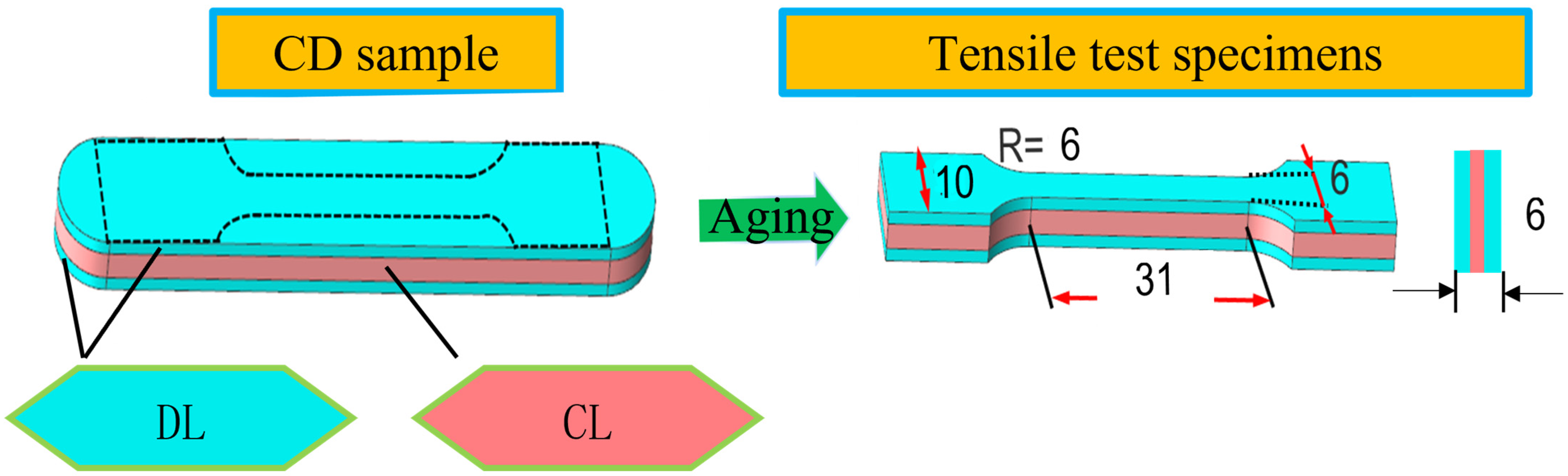

2.1. Constraint Deformation and Heat Treatment

2.2. Mechanical Property Testing

2.3. Corrosion Performance Testing

3. Results and Discussion

3.1. Microhardness of Sample

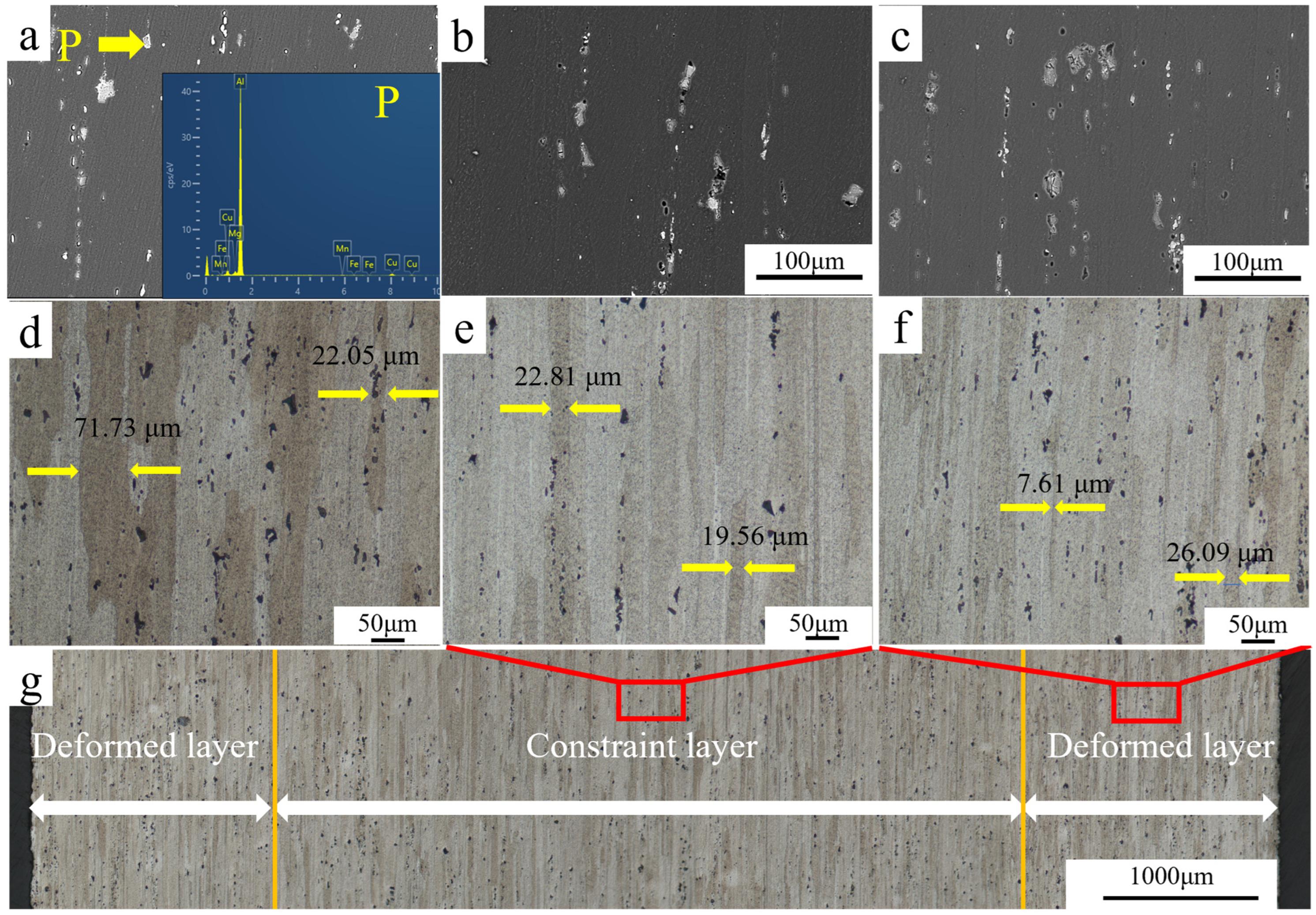

3.2. Multi-Gradient Structure

3.2.1. Grain Gradient

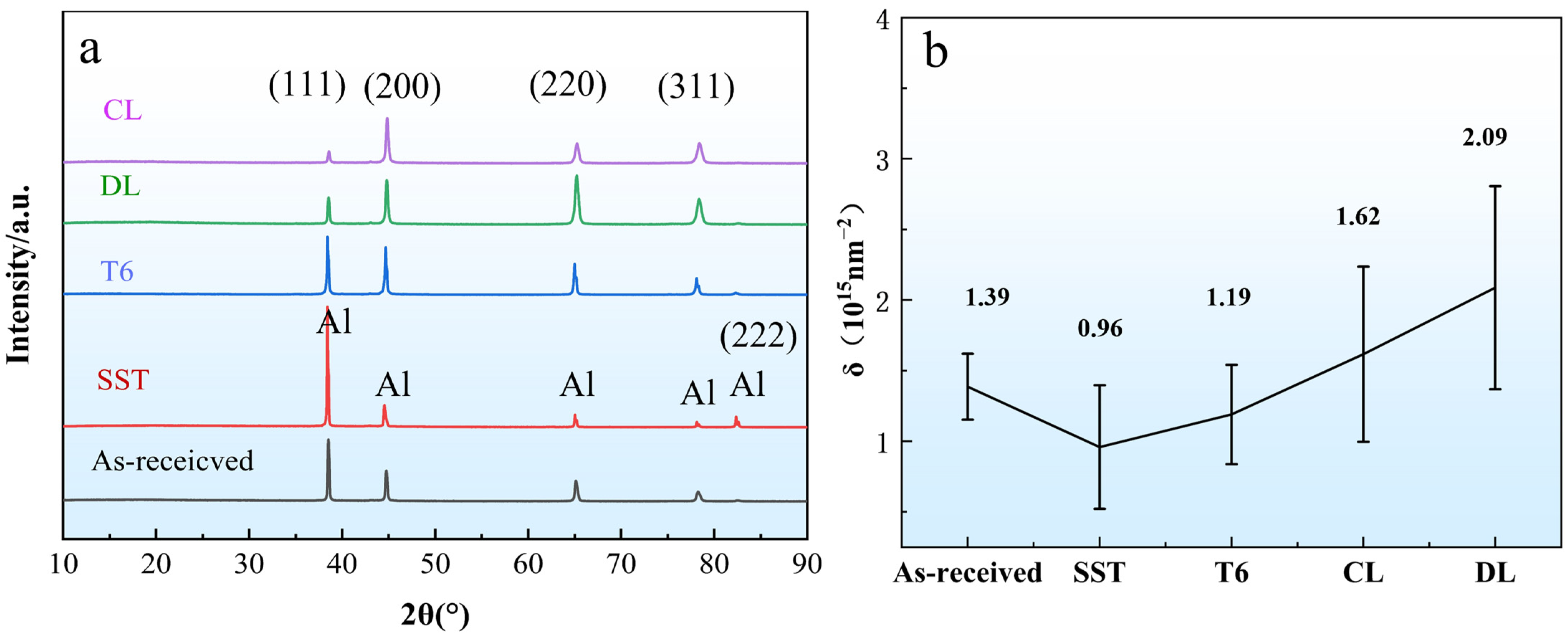

3.2.2. Dislocation Gradient

3.2.3. Heterogeneous Structure of Precipitated Phase

- [100] Al // [100] S,

- [021] Al // [010] S,

- [012] Al // [001] S.

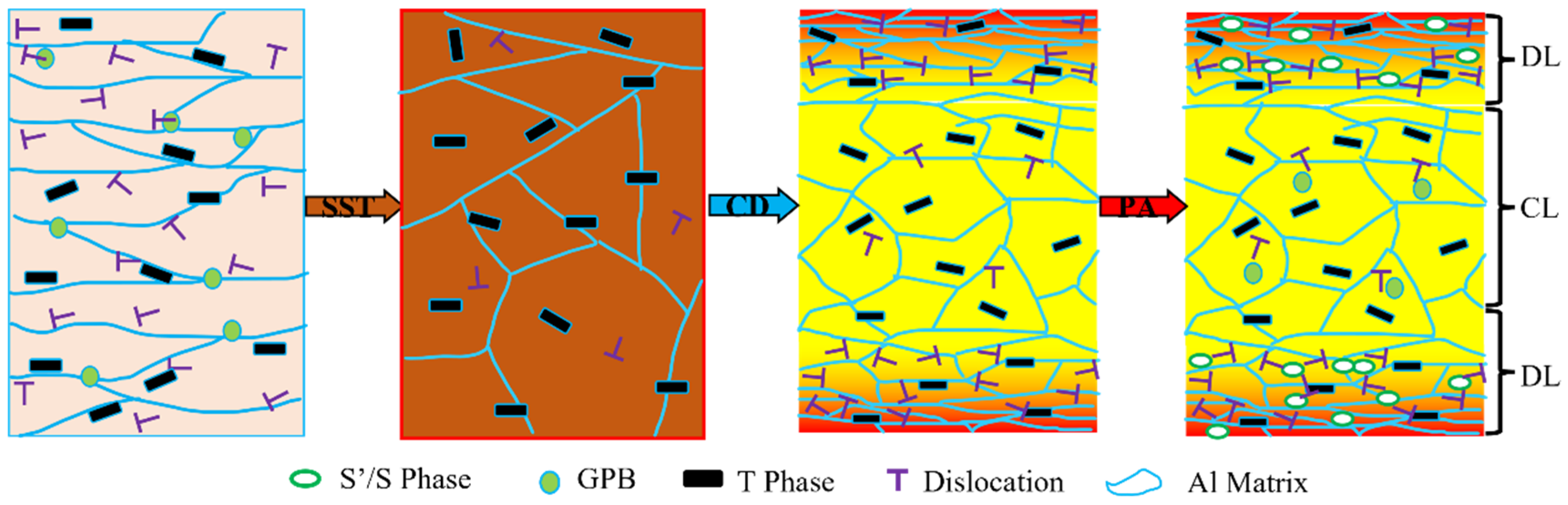

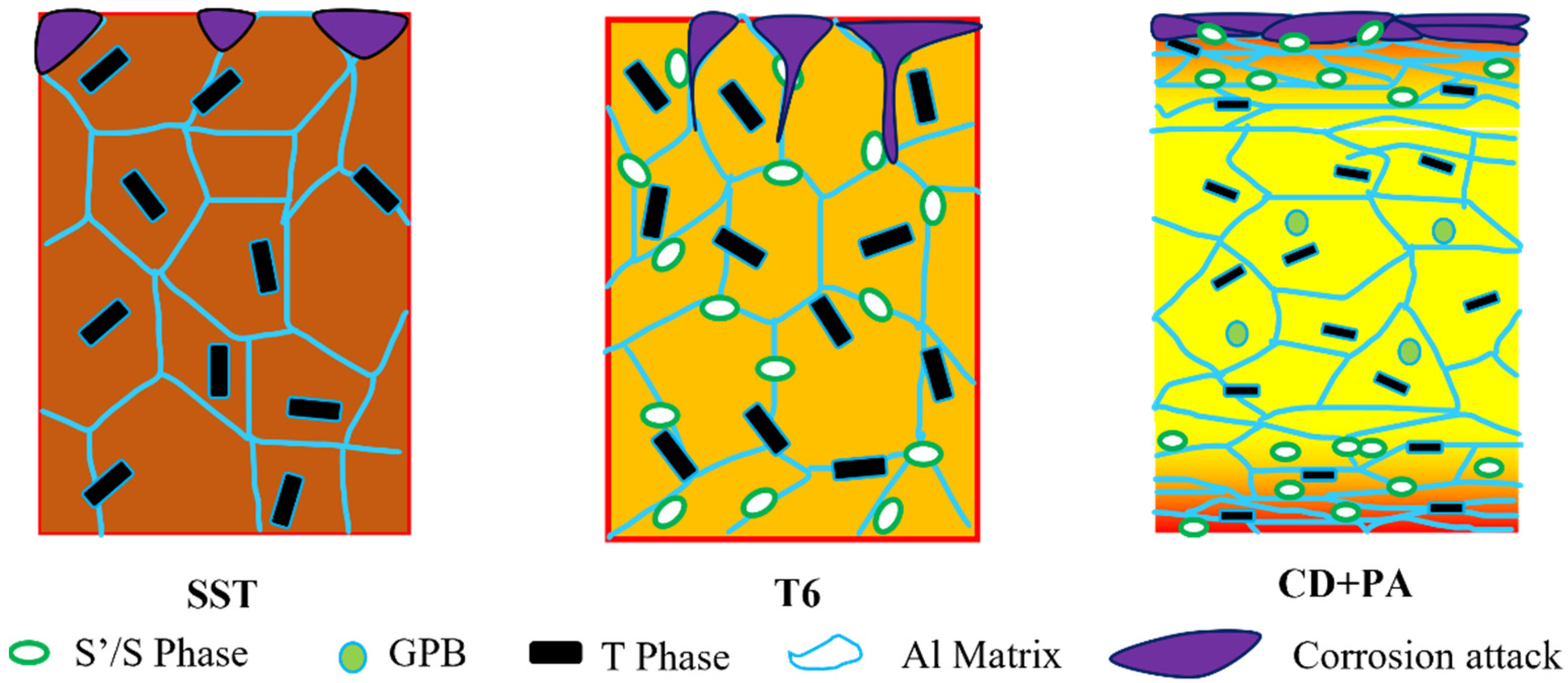

3.2.4. Microstructural Evolution During CD + PA

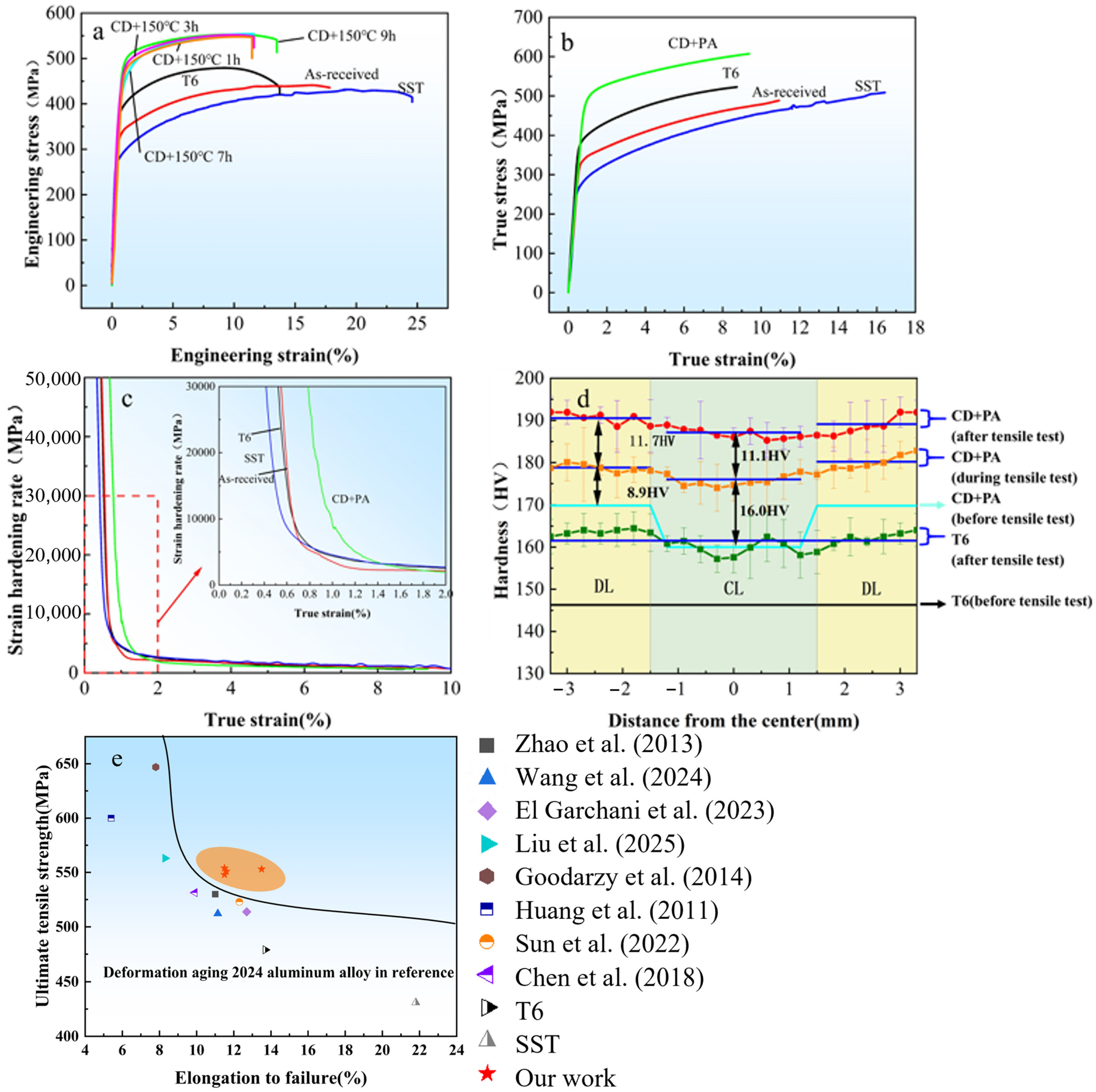

3.3. Mechanical Properties of Sample

3.3.1. Aging Behavior and Mechanical Strength

3.3.2. Yield Strength Contribution of the Deformed Layer in the Multi-Gradient Structure

3.3.3. Work Hardening Behavior Across Samples

3.3.4. HDI Hardening Mechanism

3.4. Corrosion Performance

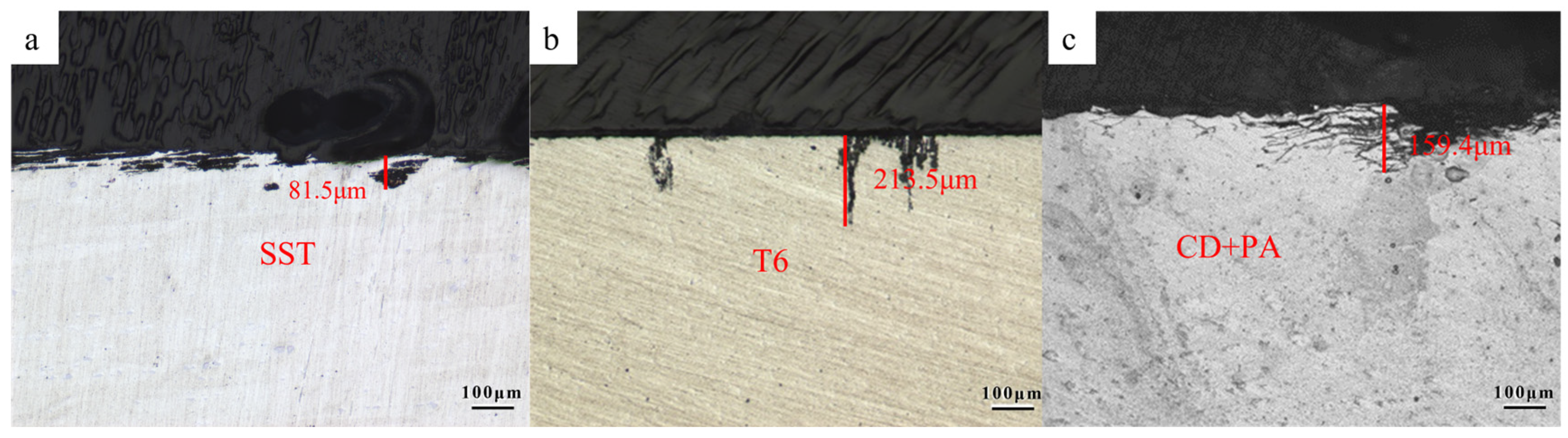

3.4.1. Intergranular Corrosion Behavior

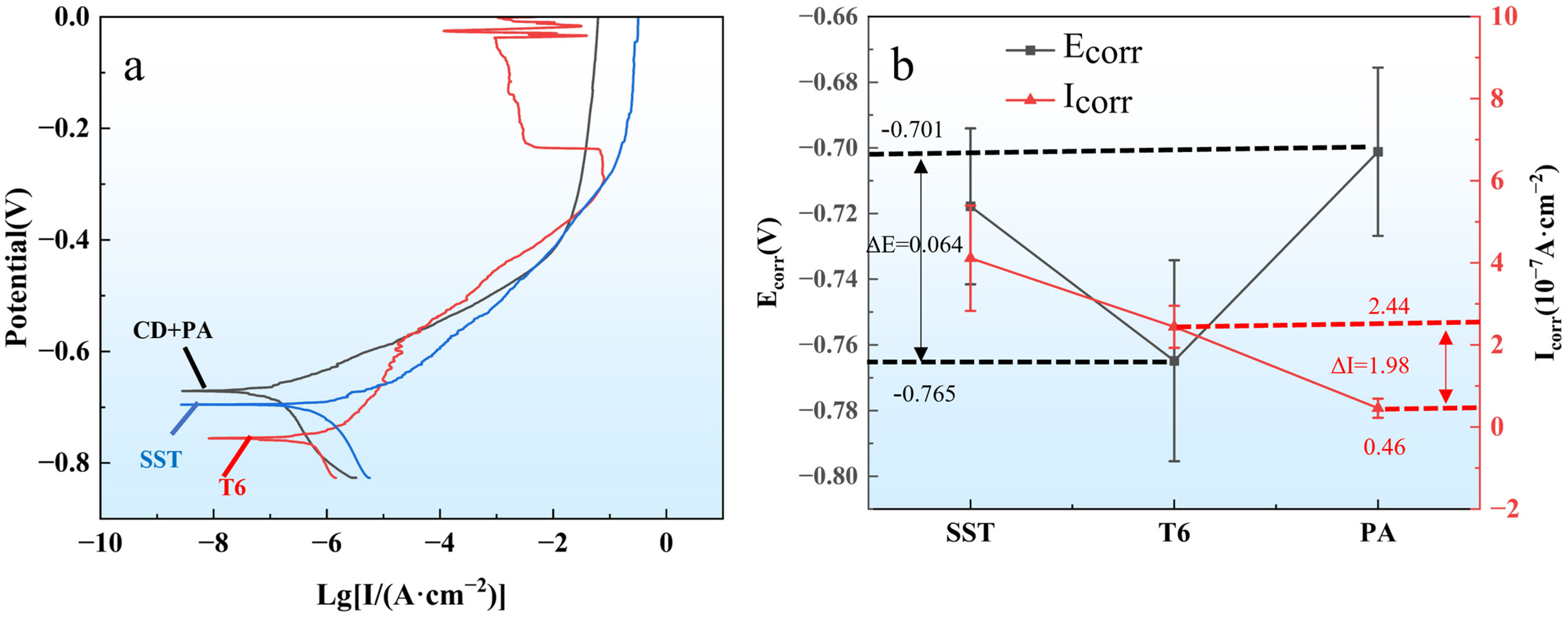

3.4.2. Electrochemical Behavior

3.4.3. Localized Corrosion Behavior of AA2024 Aluminum Alloy in Different Treatment States

4. Conclusions

- (1)

- Microstructure Changes: A multi-gradient structure consisting of grains, dislocations, and precipitates was successfully produced in AA2024 aluminum alloy using the CD + PA treatment. This gradient structure played a crucial role in enhancing the alloy’s mechanical and electrochemical properties. Compared to CL, the grain size of DL of the CD + PA-treated sample was significantly reduced from approximately 10 μm to around 20 μm, showing superior mechanical performance. The dislocation density varied significantly between the DL and the CL, from 2.09 × 1015 nm−2 in the DL to approximately 1.62 × 1015 nm−2 in the CL. This difference in dislocation density contributed to the improvement in the mechanical properties and the fine distribution of precipitates. The CD + PA treatment also promoted significant changes in the precipitate phases. In the CL, fewer GPB clusters were observed, with a density of 449 ± 124 number·μm−2. However, in the DL, the density of S′ phases increased significantly to 1265 ± 335 number·μm−2. This increase in the density of S′ precipitates in the DL region contributed to a more refined microstructure, further enhancing the strength and corrosion resistance of the alloy. Among the four major strengthening mechanisms, dislocation strengthening and precipitation strengthening play the dominant roles, contributing a yield strength of 283.05 MPa, with precipitation strengthening following closely at 179 MPa. Additionally, there is an extra HDI strain hardening during the tensile process.

- (2)

- Improvement in Mechanical Properties: The CD + PA treatment promoted grain boundary strengthening, dislocation strengthening, and precipitation strengthening. The unique deformation mechanisms between the DL and the CL were revealed by the microhardness distribution. After the tensile test, the average microhardness in the surface DL region reached around 190 HV, while the T6-treated sample had an average value of r163 HV. Additionally, the yield strength of the CD + PA sample is 495 MPa, and the fracture elongation is 13.5%, which is an improvement of 100 MPa compared to the T6 sample. The elongation remains nearly unchanged.

- (3)

- Improvement in Corrosion Resistance: The increased dislocation density in the surface DL region promoted the formation of fine and uniformly distributed precipitates, contributing to more uniform and stable corrosion behavior. In intergranular corrosion, the average maximum corrosion depth of the CD + PA sample was 164.3 ± 9.41 μm, while the T6 sample had an average maximum corrosion depth of 224.3 ± 10.1 μm. In the electrochemical tests, the average open circuit potential of the CD + PA sample was −0.70 V, higher than the T6 sample’s value of −0.76 V. The average self-corrosion current density of the CD + PA sample was 0.046 μA/cm2, significantly lower than the 0.24 μA/cm2 of the T6 sample. This further demonstrates the improved corrosion resistance of the CD + PA-treated sample. The reduced corrosion depth and lower self-corrosion current density, along with the higher self-corrosion potential, all indicate that the CD + PA treatment significantly enhances the alloy’s resistance to corrosion compared to the T6 treatment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent Development in Aluminium Alloys for the Automotive Industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Singh, D.; Rao, P.N.; Jayaganthan, R. Effect of Deformation Temperature on Mechanical Properties of Ultrafine Grained Al–Mg Alloys Processed by Rolling. Mater. Des. 2013, 50, 646–655. [Google Scholar] [CrossRef]

- Kikuchi, D.; Harada, Y.; Kumai, S. Surface Quality and Microstructure of Al-Mg Alloy Strips Fabricated by Vertical-Type High-Speed Twin-Roll Casting. J. Manuf. Process. 2019, 37, 332–338. [Google Scholar] [CrossRef]

- Tsuji, N.; Toyoda, T.; Minamino, Y.; Koizumi, Y.; Yamane, T.; Komatsu, M.; Kiritani, M. Microstructural Change of Ultrafine-Grained Aluminum during High-Speed Plastic Deformation. Mater. Sci. Eng. A 2003, 350, 108–116. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S.D.; Kumar, S.; Chattopadhyay, K. Microstructure and Texture Evolution during Accumulative Roll Bonding of Aluminium Alloy AA5086. Mater. Sci. Eng. A 2011, 528, 8469–8478. [Google Scholar] [CrossRef]

- Lei, W.; Yong, Y.; Yaming, W.; Ying, J. Effect of Nanocrystalline Surface and Iron-Containing Layer Obtained by SMAT on Tribological Properties of 2024 Al Alloy. Rare Met. Mater. Eng. 2015, 44, 1320–1325. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Three Strategies to Achieve Uniform Tensile Deformation in a Nanostructured Metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

- Shahsavari, A.; Karimzadeh, F.; Rezaeian, A.; Heydari, H. Significant Increase in Tensile Strength and Hardness in 2024 Aluminum Alloy by Cryogenic Rolling. Procedia Mater. Sci. 2015, 11, 84–88. [Google Scholar] [CrossRef]

- Hassanpour, H.; Jamaati, R.; Hosseinipour, S.J. Effect of Gradient Microstructure on the Mechanical Properties of Aluminum Alloy. Mater. Charact. 2021, 174, 111023. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.; Höppel, H.W.; Göken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface Affected Zone for Optimal Strength and Ductility in Heterogeneous Laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef]

- Wu, X.L.; Jiang, P.; Chen, L.; Zhang, J.F.; Yuan, F.P.; Zhu, Y.T. Synergetic Strengthening by Gradient Structure. Mater. Res. Lett. 2014, 2, 185–191. [Google Scholar] [CrossRef]

- Irmer, D.; Yildirim, C.; Sennour, M.; Esin, V.A.; Moussa, C. Effect of Second-Phase Precipitates on Deformation Microstructure in AA2024 (Al–Cu–Mg): Dislocation Substructures and Stored Energy. J. Mater. Sci. 2024, 59, 18978–19002. [Google Scholar] [CrossRef]

- Xu, P.; Luo, H.; Han, Z.; Zou, J. Tailoring a Gradient Nanostructured Age-Hardened Aluminum Alloy Using High-Gradient Strain and Strain Rate. Mater. Des. 2015, 85, 240–247. [Google Scholar] [CrossRef]

- Wu, X.; Tao, N.; Hong, Y.; Xu, B.; Lu, J.; Lu, K. Microstructure and Evolution of Mechanically-Induced Ultrafine Grain in Surface Layer of AL-Alloy Subjected to USSP. Acta Mater. 2002, 50, 2075–2084. [Google Scholar] [CrossRef]

- Akiyama, E.; Zhang, Z.; Watanabe, Y.; Tsuzaki, K. Effects of Severe Plastic Deformation on the Corrosion Behavior of Aluminum Alloys. J. Solid. State Electrochem. 2009, 13, 277–282. [Google Scholar] [CrossRef]

- Sun, Q.; Han, Q.; Xu, R.; Zhao, K.; Li, J. Localized Corrosion Behaviour of AA7150 after Ultrasonic Shot Peening: Corrosion Depth vs. Impact Energy. Corros. Sci. 2018, 130, 218–230. [Google Scholar] [CrossRef]

- Wen, L.; Wang, Y.; Zhou, Y.; Guo, L.X.; Ouyang, J.H. Iron-Rich Layer Introduced by SMAT and Its Effect on Corrosion Resistance and Wear Behavior of 2024 Al Alloy. Mater. Chem. Phys. 2011, 126, 301–309. [Google Scholar] [CrossRef]

- Liu, X.; Frankel, G.S. Effects of Compressive Stress on Localized Corrosion in AA2024-T3. Corros. Sci. 2006, 48, 3309–3329. [Google Scholar] [CrossRef]

- Chumaevskii, A.V.; Zykova, A.P.; Gusarova, A.V.; Guryanov, D.A.; Rubtsov, V.E.; Kolubaev, E.A. Regularities of Structure Formation in AA2024 Alloy During High-Intensity Plastic Deformation Under Conditions of Adhesion-Diffusion Friction Interaction. Russ. Phys. J. 2022, 65, 303–311. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Navaser, M.; Atapour, M. Effect of Friction Stir Processing on Pitting Corrosion and Intergranular Attack of 7075 Aluminum Alloy. J. Mater. Sci. Technol. 2017, 33, 155–165. [Google Scholar] [CrossRef]

- Ilieva, M.; Radev, R. Effect of Severe Plastic Deformation by ECAP on Corrosion Behaviour of Aluminium Alloy AA 7075. Arch. Mater. Sci. Eng. 2016, 81, 55–61. [Google Scholar] [CrossRef]

- Asquith, D.T.; Yerokhin, A.L.; Yates, J.R.; Matthews, A. The Effect of Combined Shot-Peening and PEO Treatment on the Corrosion Performance of 2024 Al Alloy. Thin Solid Film. 2007, 516, 417–421. [Google Scholar] [CrossRef]

- Ye, Z.; Liu, D.; Li, C.; Zhang, X.; Yang, Z.; Lei, M. Effect of Shot Peening and Plasma Electrolytic Oxidation on the Intergranular Corrosion Behavior of 7A85 Aluminum Alloy. Acta Metall. Sin. Engl. Lett. 2014, 27, 705–713. [Google Scholar] [CrossRef]

- GB/T 16865-2013; General Rules for Sampling and Sample Preparation of Wrought Aluminum and Aluminum Alloys. China Standards Press: Beijing, China, 2013.

- Mariya Joseph, H.; Poornima, N. Synthesis and Characterization of ZnO Nanoparticles. Mater. Today Proc. 2019, 9, 7–12. [Google Scholar] [CrossRef]

- Zhao, Z.; Lin, J.; Xiao, Y.; Min, J. Effects of Grain Size and Dislocation Density on Thermally-Induced Martensitic Transformation of Nanocrystalline NiTi Alloys. J. Alloys Compd. 2024, 978, 173490. [Google Scholar] [CrossRef]

- GB/T 22639-2022; Test Method for Exfoliation Corrosion of Aluminum Alloy Products. China Standards Press: Beijing, China, 2022.

- Zhao, Y.L.; Yang, Z.Q.; Zhang, Z.; Su, G.Y.; Ma, X.L. Double-Peak Age Strengthening of Cold-Worked 2024 Aluminum Alloy. Acta Mater. 2013, 61, 1624–1638. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J.; Gao, N. Precipitation Hardening in Al–Cu–Mg Alloys Revisited. Scr. Mater. 2006, 54, 287–291. [Google Scholar] [CrossRef]

- Feng, Z.; Yang, Y.; Huang, B.; Han, M.; Luo, X.; Ru, J. Precipitation Process along Dislocations in Al–Cu–Mg Alloy during Artificial Aging. Mater. Sci. Eng. A 2010, 528, 706–714. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, S.-H.; Park, J.-H.; Kim, H.-W.; Lee, J.-C. Role of Mg in Simultaneously Improving the Strength and Ductility of Al–Mg Alloys. Mater. Sci. Eng. A 2016, 657, 115–122. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Wang, Z.; Fang, B.; Song, R.; Zheng, Z. Effects of Re-Ageing Treatment on Microstructure and Tensile Properties of Solution Treated and Cold-Rolled Al–Cu–Mg Alloys. Mater. Sci. Eng. A 2016, 650, 254–263. [Google Scholar] [CrossRef]

- Huskins, E.L.; Cao, B.; Ramesh, K.T. Strengthening Mechanisms in an Al–Mg Alloy. Mater. Sci. Eng. A 2010, 527, 1292–1298. [Google Scholar] [CrossRef]

- Li, C.; Deng, B.; Dong, L.; Liu, X.; Du, K.; Shi, B.; Dong, Y.; Peng, F.; Zhang, Z. Effect of Zn Addition on the Microstructure and Mechanical Properties of As-Cast BCC Mg-11Li Based Alloys. J. Alloys Compd. 2022, 895, 162718. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength with Coarse-Grain Ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lv, L.; Zhen, L.; Dai, S. Precipitation Strengthening Model of AA 7055 Aluminium Alloy. Acta Met. Sin. 2020, 57, 353–362. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured Materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Perspective on Hetero-Deformation Induced (HDI) Hardening and Back Stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y.T. Extraordinary Strain Hardening by Gradient Structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed]

- Nix, W.D.; Gao, H. Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X. Microstructure and Flow Stress of Polycrystals and Single Crystals. Acta Mater. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Song, Q.; Tian, K.; Fei, S.; Deng, H.; Shen, G. Effects of Ultrasonic Shot Peening Followed by Surface Mechanical Rolling on Mechanical Properties and Fatigue Performance of 2024 Aluminum Alloy. Eng. Fract. Mech. 2024, 311, 110538. [Google Scholar] [CrossRef]

- El Garchani, F.E.; Lgaz, H.; Kaya, S.; Lee, H.-S.; Ibrahim, S.M.; Chafiq, M.; Ko, Y.G.; Kabiri, M.R. Effects of Heat Treatment on the Corrosion Behavior and Mechanical Properties of Aluminum Alloy 2024. J. Mater. Res. Technol. 2023, 25, 1355–1363. [Google Scholar] [CrossRef]

- Liu, F.; Tu, Y.; Wang, Q.; Yang, W. Microstructure Evolution and Mechanical Behavior of 2024 Aluminum Alloy under Electric Pulse Treatment. J. Alloys Compd. 2025, 1010, 177237. [Google Scholar] [CrossRef]

- Goodarzy, M.H.; Arabi, H.; Boutorabi, M.A.; Seyedein, S.H.; Hasani Najafabadi, S.H. The Effects of Room Temperature ECAP and Subsequent Aging on Mechanical Properties of 2024 Al Alloy. J. Alloys Compd. 2014, 585, 753–759. [Google Scholar] [CrossRef]

- Huang, Y.J.; Chen, Z.G.; Zheng, Z.Q. A Conventional Thermo-Mechanical Process of Al–Cu–Mg Alloy for Increasing Ductility While Maintaining High Strength. Scr. Mater. 2011, 64, 382–385. [Google Scholar] [CrossRef]

- Sun, L.; Chen, L.; Guo, Y.; Zhao, G. Experimental Study and Optimization on Solution and Artificial Aging of Cold-Rolled 2024 Al Alloy Sheet. J. Mater. Eng. Perform. 2022, 31, 5419–5431. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, J.; Liu, C.; Wang, F. Effect of Pre-Deformation on the Pre-Corrosion Multiaxial Fatigue Behaviors of 2024-T4 Aluminum Alloy. Int. J. Fatigue 2018, 108, 35–46. [Google Scholar] [CrossRef]

- Huang, Y.; Robson, J.D.; Prangnell, P.B. The Formation of Nanograin Structures and Accelerated Room-Temperature Theta Precipitation in a Severely Deformed Al–4 wt.% Cu Alloy. Acta Mater. 2010, 58, 1643–1657. [Google Scholar] [CrossRef]

- Dovletoglou, E.; Skarvelis, P.; Stergiou, V.; Alexopoulos, N.D. Effect of Corrosion Exposure on the Mechanical Performance of 2024 Aluminum Alloy Electron Beam Welded Joints. Procedia Struct. Integr. 2018, 10, 73–78. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Yang, N.; Gall, K.; McDowell, D.; Fan, J.; Gullett, P. High Cycle Fatigue Mechanisms in a Cast AM60B Magnesium Alloy. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 1045–1056. [Google Scholar] [CrossRef]

- Hilpert, M.; Wagner, L. Corrosion Fatigue Behavior of the High-Strength Magnesium Alloy AZ 80. J. Mater. Eng. Perform. 2000, 9, 402–407. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, P.; Li, H.; Fang, B.; Song, R.; Zheng, Z. The Intergranular Corrosion Susceptibility of 2024 Al Alloy during Re–Ageing after Solution Treating and Cold–Rolling. Corros. Sci. 2017, 114, 156–168. [Google Scholar] [CrossRef]

| Mg | Mn | Fe | Si | Cu | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 4.51 | 0.54 | 0.3 | 0.085 | 0.015 | 0.073 | 0.054 | 0.03 | Bal |

| Region and State | SST | CL (CD + PA) | DL (CD + PA) |

|---|---|---|---|

| Coarse phase density (number·cm−2) | 4.85 ± 0.3 × 104 | 5.43 ± 0.2 × 104 | 24.17 ± 0.5 × 104 |

| Rolling microstructure bandwidth (μm) | 62.13 ± 10.55 | 19.17 ± 5.78 | 11.22 ± 6.37 |

| Dislocation density (1015 nm−2) | 0.96 | 1.62 | 2.09 |

| Precipitate density (FA/number·μm−2) | -- | 449 ± 124 | 1265 ± 335 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Z.; Zhou, L.; Li, J.; Duan, Y.; Peng, M.; Xiao, H.; Du, X.; Zhao, Y.; Li, M. Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures. Metals 2025, 15, 177. https://doi.org/10.3390/met15020177

Xie Z, Zhou L, Li J, Duan Y, Peng M, Xiao H, Du X, Zhao Y, Li M. Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures. Metals. 2025; 15(2):177. https://doi.org/10.3390/met15020177

Chicago/Turabian StyleXie, Zhenwei, Liexing Zhou, Jun Li, Yonghua Duan, Mingjun Peng, Hongbo Xiao, Xiong Du, Yuanjie Zhao, and Mengnie Li. 2025. "Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures" Metals 15, no. 2: 177. https://doi.org/10.3390/met15020177

APA StyleXie, Z., Zhou, L., Li, J., Duan, Y., Peng, M., Xiao, H., Du, X., Zhao, Y., & Li, M. (2025). Mechanical and Corrosion Properties of AA2024 Aluminum Alloy with Multimodal Gradient Structures. Metals, 15(2), 177. https://doi.org/10.3390/met15020177