Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints

Abstract

:1. Introduction

2. Materials and Methods

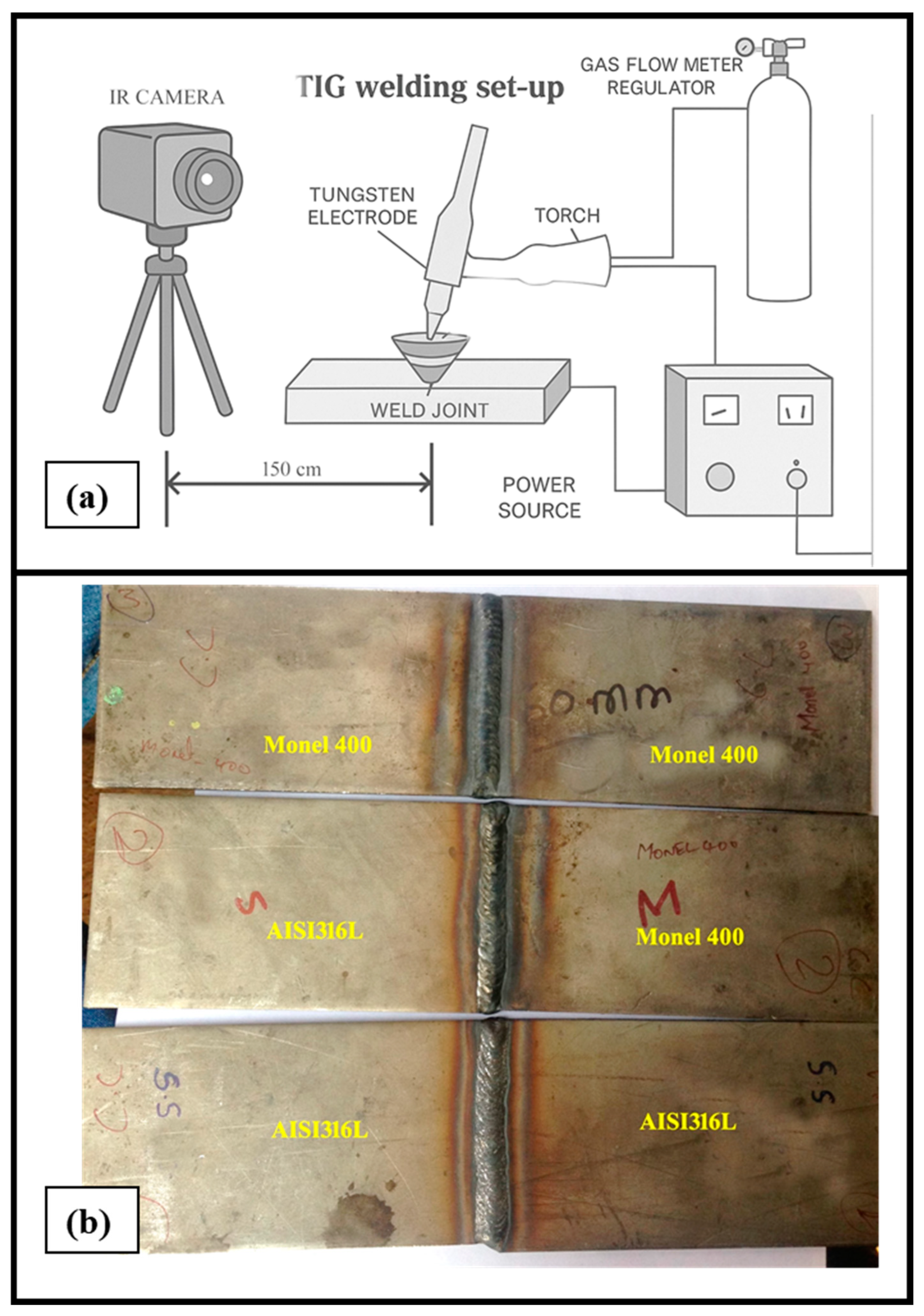

2.1. Welding Processes

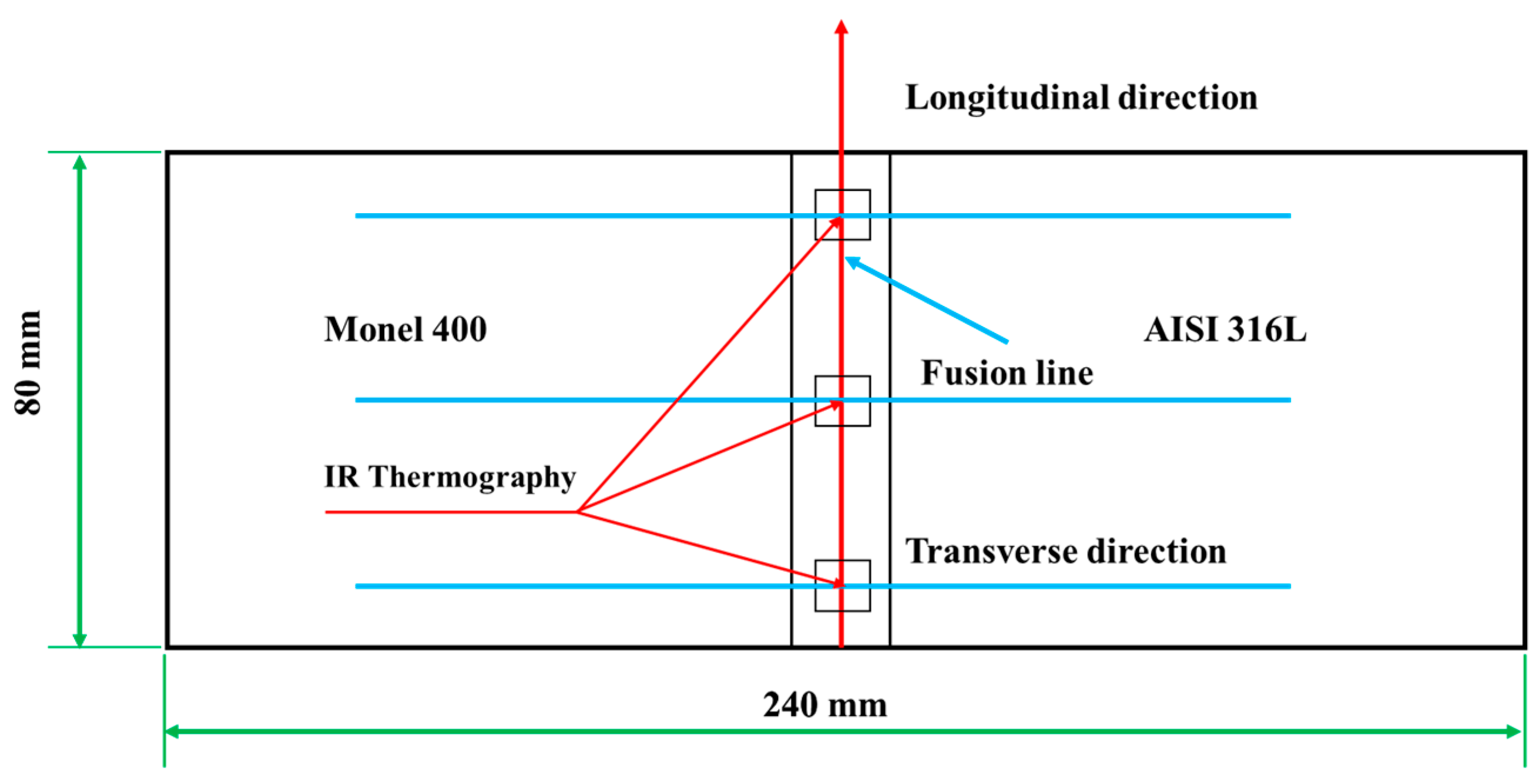

2.2. Infrared Thermography

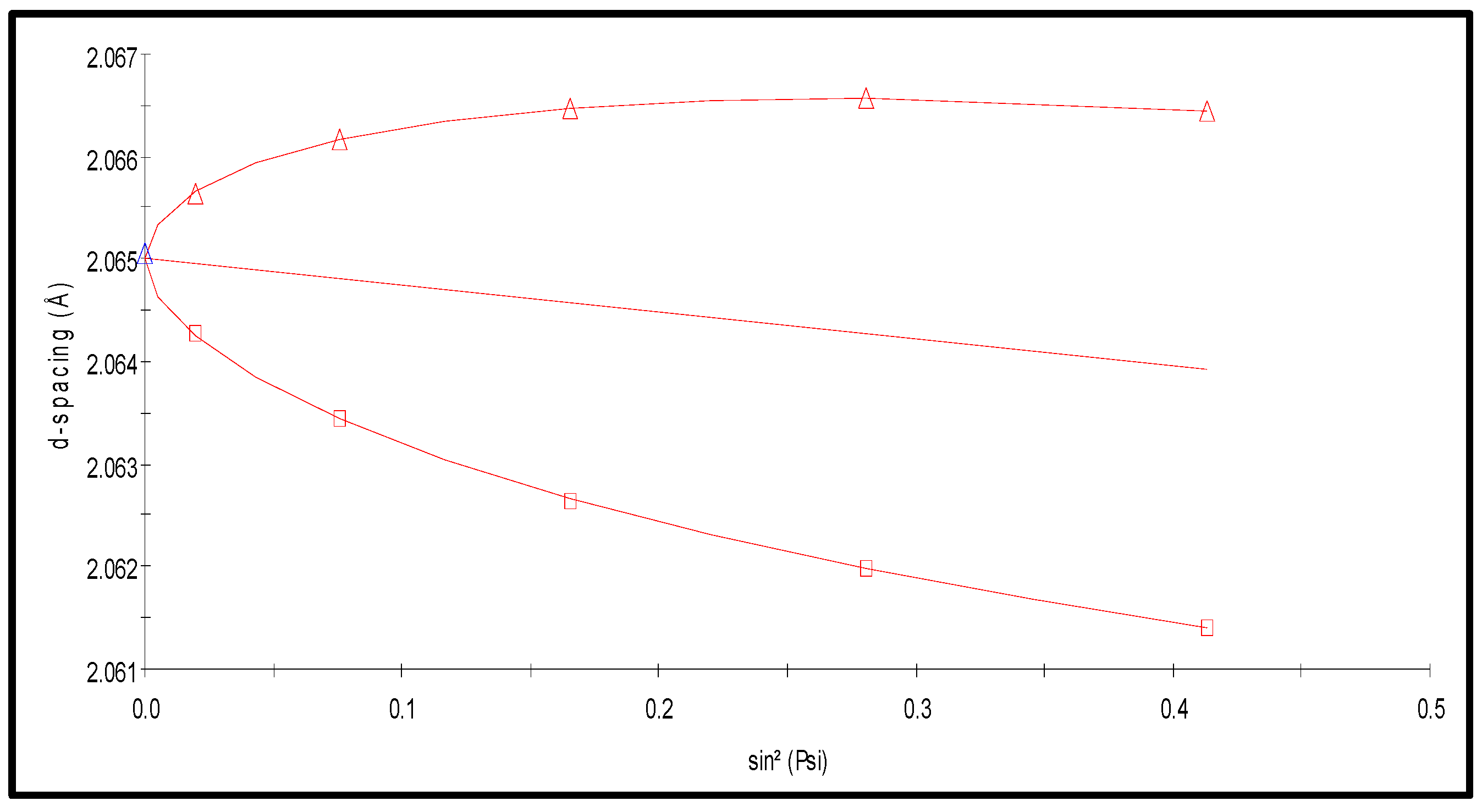

2.3. Residual Stress Measurement

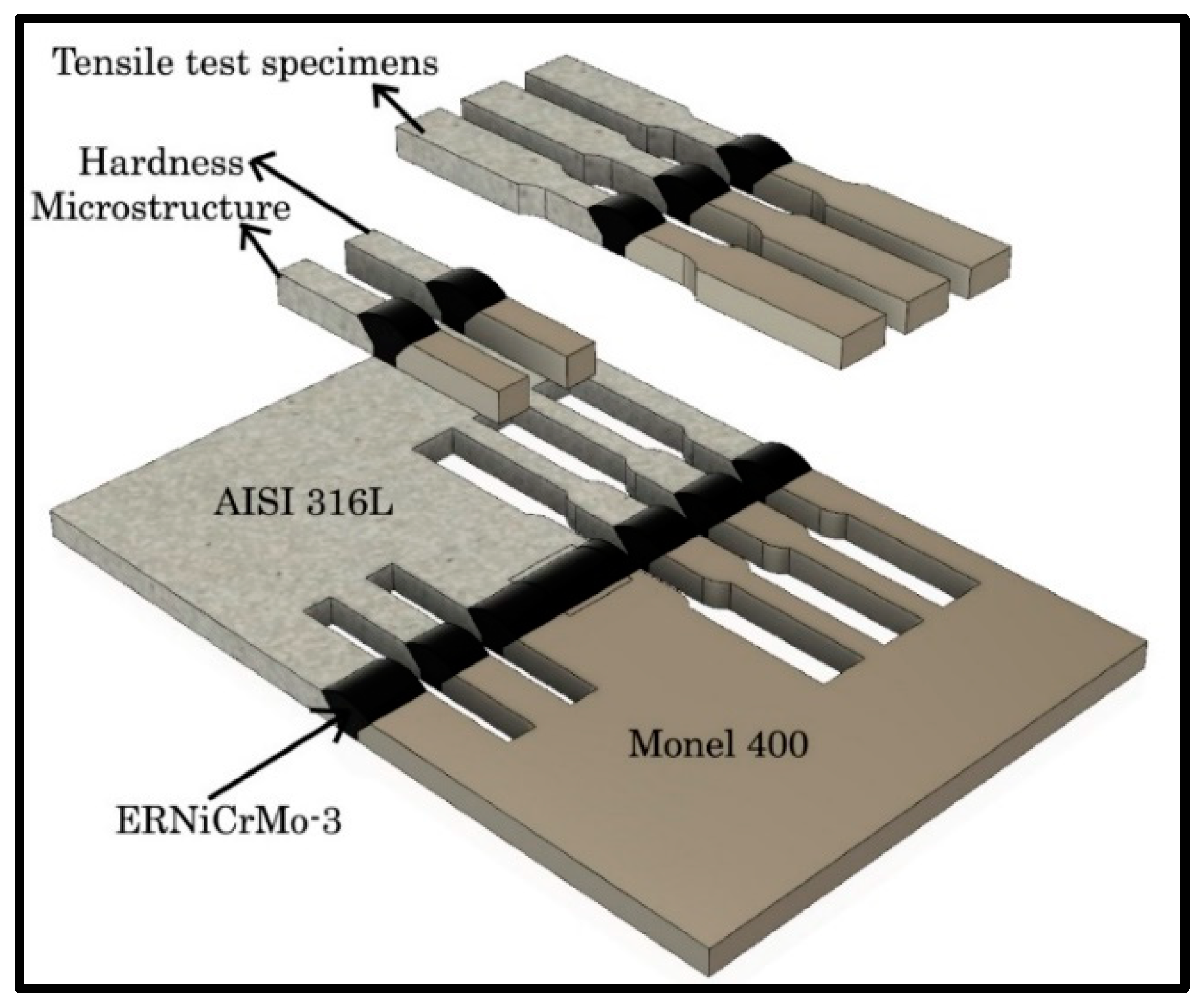

2.4. Microstructural Characterization

2.5. Mechanical Testing

3. Results and Discussion

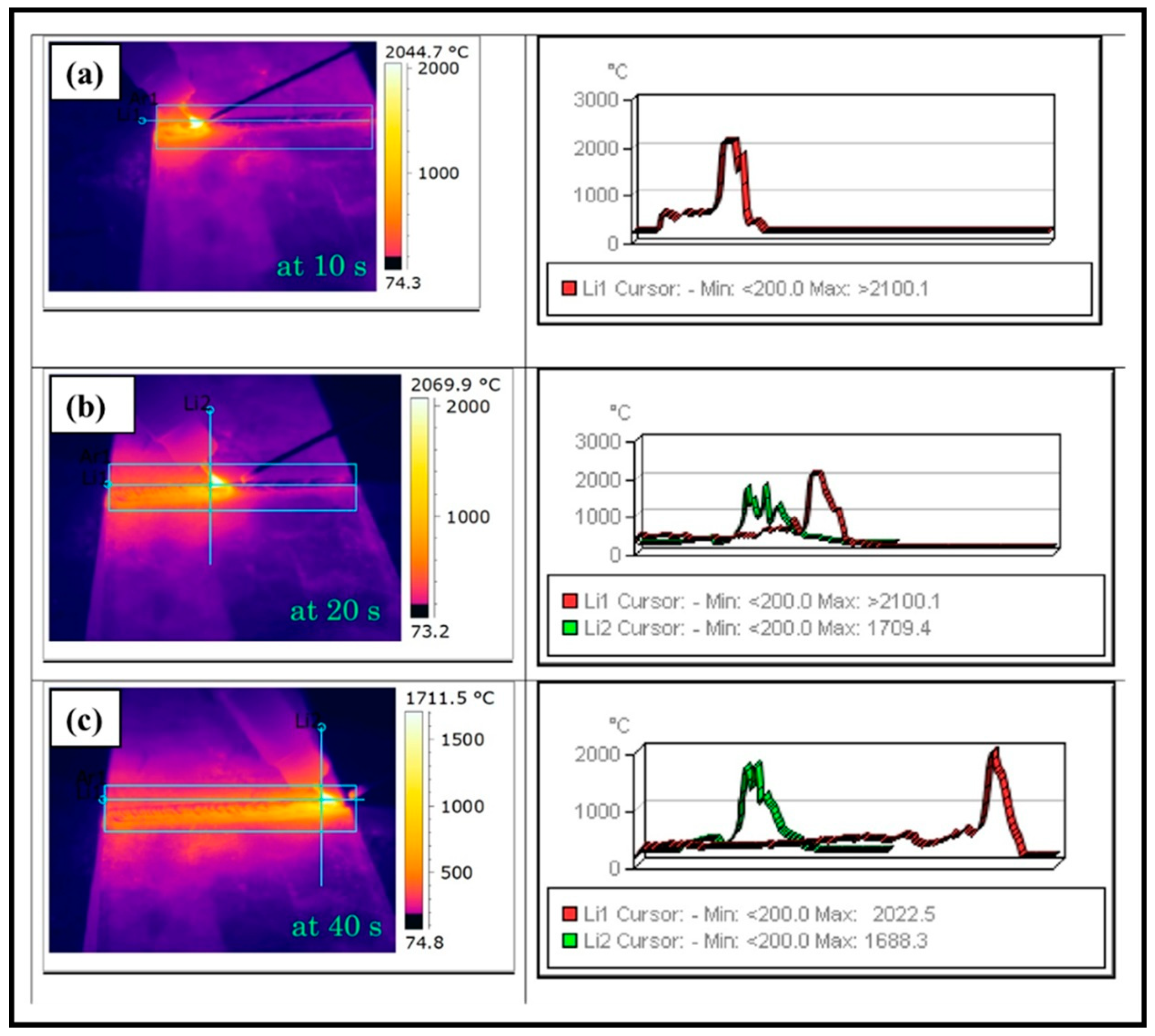

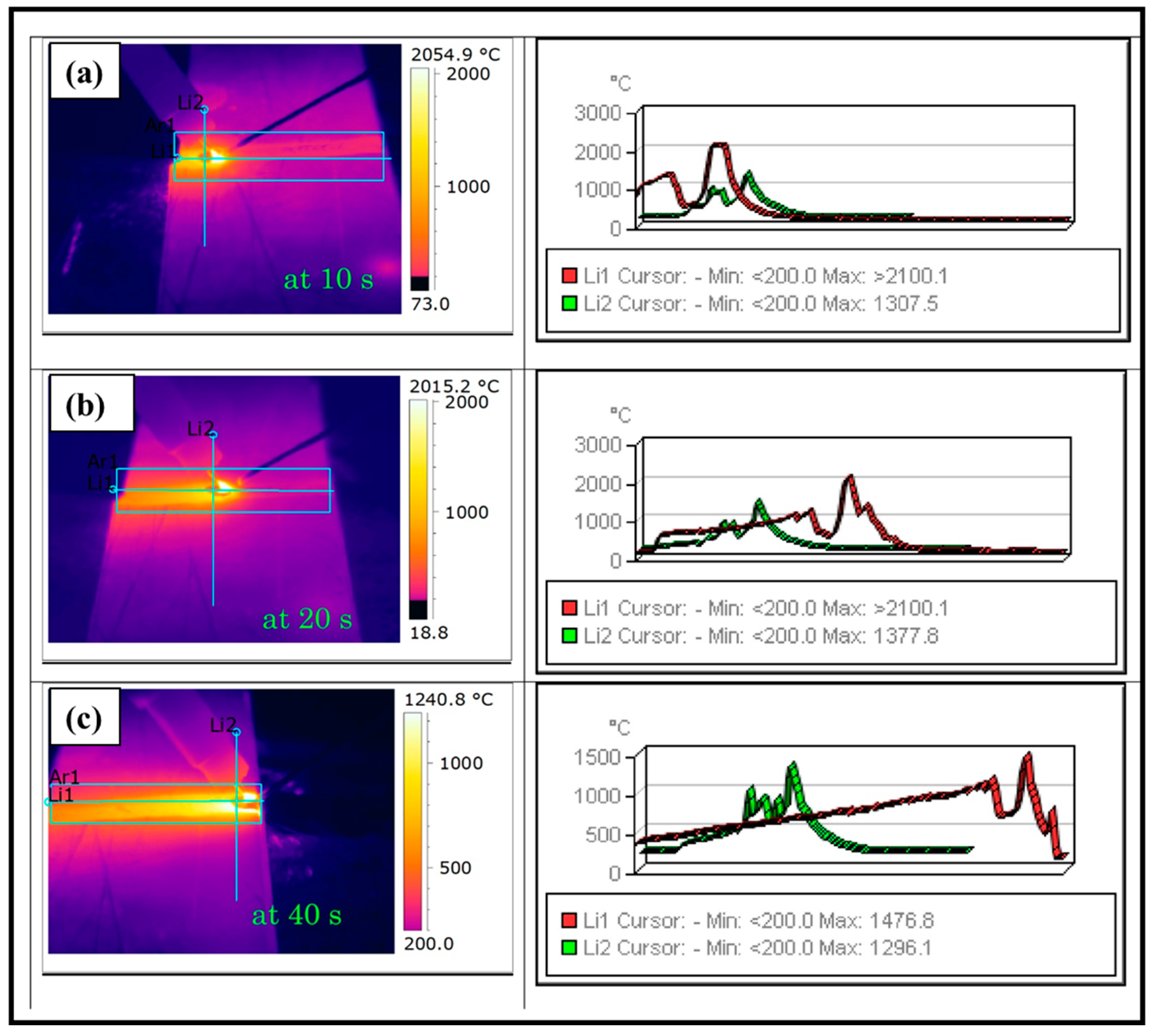

3.1. Infrared Thermal Cycles

3.2. Residual Stresses

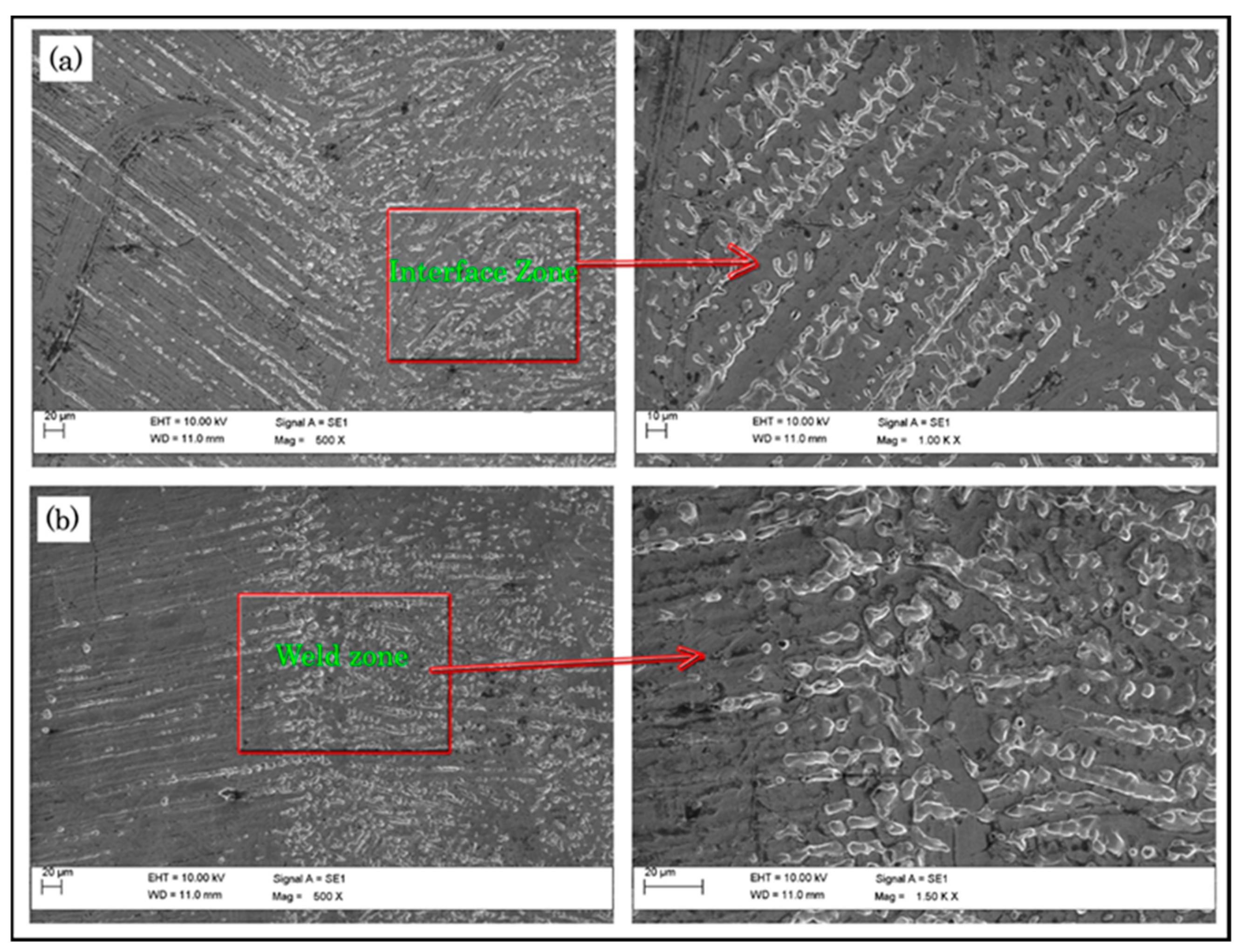

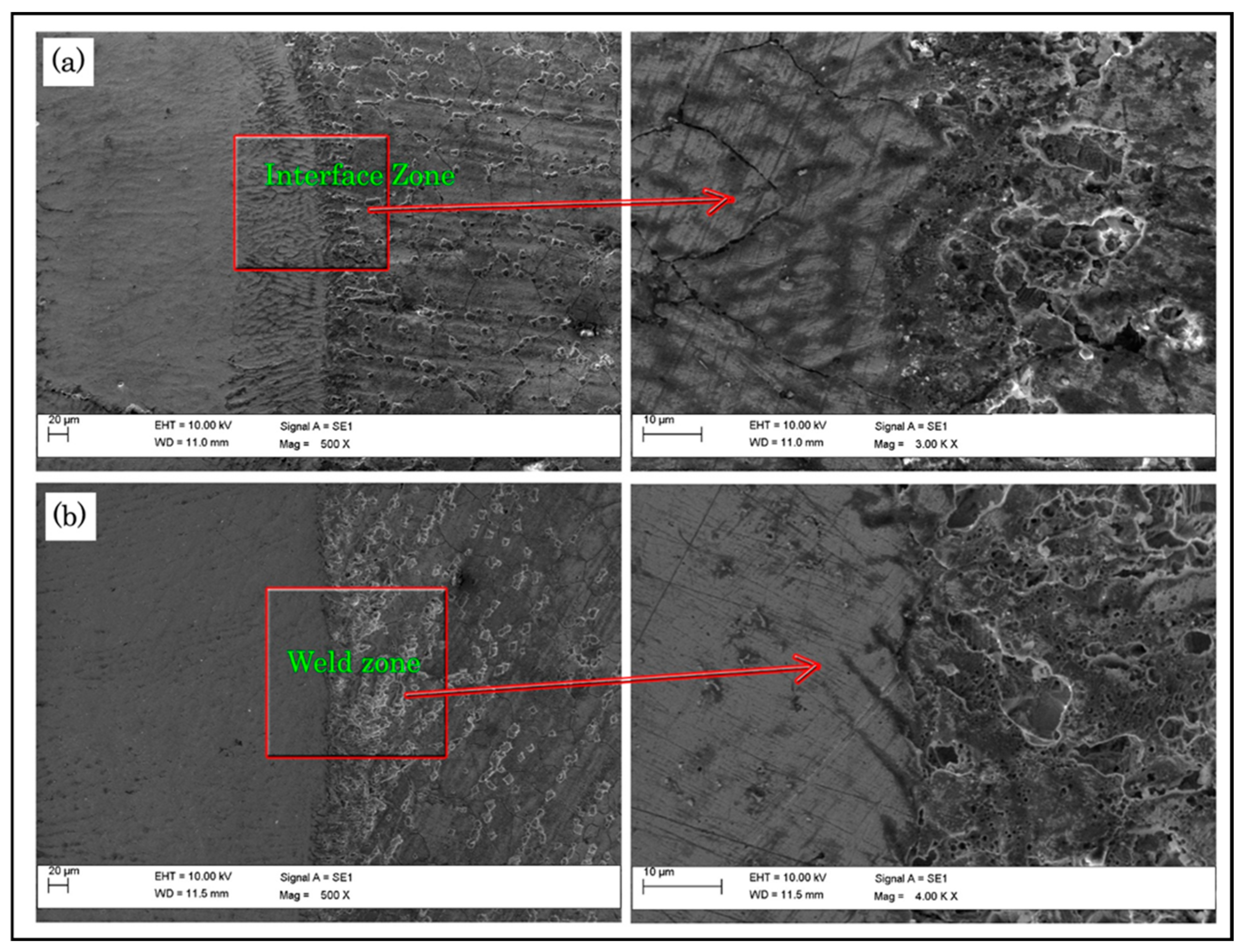

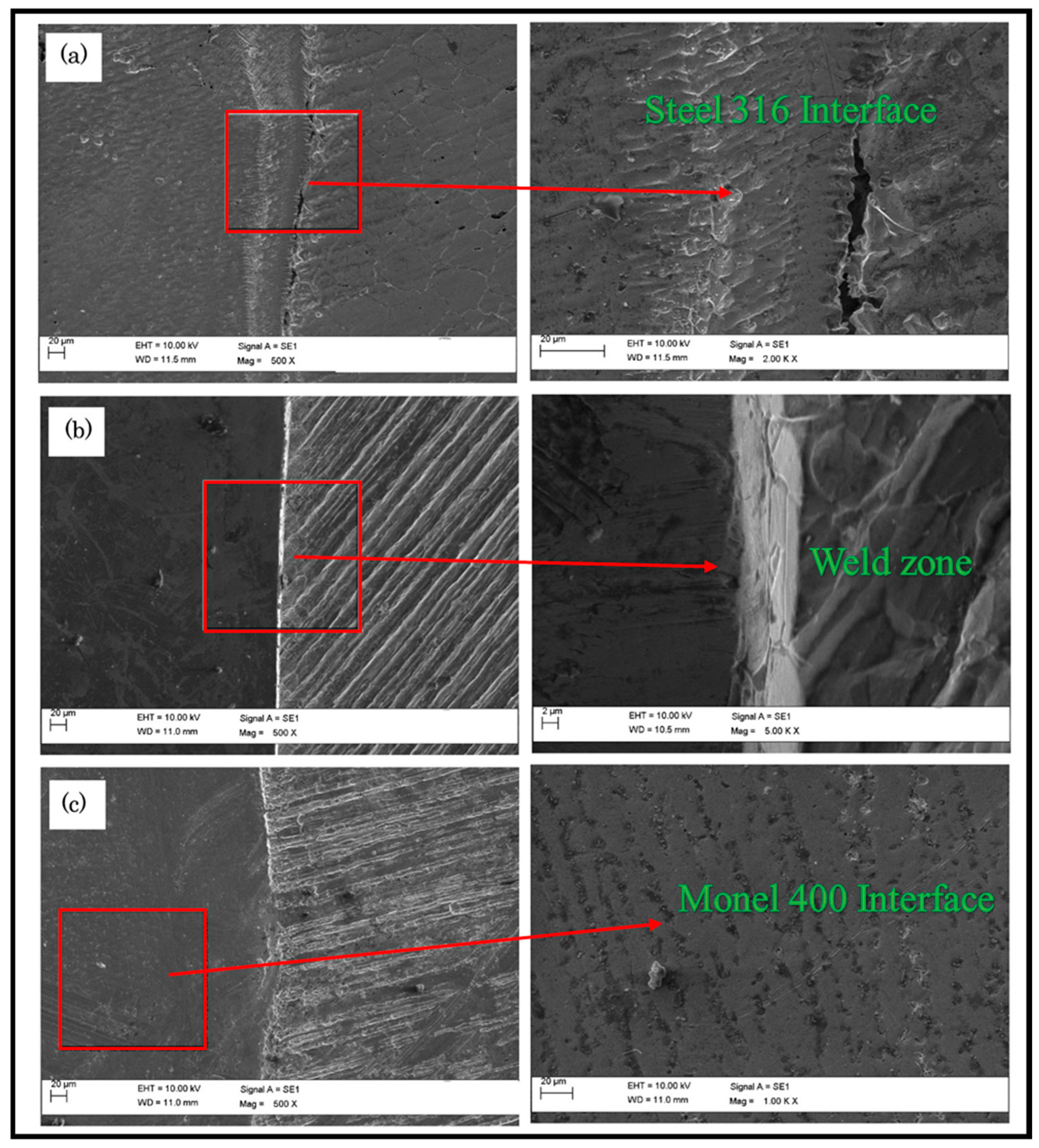

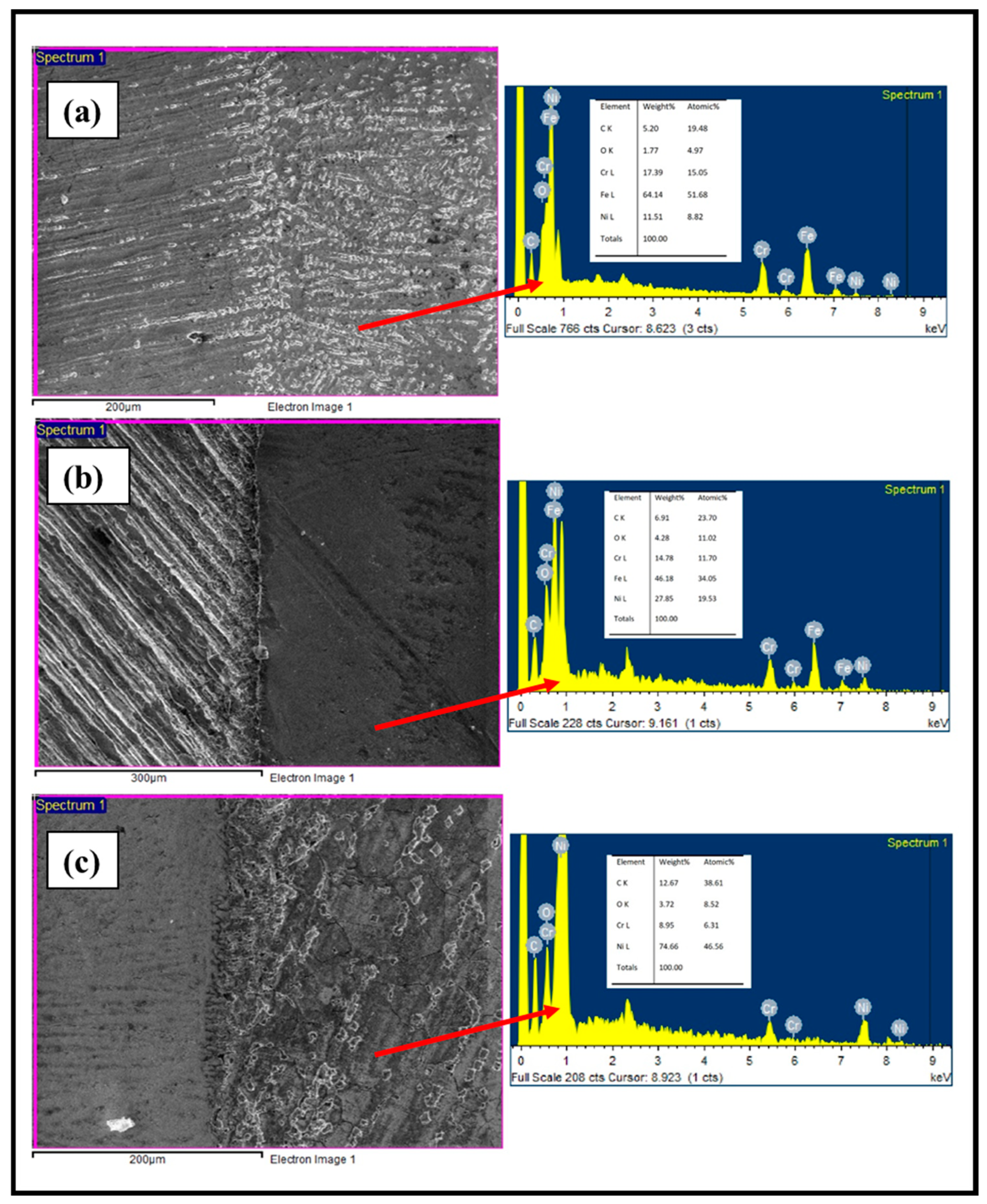

3.3. Microstructural Evolution

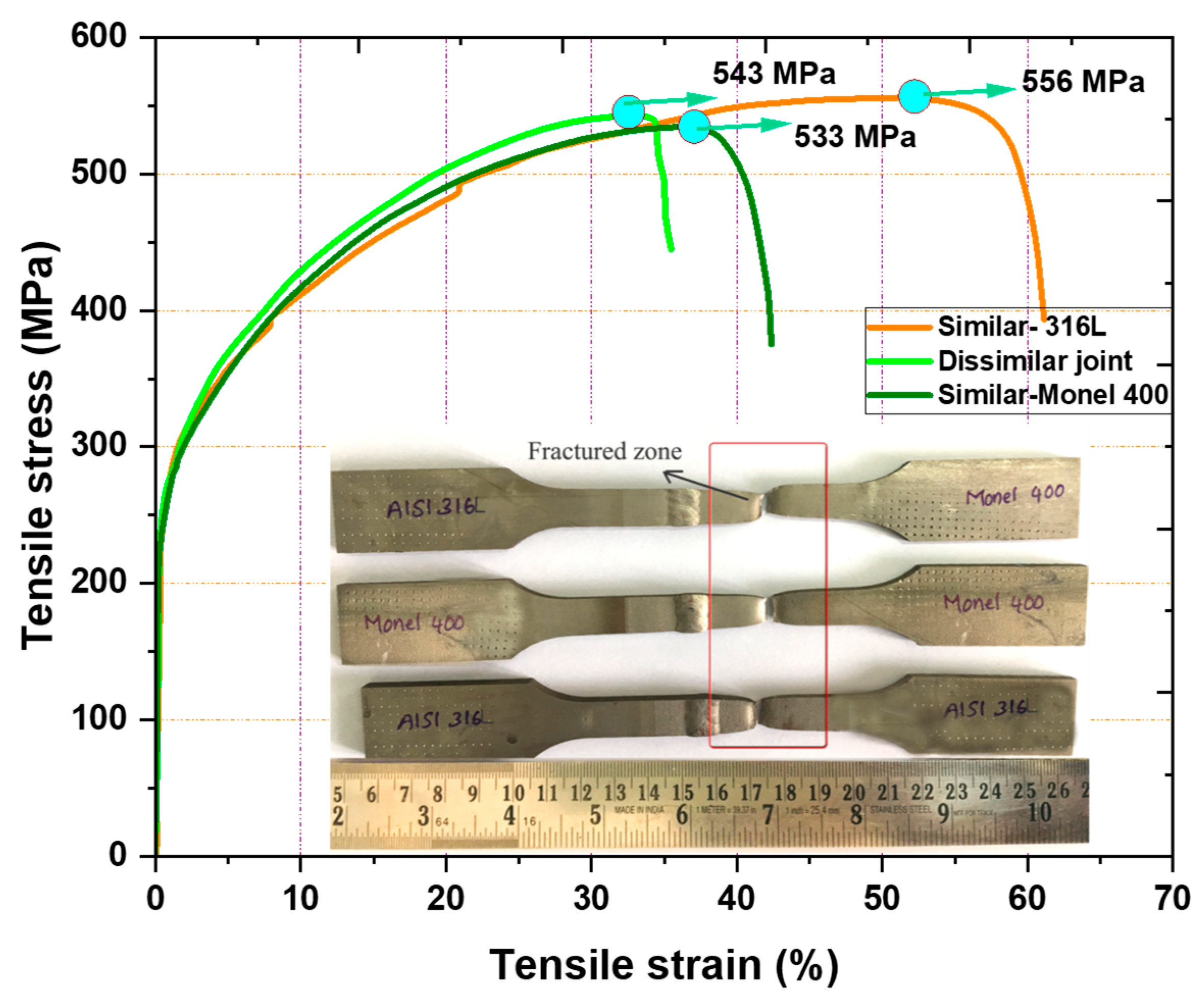

3.4. Tensile Properties

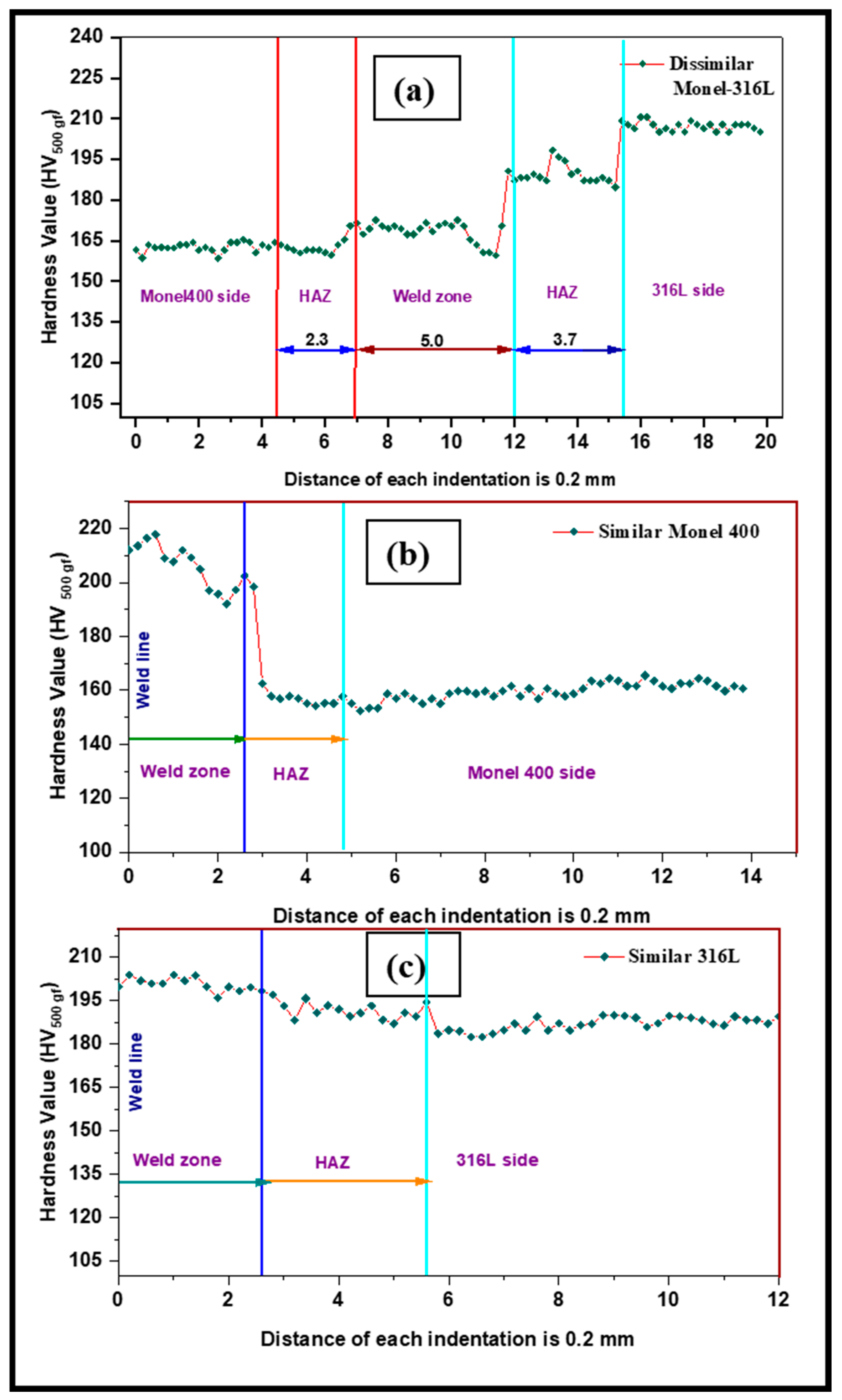

3.5. Microhardness

4. Conclusions

- The maximum temperature in corresponding welds of Monel 400 was 1788 °C, and that for AISI 316L was 1750 °C. In the dissimilar joints between Monel 400 and AISI 316L, a non-uniform temperature field was noticed, with high thermal gradients showing variations in the thermal characteristics of the two materials.

- The weldments of Monel 400 and AISI 316L had compressive residual stresses of 293 MPa in the weld region as a result of contrasting thermal expansion and cooling rates. Similarly, welds of Monel 400 exhibited 235 MPa of compressive stress, while AISI 316L joints displayed 57 MPa of tensile stress based on their own thermal properties and shrinkage characteristics.

- Dissimilar weldments between Monel 400 and AISI 316L exhibited a UTS of 543 MPa, which is lower than that of a similar AISI 316L joint (556 MPa) but higher than that of a similar Monel 400 weld (533 MPa).

- Similar Monel 400 welded samples exhibited the highest average microhardness of 203 HV, with similar AISI 316L welds at 207 HV; the average microhardness found in dissimilar joints was 168 HV.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TIG | tungsten inert gas |

| GTAW | gas tungsten arc welding |

| IRT | infrared thermography |

| XRD | X-ray diffraction |

| EDS | Energy-dispersive spectroscopy |

| SEM | scanning electron microscopy |

| FEA | finite element analysis |

| UTM | universal testing machine |

| YS | yield strength |

| HAZ | heat-affected zone |

| RS | residual stress |

| UTS | ultimate tensile strength |

References

- Yang, J.; Dong, H.; Wu, G.; Xiong, F. Experimental and Numerical Simulation Study on Microstructure, Residual Stress and Mechanical Properties of Fe–Mn–C–Cr Cryogenic High-Manganese Steel Arc-Welded Joint. J. Mater. Res. Technol. 2025, 35, 1335–1347. [Google Scholar] [CrossRef]

- Kumar, A.S.; Sharma, S.K.; Shukla, A.K. Microstructural, Mechanical, and Thermal Analysis of SS316L Weldment for Marine Engineering Application. J. Mater. Eng. Perform. 2024, 33, 13502–13515. [Google Scholar] [CrossRef]

- Kumar, S.; Madugula, N.S.; Kumar, R.; Kumar, N.; Giri, J.; Kanan, M. An Extensive Analysis of GTAW Process and Its Influence on the Microstructure and Mechanical Properties of SDSS 2507. J. Mater. Res. Technol. 2024, 33, 8675–8686. [Google Scholar] [CrossRef]

- Güler, Ö.; Albayrak, M.G.; Başgöz, Ö.; Kavaz, E.; Alkarrani, H.; ALMisned, G.; Tekin, H.O. Development and In-Depth Experimental Characterization of Novel TiZrNbHfTaOx Reinforced 316L Stainless Steel for Advanced Nuclear Applications. Nucl. Eng. Des. 2024, 428, 113516. [Google Scholar] [CrossRef]

- Agostini, P.; Coppola, R.; Hofmann, M.; Ohms, C.; Tucek, K. Stress Distribution in a 316L(N) Steel Narrow Gap TIG Model Weld for Gen IV Nuclear Applications. Nucl. Mater. Energy 2022, 32, 101203. [Google Scholar] [CrossRef]

- Kumar, S.; Ramakrishna, A.; Madugula, N.S.; Kumar, N.; Kapoor, M.; Bhatia, H.S. Evolution of Surface Morphology and Mechanical Characterization of GTAW Welded SDSS Thin Sheets. Results Surf. Interfaces 2025, 18, 100412. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Ravi Kumar, R.; Chaursaia, P.K.; Ali, B. Thermo-mechanical analysis of laser welding of Grade 91 steel plates. Optik 2021, 245, 167510. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Vasudevan, M.; Das, P.K.; Alam, M.M.; Kumar, K.S.; Prabhakar, S. FEM based thermal and mechanical analysis of comparative study of TIG and A-TIG welding on P91 steel. Sci. Rep. 2025, 15, 10271. [Google Scholar] [CrossRef]

- Luca, R.; Paolo, F.; Filippo, B. The Influence of Metallurgical Data on Residual Stresses in Computational Welding. Proc. Struct. Integr. 2018, 9, 55–63. [Google Scholar] [CrossRef]

- Ma, M.; Wei, W.; Zhang, H.; Yao, Z.; Sun, Y.; Chen, M.; Wu, F. Dissimilar Gas Tungsten Arc Welding of AlCoCrFeNi2.1 Eutectic High Entropy Alloy to 316L Stainless Steel. J. Mater. Res. Technol. 2025, 35, 7065–7073. [Google Scholar] [CrossRef]

- Zhuang, J.; Gong, M.; Yang, J.; Liao, B.; Yu, Z.; Zhou, S.; Gao, M. Insight into the Alternative Galvanic Corrosion Behaviors of the Laser-Arc Hybrid Welded Magnesium/Aluminum Dissimilar Joints. Corros. Sci. 2025, 246, 112763. [Google Scholar] [CrossRef]

- Xu, G.; Liu, L.; Deng, Y.; Zeng, Y.; Cao, J.; Tang, L.; Peng, X.; Duan, J.; Liang, M.; Pan, Q. Microstructure Characteristics and Corrosion Behavior of Metal Inert Gas Welded Dissimilar Joints of 6005A Modified by Sc and 5083 Alloys. Trans. Nonferrous Met. Soc. China 2025, 35, 60–76. [Google Scholar] [CrossRef]

- Ai, Y.; Ye, C.; Liu, J.; Zhou, M. Study on the Evolution Processes of Keyhole and Melt Pool in Different Laser Welding Methods for Dissimilar Materials Based on a Novel Numerical Model. Int. Commun. Heat Mass Transf. 2025, 163, 108629. [Google Scholar] [CrossRef]

- Denisov, V.; Saykov, I.V.; Kapustin, R.D. Explosion welding of Al + Cu bimetallic joints for electrical contacts. WeLD Int. 2017, 31, 773–776. [Google Scholar] [CrossRef]

- Wei, Y.; Li, H.; Sun, F.; Zou, J. The Interfacial Characterization and Performance of Cu/Al-Conductive Heads Processed by Explosion Welding, Cold Pressure Welding, and Solid-Liquid Casting. Metals 2019, 9, 237. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Rajyalakshmi, G. Thermal Fields and Residual Stresses Analysis in TIG Weldments of SS 316 and Monel 400 by Numerical Simulation and Experimentation. Mater. Res. Express 2019, 6, 0865e2. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Sonia, P.; Aslesha, C.L.; Vardhan, T.V.; Ahmed, F.; Kumar, A.; Chandrashekar, R.; Abdo, H.S.; Alnaser, I. Investigations on Corrosion Rate, Mechanical Properties and Structural Homogeneity of Interpulse TIG Dissimilar Weldments. J. Mater. Res. Technol. 2024, 32, 2537–2546. [Google Scholar] [CrossRef]

- ASTM E8/E8M-11; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2011.

- Song, G.; Xu, Z.; Lang, Q.; Liu, X.; Wang, H.; Liu, L. A Laser-Induced TIG Arc Narrow-Gap Welding Technique for TC4 Titanium Alloy Thick Plates Based on the Spatial Position Control of Laser, Arc and Filler Wire. Metals 2024, 14, 510. [Google Scholar] [CrossRef]

- Bhaumik, S.; Mukherjee, M.; Sarkar, P.; Nayek, A.; Paleu, V. Microstructural and Wear Properties of Annealed Medium Carbon Steel Plate (EN8) Cladded with Martensitic Stainless Steel (AISI410). Metals 2020, 10, 958. [Google Scholar] [CrossRef]

- Vaikar, S.J.; Narayanan, V.; George, J.C.; Kanish, T.C.; Ramkumar, K.D. Effect of weld microstructure on the tensile properties and impact toughness of the naval, marine-grade steel weld joints. J. Mater. Res. Technol. 2022, 19, 3724–3737. [Google Scholar] [CrossRef]

- Chandrasekar, V.; Ramkumar, K.D. Effect of Nb-free consumables on the microstructure and structural integrity of pressure vessel grades of dissimilar austenitic stainless steel welded joints. J. Mater. Res. Technol. 2022, 18, 3443–3456. [Google Scholar] [CrossRef]

- Maurya, A.K.; Pandey, C.; Chhibber, R. Influence of Heat Input on Weld Integrity of Weldments of Two Dissimilar Steels. Mater. Manuf. Process. 2023, 38, 379–400. [Google Scholar] [CrossRef]

- Xie, J.; Ma, Y.; Wang, M.; Li, H.; Fang, N.; Liu, K. Interfacial Characteristics and Residual Welding Stress Distribution of K4750 and Hastelloy X Dissimilar Superalloys Joints. J. Manuf. Process. 2021, 67, 253–261. [Google Scholar] [CrossRef]

- Kumar, A.; Pandey, S.M.; Sirohi, S.; Fydrych, D.; Pandey, C. P92 Steel and Inconel 617 Alloy Welds Joint Produced Using ERNiCr-3 Filler with GTAW Process: Solidification Mechanism, Microstructure, Mechanical Properties and Residual Stresses. Heliyon 2023, 9, e18959. [Google Scholar] [CrossRef] [PubMed]

- Ghumman, K.Z.; Ali, S.; Khan, N.B. Optimization of TIG Welding Parameters for Enhanced Mechanical Properties in AISI 316L Stainless Steel Welds. Int. J. Adv. Manuf. Technol. 2025, 136, 353–365. [Google Scholar] [CrossRef]

- Aarbogh, H.M.; Hamide, M.; Fjaer, H.G.; Mo, A.; Bellet, M.; Aarbogh, H.M.; Hamide, M.; Fjaer, H.G.; Mo, A.; Bellet, M. Experimental validation of finite element codes for welding deformations Experimental validation of finite element codes for welding deformations Experimental validation of finite element codes for welding deformations. J. Mater. Process. Technol. 2010, 13, 1681–1689. [Google Scholar] [CrossRef]

- Attarha, M.J.; Sattari-Far, I. Study on welding temperature distribution in thin welded plates through experimental measurements and finite element simulation. J. Mater. Process. Technol. 2011, 211, 688–694. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Vasudevan, M.; Elumalai, P.V.; Akram, M.; Attar, P.R.; Krishnasamy, E. Numerical and experimental analysis of temperature and residual stress of GTA and LASER welding for grade 91 steel. Int. J. Interact. Des. Manuf. 2024. [Google Scholar] [CrossRef]

- Vasantharaja, P.; Vasudevan, M.; Palanichamy, P. Effect of welding processes on the residual stress and distortion in type 316LN stainless steel weld joints. J. Manuf. Process. 2015, 19, 187–193. [Google Scholar] [CrossRef]

- Sadek, A.A.; Abass, M.; Zaghloul, B.; Elrefaey, A.; Ushio, M. Investigation of dissimilar joints between low carbon steel and Monel 400. Trans. JWRI 2000, 29, 21–28. [Google Scholar]

- Raj, S.; Biswas, P. Experimental investigation of the effect of induction preheating on the microstructure evolution and corrosion behaviour of dissimilar FSW (IN718 and SS316L) joints. J. Manuf. Process. 2023, 95, 143–159. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Adithya, G.S.; Ramadevi, R.S.; Sonia, P.; Saxena, K.K.; Kumar, N.; Eldin, S.M.; Al-kafaji, F.H.K. Metallurgical, mechanical and corrosion behaviour of pulsed and constant current TIG dissimilar welds of AISI 430 and Inconel 718. J. Mater. Res. Technol. 2023, 24, 6652–6664. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Naren, S.V.; Karthik Paga, V.R.; Tiwari, A.; Arivazhagan, N. Development of Pulsed Current Gas Tungsten Arc Welding Technique for Dissimilar Joints of Marine Grade Alloys. J. Manuf. Process. 2016, 21, 201–213. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Arivazhagan, N.; Narayanan, S. Effect of Filler Materials on the Performance of Gas Tungsten Arc Welded AISI 304 and Monel 400. Mater. Des. 2012, 40, 70–79. [Google Scholar] [CrossRef]

- Yadav, L.K.; Misra, J.P.; Tyagi, R. Microstructural, mechanical, and corrosion behaviour analysis of Monel 400 fabricated using CMT-WAAM. Mater. Today Commun. 2025, 42, 111153. [Google Scholar] [CrossRef]

- Shanthos Kumar, G.; Raghukandan, K.; Saravanan, S.; Sivagurumanikandan, N. Optimization of parameters to attain higher tensile strength in pulsed Nd: YAG laser welded Hastelloy C-276–Monel 400 sheets. Infrared Phys. Technol. 2019, 100, 1–10. [Google Scholar] [CrossRef]

- Shen, J.; Taek Choi, Y.; Gonçalves, R.; Schell, N.; Yang, J.; Zeng, Z.; Catarina Baptista, A.; Seop Kim, H.; Oliveira, J.P. Synergistic effects of Monel 400 filler wire in gas metal arc welding of CoCrFeMnNi high entropy alloy. Mater. Des. 2024, 242, 112996. [Google Scholar] [CrossRef]

- Yegaie, Y.S.; Kermanpur, A.; Shamanian, M. Numerical simulation and experimental investigation of temperature and residual stresses in GTAW with a heat sink process of Monel 400 plates. J. Mater. Process. Technol. 2010, 210, 1690–1701. [Google Scholar] [CrossRef]

- Balat-Pichelin, M.; Sans, J.L.; Bêche, E. Spectral directional and total hemispherical emissivity of virgin and oxidized 316L stainless steel from 1000 to 1650 K. Infrared Phys. Technol. 2022, 123, 104156. [Google Scholar] [CrossRef]

- Moraes, C.A.P.; Chludzinski, M.; Nunes, R.M.; Lemos, G.V.B.; Reguly, A. Residual stress evaluation in API 5L X65 girth welded pipes joined by friction welding and gas tungsten arc welding. J. Mater. Res. Technol. 2019, 8, 988–995. [Google Scholar] [CrossRef]

- Kessal, B.A.; Fares, C.; Meliani, M.H.; Alhussein, A.; Bouledroua, O.; François, M. Effect of gas tungsten arc welding parameters on the corrosion resistance and the residual stress of heat affected zone. Eng. Fail. Anal. 2020, 107, 104200. [Google Scholar] [CrossRef]

- Tabrizi, R.; Sabzi, M.; Mousavi Anijdan, S.H.; Eivani, A.R.; Park, N.; Jafarian, H.R. Comparing the effect of continuous and pulsed current in the GTAW process of AISI 316L stainless steel welded joint: Microstructural evolution, phase equilibrium, mechanical properties and fracture mode. J. Mater. Res. Technol. 2021, 15, 199–212. [Google Scholar] [CrossRef]

- Sabzi, M.; Mousavi Anijdan, S.H.; Eivani, A.R.; Park, N.; Jafarian, H.R. The effect of pulse current changes in PCGTAW on microstructural evolution, drastic improvement in mechanical properties, and fracture mode of dissimilar welded joint of AISI 316L-AISI 310S stainless steels. Mater. Sci. Eng. A 2021, 823, 141700. [Google Scholar] [CrossRef]

| Base/Filler Metals | Fe | Cr | Ni | Mo | Mn | C | Cu | Si |

|---|---|---|---|---|---|---|---|---|

| ERNiCrMo-3 | 5.0 | 21.5 | Bal | 9.0 | 0.5 | 0.1 | 0.5 | 0.5 |

| AISI 316L | Bal | 17.6 | 10.6 | 2.5 | 2.0 | 0.03 | Nil | 0.9 |

| Monel 400 | 2.5 | Nil | Bal | Nil | 2.0 | 0.3 | 31.65 | 0.5 |

| Base Metals | Coefficient of Linear Thermal Expansion (α), m/m/°C | Density (ρ), kg/m3 | Thermal Conductivity (k), W/m°C | Poisson’s Ratio (ϑ) |

|---|---|---|---|---|

| AISI 316L | 16.2 | 7980 | 16.4 | 0.28 |

| Monel 400 | 13.6 | 8380 | 21.8 | 0.32 |

| Weld Type Similar/ Dissimilar | Arc Voltage (V), V | Welding Current (I), A | Welding Speed (S), mm/min | Heat Input Rate (Q), kJ/mm |

|---|---|---|---|---|

| (a) AISI 316L-AISI 316L | 14 | 130 | 108 | 0.708 |

| (b) Monel400-AISI 316L | 14 | 135 | 102 | 0.718 |

| (c) Monel400-Monel400 | 14 | 135 | 102 | 0.718 |

| Weld Type | Distance (mm) | Location | Slope (m) | tan (dy/dx) | Young’s Modulus (MPa) | Poisson Ratio, (ϑ) | D-Spacing (A) | RS MPa |

|---|---|---|---|---|---|---|---|---|

| Dissimilar Monel AISI 316L | 50 | Monel Base | −0.0014 | −0.0014 | 1.82 × 105 | 0.32 | 1.0744 | −178 |

| 15 | Monel HAZ | −0.0008 | −0.0008 | 1.82 × 105 | 0.32 | 1.0744 | −109 | |

| 5 | Monel Interface | 0.0002 | 0.0002 | 1.82 × 105 | 0.32 | 1.0744 | 28 | |

| 0 | Weld Center | −0.0023 | −0.0023 | 1.82 × 105 | 0.3 | 1.0819 | −293 | |

| 5 | 316L Interface | −0.0006 | −0.0006 | 1.94 × 105 | 0.3 | 1.0819 | −85 | |

| 15 | 316L HAZ | −0.0017 | −0.0017 | 1.94 × 105 | 0.3 | 1.0819 | −230 | |

| 50 | 316L Base | −0.0017 | −0.0017 | 1.94 × 105 | 0.3 | 1.0819 | −240 | |

| Similar Monel 400 | 15 | Monel HAZ | 0.0008 | 0.0008 | 1.82 × 105 | 0.32 | 1.0744 | 97 |

| 5 | Monel Interface | 0.0003 | 0.0003 | 1.82 × 105 | 0.32 | 1.0744 | 41 | |

| 0 | Monel weld | −0.0018 | −0.0018 | 1.82 × 105 | 0.32 | 1.0744 | −235 | |

| Similar AISI 316L | 15 | 316L HAZ | −0.0021 | −0.0021 | 1.94 × 105 | 0.3 | 1.0819 | −285 |

| 5 | 316L Interface | −0.0001 | −0.0001 | 1.94 × 105 | 0.3 | 1.0819 | −12 | |

| 0 | 316L weld | 0.0004 | 0.0004 | 1.94 × 105 | 0.3 | 1.0819 | 57 |

| Weld Type | Y.S (MPa) | UTS (MPa) | % Elongation | Fractured Location |

|---|---|---|---|---|

| AISI 316L similar | 261 | 556 | 53.58 | HAZ of AISI 316L |

| Monel 400-AISI 316L | 253 | 543 | 26.48 | Base metal Monel 400 |

| Monel 400 similar | 244 | 533 | 36.74 | Base metal Monel 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yelamasetti, B.; Sushma, S.P.; Mohammed, Z.; Altammar, H.; Khan, M.F.; Moinuddin, S.Q. Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints. Metals 2025, 15, 469. https://doi.org/10.3390/met15050469

Yelamasetti B, Sushma SP, Mohammed Z, Altammar H, Khan MF, Moinuddin SQ. Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints. Metals. 2025; 15(5):469. https://doi.org/10.3390/met15050469

Chicago/Turabian StyleYelamasetti, Balram, Sri Phani Sushma, Zubairuddin Mohammed, Hussain Altammar, Mohammad Faseeulla Khan, and Syed Quadir Moinuddin. 2025. "Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints" Metals 15, no. 5: 469. https://doi.org/10.3390/met15050469

APA StyleYelamasetti, B., Sushma, S. P., Mohammed, Z., Altammar, H., Khan, M. F., & Moinuddin, S. Q. (2025). Synergistic Effects of Thermal Cycles and Residual Stress on Microstructural Evolution and Mechanical Properties in Monel 400 and AISI 316L Weld Joints. Metals, 15(5), 469. https://doi.org/10.3390/met15050469