Study of the Surface Structural Transformation and Mechanical Properties of 65Mn Steel Modified by Pulsed Detonation–Plasma Technology

Abstract

1. Introduction

2. Experimental Method

2.1. Material and Sample Preparation

2.2. Microstructure Characterization and Mechanical Properties Testing

3. Results and Discussion

4. Conclusions

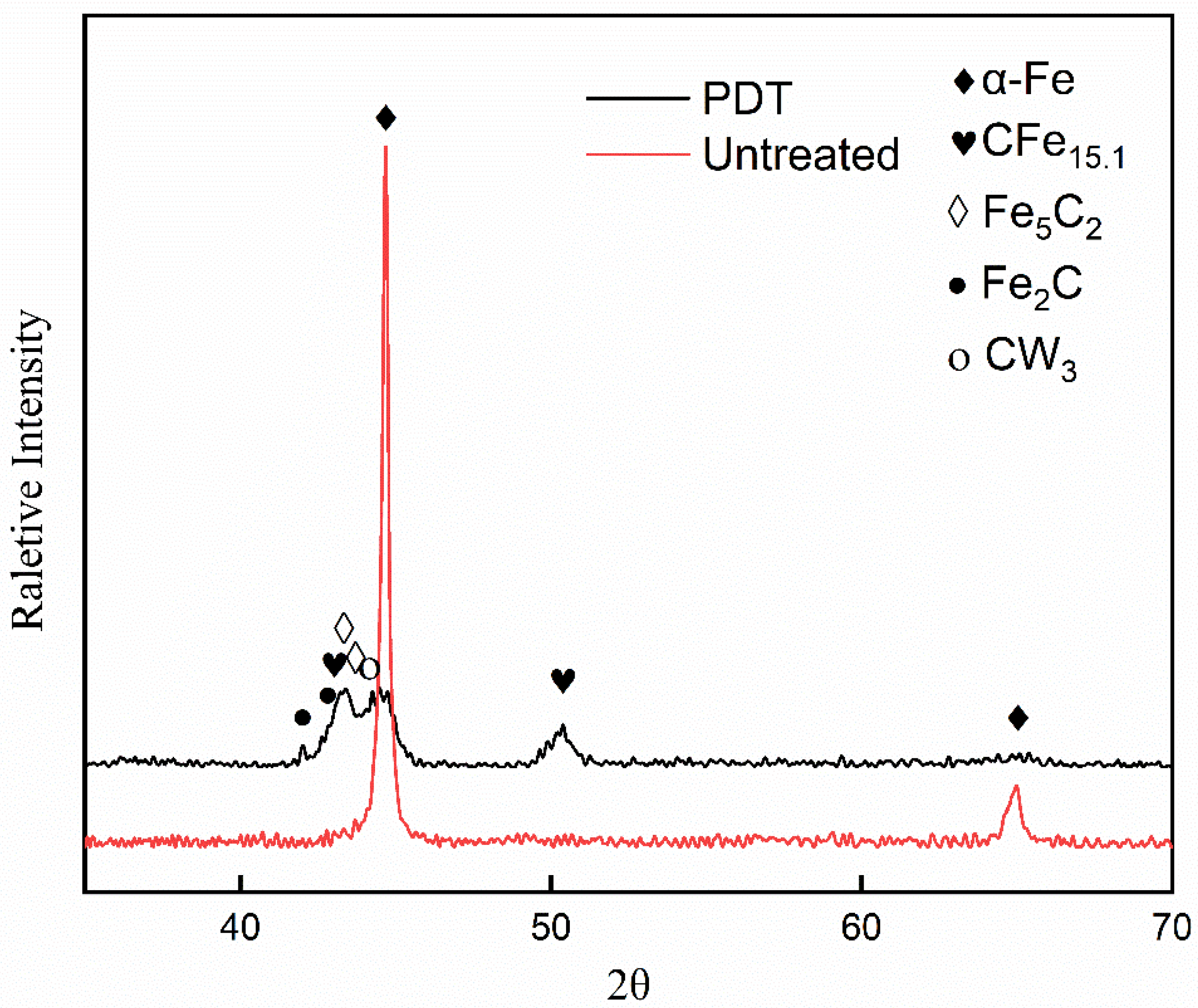

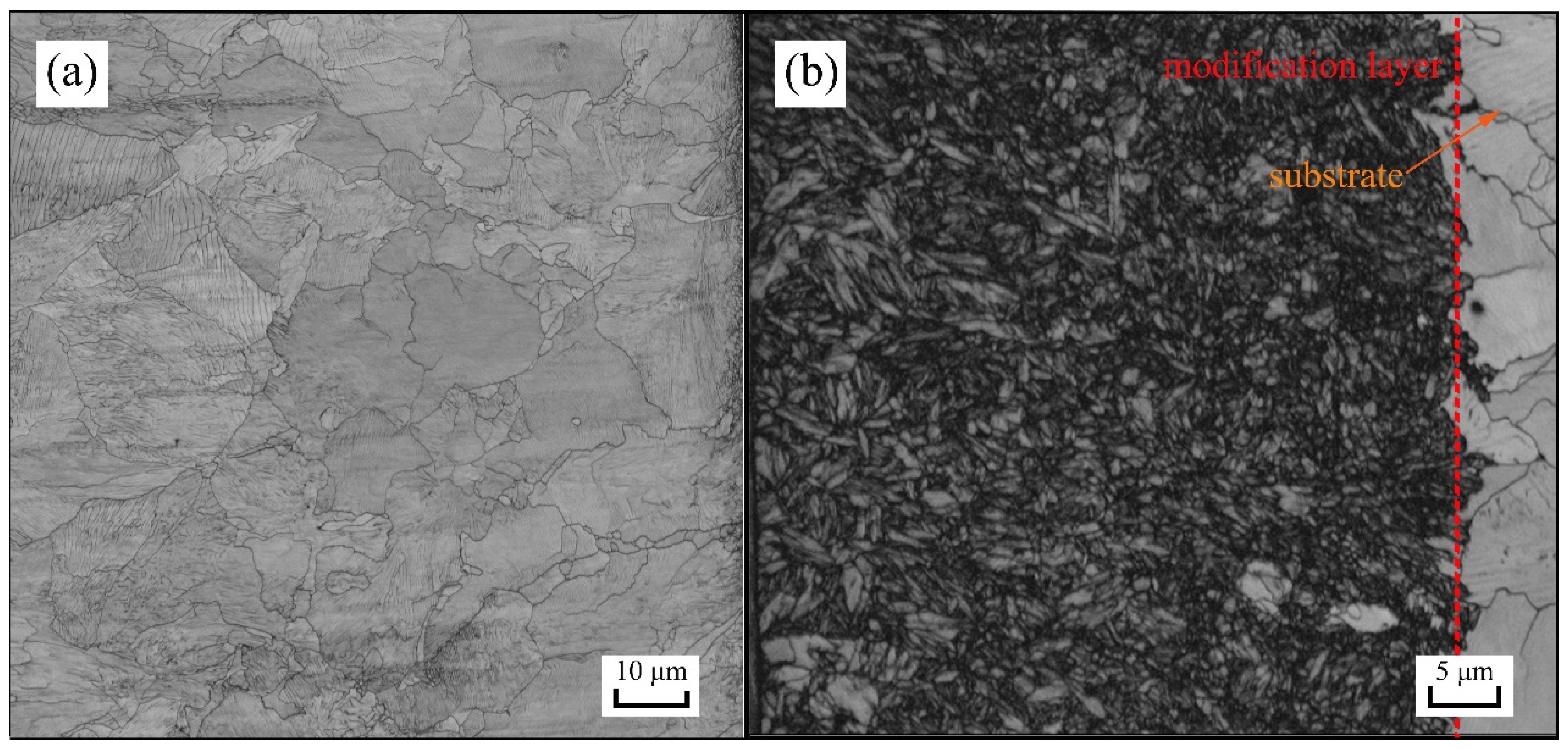

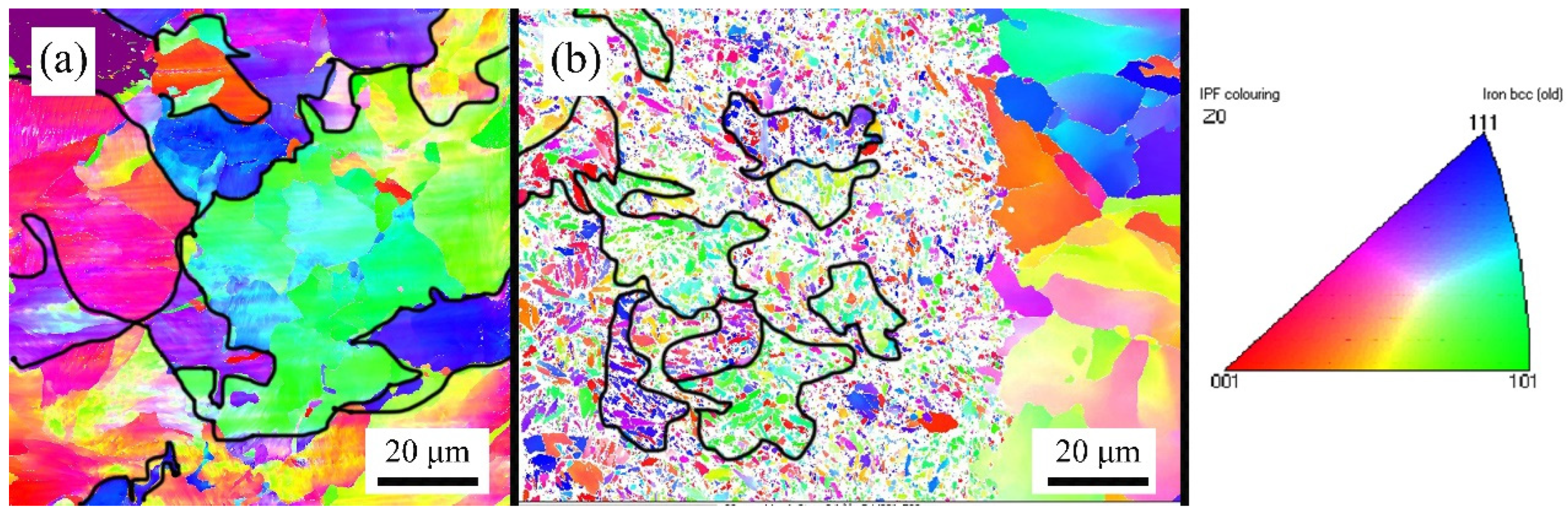

- PDT treatment will induce rapid solid-phase transformation and cause a modified layer to form on the surface of materials. The modified layer microstructures change from a lamellar pearlite and ferrite structure to martensite, tiny amounts of austenite, and a ferrite structure, containing a large number of small-angle grain boundaries.

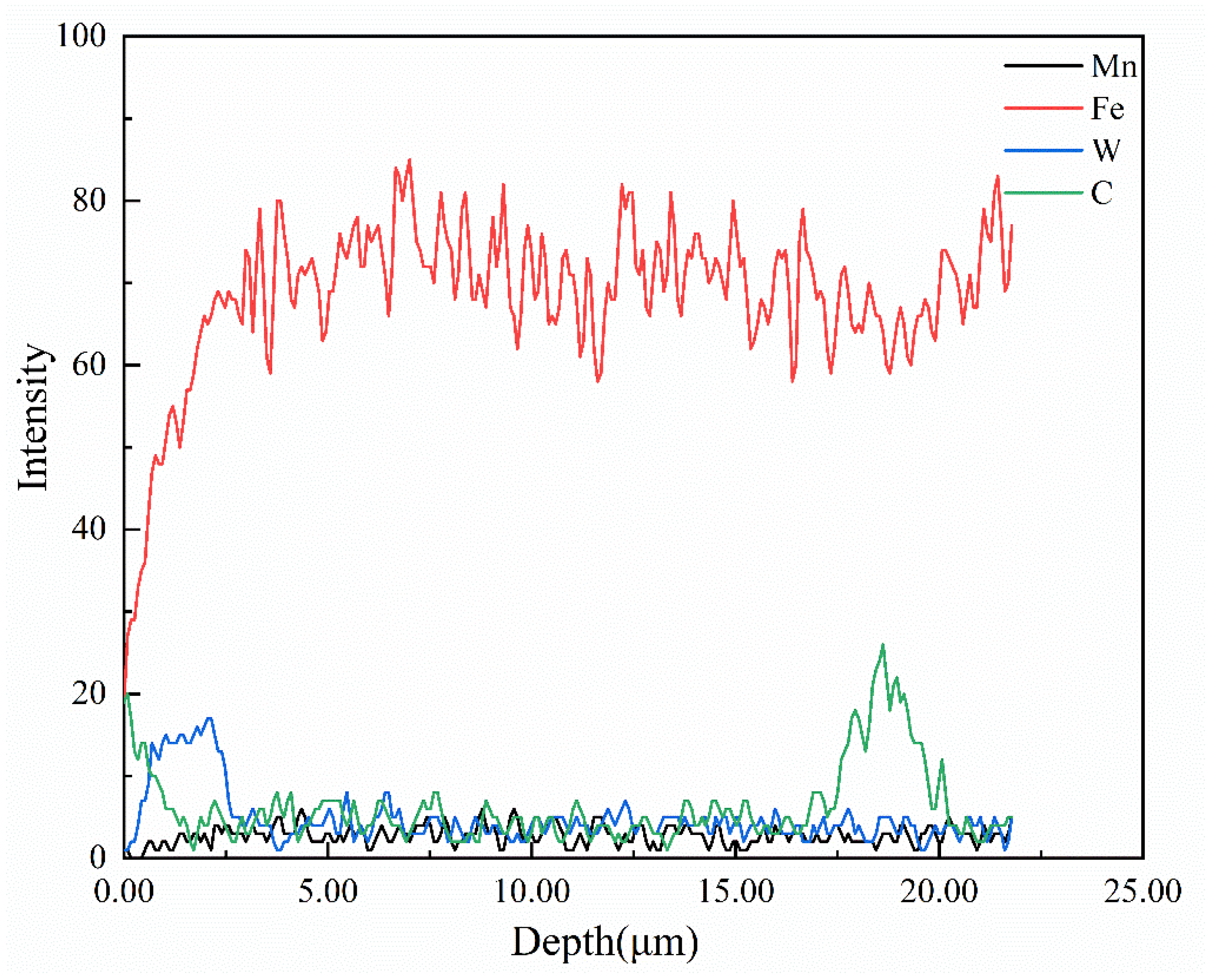

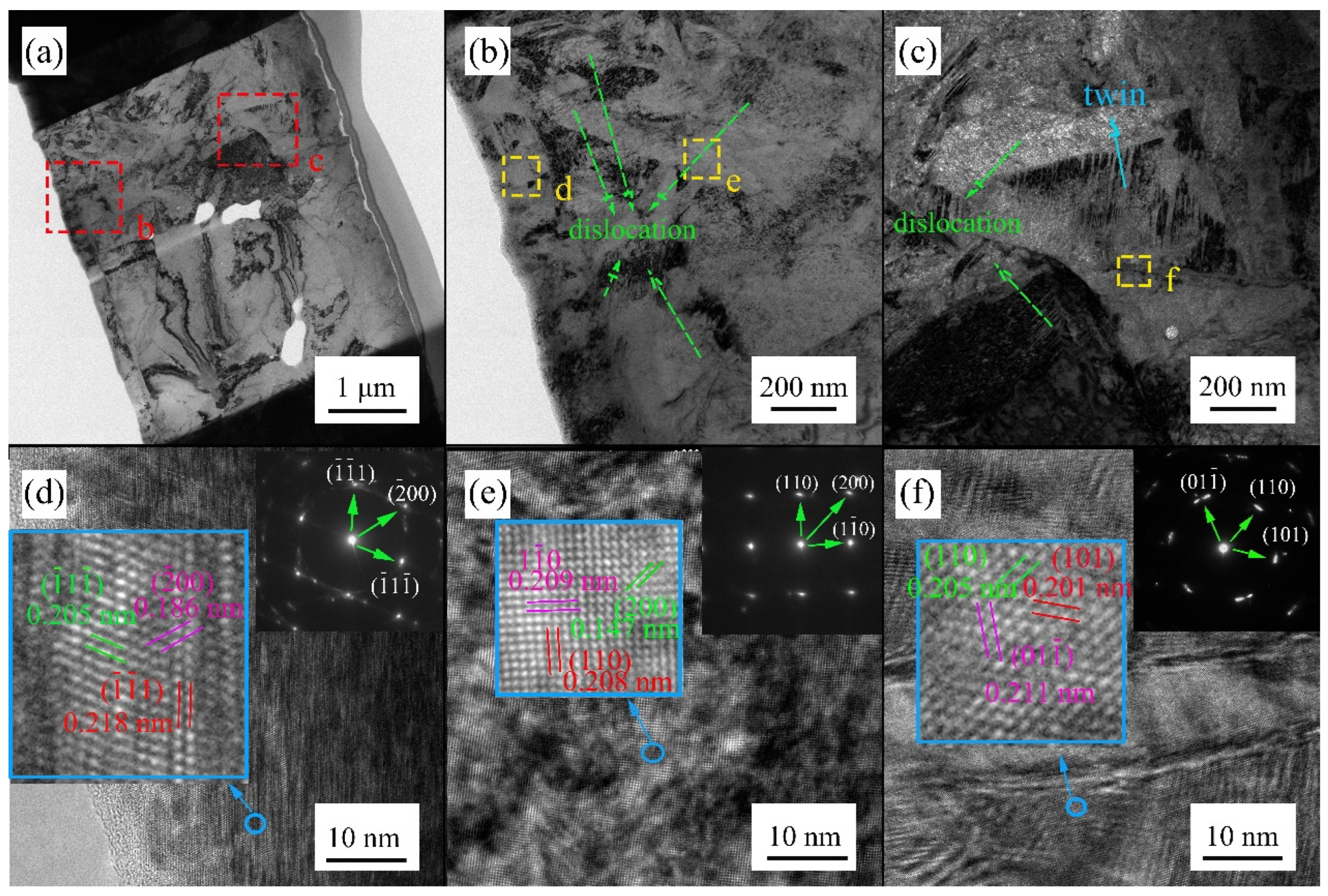

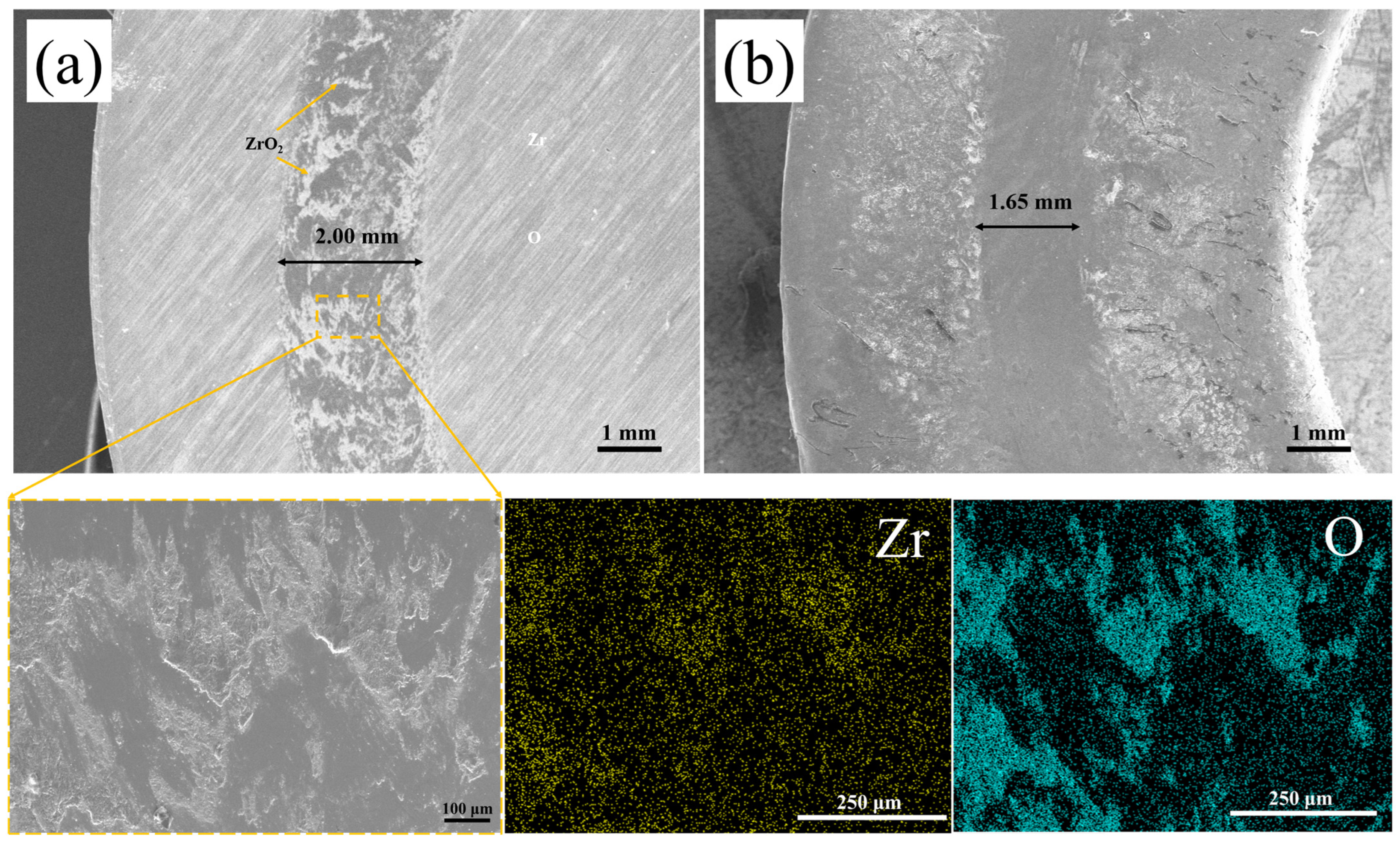

- The modified layer is divided into the infiltration layer and heat-affected layer. A new W3C phase is produced because of the re-melting of the infiltrating layer, while almost no infiltration of W is detected in the heat-affected layer. Due to the effect of the explosion impact, serious distortion exists in the modified layer and a large number of dislocations and twin crystals are formed.

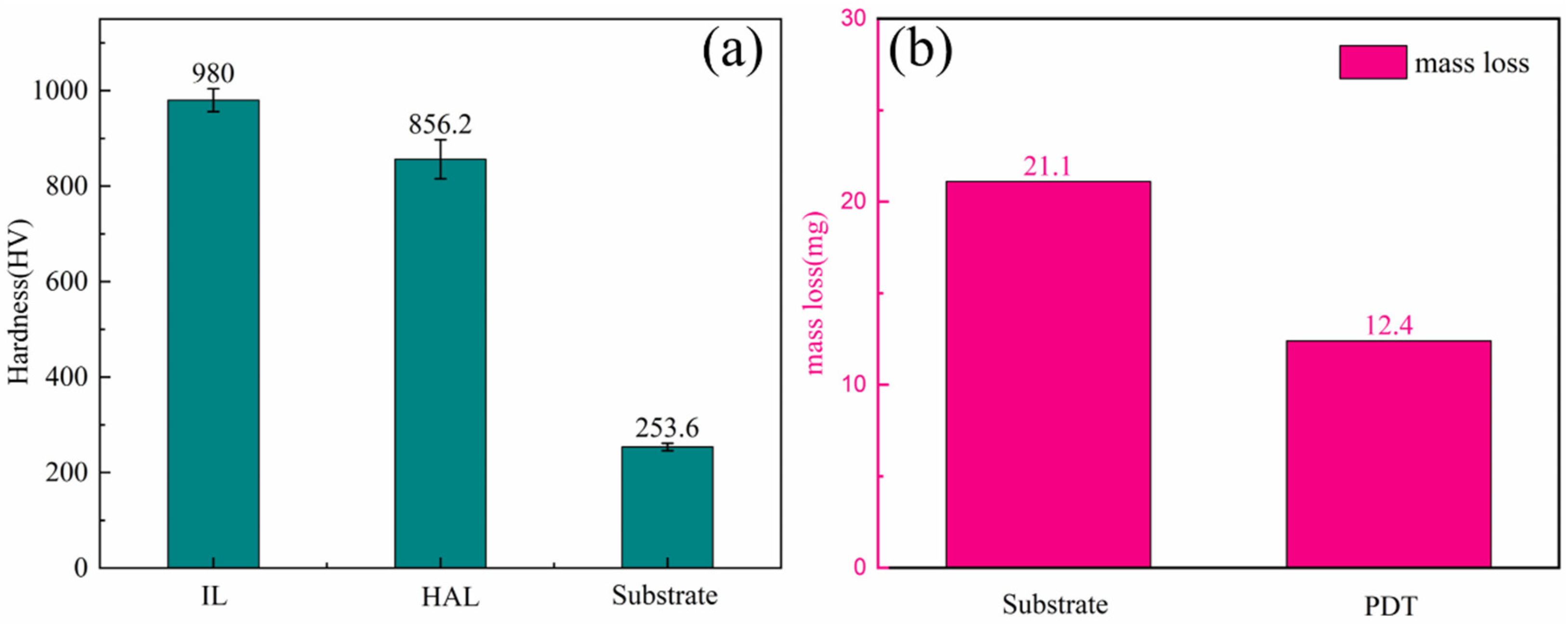

- After the PDT treatment, the hardness of the modified layer, heat-affected layer, and substrate is 980 HV, 856.2 HV, and 250 HV, respectively. The mass loss of the sample before and after the PDT treatment is 21.1 mg and 12.4 mg, respectively. The microstructure of the substrate has a significant effect on the PTD process. The hardness and wear resistance of the modified layer are greatly improved compared with the substrate because of the combined effect of the solid-phase transformation, element infiltration, and distortion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.-X.; Chen, J.-S.; Wang, X.-N.; Shen, X.-J.; Cen, Y.-M.; Chen, J.; Chu, Y.-J.; Han, Y.-J. Microstructure distribution and bending fracture mechanism of 65Mn steel in the laser surface treatment. Mater. Sci. Eng. A 2022, 850, 143568. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Li, D.; Jing, P.; Yin, H.; Wu, H.; Xie, Y.; Wang, X. Effect of nano-La2O3 doping on the tribological behavior of laser cladded WC-12Co coating on 65Mn steel under water lubrication condition. Tribol. Int. 2022, 169, 107428. [Google Scholar] [CrossRef]

- Lu, Y.; Peng, Y.; Shi, Z. Plasma nitrided 65Mn steel: Microstructure, tribocorrosion and electrochemical properties and DFT calculation. Wear 2024, 544–545, 205319. [Google Scholar] [CrossRef]

- Okan, U.; Remzi, V. Almen intensity eff.ect on microstructure and mechanical properties of low carbon steel subjected to severe shot peening. Appl. Surf. Sci. 2014, 290, 40–47. [Google Scholar]

- Wang, Y.; Sun, J.; Jiang, T.; Yang, C.; Tan, Q.; Guo, S.; Liu, Y. Laser treatment of 430 ferritic stainless steel for enhanced mechanical properties. Mater. Sci. Eng. A 2022, 831, 142205. [Google Scholar] [CrossRef]

- Mao, X.; Sun, J.; Zhou, X.; Sun, W.; Zhao, X. Effect of Annealing Temperature on Surface Gradient Fine Microstructure and Wear Resistance of Low-Carbon Steel. J. Mater. Eng. Perform. 2020, 29, 6952–6959. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Yuan, X.; Chen, K.; Xu, R. Effects of boronizing treatment on corrosion resistance of 65Mn steel in two acid mediums. Phys. Procedia 2013, 50, 124–130. [Google Scholar] [CrossRef]

- Rott, M.; Raif, M.; Igenbergs, E. Surface modification processes by hypervelocity plasma pulses. Int. J. Impact Eng. 2006, 33, 691–702. [Google Scholar] [CrossRef]

- Shmehey, V.; Podoynitsyn, S.; Vasilik, N. Application of the ballistic plasmatron of super adiabatic compression for surface treatment. Surf. Coat. Technol. 2006, 200, 4939–4946. [Google Scholar]

- Chivel, Y.; Kuznechik, O. Atmospheric pressure pulsed-periodic source of high energy plasma flows and its applications. Surf. Coat. Technol. 2011, 205, 347–350. [Google Scholar] [CrossRef]

- Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Liu, J.; Nyambura, S.M. Evaluation of thermal shock failure mechanism of arc-sprayed Fe-based coatings deposited on different substrates. Surf. Coat. Technol. 2023, 474, 130081. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.; Jiang, T.; Yang, C.; Tan, Q.; Guo, S.; Liu, Y. Super strength of 65Mn spring steel obtained by appropriate quenching and tempering in an ultrafine grain condition. Mater. Sci. Eng. A 2019, 754, 1–8. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, Y.; Wang, X. Preparation of WC coatings via additive manufacturing technology: Microstructure, friction properties, and finite element simulation. Mater. Lett. 2025, 384, 138072. [Google Scholar] [CrossRef]

- Wu, X.; Feng, S.; Zhang, W. Microstructure, phase composition and wear properties of iron-based gradient coatings by laser cladding on 65Mn steel. Surf. Coat. Technol. 2024, 477, 130290. [Google Scholar] [CrossRef]

- Korotkov, V.A.; Rastegaeva, I.I.; Merson, D.L. A study of the wear resistance of chromium cladding by dry friction on steel and an abrasive. J. Frict. Wear 2020, 41, 52–57. [Google Scholar] [CrossRef]

- Long, W.; Liu, D.; Dong, X.; Wu, A. Laser power effects on properties of laser brazing diamond coating. Surf. Eng. 2020, 36, 1315–1326. [Google Scholar] [CrossRef]

- Dong, Y.; Cui, X.; Li, J.; Hu, Y.; Jin, G.; Li, Q.; Liu, J.; Fan, P. Effect of carburizing nitriding compound treatment on microstructure evolution and properties of low carbon gear steel. Mater. Chem. Phys. 2025, 337, 130489. [Google Scholar] [CrossRef]

- Özbek, Y.Y.; Durman, M.; Akbulut, H. Wear Behavior of AISI 8620 Steel Modified by a Pulse Plasma Technique. Tribol. Trans. 2009, 52, 213–222. [Google Scholar] [CrossRef]

- Özbek, Y.Y. Surface properties of AISI 4140 steel modified by pulse plasma technique. J. Mater. Res. Technol. 2020, 9, 2176–2185. [Google Scholar] [CrossRef]

- Özbek, Y.Y. The surface properties of hot work steel modificated with pulse plasma treatment. Sak. Üniversitesi Bilim. EnstitüSü Derg. 2017, 21, 98–104. [Google Scholar]

- Luo, J.; Chen, Y.; Xu, J.; Lu, D. Effect of plasma-pulsed detonation treatment on microstructure and properties of the Ti-6Al-4V surface. Surf. Coat. Technol. 2019, 366, 164–169. [Google Scholar] [CrossRef]

- Zou, J.; Lu, L.; Kolisnichenko, O.; Chen, W.; Yu, J.-M. Gas nitriding of a plasma detonation modified die steel. Mater. Lett. 2021, 287, 129297. [Google Scholar] [CrossRef]

- Özbek, Y.; Akbulut, H.; Durman, M. surface properties of M2 steel treated by pulse plasma technique. Vacuum 2015, 122, 90–95. [Google Scholar] [CrossRef]

- Özbek, Y.Y.; Gökkaya, T. Development of Surface Properties of High-Carbon Steel by Pulse Plasma Technique. Tribol. Trans. 2022, 65, 695–704. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, H.; Zhang, L.; Lu, L.; Lu, D. Microstructure and Properties of Modified Layer on the 65Mn Steel Surface by Pulse Detonation-Plasma Technology. J. Mater. Eng. Perform. 2022, 31, 1562–1572. [Google Scholar] [CrossRef]

- Najmeh, A.; Reza, N.L.; Davood, K. Particle in cell simulations of the pulsed plasma sheath: Dependence on pulse parameters. J. Electrostat. 2022, 117, 103723. [Google Scholar]

- Liu, S.Y.; Zhang, J.Y.; Kuang, J.; Bao, X.Y.; Zhang, D.D.; Zhang, C.L.; Yang, J.K.; Liu, G.; Sun, J. Designing hetero-structured ultra-strong and ductile Zr- 2.5Nb alloys: Utilizing the grain size-dependent martensite transformation during quenching. J. Mater. Sci. Technol. 2022, 125, 198–211. [Google Scholar] [CrossRef]

- Easton, M.A.; StJohn, D.H. Improved prediction of the grain size of aluminum alloys that includes the effect of cooling rate. Mater. Sci. Eng. A 2008, 486, 8–13. [Google Scholar] [CrossRef]

- Kakitani, R.; Oliveira, R.; Reyes, R.V.; Rodrigues, A.V.; Bertelli, F.; Garcia, A.; Spinelli, J.E.; Cheung, N. Metal/mold thermal conductance affecting ultrafine scale microstructures in aluminum eutectic alloys. Case Stud. Therm. Eng. 2021, 26, 101144. [Google Scholar] [CrossRef]

- Meng, W.; Lei, Y.; Wang, X.; Ma, Q.; Hu, L.; Xie, H.; Yin, X. Interface characteristics and mechanical properties of wire-arc depositing Inconel 625 superalloy on ductile cast iron. Surf. Coat. Technol. 2022, 440, 128493. [Google Scholar] [CrossRef]

- Goswami, D.; Chattopadhyay, S.; Das, J. Effect of the post annealing cooling rate on the martensitic transformation and the magnetocaloric effect in Ni-Mn-Sn ribbons. Mater. Res. Bull. 2023, 160, 112129. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Zhu, K.; Wang, C.; Xu, W. An integral transformation model for the combined calculation of key martensitic transformation temperatures and martensite fraction. Mater. Design. 2022, 219, 110769. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, M.; Zhang, X. Ultra-flash annealing constructed heterogeneous austenitic stainless steel with excellent strength-ductility. Mater. Charact. 2022, 192, 112182. [Google Scholar] [CrossRef]

- Wang, J.; Qu, S.; Lai, F.; Deng, Y.; Li, X. Effect of ultrasonic surface rolling on microstructural evolution and fretting wear resistance of 20CrMoH steel under different quenching temperatures. Mater. Chem. Phys. 2022, 228, 126362. [Google Scholar] [CrossRef]

- Liao, L.; Gao, R.; Yang, Z.; Wu, S.; Wan, Q. A study on the wear and corrosion resistance of high-entropy alloy treated with laser shock peening and PVD coating. Surf. Coat. Technol. 2022, 437, 128281. [Google Scholar] [CrossRef]

- Haiko, O.; Javaheri, V.; Valtonen, K.; Kaijalainen, A.; Hannula, J.; Kömi, J. Effect of prior austenite grain size on the abrasive wear resistance of ultra-high strength martensitic steels. Wear 2020, 454–455, 203336. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, Y.; Jia, N.; Wang, J.; Zhao, S.-X. Acicular martensite induced superior strength-ductility combination in a 20Cr2Ni2MoV steel. Mater. Sci. Eng. A 2022, 848, 143400. [Google Scholar] [CrossRef]

- Rai, P.K.; Shekhar, S.; Mondal, K. Effects of grain size gradients on the fretting wear of a specially-processed low carbon steel against AISI E52100 bearing steel. Wear 2018, 412–413, 1–13. [Google Scholar] [CrossRef]

- Dehsorkhi, R.N.; Sabooni, S.; Karimzadeh, F.; Rezaeian, A.; Enayati, M. The effect of grain size and martensitic transformation on the wear behavior of AISI 304L stainless steel. Mater. Design. 2014, 64, 56–62. [Google Scholar] [CrossRef]

- Tianmin, S.; Meng, H.; Yuen, T.H. Impact wear behavior of laser hardened hypoeutectoid 2Cr13 martensite stainless steel. Wear 2003, 255, 444–455. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, L.; Liu, K.; Lu, L.; Lu, D.; Zhou, H. Effect of Pulse Detonation-Plasma Technology Treatment on T8 Steel Microstructures. J. Mater. Eng. Perform. 2017, 26, 6198–6206. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, H.; Hou, T.; Hu, F.; Zheng, P.; Wu, K. Hardness increases due to (Fe, Cr)2C carbide precipitated during natural aging in high chromium cast iron. Vacuum 2023, 209, 111766. [Google Scholar] [CrossRef]

- Chitra, V.; Ramachandran, S.; Anandaraj, V. Experimental analysis on hardness of textile steel components with tungsten carbide coatings. Mater. Today Proc. 2021, 47, 4562–4565. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Zhang, M.; Yang, X.; Chen, W.; Lu, L. Study of the Surface Structural Transformation and Mechanical Properties of 65Mn Steel Modified by Pulsed Detonation–Plasma Technology. Metals 2025, 15, 473. https://doi.org/10.3390/met15050473

He Y, Zhang M, Yang X, Chen W, Lu L. Study of the Surface Structural Transformation and Mechanical Properties of 65Mn Steel Modified by Pulsed Detonation–Plasma Technology. Metals. 2025; 15(5):473. https://doi.org/10.3390/met15050473

Chicago/Turabian StyleHe, Youxing, Mingming Zhang, Xuebing Yang, Wenfu Chen, and Lei Lu. 2025. "Study of the Surface Structural Transformation and Mechanical Properties of 65Mn Steel Modified by Pulsed Detonation–Plasma Technology" Metals 15, no. 5: 473. https://doi.org/10.3390/met15050473

APA StyleHe, Y., Zhang, M., Yang, X., Chen, W., & Lu, L. (2025). Study of the Surface Structural Transformation and Mechanical Properties of 65Mn Steel Modified by Pulsed Detonation–Plasma Technology. Metals, 15(5), 473. https://doi.org/10.3390/met15050473