Effects of Composition on Melt Fillability and Impact Resistance of TiAl Alloys for Thin-Blade Turbine Wheels: Laboratory Predictions and Product Verification

Abstract

:1. Introduction

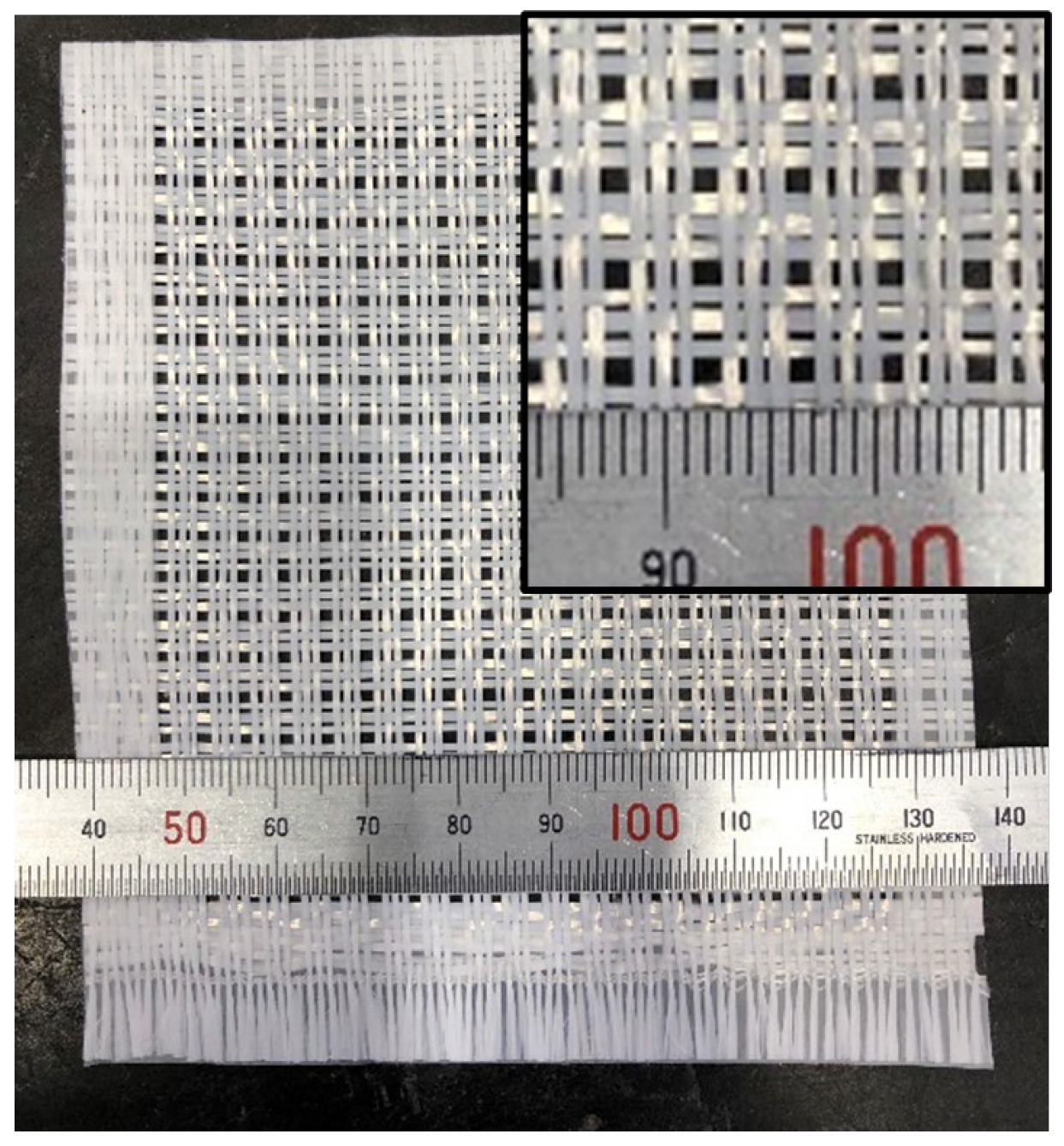

2. Method for Laboratory Prediction of Fillability of TiAl Alloy Melts in Thin-Walled Parts

3. Materials and Methods

3.1. Laboratory Evaluation Methods for Melt Fillability and Impact Resistance

3.1.1. Materials

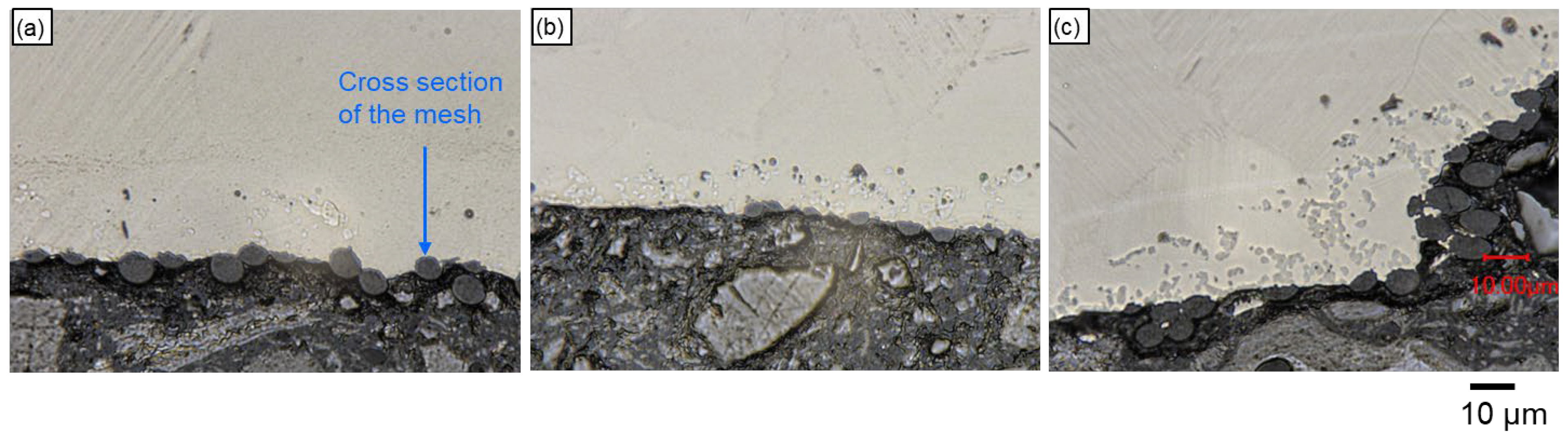

3.1.2. Evaluation Method

3.2. Turbine Wheel Test Procedures

4. Results

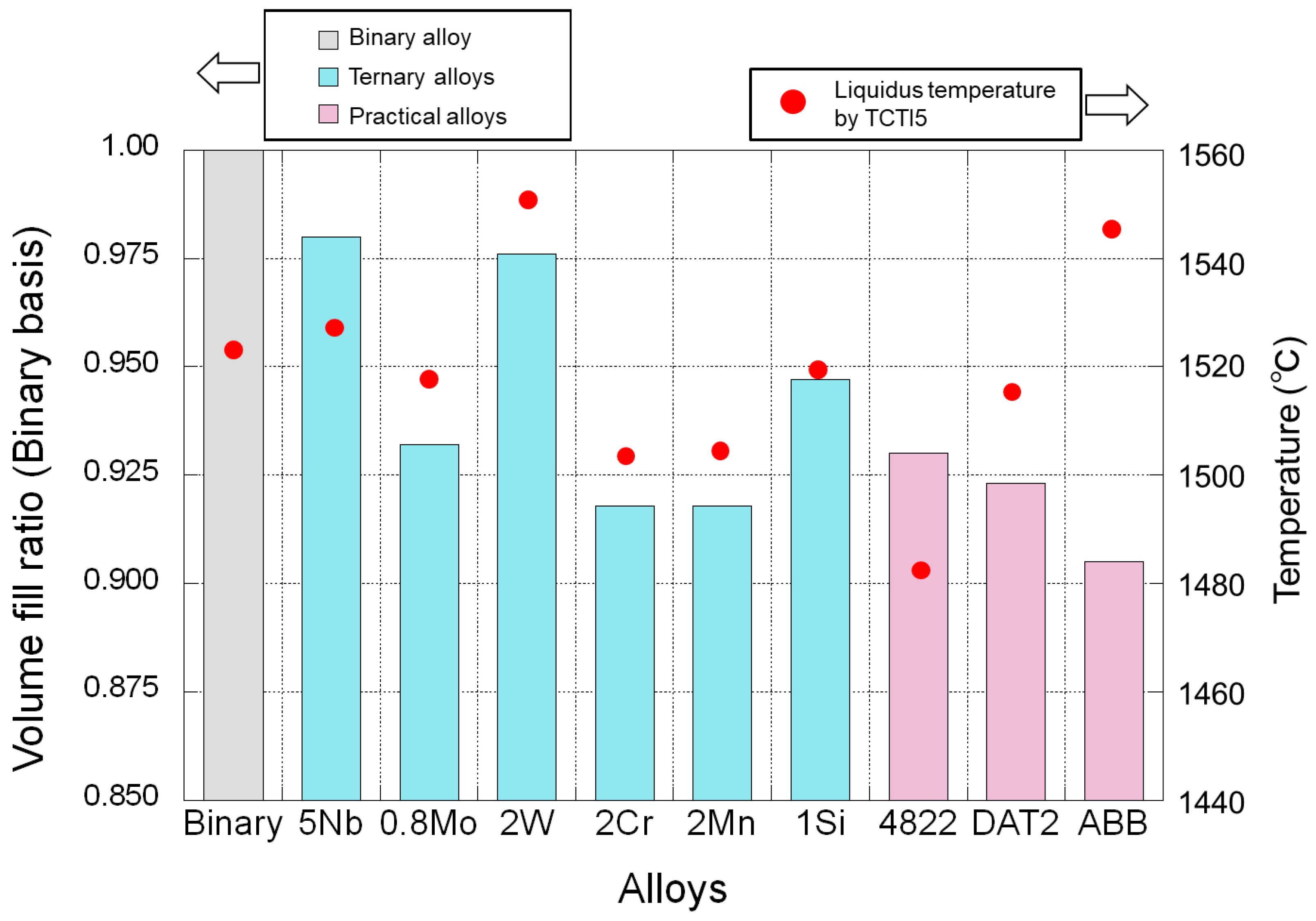

4.1. Molten Metal Permeability to Mesh and Impact Resistance in Laboratory

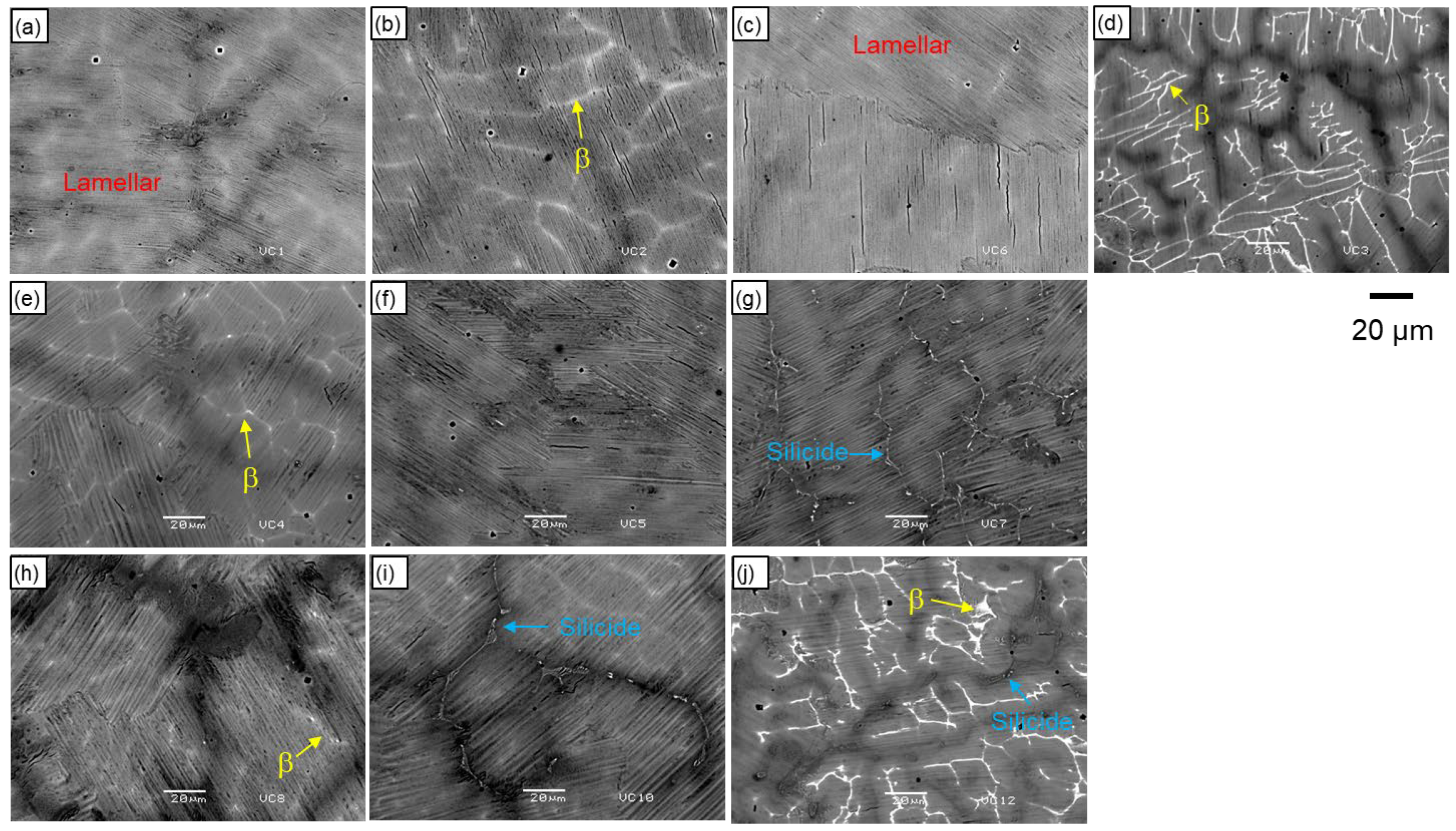

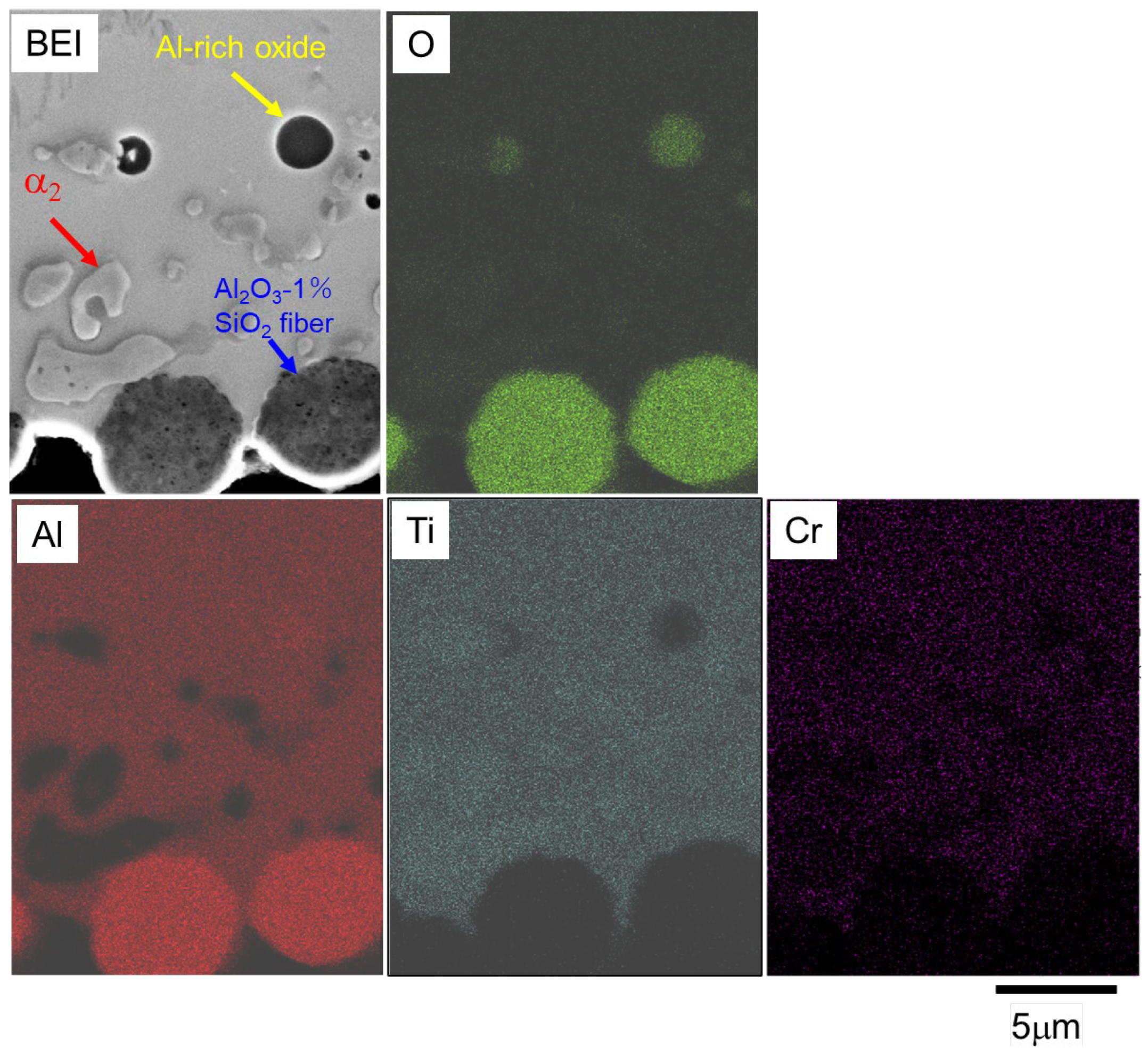

4.1.1. Microstructure

4.1.2. Molten Metal Permeability to Mesh

4.1.3. Impact Resistance at 25 and 850 °C

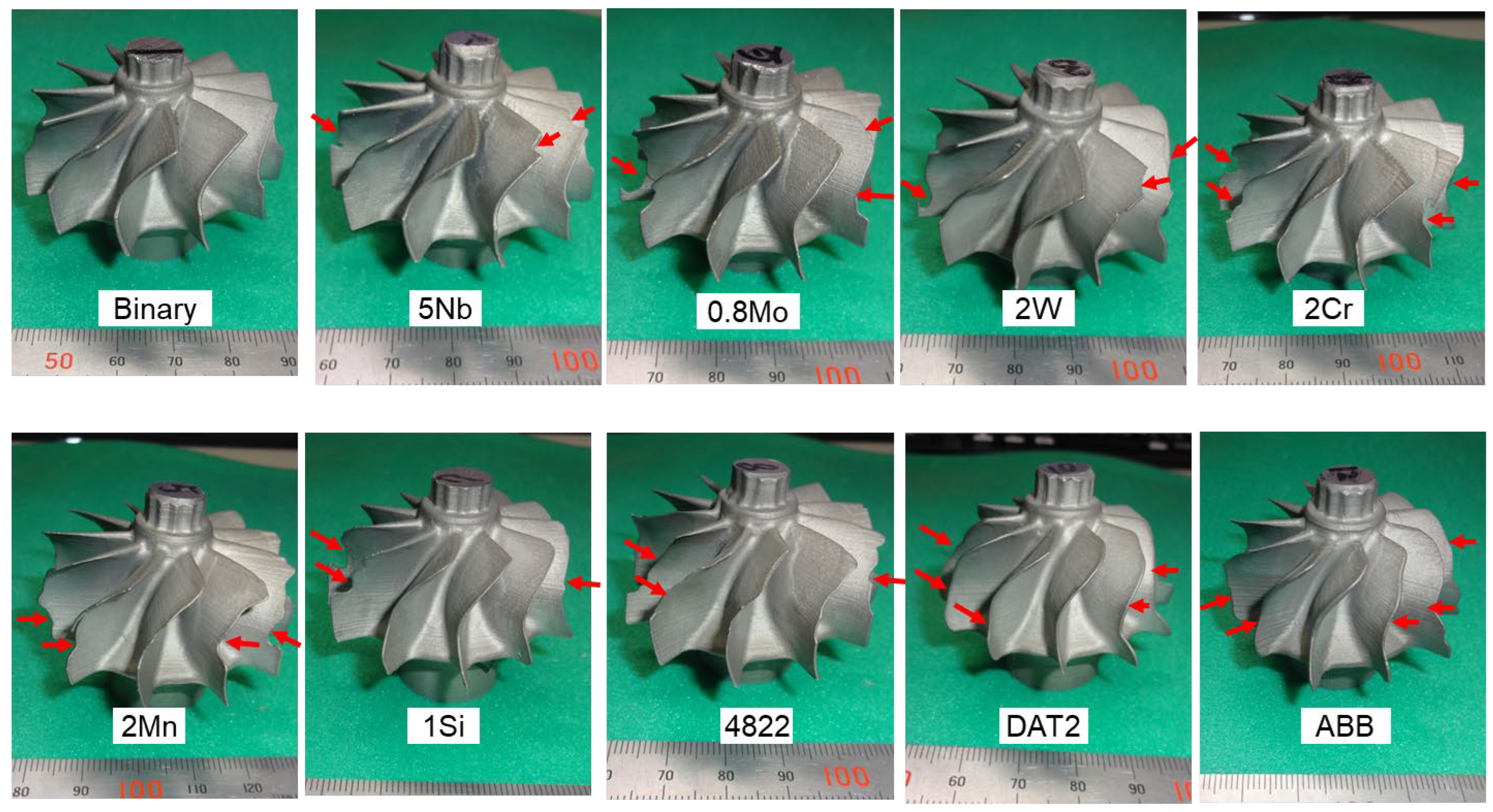

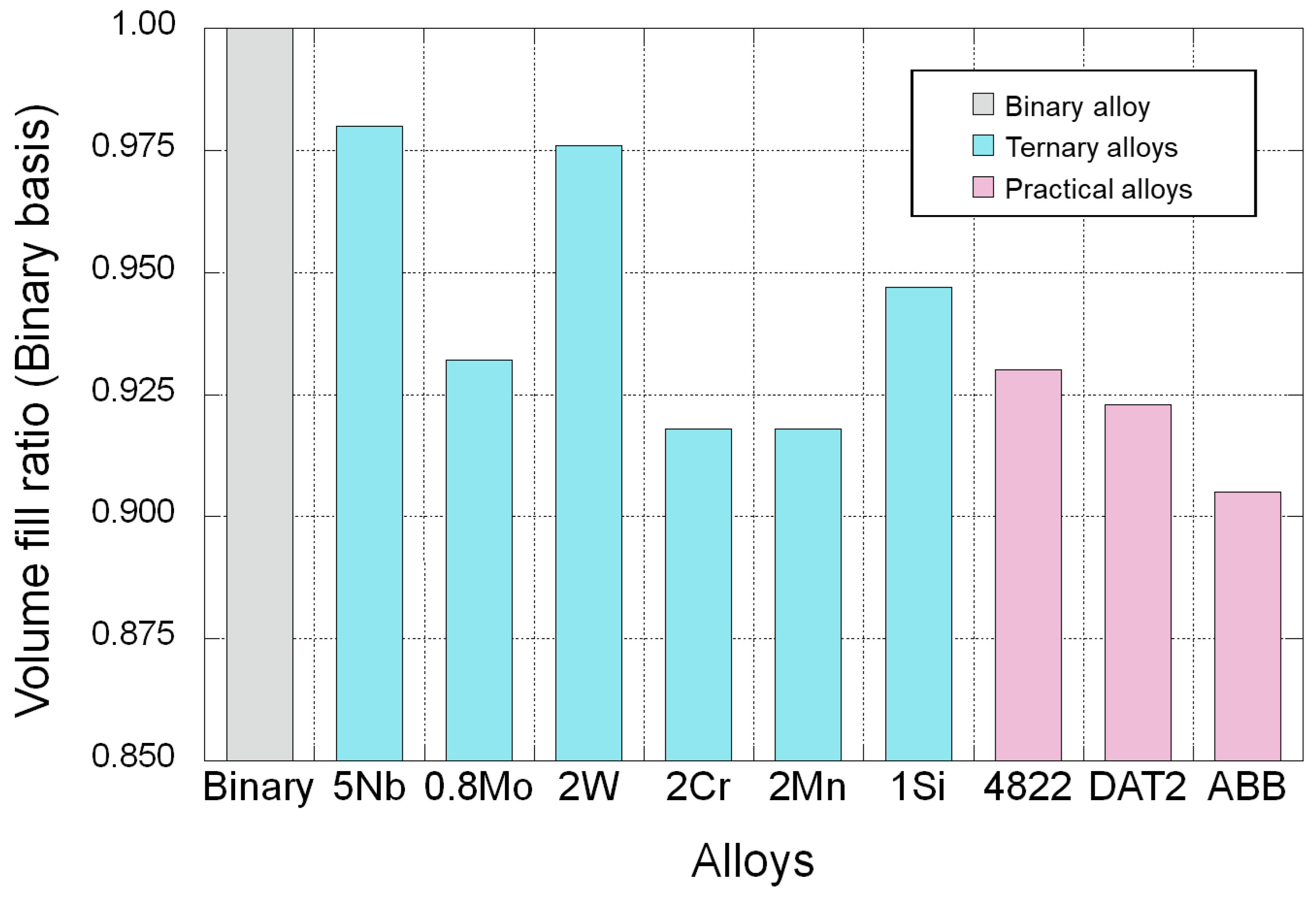

4.2. Validation of Results Using Turbine Wheel Casting

5. Discussion

5.1. Effect of Composition on Molten Metal Fillability in Thin Turbine Wheel Blades

5.2. Evaluation of Existing Practical TiAl Alloys and Potential for Development of New Alloys

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bartolotta, P.; Barrett, J.; Kelly, T.; Smashey, R. The use of cast Ti-48Al-2Cr-2Nb in jet engines. JOM 1997, 49, 48–50. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Noda, T. Application of cast gamma TiAl for automobiles. Intermetallics 1998, 6, 709–713. [Google Scholar] [CrossRef]

- Koyanagi, Y.; Sumi, Y.; Takabayashi, H. Development of titanium aluminide alloy with good high temperature properties for turbine wheel. Denki Seiko 2014, 85, 121–125. (In Japanese) [Google Scholar]

- Tetsui, T. Development of a TiAl turbocharger for passenger vehicles. Mater. Sci. Eng. A 2002, 329–331, 582–588. [Google Scholar] [CrossRef]

- AeroEdge. AeroEdge Was Invited to the Ceremony for Celebrating the Delivery of One Million TiAl Blades. Available online: https://aeroedge.co.jp/en/news/newsrelease/857/ (accessed on 23 January 2025).

- Kim, S.-W.; Hong, J.K.; Na, Y.-S.; Yeom, J.-T.; Kim, S.E. Development of TiAl alloys with excellent mechanical properties and oxidation resistance. Mater Des. 2014, 54, 814–819. [Google Scholar] [CrossRef]

- Kawaura, H.; Nishino, K.; Saito, T. Effects of alloying elements on foreign object damage resistance of cast-TiAl base alloys. J. Jpn. Inst. Met. 2002, 66, 451–458. (In Japanese) [Google Scholar] [CrossRef]

- Tetsui, T. Selection of additive elements focusing on impact resistance in practical TiAl cast alloys. Metals 2022, 12, 544. [Google Scholar] [CrossRef]

- Harding, R.A.; Wickins, M. Temperature measurements during induction skull melting of titanium aluminide. Mater. Sci. Technol. 2003, 19, 1235–1246. [Google Scholar] [CrossRef]

- Han, J.; Liu, Z.; Jia, Y.; Wang, T.; Zhao, L.; Guo, J. Effect of TiB2 addition on microstructure and fluidity of cast TiAl alloy. Vacuum 2020, 174, 109210. [Google Scholar] [CrossRef]

- Li, B.S.; Liu, A.H.; Nan, H.; Bi, W.S.; Guo, J.J.; Fu, H.Z. Wettability of TiAl alloy melt on ceramic moulds in electromagnetic field. Trans. Nonferrous Met. Soc. China 2008, 18, 518–522. [Google Scholar] [CrossRef]

- Nitivy. Heat-Resistant Fiber Nitivy ALF™. Available online: https://www.nitivy.co.jp/en/products/alf/ (accessed on 16 January 2025).

- Tetsui, T.; Mizuta, K. Detrimental effects of βo-phase on practical properties of TiAl Alloys. Metals 2024, 14, 908. [Google Scholar] [CrossRef]

- Lapin, J.; Nazmy, M. Microstructure and creep properties of a cast intermetallic Ti–46Al–2W–0.5Si alloy for gas turbine applications. Mater. Sci. Eng. A 2004, 380, 298–307. [Google Scholar] [CrossRef]

- Xu, Q.; Fang, H.; Wu, C.; Wang, Q.; Cui, H.; Chen, R. Microstructure evolution and its effect on mechanical properties of cast Ti48Al6NbxSi alloys. China Foundry 2020, 17, 416–422. [Google Scholar] [CrossRef]

- Kuang, J.P.; Harding, R.A.; Campbell, J. Examination of defects in gamma titanium aluminide investment castings. Int. J. Cast Met. Res. 2000, 13, 125–134. [Google Scholar] [CrossRef]

- Kim, M.-G.; Sung, S.-Y.; Kim, Y.-J. Microstructure, metal-mold reaction and fluidity of investment cast-TiAl alloys. Mater Trans. 2004, 45, 536–541. [Google Scholar] [CrossRef]

- Watanabe, K.; Miyakawa, O.; Takada, Y.; Okuno, O.; Okabe, T. Casting behavior of titanium alloys in a centrifugal casting machine. Biomaterials 2003, 24, 1737–1743. [Google Scholar] [CrossRef]

- Cheng, X.; Yuan, C.; Green, N.; Withey, P. Evaluation of the inertness of investment casting molds using both sessile drop and centrifugal casting methods. Metall. Mater. Trans. A 2013, 44, 888–898. [Google Scholar] [CrossRef]

- Güther, V.; Allen, M.; Klose, J.; Clemens, H. Metallurgical processing of titanium aluminides on industrial scale. Intermetallics 2018, 103, 12–22. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Mondal, A.; Pilone, D. Production issues in the manufacturing of TiAl turbine blades by investment casting. Procedia Struct. Integr. 2020, 25, 79–87. [Google Scholar] [CrossRef]

- Larsen, D.E.; Christodoulou, L.; Kampe, S.L.; Sadler, R. Investment-cast processing of XDTM near-γ titanium aluminides. Mater. Sci. Eng. A 1991, 144, 45–49. [Google Scholar] [CrossRef]

- Bernal, D.; Chamorro, X.; Hurtado, I.; Lopez-Galilea, I.; Bürger, D.; Weber, S.; Madariaga, I. Integration of hot isostatic pressing and heat treatment for advanced modified γ-TiAl TNM alloys. Materials 2022, 15, 4211. [Google Scholar] [CrossRef] [PubMed]

- Szkliniarz, W.; Szkliniarz, A. The characteristics of TiAl-based alloys melted in graphite crucibles. Mater. Sci. Technol. 2019, 35, 297–305. [Google Scholar] [CrossRef]

- Xu, X.; Liang, H.; Ding, H.; Davidson, K.P.; Ramanujan, R.V.; Chen, R.; Guo, J.; Fu, H. Oxidation behavior and mechanical properties of a directionally solidified high Nb TiAl based alloy between 800 °C and 900 °C. Intermetallics 2025, 176, 108538. [Google Scholar] [CrossRef]

- Feng, L.; Li, B.; Li, Q.; Gao, Y.; Pei, Z.; Liang, C. Enhancement of mechanical properties and oxidation resistance of TiAl alloy with addition of Nb and Mo alloying elements. Mater. Chem. Phys. 2024, 316, 129148. [Google Scholar] [CrossRef]

- Zhao, P.; Ma, H.; Li, X.; Gao, M.; Ma, Y.; Liu, K. Insights into the role of W/B alloying on high-temperature oxidation behavior of Ti42Al5Mn alloy. J. Mater. Sci. Technol. 2024, 178, 188–200. [Google Scholar] [CrossRef]

- Shida, Y.; Anada, H. Role of W, Mo, Nb and Si on oxidation of TiAl in air at high temperatures. Mater. Trans. JIM 1994, 35, 623–631. [Google Scholar] [CrossRef]

- Fröbel, U.; Stark, A.; Paul, J.; Pyczak, F. Assessment of the capability of Zr, Y, La, Gd, Dy, C, and Si to enhance the creep strength of gamma titanium aluminide alloys based on their effect on flow stress and thermal activation parameters. Intermetallics 2023, 162, 108018. [Google Scholar] [CrossRef]

- Du, X.-W.; Wang, J.N.; Zhu, J. The influence of Si alloying on the crept microstructure and property of a TiAl alloy prepared by powder metallurgy. Intermetallics 2001, 9, 745–753. [Google Scholar] [CrossRef]

- Kamyshnykova, K.; Lapin, J.; Pelachová, T.; Cegan, T.; Jurica, J.; Volodarskaja, A. Microstructure and mechanical properties of Ti–45Al–2W–xC alloys. Intermetallics 2022, 148, 107618. [Google Scholar] [CrossRef]

- Song, L.; Hu, X.; Wang, L.; Stark, A.; Lazurenko, D.; Lorenz, U.; Lin, J.; Pyczak, F.; Zhang, T. Microstructure evolution and enhanced creep property of a high Nb containing TiAl alloy with carbon addition. J. Alloys Compd. 2019, 807, 151649. [Google Scholar] [CrossRef]

| System | Sample ID | Nominal Composition (at.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Al | Nb | Mo | W | Cr | Mn | Si | C | ||

| Binary alloy | Binary | Bal. | 46.5 | |||||||

| Ternary alloys | 5Nb | Bal. | 46.5 | 5.0 | ||||||

| 0.8Mo | Bal. | 46.5 | 0.8 | |||||||

| 2W | Bal. | 46.5 | 2.0 | |||||||

| 2Cr | Bal. | 46.5 | 2.0 | |||||||

| 2Mn | Bal. | 46.5 | 2.0 | |||||||

| 1Si | Bal. | 46.5 | 1.0 | |||||||

| Practical alloys | 4822 | Bal. | 48.0 | 2.0 | 2.0 | |||||

| DAT2 | Bal. | 46.5 | 3.2 | 0.8 | 0.7 | 0.1 | ||||

| ABB | Bal. | 46.0 | 2.0 | 1.0 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetsui, T.; Lee, Y.-Y.; Vaubois, T.; Sallot, P. Effects of Composition on Melt Fillability and Impact Resistance of TiAl Alloys for Thin-Blade Turbine Wheels: Laboratory Predictions and Product Verification. Metals 2025, 15, 474. https://doi.org/10.3390/met15050474

Tetsui T, Lee Y-Y, Vaubois T, Sallot P. Effects of Composition on Melt Fillability and Impact Resistance of TiAl Alloys for Thin-Blade Turbine Wheels: Laboratory Predictions and Product Verification. Metals. 2025; 15(5):474. https://doi.org/10.3390/met15050474

Chicago/Turabian StyleTetsui, Toshimitsu, Yu-Yao Lee, Thomas Vaubois, and Pierre Sallot. 2025. "Effects of Composition on Melt Fillability and Impact Resistance of TiAl Alloys for Thin-Blade Turbine Wheels: Laboratory Predictions and Product Verification" Metals 15, no. 5: 474. https://doi.org/10.3390/met15050474

APA StyleTetsui, T., Lee, Y.-Y., Vaubois, T., & Sallot, P. (2025). Effects of Composition on Melt Fillability and Impact Resistance of TiAl Alloys for Thin-Blade Turbine Wheels: Laboratory Predictions and Product Verification. Metals, 15(5), 474. https://doi.org/10.3390/met15050474