Experimental Investigation and Optimization of Tool Life in High-Pressure Jet-Assisted Turning of Inconel 718

Abstract

1. Introduction

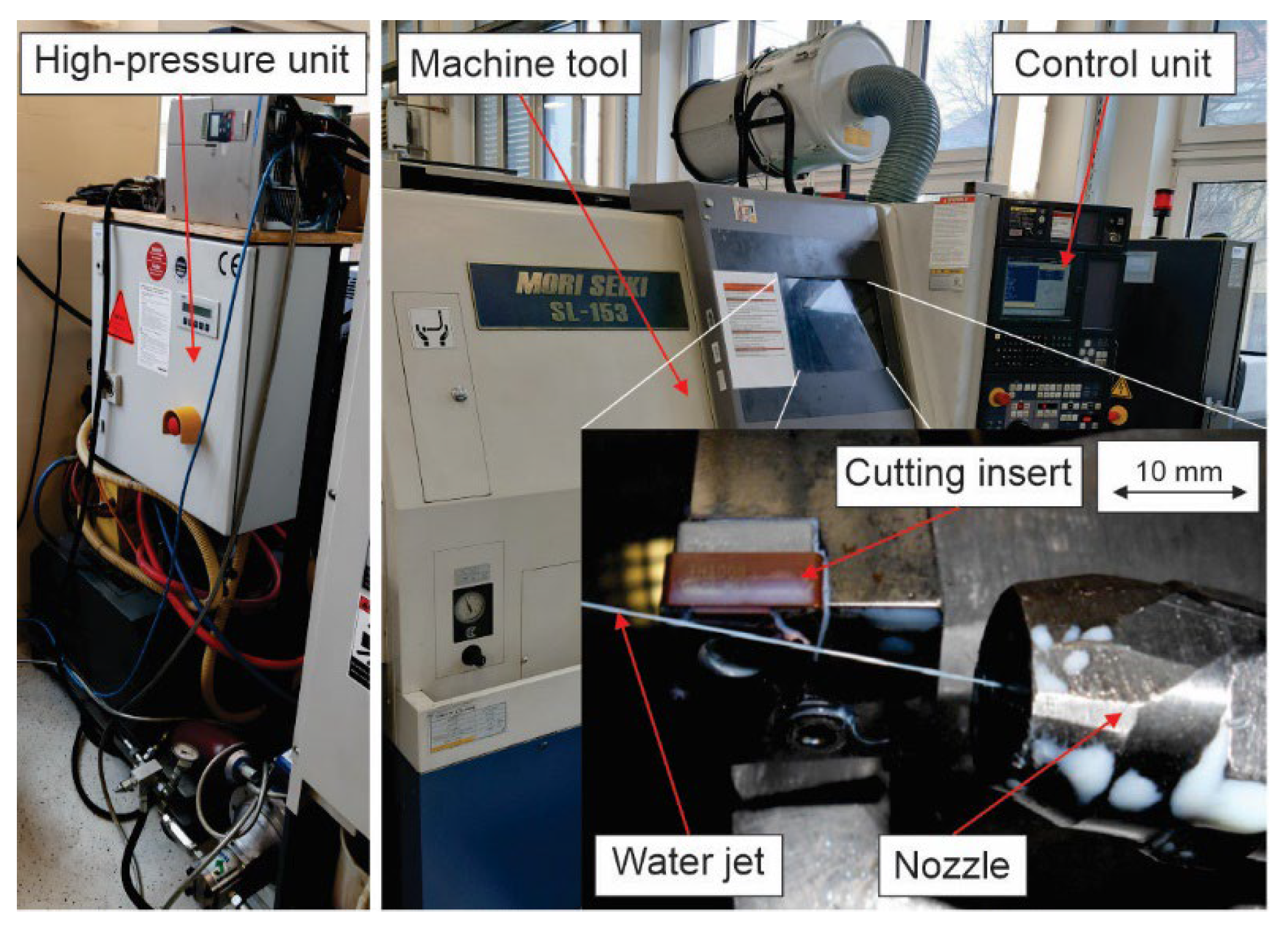

2. Experimental Procedures

2.1. Workpiece Material, Machine Tool, and Cutting Tool

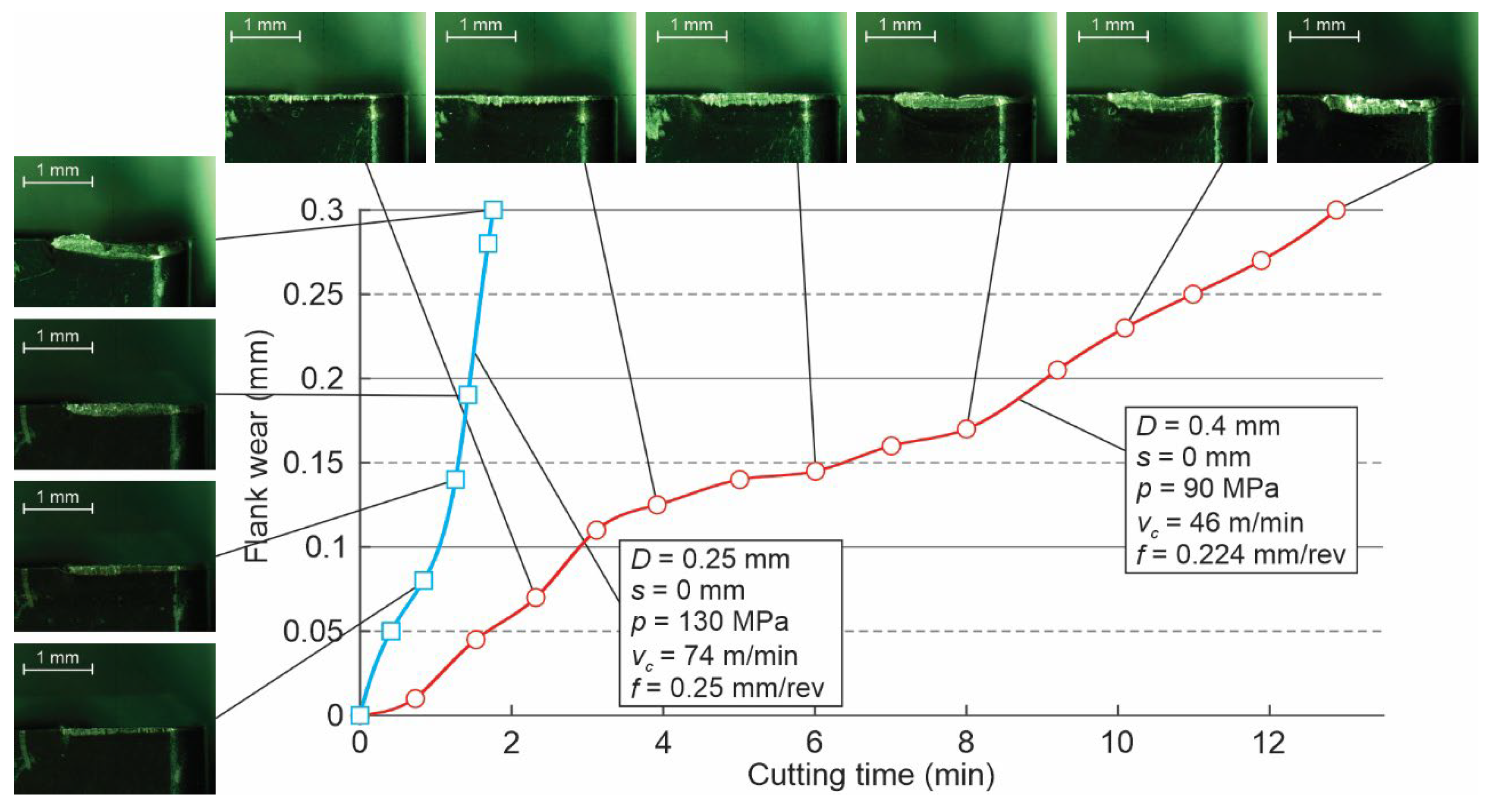

2.2. Preliminary Experiments

2.3. Design of Main Experiments

2.4. Measurements

3. Experimental Results and Data Analysis

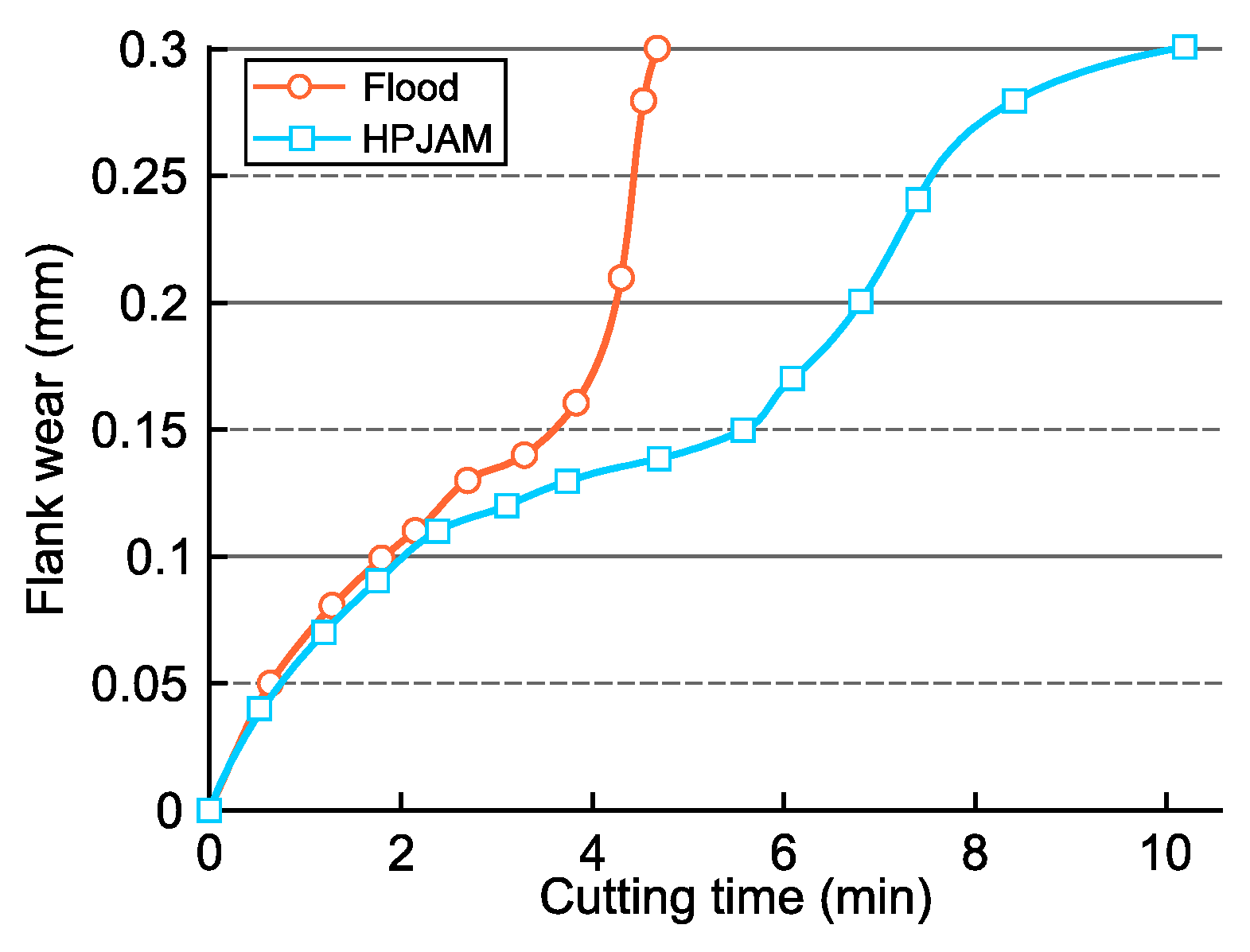

3.1. Tool Life Under HPJA and Flood Coolant–Lubricant Conditions

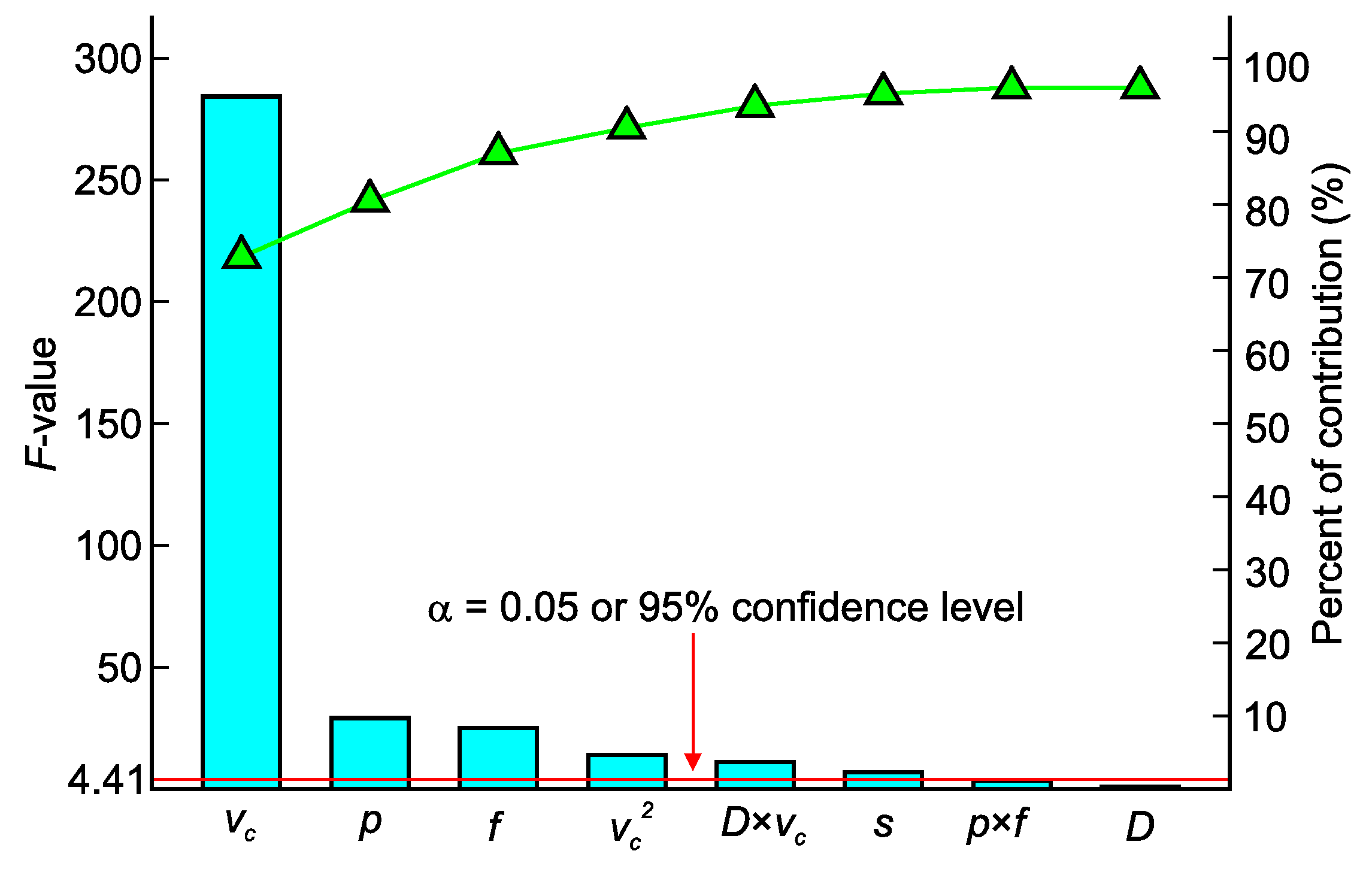

3.2. Analysis of Variance

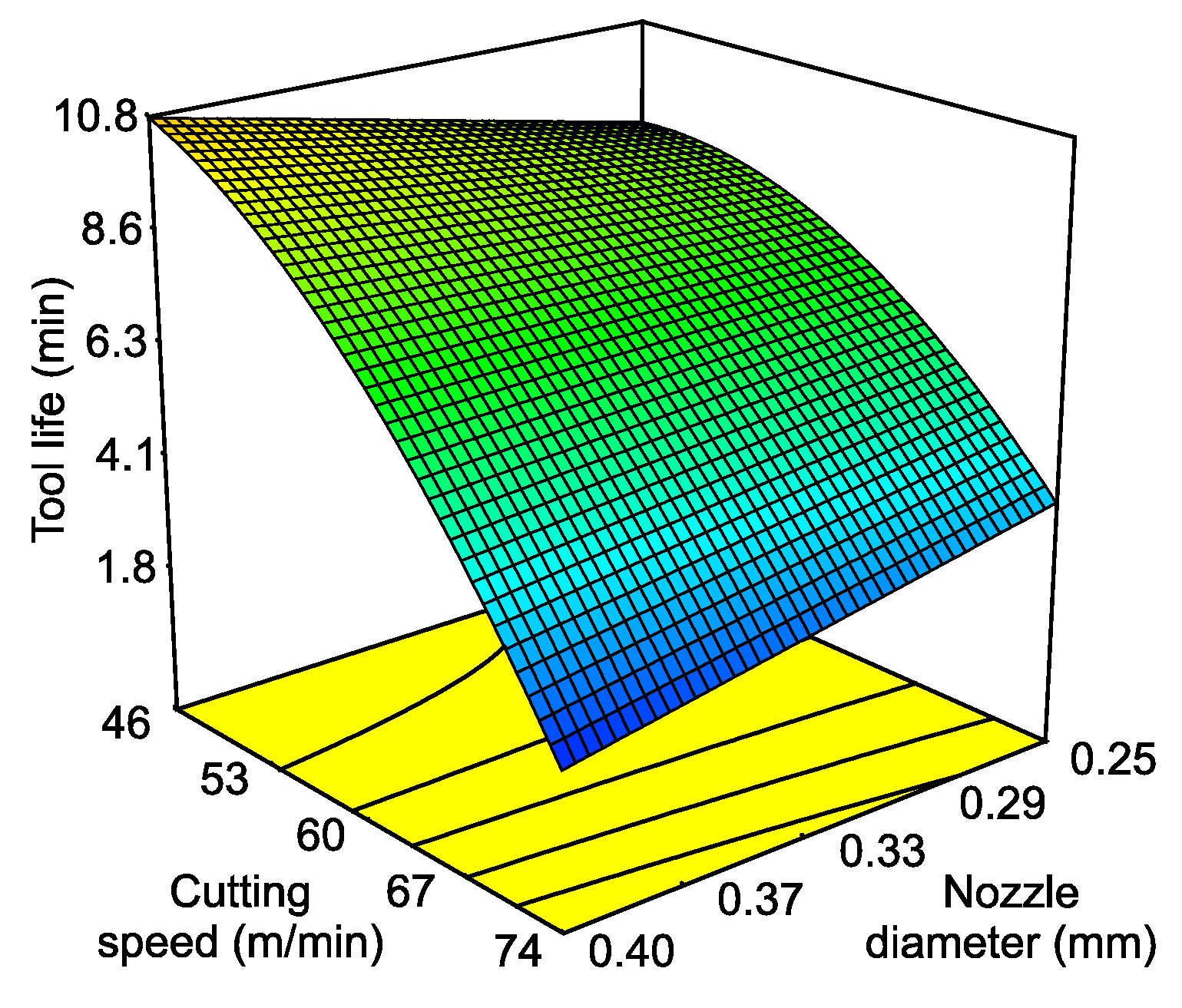

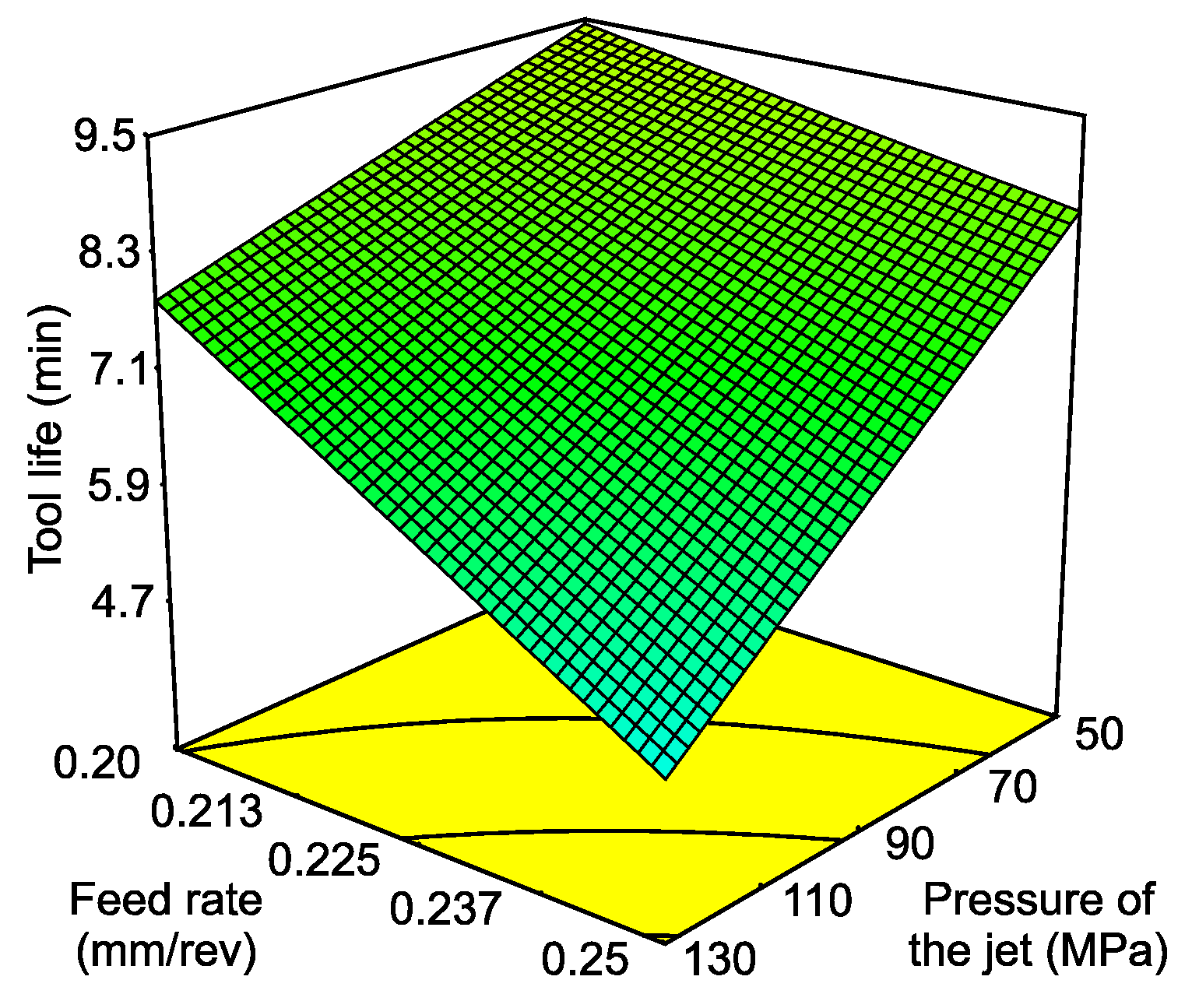

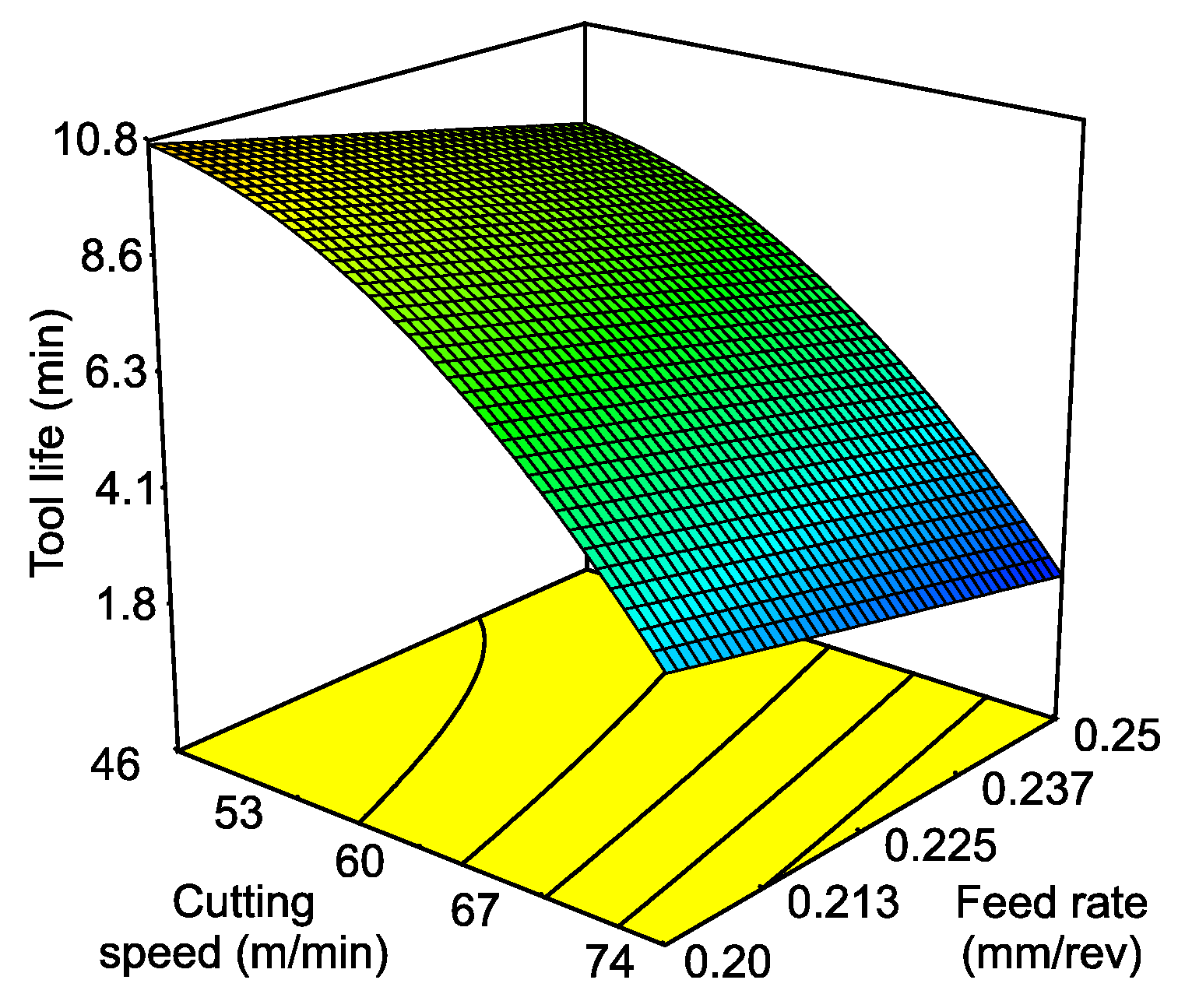

3.3. Response Surface Graphic Analysis

4. Optimization

4.1. Biogeography-Based Optimization

- Find X = [D, s, p, vc, f]

- Maximize T(X)

- Subject the putative solution to the constraints, as follows: 0.25 ≤ D ≤ 0.4, 0 ≤ s ≤ 3, 50 ≤ p ≤ 130, 46 ≤ vc ≤ 74, 0.2 ≤ f ≤ 0.25.

4.2. Confirmation Experiment

5. Discussion

6. Conclusions

- HPJA machining is undoubtedly capable of creating machining conditions that extend tool life compared to conventional flood cooling when turning difficult-to-machine materials, namely the nickel-based alloy Inconel 718, with carbide inserts.

- The results show that the dominant factor influencing tool life is cutting speed, which accounted for almost 74% of the total variability of the model. Other factors that have a significant influence on tool life are, in descending order, the pressure of the jet, the feed rate and the distance of jet impact. The results show that the nozzle diameter has an influence on tool life only in interaction with the cutting speed. The product (vc2) also appears to be significant. The results revealed that a significant increase in tool life can be achieved when the cutting speed is reduced. According to the results presented, tool life increases with a reduction in jet pressure. The results also show that the lower the feed rate and the jet impact distance, the longer the tool life, while the smaller the nozzle diameter, the shorter the tool life.

- Jet pressures above 50 MPa do not improve tool life; in fact, they reduce it due to the shorter coolant-interaction time caused by higher jet velocities.

- Non-dispersed water-jet nozzles enable precise targeting and effective cooling/lubrication with lower flow rates, improving tool life compared to standard HPJA systems.

- A mathematical model for tool-life prediction in HPJA machining of Inconel 718 was developed based on RSM. The formulated mathematical model is statistically significant and very useful for prediction purposes.

- Based on the BBO algorithm, the optimum parameter combination for tool life was determined to be D = 0.4 mm, s = 0 mm, p = 50 MPa, vc = 46 m/min and f = 0.2 mm/rev.

- A confirmation test validated the results of the optimization and showed an improvement in tool life of 8.4% under optimal conditions compared to the best result of the 27 experimental runs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pedroso, A.F.V.; Sousa, V.F.C.; Sebbe, N.P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Jesus, A.M.P. A comprehensive review on the conventional and non-conventional machining and tool-wear mechanisms of Inconel. Metals 2023, 13, 585. [Google Scholar] [CrossRef]

- Matos, F.; Silva, T.E.F.; Sousa, V.F.C.; Marques, F.; Figueiredo, D.; Silva, F.J.G.; de Jesus, A.M.P. On the influence of binder material in PCBN cutting tools for turning operations of Inconel 718. Metals 2023, 13, 934. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef]

- Cica, D.; Kramar, D. Multi-objective optimization of high-pressure jet-assisted turning of Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 105, 4731–4745. [Google Scholar] [CrossRef]

- Rotella, G.; Dillon, O.W., Jr.; Umbrello, D.; Settineri, L.; Jawahir, I.S. The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2014, 71, 47–55. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Cica, D.; Kramar, D. Machinability investigation and sustainability analysis of high-pressure coolant assisted turning of the nickel-based superalloy Inconel 718. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 237, 43–54. [Google Scholar] [CrossRef]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J. Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools. J. Mater. Process. Technol. 2004, 153–154, 1045–1050. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J. Finish machining of nickel-base Inconel 718 alloy with coated carbide tool under conventional and high-pressure coolant supplies. Tribol. Trans. 2005, 48, 76–81. [Google Scholar] [CrossRef]

- Sharman, A.; Hughes, J.; Ridgway, K. Surface integrity and tool life when turning Inconel 718 using ultra-high pressure and flood coolant systems. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2008, 222, 653–664. [Google Scholar] [CrossRef]

- Klocke, F.; Sangermann, H.; Krämer, A.; Lung, D. Influence of a high-pressure lubricoolant supply on thermo-mechanical tool load and tool wear behaviour in the turning of aerospace materials. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2011, 225, 52–61. [Google Scholar] [CrossRef]

- Machado, A.R.; Wallbank, J.; Pashby, I.; Ezugwu, E.O. Tool performance and chip control when machining Ti6Al4V and Inconel 901 using high pressure coolant supply. Mach. Sci. Technol. 1998, 2, 1–12. [Google Scholar] [CrossRef]

- Colak, O. Investigation on machining performance of Inconel 718 in high pressure cooling conditions. Stroj. Vestn. J. Mech. Eng. 2012, 58, 683–690. [Google Scholar] [CrossRef]

- Magri, A.; Diniz, A.E.; Suyama, D.I. Evaluating the use of high-pressure coolant in turning process of Inconel 625 nickel-based alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 232, 1182–1192. [Google Scholar] [CrossRef]

- Vagnorius, Z.; Sørby, K. Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2011, 54, 83–92. [Google Scholar] [CrossRef]

- Hoier, P.; Klement, U.; Alagan, N.T.; Beno, T.; Wretland, A. Flank wear characteristics of WC-Co tools when turning Alloy 718 with high-pressure coolant supply. J. Manuf. Process. 2017, 30, 116–123. [Google Scholar] [CrossRef]

- Behera, B.C.; Alemayehu, H.; Ghosh, S.; Rao, P.V. A comparative study of recent lubri-coolant strategies for turning of Ni-based superalloy. J. Manuf. Process. 2017, 30, 541–552. [Google Scholar] [CrossRef]

- Fang, Y.; Obikawa, T. Turning of Inconel 718 using inserts with cooling channels under high pressure jet coolant assistance. J. Mater. Process. Tech. 2017, 247, 19–28. [Google Scholar] [CrossRef]

- Alagan, N.T.; Hoier, P.; Zeman, P.; Klement, U.; Beno, T.; Wretland, A. Effects of high-pressure cooling in the flank and rake faces of WC tool on the tool wear mechanism and process conditions in turning of alloy 718. Wear 2019, 434–435, 102922. [Google Scholar] [CrossRef]

- Alagan, N.T.; Zeman, P.; Hoier, P.; Beno, T.; Klement, U. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling. J. Manuf. Process. 2019, 37, 606–616. [Google Scholar] [CrossRef]

- Alagan, N.T.; Hoier, P.; Beno, T.; Klement, U.; Wretland, A. Coolant boiling and cavitation wear—A new tool wear mechanism on WC tools in machining alloy 718 with high-pressure coolant. Wear 2020, 452–453, 203284. [Google Scholar] [CrossRef]

- Suárez, A.; López de Lacalle, L.N.; Polvorosa, R.; Veiga, F.; Wretland, A. Effects of high-pressure cooling on the wear patterns on turning inserts used on Alloy IN718. Mater. Manuf. Process. 2017, 32, 678–686. [Google Scholar] [CrossRef]

- Khochtali, H.; Ayed, Y.; Zemzemi, F.; Bensalem, W. Tool wear characteristics in rough turning of Inconel 718 with coated carbide tool under conventional and high-pressure coolant supplies. Int. J. Adv. Manuf. Technol. 2021, 114, 2371–2386. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Nasr, G.; Soltantarzeh, M.; Davoodi, B.; Hajaliakbari, A. Assessment of tool wear mechanisms in high-pressure jet-assisted turning process of a nickel-based superalloy. Wear 2020, 460–461, 203454. [Google Scholar] [CrossRef]

- Hoier, P.; Klement, U.; Alagan, N.T.; Beno, T.; Wretland, A. Characterization of tool wear when machining Alloy 718 with high-pressure cooling using conventional and surface-modified WC-Co tools. J. Superhard Mater. 2017, 39, 178–185. [Google Scholar] [CrossRef]

- Li, L.; Wu, M.; Liu, X.; Cheng, Y.; Yu, Y. Experimental study of the wear behavior of PCBN inserts during cutting of GH4169 superalloys under high-pressure cooling. Int. J. Adv. Manuf. Technol. 2018, 95, 1941–1951. [Google Scholar] [CrossRef]

- Díaz-Álvarez, A.; Díaz-Álvarez, J.; Cantero, J.L.; Miguélez, M.H. High-pressure cooling in finishing turning of Haynes 282 using carbide tools: Haynes 282 and Inconel 718 comparison. Metals 2021, 11, 1916. [Google Scholar] [CrossRef]

- Courbon, C.; Kramar, D.; Krajnik, P.; Pusavec, F.; Rech, J.; Kopac, J. Investigation of machining performance in high pressure jet assisted turning of Inconel 718: An experimental study. Int. J. Mach. Tools Manuf. 2009, 49, 1114–1125. [Google Scholar] [CrossRef]

- ISO 13399-1:2006; Cutting Tool Data Representation and Exchange—Part 1: Overview, Fundamental Principles and General Information Model. ISO: Geneva, Switzerland, 2006.

- ISO 3685:1993; Tool-Life Testing with Single-Point Turning Tools. ISO: Geneva, Switzerland, 1993.

- Naves, V.T.G.; Da Silva, M.B.; Da Silva, F.J. Evaluation of the effect of application of cutting fluid at high pressure on tool wear during turning operation of AISI 316 austenitic stainless steel. Wear 2013, 302, 1201–1208. [Google Scholar] [CrossRef]

- Simon, D. Biogeography-based optimization. IEEE Trans. Evol. Comput. 2008, 12, 702–713. [Google Scholar] [CrossRef]

| Machining Parameters | Level | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Nozzle diameter, D (mm) | 0.25 | 0.3 | 0.4 |

| Jet impact distance, s (mm) | 0 | 1.5 | 3 |

| Pressure of the jet, p (MPa) | 50 | 90 | 130 |

| Cutting speed, vc (m/min) | 46 | 57 | 74 |

| Feed rate, f (mm/rev) | 0.2 | 0.224 | 0.25 |

| No. | Machining Parameters | Tool Life (min) | ||||

|---|---|---|---|---|---|---|

| D (mm) | s (mm) | p (MPa) | vc (m/min) | f (mm/rev) | ||

| 1. | 0.25 | 0 | 50 | 46 | 0.2 | 10.54 |

| 2. | 0.25 | 0 | 90 | 57 | 0.224 | 8.77 |

| 3. | 0.25 | 0 | 130 | 74 | 0.25 | 1.76 |

| 4. | 0.25 | 1.5 | 50 | 46 | 0.25 | 10.20 |

| 5. | 0.25 | 1.5 | 90 | 57 | 0.2 | 9.79 |

| 6. | 0.25 | 1.5 | 130 | 74 | 0.224 | 2.26 |

| 7. | 0.25 | 3 | 50 | 46 | 0.224 | 8.75 |

| 8. | 0.25 | 3 | 90 | 57 | 0.25 | 5.75 |

| 9. | 0.25 | 3 | 130 | 74 | 0.2 | 3.52 |

| 10. | 0.3 | 0 | 50 | 57 | 0.2 | 11.55 |

| 11. | 0.3 | 0 | 90 | 74 | 0.224 | 3.07 |

| 12. | 0.3 | 0 | 130 | 46 | 0.25 | 7.15 |

| 13. | 0.3 | 1.5 | 50 | 57 | 0.25 | 8.08 |

| 14. | 0.3 | 1.5 | 90 | 74 | 0.2 | 3.50 |

| 15. | 0.3 | 1.5 | 130 | 46 | 0.224 | 7.35 |

| 16. | 0.3 | 3 | 50 | 57 | 0.224 | 9.51 |

| 17. | 0.3 | 3 | 90 | 74 | 0.25 | 2.14 |

| 18. | 0.3 | 3 | 130 | 46 | 0.2 | 10.10 |

| 19. | 0.4 | 0 | 50 | 74 | 0.2 | 3.93 |

| 20. | 0.4 | 0 | 90 | 46 | 0.224 | 12.88 |

| 21. | 0.4 | 0 | 130 | 57 | 0.25 | 6.25 |

| 22. | 0.4 | 1.5 | 50 | 74 | 0.25 | 2.88 |

| 23. | 0.4 | 1.5 | 90 | 46 | 0.2 | 11.00 |

| 24. | 0.4 | 1.5 | 130 | 57 | 0.224 | 8.05 |

| 25. | 0.4 | 3 | 50 | 74 | 0.224 | 3.32 |

| 26. | 0.4 | 3 | 90 | 46 | 0.25 | 8.58 |

| 27. | 0.4 | 3 | 130 | 57 | 0.2 | 6.99 |

| Source | DOF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 270.97 | 33.87 | 46.08 | <0.0001 |

| D | 1 | 0.084 | 0.084 | 0.11 | 0.7395 |

| s | 1 | 5.20 | 5.20 | 7.08 | 0.0159 |

| p | 1 | 21.33 | 21.33 | 29.02 | <0.0001 |

| vc | 1 | 208.96 | 208.96 | 284.26 | <0.0001 |

| f | 1 | 18.36 | 18.36 | 24.98 | <0.0001 |

| D × vc | 1 | 8.08 | 8.08 | 11 | 0.0038 |

| p × f | 1 | 2.32 | 2.32 | 3.16 | 0.0923 |

| vc2 | 1 | 10.21 | 10.21 | 13.89 | 0.0015 |

| Residual | 18 | 13.23 | 0.74 | ||

| Total | 26 | 284.2 | |||

| Std. dev. | 0.86 | R2 | 0.9534 | ||

| Mean | 6.95 | R2Adj | 0.9328 | ||

| S/N ratio | 20.905 | R2Pred | 0.8903 |

| Parameter Settings | Machining Parameters | Tool Life (min) | Improvement (%) | ||||

|---|---|---|---|---|---|---|---|

| D (mm) | s (mm) | p (MPa) | vc (m/min) | f (mm/rev) | |||

| Initial | 0.40 | 0 | 90 | 46 | 0.224 | 12.88 | 8.4 |

| BBO | 0.40 | 0 | 50 | 46 | 0.2 | 13.96 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kramar, D.; Cica, D. Experimental Investigation and Optimization of Tool Life in High-Pressure Jet-Assisted Turning of Inconel 718. Metals 2025, 15, 477. https://doi.org/10.3390/met15050477

Kramar D, Cica D. Experimental Investigation and Optimization of Tool Life in High-Pressure Jet-Assisted Turning of Inconel 718. Metals. 2025; 15(5):477. https://doi.org/10.3390/met15050477

Chicago/Turabian StyleKramar, Davorin, and Djordje Cica. 2025. "Experimental Investigation and Optimization of Tool Life in High-Pressure Jet-Assisted Turning of Inconel 718" Metals 15, no. 5: 477. https://doi.org/10.3390/met15050477

APA StyleKramar, D., & Cica, D. (2025). Experimental Investigation and Optimization of Tool Life in High-Pressure Jet-Assisted Turning of Inconel 718. Metals, 15(5), 477. https://doi.org/10.3390/met15050477