Research on Microstructure and Mechanical Properties of Ultrasonic-Assisted Gas Metal Arc Welding Additive Manufacturing with High-Nitrogen Steel Welding Wire

Abstract

1. Introduction

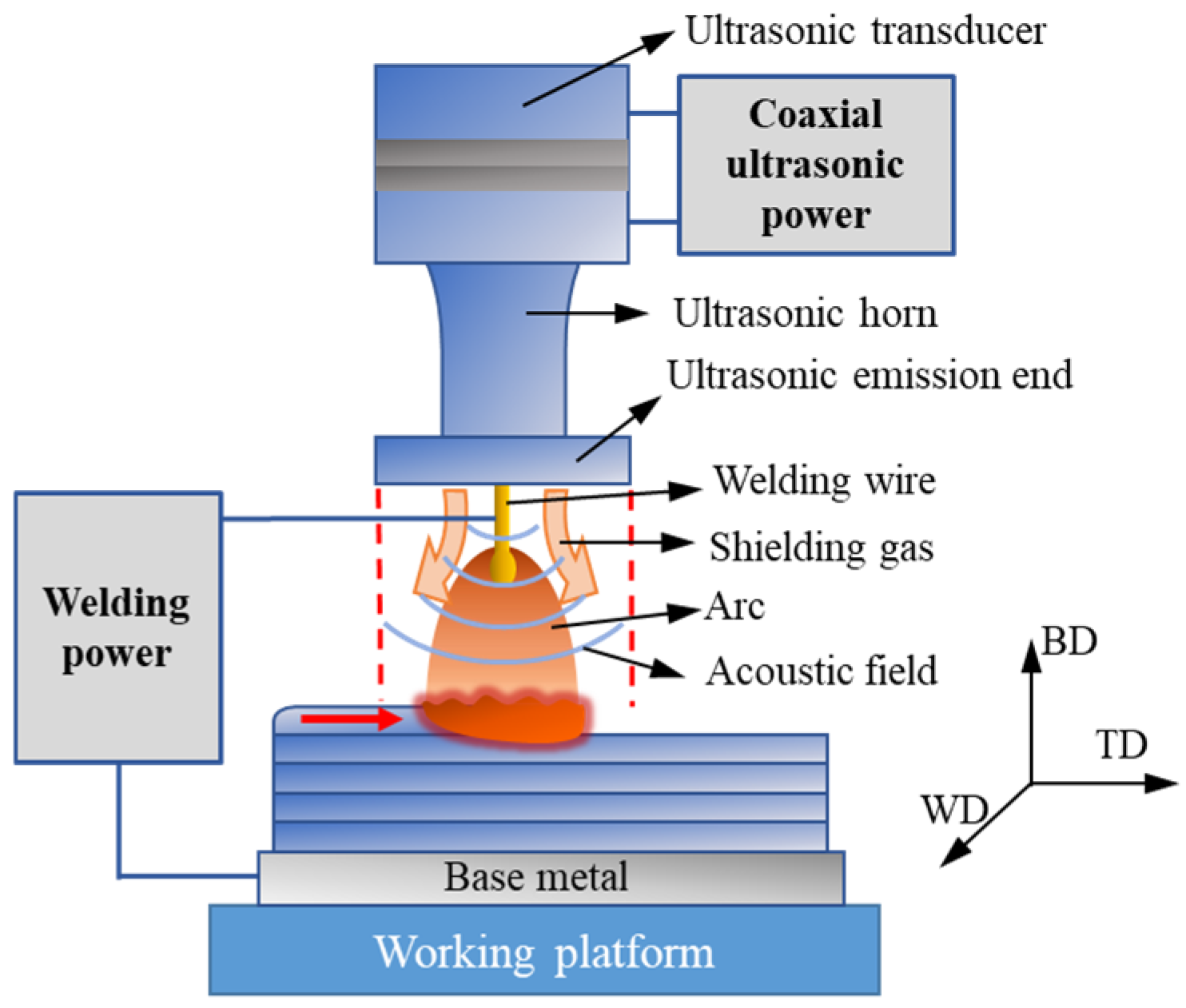

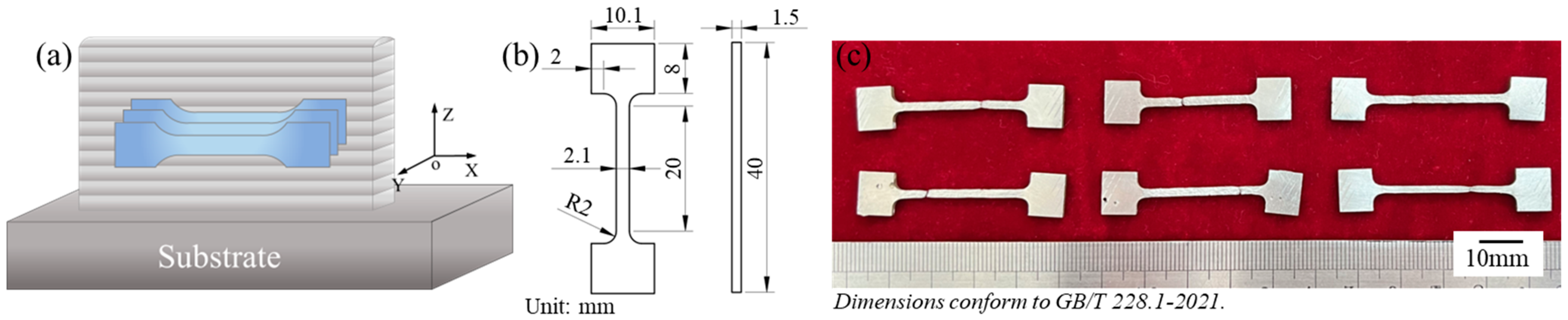

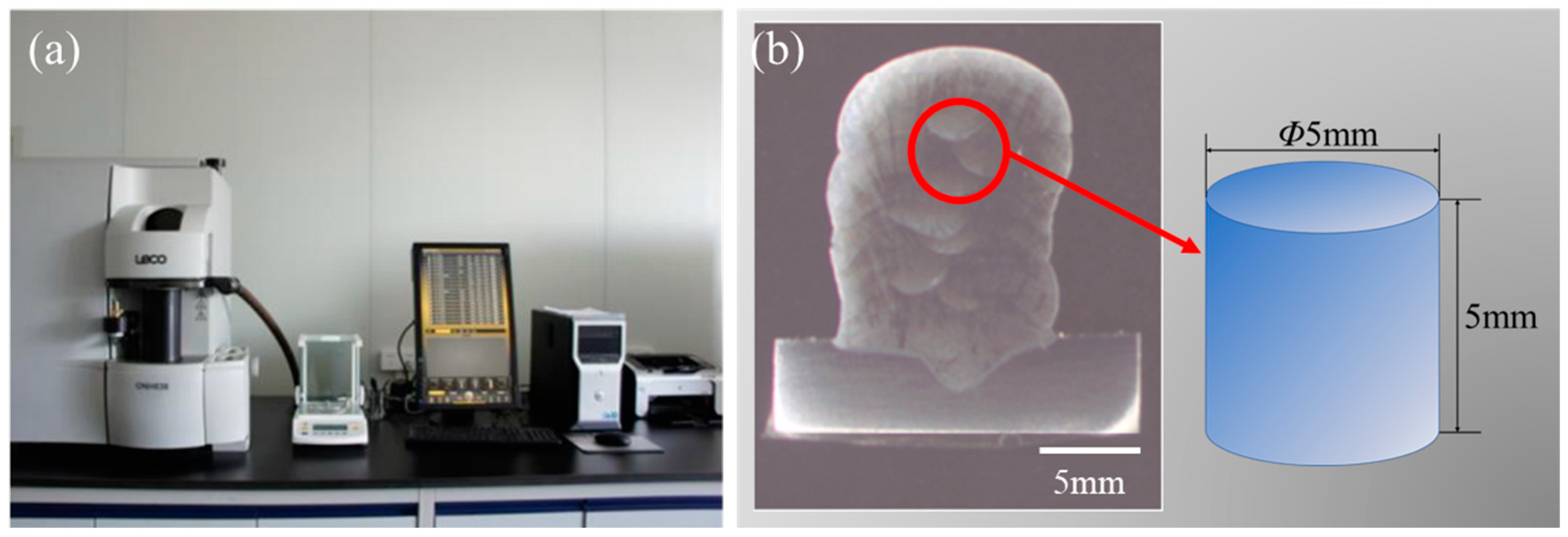

2. Materials and Methods

3. Results

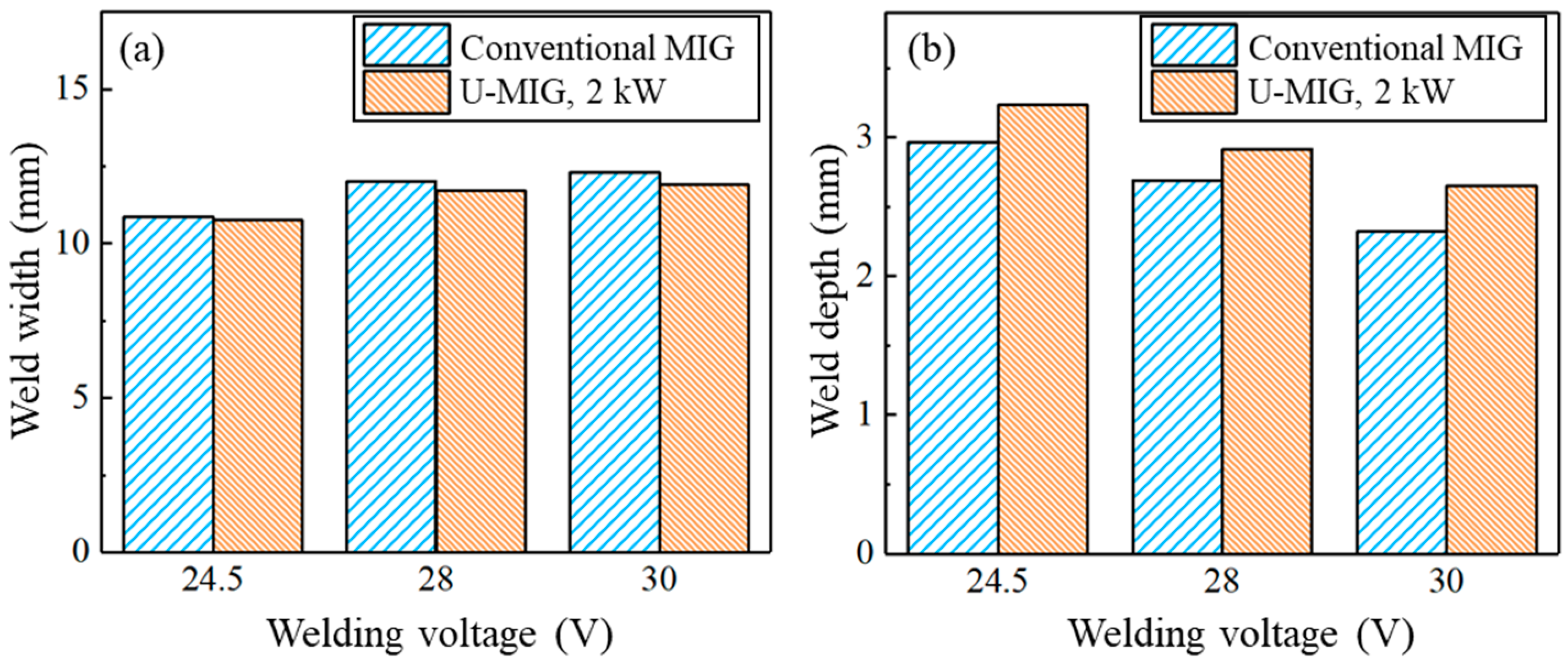

3.1. Geometric Dimensions of Single-Layer U-GMAW-AM

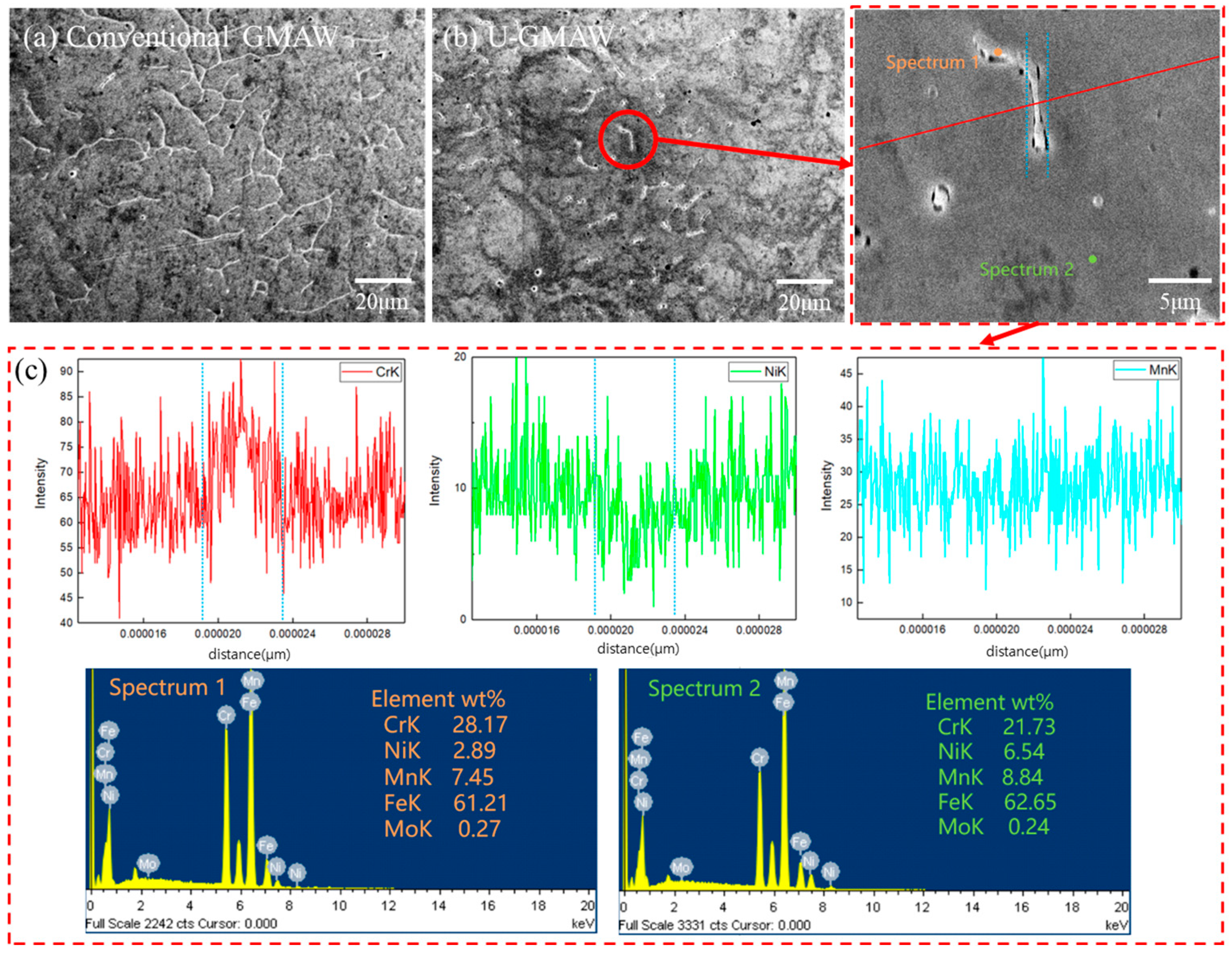

3.2. Nitrogen Pores of Conventional and U-GMAW-AM

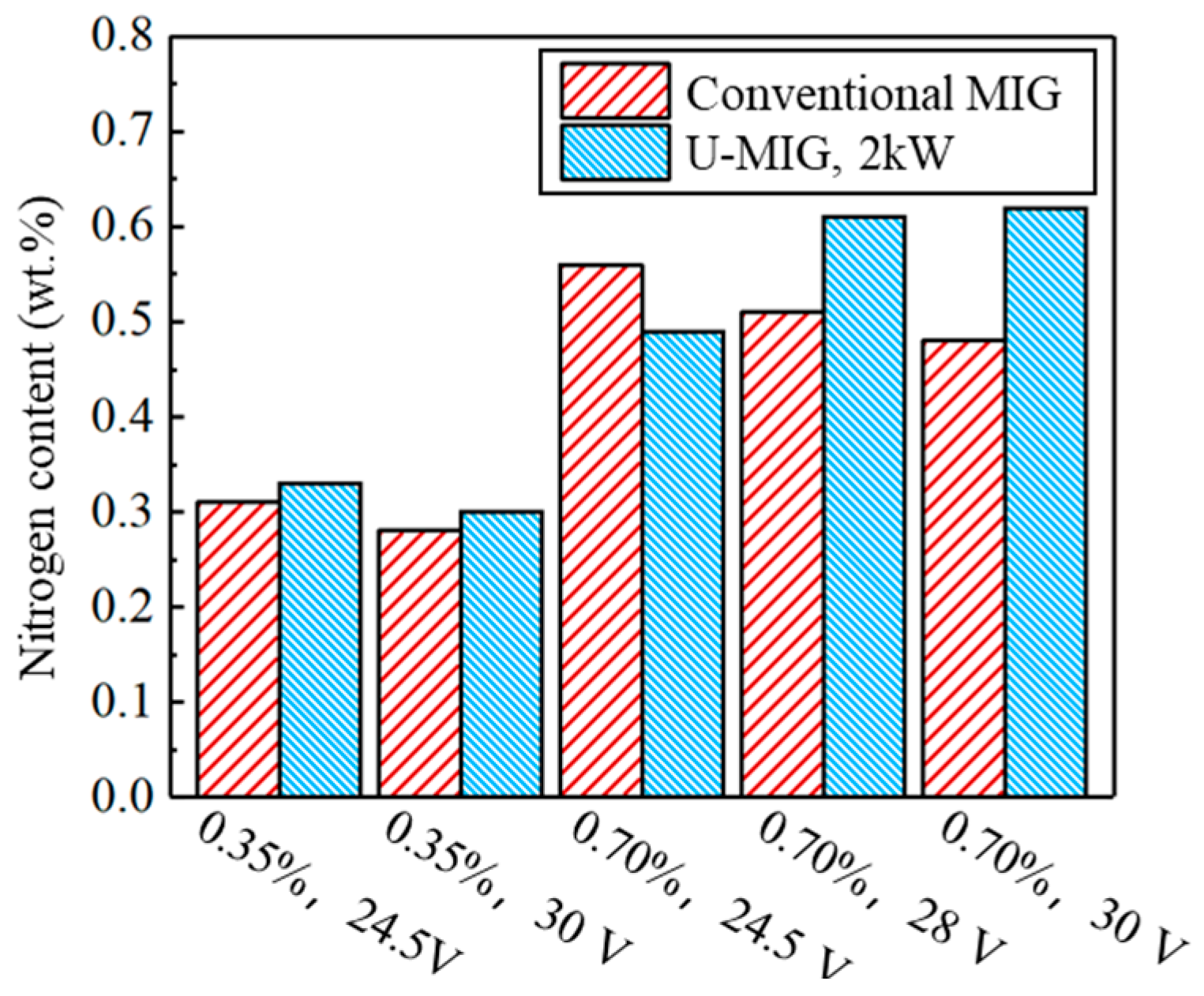

3.3. Nitrogen Content of Conventional and U-GMAW-AM

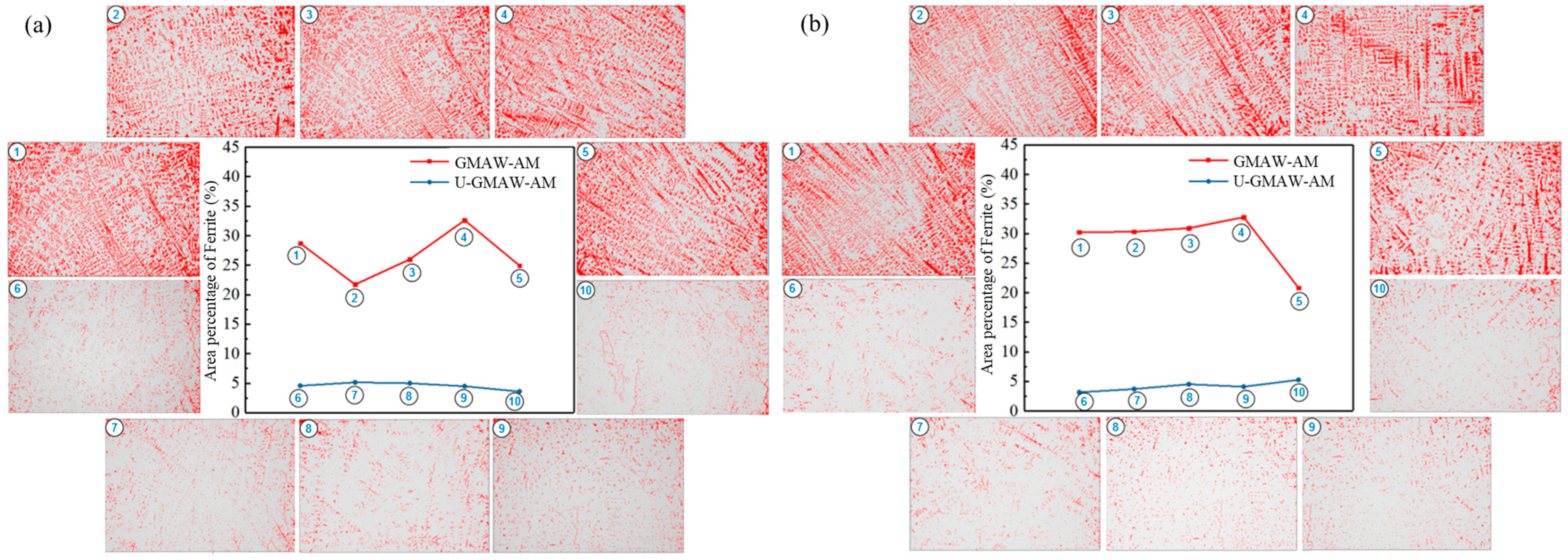

3.4. Microstructure of Conventional and U-GMAW-AM

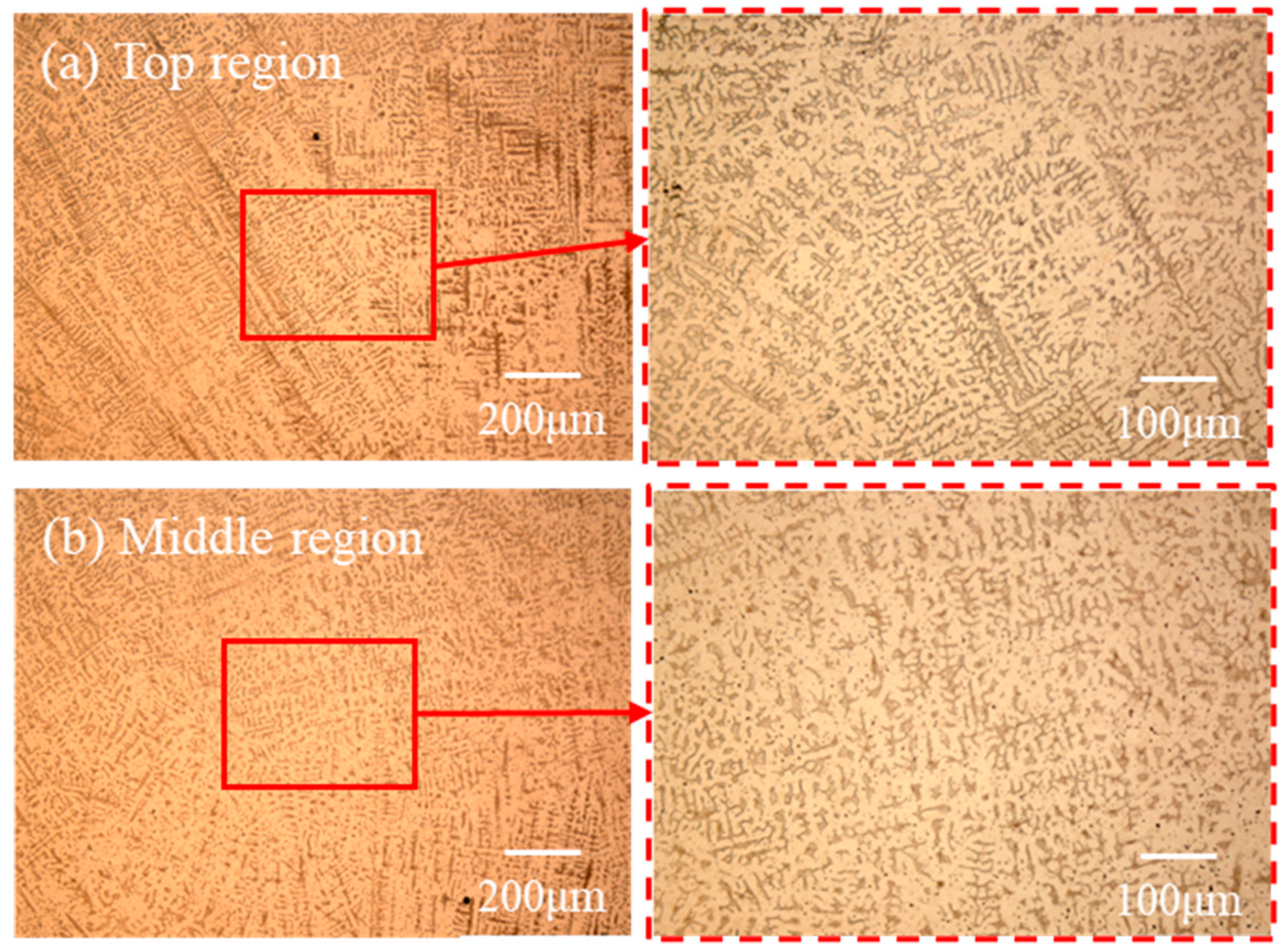

3.4.1. Microstructure of 0.35 wt.% Nitrogen Wire

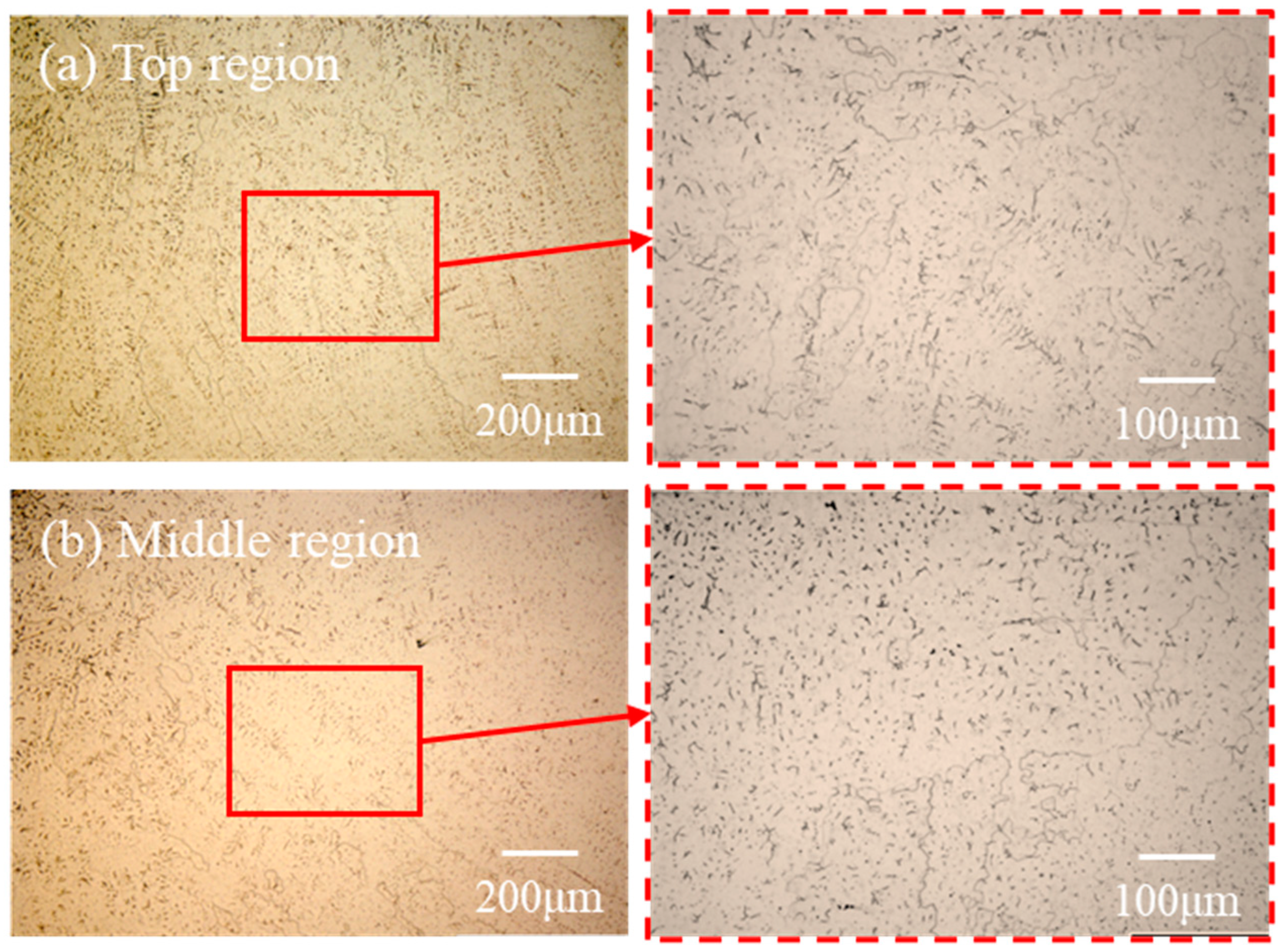

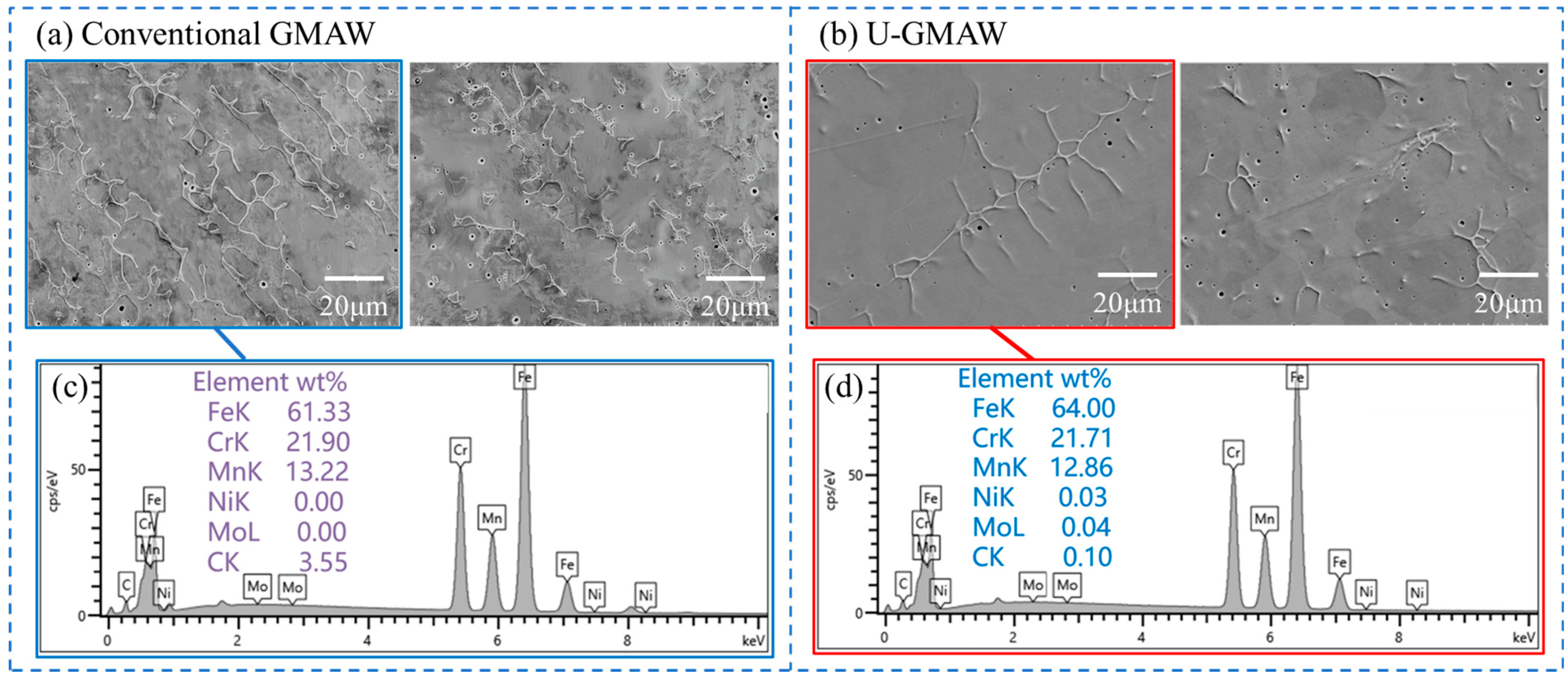

3.4.2. Microstructure of AM Components of 0.70 wt.% Nitrogen Wire

3.5. Mechanical Properties of Conventional and U-GMAW-AM

4. Discussion

4.1. Influence of Ultrasonic Assistance on Nitrogen Pores and Nitrogen Content

4.2. Influence of Ultrasonic Assistance on Microstructure

4.2.1. Influence of Ultrasonic Assistance on Microstructure of 0.35 wt.% Nitrogen Wire

4.2.2. Influence of Ultrasonic Treatment on Microstructure of 0.70 wt.% Nitrogen Wire

4.3. Influence of Ultrasonic Treatment on Mechanical Properties

4.3.1. Tensile Properties

4.3.2. Hardness

5. Conclusions

- The introduction of coaxial ultrasonic assistance into gas metal arc welding additive manufacturing (GMAW-AM) significantly alters molten pool geometry by increasing penetration depth while slightly reducing weld bead width. These changes promote enhanced interlayer fusion and dimensional consistency in multi-layer fabrication of high-nitrogen steels.

- Ultrasonic treatment effectively suppresses nitrogen loss during metal transfer and solidification. For 0.70 wt.% nitrogen wires, ultrasonic application increased the final nitrogen content by up to 29.17% under optimized parameters. This is attributed to the acoustic radiation pressure and cavitation-induced effects that reduce droplet size and nitrogen bubble growth in the droplet transfer process, allowing them to escape from the molten pool, thereby stabilizing nitrogen in solution.

- Microstructural analyses indicate that ultrasonic processing leads to significant refinement of dendritic ferrite in 0.35 wt.% nitrogen wires and a substantial reduction in both the content and coarseness of skeletal ferrite in 0.70 wt.% nitrogen wires. These microstructural changes reflect improved phase balance and enhanced austenite stability, which are attributed to increased nitrogen retention. By improving nitrogen retention, ultrasonic assistance modifies the solidification mode of high-nitrogen steel, which promotes interstitial solid solution strengthening, suppresses ferrite formation, and facilitates the development of finer, more homogeneous microstructures.

- Mechanical testing confirms improvements in tensile properties and hardness after ultrasonic assistance. The 0.70 wt.% nitrogen components fabricated under ultrasonic conditions exhibited an ultimate tensile strength increase of over 100 MPa and a hardness increase exceeding 25%, primarily attributed to the ultrasonic-induced microstructural refinement and nitrogen retention.

- The combined results demonstrate that ultrasonic-assisted GMAW-AM provides a novel approach for regulating nitrogen behavior in high-nitrogen steel additive manufacturing. By effectively suppressing nitrogen evaporation, this technique enhances nitrogen retention, refines the solidification microstructure, and improves mechanical performance. The underlying mechanism offers theoretical support for process–microstructure control and mechanical property improvement in arc-based additive manufacturing of nitrogen-rich steels.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yun, P.; Song, L.; Zhao, L.; Chengyong, M.; Haiyan, Z.; Zhiling, T. Research status of weldability of advanced steel. Acta Met. Sin. 2020, 56, 601–618. [Google Scholar]

- Katada, Y.; Sagara, M.; Kobayashi, Y.; Kodama, T. Fabrication of high strength high nitrogen stainless steel with excellent corrosion resistance and its mechanical properties. Mater. Manuf. Process. 2001, 19, 19–30. [Google Scholar] [CrossRef]

- Svyazhin, A.; Kaputkina, L.; Smarygina, I.; Kaputkin, D. Nitrogen steels and high-nitrogen steels: Industrial technologies and properties. Steel Res. Int. 2022, 93, 2200160. [Google Scholar] [CrossRef]

- Harzenmoser, M. Welding of high nitrogen steels. Mater. Manuf. Process. 2004, 19, 75–86. [Google Scholar] [CrossRef]

- Muthu, S.M.; Veeman, D.; Vijayakumar, A.; Prabu, S.S.; Sujai, S.; Arvind, M.; Gobinath, E. Evaluation of metallurgical and mechanical characteristics of the ferritic stainless steel AISI 430 produced by GTAW-based WAAM. Mater. Lett. 2024, 354, 135362. [Google Scholar] [CrossRef]

- Akbarzadeh, E.; Yurtışık, K.; Gür, C.H.; Saeid, T.; Tavangar, R. Influence of shielding gas on the microstructure and mechanical properties of duplex stainless steel in wire arc additive manufacturing. Met. Mater. Int. 2024, 30, 1977–1996. [Google Scholar] [CrossRef]

- Yang, G.; Deng, F.; Zhou, S.; Wu, B.; Qin, L.; Zheng, J. Influence of shielding gas nitrogen content on the microstructure and mechanical properties of Cu-reinforced maraging steel fabricated by wire arc additive manufacturing. Mater. Sci. Eng. A 2022, 832, 142463. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, Y.; Huang, Y.; Wang, K.; Kong, J.; Du, Z.; Wu, T.; Zhou, M. Precipitation characteristics and tensile properties of high-nitrogen chromium-manganese steel fabricated by wire and arc additive manufacturing with isothermal post-heat treatment. Mater. Des. 2023, 225, 111536. [Google Scholar] [CrossRef]

- Guo, S.; Li, Y.; Duan, M.; Wang, P.; Gu, J.; Peng, Y.; Liu, J.; Zhou, Q.; Wang, M.; Wang, K. Microstructure and mechanical properties of high nitrogen steel–high strength steel bimetallic multi-layered steels fabricated by plasma-arc additive manufacturing. Mater. Today Commun. 2023, 37, 107538. [Google Scholar] [CrossRef]

- Zhang, X.W. Application of metal additive manufacturing in aero-engine. J. Aerosp. Power 2016, 31, 10–16. [Google Scholar]

- Kai, T.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Berns, H. Manufacture and application of high nitrogen steels. ISIJ Int. 1996, 36, 909–914. [Google Scholar] [CrossRef]

- Cui, B.; Liu, S.; Zhang, F.; Luo, T.; Feng, M. Effect of welding heat input on pores in laser-arc hybrid welding of high nitrogen steel. Int. J. Adv. Manuf. Technol. 2021, 119, 421–434. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Ding, J.; Xie, Q.; Zhang, X.; Wang, K. Problems in Welding of High Nitrogen Steel: A Review. Metals 2022, 12, 1273. [Google Scholar] [CrossRef]

- Liao, J. Nitride precipitation in weld HAZs of a duplex stainless steel. ISIJ Int. 2001, 41, 460–467. [Google Scholar] [CrossRef]

- Ogawa, M.; Hiraoka, K.; Katada, Y.; Sagara, M.; Tsukamoto, S. Chromium nitride precipitation behavior in weld heat-affected zone of high nitrogen stainless steel. ISIJ Int. 2002, 42, 1391–1398. [Google Scholar] [CrossRef]

- Gurrala, A.K.; Tirumalla, A.; Sheik, S.; Mohammed, R. Role of nitrogen shielding environment on microstructure and corrosion behavior of 2205 duplex stainless-steel A-GTA welds. Mater. Today Proc. 2022, 66, 595–601. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, Y.; Lu, X.; Zhang, T.; Bai, Y.; Ma, Q. Effects of N2 content in shielding gas on microstructure and toughness of cold metal transfer and pulse hybrid welded joint for duplex stainless steel. Mater. Sci. Eng. A 2023, 872, 144936. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, H.; Xu, L.; Han, Y.; Zhao, L.; Zhou, C. Effects of nitrogen in shielding gas on microstructure evolution and localized corrosion behavior of duplex stainless steel welding joint. Appl. Surf. Sci. 2017, 404, 110–128. [Google Scholar] [CrossRef]

- Qiang, W.; Wang, K. Shielding gas effects on double-sided synchronous autogenous GTA weldability of high nitrogen austenitic stainless steel. J. Mater. Process. Technol. 2017, 250, 169–181. [Google Scholar] [CrossRef]

- Hertzman, S.; Pettersson, R.J.; Blom, R.; Kivineva, E.; Eriksson, J. Influence of shielding gas composition and welding parameters on the N-content and corrosion properties of welds in N-alloyed stainless steel grades. ISIJ Int. 1996, 36, 968–976. [Google Scholar] [CrossRef]

- Hosseini, V.A.; Wessman, S.; Hurtig, K.; Karlsson, L. Nitrogen loss and effects on microstructure in multipass TIG welding of a super duplex stainless steel. Mater. Des. 2016, 98, 88–97. [Google Scholar] [CrossRef]

- Speidel, M.O. New nitrogen-bearing austenitic stainless steels with high strength and ductility. Met. Sci. Heat Treat. 2005, 47, 489–493. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.L. Design and evaluation of nitrogen-rich welding wires for high nitrogen stainless steel. J. Mater. Process. Technol. 2021, 288, 116885. [Google Scholar] [CrossRef]

- Wendler, M.; Weiß, A.; Krüger, L.; Mola, J.; Franke, A.; Kovalev, A.; Wolf, S. Effect of manganese on microstructure and mechanical properties of cast high alloyed Cr Mn Ni-N steels. Adv. Eng. Mater. 2013, 15, 558–565. [Google Scholar] [CrossRef]

- Cheng, B.S.; Wei, F.X.; Ramamurty, U. Ambient pressure fabrication of Ni-free high nitrogen austenitic stainless steel using laser powder bed fusion method. Addit. Manuf. 2022, 55, 102810. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, C.L. Optimization of the microstructure and mechanical properties of the high nitrogen stainless steel weld by adding nitrides to the molten pool. J. Manuf. Process. 2020, 49, 355–364. [Google Scholar] [CrossRef]

- Evans, G.M. Effect of nitrogen on C-Mn steel welds containing titanium and boron. Weld. J. 1998, 77, 239-s. [Google Scholar]

- Li, J.; Li, H.; Liang, Y.; Liu, P.; Yang, L. The Microstructure and Mechanical Properties of Multi-Strand, Composite Welding-Wire Welded Joints of High Nitrogen Austenitic Stainless Steel. Materials 2019, 12, 2944. [Google Scholar] [CrossRef]

- Kumar, N.; Arora, N.; Goel, S.K. Study on metallurgical and mechanical aspects of GMA welded nitronic steel under the influence of weld quenching. J. Manuf. Process. 2020, 56, 116–130. [Google Scholar] [CrossRef]

- Sun, Q.J. Research on Ultrasonic-Arc Behaviors and Ultrasonic Assisted TIG Welding Method. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2010; p. 19. [Google Scholar]

- Fan, Y.Y. Research on Ultrasonic Assisted Gas Metal Arc Welding and Metal Transfer Behavior. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2011; pp. 19–21. [Google Scholar]

- Chen, C. Research on Pulsed Ultrasonic Assisted Arc Welding Characteristics. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2011; pp. 41–62. [Google Scholar]

- Luo, J.; He, Z.; Liu, Z.; Hua, Z.; Teng, B.; Fan, C. The Influence of Coaxial Ultrasound on the Droplet Transfer of High Nitrogen Steel GMAW Process. Materials 2024, 17, 5509. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- Sano, M.; Fujita, Y.; Mori, K. Formation of bubbles at single nonwetted nozzles in mercury. Metall. Trans. B 1976, 7, 300–301. [Google Scholar] [CrossRef]

- Ishii, F.; Ban-Ya, S.; Fuwa, T. Solubility of nitrogen in liquid iron and iron alloys containing the group VIa elements. Tetsu Hagane 1982, 68, 946–955. [Google Scholar] [CrossRef]

- Anson, D.; Pomfret, R.J.; Hendry, A. Prediction of the solubility of nitrogen in molten duplex stainless steel. ISIJ Int. 1996, 36, 750–758. [Google Scholar] [CrossRef]

- Schaeffler, A.L. Constitution diagram for stainless steel weld metal. Met. Prog. 1949, 56, 680. [Google Scholar]

- DeLong, W.T. Ferrite in austenitic stainless steel weld metal. Weld. J. 1974, 53, 273s–286s. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–178. [Google Scholar]

- Wu, T.; Liu, J.; Wang, K.; Wang, L.; Zhang, X. Microstructure and mechanical properties of wire-powder hybrid additive manufacturing for high nitrogen steel. J. Manuf. Process. 2021, 70, 248–258. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Berns, H. High Nitrogen Steels: Structure, Properties, Manufacture, Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1999; pp. 2–4. [Google Scholar]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Ryen, Ø.; Holmedal, B.; Nijs, O.; Nes, E.; Sjölander, E.; Ekström, H.-E. Strengthening mechanisms in solid solution aluminum alloys. Metall. Mater. Trans. A 2006, 37, 1999–2006. [Google Scholar] [CrossRef]

- Reed, R.P. Nitrogen in austenitic stainless steels. Jom 1989, 41, 16–21. [Google Scholar] [CrossRef]

- Fleischer, R.L. Substitutional solution hardening. Acta Metall. 1963, 11, 203–209. [Google Scholar] [CrossRef]

| Element | N | C | Si | Mn | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| Content | 0.35 | 0.071 | 0.832 | 8.84 | 22.26 | 6.54 | 0.27 | Bal. |

| Content | 0.70 | 0.072 | 0.432 | 13.42 | 21.90 | 0.30 | 0.04 | Bal. |

| Number | Voltage (V) | Wire Feeding Speed (m/min) | Travel Speed (mm/min) | Ultrasonic Power (W) |

|---|---|---|---|---|

| 1 | 24.5 | 7 | 360 | 0 |

| 2 | 24.5 | 7 | 360 | 2k |

| 3 | 28 | 7.5 | 360 | 0 |

| 4 | 28 | 7.5 | 360 | 2k |

| 5 | 30 | 7.5 | 360 | 0 |

| 6 | 30 | 7.5 | 360 | 2k |

| Number | Nitrogen Content (%) | Welding Voltage (V) | Ultrasonic Power (kW) | Transfer Mode | Nitrogen Loss (%) |

|---|---|---|---|---|---|

| 1 | 0.35 | 24.5 | 0 | short-circuit transfer | 0.04 |

| 2 | 2 | 0.02 | |||

| 3 | 30 | 0 | globular transfer | 0.07 | |

| 4 | 2 | 0.05 | |||

| 5 | 0.7 | 24.5 | 0 | short-circuit transfer | 0.14 |

| 6 | 2 | 0.21 | |||

| 7 | 28 | 0 | globular transfer | 0.19 | |

| 8 | 2 | short-circuit transfer | 0.09 | ||

| 9 | 30 | 0 | globular transfer | 0.22 | |

| 10 | 2 | 0.08 |

| Number | Nitrogen Content (wt.%) | Voltage (V) | WFS (m/min) | Ultrasonic Power (W) | Average Tensile Strength (MPa) | Average Elongation (%) |

|---|---|---|---|---|---|---|

| 1 | 0.35 | 24.5 | 7 | 0 | 654.7 | 11.2 |

| 2 | 24.5 | 7 | 2k | 712.9 | 38.2 | |

| 3 | 0.70 | 28 | 7.5 | 0 | 785.8 | 25.0 |

| 4 | 28 | 7.5 | 2k | 953.8 | 27.5 | |

| 5 | 30 | 7.5 | 0 | 786.5 | 22.0 | |

| 6 | 30 | 7.5 | 2k | 919.1 | 31.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; He, Z.; Hua, Z.; Fan, C. Research on Microstructure and Mechanical Properties of Ultrasonic-Assisted Gas Metal Arc Welding Additive Manufacturing with High-Nitrogen Steel Welding Wire. Metals 2025, 15, 491. https://doi.org/10.3390/met15050491

Luo J, He Z, Hua Z, Fan C. Research on Microstructure and Mechanical Properties of Ultrasonic-Assisted Gas Metal Arc Welding Additive Manufacturing with High-Nitrogen Steel Welding Wire. Metals. 2025; 15(5):491. https://doi.org/10.3390/met15050491

Chicago/Turabian StyleLuo, Jiawen, Zhizheng He, Zihuan Hua, and Chenglei Fan. 2025. "Research on Microstructure and Mechanical Properties of Ultrasonic-Assisted Gas Metal Arc Welding Additive Manufacturing with High-Nitrogen Steel Welding Wire" Metals 15, no. 5: 491. https://doi.org/10.3390/met15050491

APA StyleLuo, J., He, Z., Hua, Z., & Fan, C. (2025). Research on Microstructure and Mechanical Properties of Ultrasonic-Assisted Gas Metal Arc Welding Additive Manufacturing with High-Nitrogen Steel Welding Wire. Metals, 15(5), 491. https://doi.org/10.3390/met15050491