3. Results and Discussion

The Cu

71Al

17.5Mn

11.5 SMA sample was composed of a single austenite phase β

1 with L2

1 crystallographic structure at room temperature. When a stress applied in the sample was higher than the critical stress of MT, a stress-induced MT of β

1 → β

1′ occurred and the β

1′ martensite had an 18R ordered structure. The phase structure and transformation behavior have been determined by X-ray diffraction (XRD, SmartLab, Rigaku Corporation, Matsubara-cho, Akishima-shi, Tokyo, Japan) and transmission electron microscopy (TEM, F20, FEI, Hillsboro, OR, USA) operated at 200 kV at room temperature in previous work by authors and other researchers [

18,

19,

20,

21,

22].

The DSC curve during the heating/cooling process of the as-quenched sample is shown in

Figure 1. An exothermic peak corresponding to the MT during cooling and an endothermic peak corresponding to the reverse austenitic transformation during heating can be clearly observed. The MT and reverse transformation temperatures can be obtained from the curve: the MT starting temperature was

Ms = 247 K, the MT finishing temperature was

Mf = 235 K, the reverse transformation starting temperature was

AS = 253 K and the reverse transformation finishing temperature was

Af = 265 K; the thermal hysteresis was 18 K.

The EBSD orientation map and the inverse pole figures (

Figure 2) illustrate that the columnar-grained Cu-Al-Mn sample has a strong <001> oriented texture along the SD (solidification direction).

The tensile stress-strain curves for the columnar-grained Cu

71Al

17.5Mn

11.5 SMA are shown in

Figure 3; these were tested at the same loading strain rate

of 0.05 s

−1 while gradually increasing the unloading strain rates

from 0.005 to 0.19 s

−1. Specifically, nine strain rates of 0.005, 0.01, 0.05, 0.07, 0.096, 0.1, 0.13, 0.15, and 0.19 s

−1 were chosen. It should be noted that in order to avoid the experimental deviation from different samples, the test was carried out using the same sample at each measuring temperature. For all the test conditions in

Figure 3, when the measuring temperature was ≤393 K, an almost 100% strain recovery could be observed after the samples underwent a loading strain of 10%, indicating an excellent superelasticity of the columnar-grained Cu

71Al

17.5Mn

11.5 SMA. With increasing tensile cycles, both the critical stresses of MT and reverse transformation were decreased gradually. Because the loading strain rate is constant, the stress of MT decreasing in loading processes can be attributed to the influence of cycle numbers, which may be related to the fatigue effect. However, the stress of reverse transformation in unloading processes may be affected by loading processes, strain rates or cycle numbers.

In this work, the influence of loading processes can be excluded as a result of the same loading strain and loading strain rate. In order to clarify the influence of cycle numbers or strain rate on the unloading curves, a comparative tensile test with 10 cycles was carried on at a constant unloading rate of 0.05 s

−1, and the stress-strain curves are shown in

Figure 4a. Comparing the stress-strain curve tested at 291 K in

Figure 3 and the curve in

Figure 4a, the reduction of the transformation stress has closed relations with the increase in cycle numbers. In other words, the strain rate has little effect on the transformation stress of columnar-grained Cu

71Al

17.5Mn

11.5 SMA, which is different from the phenomenon that was observed in Ti-Ni alloys [

14,

15]. For Ti-Ni alloys, with increasing strain rates, the stress-strain loop enlarges clearly; that is, the loading stress increases and unloading stress decreases. The strain rate sensitivity of the transformation stress in SMAs is related to the capability of stress relaxation, which is caused by martensite nucleation and growth during the MT process. Under constant strain conditions, the MT of Ti-Ni SMAs requires 3 min to induce a stress relaxation of 50 MPa [

15]. In other words, when the strain rate exceeds 0.02 s

−1 of Ti-Ni SMAs, the stress will clearly increase as a result of stress relaxation hysteresis.

Figure 3 and

Figure 4a indicate that the phenomenon of transformation stress increase is not observed in columnar-grained Cu

71Al

17.5Mn

11.5 SMAs until the strain rate reaches 0.19 s

−1, which means that the stress relaxation capacity of columnar-grained Cu

71Al

17.5Mn

11.5 SMAs is more than 10 times that of Ti-Ni SMAs. Therefore, the strain rate sensitivity of columnar-grained Cu

71Al

17.5Mn

11.5 SMAs is dramatically lower than that of Ti-Ni SMAs.

In order to study the effect of measuring temperature on tensile stress-strain curves of the columnar-grained Cu

71Al

17.5Mn

11.5 SMA, a series of tensile cycle tests were carried out between the temperature range from 291 to 420 K, and the results are subsequently drawn in

Figure 3. A comparison of these stress-strain curves indicates that as the measuring temperature rises, the MT stress increases gradually. When the measuring temperature reaches 420 K, the recoverable strain of the sample decreases rapidly with the increase in the number of tensile cycles. The microstructure observation found that a large number of dislocations were observed in the sample, indicating that the tensile stress was high enough to start the dislocation slip. This phenomenon implies the deformation mechanism begins to change from superelastic deformation induced by phase transformation to permanent plastic deformation caused by a dislocation slip when the sample deforms at 420 K, which can be defined as the critical temperature of stress-induced MT in columnar-grained Cu

71Al

17.5Mn

11.5 alloys. Therefore, the upper limit of the temperature window of the eCE of columnar-grained Cu

71Al

17.5Mn

11.5 alloys is less than 420 K. In other words, the temperature window of the columnar-grained Cu

71Al

17.5Mn

11.5 alloy is 265–393 K. The width of the temperature window is 128 K.

On the basis of the first cycle of the measured stress–strain curve in the temperature range of 291–393 K, the MT critical stress (σ

c) as a function of

TA is plotted in

Figure 4b.

Figure 4b indicates that σ

c linearly increases with the increase of measuring temperature in the range of 291–393 K, and dσ

c/d

TA = 1.40 MPa/K for the columnar-grained Cu

71Al

17.5Mn

11.5 alloy, which can be determined by linear fitting.

Figure 5 indicates the temperature change of the columnar-grained Cu

71Al

17.5Mn

11.5 SMA samples in loading-unloading cycles at different measuring temperatures. It can be seen from

Figure 5a–d that at a constant strain rate (0.05 s

−1), the Δ

T values measured from both loading and unloading processes for different cycles are almost unchanged in the temperature range of 291–393 K, which indicates that no evident influence of cycle numbers on Δ

T was observed after 10 tensile cycles at a constant strain rate; this implies a good stability of the eCE in the columnar-grained Cu

71Al

17.5Mn

11.5 SMA. When the strain rate is less than 0.05 s

−1, |Δ

T| increases with increasing

. When the strain rate reaches 0.05 s

−1 or above, |Δ

T| achieves saturation. For instance, at

TA = 291 K, when

increases from 0.005 to 0.05 s

−1, Δ

T changes from 7.53 to 11.21 K. After

reaches 0.05 s

−1, the Δ

T values remain constant within the range of 11.21–11.51 K. For different

TA values, the variation trends of the

T vs.

t curves from the samples with increasing

are similar.

In addition, the phenomenon of temperature irreversibility can also be found from

Figure 5; that is, the absolute values of the temperature change between loading and unloading are not equal. For example, when the strain rate is 0.05 s

−1 at 291 K, the loading temperature rises are 14.8–15.3 K (

Figure 5a) and 13.7–13.9 K (

Figure 5b), while the unloading temperature drops are 13.2–13.5 K (

Figure 3a) and 11.2 K (

Figure 5b). The absolute value of the unloading temperature drop is 1.6–2.7 K, which is lower than the loading temperature rise. Irreversibility is caused by the existence of the hysteresis area during the loading-unloading process. The formation of the hysteresis area is directly related to the frictional origin during the transformation. These frictions include the interfacial friction between martensite and austenite, the interaction between the phase interface and grain boundary, or other defects [

12,

14]. When the measuring temperature reached 420 K, as a result of the occurrence of irreversible deformation caused by a dislocation slip, the return strain gradually reduced with the increasing stretching cycles, resulting in a gradually reduced temperature change, as shown in

Figure 5e.

On the basis of the

T-

t profiles (four typical profiles are shown in

Figure 5), a high |Δ

T| value of 11.3–16.5 K can be obtained in the columnar-grained Cu

71Al

17.5Mn

11.5 SMA during unloading processes, covering a wide temperature range of more than 100 K. The entropy change of the phase transformation associated with the elastocaloric cooling can be estimated as

where

Cp is the heat capacity, measured to be 455 J/kg·K for the Cu

71Al

17.5Mn

11 SMA [

10]. Strictly speaking, when calculating the adiabatic temperature change or entropy change, because of the coexistence of two phases during transformation, we should consider that

Cp =

xCpA + (1 −

x)

CpM, where

x is the fraction of the authentic phase, and

CpA and

CpM are the heat capacity of the authentic phase and martensitic phase, respectively. However,

CpA and

CpM are approximately equal for SMAs [

23]. Therefore, in the actual measurement and calculation, we supposed

Cp ≈

CpA ≈

CpM. In this paper, we experimentally measured the

CpA value and used it in the calculation. According to the Δ

T values measured above, the maximum Δ

S can be estimated to be 19.5 J/(kg·K). Additionally, Δ

S can also be calculated from the Clausius-Clapeyron equation:

where

ρ is the density and

ε is the transformation strain. For the columnar-grained Cu

71Al

17.5Mn

11.5 SMA, dσ

c/d

TA and ε can be determined to be 1.40 MPa/K from

Figure 4b and 8.3% from

Figure 3, and

ρ = 7.40 × 10

3 kg/m

3 [

24]. The calculated Δ

S value from the Clausius-Clapeyron equation is about 15.7 J/(kg·K), which is smaller than the calculation results based on Δ

T. In addition, the theoretical maximum of the isothermal entropy change also can be calculated to be 25.0 J/kg·K by the latent heat of phase transformation determined by DSC measurement [

10]. Therefore, the entropy change estimated on the basis of the experimental data in this paper approached ∼78% of its theoretical value. It is generally believed that the latent heat of phase transformation determined by the DSC method corresponds to a completed entropy change from 100% phase transformation without any loss, thus often called the theoretical entropy change. The entropy change value estimated on the basis of the experimentally measured ∆

T value is less than the theoretical entropy change, because of the existence of internal frictions induced by the phase interface frictions and the interactions between phase migration and defects. In addition, in the actual tensile deformation processes, incomplete MT may be another probable cause of the smaller entropy change value estimated by stress-strain curves. According to the above discussion, the energy loss induced by internal frictions is about 5.5 J/(kg·K) for the columnar-grained Cu

71Al

17.5Mn

11.5 SMA.

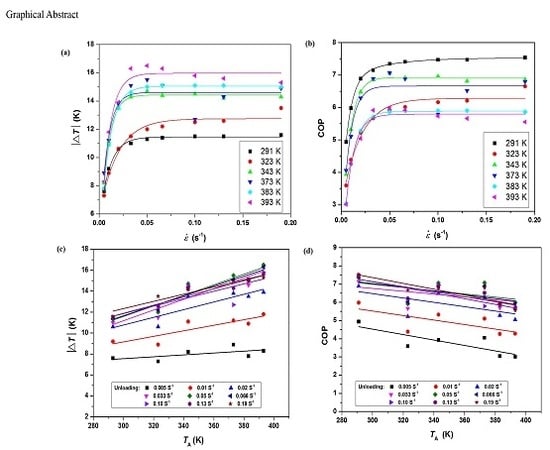

The |Δ

T| value and the COP for unloading processes in the columnar-grained Cu

71Al

17.5Mn

11.5 SMA as a function of

and

TA are summarized in

Figure 6. The COP of the material, which describes the cooling efficiency, is defined by the ratio of cooling power (Δ

Q) to input work (Δ

W) [

25]:

where Δ

Q can be estimated from the latent heat, which is Δ

Tad ×

Cp (Δ

Tad is the adiabatic temperature change), and Δ

W can be obtained by integrating the area enclosed by the stress hysteresis loop (

Figure 3).

Figure 6a indicates that all |Δ

T| vs.

curves show a similar variation trend. At first, the |Δ

T| value increases with increasing

. When the strain rate reaches 0.05 s

−1, the |Δ

T| value remains almost unchanged, implying it achieves saturation. The critical strain rate

corresponding to the onset of |Δ

T| saturation is less than that of Ti-Ni alloy, which was reported as 0.2 s

−1 [

13]. In other words, it is easier to reach near-adiabatic conditions using the columnar-grained Cu

71Al

17.5Mn

11.5 SMA. In the process of MT (reverse MT), the homogeneity of martensite (austenite) nucleation and extension is a noteworthy factor to influence

. The more homogeneously the MT occurs in the sample, the lower the

value [

12]. The columnar-grained Cu-Al-Mn SMA has a homogeneous contribution of stress/strain in the whole sample as a result of a high deformation and transformation compatibility among grains [

26]. Therefore, the martensite (austenite) can nucleate and grow homogeneously in the columnar-grained samples. Furthermore, the Cu-based SMAs have a higher thermal conductivity compared to the Ti-Ni alloy, which also helps to obtain a uniform temperature distribution within a very short period of time. The above two reasons show that the columnar-grained Cu

71Al

17.5Mn

11.5 SMA has a low

, which can reduce the design difficulty of refrigeration devices.

Figure 6b indicates that the variation trend of COP with increasing strain rate is consistent with |Δ

T|, while the variations of |Δ

T| and COP with

TA are the opposite, as shown in

Figure 6c,d. For refrigeration device or system design, a higher |Δ

T| and COP are expected. For the columnar-grained Cu

71Al

17.5Mn

11.5 SMA, in order to achieve a stable and high refrigeration capability and COP, the applied strain rates should be more than 0.05 s

−1.