Abstract

With the motto of “doing it right the first time”, this study focuses on spearheading the integration of designers, constructors, and facility mangers, at the outset of the planning/design stage, by providing easy-to-read tables summarising (1) knowledge learnt from past mistakes and (2) maintainability benchmarks, to ensure high maintainability for Basements and Wet Areas. The commonly occurring problems in Basements and Wet Areas of a total of 110 buildings comprising of commercial, hotels, industrial, institutions, healthcare facilities, and residential facilities were evaluated using case and field studies. Face-to-face interviews and workshops with the respective professionals involved in the design, construction, operation and maintenance (O&M) of the buildings were conducted for detailed investigation on each problem for their (a) problem types, (b) extent of problem, (c) failure mechanism, (d) good practices in design/construction/O&M/facilities management (FM), and (e) environmental issues. Easy-to-read tables of checklists based on a preventive/predictive performance-based approach, which defines acceptable standards in design, construction and O&M/FM practices, were derived. The checklists help enhance the integration of designers, constructors, and facilities managers (FM), ensuring high maintainability and productivity right at the outset of the planning/design stage. They also help professionals derive, customise, and validate their own Maintainable Design Appraisal System (MDAS) according to their own needs.

1. Introduction

Maintainability is defined as the ability to achieve the optimum performance throughout the lifespan of a facility within the minimum life cycle cost.

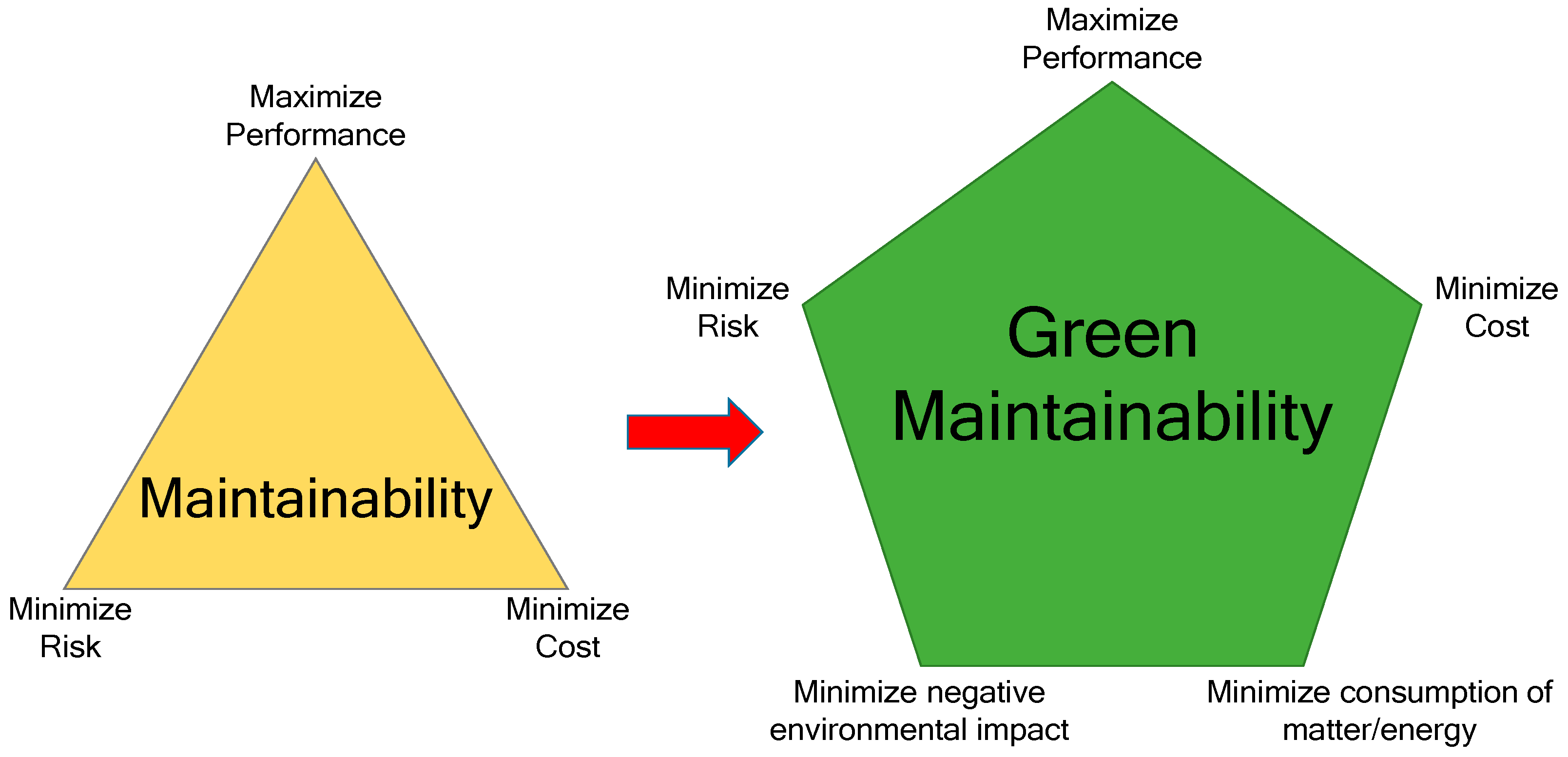

Today, it is implicit that “design for maintainability” shall further consider sustainable design with an efficient use of resources and emphasis on environmental consciousness and practices. Termed as Green Maintainability, it requires considerations to maximise the performance and energy efficiency while minimising the total life cycle cost, embodied energy, environmental impact, and consumption of matter/energy throughout the life cycle of a facility, right from the planning/design stage (Figure 1) [1,2].

Figure 1.

Definitions of maintainability and Green Maintainability.

It has been shown that the lack of considerations on maintainability during the design and construction stages has led to building defects that account for the expenditure of billions of dollars throughout the building’s life cycle. More so, the potentially unsafe conditions of buildings can be detrimental to the lives and health of users. This raises the need to identify sources of defects with significant attention to design, detailing, materials, construction quality, and environmental factors at the outset. In order to improve the maintainability of buildings and to attain maintenance productivity over its lifetime, the underlying risk factors of buildings’ life cycle need to be identified and factored right from the planning/design stage.

The objectives of this study are as follows:

- To build upon existing maintainability research for Basements and Wet Areas by updating the existing databank and reviewing the state-of-the-art of regional and global counterparts in terms of standards and best practices with emphasis on ease of maintenance, productivity, labour efficiency, safety, and sustainability.

- To establish, develop, and verify critical indicators of facility design, construction, and maintenance on the outset of planning/design stage.

- To provide the basis for users to derive, customize, and validate their own stakeholder-based Maintainable Design Appraisal System (MDAS) at the outset, so as to enable a critical design for maintainability parameters for Basements and Wet Areas in terms of (i) ease of maintenance, (ii) productivity, (iii) labour efficiency, (iv) safety and (v) sustainability.

2. Materials and Methods

The state-of-the-art of regional and global counterparts in terms of standards and best practices were reviewed. Relevant global standards relating to maintainability factors (e.g., SS, BS, ISO, EN, AS, ASTM) were incorporated in the databank as the foundation phase for the creation of a viable and evidenced based appraisal system. The relevant international and national standards and best practices consulted for the study are listed at the end of the paper, after the “References”, under “Normative References/Standards” for Basements and Wet Areas, respectively.

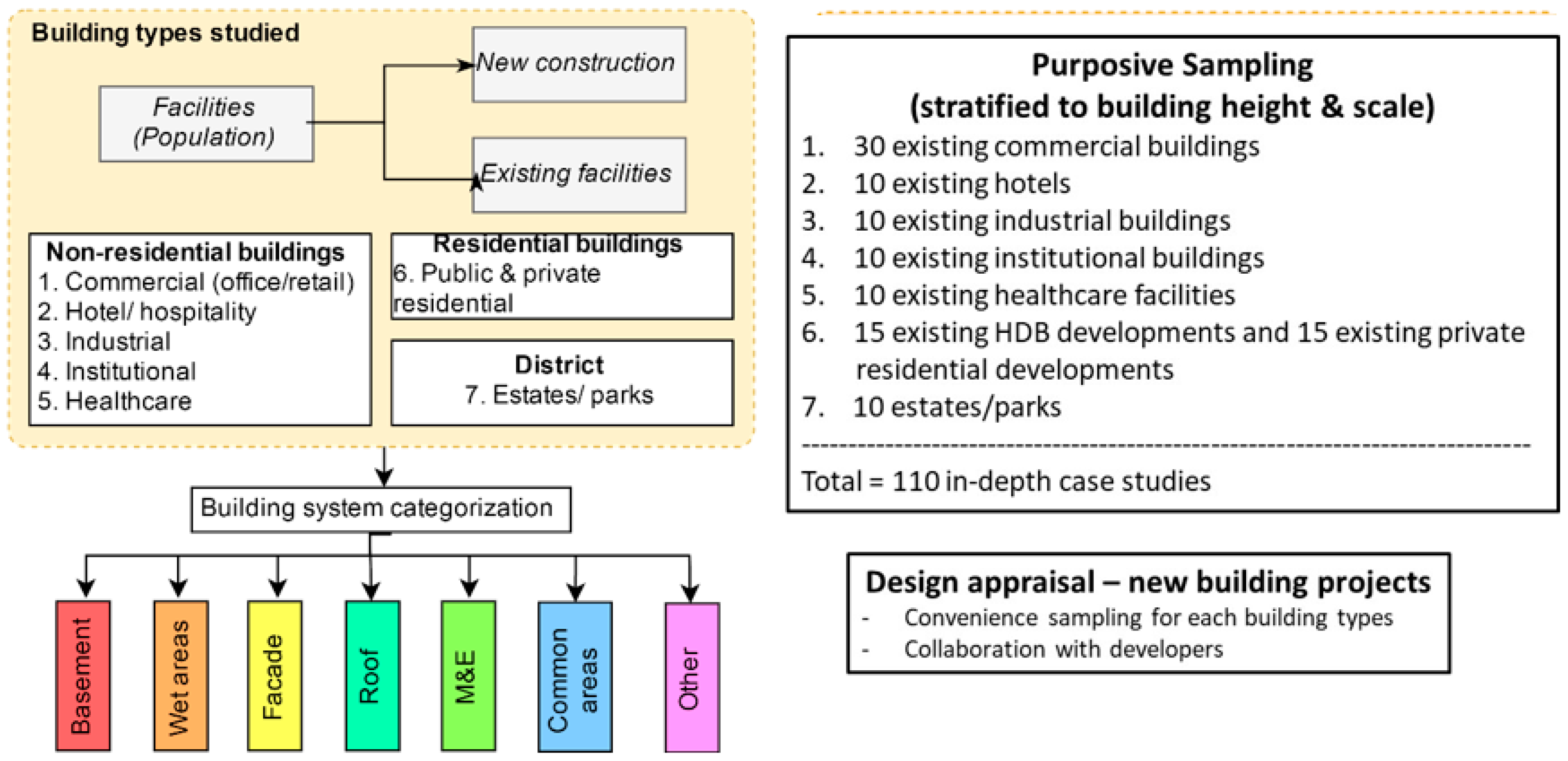

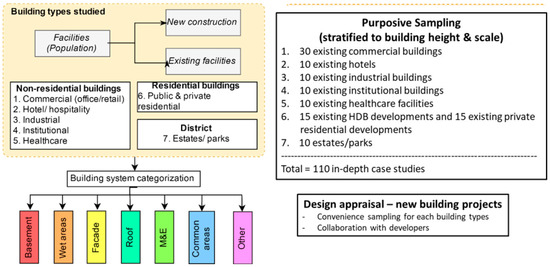

Case and field studies of commonly occurring problems in Basements and Wet Areas of a total of 110 buildings comprising of commercial, hotels, industrial, institutions, healthcare facilities, and residential facilities were conducted. The multiple case studies involved three major broad classifications of building types as non-residential buildings, residential buildings, and districts (estates/parks). Each of them was categorized into seven building components/system (e.g., basement, wet areas, facades, roof, M&E, common areas, and green technologies). The building types, building system categorization, samples, and sampling of buildings are shown in Figure 2. Typical configurations of Basements and Wet Areas investigated are the conventional types as shown in Figure 3 and Figure 4.

Figure 2.

Case building selection and sampling.

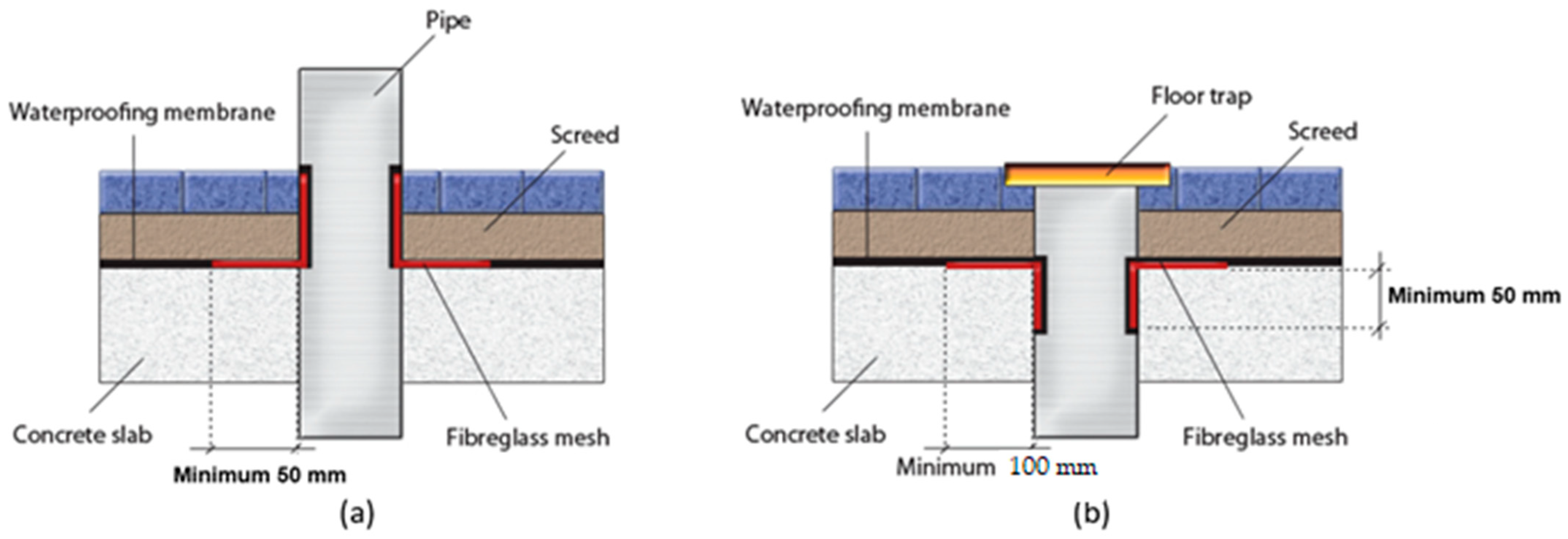

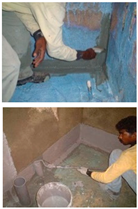

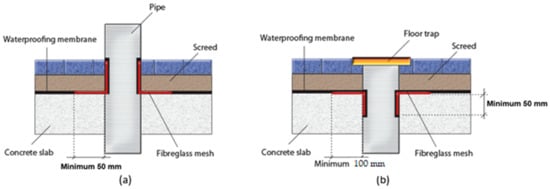

Figure 3.

Conventional Wet Area waterproofing details at (a) pipe penetrations and (b) floor traps.

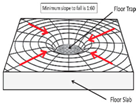

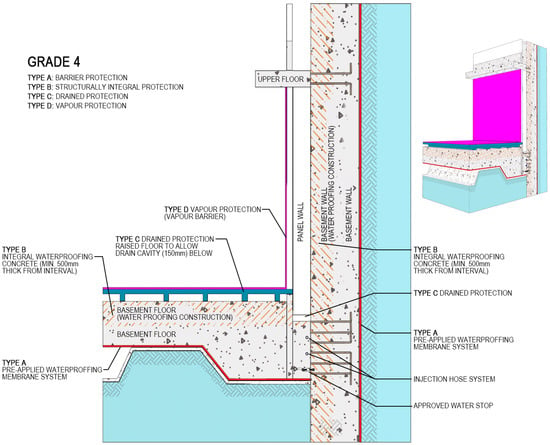

Figure 4.

Conventional Basement wall and floor configuration with waterproofing details for Types A to D.

Factors considered in the study are shown in Table 1. Work studies were conducted on maintenance activities (i.e., cleaning, repair, and replacement) of different building systems for different building typologies. Work study in this regard is a systematic investigation of all factors affecting the efficiency and economy of maintenance activities with the prime aim of improving productivity. Both method studies and work measurement techniques such as time studies and activity sampling were used.

Table 1.

Factors considered for case and field studies.

Face-to-face interviews and workshops with the respective professionals involved in the design, construction, and operation of the buildings were conducted for detailed investigation on each problem for their (a) problem types, (b) extent of problem, (c) failure mechanism, (d) good practices in design/construction/facilities management (FM) and (e) environmental issues.

3. Results

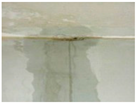

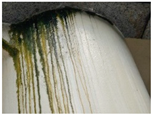

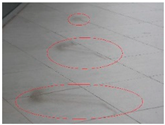

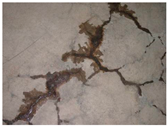

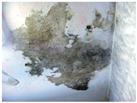

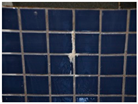

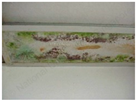

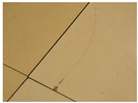

Anomalies were categorised and analysed according to types, locations, extents, frequencies, causes, and the roles of professionals. As the purpose of this paper is to provide easy-to-read tables of checklists based on a preventive/predictive performance-based approach, with defined acceptable standards in design, construction and operation and maintenance (O&M)/FM practices, results are shown in Table 2, Table 3 and Table 4 for Basements and Table 5, Table 6 and Table 7 for Wet Areas. Each table addresses the common defects and the corresponding design/construction/FM issues, with standards/guidelines/recommendations for the structural, architectural, and service components for Basement and Wet Areas, to be taken into account at the outset of the planning/design stage. For example, the “corrosion and spalling of concrete” in a basement is classified as a structural defect, which is highlighted with photographs taken from case studies, and the corresponding design, construction, and maintenance standards/guidelines to be considered at the outset of planning/design stage.

Table 2.

Basements—Structural components e.g., floors, slabs, walls and other load-bearing and non-loading components.

Table 3.

Basements—Architectural components e.g., finishes, furnishings, and other elements that contribute to the aesthetic value and liveability.

Table 4.

Basements—Service components that include vertical and horizontal circulation systems, electro-mechanical connections, and sanitary connections.

Table 5.

Wet Areas—Structural components e.g., floors, slabs, walls, and other load-bearing and non-loading components.

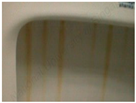

Table 6.

Wet Areas—Architectural components e.g., finishes, furnishings, and other elements that contribute to the aesthetic value and liveability.

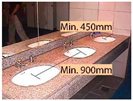

Table 7.

Wet Areas—Service components that include vertical and horizontal circulation systems, electro-mechanical connections, and sanitary connections.

3.1. Basements

Table 2 shows the concerns for design, construction, and maintenance at the outset of the planning/design stage, for structural components e.g., floors, slabs, walls, and other load bearing and non-loading components.

Table 3 shows the concerns for design, construction and maintenance at the outset of the planning/design stage, for architectural components e.g., finishes, furnishings, and other elements that contribute to the aesthetic value and liveability.

Table 4 shows the concerns for design, construction, and maintenance at the outset of the planning/design stage, for service components that include vertical and horizontal circulation systems, electro-mechanical connections, and sanitary connections.

3.2. Wet Areas

Table 5 shows the concerns for design, construction, and maintenance at the outset of the planning/design stage, for structural components e.g., floors, slabs, walls, and other load-bearing and non-loading components.

Table 6 shows the concerns for design, construction, and maintenance at the outset of the planning/design stage, for architectural components e.g., finishes, furnishings, and other elements that contribute to the aesthetic value and liveability.

Table 7 shows the concerns for design, construction, and maintenance at the outset of the planning/design stage, for service components, which include vertical and horizontal circulation systems, electro-mechanical connections, and sanitary connections.

4. Discussion

The results showed that, common to both Basements and Wet Areas, most anomalies evaluated were associated with the following:

- (a)

- Inadequate provisions and details of the waterproofing membranes over discontinuities.

- (b)

- Inadequate provisions of the movement joints between structural elements.

- (c)

- Existence of a large number of discontinuities (penetrations).

- (d)

- Inadequate provisions for the drainage.

- (e)

- Poor planning and workmanship of application of the flooring, waterproofing membrane, and plumbing.

The results indicated that 11 factors were significant in causing seepage/leakages. They can be grouped as follows:

- Design factors

- Inappropriate waterproofing system adopted

- Lack of poor drainage design detailing

- Lack of waterproofing detailing

- Construction factors

- Insufficient compaction

- Improper installation of construction joints

- Improper installation of waterproofing

- Damage of waterproofing during construction

- Insufficient curing of waterproofing

- Maintenance factors

- Lack of regular inspection to detect defects

- Delayed repair to initial defect

- Deterioration of waterproofing

The evaluation of results are reflected in the checklist as shown in Table 2, Table 3, Table 4, Table 5, Table 6 and Table 7. The checklists may be used to assist professionals to synergise at the outset, the operational requirements and expected maintenance performance outcomes of a facility, with risk assessment adequately conducted at the planning/design stage. They also assist in the coordination among all professionals for accurate transfer of information throughout the complete delivery process to achieve high maintainability.

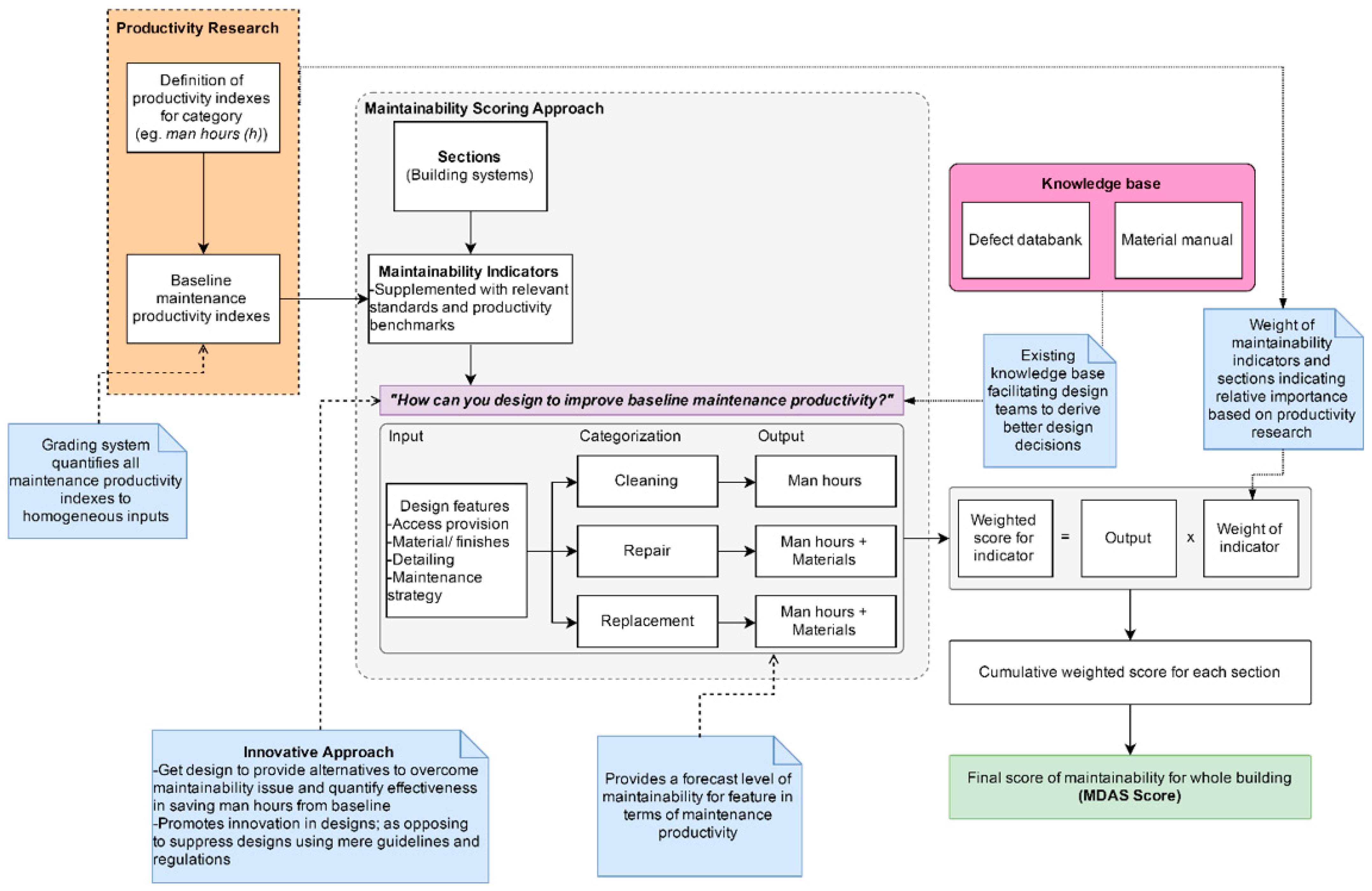

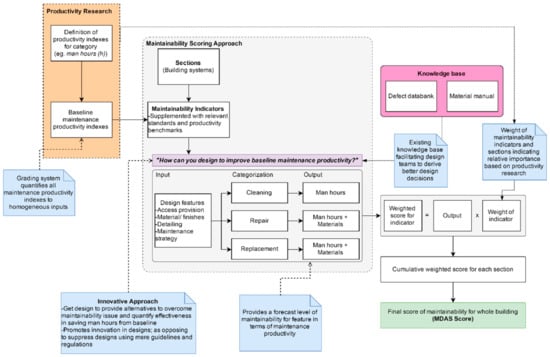

By selecting the appropriate clauses from the checklist, professionals may readily derive, customise, and validate their own Maintainable Design Appraisal System (MDAS) according to their specific needs, with assigned weighted additives for their criticality used to compute a cumulative MDAS score [25,26] signifying a realistic and effective indicator of maintainability. An example of one such formulation is illustrated in Figure 5.

Figure 5.

Formulation of the Maintainable Design Appraisal System (MDAS).

Arising from the study, design, construction and O&M/FM teams are recommended to consider, at the outset of planning/design stage, the following.

4.1. Designs

In general, the following are recommended for the design team (including architect, M&E engineer, structural and civil engineer):

- (a)

- To consider the implications of design on future maintenance of the buildings and facilities, including considerations for access, cost effectiveness, and safe maintenance.

- (b)

- To provide a statement for complex or unique design features on how these special features should be maintained, including the access for maintenance.

- (c)

- To explore attributes of building materials, in order to specify the correct materials and building components for use in construction.

- (d)

- To consider the different M&E systems and its efficiency performance, in order to specify the correct systems for use in construction.

- (e)

- To alert owners or users on the impact of new materials and systems on future maintenance that are incorporated in the buildings and facilities.

- (f)

- To improve on the design and detailing of the buildings and facilities with a view to achieving maintainability but without sacrificing on the design.

- (g)

- To recommend the use of locally green-certified materials, especially interior products, for the better health and well-being of building occupants.

- (h)

- To consider the life cycle of the materials and products in accordance with the requirements of the owner.

- (i)

- To adopt advanced building information modelling techniques, such as soft clash detection using BIM, to ensure that clear access and sufficient headroom for M&E equipment is provided to facilitate future maintenance and replacement.

- (j)

- To consider designs that facilitate the adoption of technology to improve the efficiency of maintenance processes/works and to achieve the optimisation of building systems performance.

4.2. Construction

In general, the following are recommended for the construction team (including builder, sub-contractor, and supplier):

- (a)

- To focus on achieving good workmanship in construction to reduce defects and failures.

- (b)

- To ensure the proper and safe integration and coordination of different trades and elements during the construction.

- (c)

- To suggest more efficient design and to adopt more effective construction methods to achieve high maintainability.

- (d)

- To suggest the use of suitable materials to improve the maintainability of buildings and facilities.

- (e)

- To continually update the BIM model to ensure accuracy of the final model in synchronisation with actual as-built details.

4.3. Operation and Maintenance

In general, the following are recommended for the maintenance team (including facilities manager and property manager):

- (a)

- To promote proper and safe usage of buildings, systems, and plants.

- (b)

- To use correct equipment and tools in maintenance work.

- (c)

- To establish, when possible, a feedback loop to design and construction in the value chain by examining the gaps between design and maintenance, and construction and maintenance.

- (d)

- To consider the application of technology such as use of electronic devices to record and retrieve maintenance records and progress.

- (e)

- To consider the application of technology such as the use of robots to maintain difficult or inaccessible sites.

- (f)

- To undertake regular upkeep and maintenance by establishing effective maintenance programmes.

- (g)

- To engage owners, tenants, and occupiers in the maintenance programmes.

- (h)

- To consider the use of locally green-certified materials, especially interior products, for the better health and well-being of building occupants.

- (i)

- To consider technology adoption to:

- Reduce/optimise the manpower demand for maintenance works

- Improve the efficiency of maintenance processes/works

- Achieve the optimisation of building systems performance.

- (j)

- To adopt the necessary BIM data for asset management and potential integration with computerised maintenance management systems and/or building management systems to facilitate the automation and digitisation of maintenance works.

5. Conclusions

Results of data collected using case and field studies as well as face-to-face interviews on Basements and Wet Areas of a total of 110 buildings comprising of commercial, hotels, industrial, institutions, healthcare facilities, and residential facilities were evaluated. From these, we derived easy-to-read tables of checklists based on a preventive/predictive performance-based approach, which define acceptable standards in design, construction, and O&M/FM practices. The critical indicators for design, construction, operation, and maintenance of facilities for basements and wet areas were presented. This study provides information for building and real estate professionals involved in the design, construction, and operation of a facility by:

- Enhancing the high maintainability of facilities through identifying the common maintainability issues and corresponding requirements for designers, constructors, and facilities managers at the outset of the planning/design stage.

- Recommending best practices for the respective professionals from design, construction, to operation/maintenance stages, in a practical, concerted, and conscientious manner towards high maintainability, safety, productivity, and environmentally friendly goals.

- Inculcate a conscious effort and commitment for all building and real estate professionals to take into consideration the whole life performance and economic value of a facility within the environmental constraints.

With the results from the evidence-based empirical studies conducted, the development and validation of the stakeholder-based appraisal system (MDAS) could be customised by users with assigned weighted additives for their criticality used to compute a cumulative MDAS score signifying a realistic and effective indicator of maintainability for their properties.

| Normative References/Standards Referred to for Basements in Table 2, Table 3 and Table 4 | |

| ASTM C1193-16 | Standard Guide for Use of Joint Sealants |

| ASTM C33/C33M-16e1 | Standard Specification for Concrete Aggregates |

| BS 1881-210 | Testing hardened concrete. Determination of the potential carbonation resistance of concrete. Accelerated carbonation method |

| BS 6093 | Design of joints and jointing in building construction. Guide |

| BS 6150 | Painting of buildings. Code of practice |

| BS 6213 | Selection of construction sealants. Guide |

| BS 6398 | Specification for bitumen damp-proof courses for masonry |

| BS 8000-0 | Workmanship on construction sites. Introduction and general principles |

| BS 8004 | Code of practice for foundations |

| BS 8102 | Code of practice for protection of below ground structures against water from the ground |

| BS 8204-1 | Screeds, bases and in situ floorings. Concrete bases and cementitious levelling screeds to receive floorings. Code of practice |

| BS 8204-2 | Screeds, bases and in situ floorings. Concrete wearing surfaces. Code of practice |

| BS 8210 | Guide to facilities maintenance management |

| BS 8215 | Code of practice for design and installation of damp-proof courses in masonry construction |

| BS EN 12845 | Fixed firefighting systems. Automatic sprinkler systems. Design, installation and maintenance |

| BS EN 13139 | Aggregates for mortar |

| BS EN 14630 | Products and systems for the protection and repair of concrete structures. Test methods. Determination of carbonation depth in hardened concrete by the phenolphthalein method |

| BS EN 1504-2 | Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. Surface protection systems for concrete |

| BS EN 1504-3 | Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. Structural and non-structural repair |

| BS EN 1504-5 | Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. Concrete injection |

| BS EN 1504-9 | Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. General principles for use of products and systems |

| BS EN 1992-1-1 | Eurocode 2: Design of concrete structures. General rules and rules for buildings |

| BS EN 1992-1-2 | Eurocode 2. Design of concrete structures. General rules. Structural fire design |

| BS EN 1992-3 | Eurocode 2. Design of concrete structures. Liquid retaining and containing structures |

| BS EN 752 | Drain and sewer systems outside buildings. Sewer system management |

| BS EN ISO 11600 | Building construction. Jointing products. Classification and requirements for sealants |

| CP 4 | Code of practice for foundations |

| CP 52 | Code of practice for automatic fire sprinkler system |

| CP 65-1 | Code of practice for structural use of concrete—Design and construction |

| EN 1997 | Geotechnical design |

| SS 150 | Specification for emulsion paint for decorative purposes |

| SS 509-1 | Code of practice for cleaning and surface repair of buildings—Part 1: Cleaning of natural stone, brick, terracotta, concrete and rendered finishes |

| SS 542 | Code of practice for painting of buildings |

| SS 608 | Code of practice for gas installation |

| SS 637 (formerly CP 82) | Code of practice for waterproofing of reinforced concrete buildings |

| SS EN 12620 | Specification for aggregates for concrete |

| SS EN 1992-1-1 | Eurocode 2: Design of concrete structures, Part 1.1 General rules and rules for buildings |

| SS EN 1992-1-2 | Eurocode 2: Design of concrete structures, Part 1.2 General rules—Structural fire design |

| Normative References/Standards Referred to for Wet Areas in Table 5, Table 6 and Table 7 | |

| ANSI A118.15 | American National Standard Specifications for Improved Modified Dry-Set Cement Mortar (improved modified mortar) |

| AS 3740 | Waterproofing of domestic wet areas |

| ASTM C1400-11 | Standard Guide for Reduction of Efflorescence Potential in New Masonry Walls |

| BS 5385-1 | Wall and floor tiling. Design and installation of ceramic, natural stone and mosaic wall tiling in normal internal conditions. Code of practice |

| BS 5385-3 | Wall and floor tiling. Design and installation of internal and external ceramic and mosaic floor tiling in normal conditions. Code of practice |

| BS 6093 | Design of joints and jointing in building construction. Guide |

| BS 6150 | Painting of buildings. Code of practice |

| BS 6270-3 | Code of practice for cleaning and surface repair of buildings. Metals (cleaning only) |

| BS 8000-0 | Workmanship on construction sites. Introduction and general principles |

| BS 8000-11 | Workmanship on building sites. Internal and external wall and floor tiling. Ceramic and agglomerated stone tiles, natural stone and terrazzo tiles and slabs, and mosaics. Code of practice |

| BS 8000-9 | Workmanship on building sites. Cementitious levelling screeds and wearing screeds. Code of practice |

| BS 812-109 | Testing aggregates. Methods for determination of moisture content |

| BS 8204-1 | Screeds, bases and in situ floorings. Concrete bases and cementitious levelling screeds to receive floorings. Code of practice |

| BS 8204-2 | Screeds, bases and in situ floorings. Concrete wearing surfaces. Code of practice |

| BS 8210 | Guide to facilities maintenance management |

| BS 8215 | Code of practice for design and installation of damp-proof courses in masonry construction |

| BS 8221-1 | Code of practice for cleaning and surface repair of buildings. Cleaning of natural stone, brick, terracotta and concrete |

| BS 8221-2 | Code of practice for cleaning and surface repair of buildings. Surface repair of natural stones, brick and terracotta |

| BS 8542 | Calculating domestic water consumption in non-domestic buildings. Code of practice |

| BS 8554 | Code of practice for the sampling and monitoring of hot and cold water services in buildings |

| BS 8595 | Code of practice for the selection of water reuse systems |

| BS EN 12004-1 | Adhesives for ceramic tiles. Requirements, assessment and verification of constancy of performance, classification and marking |

| BS EN 12056-2 | Gravity drainage systems inside buildings. Sanitary pipework, layout and calculation |

| BS EN 1504-5 | Products and systems for the protection and repair of concrete structures. Definitions, requirements, quality control and evaluation of conformity. Concrete injection |

| BS EN 1992-1-1 | Eurocode 2: Design of concrete structures. General rules and rules for buildings |

| BS EN 1992-3 | Eurocode 2. Design of concrete structures. Liquid retaining and containing structures |

| BS EN 771-1 | Specification for masonry units. Clay masonry units |

| BS EN ISO 12944-4 | Paints and varnishes. Corrosion protection of steel structures by protective paint systems. Types of surface and surface preparation |

| BS EN ISO 1513 | Paints and varnishes. Examination and preparation of test samples |

| BS ISO 10880 | Non-destructive testing. Infrared thermographic testing. General principles |

| CP 68 | Code of practice for ceramic wall and floor tiling |

| ISO 10545-1 | Ceramic tiles—Part 1: Sampling and basis for acceptance |

| ISO 13006 | Ceramic tiles—Definitions, classification, characteristics and marking |

| ISO 13007-1 | Ceramic tiles—Grouts and adhesives—Part 1: Terms, definitions and specifications for adhesives |

| ISO 13007-5 | Ceramic tiles—Grouts and adhesives—Part 5: Requirements, test methods, evaluation of conformity, classification and designation of liquid-applied waterproofing membranes for use beneath ceramic tiling bonded with adhesives |

| ISO 28841 | Guidelines for simplified seismic assessment and rehabilitation of concrete buildings |

| ISO 4356 | Bases for the design of structures—Deformations of buildings at the serviceability limit states |

| SS 509-1 | Code of practice for cleaning and surface repair of buildings—Part 1: Cleaning of natural stone, brick, terracotta, concrete and rendered finishes |

| SS 509-2 | Code of practice for cleaning and surface repair of buildings—Surface repair of natural stones, brick, terracotta and rendered finishes |

| SS 542 | Code of practice for painting of buildings |

| SS 637 (formerly CP 82) | Code of practice for waterproofing of reinforced concrete buildings |

| SS EN 1992-1-1 | Eurocode 2: Design of concrete structures, Part 1.1 General rules and rules for buildings |

| SS EN 934-2 | Admixtures for concrete, mortar and grout—Part 2: Definitions, requirements—Concrete admixtures—Definitions, requirements, conformity, marking and labelling |

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Chew, M.Y.L. Maintainability of Facilities—Green FM for Building Professionals, 2nd ed.; World Scientific: Singapore, 2016. [Google Scholar]

- Chew, M.Y.L.; Ashan, A.; Conejos, S. Design for Maintainability; World Scientific: Singapore, 2018. [Google Scholar]

- Building and Construction Authority. Waterproofing for Internal Wet Areas, 2nd ed.; Building and Construction Authority (BCA): Singapore, 2003.

- Public Utilities Board. Code of Practice on Surface Water Drainage; Public Utilities Board (PUB): Singapore, 2013.

- Public Utilities Board. Flood Protection Measures, Flood Management. 2016. Available online: www.pub.gov.sg/drainage/floodmanagement/floodprotectionmeasures (accessed on 26 January 2021).

- Public Utilities Board. Managing Urban Runoff—Drainage Handbook, 1st ed.; Public Utilities Board (PUB): Singapore, 2013.

- Building and Construction Authority. Good Industry Practices—Waterproofing for External Wall, 2nd ed.; Building and Construction Authority (BCA): Singapore, 2004.

- Building and Construction Authority. CONQUAS® The BCA Construction Quality Assessment System, 9th ed.; Building and Construction Authority (BCA): Singapore, 2017.

- Land Transport Authority. Materials and Workmanship Specification for Architectural Work; Land Transport Authority (LTA): Singapore, 2009.

- Singapore Green Building Council Green Certification for Products. Available online: www.sgbc.sg (accessed on 26 January 2021).

- Public Utilities Board. Code of Practice on Surface Water Drainage, 7th ed.; Public Utilities Board (PUB): Singapore, 2018.

- Land Transport Authority. Civil Design Criteria; Land Transport Authority (LTA): Singapore, 2010.

- Building and Construction Authority. Precast Concrete Elements; Building and Construction Authority (BCA): Singapore, 2006.

- Housing and Development Board. Ceiling Leaks, Home Care Guide. 2017. Available online: www.hdb.gov.sg/cs/infoweb/residential/living-in-an-hdb-flat/home-maintenance/ceiling-leaks (accessed on 22 January 2021).

- Housing and Development Board. Spalling Concrete; Home Care Guide; Housing and Development Board (HDB): Singapore, 2017.

- Building and Construction Authority. Good Industry Practices—Painting, 2nd ed.; Building and Construction Authority (BCA): Singapore, 2004.

- Building and Construction Authority. Design and Material Selection for Quality; Building and Construction Authority (BCA): Singapore, 2009; Volume 2.

- Building and Construction Authority. Marble & Granite Finishes, 2nd ed.; Building and Construction Authority (BCA): Singapore, 2003.

- Building and Construction Authority. Ceramic Tiling, 2nd ed.; Building and Construction Authority (BCA): Singapore, 2003.

- Building and Construction Authority. Design and Material Selection for Quality; Building and Construction Authority (BCA): Singapore, 2008; Volume 1.

- Public Utilities Board. Plumbing Works. Water Supply. 2016. Available online: https://www.pub.gov.sg/watersupply/plumbingworks (accessed on 22 March 2017).

- Building and Construction Authority. Prefabricated Bathroom Unit (PBU); Building and Construction Authority (BCA): Singapore, 2014.

- Restroom Association. A Guide to Better Public Toilet Design and Maintenance, 3rd ed.; Restroom Association: Singapore, 2013. [Google Scholar]

- Public Utilities Board. Code of Practice on Sewerage and Sanitary Works, 2nd ed.; Public Utilities Board (PUB): Singapore, 2019.

- Chew, M.Y.L.; Egodage, N.D.D.S.; Tan, S.S. A neural network approach to assessing building facade maintainability in the tropics. Constr. Manag. Econ. 2004, 22, 581–594. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Egodage, N.D.D.S. Factorial Method for Performance Assessment of Building Facades. J. Constr. Eng. Manag. 2004, 130, 525–533. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).