Fire Resistance Behaviour of Geopolymer Concrete: An Overview

Abstract

:1. Introduction

2. Methodology

3. Impact of Fire on Concrete

3.1. Physico-Chemical Modifications

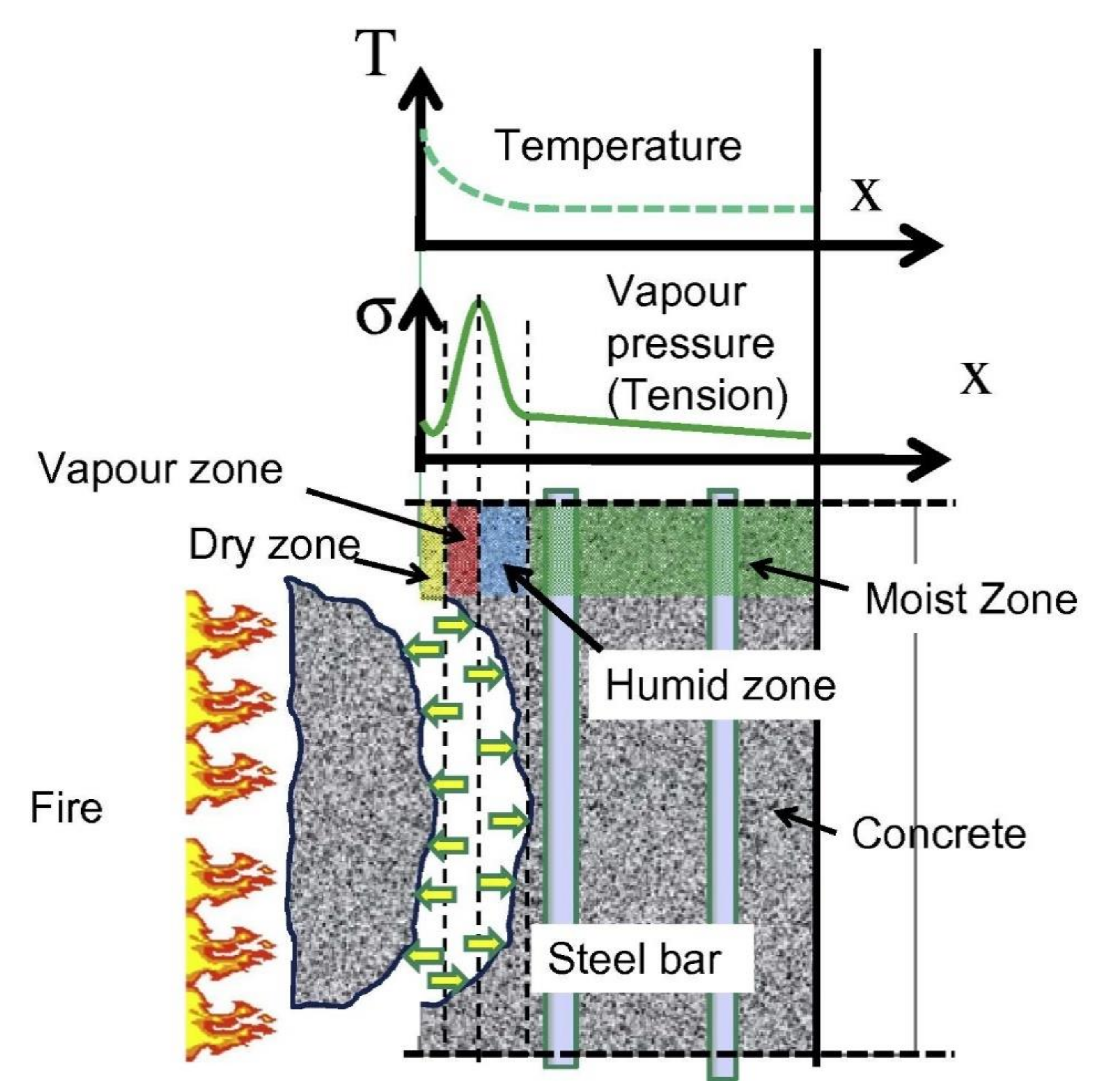

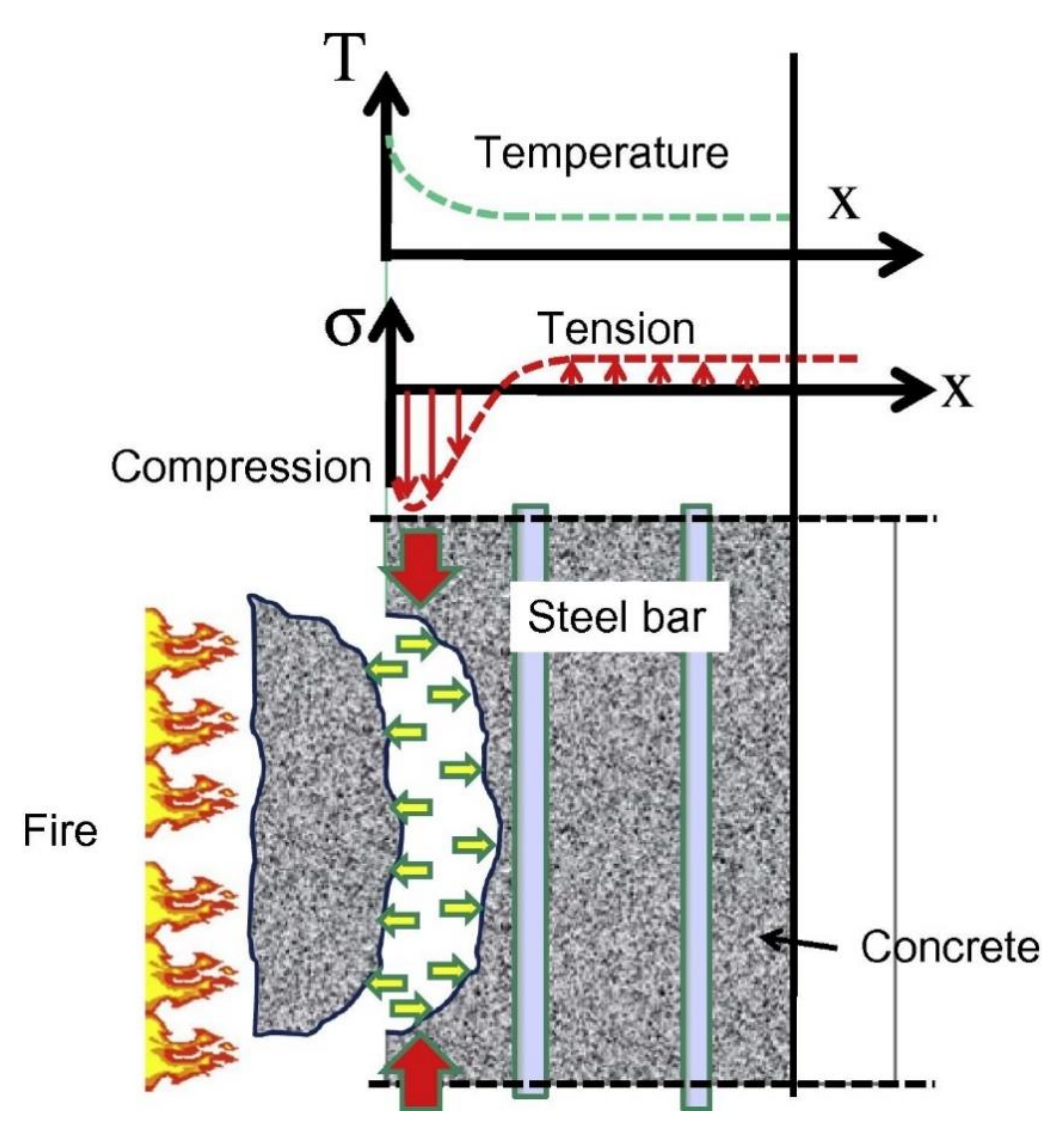

3.2. Spalling of Concrete

4. Post-Fire Properties

4.1. Residue Compressive Strength

4.2. Post-Heating Visual Observation of Samples

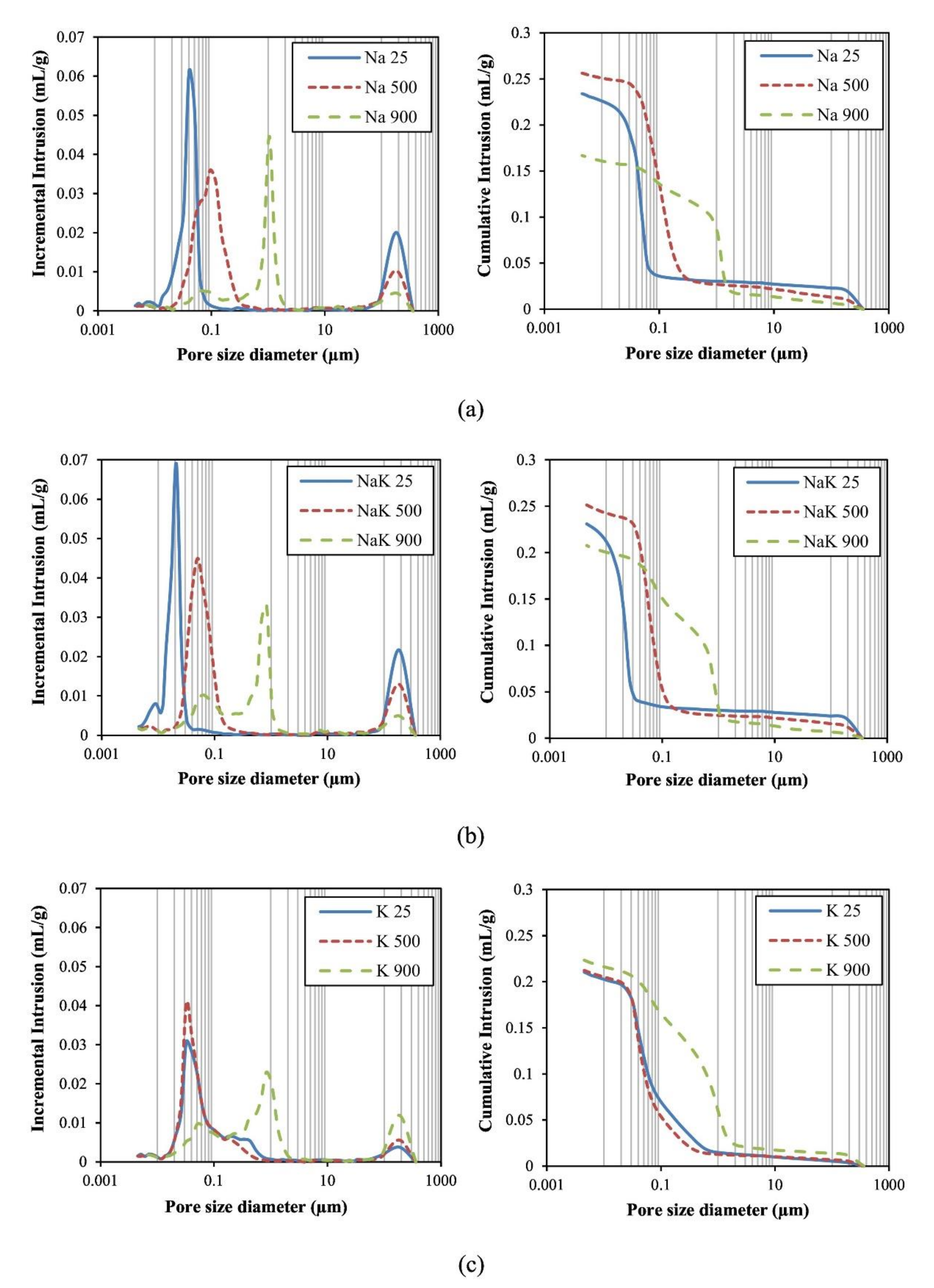

4.3. Pore Structure

4.4. Flexural Behaviour

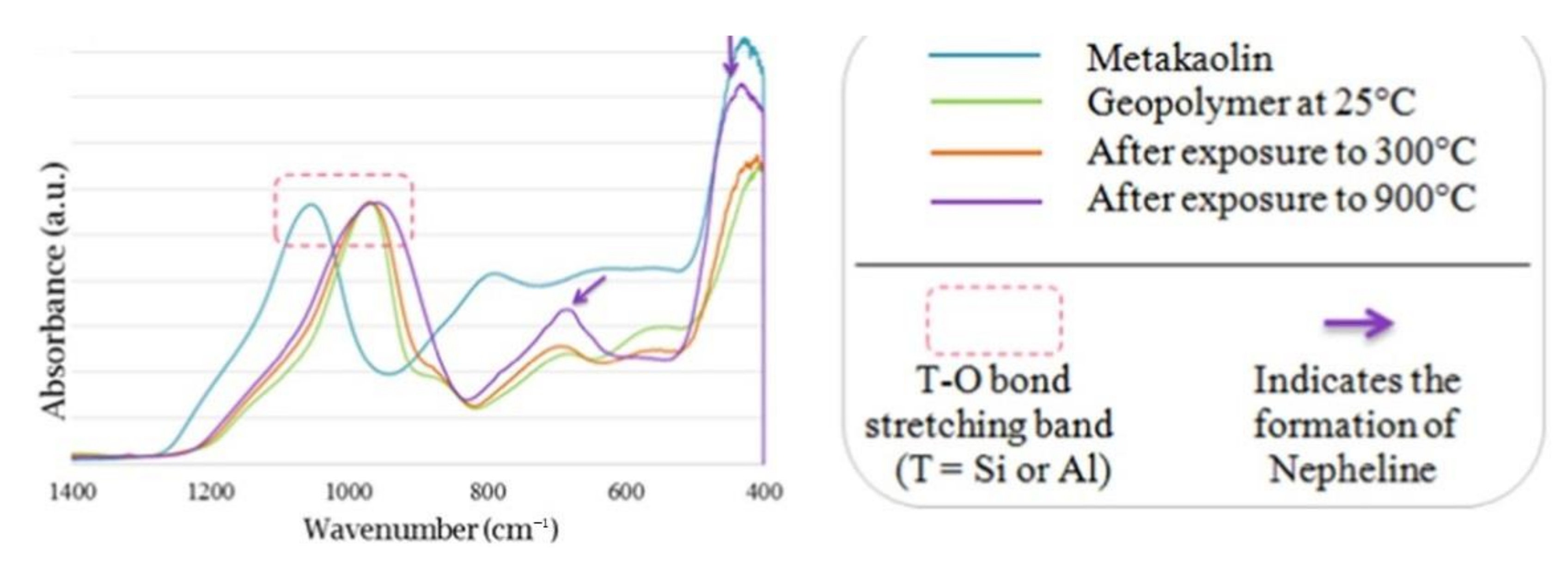

4.5. Chemical Stability

4.6. Volume Stability, Mass Loss and Shrinkage

4.7. Sustainability and Stability of Geopolymer Composite

4.8. Impact of Thermal Creep on Compressive Strength

4.9. Elastic Modulus

4.10. Stress-Strain Behaviour

4.11. Progression of Adhesion Bonding

5. Life Cycle Assessment

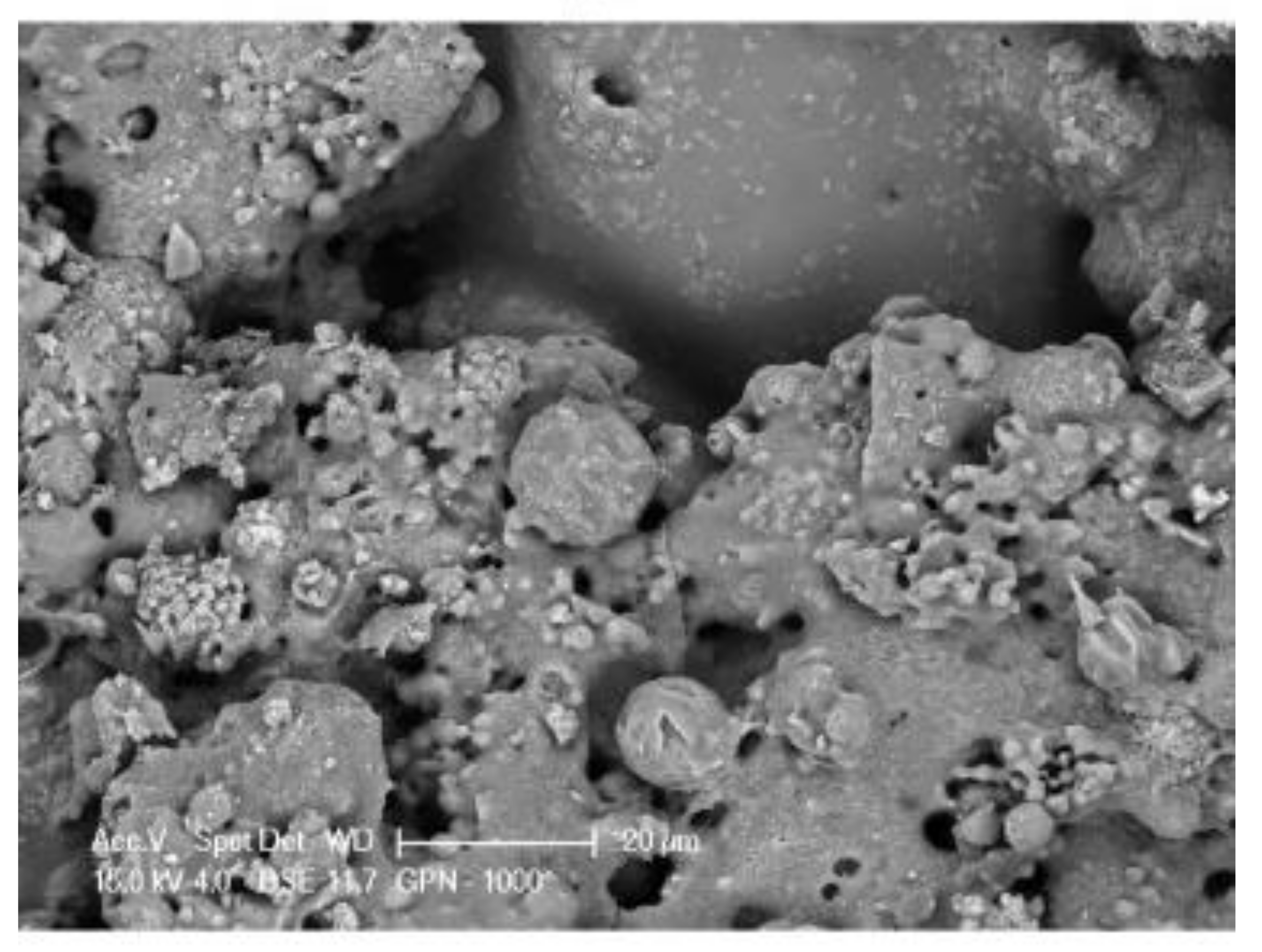

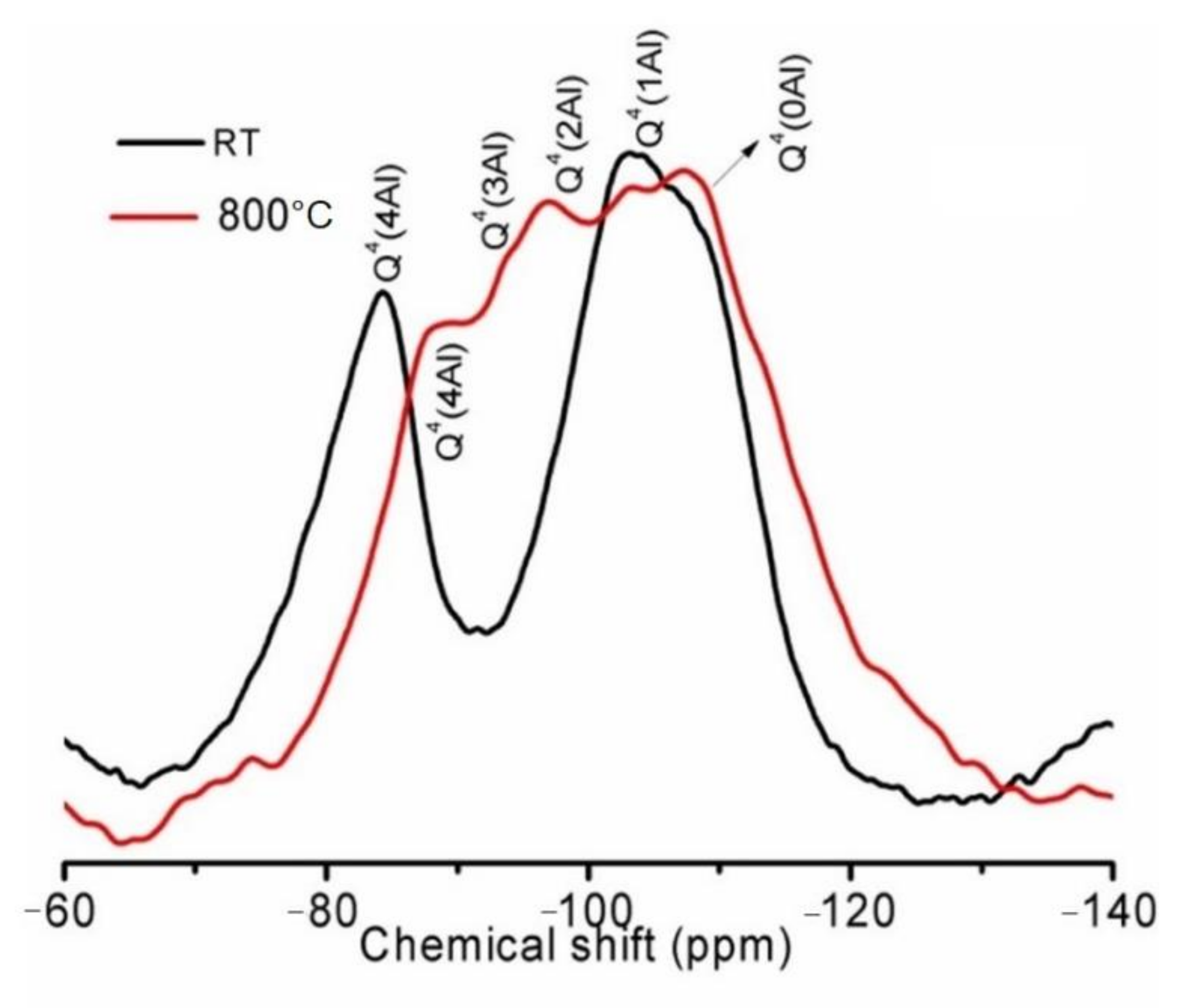

6. Micro-Structural Behaviour

7. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Wang, S.-D.; Pu, X.-C.; Scrivener, K.L.; Pratt, P.L. Alkali-activated slag cement and concrete: A review of properties and problems. Adv. Cem. Res. 1995, 7, 93–102. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Institut Géopolymère: Saint-Quentin, France, 2008. [Google Scholar]

- Duxson, P.; Fernandez-Jimenez, A.; Provis,, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Thermal resistance of fly ash based rubberized geopolymer concrete. J. Build. Eng. 2018, 19, 420–428. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Z.; Zhang, Y. Development of sustainable cementitious materials. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 55–76. [Google Scholar]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Panias, D.; Sakkas, K. The Valorisation of Glass Wastes for the Development of Geopolymer Composites–Mechanical Properties and Rheological Characteristics: A Review. Constr. Build. Mater. 2019, 220, 547–564. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Nicolaides, D.; Panias, D.; Sakkas, K. The Valorisation of Glass Wastes for the Development of Geopolymer Composites–Durability Properties: A Review. Constr. Build. Mater. 2019, 222, 676–687. [Google Scholar] [CrossRef]

- Łach, M.; Mikuła, J.; Lin, W.T.; Bazan, P.; Figiela, B.; Korniejenko, K. Development and characterization of thermal insulation geopolymer foams based on fly ash. Proc. Eng. Technol. Innov. 2020, 16, 23–29. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Durability Properties of Green Concrete Incorporating Various Waste: A Review. J. Mater. Eng. Struct. 2019, 6, 469–484. [Google Scholar]

- Luhar, S.; Dave, U. Investigations on mechanical properties of fly ash and slag based geopolymer Concrete. Indian Concr. J. 2016, 5, 34–41. [Google Scholar]

- Hýsek, Š.; Frydrych, M.; Herclík, M.; Louda, P.; Fridrichová, L.; Le Van, S. Le Chi, H. Fire-Resistant Sandwich-Structured Composite Material Based on Alternative Materials and Its Physical and Mechanical Properties. Materials 2019, 12, 1432. [Google Scholar] [CrossRef] [Green Version]

- Luhar, S.; Agrawal, P.; Goswami, S.; Chaudhary, S. Strength Property of Rice Husk Based Geopolymer Mortar. Indian Concr. J. 2018, 92. [Google Scholar]

- Luhar, S.; Luhar, I. Application of artificial neural network for predicting compressive strength of geopolymer concrete. Indian Concr. J. 2019, 93, 38–43. [Google Scholar]

- Peng, X.; Li, H.; Shuai, Q.; Wang, L. Fire Resistance of Alkali Activated Geopolymer Foams Produced from Metakaolin and Na2O2. Materials 2020, 13, 535. [Google Scholar] [CrossRef] [Green Version]

- Luhar, S.; Luhar, I. Effect of different variables on fly ash based geopolymer concrete. Indian Concr. J. 2020, 94, 62–68. [Google Scholar]

- Luhar, S.; Luhar, I. Microstructural and strength behaviour of fly ash based geopolymer mortar. Int. J. Recent Technol. Eng. 2020, 8, 420–428. [Google Scholar]

- Fernandez-Jimenez, A.; Palomo, A. Engineering properties of alkali-activated fly ash concrete. ACI Mater. J. 2006, 103, 106–112. [Google Scholar]

- Davidovits, J. High-alkali cements for 21st century concretes. ACI Spec. Publ. SP 1994, 144, 383–398. [Google Scholar]

- Fernandez-Jimenez, A.; Palomo, J.G.; Puertas, F. Alkali activated slag mortars: Mechanical strength behaviour. Cem. Concr. Res. 1999, 29, 1313–1321. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y. Alkali activation of Australian slag cements. Cem. Concr. Res. 1999, 29, 113–120. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Strength of rubberized geopolymer concrete: Application of Taguchi method for effect of different factors. Int. J. Recent Technol. Eng. 2020, 8. [Google Scholar]

- Luhar, S.; Luhar, I. Carbonation and Microstructural Studies of Fly Ash Based Geopolymer Mortar. Int. J. Recent Technol. Eng. 2020, 8. [Google Scholar]

- Luhar, S.; Luhar, I. Application of Seawater and Sea Sand to Develop Geopolymer Composites. Int. J. Recent Technol. Eng. 2020, 8. [Google Scholar]

- Luhar, S.; Luhar, I. Additive Manufacturing in the Geopolymer Construction Technology: A Review. Open Constr. Build. Technol. J. 2020, 14, 150–165. [Google Scholar] [CrossRef]

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and Starch—Alternative Binders for Bio-Based Building Materials: A Review and Life-Cycle Assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Gupta, R. Durability performance evaluation of green geopolymer concrete. Eur. J. Environ. Civ. Eng. 2020, 1–49. [Google Scholar] [CrossRef]

- Luhar, S.; Rajamane, N.P.; Corbu, O.; Luhar, I. Impact of incorporation of volcanic ash on geopolymerization of eco-friendly geopolymer composites: A review. In Proceedings of the International Conference on Innovative Research—ICIR EUROINVENT, Iasi, Romania, 16–17 May 2019; IOP Publishing: Bristol, UK, 2019; p. 012001. [Google Scholar]

- Lin, K.Y.; Lee, W.H.; Cheng, T.W.; Luhar, S.; Wu, C.-C.; Hsu, T.-K. Geopolymer system for the stabilization of Basic Oxygen Furnace Slag. In Proceedings of the 15th International Symposium on East Asian Resources Recycling Technology (EARTH 2019), South Korea, 13–17 October 2019. [Google Scholar]

- Sanjayan, J.G.; Stocks, L.J. Spalling of high-strength silica fume concrete in fire. ACI Mater. J. 1993, 90, 170–173. [Google Scholar]

- Crozier, D.A.; Sanjayan, J.G. Chemical and physical degradation of concrete at elevated temperatures. Concr. Aust. 1999, 25, 18–20. [Google Scholar]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. Thermal evolution of metakaolin geopolymers: Part 1—physical evolution. J. Non Cryst. Solids 2006, 352, 5541–5555. [Google Scholar] [CrossRef]

- Barbosa, V.F.F.; MacKenzie, K.J.D. Synthesis and thermal behaviour of potassium sialate geopolymers. Mater. Lett. 2003, 57, 1477–1482. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. The thermal evolution of metakaolin geopolymers: Part 2—Phase stability and structural development. J. Non Cryst. Solids 2007, 353, 2186–2200. [Google Scholar] [CrossRef]

- Krivenko, P.V.; Kovalchuk, G.Y. Directed synthesis of alkaline aluminosilicate minerals in a geocement matrix. J. Mater. Sci. 2007, 42, 2944–2952. [Google Scholar] [CrossRef]

- Barbosa, V.F.F.; MacKenzie, K.J.D. Thermal behaviour of inorganic geopolymers and composites derived from sodium poLysialate. Mater. Res. Bull. 2003, 38, 319–331. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Al-bakri, A.M.M.; Kamarudin, H.; Nizar, I.K.; Saif, A.A. Effects of elevated temperatures on the thermal behaviour and mechanical performance of fly ash geopolymer paste, mortar and light weight concrete. Constr. Build. Mater. 2014, 50, 337–387. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Temuujin, J.; van-Riessen, A. Thermal analysis of geopolymer pastes synthesized from five fly ashes of variable compositions. J. Non Cryst. Solids 2012, 358, 1830–1839. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- Nayaka, R.R.; Alengaram, U.J.; Jumaat, M.Z.; Yusoff, S.B.; Alnahhal, M.F. High volume cement replacement by environmental friendly industrial by-product palm oil clinker powder in cement–lime masonry mortar. J. Clean. Prod. 2018, 190, 272–284. [Google Scholar] [CrossRef]

- Bakharev, T. Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperatures curing. Cem. Concr. Res. 2006, 36, 1134–1147. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsile, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Guerrieri, M.; Sanjayan, J.G. Behaviour of combined fly ash/slag based geopolymers when exposed to high temperatures. Fire Mater. 2010, 34, 163–175. [Google Scholar]

- Rickard, W.D.A.; Vickers, L.; van Riessen, A. Performance of fibre reinforced, lowdensity metakaolin geopolymers under simulated fire conditions. Appl. Clay Sci. 2013, 73, 71–77. [Google Scholar] [CrossRef]

- Giancaspro, J.; Balaguru, P.N.; Lyon, R.E. Use of inorganic polymer to improvethe fire response of balsa sandwich structures. J. Mater. Civ. Eng. 2006, 18, 390–397. [Google Scholar] [CrossRef]

- Lyon, R.E.F.; Foden, A.J.; Balaguru, P.; Davidovits, J.; Davidovits, M. Properties of geopolymer matrix in carbon fibre composites. In Proceedings of the 2nd International Conference Geopolymere, Geopolymer Institute, Saint-Quentin, France, 1–2 July 1999; pp. 67–73. [Google Scholar]

- Davidovits, J. Fireproof geopolymeric cements. In Proceedings of the 2nd International Conference Geopolymere, Geopolymer Institute, Saint-Quentin, France, 30 June–2 July 1999; pp. 165–169. [Google Scholar]

- Liefke, E. Industrial applications of foamed inorganic polymers. In Proceedings of the 2nd International Conference Geopolymere, Geopolymer Institute, Saint-Quentin, France, 1–2 July 1999; pp. 189–199. [Google Scholar]

- Büchler, C. Fire safety in industrial buildings and nuclear power plants with airfilters made of geopolymer composite. In Proceedings of the 2nd International Conference Geopolymere, Geopolymer Institute, Saint-Quentin, France, 1–2 July 1999; pp. 181–188. [Google Scholar]

- Messina, F.; Ferone, C.; Colangelo, F.; Roviello, G.; Cioffi, R. Alkali activated waste fly ash as sustainable composite: Influence of curing and pozzolanic admixtures on the early-age physico-mechanical properties and residual strength after exposure at elevated temperature. Compos. Part B Eng. 2018, 132, 161–169. [Google Scholar] [CrossRef]

- Gourley, J.T.; Johnson, G.B. Developments in geopolymer precast concrete. In Proceedings of the World Congress Geopolymer, Geopolymer Institute, Saint-Quentin, France, 28 June–1 July 2005; pp. 139–143. [Google Scholar]

- Perera, D.S.; Trautman, R.L. Geopolymers with the potential for use as refractory Castables. Adv. Technol. Mater. Mater. Process. 2005, 7, 187–190. [Google Scholar]

- Kamseu, E.; Rizzuti, A.; Leonelli, C.; Perera, D. Enhanced thermal stability in K2O-metakaolin-based geopolymer concretes by Al2O3 and SiO2 fillers addition. J. Mater. Sci. 2010, 45, 1715–1724. [Google Scholar] [CrossRef]

- Temuujin, J.; Rickard, W.; Lee, M.; van Riessen,, A. Preparation and thermal properties of fire resistant metakaolin-based geopolymer-type coatings. J. Non Cryst. Solids 2011, 357, 1399–1404. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; van Riessen, A. Performance of solid and cellular structured fly ash geopolymers exposed to a simulated fire. Cem. Concr. Compos. 2014, 48, 75–82. [Google Scholar] [CrossRef]

- Sakkas, K.; Nomikos, P.; Sofianos, A.; Panias, D. Inorganic polymeric materials for passive fire protection of underground constructions. Fire Mater. 2013, 37, 140–150. [Google Scholar] [CrossRef]

- Whittaker, E.J.W.; Muntus, R. Ionic radii for use in geochemistry. Geochim. Cosmochim. Acta 1970, 34, 945–956. [Google Scholar] [CrossRef]

- Huang, L.; Kieffer, J. Structural origin of negative thermal expansion in high-temperature silica polymorphs. Phys. Rev. Lett. 2005, 95, 215901. [Google Scholar] [CrossRef]

- Zuda, L.; Černý, R. Measurements of linear thermal expansion coefficient of alkali-activated aluminosilicate composites up to 1000 °C. Cem. Concr. Compos. 2009, 31, 263–267. [Google Scholar] [CrossRef]

- Konon, M.Y.; Stolyar, S.V.; Dikaya, L.F.; Polyakova, I.G.; Drozdova, I.A.; Antropova, T.V. Physicochemical properties of glasses of the Na2O–B2O3–SiO2–Fe2O3 system in the 8Na2O/70SiO2 section 1. Glas. Phys. Chem. 2015, 41, 116–121. [Google Scholar] [CrossRef]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Lyon, R.E.; Balaguru, P.N.; Foden, A.; Sorathia, U.; Davidovits, J.; Davidovics, M. Fire resistant aluminosilicate composites. Fire Mater. 1997, 21, 67–73. [Google Scholar] [CrossRef]

- Kong, D.; Sanjayan, J.; Sagoe-Crentsil, K. Factors affecting the performance of metakaolin geopolymers exposed to elevated temperatures. J. Mater. Sci. 2008, 43, 824–831. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali activated slag (Si+Ca) and Metakaolin (Si+Al) cement. Cem. Concr. Res. 2005, 40, 1341–1349. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Palomo, A.; Criado, M. Microstructure development of alkali activated fly ash cement, a descriptive model. Cem. Concr. Res. 2005, 35, 120–126. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, J.G.; Lee, N.K.; Lee, H.K. Physiochemical properties of binder gel in alkali activated fly ash/slag exposed to high temperature. Cem. Concr. Res. 2016, 89, 72–79. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behaviour of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- Bernal, S.; Rodríguez, E.; Mejía de Gutiérrez, R.; Gordillo, M.; Provis, J. Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/ slag blends. J. Mater. Sci. 2011, 46, 5477–5486. [Google Scholar] [CrossRef]

- Lahoti, M.; Yang, E.-H.; Tan, K.H. Developments in Strategic Ceramic Materials II. In Influence of Mix Design Parameters on Geopolymer Mechanical Properties and Microstructure; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 21–33. [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; van Deventer, J.S.J. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Subaer, A.; van Riessen, A. Thermo-mechanical and microstructural characteri-sation of sodium-poly(sialate-siloxo) (Na-PSS) geopolymers. J. Mater. Sci. 2007, 42, 3117–3123. [Google Scholar] [CrossRef]

- Lin, T.S.; Jia, D.C.; He, P.G.; Wang, M.R. Thermomechanical and microstructural characterisation of geopolymers with alpha alumina particulate filler. Int. J. Thermophys. 2009, 30, 1568–1577. [Google Scholar] [CrossRef]

- Bell, J.; Gordon, M.; Kriven, W.M.; Comrie, D. Graphite fiber reinforced geopoly-mer molds for near net shape casting of molten diferrous silicide, conferencepaper. In Proceedings of the Workshop on Geopolymers and Geopolymer Concrete, Perth, Western Australia, 28–29 September 2005; p. 12. [Google Scholar]

- Silva, F.J.; Mathias, A.F.; Thaumaturgo, C. Evaluation of the fracture toughnessin poly(sialate-siloxo) composite matrix, conference paper. Geopolymer 1999, 99, 97–106. [Google Scholar]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. Physical evolution of Na-geopolymer derived from metakaolin up to 1000 °C. J. Mater. Sci. 2007, 42, 3044–3054. [Google Scholar] [CrossRef]

- He, P.; Jia, D.; Wang, M.; Zhou, Y. Thermal evolution and crystallization kinetics of potassium-based geopolymer. Ceram. Int. 2011, 37, 59–63. [Google Scholar] [CrossRef]

- Vidal, L.; Joussein, E.; Colas, M.; Absi, J.; Rossignol, S. Effect of the addition of ammonium molybdate on metakaolin-based geopolymer formation: Shrinkage and crystallization. Powder Technol. 2015, 275, 211–219. [Google Scholar] [CrossRef]

- Kuenzel, C.; Li, L.; Vandeperre, L.; Boccaccini, A.R.; Cheeseman, C.R. Influence of sand on the mechanical propeties of metakaolin geopolymers. Constr. Build. Mater. 2014, 66, 442–446. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.J.; Zhou, W.; Luo, W.J.; Shen, C.H. An investigation of the microstructure and durability of a fluidized bed fly ash-metakaolin geopolymer after heat and acid exposure. Mater. Des. 2015, 74, 125–137. [Google Scholar] [CrossRef]

- Samal, S.; Thanh, N.P.; Petríková, I.; Marvalová, B. Improved mechanical properties of various fabric-reinforced geocomposites at elevated temperature. J. Met. 2015, 67, 1478–1485. [Google Scholar]

- Sarker, P.K.; Kelly, S.; Yao, Z.T. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Tugnoli, A.; Moricone, R.; Scarponi, G.E.; Cozzani, V. Effective thermal conductivity of fibrous fireproofing materials. Int. J. Therm. Sci. 2019, 136, 107–120. [Google Scholar] [CrossRef]

- Suvorov, S.A.; Skurikhin, V.V. Vermiculite—A promising material for high-temperature heat insulators. Refract. Ind. Ceram. 2003, 44, 186–193. [Google Scholar] [CrossRef]

- Murri, N.A.; Rickard, W.D.A.; Bignozzi, M.C.; van Riessen, A. High temperature behaviour of ambient cured alkali-activated materials based on ladle slag. Cem. Concr. Res. 2013, 43, 51–61. [Google Scholar] [CrossRef]

- Mohamedbhai, G.T.G. Effect of exposure time and rates of heating and cooling on residual strength of heated concrete. Mag. Concr. Res. 1986, 38, 151–158. [Google Scholar] [CrossRef]

- Heikal, M. Effect of temperature on the physico-mechanical and mineralogical properties of homra pozzolanic cement pastes. Cem. Concr. Res. 2000, 30, 1835–1839. [Google Scholar] [CrossRef]

- Khoury, G.A.; Grainger, B.N.; Sullivan, P.J.E. Strain of concrete during fast cooling form 600 °C under load. Mag. Concr. Res. 1986, 38, 3–12. [Google Scholar] [CrossRef]

- Li, Z.; Xu, J.; Bai, E. Static and dynamic mechanical properties of concrete after high temperature exposure. Mater. Sci. Eng. A 2012, 544, 27–32. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage due to elevated temperatures in metakaolinite-based geopolymer pastes. In Proceedings of the International Workshop on Geopolymer and Geopolymer Concrete, Perth, Australia, 28–29 September 2005. [Google Scholar]

- Papayianna, I.; Valliasis, T. Heat deformations of fly ash concrete. Cem. Concr. Comp. 2005, 27, 249–254. [Google Scholar] [CrossRef]

- Poon, C.S.; Azhar, S.; Anson, M.; Wong, Y.L. Performance of metakaolin concrete at elevated temperatures. Cem. Concr. Comp. 2003, 25, 83–89. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.; Rangan, B. An investigation of the mechanisms for strength gain or loss of geopolymer mortar after exposure to elevated temperature. J. Mater. Sci. 2009, 44, 1873–1880. [Google Scholar] [CrossRef] [Green Version]

- Khoury, G.A. Effect of fire on concrete and concrete structures. Fire Concr. 2000, 2, 429–447. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Wang, Y.; Yan, F. Preparation of macroporous ceramic from metakaolinite-based geopolymer by calcination. Ceram. Int. 2015, 41, 11177–11183. [Google Scholar] [CrossRef]

- Temuujin, J.; Rickard, W.; Van Riessen, A. Characterization of various fly ashes for preparation of geopolymers with advanced applications. Adv. Powder Technol. 2013, 24, 495–498. [Google Scholar] [CrossRef]

- Zhang, H.; Kodur, V.; Bo, W.U.; Wang, C.F. Thermal behaviour and mechanical properties of geopolymer mortar after exposure to elevated temperatures. Constr. Build. Mater. 2016, 109, 17–24. [Google Scholar] [CrossRef]

- Temuujin, J.; Williams, R.P.; Van Riessen, A. Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J. Mater. Process. Technol. 2009, 209, 5276–5280. [Google Scholar] [CrossRef]

- Fan, F.; Guoji, X.U.; Peng, H.; Cai, C.S. Mechanical and thermal properties of fly ash based geopolymers. Constr. Build. Mater. 2018, 160, 66–81. [Google Scholar] [CrossRef]

- Demirel, B.; Kelestemur, O. Effect of elevated temperature on the mechanical properties of concrete produced with finely ground pumice and silica fume. Fire Saf. J. 2010, 45, 385–391. [Google Scholar] [CrossRef] [Green Version]

- Hosan, A.; Haque, S.; Shaikh, F. Compressive behaviour of sodium and potassium activators synthetized fly ash geopolymer at elevated temperatures: A comparative study. J. Build. Eng. 2016, 8, 123–130. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W. Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cem. Concr. Compos. 2017, 78, 108–119. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Qi, S.L.; Cao, L.; Wua, B. Development of metakaolin–fly ash based geopolymers for fire resistance applications. Constr. Build. Mater. 2014, 55, 38–45. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Tan, K.H.; Yang, E.-H. Effect of alkali cation type on strength endurance of fly ash geopolymers subject to high temperature exposure. Mater. Des. 2018, 154, 8–19. [Google Scholar] [CrossRef]

- Samal, S. Effect of high temperature on the microstructural evolution of fiber reinforced geopolymer composite. Heliyon 2019, 5, e01779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, Z.; Sanjayan, G.J.; Collins, F. Effect of transient creep on compressive strength of geopolymer concrete for elevated temperature exposure. Cem. Concr. Res. 2014, 56, 182–189. [Google Scholar] [CrossRef]

- Lahoti, L.; Wong, K.K.; Yang, E.-H.; Tan, K.H. Effects of Si/Al molar ratio on strength endurance and volume stability of metakaolin geopolymers subject to elevated temperature. Ceram. Int. 2018, 44, 5726–5734. [Google Scholar] [CrossRef]

- Mathewa, G.; Joseph, B. Flexural behaviour of geopolymer concrete beams exposed to elevated temperatures. J. Build. Eng. 2018, 15, 311–317. [Google Scholar] [CrossRef]

- Kljajević, L.M.; Nenadović, S.S.; Nenadović, M.T.; Bundaleski, N.K.; Todorović, B.Ž.; Pavlović, V.B.; Rakočević, Z.L. Structural and chemical properties of thermally treated geopolymer samples. Ceram. Int. 2017, 43, 6700–6708. [Google Scholar] [CrossRef]

- Sivasakthi, M.; Jeyalakshmi, R.; Rajamane, N.P.; Rinu, J. Thermal and structural micro analysis of micro silica blended fly ash based geopolymer composites. J. Non Cryst. Solids 2018, 499, 117–130. [Google Scholar]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, C.; Cao, M.; Zhang, Y.; Azevedo, C. Influence of different fibers on the change of pore pressure of self-consolidating concrete exposed to fire. Constr. Build. Mater. 2016, 113, 456–469. [Google Scholar] [CrossRef] [Green Version]

- Vu, X.H.; Malecot, Y.; Daudeville, L.; Buzaud, E. Effect of the water/cement ratio on concrete behavior under extreme loading. Int. J. Numer. Anal. Meth. Geomech. 2009, 33, 1867–1888. [Google Scholar] [CrossRef]

- Shoukry, S.N.; William, W.G.; Downie, B.; Riad, M.Y. Effect of moisture and temperature on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 688–696. [Google Scholar] [CrossRef]

- Ichikawa, Y.; England, G.L. Prediction of moisture migration and pore pressure build-up in concrete at high temperatures. Nucl. Eng. Des. 2004, 228, 245–259. [Google Scholar] [CrossRef] [Green Version]

- Ozawa, M.; Uchida, S.; Kamada, T.; Morimoto, H. Study of mechanisms of explosive spalling in high-strength concrete at high temperatures using acoustic emission. Constr. Build. Mater. 2012, 37, 621–628. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G. Stress–strain behaviour and abrupt loss of stiffness of geopolymer at elevated temperatures. Cem. Concr. Compos. 2010, 32, 657–664. [Google Scholar] [CrossRef]

- Vickers, L.; Rickard, W.D.; van Riessen, A. Strategies to control the high temperature shrinkage of fly ash based geopolymers. Thermochim. Acta 2014, 580, 20–27. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Williams, R.; Temuujin, J.; van Riessen, A. Assessing the suitability of three Australian fly ashes as an aluminosilicate source for geopolymers in high temperature applications. Mater. Sci. Eng. A 2011, 528, 3390–3397. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, S.; Wang, Y.C.; Xu, D.L. Microstructural and strength evolutions of geopolymer composite reinforced by resin exposed to elevated temperature. J. Non Cryst. Solids 2012, 358, 620–624. [Google Scholar] [CrossRef]

- Sabbatini, A.; Vidal, L.; Pettinari, C.; Sobrados, I.; Rossignol, S. Control of shaping and thermal resistance of metakaolin-based geopolymers. Mater. Des. 2017, 116, 374–385. [Google Scholar] [CrossRef]

- Koleżyński, A.; Król, M.; Żychowicz, M. The structure of geopolymers—Theoretical studies. J. Mol. Struct. 2018, 1163, 465–471. [Google Scholar] [CrossRef]

- Barbosa, V.; McKenzie, K. Thermal behavior of inorganic polymers and composites derives from sodium polysialate. Mater. Res. Bull. 2003, 38, 319–331. [Google Scholar] [CrossRef]

- Dal Pozzo, A.; Carabba, L.; Bignozzi, M.C.; Tugnoli, A. Life cycle assessment of a geopolymer mixture for fireproofing applications. Int. J. Life Cycle Assess. 2019, 24, 1–15. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Pastor, J.Y.; Martin, A. New cementitious materials based on alkali-activated fly ash: Performance at high temperatures. J. Am. Ceram. Soc. 2008, 91, 3308–3314. [Google Scholar] [CrossRef] [Green Version]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. Evolution of gel structure during thermal processing of Na-geopolymer gels. Langmuir 2006, 22, 8750–8757. [Google Scholar] [CrossRef] [PubMed]

| Reference | Observations |

|---|---|

| Zhang et al. [98] | The geopolymer mortar manifests higher bending and tensile strength temperature degradation than OPC mortar, but inferior degradation in compressive and bond strength. |

| Hosan et al. [102] | The compressive strength is significantly improved with the Na2SiO3/NaOH ratio 3, where the residual compressive resistance is raised up to 600 °C. |

| Duan et al. [103] | The compressive resistance of geopolymers diminished during thermal cycles. The losses in mass and compressive strength amplified with rise in temperature. |

| Zhang et al. [104] | The geopolymer samples prepared with metakaolin and fly ash display analogous bending and compressive performance, both at ambient temperatures and after exposure to high temperatures as for OPC specimens. In practical building applications, geopolymers based on metakaolin and fly ash therefore deliver a viable alternate to traditional OPC. |

| Lahoti et al. [105] | The geopolymer with potassium was substantially amended (30–40%) as well as the geopolymer made with sodium was declined (10%) and after exposure to elevated temperatures, the strength of a mixed sodium and of a potassium geopolymer remained unaffected. |

| Kong and Sanjayan [43] | The research designates the two major features for geopolymer activity at a high temperature (800 °C) i.e., specimen and aggregate sizes. The size of aggregates greater than 10 mm lead to in healthier strength at low and high temperatures. The thermal instability between the geopolymer matrix and aggregates is the outcome of a heavy loss of geopolymer concrete at elevated temperatures. |

| Samal [106] | The geopolymers had a significant effect on thermal shrinkage decline as Si/Al ratios amplified due to trim down in porosity during the process of dehydroxylation as well as sintering. |

| Sarker et al. [83] | Following the fire exposures, less harm was observed to the geopolymer concrete samples as regards cracking than to the OPC concrete specimens. There was considerable spalling in the concrete cylinders of the OPC for exposures between 800 and 1000 °C though geopolymer concrete samples were not spalled. In particular, the samples of geopolymer concrete maintained higher strength than the specimens of OPC. |

| Pan et al. [107] | The strength of geopolymer was up by 192% at 550 °C in contrast to the original strength value, while the strength of OPC paste changed slightly. The percentage residual strength of both geopolymer and OPC concrete after exposure to 550 °C was nevertheless close. |

| Lahoti et al. [108] | Upon high-temperature exposure to 900 °C, all the geopolymer specimens experienced reduced compressive strength. While the geopolymer mixes disclosed strong chemical stability on a microscale, their volumes at mesoscale were poorly stable and thermal shrinking was extremely high. |

| Mathew and Joseph [109] | At ambient temperature, the deformation attributes of geopolymer concrete beams are identical to those of reinforced cement beams. The strain compatibility method, therefore, underestimates the deformation behaviour of strengthened geopolymer concrete beams when exposed to high temperatures. |

| Kljajević et al. [110] | Cross-linking of polymer changes in geopolymer samples at 600 °C reduces the number of bonding of Si-O-Na. Thermal action at 900 °C declines oxygen and articulated sodium significantly, following major morphological changes, i.e., the creation of a complex pore structure. |

| Sivasakthi et al. [111] | The geopolymer paste and mortar’s linear dimensional stability remnants unchanged until 800 °C. 10% of the addition of micro silica has more filling effect, thus growing compressive strength by damaging the integrity of the bulk specimen of geopolymer composites. |

| Luhar et al. [5] | The rubberized geopolymer concrete, loss of strength at elevated temperatures is only somewhat more than the control geopolymer concrete, due to the possible inconsistencies of the integral materials coefficients of thermal expansion. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. https://doi.org/10.3390/buildings11030082

Luhar S, Nicolaides D, Luhar I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings. 2021; 11(3):82. https://doi.org/10.3390/buildings11030082

Chicago/Turabian StyleLuhar, Salmabanu, Demetris Nicolaides, and Ismail Luhar. 2021. "Fire Resistance Behaviour of Geopolymer Concrete: An Overview" Buildings 11, no. 3: 82. https://doi.org/10.3390/buildings11030082

APA StyleLuhar, S., Nicolaides, D., & Luhar, I. (2021). Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings, 11(3), 82. https://doi.org/10.3390/buildings11030082