Comparison of Downdraught and Up Draft Passive Air Conduction Systems (PACS) in a Winery Building

Abstract

:1. Introduction

2. Materials and Methods

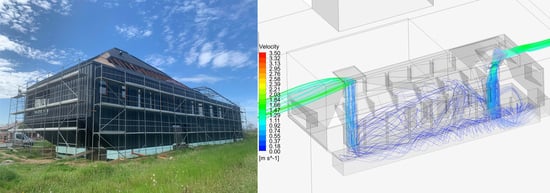

2.1. Building and Site

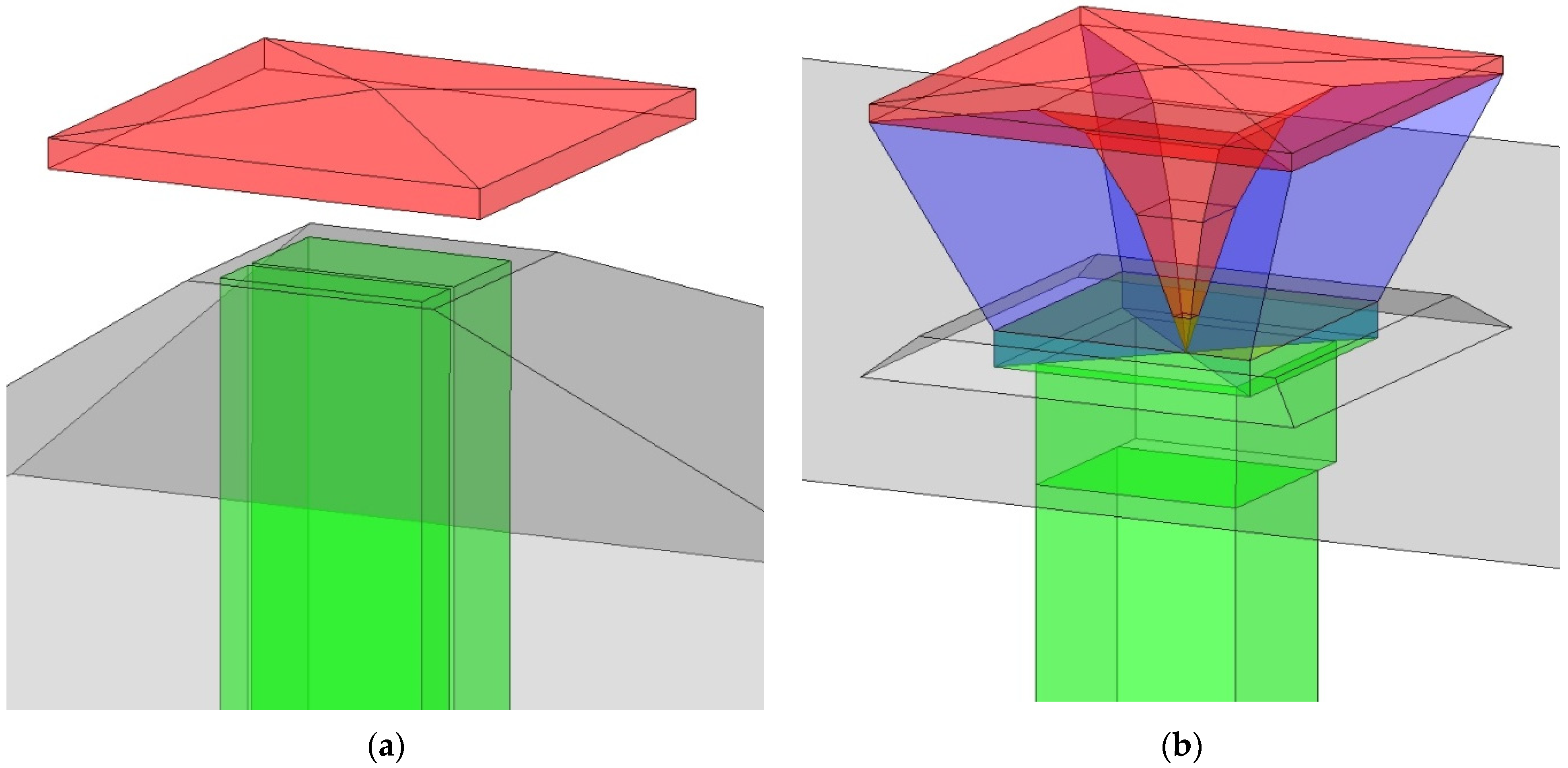

2.2. Simulations and Model Set Up

3. Results

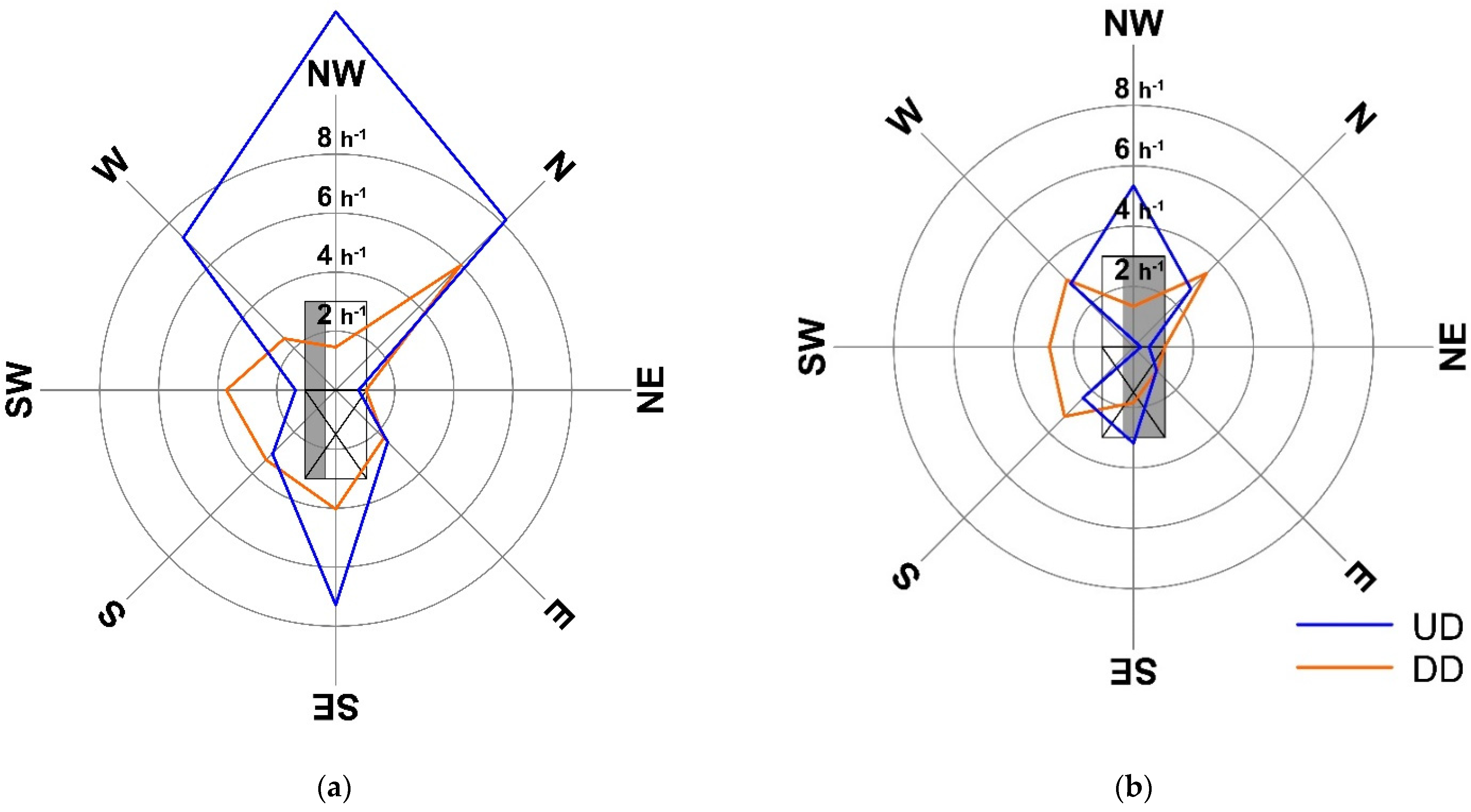

3.1. Scenario Site A—Lower Density, Closer Neighbors

3.2. Scenario Site B—Higher Density, Further Neighbors

4. Discussion

Limitations

5. Conclusions

6. Outlook

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Variable | Grid 3 (Coarse) | Grid 2 (Medium) | Grid 1 (Fine) | |

|---|---|---|---|---|

| N—number of elements | 2,033,824 | 4,396,469 | 9,503,743 | |

| V—volume of the mesh [m3] | 3,196,074 | 3,196,074 | 3,196,074 | |

| —volume flow rate [m3/h] (total) | 3.29 | 3.23 | 3.21 | |

| h—representative cell size [m] | 1.163 | 0.899 | 0.685 | |

| Grid 3 Related to Grid 2 | Grid 2 Related to Grid 1 | |||

| r—refinement factor | 1.293 | |||

| p—apparent order | 3.980 | |||

| —extrapolated value | 3.198 | |||

| —approximate relative error | 1.76% | 0.64% | ||

| eext—extrapolated relative error | 1.00% | 0.36% | ||

| —fine-grid convergence index | 1.24% | 0.45% | ||

References

- United Nations Framwork Convention on Climate Change: Report of the Conference of the Parties on its Twenty-First Session, held in Paris from 30 November to 13 December 2015. Available online: http://unfcc.int/resource/docs/cop21/eng/10.pdf (accessed on 16 June 2021).

- European Comission. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0112:FIN:EN:PDF (accessed on 16 June 2021).

- Schmalensee, R.; Stoker, T.M.; Judson, R.A. World carbon dioxide emissions: 1950–2050. Rev. Econ. Stat. 1998, 80, 15–27. [Google Scholar] [CrossRef]

- Akashi, O.; Hijioka, Y.; Masui, T.; Hanaoka, T.; Kainuma, M. GHG emission scenarios in Asia and the world: The key technologies for significant reduction. Energy Econ. 2012, 34, S346–S358. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Hamdy, M.; Hasan, A.; Siren, K. Applying a multi-objective optimization approach for Design of low-emission cost-effective dwellings. Build. Environ. 2011, 46, 109–123. [Google Scholar] [CrossRef]

- Aflaki, A.; Mahyuddin, N.; Mahmoud, Z.A.-C.; Baharum, M.R. A review on natural ventilation applications through building façade components and ventilation openings in tropical climates. Energy Build. 2015, 101, 153–162. [Google Scholar] [CrossRef]

- Chenari, B.; Dias Carrilho, J.; Gameiro Da Silva, M. Towards sustainable, energy-efficient and healthy ventilation strategies in buildings: A review. Renew. Sustain. Energy Rev. 2016, 59, 1426–1447. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. The EPA Cost of Illness Handbook; U.S. Environmental Protection Agency: Washington, DC, USA, 2007. Available online: http://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=901A0E00.txt (accessed on 16 June 2021).

- Coelho, M.; Baptista, F.; Fitas Da Cruz, V. Comparison of four natural ventilation systems in a Mediterranean greenhouse. Acta Hortic. 2006, 719, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Tomasello, N.; Valenti, F.; Cascone, G.; Porto, S.M.C. Development of a CFD model to simulate natural ventilation in a semi-open free-stall barn for dairy cows. Buildings 2019, 9, 183. [Google Scholar] [CrossRef] [Green Version]

- Nosek, Š.; Kluková, Z.; Jakubcová, M.; Yi, Q.; Janke, D.; Demeyer, P.; Jaňour, Z. The impact of atmospheric boundary layer, opening configuration and presence of animals on the ventilation of a cattle barn. J. Wind Eng. Ind. Aerodyn. 2020, 201. [Google Scholar] [CrossRef]

- Rong, L.; Liu, D.; Pedersen, E.F.; Zhang, G. The effect of wind speed and direction and surrounding maize on hybrid ventilation in a dairy cow building in Denmark. Energy Build. 2014, 86, 25–34. [Google Scholar] [CrossRef]

- Tanasić, N.; Jankes, G.; Skistad, H. Cfd analysis and airflow measurements to approach large industrial halls energy efficiency: A case study of a cardboard mill hall. Energy Build. 2011, 43, 1200–1206. [Google Scholar] [CrossRef]

- Kistelegdi, I.; Baranyai, B. Windkanaluntersuchungen zwecks Quantifizierung und Validierung der Wirkung von Windinduktion und thermischen Auftriebskräften auf die natürliche Lüftung eines industriellen Innovationszentrums. Bauphysik 2012, 34, 229–237. [Google Scholar] [CrossRef]

- Cañas, I.; Mazarrón, F.R. The effect of traditional wind vents called zarceras on the hygrothermal behaviour of underground wine cellars in Spain. Build. Environ. 2009, 44, 1818–1826. [Google Scholar] [CrossRef]

- Mazarrón, F.R.; Porras-Amores, C.; Cid-Falceto, J.; Cañas, I. Natural ventilation in underground wine cellars. In Proceedings of the International Conference on Agricultura Engineering, Valencia, Spain, 8–12 July 2012; pp. 1–5. [Google Scholar]

- Mazarrón, F.R.; Porras-Amores, C.; Cañas-Guerrero, I. Annual evolution of the natural ventilation in an underground construction: Influence of the access tunnel and the ventilation chimney. Tunn. Undergr. Space Technol. 2015, 49, 188–198. [Google Scholar] [CrossRef]

- Bahadori, M.N. Passive Cooling Systems in Iranian Architecture. Sci. Am. 1978, 238, 144–154. [Google Scholar] [CrossRef]

- Saadatian, O.; Haw, L.C.; Sopian, K.; Sulaiman, M.Y. Review of windcatcher technologies. Renew. Sustain. Energy Rev. 2012, 16, 1477–1495. [Google Scholar] [CrossRef]

- Hughes, B.R.; Calautit, J.K.; Ghani, S.A. The development of commercial wind towers for natural ventilation: A review. Appl. Energy 2012, 92, 606–627. [Google Scholar] [CrossRef]

- Khan, N.; Su, Y.; Riffat, S.B. A review on wind driven ventilation techniques. Energy Build. 2008, 40, 1586–1604. [Google Scholar] [CrossRef]

- Omrani, S.; Garcia-Hansen, V.; Capra, B.; Drogemuller, R. Natural ventilation in multi-storey buildings: Design process and review of evaluation tools. Build. Environ. 2017, 116, 182–194. [Google Scholar] [CrossRef] [Green Version]

- Jomehzadeh, F.; Nejat, P.; Kaiser, J.; Badruddin, M.; Yusof, M.; Ahmad, S.; Richard, B.; Noor, M.; Muhammad, W. A review on windcatcher for passive cooling and natural ventilation in buildings, Part 1: Indoor air quality and thermal comfort assessment. Renew. Sustain. Energy Rev. 2017, 70, 736–756. [Google Scholar] [CrossRef]

- Takayama, A.; Asano, K.; Shuchi, S.; Hasegawa, K. Study on reusing abandoned chimneys as solar chimneys to induce breeze in residential areas. In Proceedings of the PLEA2009—26th Conference on Passive and Low Energy Architecture, Quebec City, QC, Canada, 22–24 June 2009. [Google Scholar]

- Hughes, B.R.; Mak, C.M. A study of wind and buoyancy driven flows through commercial wind towers. Energy Build. 2011, 43, 1784–1791. [Google Scholar] [CrossRef]

- Lim, C.H.; Omidreza, S.; Sopian, K.; Yusof Sulaiman, M.; Mat, S.; Salleh, E.; Ng, K.C. Design configurations analysis of wind-induced natural ventilation tower in hot humid climate using computational fluid dynamics. Int. J. Low-Carbon Technol. 2015, 10, 332–346. [Google Scholar] [CrossRef] [Green Version]

- van Hooff, T.; Blocken, B.; Aanen, L.; Bronsema, B. A venturi-shaped roof for wind-induced natural ventilation of buildings: Wind tunnel and CFD evaluation of different design configurations. Build. Environ. 2011, 46, 1797–1807. [Google Scholar] [CrossRef] [Green Version]

- Badran, A.A. Performance of cool towers under various climates in Jordan. Energy Build. 2003, 35, 1031–1035. [Google Scholar] [CrossRef]

- Sadeghi, M.; De Dear, R.; Samali, B.; Wood, G. Optimization of Wind Tower Cooling Performance: A Wind Tunnel Study of Indoor Air Movement and Thermal Comfort. Procedia Eng. 2016, 180, 611–620. [Google Scholar] [CrossRef]

- Saif, J.; Wright, A.; Khattak, S.; Elfadli, K. Keeping cool in the desert: Using wind catchers for improved thermal comfort and indoor air quality at half the energy. Buildings 2021, 11, 100. [Google Scholar] [CrossRef]

- Bahadori, M.N.; Pakzad, A.R. Performance evaluation of new designs of wind towers. In Proceedings of the American Society of Mechanical Engineers, Fluids Engineering Division, Montreal, QC, Canada, 4–18 July 2002; Volume 257, pp. 1015–1022. [Google Scholar]

- Hedayat, Z.; Belmans, B.; Ayatollahi, M.H.; Wouters, I.; Descamps, F. Performance assessment of ancient wind catchers—An experimental and analytical study. Energy Procedia 2015, 78, 2578–2583. [Google Scholar] [CrossRef] [Green Version]

- Mohamadabadi, H.D.; Dehghan, A.A.; Ghanbaran, A.H.; Movahedi, A.; Mohamadabadi, A.D. Numerical and experimental performance analysis of a four-sided wind tower adjoining parlor and courtyard at different wind incident angles. Energy Build. 2018, 172, 525–536. [Google Scholar] [CrossRef]

- American Society of Heating Refrigerating and Air-conditioning Engineers. ASHRAE Standard 62.1-2019—Ventilation for Acceptable Indoor Air Quality; ASHRAE Bookstore: Atlanta, GA, USA, 2019. [Google Scholar]

- European Committee for Standardizatoin. EN 15251:2007—Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics. Available online: http://standards.iteh.ai/catalog/standards/cen/p92485123-bf64-40e3-9387-9724a642eae8/en-15251-2007 (accessed on 16 June 2021).

- Hungarian Ministry for Innovation and Technology. 7/2006. (V.24.) TNM rendelet–Az Épületek Energetikai Jellemzőinek Meghatározásáról. Available online: http://net.jogtar.hu/jogszabaly?docid=a0600007.tnm (accessed on 16 June 2021).

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future köppen-geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [Green Version]

- Remund, J. Accuracy of Meteonorm.–User Manual-2015. Available online: www.meteonorm.com/assets/publications/Accuracy_of_Meteonorm_7.pdf (accessed on 16 June 2021).

- de Dear, R.J.; Brager, G.S. Developing an adaptive model of thermal comfort and preference. ASHRAE Trans. 1998, 104, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Katona, Á.L.; Xuan, H.; Elhadad, S.; Kistelegdi, I.; Háber, I.E. High-Resolution CFD and In-Situ Monitoring Based Validation of an Industrial Passive Air Conduction System (PACS). Energies 2020, 13, 3157. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, Z.; Malkawi, A. Investigating natural ventilation potentials across the globe: Regional and climatic variations. Build. Environ. 2017, 122, 386–396. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Keshmiri, A. Computational simulation of wind microclimate in complex urban models and mitigation using trees. Buildings 2021, 11, 112. [Google Scholar] [CrossRef]

- Huang, H.; Ooka, R.; Chen, H.; Kato, S. Optimum design for smoke-control system in buildings considering robustness using CFD and Genetic Algorithms. Build. Environ. 2009, 44, 2218–2227. [Google Scholar] [CrossRef]

- Kuznik, F.; Rusaouën, G.; Brau, J. Experimental and numerical study of a full scale ventilated enclosure: Comparison of four two equations closure turbulence models. Build. Environ. 2007, 42, 1043–1053. [Google Scholar] [CrossRef]

- Rohdin, P.; Moshfegh, B. Numerical predictions of indoor climate in large industrial premises. A comparison between different k-ε models supported by field measurements. Build. Environ. 2007, 42, 3872–3882. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, X.; Zhang, Y.; Riskowski, G.L. Analysis of airflow in a full-scale room with non-isothermal jet ventilation using PTV techniques. ASHRAE Trans. 2007, 113, 414–425. [Google Scholar]

- Mohamed, M.F.; King, S.; Behnia, M.; Prasad, D. Coupled outdoor and indoor airflow prediction for buildings using Computational Fluid Dynamics (CFD). Buildings 2013, 3, 399–421. [Google Scholar] [CrossRef] [Green Version]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. J. Fluids Eng. Trans. ASME 2008, 130. [Google Scholar] [CrossRef] [Green Version]

- Balogh, M.; Parente, A.; Benocci, C. RANS simulation of ABL flow over complex terrains applying an Enhanced k-ε model and wall function formulation: Implementation and comparison for fluent and OpenFOAM. J. Wind Eng. Ind. Aerodyn. 2012, 104–106, 360–368. [Google Scholar] [CrossRef]

- Balogh, M.; Parente, A. Realistic boundary conditions for the simulation of atmospheric boundary layer flows using an improved k-ε model. J. Wind Eng. Ind. Aerodyn. 2015, 144, 183–190. [Google Scholar] [CrossRef]

- Cheng, J.; Qi, D.; Katal, A.; Wang, L.; Stathopoulos, T. Evaluating wind-driven natural ventilation potential for early building design. J. Wind Eng. Ind. Aerodyn. 2018, 182, 160–169. [Google Scholar] [CrossRef]

- Javanroodi, K.; Mahdavinejad, M.; Nik, V.M. Impacts of urban morphology on reducing cooling load and increasing ventilation potential in hot-arid climate. Appl. Energy 2018, 231, 714–746. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Hussen, H.M.; Calautit, J.K.; Abd Majid, M.Z. Application of wind as a renewable energy source for passive cooling through windcatchers integrated with wing walls. Energies 2018, 11, 2536. [Google Scholar] [CrossRef] [Green Version]

- Sakiyama, N.R.M.; Frick, J.; Bejat, T.; Garrecht, H. Using CFD to Evaluate Natural Ventilation through a 3D Parametric Modeling Approach. Energies 2021, 14, 2197. [Google Scholar] [CrossRef]

- Soltani, M.; Dehghani-Sanij, A.; Sayadnia, A.; Kashkooli, F.M.; Gharali, K.; Mahbaz, S.; Dusseault, M.B. Investigation of airflow patterns in a new design of wind tower with awetted surface. Energies 2018, 11, 1100. [Google Scholar] [CrossRef] [Green Version]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Zhong, F.; Calautit, J. Design of a passive downdraught evaporative cooling windcatcher (PDEC-WC) system for greenhouses in hot climates. Energies 2020, 13, 2934. [Google Scholar] [CrossRef]

| Region | Validated Mesh | Current Mesh |

|---|---|---|

| Total domain size | 500 m × 500 m × 100 m | 200 m × 200 m × 80 m |

| Atmospheric | 6 m | 4 m |

| Macro environment | 3 m | 2 m |

| Micro environment | 2 m | 1 m |

| Near building walls | 0.5 m | 0.3 m |

| Towers/openings | 0.3 m | 0.1 m |

| Interior | 0.2 m | 0.25 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katona, Á.L.; Háber, I.E.; Kistelegdi, I. Comparison of Downdraught and Up Draft Passive Air Conduction Systems (PACS) in a Winery Building. Buildings 2021, 11, 259. https://doi.org/10.3390/buildings11060259

Katona ÁL, Háber IE, Kistelegdi I. Comparison of Downdraught and Up Draft Passive Air Conduction Systems (PACS) in a Winery Building. Buildings. 2021; 11(6):259. https://doi.org/10.3390/buildings11060259

Chicago/Turabian StyleKatona, Ádám László, István Ervin Háber, and István Kistelegdi. 2021. "Comparison of Downdraught and Up Draft Passive Air Conduction Systems (PACS) in a Winery Building" Buildings 11, no. 6: 259. https://doi.org/10.3390/buildings11060259

APA StyleKatona, Á. L., Háber, I. E., & Kistelegdi, I. (2021). Comparison of Downdraught and Up Draft Passive Air Conduction Systems (PACS) in a Winery Building. Buildings, 11(6), 259. https://doi.org/10.3390/buildings11060259