Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach

Abstract

:1. Introduction

2. Literature Review

2.1. Modular Construction

2.2. Barriers to the Adoption of Modular Construction

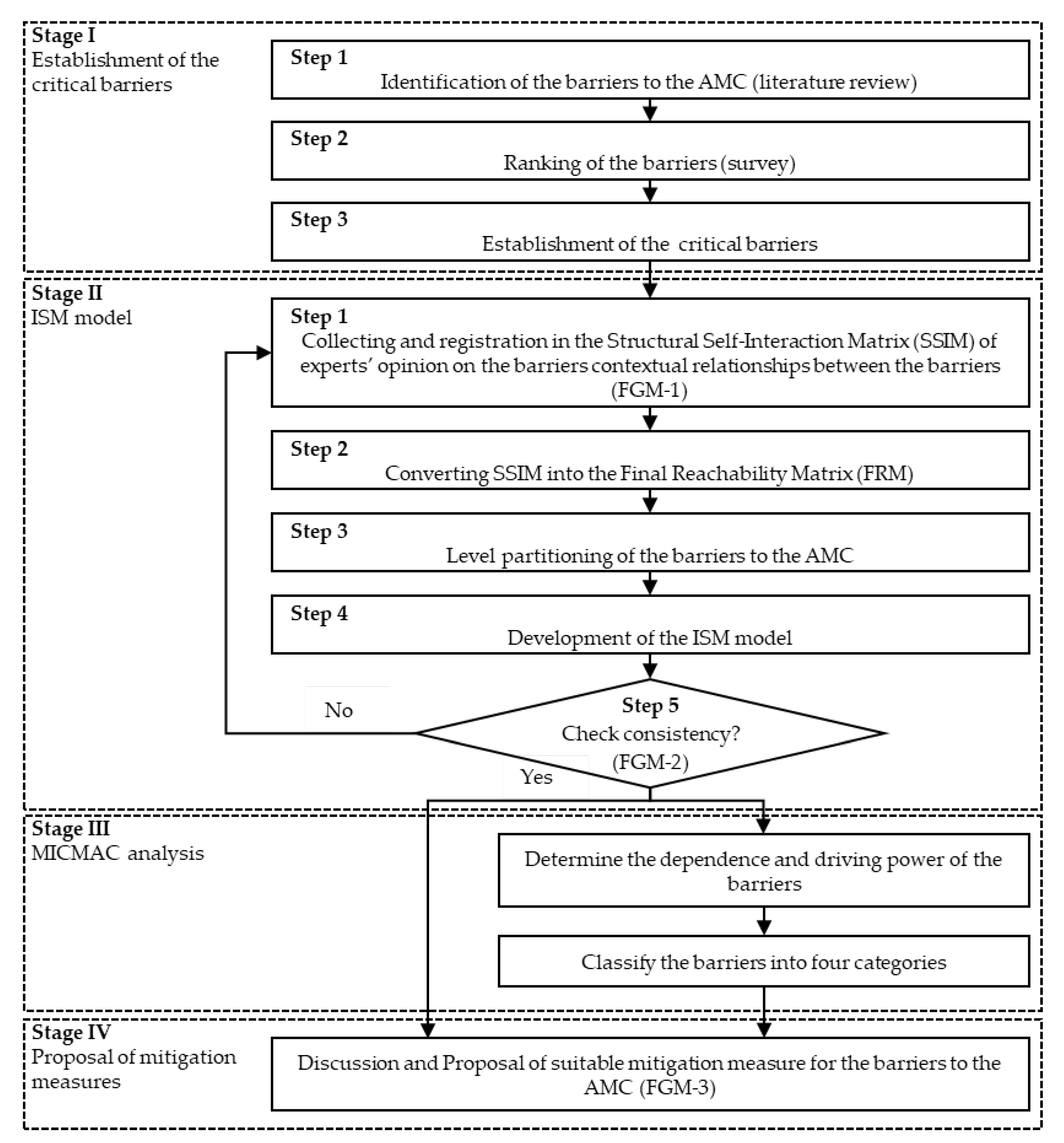

3. Material and Methods

3.1. Stage I: Establishment of the Critical Barriers to the AMC

3.2. Stage II: ISM Model

3.3. Stage III: MICMAC Analysis

3.4. Stage IV: Proposal of the Mitigation Measures

4. Results

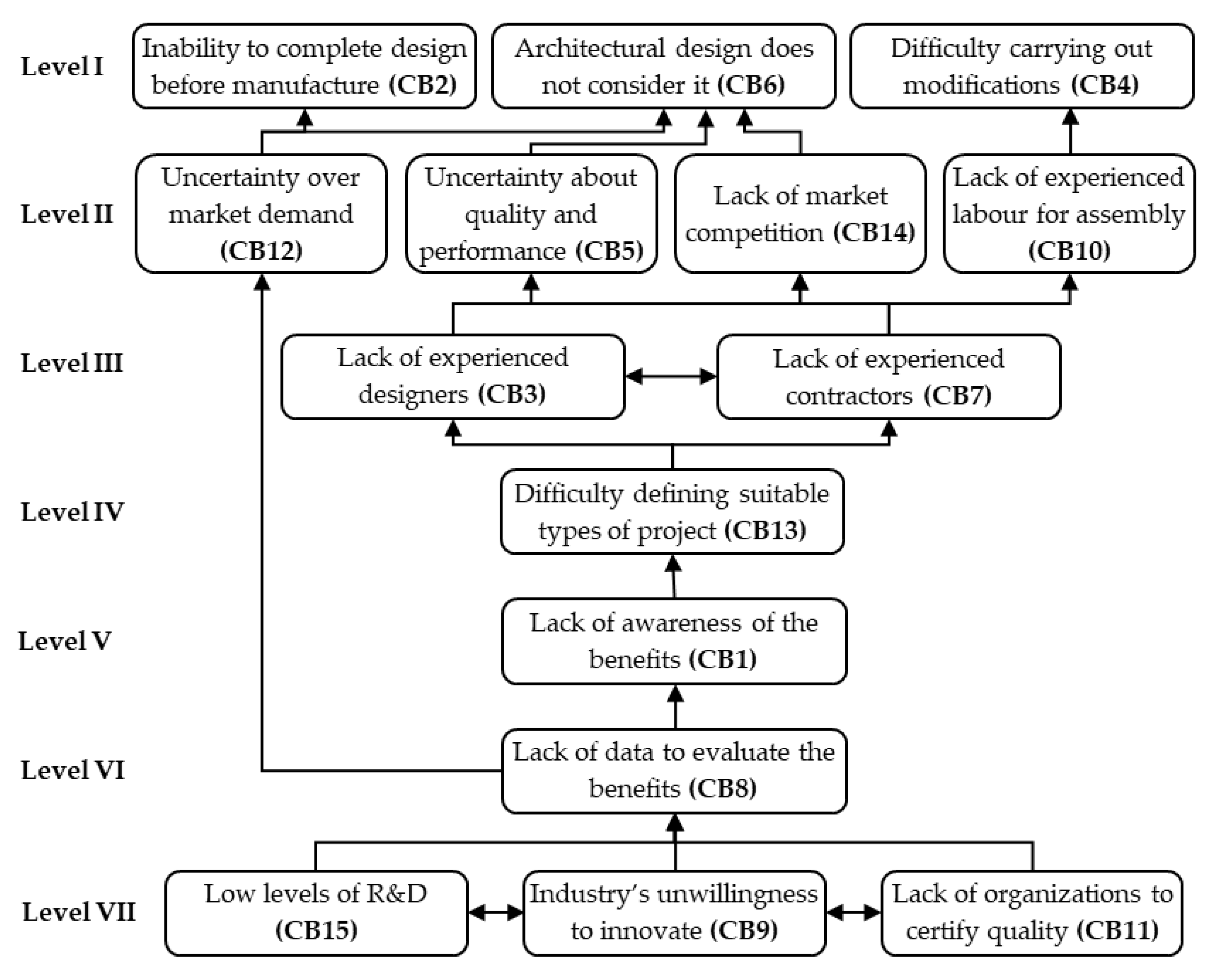

4.1. ISM Model

4.2. MICMAC Analysis

5. Discussion and Mitigation Measures

5.1. Discussion

5.2. Mitigation Measures

6. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Ranking of the Barriers to the AMC

| Code | Barrier | RII | Rank | Code | Description | RII | Rank |

|---|---|---|---|---|---|---|---|

| B3 | Lack of awareness of the benefits | 0.813 | 1 | B33 | Transport restrictions | 0.707 | 22 |

| B21 | Inability to complete design before manufacturing stage | 0.807 | 2 | B7 | Fragmentation of the supply chain | 0.704 | 23 |

| B25 | Lack of experienced designers | 0.796 | 3 | B18 | Higher construction costs | 0.702 | 24 |

| B41 | Difficulty carrying out on-site modifications | 0.793 | 4 | B17 | Higher initial costs | 0.696 | 25 |

| B4 | Uncertainty over quality and performance | 0.789 | 5 | B34 | Transportation costs | 0.696 | 25 |

| B26 | Architectural design does not consider modular construction | 0.767 | 6 | B14 | Lack of governmental incentives | 0.693 | 27 |

| B30 | Lack of experienced contractors | 0.767 | 6 | B19 | Difficulty achieving economies of scale | 0.691 | 28 |

| B5 | Lack of data to evaluate the benefits | 0.764 | 8 | B20 | Difficulty obtaining financial investment | 0.687 | 29 |

| B8 | Industry’s unwillingness to innovate | 0.758 | 9 | B37 | Complex logistical management | 0.68 | 30 |

| B40 | Lack of experienced labor for on-site assembly | 0.738 | 10 | B42 | Low tolerance between manufactured components and on-site assembly | 0.667 | 31 |

| B12 | Lack of accredited organizations to certify the quality of the manufactured components | 0.733 | 11 | B28 | Aesthetic limitations | 0.66 | 32 |

| B2 | Uncertainty over market demand | 0.729 | 12 | B15 | Lack of legal framework | 0.658 | 33 |

| B27 | Difficulty defining the most suitable types of project | 0.729 | 12 | B39 | Restrictions for unloading and storing components | 0.653 | 34 |

| B9 | Lack of market competition | 0.727 | 14 | B36 | Additional protection required | 0.647 | 35 |

| B11 | Low levels of R&D in the industry | 0.727 | 15 | B16 | Shortage of land available for large scale developments | 0.638 | 36 |

| B23 | Inflexibility to apply changes to the design | 0.724 | 16 | B38 | Requirement for high-capacity cranes | 0.638 | 36 |

| B32 | Lack of suppliers of prefabricated components | 0.724 | 17 | B35 | Impact of the mobilization on the structural integrity of the components | 0.616 | 38 |

| B1 | Clients’ misconceptions | 0.718 | 18 | B10 | Construction industry’s risk aversion | 0.562 | 39 |

| B31 | Lack of experienced collaboration groups | 0.716 | 19 | B22 | Longer lead-in times during the design stage | 0.558 | 40 |

| B24 | Need for close collaboration between stakeholders | 0.713 | 20 | B29 | Intricate design | 0.544 | 41 |

| B13 | Lack of governmental regulations (codes and standards) | 0.709 | 21 | B6 | Risk of increasing unemployment | 0.507 | 42 |

Appendix B. Conical Matrix of the Final Reachability Matrix

| CB (i/j) 1 | 2 | 4 | 6 | 5 | 10 | 12 | 14 | 3 | 7 | 13 | 1 | 8 | 9 | 11 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | I | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 4 | 0 | I | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 6 | 0 | 0 | I | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 5 | 0 | 0 | 1 | II | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10 | 0 | 1 | 0 | 0 | II | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 12 | 1 | 0 | 1 | 0 | 0 | II | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 14 | 0 | 0 | 1 | 0 | 0 | 0 | II | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | III | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 7 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | III | 0 | 0 | 0 | 0 | 0 | 0 |

| 13 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | IV | 0 | 0 | 0 | 0 | 0 |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | V | 0 | 0 | 0 | 0 |

| 8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | VI | 0 | 0 | 0 |

| 9 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | VII | 1 | 1 |

| 11 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | VII | 1 |

| 15 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | VII |

References

- McKinsey Global Institute. Reinventing Construction: A Route To Higher Productivity; McKinsey Global Institute: New York, NY, USA, 2017. [Google Scholar]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Lopez, R.; Chong, H.; Pereira, C. Obstacles Preventing the Off-Site Prefabrication of Timber and MEP Services: Qualitative Analyses from Builders and Suppliers in Australia. Buildings 2022, 12, 1044. [Google Scholar] [CrossRef]

- Sharafi, P.; Rashidi, M.; Samali, B.; Ronagh, H.; Mortazavi, M. Identification of Factors and Decision Analysis of the Level of Modularization in Building Construction. J. Archit. Eng. 2018, 24, 04018010. [Google Scholar] [CrossRef]

- Gibb, A.G.F.; Isack, F. Re-Engineering through Pre-Assembly: Client Expectations and Drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Loizou, L.; Barati, K.; Shen, X.; Li, B. Quantifying Advantages of Modular Construction: Waste Generation. Buildings 2021, 11, 622. [Google Scholar] [CrossRef]

- Jang, H.; Ahn, Y.; Roh, S. Comparison of the Embodied Carbon Emissions and Direct Construction Costs for Modular and Conventional Residential Buildings in South Korea. Buildings 2022, 12, 51. [Google Scholar] [CrossRef]

- Chauhan, K.; Peltokorpi, A.; Lavikka, R.; Seppänen, O. The Monetary and Non-Monetary Impacts of Prefabrication on Construction: The Effects of Product Modularity. Buildings 2022, 12, 459. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life Cycle Performance of Modular Buildings: A Critical Review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Smith, R.E.; Rice, T. Offsite Architecture: Constructing the Future. In Offsite Architecture: Constructing the Future; Smith, R.E., Quale, J.D., Eds.; Routledge: London, UK, 2017; p. 19. ISBN 9781317588825. [Google Scholar]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key Constraints and Mitigation Strategies for Prefabricated Prefinished Volumetric Construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Khan, A.; Yu, R.; Liu, T.; Guan, H.; Oh, E. Drivers towards Adopting Modular Integrated Construction for Affordable Sustainable Housing: A Total Interpretive Structural Modelling (TISM) Method. Buildings 2022, 12, 637. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A Study of Literature in Modular Integrated Construction—Critical Review and Future Directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Shin, J.; Choi, B. Design and Implementation of Quality Information Management System for Modular Construction Factory. Buildings 2022, 12, 654. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Modular Construction: Determining Decision-Making Factors and Future Research Needs. J. Manag. Eng. 2020, 36, 04020085. [Google Scholar] [CrossRef]

- Tatum, C.B.; Vanegas, J.A.; Williams, J.M. Constructability Improvement Using Prefabrication, Preassembly, and Modularization; University of Texas at Austin: Austin, TX, USA, 1987. [Google Scholar]

- Rahman, M.M. Barriers of Implementing Modern Methods of Construction. J. Manag. Eng. 2014, 30, 69–77. [Google Scholar] [CrossRef]

- Blismas, N.; Pendlebury, M.; Gibb, A.; Pasquire, C. Constraints to the Use of Off-Site Production on Construction Projects. Archit. Eng. Des. Manag. 2005, 1, 153–162. [Google Scholar] [CrossRef]

- Azhar, S.; Lukkad, M.Y.; Ahmad, I. An Investigation of Critical Factors and Constraints for Selecting Modular Construction over Conventional Stick-Built Technique. Int. J. Constr. Educ. Res. 2013, 9, 203–225. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the Transition towards Off-Site Construction in China: An Interpretive Structural Modeling Approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Feng, H.; Wang, Y.; Fan, S. ISM-Based Relationship among Critical Factors That Affect the Choice of Prefabricated Concrete Buildings in China. Int. J. Constr. Manag. 2022, 22, 792–977. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, Y. Research on the Constraints of the Development of Prefabricated Building in Dalian Based on ISM. In Proceedings of the ICCREM 2019—Innovative Construction Project Management and Construction Industrialization; Wang, Y., Al-Hussein, M., Shen, G.Q.P., Eds.; American Society of Civil Engineers (ASCE): Banff, AB, Canada, 2019; pp. 461–474. [Google Scholar]

- Choi, J.O.; Bin Chen, X.; Kim, T.W. Opportunities and Challenges of Modular Methods in Dense Urban Environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the Adoption of Modular Integrated Construction: Systematic Review and Meta-Analysis, Integrated Conceptual Framework, and Strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Abowitz, D.A.; Toole, T.M. Mixed Method Research: Fundamental Issues of Design, Validity, and Reliability in Construction Research. J. Constr. Eng. Manag. 2010, 136, 108–116. [Google Scholar] [CrossRef]

- Schoonenboom, J.; Johnson, R.B. How to Construct a Mixed Methods Research Design. Kolner Z. Soz. Sozpsychol. 2017, 69, 107–131. [Google Scholar] [CrossRef] [PubMed]

- Morgan, D.L. Focus Groups. Annu. Rev. Sociol. 1996, 22, 129–152. [Google Scholar] [CrossRef]

- Marshall, C.; Rossman, G.B. Designing Qualitative Research, 6th ed.; SAGE Publications: London, UK, 2015. [Google Scholar]

- Kitzinger, J. Qualitative Research: Introducing Focus Groups. BMJ 1995, 311, 299. [Google Scholar] [CrossRef] [PubMed]

- Nassar-McMillan, S.; Borders, L. Use of Focus Groups in Survey Item Development. Qual. Rep. 2002, 7, 1–12. [Google Scholar] [CrossRef]

- Larson, K.; Grudens-Schuck, N.; Allen, B. Methodology Brief: Can You Call It a Focus Group? University of Tennessee Extension’s Community Economic Development Publications; University of Tennessee: Knoxville, TN, USA, 2004. [Google Scholar]

- Shen, L.; Song, X.; Wu, Y.; Liao, S.; Zhang, X. Interpretive Structural Modeling Based Factor Analysis on the Implementation of Emission Trading System in the Chinese Building Sector. J. Clean. Prod. 2016, 127, 214–227. [Google Scholar] [CrossRef]

- Lu, N.; Liska, R.W. Designers’ and General Contractors’ Perceptions of Offsite Construction Techniques in the United State Construction Industry. Int. J. Constr. Educ. Res. 2008, 4, 177–188. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.F.; Dainty, A.R.J. Perspective of UK Housebuilders on the Use of Offsite Modern Methods of Construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New Advancements, Challenges and Opportunities of Multi-Storey Modular Buildings—A State-of-the-Art Review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Bernstein, H.M.; McGraw Hill Construction. Prefabrication and Modularization: Increasing Productivity in the Construction Industry (SmartMarket Report); McGraw Hill Construction: Bedford, UK, 2011; ISBN 9781934926352. [Google Scholar]

- Forza, C. Survey Research in Operations Management: A Process-Based Perspective. Int. J. Oper. Prod. Manag. 2002, 22, 152–194. [Google Scholar] [CrossRef]

- Skitmore, M.; Smyth, H. Marketing and Pricing Strategy. In Construction Supply Chain Management: Concepts and Case Studies; Pryke, S., Ed.; Wiley-Blackwell: Oxford, UK, 2009; pp. 92–111. ISBN 1444319418. [Google Scholar]

- Sax, L.J.; Gilmartin, S.K.; Bryant, A.N. Assessing Response Rate and Nonreponse Bias in Web and Paper Surveys. Res. High. Educ. 2003, 44, 409–432. [Google Scholar] [CrossRef]

- Rungtusanatham, M.J.; Choi, T.Y.; Hollingworth, D.G.; Wu, Z.; Forza, C. Survey Research in Operations Management: Historical Analyses. J. Oper. Manag. 2003, 21, 475–488. [Google Scholar] [CrossRef]

- Moser, C.A.; Kalton, G. Survey Methods in Social Investigation, 1st ed.; Routledge: London, UK, 1971. [Google Scholar]

- Flynn, B.B.; Sakakibara, S.; Schroeder, R.G.; Bates, K.A.; Flynn, E.J. Empirical Research Methods in Operations Management. J. Oper. Manag. 1990, 9, 250–284. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using IBM SPSS Statistics, 4th ed.; Sage Publications: London, UK, 2013; ISBN 978-1446249185. [Google Scholar]

- Arantes, A.; Ferreira, L.M.D.F. A Methodology for the Development of Delay Mitigation Measures in Construction Projects. Prod. Plan. Control 2021, 32, 228–241. [Google Scholar] [CrossRef]

- Ma, G.; Jia, J.; Ding, J.; Shang, S.; Jiang, S. Interpretive Structural Model Based Factor Analysis of BIM Adoption in Chinese Construction Organizations. Sustainability 2019, 11, 1982. [Google Scholar] [CrossRef]

- Wu, P.; Xu, Y.; Jin, R.; Lu, Q.; Madgwick, D.; Hancock, C.M. Perceptions towards Risks Involved in Off-Site Construction in the Integrated Design & Construction Project Delivery. J. Clean. Prod. 2019, 213, 899–914. [Google Scholar] [CrossRef]

- Lavrakas, P.J. Encyclopedia of Survey Research Methods; SAGE Publications: New York, NY, USA, 2008; ISBN 9781412918084. [Google Scholar]

- Warfield, J.N. Developing Subsystem Matrices in Structural Modeling. IEEE Trans. Syst. Man Cybern. 1974, SMC-4, 74–80. [Google Scholar] [CrossRef]

- Sushil Interpreting the Interpretive Structural Model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [CrossRef]

- Venkatesh, V.G.; Rathi, S.; Patwa, S. Analysis on Supply Chain Risks in Indian Apparel Retail Chains and Proposal of Risk Prioritization Model Using Interpretive Structural Modeling. J. Retail. Consum. Serv. 2015, 26, 153–167. [Google Scholar] [CrossRef]

- Kwak, D.W.; Rodrigues, V.S.; Mason, R.; Pettit, S.; Beresford, A. Risk Interaction Identification in International Supply Chain Logistics: Developing a Holistic Model. Int. J. Oper. Prod. Manag. 2018, 38, 372–389. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM Approach for the Barrier Analysis in Implementing Green Supply Chain Management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Wu, W.S.; Ang, C.F.; Chang, J.C.; Château, P.; Chang, Y.C. Risk Assessment by Integrating Interpretive Structural Modeling and Bayesian Network, Case of Offshore Pipeline Project. Reliab. Eng. Syst. Saf. 2015, 142, 515–524. [Google Scholar] [CrossRef]

- Liu, H.; Skibniewski, M.J.; Wang, M. Identification and Hierarchical Structure of Critical Success Factors for Innovation in Construction Projects: Chinese Perspective. J. Civ. Eng. Manag. 2016, 22, 401–416. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to Building Information Modeling (BIM) Implementation in China’s Prefabricated Construction: An Interpretive Structural Modeling (ISM) Approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Abuzeinab, A.; Arif, M.; Qadri, M.A. Barriers to MNEs Green Business Models in the UK Construction Sector: An ISM Analysis. J. Clean. Prod. 2017, 160, 27–37. [Google Scholar] [CrossRef]

- Shoar, S.; Chileshe, N. Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach. Sustainability 2021, 13, 9578. [Google Scholar] [CrossRef]

- Onososen, A.; Musonda, I. Barriers to BIM-Based Life Cycle Sustainability Assessment for Buildings: An Interpretive Structural Modelling Approach. Buildings 2022, 12, 324. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Mishra, N.; Singh, A.; Rana, N.P.; Dwivedi, Y.K. Interpretive Structural Modelling and Fuzzy MICMAC Approaches for Customer Centric Beef Supply Chain: Application of a Big Data Technique. Prod. Plan. Control 2017, 28, 945–963. [Google Scholar] [CrossRef] [Green Version]

- Duperrin, J.-C.; Godet, M. Méthode de Hiérarchisation des Éléments d’un Système: Essai de Prospective du Système de l’énergie Nucléaire dans son Contexte Sociétal; Centre National de L’entrepreneuriat (CNE): Nancy, France, 1973. [Google Scholar]

- Zaidi, S.A.H.; Mirza, F.M.; Hou, F.; Ashraf, R.U. Addressing the Sustainable Development through Sustainable Procurement: What Factors Resist the Implementation of Sustainable Procurement in Pakistan? Socioecon. Plann. Sci. 2019, 68, 100671. [Google Scholar] [CrossRef]

- Bianco, D.; Filho, M.G.; Osiro, L.; Ganga, G.M.D.; Tortorella, G.L. The Driving and Dependence Power between Lean Leadership Competencies: An Integrated ISM/Fuzzy MICMAC Approach. Prod. Plan. Control 2021, 1, 1–25. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical Success Factors for Modular Integrated Construction Projects: A Review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Gaudenzi, B.; Borghesi, A. Managing Risks in the Supply Chain Using the AHP Method. Int. J. Logist. Manag. 2006, 17, 114–136. [Google Scholar] [CrossRef]

- Arantes, A.; Ferreira, L.M.D.F. Underlying Causes and Mitigation Measures of Delays in Construction Projects An Empirical Study. J. Financ. Manag. Prop. Constr. 2020, 25, 165–181. [Google Scholar] [CrossRef]

| Code | Description of the Barriers | References |

|---|---|---|

| B1 | Clients’ misconceptions | [2,17,19,20,23,24,33,34] |

| B2 | Uncertainty over market demand | [2,12,13,17,20,24,35] |

| B3 | Lack of awareness of the benefits | [2,11,19,24] |

| B4 | Uncertainty over quality and performance | [2,5,10,17,20,23,24,34] |

| B5 | Lack of data to evaluate the benefits | [2,10,13,19,24] |

| B6 | Risk of increasing unemployment | [2] |

| B7 | Fragmentation of the supply chain | [2,10,17,24,34] |

| B8 | Industry’s unwillingness to innovate | [2,10,17,19,20,23,24] |

| B9 | Lack of market competition | [2,17,18,24] |

| B10 | Construction industry’s risk aversion | [2,17,24,34] |

| B11 | Low levels of R&D in the industry | [2,24] |

| B12 | Lack of accredited organizations to certify the quality of manufactured components | [2,5,17,18,24] |

| B13 | Lack of governmental regulations (codes and standards) | [2,10,13,20,24,34,36] |

| B14 | Lack of governmental incentives | [2,17,20,24] |

| B15 | Lack of legal framework | [2,24,34] |

| B16 | Shortage of land available for large scale developments | [17,34] |

| B17 | Higher initial costs | [2,11,13,17,24,34,36] |

| B18 | Higher construction costs | [5,11,17,33] |

| B19 | Difficulty achieving economies of scale | [2,5,17,24,34] |

| B20 | Difficulty obtaining financial investment | [17,18,24,33] |

| B21 | Inability to complete design before manufacture | [5,11,17,18,19,23,24,34] |

| B22 | Longer lead-in times during design stage | [2,5,11,17,24] |

| B23 | Inflexibility to apply changes to the design | [2,11,17,19,24] |

| B24 | Need for close collaboration between stakeholders | [11,17,19,20,24] |

| B25 | Lack of experienced designers | [2,5,11,17] |

| B26 | Architectural design does not consider modular construction | [19,37] |

| B27 | Difficulty defining the most suitable projects | [10] |

| B28 | Aesthetic limitations | [2,20,24,33] |

| B29 | Intricate design | [2,24] |

| B30 | Lack of experienced contractors | [2,10,17,20,23,24,36,37] |

| B31 | Lack of experienced collaboration groups | [2,5,10,24] |

| B32 | Lack of suppliers of prefabricated components | [2,5,17,18,19,23,24,34,36] |

| B33 | Transport restrictions | [2,10,36,11,13,17,18,19,23,24,33] |

| B34 | Transportation costs | [10,17,24,33] |

| B35 | Impact of mobilization on the structural integrity of components | [24,33,36] |

| B36 | Additional protection required | [11,24] |

| B37 | Complex logistical management | [11,20,23,24] |

| B38 | Requirement for high-capacity cranes | [5,24] |

| B39 | Restrictions for unloading and storing components | [2,11,18,20,24] |

| B40 | Lack of experienced labor for on-site assembly | [2,11,18,24,36] |

| B41 | Difficulty carrying out on-site modifications | [19,24,33] |

| B42 | Low tolerance between manufactured components and on-site assembly | [3,17,24] |

| Respondent Group | Potential Respondents | Number of Responses | Frequency of Responses (%) | Response Rate (%) | Respondents’ Experience (Years) | |||

|---|---|---|---|---|---|---|---|---|

| <5 | 5–10 | 10–20 | >20 | |||||

| Contractors | 150 | 30 | 33.3 | 20.0 | 1 | 4 | 7 | 18 |

| Consultants | 150 | 49 | 54.4 | 32.7 | 2 | 8 | 19 | 20 |

| Clients | 25 | 11 | 12.2 | 44.0 | 0 | 1 | 5 | 5 |

| Total | 325 | 90 | 100 | 27.7 | 3 (3.3%) | 13 (14.4%) | 31 (34.4%) | 43 (47.8%) |

| Code | Critical Barrier |

|---|---|

| CB1 | Lack of awareness of the benefits |

| CB2 | Inability to complete design before the manufacturing stage |

| CB3 | Lack of experienced designers |

| CB4 | Difficulty carrying out on-site modifications |

| CB5 | Uncertainty over quality and performance |

| CB6 | Architectural design does not consider modular construction |

| CB7 | Lack of experienced contractors |

| CB8 | Lack of data to evaluate the benefits |

| CB9 | Industry’s unwillingness to innovate |

| CB11 | Lack of accredited organizations to certify the quality of the manufactured components |

| CB12 | Uncertainty over market demand |

| CB13 | Difficulty defining the most suitable types of project |

| CB14 | Lack of market competition |

| CB15 | Low levels of R&D in the industry |

| CB (i/j) 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | - | O | O | O | V | V | O | A | O | O | O | V | V | O | A |

| 2 | - | O | O | O | O | O | O | A | O | O | A | O | O | O | |

| 3 | - | O | V | V | X | O | A | O | O | O | A | O | O | ||

| 4 | - | O | O | O | O | O | A | O | O | O | O | O | |||

| 5 | - | V | A | A | O | O | A | O | O | O | A | ||||

| 6 | - | A | A | A | O | O | A | A | A | O | |||||

| 7 | - | O | A | V | O | O | A | V | O | ||||||

| 8 | - | O | O | O | V | O | O | A | |||||||

| 9 | - | V | X | O | O | V | X | ||||||||

| 10 | - | O | O | O | O | O | |||||||||

| 11 | - | O | O | O | A | ||||||||||

| 12 | - | O | O | O | |||||||||||

| 13 | - | O | A | ||||||||||||

| 14 | - | O | |||||||||||||

| 15 | - |

| CB (i/j) 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| 2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 5 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 7 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 |

| 8 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 9 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 |

| 10 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 11 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 |

| 12 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 13 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 14 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| 15 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| CB (i/j) 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | DVP 3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1* | 1* | 1* | 1 | 1 | 1* | 0 | 0 | 1* | 0 | 1 | 1 | 1* | 0 | 11 |

| 2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 3 | 0 | 0 | 1 | 1* | 1 | 1 | 1 | 0 | 0 | 1* | 0 | 0 | 0 | 1* | 0 | 7 |

| 4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 5 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| 6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 7 | 0 | 0 | 1 | 1* | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 7 |

| 8 | 1 | 1* | 1* | 1* | 1 | 1 | 1* | 1 | 0 | 1* | 0 | 1 | 1* | 1* | 0 | 12 |

| 9 | 1* | 1 | 1 | 1* | 1* | 1 | 1 | 1* | 1 | 1 | 1 | 1* | 1* | 1 | 1 | 15 |

| 10 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 2 |

| 11 | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 1 | 1* | 1 | 1* | 1* | 1* | 1* | 15 |

| 12 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 3 |

| 13 | 0 | 0 | 1 | 1* | 1* | 1 | 1 | 0 | 0 | 1* | 0 | 0 | 1 | 1* | 0 | 8 |

| 14 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 2 |

| 15 | 1 | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1 | 1* | 1 | 1* | 1 | 1* | 1 | 15 |

| DEP2 | 5 | 7 | 8 | 10 | 9 | 12 | 8 | 4 | 3 | 9 | 3 | 6 | 6 | 9 | 3 |

| Barriers | Reachability Set | Antecedent Set | Intersection Set | Iteration/Level |

|---|---|---|---|---|

| CB2 | CB2 | CB: 1, 2, 8, 9, 11, 12, 15 | CB2 | I |

| CB4 | CB4 | CB: 1, 3, 4, 7, 8, 9, 10, 11, 13, 15 | CB4 | I |

| CB6 | CB6 | CB: 1, 3, 5, 6, 7, 8, 9, 11, 12, 13, 14, 15 | CB6 | I |

| CB5 | CB5 | CB: 1, 3, 5, 7, 8, 9, 11, 13, 15 | CB5 | II |

| CB10 | CB10 | CB: 1, 3, 7, 8, 9, 10, 11, 13, 15 | CB10 | II |

| CB12 | CB12 | CB: 1, 8, 9, 11, 12, 15 | CB12 | II |

| CB14 | CB14 | CB: 1, 3, 7, 8, 9, 11, 13, 14, 15 | CB14 | II |

| CB3 | CB: 3, 7 | CB: 1, 3, 7, 8, 9, 11, 13, 15 | CB: 3, 7 | III |

| CB7 | CB: 3, 7 | CB: 1, 3, 7, 8, 9, 11, 13, 15 | CB: 3, 7 | III |

| CB13 | CB13 | CB: 1, 8, 9, 11, 13, 15 | CB13 | IV |

| CB1 | CB1 | CB: 1, 8, 9, 11, 15 | CB1 | V |

| CB8 | CB8 | CB: 8, 9, 11, 15 | CB8 | VI |

| CB9 | CB: 9, 11, 15 | CB: 9, 11, 15 | CB: 9, 11, 15 | VII |

| CB11 | CB: 9, 11, 15 | CB: 9, 11, 15 | CB: 9, 11, 15 | VII |

| CB15 | CB: 9, 11, 15 | CB: 9, 11, 15 | CB: 9, 11, 15 | VII |

| Code | Description of Mitigation Measures | Root Barriers | Autonomous Barriers | Remaining Barriers Indirectly Mitigated |

|---|---|---|---|---|

| M1 | Increasing R&D levels through governmental incentives | CB15 | ||

| M2 | Improving quality certification of modular components with assessment tools and guidelines for inspections (on- and off-site) | CB11 | CB: 1, 5, 8, 12, 14 | |

| M3 | Developing holistic, value-based evaluation methods and standard methods of data collection for modular construction | CB:9, 11 | CB: 1, 5, 6, 8, 13, 14 | |

| M4 | Developing codes and standards for modular construction | CB11 | CB: 3, 6, 7, 14 | |

| M5 | Promoting the use of BIM to improve communication and coordination among project stakeholders | CB9 | CB: 2, 13 | |

| M6 | Offering public training courses for project teams and workers to enhance their knowledge and skills | CB9 | CB: 1, 2, 3, 5, 6, 7, 10, 13, 14 | |

| M7 | Promoting the use of modular construction in public projects | CB9 | CB: 3, 5, 6, 7, 8, 12, 13, 14 | |

| M8 | Increasing awareness on modular construction with assessments from research institutions | CB9 | CB: 1, 3, 5, 6, 7, 9, 12, 13, 14 | |

| M9 | Enhancing decision-making processes between modular and traditional construction with holistic, value-based comparisons | CB9 | CB: 6, 13 | |

| M10 | Encouraging early on collaborations between project stakeholders | CB: 2, 3, 4, 6, 7, 13 | ||

| M11 | Increasing confidence in modular practitioners through quality certification | CB12 | CB: 5, 6, 14 | |

| M12 | Promoting early freeze and optimization of the design | CB2 | CB4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, A.M.; Arantes, A.; Cruz, C.O. Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach. Buildings 2022, 12, 1509. https://doi.org/10.3390/buildings12101509

Ribeiro AM, Arantes A, Cruz CO. Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach. Buildings. 2022; 12(10):1509. https://doi.org/10.3390/buildings12101509

Chicago/Turabian StyleRibeiro, Adriana Machado, Amílcar Arantes, and Carlos Oliveira Cruz. 2022. "Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach" Buildings 12, no. 10: 1509. https://doi.org/10.3390/buildings12101509

APA StyleRibeiro, A. M., Arantes, A., & Cruz, C. O. (2022). Barriers to the Adoption of Modular Construction in Portugal: An Interpretive Structural Modeling Approach. Buildings, 12(10), 1509. https://doi.org/10.3390/buildings12101509