The Load-Bearing Capacity and Deformability of Connections of Wooden Elements with Composite Materials Based on Fiberglass

Abstract

1. Introduction

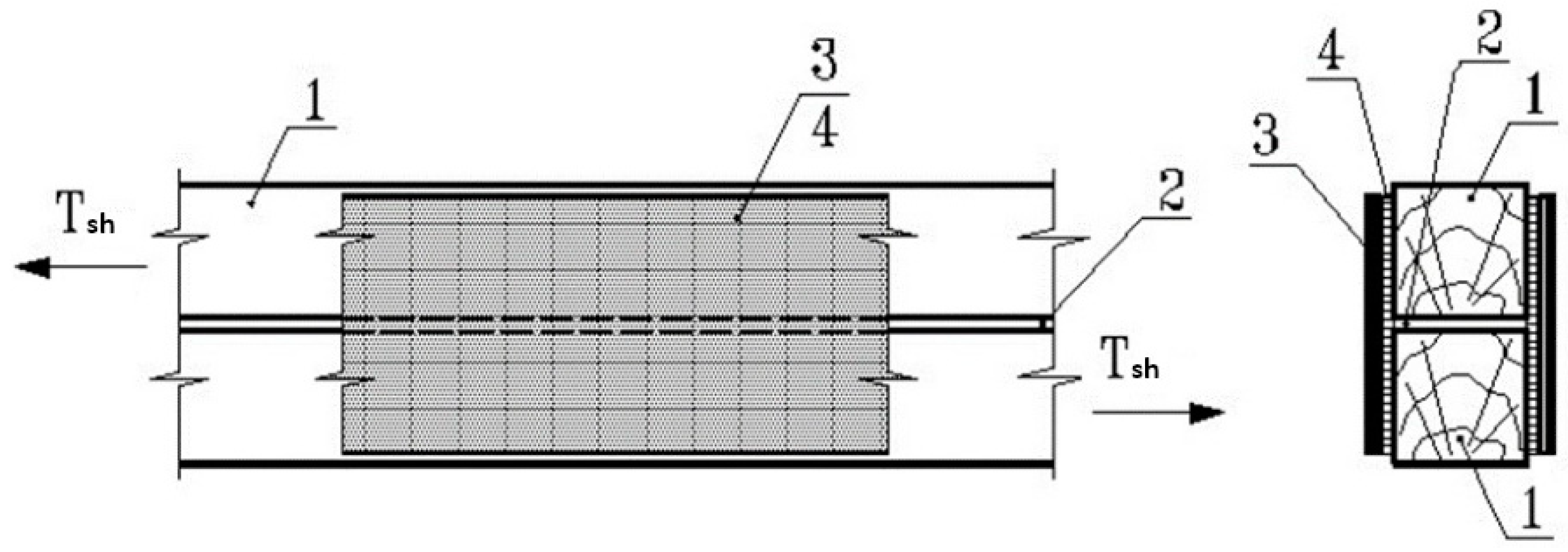

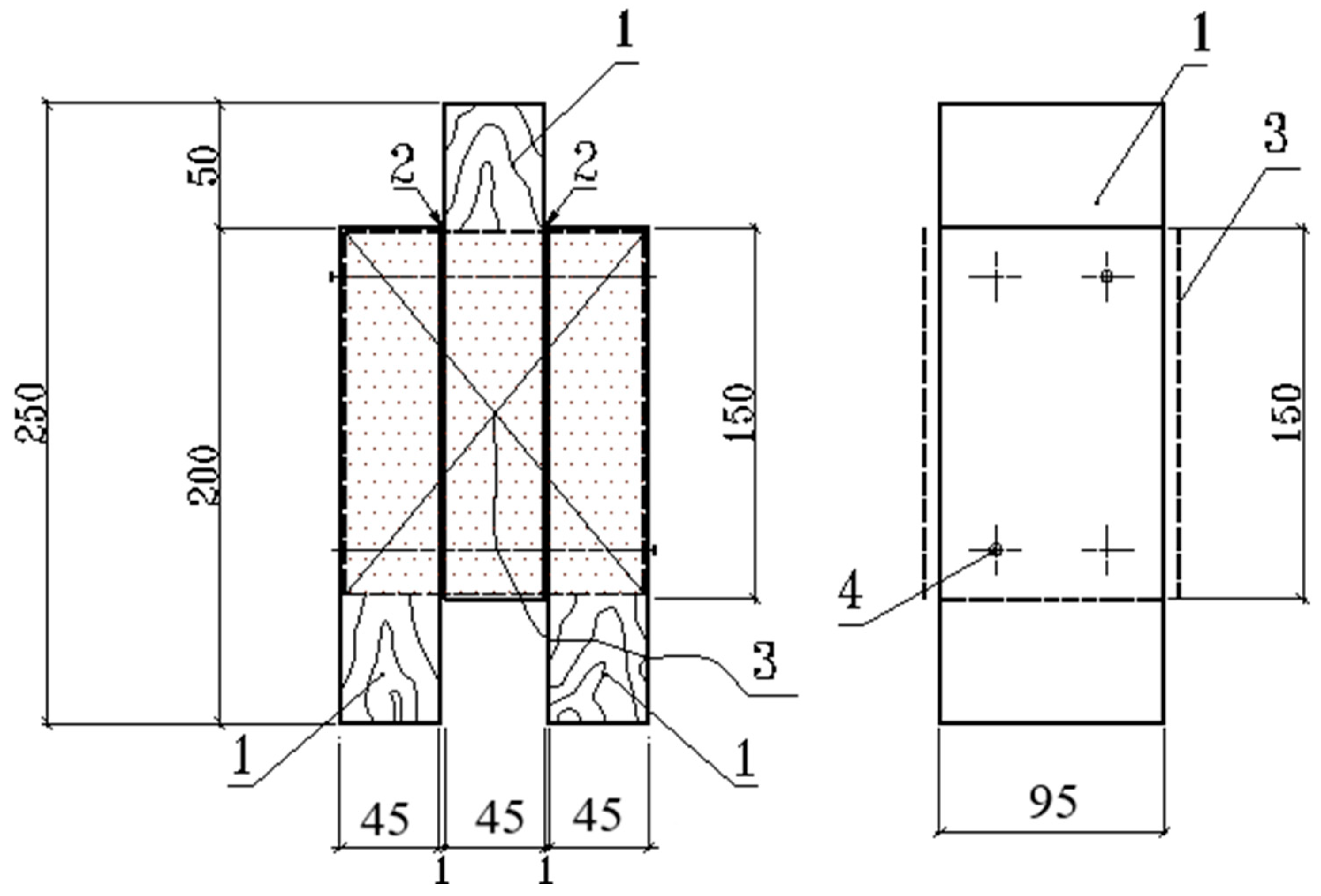

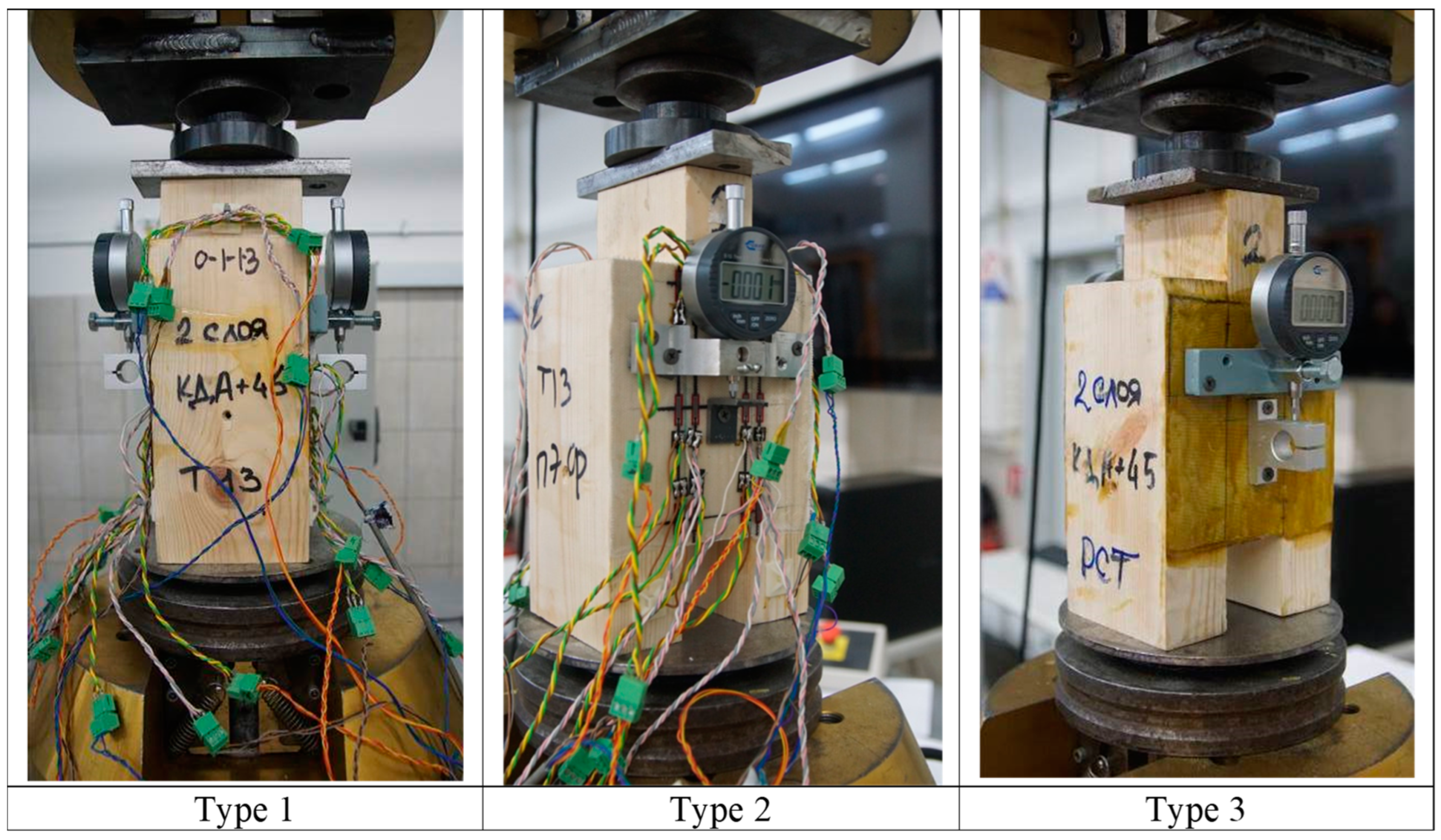

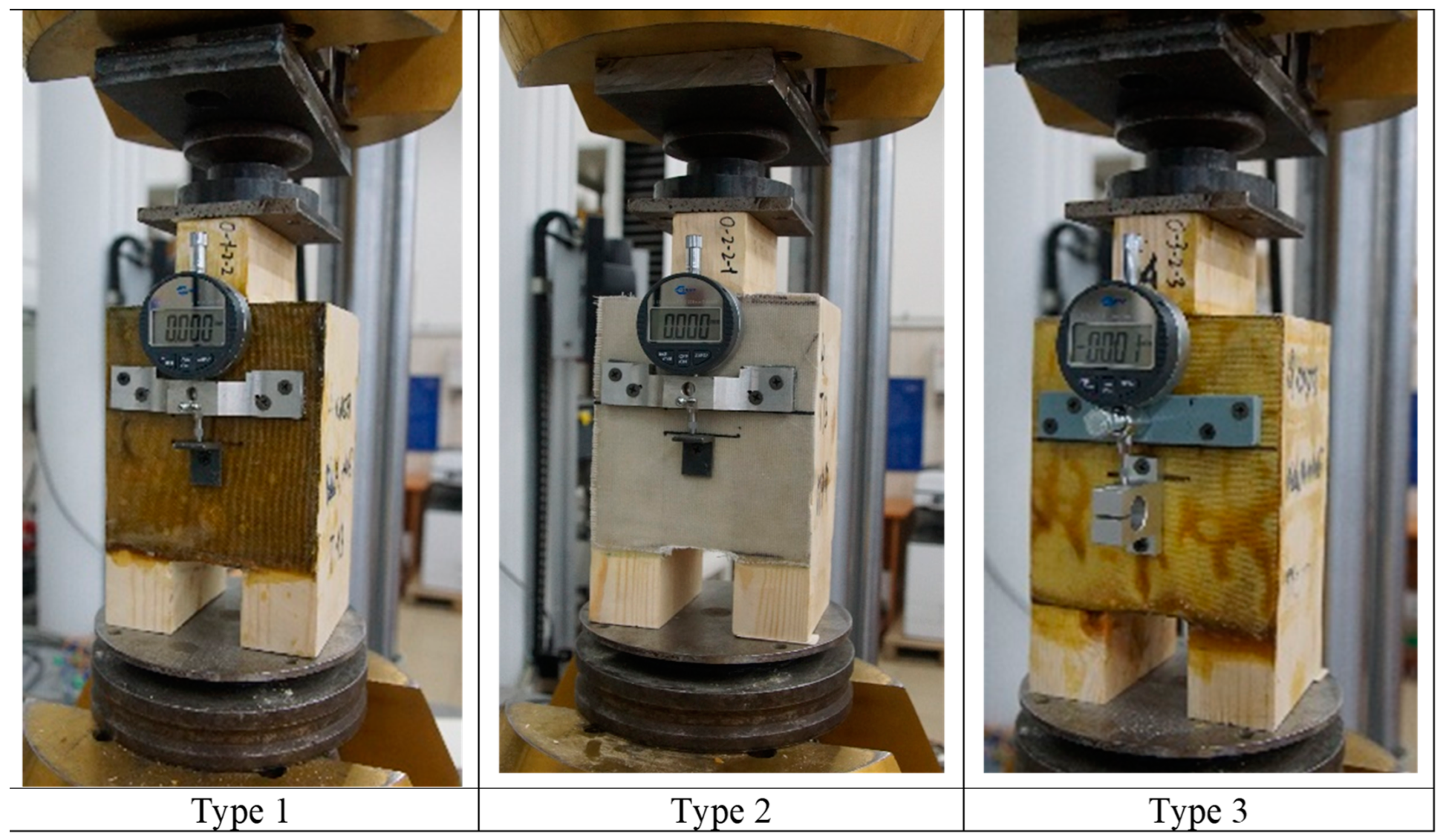

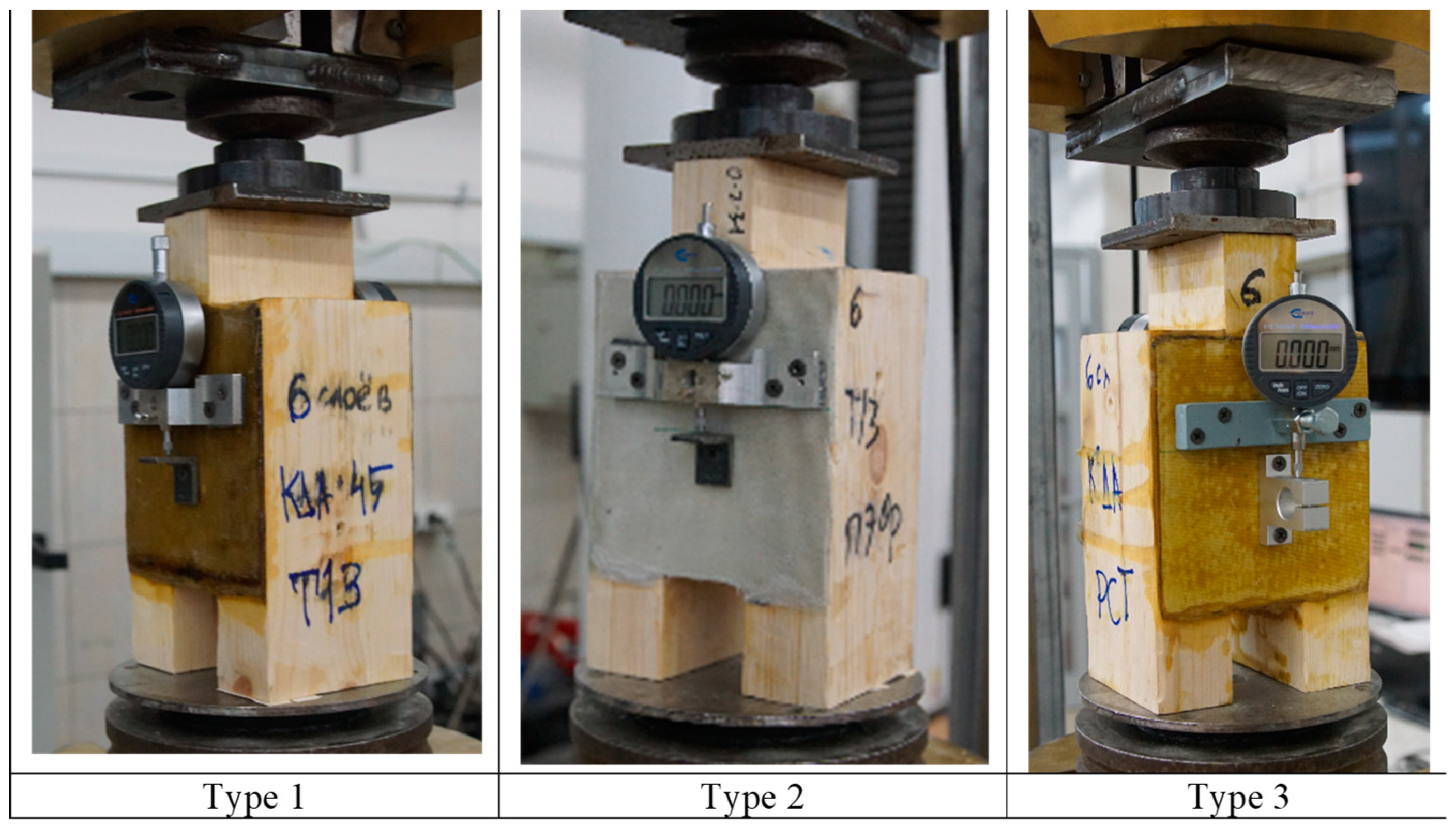

2. Materials and Methods

3. Results

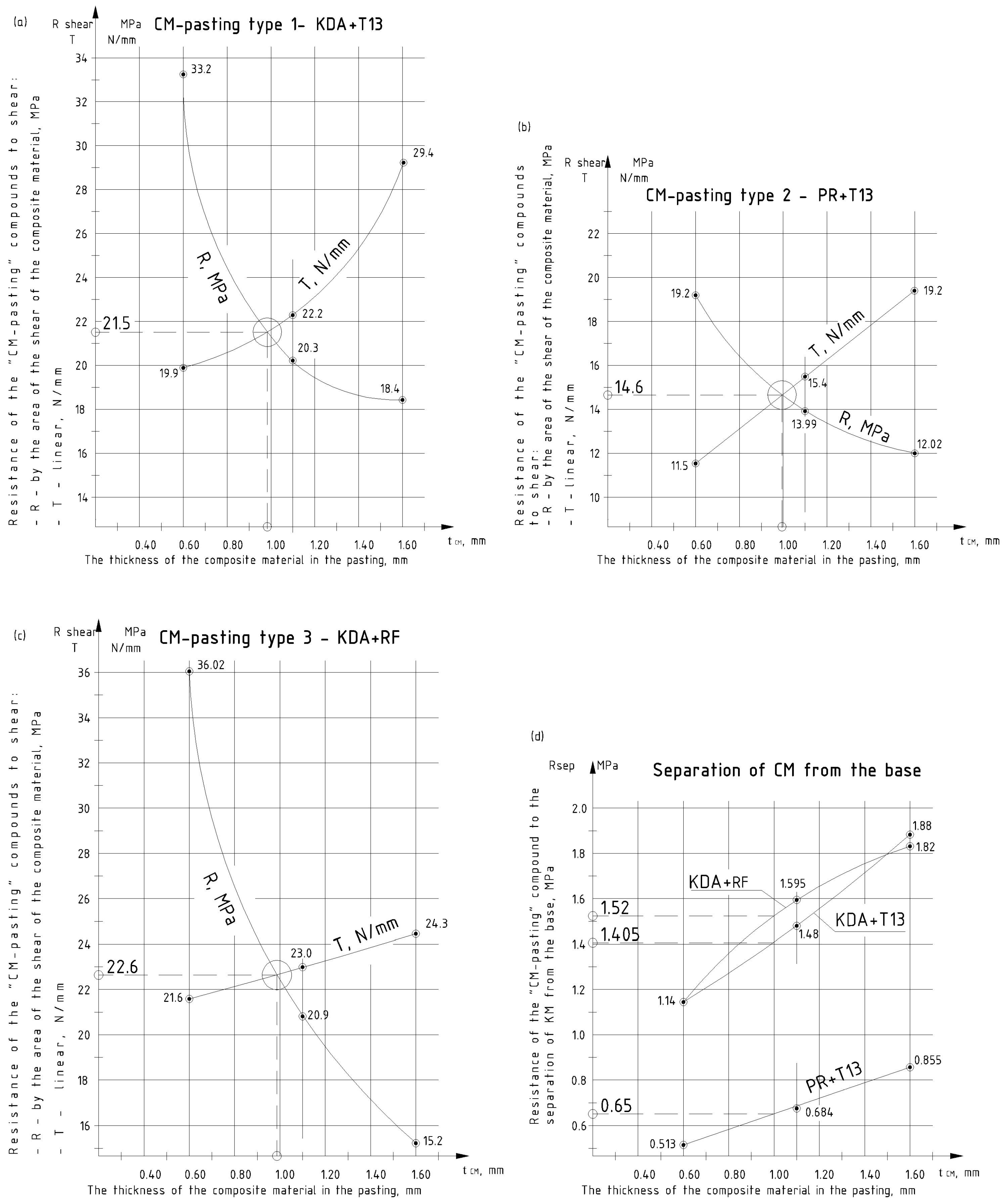

- By a destructive force:

- At a force corresponding to the upper boundary of the area of elastic joint operation:

- By the area of the cut of the composite material along the length of the seam as linear shear resistance.

- As the linear bearing capacity of the joint—by 1 cm (mm) of the seam length:where Np is the force corresponding to the calculated bearing capacity of the sample (kN (N)); navg is the resistance of the joint to the shear force on the separation of the composite material from the base:TFGC = Np/(navg × Lseam),where npl = 2 is the number of separation planes.RsepFGC = Np/[npl × (Lseam × b)],

- As the resistance of the joint to shear force along shear:where (Lseam ∗ tFGC) is the working cross-sectional area per 1 slice in the sample; b is the width of the wooden element.RavgFGC = Np/[navg ∗ (Lseam ∗ tFGC)],

- −

- The design of the shear resistance of the composite material for type 1 joints RavgFGC1 = 21.5 MPa, for type 2 joints RavgFGC2 = 14.6 MPa, and for type 3 joints RavgFGC3 = 22.6 MPa.

- −

- The calculated resistance toward the separation of the composite material from the base for type 1 joints RavgFGC1 = 1.4 MPa, for type 2 joints RavgFGC2 = 0.65 MPa, and for type 3 joints RavgFGC3 = 1.5 MPa.

4. Discussion

- The design in shear resistance of the composite material:

- −

- For fiberglass connections type 1 (KDA-M + T13) and type 3 (KDA-M + RF):RshFGC = 20 MPa.

- −

- For fiberglass connections type 2 (PR + T13):RshFGC = 14 MPa.

- The calculated resistance to the separation of the composite material from the base:

- −

- For connections type 1 (KDA-M + T13) and type 3 (KDA-M + RF):

- For composite material thickness up to 1 mm Rsep·FGC = 0.9 MPa;

- For composite material thickness from 1 mm to 1.6 mm Rsep·FGC = 1.0 MPa;

- For composite material thickness more than 1.6 mm Rsep·FGC = 1.1 MPa.

- −

- For connections type 2 (PR + T13):

- For composite material thickness up to 1 mm Rsep·FGC = 0.5 MPa;

- For composite material thickness from 1 mm to 1.6 mm Rsep·FGC = 0.68 MPa;

- For composite material thickness more than 1.6 mm Rsep·FGC = 0.85 MPa.

- The deformability of connections at the level of calculated load-bearing capacity:

- −

- For connections type 1 and type 3 Dp/Nd = 0.0021 mm/kN;

- −

- For connections type 2 Dp/Nd = 0.0031 mm/ kN.

- −

- For this type of compound, based on an epoxy matrix and T13 fiberglass or RF fiberglass RshFGC = 20 MPa;

- −

- For this type of compound, based on a polyester matrix and T13 fiberglass RshFGC = 14 MPa.

- (a)

- From the shearing conditions of the composite material:where RshearFGC = RshFGC/(γm ∗ γmn) is the calculated resistance of fiberglass connection; RshCM is the design shear resistance of the composite material; γm = 1.2 is the reliability coefficient for a composite material in this type of compound; γmn = 1.4 is the reliability coefficient by the method of manufacturing a joint for the manual molding of a composite material and a cold-curing epoxy matrix under construction site conditions, where γmn = 1.1 in conditions of organized production; LFGC = LO −2 × 50 is the estimated length of this compound; tFGC is the thickness of this compound; and nsh is the number of calculated shears of this type of compound in the calculated area.[Tshear FGC] = RshearFGC × LFGC × tFGC × nsh,

- (b)

- From the condition of separation of the composite material from the surface of wooden elements:where RSEP = RsepFGC/(γm ∗ γmn) is the calculated resistance of the fiberglass joint to the separation from the surface of the wooden element; RsepFGC—see point 8.62; and npl − npl = 2 is the number of planes separation of the fiberglass from the wooden element in the design area. The estimated length of this compound should be taken as 2 × 50 mm less than the actual length of the pasting LO at the estimated seam.[TSEP FGC] = RSEP × LFGC × h1 × npl,

5. Conclusions

- Calculated shear resistance of composite material for type 1 joints (KDA-M + T13) and type 3 (KDA-M + RF) RavgFGC = 20 MPa.

- Calculated shear resistance of composite material for type 2 joints (PR + T13) RavgFGC = 14 MPa.

- Calculated resistance to the separation of composite material from the base for type 1 joints (KDA-M + T13) and type 3 (KDA-M + RF):

- −

- For composite material thickness up to 1 mm Rsep·FGC = 0.9 MPa;

- −

- For composite material thickness from 1 mm to 1.6 mm Rsep·FGC = 1.0 MPa;

- −

- For composite material thickness greater than 1.6 mm Rsep·FGC = 1.1 MPa.

- Calculated resistance to the separation of the composite material from the base for type 2 joints (PR + T13):

- −

- For composite material thickness up to 1 mm Rsep·FGC = 0.5 MPa;

- −

- For composite material thickness from 1 mm to 1.6 mm Rsep·FGC = 0.68 MPa;

- −

- For composite material thickness greater than 1.6 mm Rsep·FGC = 0.85 MPa.

- Total deformations at the level of the calculated load-bearing capacity of this type of compound were Dp = 0.024−0.038 mm, which corresponds to the intensity of deformation growth on average Dp/Nd = 0.0019−0.0023 mm/kN for type 1 and type 3 joints, and 0.0031 for type 2 joints.

- The recommended ratio between the width of the glued surfaces of the wooden elements and the thickness of the composite material tFGC = 1/45 bpasting has been determined.

- To ensure the operation of this type of compound from the cut-off condition of the composite material, the minimum thickness layer in the working joint should be at least tFGC = 1 mm.

- Similar studies need to be carried out on samples using linear and beam models.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Rutman, U.L.; Meleshko, V.A. The generalization of the flexibility method for elastoplastic computation of rod systems. Mater. Phys. Mech. 2017, 31, 67–70. [Google Scholar]

- Kozinetc, K.G.; Kärki, T.; Barabanshchikov, Y.G.; Lahtela, V.; Zotov, D.K. Mechanical properties of sustainable wooden structures reinforced with Basalt Fiber Reinforced Polymer. Mag. Civ. Eng. 2020, 100. [Google Scholar] [CrossRef]

- Togay, A.; Döngel, N.; Söğütlü, C.; Ergin, E.; Uzel, M.; Güneş, S. Determination of the Modulus of Elasticity of Wooden Construction Elements Reinforced with Fiberglass Wire Mesh and Aluminum Wire Mesh. BioResources 2017, 12, 2466–2478. [Google Scholar] [CrossRef]

- Trummer, A.; Wilhelm, F. Zuschnitt 17. Holz + Proholz. Austria 2005, 11, 24. [Google Scholar][Green Version]

- Blaß, H.; Romani, M. Biegezugverstärkung von Brettschichtholz mit CFK- und AFK-Lamellen. Bautechnik 2002, 79, 216–224. [Google Scholar][Green Version]

- Blaß, H.; Romani, M. Tragfähigkeitsuntersuchungen an Verbundträgern aus BS-Holz und Faserverbundkunststoff-Lamellen. Eur. J. Wood Wood Prod. 2001, 59, 364–373. [Google Scholar][Green Version]

- Lisyatnikov, M.S.; Glebova, T.O.; Ageev, S.P.; Ivaniuk, A.M. Strength of Wood Reinforced with a Polymer Composite for Crumpling across the Fibers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 896, 012062. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/896/1/012062/pdf (accessed on 17 October 2023). [CrossRef]

- Zachary, C.; Kavan, S. Feasibility of Strengthening Glulam Beams with Prestressed Basalt Fibre Reinforced Polymers; Department of Civil and Environmental Engineering, Division of Structural Engineering Steel and Timber Structures, Chalmers University of Technology: Göteborg Sweden, 2012. [Google Scholar]

- Stoyanov, V.O. Strength and Deformability of Bent Wooden Elements Reinforced with Polymer Composites. Master’s Thesis, TSNIISK Named after V.A. Kucherenko—M, Moscow, Russia, 2018. (In Russian). [Google Scholar]

- Schober, K.-U. Hochleistungskunststoffe für die Tragwerksverstärkung von Holzkonstruktionen im Bestand. Z. Nachhalt. Bau. Bauwerkserhaltung Denkmalpfl. Sonderdr. Bausubstanz 2010, 4, 38–43. [Google Scholar]

- Geshanov, I.; Kachlakev, D. Composite reinforce concrete-timber floor system externally strengthened with CFRP composite. In Proceedings of the 13th International Conference SFR, Edinburgh, UK, 6–9 September 2010; pp. 151–153. [Google Scholar]

- CNR-DT 201 Advisory Committee on Technical Recommendations for Construction. Italy. 2005, p. 58. Available online: https://www.cnr.it/en/node/2637 (accessed on 17 October 2023).

- Franke, S.; Franke, B.; Harte, A.M. Failure modes and reinforcement techniques for timber beams—State of the art. Constr. Build. Mater. 2015, 97, 2–14. [Google Scholar] [CrossRef] [PubMed]

- Zhou, A.; Tam, L.; Zechuan, Y.; Lau, D. Effect of moisture on the mechanical properties of CFRP–wood composite: An experimental and atomistic investigation. Compos. Part B 2015, 71, 63–73. [Google Scholar] [CrossRef]

- Tam, L.; Zhou, A.; Yu, Z.; Qiu, Q.; Lau, D. Understanding the effect of temperature on the interfacial behavior of CFRP-wood composite via molecular dynamics simulations. Compos. Part B 2017, 109, 227–237. [Google Scholar] [CrossRef]

- Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1995.1.1.2004.pdf (accessed on 17 October 2023).

- Eurocode 5: Design of Timber Structures—Part 1-2: General—Structural Fire Design. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1995.1.2.2004.pdf (accessed on 17 October 2023).

- Eurocode 5: Design of Timber Structures—Part 2: Bridges. Available online: https://www.phd.eng.br/wp-content/uploads/2015/02/en.1995.2.2004.pdf (accessed on 17 October 2023).

- DIN EN 408-2012; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. Beuth Verlag GmbH: Berlin, Germany, 2012.

- ACI 440R-96; State-of-the-Art Report on Fiber Reinforced Plastic (FRP) Reinforcement for Concrete Structures, Reported by ACI Committee. ACI Committee: Farmington Hills, MI, USA, 2002. Available online: https://www.alientechnologies.ru/wp-content/uploads/440r_96-State-of-the-Art-Report-on-Fiber-Reinforced-Plastic-Reinforcement-for-Concrete-Structures.pdf (accessed on 17 October 2023).

- SP 64.13330.2017; Wooden Structures. Updated Version of SNiP II-25-80. Ministry of Construction and Housing and Communal Services of the Russian Federation: Moscow, Russia, 2018.

- Ivanov, Y.M. Recommendations for Testing Joints of Wooden Structures; Stroyizdat: Moscow, Russia, 1981. [Google Scholar]

- Corradi, M.; Borri, A.; Righetti, L.; Speranzini, E. Uncertainty analysis of FRP reinforced timber beams. Compos. B Eng. 2017, 113, 174–184. [Google Scholar] [CrossRef]

- Shekarchi, M.; Farahani, E.M.; Oskouei, A.V. Effect of seawater on pull-out behavior of glued-in single rods set parallel to the grain of timber joints. Constr. Build. Mater. 2019, 222, 342–357. [Google Scholar] [CrossRef]

- De Luca, V.; Marano, C. Prestressed glulam timbers reinforced with steel bars. Constr. Build. Mater. 2012, 30, 206–217. [Google Scholar] [CrossRef]

- Schober, K.-U.; Tannert, T. Hybrid connections for timber structures. Wood Prod. 2016, 74, 369–377. [Google Scholar] [CrossRef]

| No. | Components | GOST, TU | Mass Parts | Polymerization Temperature | Technological Viability (t = 25 °C), min |

|---|---|---|---|---|---|

| 1 | Resin KDA-M | TU 2225-042-17411121-2008 | 100 | from +5 °C to +35 °C | 60 |

| Hardener Etal-45 | TU 2257-045-18826195-01 | 50 | |||

| 2 | Resin ED-20 | GOST 10587 | 100 | Not lower than 18 °C to +35 °C | 30 |

| Hardener PEPA | TU 6-02-594-80 | 10 ÷ 15 | |||

| Plasticizer DBP | GOST 8728 | 5 ÷ 10 | |||

| 3 | Polyester resin PolyTay 303TAE | GOST 27952 | 100 | 20 °C | 120 |

| Hardener Butanox-M50 | 2.5 |

| Series | No. | Sample Brand | Connection Type | Number of Layers | Composition | Wood Grade Type |

|---|---|---|---|---|---|---|

| 1 —samples of 2nd layer of fiberglass | 1 | O-1-1-1 | 1 | 2 layers | KDA/Etal 45 + T13 | 2 |

| 2 | O-1-1-2 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 3 | O-1-1-3 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 4 | O-2-1-1 | 2 | 2 layers | PR/B-M50 + T13 | 2 | |

| 5 | O-2-1-2 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 6 | O-2-1-3 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 7 | O-3-1-1 | 3 | 2 layers | KDA/Etal 45 + RF | 2 | |

| 8 | O-3-1-2 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- | |

| 9 | O-3-1-3 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- |

| Series | No. | Sample Brand | Connection Type | Number of Layers | Composition | Wood Grade Type |

|---|---|---|---|---|---|---|

| 2 —samples of 4th layer of fiberglass | 10 | O-1-2-1 | 1 | 4 layers | KDA/Etal 45 + T13 | 2 |

| 11 | O-1-2-2 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 12 | O-1-2-3 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 13 | O-2-2-1 | 2 | 4 layers | PR/B-M50 + T13 | 2 | |

| 14 | O-2-2-2 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 15 | O-2-2-3 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 16 | O-3-2-1 | 3 | 4 layers | KDA/Etal 45 + RF | 2 | |

| 17 | O-3-2-2 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- | |

| 18 | O-3-2-3 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- |

| Series | No. | Sample Brand | Connection Type | Number of Layers | Composition | Wood Grade Type |

|---|---|---|---|---|---|---|

| 3 —samples of 6 layers of fiberglass | 19 | O-1-3-1 | 1 | 6 layers | KDA/Etal 45 + T13 | 2 |

| 20 | O-1-3-2 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 21 | O-1-3-3 | 1 | -- “ -- | KDA/Etal 45 + T13 | -- “ -- | |

| 22 | O-2-3-1 | 2 | 6 layers | PR/B-M50 + T13 | 2 | |

| 23 | O-2-3-2 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 24 | O-2-3-3 | 2 | -- “ -- | PR/B-M50 + T13 | -- “ -- | |

| 25 | O-3-3-1 | 3 | 6 layers | KDA/Etal 45 + RF | 2 | |

| 26 | O-3-3-2 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- | |

| 27 | O-3-3-3 | 3 | -- “ -- | KDA/Etal 45 + RF | -- “ -- |

| Connection Type | Sample Brand | tmax sec. | t = tmax/38.2 sec. | Lg t sec. | Reliability Coefficients | Nmax kN | |

|---|---|---|---|---|---|---|---|

| γν by Formula | Required by NI-II | ||||||

| 1 | O-1-1-1 | 740 | 19.372 | 1.287 | 2.94 | 36 | |

| O-1-1-2 | 644 | 16.859 | 1.227 | 2.95 | 33 | ||

| O-1-1-3 | 837 | 21.911 | 1.341 | 2.93 | 36.4 | ||

| Avg. | 740 | 2.937 | 1.3 | 35.13 | |||

| 2 | O-2-1-1 | 393 | 10.288 | 1.012 | 2.99 | 24.1 | |

| O-2-1-2 | 397 | 10.393 | 1.017 | 2.99 | 24 | ||

| O-2-1-3 | 393 | 10.288 | 1.012 | 2.99 | 24 | ||

| Avg. | 394 | 2.989 | 1.3 | 24.03 | |||

| 3 | O-3-1-1 | 1185 | 31.021 | 1.492 | 2.90 | 47.8 | |

| O-3-1-2 | 555 | 14.529 | 1.162 | 2.96 | 30 | ||

| O-3-1-3 | 763 | 19.974 | 1.300 | 2.93 | 36.1 | ||

| Avg. | 834 | 2.931 | 1.3 | 37.97 | |||

| Connection Type | Sample Brand | tmax sec. | t = tmax/38.2 sec. | Lg t sec. | Reliability Coefficients | Nmax kN | |

|---|---|---|---|---|---|---|---|

| γν by Formula | Required by NI-II | ||||||

| 1 | O-1-2-1 | 845 | 22.120 | 1.345 | 2.93 | 39 | |

| O-1-2-2 | 844 | 22.094 | 1.344 | 2.93 | 38.9 | ||

| O-1-2-3 | 846 | 22.147 | 1.345 | 2.93 | 39 | ||

| Avg. | 845 | 2.926 | 1.3 | 38.97 | |||

| 2 | O-2-2-1 | 840 | 21.990 | 1.342 | 2.93 | 38.2 | |

| O-2-2-2 | 843 | 22.068 | 1.344 | 2.93 | 38.9 | ||

| O-2-2-3 | 850 | 22.251 | 1.347 | 2.93 | 38.9 | ||

| Avg. | 844 | 2.926 | 1.3 | 38.67 | |||

| 3 | O-3-2-1 | 1854 | 48.521 | 1.686 | 2.86 | 45 | |

| O-3-2-2 | 643 | 16.832 | 1.226 | 2.95 | 33 | ||

| O-3-2-3 | 956 | 25.026 | 1.398 | 2.92 | 42 | ||

| Avg. | 1151 | 2.908 | 1.3 | 40.0 | |||

| Connection Type | Sample Brand | tmax sec. | t = tmax/38.2 sec. | Lg t sec. | Reliability Coefficients | Nmax kN | |

|---|---|---|---|---|---|---|---|

| γν by Formula | Required by NI-II | ||||||

| 1 | O-1-3-1 | 1591 | 41.649 | 1.620 | 2.87 | 57 | |

| O-1-3-2 | 1310 | 34.293 | 1.535 | 2.89 | 49.6 | ||

| O-1-3-3 | 1184 | 30.995 | 1.491 | 2.90 | 46.3 | ||

| Avg. | 1326 | 2.887 | 1.3 | 50.97 | |||

| 2 | O-2-3-1 | 949 | 24.843 | 1.395 | 2.92 | 41.4 | |

| O-2-3-2 | 943 | 24.686 | 1.392 | 2.92 | 39 | ||

| O-2-3-3 | 1085 | 28.403 | 1.453 | 2.92 | 45 | ||

| Avg. | 992 | 2.913 | 1.3 | 41.8 | |||

| 3 | O-3-3-1 | 1200 | 31.414 | 1.497 | 2.90 | 48 | |

| O-3-3-2 | 1062 | 27.801 | 1.444 | 2.91 | 43.4 | ||

| O-3-3-3 | 751 | 19.660 | 1.294 | 2.94 | 36 | ||

| Avg. | 1004 | 2.913 | 1.3 | 42.47 | |||

| Type of Fiberglass | Number of Layers | Dp/Np at the RNS ∗ Level of the Sample, mm/kN | Resistance of the Fiberglass Joint to Shear | ||

|---|---|---|---|---|---|

| By the Area of the Shear RavgFGC, MPa | Linear, TFGC, N/mm | Separation, RsepFGC, MPa | |||

| Type 1 KDA + T13 | 2 layers | 0.00199 | 33.23 | 19.9 | 0.886 |

| 4 layers | 0.00191 | 20.18 | 22.2 | 0.987 | |

| 6 layers | 0.00178 | 18.40 | 29.4 | 1.308 | |

| Type 2 PR + T13 | 2 layers | 0.00362 | 19.23 | 11,5 | 0.513 |

| 4 layers | 0.00254 | 13.99 | 15.4 | 0.684 | |

| 6 layers | 0.00313 | 12.02 | 19.2 | 0.855 | |

| Type 3 KDA + RF | 2 layers | 0.00295 | 36.02 | 21.6 | 0.960 |

| 4 layers | 0.00240 | 20.87 | 23.0 | 1.020 | |

| 6 layers | 0.00162 | 15.20 | 24.3 | 1.081 | |

| Type Fiberglass | Thickness Fiberglass | Rsep·FGC, MPa |

|---|---|---|

| KDA-M + T13 KDA-M + RF | up to 1 mm | 0.9 |

| from 1 mm to 1.6 mm | 1.0 | |

| more than 1.6 mm | 1.1 | |

| PR + T13 | up to 1 mm | 0.5 |

| from 1 mm to 1.6 mm | 0.68 | |

| more than 1.6 mm | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tusnin, A.; Nikolay, L.; Aleksandr, K. The Load-Bearing Capacity and Deformability of Connections of Wooden Elements with Composite Materials Based on Fiberglass. Buildings 2023, 13, 3063. https://doi.org/10.3390/buildings13123063

Tusnin A, Nikolay L, Aleksandr K. The Load-Bearing Capacity and Deformability of Connections of Wooden Elements with Composite Materials Based on Fiberglass. Buildings. 2023; 13(12):3063. https://doi.org/10.3390/buildings13123063

Chicago/Turabian StyleTusnin, Alexander, Linkov Nikolay, and Klyukin Aleksandr. 2023. "The Load-Bearing Capacity and Deformability of Connections of Wooden Elements with Composite Materials Based on Fiberglass" Buildings 13, no. 12: 3063. https://doi.org/10.3390/buildings13123063

APA StyleTusnin, A., Nikolay, L., & Aleksandr, K. (2023). The Load-Bearing Capacity and Deformability of Connections of Wooden Elements with Composite Materials Based on Fiberglass. Buildings, 13(12), 3063. https://doi.org/10.3390/buildings13123063