Abstract

Guided by the technical requirements for tunnel fire safety, an overview of tunnel piston wind, combustion models, and full-size and small tunnel fire tests is presented. Firstly, the theoretical model and numerical calculation methods for piston wind tunnel fires are presented from the perspective of numerical simulation. Then, full-scale and small-scale test models for tunnel fires are presented, and the advantages and disadvantages of single-row, multi-row, single-fire source, and multi-fire source test methods are described. Finally, key breakthrough directions for future numerical and experimental research on piston winds and tunnel fires are proposed, specifically the mastery of underground tunnel fire development prediction methods. This involves mastering the full-scene elemental fire testing technology for underground tunnel operation systems; developing multi-channel data acquisition technology for fire tests under the effect of multiple disturbances such as high temperature and high humidity; and mastering the smoke flow law during fires in complex tunnel projects.

1. Introduction

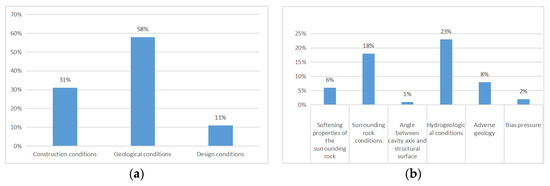

1.1. Current Status of Tunnel Development

Tunnels are an important part of the world’s transport system today. The construction of tunnels not only relieves the increasing pressure of ground traffic but also overcomes the inconvenience of mountain peaks, rivers and seas, and other terrain and is of great significance in building a faster, safer, and more three-dimensional urban transport network. According to the geographical locations of the tunnels, they can generally be divided into tunnels through mountains, cross-sea tunnels, underground tunnels, etc. According to the statistics of China Statistical Information Network, the main factors affecting the structural stability of mountain tunnels include hydrogeological conditions, construction conditions, and design conditions, among which geological conditions are the dominant factor, accounting for more than half, as shown in Figure 1.

Figure 1.

Stability factors in mountain tunnels. (a) Factors influencing structural stability. (b) Factors influencing geological conditions.

The country’s territory is vast, and its terrain is complex. The construction of tunnels can overcome the difficulties of the terrain and enhance the convenience of transportation. With the rapid growth of the national economy, tunnel construction has gradually accelerated, and China has become the country with the largest number of tunnels and the most complex tunnel system in the world. In the early years of tunnel construction, China focused on developing tunnels through mountains and across the sea, with some of the more iconic tunnel projects being the Dayaoshan Tunnel, the Qinling Tunnel, and the Jiaozhou Bay Cross-Harbour Tunnel. In the 1970s, China’s first metro tunnel was officially opened to traffic, providing a more convenient option for public transport. Due to the limited and complex nature of urban underground space resources, new tunnels are often constructed through existing tunnels, which inevitably generates additional stresses and additional deformations, creating great safety hazards [1,2]. In addition, in order to achieve greater traffic volumes, traffic densities are gradually increasing, departure intervals are being shortened, and tunnels are running multiple trains in the same direction, especially in urban metro tunnels, where urban metro trains run more frequently than inter-city trains and tunnel lengths are gradually increasing. With the development of metro construction, the number of trains running simultaneously in tunnels is bound to increase year after year. The increase in the number of trains traveling in a tunnel makes the tunnel flow field more complex, with important implications for the tunnel environment and disaster prevention [3,4,5].

1.2. Piston Wind Formation

After the sixties of the twentieth century, Japan, Britain, France, and other countries built high-speed railways. Trains, in the moments of entering and leaving the tunnel and in the tunnel rendezvous and running process, encounter aerodynamic problems that become more prominent and complex than on the bright line and will bring some new aerodynamic problems, mainly involving three major aspects, namely tunnel pressure waves, train air resistance, and tunnel environmental control. In view of this situation, the International Symposium on Aerodynamics and Ventilation of Vehicle Tunnels (ISAVVT), initiated and organized by the Institute of Fluid Engineering, the British Association for Fluid Mechanics Research, has been held every three years since 1973 to discuss and exchange the latest research results on tunnel aerodynamics from around the world.

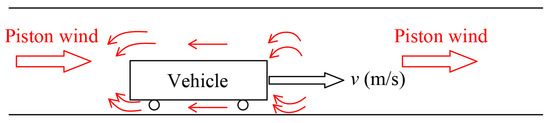

Different from other open space traffic roads, tunnels are narrow and long semi-enclosed spaces. In addition to structural calculations at the initial stage of construction, one also needs to design their internal airflow. Due to the special geometry of tunnels, there exists a special airflow form, namely tunnel piston wind [6,7,8]. When a train is moving fast in a tunnel, air does not flow as smoothly to the back of the train as it does in free space because of the limited space in the tunnel. This allows only part of the air to flow to the rear of the train through the annular space between the train and the tunnel. Most of the air accumulates in front of the train and is constantly squeezed by the front end, with the air pressure gradually rising. Eventually, driven by the train and its emissions, it moves in the direction of the train through the tunnel exit. Accordingly, since the airflow behind the train is in a state of negative pressure, part of the air from the tunnel entrance is constantly introduced into the tunnel, moving in the direction of the train to replenish the air behind the train, as shown in Figure 2. A flow in which none of the physical quantities in the flow field, such as flow velocity and flow rate, characterizing the operational state of the fluid change with time is called a constant flow, and conversely, a non-constant flow [9,10,11,12]. It can be seen that the piston wind is generated with the motion of the train, varies with time until it reaches stability, and changes accordingly with the change of the train’s motion state, so the tunnel piston wind is a non-constant flow.

Figure 2.

Piston wind inside the tunnel.

The study of tunnel aerodynamics has long been carried out in two main areas: the problem of the instantaneous pressure of the train as it drives into the tunnel and the problem of the air resistance of the train in the tunnel. Particular attention has been paid to the first problem. The piston wind problem has been touched upon in the above studies, but it lacks relevance and systematicity. In general, there appear to be four main types of approaches to theoretical research on piston winds. The first type of research uses a one-dimensional incompressible steady-state flow model, and the main purpose of the research is to determine the air resistance of the train in the tunnel. In the determination of the resistance, one must first determine the piston wind speed by using the basic equations of fluid mechanics, according to the total tunnel pressure balance, to calculate the piston wind speed, and then determine the resistance. In the head and tail studies, where airflow velocities in the tunnel are concerned, the velocity relative to the train is used. In the literature [13,14], the velocity relative to the tunnel is used when studying the friction of the train wall on the airflow in the annular space, while the velocity relative to the train is used for the tunnel wall. In the literature [15], the velocities of the annular gap airflow are used relative to the tunnel. These studies all consider tunnel length, train length, blockage ratio, travel speed, and tunnel wall and train wall friction coefficients as the main factors influencing the piston wind theory. The second type of study still uses a one-dimensional incompressible steady-state flow model, and the main objective of the study is to estimate the train air resistance based on the pressure rise in the tunnel. This approach considers that the surface drag caused by the train flanks can be estimated from the pressure rise in the tunnel. The surface drag produces a pressure gradient in the wind flow, and the determination of this gradient enables the surface drag generated by the train flanks to be estimated. The pressure gradient is based on the pressure rise value during the time between the train entering the tunnel and the pressure wave generated by the rear of the train passing. After the pressure rise value is determined, the basic equations of fluid dynamics and the equivalence relationship allow the determination of the piston wind speed and hence the train resistance. The third type of study uses a one-dimensional compressible steady-state flow model and has the same main objective as the previous two. The fourth type of research uses unsteady-state flow models and is based on numerical calculations to predict aerodynamic problems in tunnels, particularly tunnel pressure waves and, of course, piston wind velocities. The most representative of these is the one-dimensional frictional isentropic flow hypothesis proposed by Professor Vardy in the UK.

An in-depth study of piston air from a theoretical point of view will be an effective way to reduce the energy consumption of mechanical ventilation in tunnels in the current situation of increasingly tight energy supply and will also provide theoretical support and a technical reference for the design and operation of tunnel ventilation.

1.3. Tunnel Fire Hazards

Due to their narrow space and the structural constraints of the piston wind effect, tunnels are difficult to deal with and control in case of accidents [16,17]. According to statistics, fires occur relatively infrequently, but when they do occur, a large amount of toxic gas and high-temperature smoke from burning can accumulate in narrow tunnels and be difficult to eliminate. The piston effect makes the fire more easily spread and difficult to put out, and low visibility increases the difficulty of personnel evacuation and rescue, making tunnels prone to major accidents. The fire hazards in underground tunnels are even more significant. Because subways are deep underground and have less space to connect to the outside, they are more confined than other surface tunnels, and the smoke buildup is more serious [18,19]. At the same time, the high density of human traffic makes underground fire accidents often result in mass fatalities and injuries, generating huge economic losses and adverse social impacts. Statistics on the occurrence of fires in some tunnels at home and abroad in recent years are shown in Table 1.

Table 1.

Statistics on fire incidents in tunnels.

Tunnel fires can be roughly divided into two types. The first is fixed-source fires, in which the fire source is fixed at a specific location in the tunnel. These fires are often caused by a train stopping after an accident in the tunnel, or by a line or equipment. Fixed fires are mainly controlled by the mechanical ventilation system of the tunnel and, in some cases, by piston risk control [20,21,22]. The other type of fire is a moving fire source, where a train is in motion and the fire source is on the train and moving with it due to an accident, equipment failure, or human cause. The fire source moving at high speeds and the influence of the accompanying piston wind around it make the fire situation more complex and unpredictable. When a moving train is on fire, it is usually made to exit the tunnel or enter the platform to extinguish the fire and evacuate people, but it is possible that the train may be forced to stop in the tunnel due to a power supply cut, drive motor failure, emergency braking by passengers, or vandalism. High-temperature smoke can spread rapidly via the piston wind, and the constant replenishment of air by the piston wind may also intensify the fire, which is extremely detrimental to the control of the fire and the evacuation of personnel. Additionally, as the length of the tunnel increases, when multiple trains are traveling in the tunnel at the same time, the movement of the non-flaming train will have a huge impact on the flaming train in the event of a fire in one train [23,24].

A review of the current state of research shows that most of the previous work on confined space fires has been carried out on single confined space fires in tunnels or train carriages. In practice, metro trains may be stopped in a tunnel due to a power system failure caused by a fire in the carriage, with the occupants evacuating to the safety zone through the open single side door and the longitudinal evacuation platform connected to it. In this case, the smoke from the fire not only spreads and settles in the narrow, confined space of the single multi-opening train carriage but also acts as a smoke overflow through the lateral openings of the carriage to spread the smoke in the narrow, confined space of the tunnel. This leads to significant differences in the characteristic parameters of flame pattern and smoke temperature in the double confined space compared to conventional tunnel fires, and the classical prediction models for smoke spread in tunnel fire dynamics are no longer fully applicable.

1.4. Research Content

From the above studies, it can be found that a large number of scholars have carried out a lot of theoretical, experimental, and simulation research work in the tunnel flow field. However, at present, most of the research in the field of tunnels is focused on road tunnels or tunnels with single-motion trains. For special tunnels with multiple motion trains at the same time, there is a lack of research. The following aspects need to be studied in depth.

- Lack of experimental studies and 3D simulations of special tunnels or multi-motor train tunnels. Most of the current tunnel experiments and simulations have been carried out in the absence of trains or in the case of single-motion trains. Experimental studies of tunnels with dual-motion trains based on absolute motion are one of the most important ways to explore the flow field of tunnels with dual-motion trains. It is important to study the flow field of multi-motor trains in tunnels.

- It is essential to study and understand the flow patterns and their influencing factors for two trains running in a tunnel at the same time. Piston winds play an important role in tunnel ventilation, environment, energy consumption, and disaster prevention, while the piston wind law for multi-motion trains operating in tunnels is significantly different from that for single trains, and there is a lack of relevant research. Taking two trains as an example, a study of piston wind patterns and influencing factors is carried out to compare with the tunnel piston wind patterns of single-motion trains and to extend to the tunnel multi-motion train situation, providing a basis for the study of tunnel multi-motion train flow fields.

- The impact of piston winds on the tunnel environment and ventilation energy consumption still needs to be studied in more depth. The use of piston winds can improve the tunnel environment and reduce the energy consumption of mechanical ventilation in tunnels. Therefore, the use of piston winds needs to be studied in depth, and the effect of piston winds on the application of tunnels in different climatic zones needs to be analyzed quantitatively so that tunnels in different regions can make rational use of piston winds to improve their air quality and save energy consumption in mechanical ventilation.

- There is a lack of research on multi-motor train fires in tunnels. The complex piston effect makes it more difficult to control a fire if there are two trains traveling in the same direction in the same tunnel, and the non-fire train will also have an important impact on the fire train. Therefore, there is an urgent need to carry out research on the smoke flow in the event of a fire in a tunnel with a dual motion train, the critical wind speed and critical wind pressure, etc., to provide basic research on fire prevention and disaster prevention in tunnels.

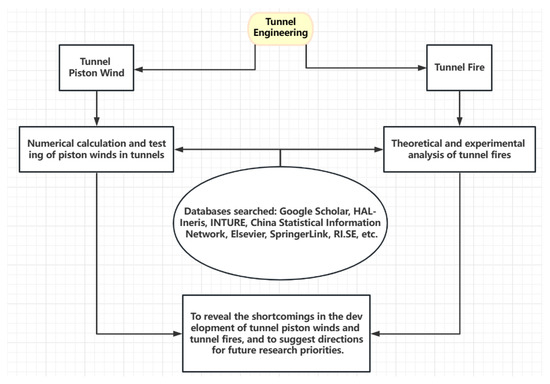

To address the shortcomings of the current study, the main research content and organization of this paper are shown in Figure 3.

Figure 3.

Flow chart of the study.

2. Current Status of Research

2.1. Current Status of Tunnel Piston Wind Research

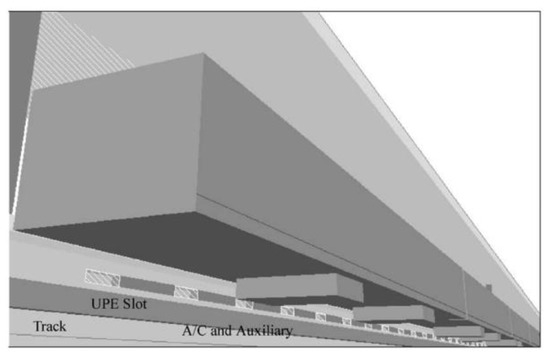

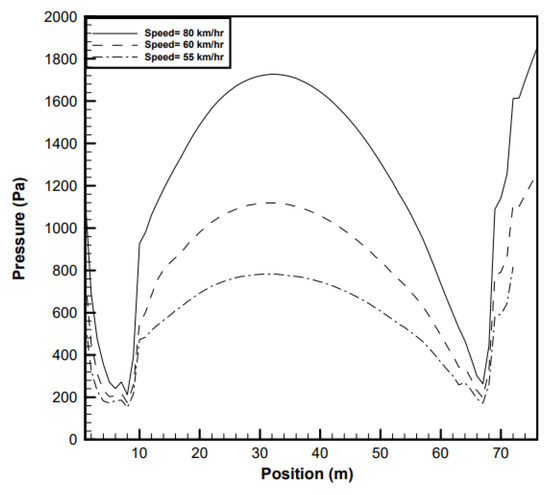

The magnitude of wind speed is one of the main parameters of the piston wind characteristics of metro trains and is studied in a comprehensive manner using theoretical analysis and calculation, computer simulation and analysis, and field instrumentation measurement and recording. With the advancement of computer science, CFD has gradually developed into one of the important methods for fluid mechanics research [25,26]. Computer simulation techniques can reduce the reliance on experimental research methods and save costs, as simulation studies are not restricted by experimental conditions and experimental working conditions. The object of study is modeled into the computer, the computational basin is meshed, and the differential equations governing the fluid flow are solved numerically to produce a discrete distribution of the flow field over a continuous region to approximate the actual fluid flow. The use of the finite volume method to numerically calculate and analyze the pressure field generated by a train passing through a tunnel at high speed has been widely recognized by scholars at home and abroad. In the 1980s, Masakatsu Fukui [27] carried out piston wind measurements and simulations for subways, reducing the cross-section of the tunnel as much as possible while maintaining the space for the underground to run, resulting in a blockage ratio of 53.2%. The airflow generated by the operation of the supply fan located at the end of the interval tunnel was used as the train piston wind. The maximum wind speed value of the train wind in the interval tunnel was simulated to be 9.2 m/s, and the maximum wind speed at the station platform staircase was about 11 m/s. NIU J Q et al. [28] investigated the effects of train acceleration, speed, and platform spacing on wind pressure when the metro train crossed the tunnel using the (RNG) k—ε dual-squared turbulence model using FLUENT software. Ming-Tsun Ke et al. [29] used a combination of 3D CFD simulation software and the underground environment simulation software SES to investigate the effect of underground operating conditions on the underground environment in Taipei and also analyzed the effect of pressure distribution caused by the piston wind effect on platform screen doors. The detailed local map of the underground station studied is shown in Figure 4, and the pressure distribution along the distance when the station area is reached at different speeds is obtained is shown in Figure 5. Zhu F et al. [30] used CFD to study the surface pressure variation of billboards at different locations in underground tunnels affected by piston wind at different train speeds. The maximum pressure on the surface of the billboard under 4 different operating conditions such as 40 km/h, 60 km/h, 80 km/h and 120 km/h were compared and analyzed, and the maximum pressure on the billboard at the maximum speed of 120 km/h was 1081.4 Pa.

Figure 4.

Local detail layout of present underground station [29].

Figure 5.

Pressure distribution along distance when the train head arriving the station area under various speeds [29].

Considering the high speed of the train, the air on the surface of the train is also driven into motion, especially in tunnels where the air is strongly compressed and the flow is restricted, resulting in relative motion between the train and the tunnel wall and the train. In order to realize the relative movement of the train into the tunnel, there are two methods in FLUENT: dynamic meshes and slip meshes [31,32], both of which can calculate transient motion, but they are fundamentally different. The dynamic mesh is the train as a whole, and the UDF is used to assign a velocity to it, which is more in line with the actual train motion, but its calculation process will produce the deformation of the mesh or the re-generation and deletion of the mesh, and the whole area mesh will be constantly updated, so the calculation time is long and convergence is difficult with the dynamic mesh method. With the guarantee of computational accuracy, the above problems do not occur with the sliding mesh method. The slip-grid method separates the entire region into moving and stationary parts and transfers information through the interface between the slip-grid regions. The governing equations are as follows [33]:

where represents the fluid velocity vector; represents the slip grid movement velocity vector.

In addition, to obtain a solution for the numerical calculation, not only the initial conditions are required, but also the correct boundary conditions need to be set. During the actual operation of the train, when the pressure waves propagate and break out of the tunnel, they dissipate into the surrounding atmosphere and do not reflect continuously as they do in the tunnel, whereas it is not possible to simulate an unlimited range of large airflow fields during the simulation calculations. This calls for the need to set a pressure far-field boundary condition, i.e., where the pressure wave does not reflect. This boundary uses Riemann invariants to describe the state of the flow field on the boundary surface of the computational region where the pressure waves are transmitted [34,35]. Zarnaghsh A et al. [36] performed several simulations using a finite volume numerical method with a dynamic mesh technique to analyze the airflow generated by a moving train in a tunnel ventilated by a jet fan and showed that, for a train in the opposite direction to the jet fan flow direction, their volume flow increases and decreases sharply when the head and tail of the train reach the jet fan.

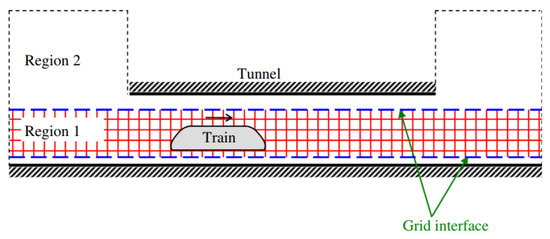

Experimental research is one of the most important methods for studying the flow field of a tunnel motion train and is divided into full-scale experimental research and reduced-size model experimental research. Although full-scale experimental studies can provide the most realistic response to all the characteristics of the research object, they have many difficulties such as expensive, difficult, and dangerous experiments, and restricted experimental conditions. The construction of a tunnel model experimental rig based on similar theories [37,38,39,40] has been widely recognized by scholars at home and abroad. Huang et al. [41] analyzed the effect of piston air and piston air shaft settings on tunnel ventilation effects by numerically simulating the station and comparing it with experimental data. Wang et al. [42] conducted a test study of the metro and monitored the tunnel on both sides of the station for air temperature. The wall surface temperature and wall heat flow density were monitored. The results showed that the heat generated by friction caused a transient increase in air temperature and wall surface temperature when the train passed by, but the piston wind generated also caused a transient increase in wall heat flow density with a large variation. The complex piston wind situation for multi-motor trains operating in tunnels has been less studied. Chu et al. [43] conducted a study for bi-directional tunnels and analyzed the piston wind characteristics when two trains crossed in the tunnel. The principle of the sliding grid method used is shown in Figure 6, and the calculation domain and boundary conditions are shown in Figure 7. Compared to one-way tunnels, bi-directional tunnels have a significantly weaker piston effect due to the increased cross-sectional area of the tunnel. With the increase in tunnel length, multiple trains traveling in the same direction in the same tunnel have emerged, and some scholars have gradually tried to establish a piston wind model for a dual-motion train based on the piston wind model for a single-motion train tunnel [44].

Figure 6.

Schematic diagram of the sliding mesh method [43].

Figure 7.

Schematic diagram of computational domain and boundary condition [43].

In the above studies, the possible existence of curves, slopes and ventilation shafts in tunnels has not been taken into account; therefore, a more comprehensive study of piston wind laws under a variety of tunnel characteristics should be carried out. In addition, in-depth research on piston wind laws should be carried out by means of full-size tunnel experiments, etc. Experimental studies of full-size real tunnels are necessary, and their experimental data will be an important support for piston wind studies of tunnel motion trains. In the normal operation of a long tunnel, if the piston air can be effectively used, the energy consumption of ventilation will be saved. However, in the process of evacuation, rescuing a train from a fire rescue station, the train will go from a constant speed through slowing until it stops, and the tunnel piston wind will demonstrate various forms of change. The tunnel makes the high-temperature smoke flow diffusion extremely complex, obviously different from the case of a fixed fire source, which will also affect ventilation and smoke exhaust in the tunnel fire. This will have a significant impact on the ventilation and evacuation of people in the tunnel during a fire. Research on piston winds in trains has focused on the aerodynamic effects of piston winds, the impact of piston winds on operational ventilation, and the impact of piston winds on the operating environment of trains and has only been conducted for short single-tube tunnels. Therefore, a study of the smoke flow mechanism at the rescue station based on the coupling of fire train operation and piston wind is needed to investigate the effect of piston wind changes on the flow of fire smoke during the process of fire train operation to the rescue station for stopping and evacuation, which will provide technical support for the development of ventilation and smoke extraction countermeasures in long railway tunnels. Considering the influence of the piston effect on fire movement, the force correlation coefficients of the piston effect in different tunnel segments at different movement stages were not explained enough in the process of establishing the calculation model. The relationship between tunnel piston air volume and train length, tunnel length, train speed, blocking ratio, train number, tunnel resistance, and other factors should be established. It can calculate the piston wind law of n trains running at the same time in the tunnel, which is suitable for the multi-motion train tunnel. This will lay the foundation for the study of piston wind in multi-motion train tunnels and form a complete system, which will be helpful for the study of the influence of piston wind on tunnel ventilation, environments, and disasters.

2.2. Current Status of Tunnel Fire Research

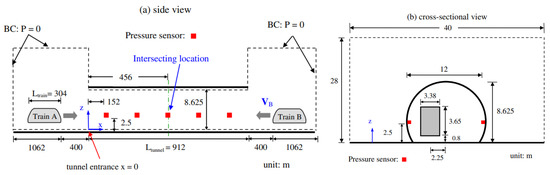

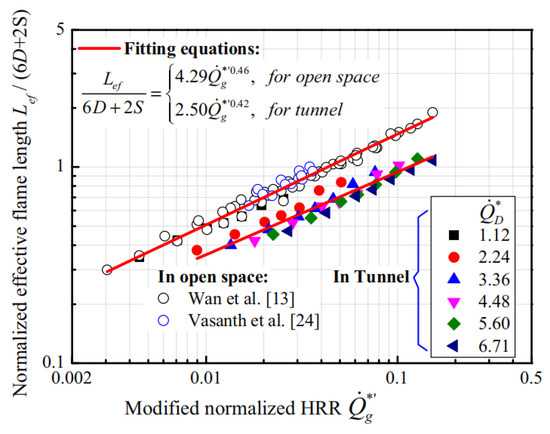

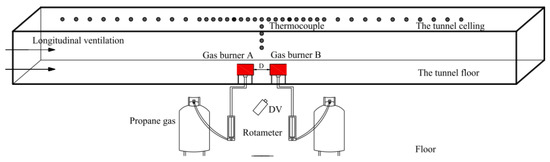

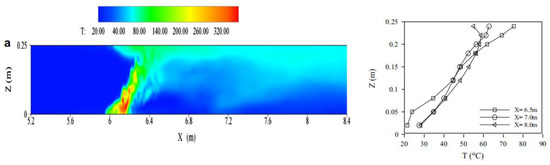

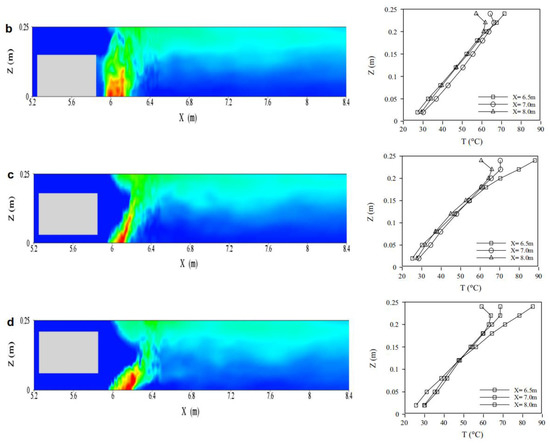

The characteristics of tunnel motion fire are affected by the piston wind generated by train motion, while a moving train fire is a turbulent combustion phenomenon. If only the development law and effective control of fire smoke diffusion are studied, the volumetric heat source model and laminar finite velocity model are not applicable compared with the eddy dissipation conceptual model and component PDF transfer model because the detailed chemical reaction process is not considered. Compared with the eddy dissipation conceptual model and component PDF transfer model, the fast response model consumes less computing resources and has a faster computing speed. In the event of a fire in a moving train in a tunnel, due to the piston wind of the train, fresh airflow from the outside continuously flows into the fire area, generating a large amount of gaseous combustion products and heat as the fire source continues to burn. The fresh airflow into the fire area mixes with the gaseous combustion products and heat to form a high temperature fire smoke stream. Afterwards, the high temperature smoke flows out of the fire zone and heat exchange occurs with the outside world [45,46,47]. Therefore, when evacuating and rescuing a train from a fire in a large tunnel, the wind flow in the tunnel can be considered as a one-dimensional unsteady flow with external heat and mass added, subject to the friction of the tunnel walls and the piston effect of the train, in a turbulent state, and described by a set of partial differential equations for unsteady flow consisting of continuity equations, momentum equations, energy equations, and gas state equations. Huaxian Wan et al. [48]. studied the temperature distribution of ceiling gas and flame support caused by two kinds of interacting energy in the tunnel in order to improve the understanding of the layout of the heat detector and water spraying device. Two identical propane burners are used as energy sources, located in the longitudinal array of the tunnel. The total energy release rate and burner spacing are different. Flame merging probability, ceiling gas temperature, vertical flame height, and longitudinal flame extension length were measured. For the two energy sources in the tunnel, the criterion of flame beginning fusion and flame complete fusion are proposed respectively, and the test device is shown in Figure 8. The results show that the higher the energy release rate, the larger the flame area of the ceiling. The prediction models of roof gas temperature field by two kinds of energy sources are established respectively when the weak plume and the strong plume impact the roof. A modified model considering normalized energy release rate, burner size, and burner spacing is proposed to predict the combination of vertical and longitudinal flame lengths of two burners in a tunnel, as shown in Figure 9.

Figure 8.

Experimental setup [48].

Figure 9.

Modified model prediction [48].

Gannouni S et al. [49] used the Fire Dynamics Simulator (FDS) to numerically study a fire in a longitudinal ventilation tunnel surrounded by obstacles. The influence of obstacle position relative to tunnel floor on critical velocity and length of inversion is analyzed. The results show that the critical ventilation velocity is less when there are obstacles in the tunnel than when there are no obstacles. This reduction increases as the height between the bottom of the obstacle and the tunnel increases (defined here as the height between the bottom of the obstacle and the tunnel floor). The length of the inversion layer decreases with the increase of ventilation volume and increases with the increase of fire heat release rate. LIU Qiong et al. [50] used FDS numerical simulations to obtain the critical wind speed for different scenarios of a tunnel fire with two fire sources at the same time, focusing on the effects of fire power and fire spacing on the critical wind speed downstream of the longitudinal wind and analyzed the changes of the critical wind speed from the energy conversion process of the smoke. CUI X Y et al. [51] constructed a FDS. A numerical model was developed to simulate a two-fire tunnel fire with different fire source widths and spacing. The distribution patterns of the longitudinal temperature near the roof plate, the fire field temperature at the center of the fire source, the tunnel flow field, and the thermal radiation near the fire field were investigated.

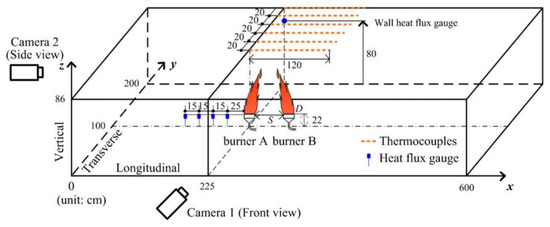

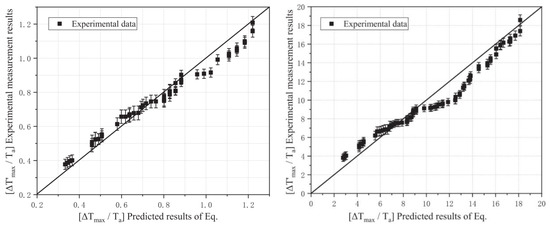

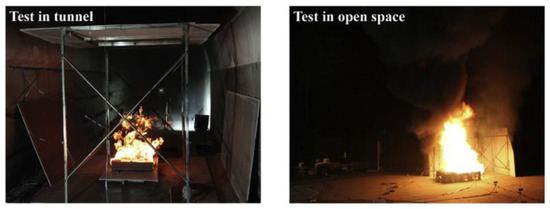

Similar to piston wind test studies, tunnel fire tests are also studied in full-scale and reduced-scale model tests. The simultaneous combustion of two or more independent fire sources is known as the multi-ignition phenomenon, and the combustion behavior of multiple sources differs from that of a single source due to the interaction between them. When the fire sources are close together, a fusion of flames can occur, leading to a regional fire with a significantly higher flame height, which greatly increases the destructiveness and danger of the fire and makes it more difficult to rescue the fire. Therefore, in order to prevent the occurrence of regional fires, a lot of research has been carried out on the problem of multiple fire sources in free space [52,53,54,55]. Multiple-fire source fire accidents can also occur in tunnels due to vehicles colliding with each other and tailgating, etc. However, little research has been conducted on multi-fire source combustion behavior in confined spaces such as tunnels of narrow dimensions. Zhang Yuchun et al. [56] conducted a series of dual-fire source tests in a 1/10 scale model tunnel. The effects of longitudinal ventilation rate, heat release rate, and fire source on the maximum temperature at the top of the tunnel were investigated, and test data on the maximum temperature under dual fire sources were obtained. By comparing with the equations, it was found that the test data could better comply with the equations. The test setup is shown in Figure 10, and the comparison of the test data with equations is shown in Figure 11. A detailed explanation of equations can be found specifically in this article. Qiang Wang et al. [57] also investigated the smoke temperature test in a tunnel without longitudinal ventilation by means of a dual fire source test and developed models for the burner separation distance S and the dimensionless heat release rate Q* and compared the experimental measured data with equations and found that the data were in good agreement. A total of 14 sets of tests on different fire sizes, longitudinal ventilation rates, and tunnel slopes were carried out on model tunnels by Yi L. et al. [58], and temperature profiles and critical rates were derived and discussed. The effect of hydraulic fire suppression systems on combustion products in tunnel fires was also investigated, focusing on carbon monoxide concentration, production, soot production, and visibility [59]. Congling Shi et al. [60] conducted an experimental study of a series of oil pool fires in full-size tunnels and open spaces to obtain mass burn rates and radial temperature distributions of flames, with the test scenario shown in Figure 12. A basic predictive model was first developed using a conventional solid flame model, but it was not very accurate, particularly in open spaces. Then, by comparing the basic prediction model with the measured temperature data, a modified model integrating line of sight factors and other aspects was proposed, and this modified model predicted a temperature rise in good agreement with the experimental data. LIU Chang et al. [13] also investigated the variation of the temperature field and the diffusion of smoke in the tunnel by building a full-size tunnel model. LEI Peng et al. [24] conducted a reduced-scale experiment in a bifurcated tunnel to study the variation of the maximum gas excess. A model to predict the maximum temperature and longitudinal temperature decay below the top of the tunnel was then proposed.

Figure 10.

Experimental setup [56].

Figure 11.

Comparison between the experimental results of maximum temperature beneath tunnel ceiling for double fire sources and equations [56].

Figure 12.

Experimental scenes [60].

In the above study, for tunnel motion fires, the focus of the study is on the smoke temperature distribution pattern and critical wind pressure and wind speed affected by the piston wind when two trains are present in the tunnel at the same time and the previous train is on fire. For the case of multi-motor train fires in very long tunnels, more in-depth studies are still needed, including the application of the critical wind pressure and wind speed model in multi-motor train tunnels and the escape plan for people in fire situations. The critical wind pressure and velocity study is based on the longitudinal ventilation mode, but not on the transverse and semi-transverse ventilation modes, and it is worthwhile to investigate in depth the smoke spread and fire control methods under different ventilation modes. In addition, the metamorphosis theory is applied to the construction of the tunnel model to shorten the length of the tunnel model and facilitate the experimental study of the model for very long tunnels, but the overall study of the metamorphosis model is relatively superficial, only within the margin of error, the applicability of the metamorphosis model for single and dual motion train tunnels is analyzed, and the maximum permissible metamorphosis rate is proposed. Further research is needed to consider whether the maximum permissible metamorphosis rate varies with tunnel length or the number of moving bodies for very long tunnels with multiple trains. It is worth mentioning that the metamorphic model shortened the longitudinal length of the tunnel model, and the tunnel along the resistance will affect the tunnel flow field, so the metamorphic theory needs to be modified. Considering the influence of the change of resistance on the piston wind after shortening the tunnel length, the resistance correction is carried out to further expand the maximum allowable metamorphism rate of the model, which is convenient for the model study of ultra-long tunnels.

2.3. Fire Prevention and Control in Tunnels

In the event of a fire inside a tunnel, there is a high risk that the fire will cause a number of other hazards to not only the vehicles traveling in the tunnel and the people inside them but also to the stability of the tunnel lining structure reducing the life of the tunnel. The tunnel lining structure is usually made up of steel and concrete, and the temperature can affect the strength of the concrete. In the event of a tunnel fire, the more enclosed environment inside the tunnel results in a rapid rise in temperature, and the scorching of high temperature smoke and open flames results in a short loss of strength of the tunnel lining structure, which can cause serious consequences of local vault collapse [61,62,63]. Fire prevention measures in tunnels are becoming more and more complicated. One common fire prevention measure is a fire panel. Due to the cracking and deformation of lining structural concrete and other factors, it is easy to cause the fire-retardant coating to fall off in a damp environment and reduce the fire protection effect. With the popular use of fireproofing panels, the interior of tunnels has also started to adopt fireproofing panels, which can extend the fire resistance limit of tunnel lining concrete by laying fireproofing panels on the smoke exhaust pipe and tunnel lining surface at the vault position in the tunnel [64,65]. In addition, a multi-sensor gradient data fusion model based on a temperature sensor, flame sensor, and smoke sensor to collect temperature information, flame information, and smoke information in the tunnel, respectively, is essential for the prevention and control of fires in the tunnel. JUN-Jie C et al. [66] proposed a data fusion method based on recursive least squares and improved supported WSN. For a single sensor node, the recursive least square method was used for data fusion within the node. HE X et al. [67] developed an improved weighted least squares algorithm based on the enhanced non-Naive Bayes classifier (ENNBC) method. Measurement data density estimation was successfully applied to effective measurement data identification and classification, effectively improving traditional direct classification methods and taking into account the dependencies between successive density attributes. The experimental results show that the proposed algorithm based on four metrics has the best classification performance, calculates the actual center of the class more accurately, and meets the real-time requirements for multi-objective tracking. TAO Q et al. [68] and others considered the special structure of separable non-linear least squares problems and compared the experimental results by comparing the parameter estimates of Gaussian function fitting models and fractional fitting models, resulting in a reduction in the dimensionality of the parameters, the number of iterations and function calculations, and an improved operational rate. Gannouni S et al. [49] believed that the longitudinal ventilation system, which is blocked upstream of the fire to limit the rise of the smoke stream, provides a strategy to protect users and vehicles. However, the presence of vehicles affects the behavior of plume fires and the movement of smoke, as shown in Figure 13.

Figure 13.

Temperature contours and temperature profiles at critical velocity condition for 1.8 kW fire: (a): no obstacle, (b): obstacle at 0 m from tunnel floor, (c): obstacle at 0.03 m. From tunnel floor 3, (d): obstacle at 0.06 m from tunnel floor [49].

In order to improve the tunnel safety, improve the tunnel service quality, increase the tunnel service capacity, reduce the accident rate and damage caused. A tunnel fire risk identification model is established from the perspectives of fire source identification, dangerous substances identification, fire load identification, fire smoke identification and toxicity identification using risk management technology. The fire risk identification model was used to assess the fire risk, and the tunnel fire prevention and control safety strategy was established through regression analysis, time series prediction, and trend prediction. Thus, the tunnel fire safety prevention ability can be significantly enhanced to avoid or reduce the probability of tunnel fire. It is important to note that safety in tunnels is relative and cannot be absolute. The identification, evaluation, and control of safety risks in tunnels must take into account the impact of people, the natural environment, and the internal systems involved. In practice, periodic fire risk checks by operations and maintenance staff and inspections of tunnel fire protection facilities are essential to effectively prevent fires in road tunnels.

Foreign research on tunnel fire risk assessment methods was carried out relatively early. In 2004, the European Commission introduced Directive 2004/54/EC and gave several examples of tunnel risk assessment implementation, among which the more commonly used ones include the Austrian tunnel risk model TuRisMo, the Dutch TUNPRIM model, the French specific hazard survey, the Italian risk analysis model, and the OECD / PIARC DG -QRA model. Although many of these tunnel fire risk assessment models have been proposed, many of the safety issues leading to the generation of tunnel fires have been discussed and a large number of important risk factors and hazard types in tunnels have been identified. However, tunnel fire risk assessment methods are still under development, and new concepts and models are constantly being proposed.

In the field of research on physical devices for road tunnel safety systems, Cigada A et al. [69] have developed a safety system capable of minimizing the risk of fire in road and rail tunnels, which monitors the infrared emission of the entire vehicle (including trains and trucks) as it enters the tunnel. The system uses infrared thermal images obtained from an infrared thermometer capable of detecting infrared radiation from the vehicle and correlates them with the top, bottom, and side views of the vehicle front to back. When the value of the vehicle’s thermal image is above a fixed threshold, the safety system automatically generates an alarm signal to stop and carefully inspect the potentially dangerous vehicle. Such a safety system has been installed and is in actual operation near the entrance to the Frejus tunnel in Italy. Parida B K et al. used a sample of 10 consecutive years of National Transportation Safety Board (NTSB) freight and passenger locomotive accident investigation reports to analyze accident causes and designed a locomotive crash fire experiment on a scaled tank to assess the prevention or mitigation of locomotive fuel tank fire Potential techniques for preventing or mitigating potential fuel tank fire hazards include fuel tank leak prevention or reducing the outflow of leaking fuel tanks, monitoring the vapor concentration in fuel tanks, and limiting the vapor concentration in tanks to maintain levels below the lower explosive limit (LEL) [70].

In the field of new tunnel risk assessment models research, Elsayed T et al. [71] did an assessment case study for the fire and explosion risk problem, using a qualitative risk assessment method with a qualitative risk matrix and a fuzzy risk assessment method using a fuzzy inference system (FIS) for risk assessment, respectively, concluding that the use of the FIS method provides a more robust fire and explosion than the qualitative matrix method risk assessment framework as well as more output information. Jančaříková E et al. calculated the risk of road tunnels according to the road tunnel safety risk analysis method defined in the Slovak Technical Specification for Road Tunnel Management TP 041 (TP 02/2011), based on a risk analysis study of possible tunnel operating conditions under both normal service and modeled emergency conditions using the Austrian tunnel risk analysis model TuRisMo [72]. Seike M et al. proposed a quantitative method for assessing fire safety in road tunnels based on numerical simulations of smoke emissions, developing a new 1D evacuation simulation method that models self-determined factors for detecting evacuation necessity. The method used fast 1D evacuation simulations with simplified smoke distributions derived from CFD, defined various smoke environment (SE) levels as a function of time, longitudinal position, and vertical position, and used 2000 simulations of random number results to determine the average number of evacuees. They tested the proposed method under various longitudinal gradients, large exothermic rates, and pre-evacuation truth time scenarios [73].

It is not possible to evaluate the fire risk of all types of tunnels, as there are many different types of tunnels and various tunnel fire-fighting systems in use, and the number of types of tunnels will continue to increase as technology advances. In the development of the tunnel fire risk assessment model, the weighting of the indicators in the quantitative calculation of the indicators is mainly based on hierarchical analysis, which affects the accuracy of the tunnel fire risk assessment. Therefore, further research is needed on how to assign weights to the indicators in a scientific and objective manner. In addition, with the close implementation of several documents, such as industry standards and national codes to improve the fire risk evaluation indicators for road tunnels, further improvement and planning of evaluation indicators is needed.

3. Conclusions and Outlook

3.1. Conclusions

The literature research has described the shortcomings of the research progress on fires in tunnels under the action of strong piston winds, and the following main conclusions have been drawn.

- The current research mainly focuses on the piston wind generated when trains pass or cross in subway tunnels and single-shaft railway tunnels. Some scholars have also studied the piston wind effect generated when trains run in double-shaft railway tunnels. However, few scholars have studied the piston wind flow law and wind speed calculation in the tunnel and auxiliary passage when the train runs in the railway tunnel with multiple shafts, multiple rescue cross passages and multiple pressure buffer passages. Meanwhile, it can be seen from the analysis of the research results that the calculation formula of the piston wind theory under different conditions can only calculate the wind speed of the train section but cannot obtain the analysis of the airflow velocity in the whole tunnel and the auxiliary channel. The numerical simulation using CFD software can only obtain the analysis of the airflow field in the whole tunnel when the train is running. It is not possible to calculate the specific piston air volume in each section of the tunnel and auxiliary tunnel.

- On the basis of the total parameter model of the piston wind set and considering the influence of longitudinal ventilation, a model of critical wind pressure and wind speed for tunnel motion train fires should be established to prevent the phenomenon of smoke backflow in tunnel motion train fires through the coupling of mechanical ventilation and piston wind from tunnel dual motion trains. The influence of six factors, namely fire power, train length, tunnel length, train speed, train deceleration, and obstruction ratio, on the critical wind pressure and critical wind speed is analyzed.

- The longitudinal slope of the tunnel, the shape of the section, the curvature of the line and the altitude of the tunnel are characteristics of the tunnel itself and, relatively speaking, these four factors can be called “established factors”. When designing a tunnel for fire and rescue, these four factors should be taken into account and their influence on the critical wind speed should be obtained as accurately as possible. In addition, there is a large gap between the size of the evacuees and the actual passenger flow, and there are still shortcomings in obtaining the evacuation routes for large flows of passengers in the event of a fire, as well as a lack of parameters to support the development and optimization of emergency plans for the behavior of groups evacuating from a fire.

- In terms of tunnel fire testing methods, the current focus is on individual testing of smoke parameters in some of the station smoke protection zones, tunnels, and trains. For large hub stations with complex structures, there are still problems with the density of test points, the comprehensiveness of parameter types, and the lack of synergy in testing multiple smoke protection zones, and there is a lack of experimental tools for the simultaneous and integrated testing of stations, tunnels, and running trains in the fire linkage mode.

3.2. Outlook

- Develop a model for the spread of combustion of typical materials applicable to different flame retardant grades and master the method of predicting fire development in metro tunnels.

- To establish a full scenario element fire test technique for the underground tunnel operation system, to propose a test error analysis and control method, and to master the theoretical system for building a full-scale experimental scenario close to the real fire scene environment.

- In view of the dynamic operating environment of the metro system during a fire, the fire dynamics parameter testing techniques applicable to train operation, sudden changes in tunnel airflow, and cooperative actions of stations and tunnels are proposed, and multi-channel data acquisition for fire tests are integrated under the effect of multiple disturbances, such as electromagnetic fields, thermal fields, high temperatures, and high humidity.

- For smoke control in complex tunnel works, the smoke flow pattern in case of fire in complex tunnel works is mastered.

- Big data-based research on the behavior of tunnel fire personnel. The techniques of survey research and data mining should be fully utilized in this field to obtain the real behavior and psychological activities of tunnel fire personnel to support the strategy of tunnel evacuation and the design of disaster prevention and mitigation facilities.

Author Contributions

All authors contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the Nature Foundation Youth Project (Research on Pre-Reinforcement Technology of GFRP Bar Anchors at the Palm Face of Shallow Buried Soft Surrounding Rock Tunnels, Project No: 51608450).

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

Xiaoyi Zhao collected the data and wrote the full paper, Zhile Shu provided financial help and proposed the research, and Xiangjun Pei helped with revisions and linguistic touch-ups.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cai, H.B.; Liu, Z.; Li, S.; Zheng, T.L. Improved analytical prediction of ground frost heave during tunnel construction using artificial ground freezing technique. Tunn. Undergr. Space Technol. 2019, 92, 103050. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, Y.; Liu, Z.Z.; Miao, L.W. Theoretical prediction model for deformations caused by construction of new tunnels undercrossing existing tunnels based on the equivalent layered method. Comput. Geotech. 2020, 123, 103565. [Google Scholar] [CrossRef]

- Li, W.H.; Liu, T.; Martinez-Vazquez, P.; Xia, Y.T.; Chen, Z.W.; Guo, Z.J. Aerodynamic effects on a railway tunnel with partially changed cross-sectional area. J. Cent. South Univ. 2022, 29, 2589–2604. [Google Scholar] [CrossRef]

- Saito, S. Optimizing cross-sectional area of tunnel entrance hood for high speed rail. J. Wind Eng. Ind. Aerodyn. 2019, 184, 296–304. [Google Scholar] [CrossRef]

- Wang, T.T.; Wu, F.; Yang, M.Z.; Ji, P.; Qian, B.S. Reduction of pressure transients of high-speed train passing through a tunnel by cross-section increase. J. Wind Eng. Ind. Aerodyn. 2018, 183, 235–242. [Google Scholar] [CrossRef]

- Kozo, F.; Takanobu, O. Aerodynamics of high speed trains passing by each other. Comput. Fluids 1995, 24, 897–908. [Google Scholar]

- Ji, Q.N.; Yang, S.; Qiu, J.Y.; Cao, X.L.; Yuan, Y.P. Aerodynamics of railway train/tunnel system: A review of recent research. Energy Built Environ. 2020, 1, 351–375. [Google Scholar]

- Tokuzo, M.; Masanobu, I.; Takashi, F.; Takakage, A. Nondimensional maximum pressure gradient of tunnel compression waves generated by offset running axisymmetric trains. J. Wind Eng. Ind. Aerodyn. 2016, 157, 23–35. [Google Scholar]

- Graf, W.H.; Suszka, L. Unsteady flow and its effect on sediment transport. In Proceedings of the 21st IAHR Congress, Melbourne, Australia, 19–23 August 1985; pp. 1–5. [Google Scholar]

- Graf, W.H.; Qu, Z. Flood hydrographs in open channels. Proc. Inst. Civ. Eng.-Water Manag. 2004, 157, 45–52. [Google Scholar] [CrossRef]

- Nezu, I. Open-channel flow turbulence and its research prospect in the 21st century. J. Hydraul. Eng. 2005, 131, 229–246. [Google Scholar] [CrossRef]

- Bombar, G.; Elçi, Ş.; Tayfur, G.; Güney, M.Ș.; Bor, A. Experimental and Numerical Investigation of Bed-Load Transport under Unsteady Flows. J. Hydraul. Eng. 2011, 137, 1276–1282. [Google Scholar] [CrossRef]

- Chang, L.; Mao, H.Z.; Cong, L.S.; Pei, H.Z.; Xiang, L.T. Temperature profile of fire-induced smoke in node area of a full-scale mine shaft tunnel under natural ventilation. Appl. Therm. Eng. 2017, 110, 382–389. [Google Scholar]

- Nayak, U.S.L.; Gralewski, Z.A.; Stevens, S.J. The aerodynamic drag of tube vehicles traveling at low subsonic speeds. In Proceedings of the 2th ISAVVT, Cambridge, UK, 23–25 March 1976; BHRA Fluid Engineering, Paper El. pp. 1–22. [Google Scholar]

- Gawthorpe, R.G.; Pope, C.W.; Green, R.H. Analysis of train drag in various configurations of a long tunnel. In Proceedings of the 3th ISAVVT, Sheffield, UK, 19–21 March 1979; BHRA Fluid Engineering, Paper G1. pp. 257–280. [Google Scholar]

- Valense, J.; Favier, D.; Magallon, D. Theoretical and experimental investigation of the piston effect in a twin tunnel. In Proceedings of the 2th ISAVVT, Cambridge, UK, 23–25 March 1976; BHRA Fluid Engineering, Paper E3. pp. 57–79. [Google Scholar]

- You, B.H.; Yan, F.L.; Jun, M.L.; Jia, X.L.; Ke, W.; Kai, Z.; Hai, H.L. Experimental investigation on maximum gas temperature beneath the ceiling in a branched tunnel fire. Int. J. Therm. Sci. 2019, 145, 105997. [Google Scholar]

- Yasushi, O.; Graham, T.A. Control of smoke flow in tunnels fires. Fire Saf. J. 1995, 25, 305–322. [Google Scholar]

- Rezatofighi, H.; Tsoi, N.; Gwak, J.Y.; Amir, S.; Ian, R.; Silvio, S. Generalized intersection over union: A metric and a loss for bounding box regression. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Long Beach, CA, USA, 15–20 June 2019; pp. 658–666. [Google Scholar]

- Li, Y.Z.; Ingason, H. Editorial: Tunnel fire safety. Fire Saf. J. 2018, 97, 85–86. [Google Scholar] [CrossRef]

- Li, Y.Z.; Ingason, H. Overview of research on fire safety in underground road and railway tunnels. Tunn. Undergr. Space Technol. 2018, 81, 568–589. [Google Scholar] [CrossRef]

- Roh, J.S.; Ryou, H.S.; Kim, D.H.; Jung, W.S.; Jang, Y.J. Critical velocity and burning rate in pool fire during longitudinal ventilation. Tunn. Undergr. Space Technol. 2007, 22, 262–271. [Google Scholar] [CrossRef]

- Li, Y.Z.; Ingason, H. Effect of cross section on critical velocity in longitudinally ventilated tunnel fires. Fire Saf. J. 2017, 91, 303–311. [Google Scholar] [CrossRef]

- Lei, P.; Chen, C.K.; Zhang, Y.L.; Xu, T.; Sun, H.K. Experimental study on temperature profile in a branched tunnel fire under natural ventilation considering different fire locations. Int. J. Therm. Sci. 2021, 159, 106631. [Google Scholar] [CrossRef]

- Liu, M.Z.; Zhu, C.G.; Zhang, H.; Zheng, W.D.; You, S.J.; Campana, P.E.; Yan, J.Y. The environment and energy consumption of a subway tunnel by the influence of piston wind. Appl. Energy 2019, 246, 11–23. [Google Scholar] [CrossRef]

- Liu, M.Z.; Jiang, L.F.; Zhang, H.; Zheng, X.J.; You, S.J.; Wei, S. An exploration on the applicability of heating tower heat pump and air source heat pump systems in different climatic regions. J. Clean. Prod. 2019, 238, 117889. [Google Scholar] [CrossRef]

- Masanori, F.; Seiyu, F.; De, F.C. Determination and simulation of piston winds for metro trains. Tunn. Rail Transit 1988, 35–45. [Google Scholar]

- Niu, J.Q.; Zhou, D.; Liang, X.F.; Liu, T.H.; Liu, S. Numerical study on the aerodynamic pressure of a metro train running between two adjacent platforms. Tunn. Undergr. Space Technol. 2017, 65, 187–199. [Google Scholar] [CrossRef]

- Ming, T.K.; Tsung, C.C.; Wen, P.W. Numerical simulation for optimizing the design of subway environmental control system. Build. Environ. 2002, 37, 1139–1152. [Google Scholar]

- Zhu, F.; Yu, Z.X.; Cao, R.Z.; Liu, Z.X. Time Variant Characteristics of Piston Wind for Billboards Affiliated with Subway Tunnels. J. Southwest Jiaotong Univ. 2018, 53, 1048–1057. [Google Scholar]

- Blom, F.J. Considerations on the spring analogy. Int. J. Numer. Methods Fluids 2015, 32, 647–668. [Google Scholar] [CrossRef]

- Iga Shin, I. An equatorially enhanced grid with smooth resolution distribution generated by a spring dynamics method. J. Comput. Phys. 2017, 330, 794–809. [Google Scholar]

- Jia, M.W.; Allen, T.C. A hydrodynamic model of a two-part underwater towed system. Ocean Eng. 2000, 27, 455–472. [Google Scholar]

- Bertoluzza, S.; Chabannes, V.; Prud’Homme, C.; Szopos, M. Boundary conditions involving pressure for the Stokes problem and applications in computational hemodynamics. Comput. Methods Appl. Mech. Eng. 2017, 322, 58–80. [Google Scholar] [CrossRef]

- Shuai, S.D.; Huo, Y.D. Analysis of a stabilized finite element method for Stokes equations of velocity boundary condition and of pressure boundary condition. J. Comput. Appl. Math. 2018, 337, 290–318. [Google Scholar]

- Zarnaghsh, A.; Abouali, O.; Emdad, H.; Goodarz, A. A numerical study of the train-induced unsteady airflow in a tunnel and its effects on the performance of jet fans. J. Wind Eng. Ind. Aerodyn. 2019, 187, 1–14. [Google Scholar] [CrossRef]

- Quintiere, J.G. Scaling applications in fire research. Fire Saf. J. 1989, 15, 3–29. [Google Scholar] [CrossRef]

- Li, Y.Z.; Ingason, H. Discussions on critical velocity and critical Froude number for smoke control in tunnels with longitudinal ventilation. Fire Saf. J. 2018, 99, 22–26. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.G.; Liu, M.Z.; Zheng, W.D.; You, S.J.; Li, B.J.; Xue, P. Mathematical modeling and sensitive analysis of the train-induced unsteady airflow in subway tunnel. J. Wind Eng. Ind. Aerodyn. 2017, 171, 67–78. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, T.; Liu, M.Z.; Zheng, W.D.; Zhu, C.G.; You, S.J.; Zhang, Y.Z. Energy performance investigation of an innovative environmental control system in subway station. Build. Environ. 2017, 126, 68–81. [Google Scholar] [CrossRef]

- Huang, Y.D.; Gao, W.; Kim, C.N. A numerical study of the train-induced unsteady airflow in a subway tunnel with natural ventilation ducts using the dynamic layering method. J. Hydrodyn. Ser. B 2010, 22, 164–172. [Google Scholar] [CrossRef]

- Wang, S.G.; Zhu, Y.X.; Jiang, Y. Actual measurement and analysis of heat flow at wall surfaces in the Beijing underground thermal environment. Tunn. Rail Transit 1997, 3, 32–37. [Google Scholar]

- Chu, C.R.; Chien, S.Y.; Wang, C.Y.; Wu, T.R. Numerical simulation of two trains intersecting in a tunnel. Tunn. Undergr. Space Technol. 2014, 42, 161–174. [Google Scholar] [CrossRef]

- Liu, M.Z. Investigation of the Piston Wind Induced by Multiple Trains and Model Simplification in Ultra-Long Tunnel. Ph.D. Thesis, Tianjin University, Tianjin, China, 2020. [Google Scholar] [CrossRef]

- Hua, X.W.; Zi, H.G.; Jie, J.; Jun, F.; Yong, M.Z. Experimental study on horizontal gas temperature distribution of two propane diffusion flames impinging on an unconfined ceiling. Int. J. Therm. Sci. 2019, 136, 1–8. [Google Scholar]

- Wan, H.X. Interaction Behaviors of Two Symmetrical Square Fires under Different Confined Conditions. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2018; pp. 97–112. [Google Scholar]

- Hans, N.; Haukur, I. Temperature stratification in tunnels. Fire Saf. J. 2011, 48, 30–37. [Google Scholar]

- Hua, X.W.; Zi, H.G.; Jie, J.; Kai, Y.L.; Jin, H.S.; Yong, M.Z. Experimental study on ceiling gas temperature and flame performances of two buoyancy-controlled propane burners located in a tunnel. Appl. Energy 2017, 185, 573–581. [Google Scholar]

- Gannouni, S.; Madd, R.B. Numerical study of the effect of blockage on critical velocity and backlayering length in longitudinally ventilated tunnel fires. Tunn. Undergr. Space Technology. 2015, 48, 147–155. [Google Scholar] [CrossRef]

- Liu, Q.; Zheng, F. Study on variation rules of critical ventilation velocity for double-source tunnel fires. J. Disaster Prev. Mitig. Eng. 2018, 38, 137–143. [Google Scholar]

- Cui, X.Y.; Zhao, J.L.; Yao, Y.Z.; Yuan, S.S.; Wu, B.; Huang, H. Numerical simulation on double fire source tunnel. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2255–2267. [Google Scholar]

- Delichatsios, M.A. A correlation for the flame height in “group” fires. Fire Sci. Technol. 2007, 26, 1–8. [Google Scholar] [CrossRef]

- Weng, W.; Kamikawa, D.; Hasemi, Y. Experimental study on merged flame characteristics from multifire sources with wood cribs. Proc. Combust. Inst. 2015, 35, 2597–2606. [Google Scholar] [CrossRef]

- Chen, C.K.; Nie, Y.L.; Zhang, Y.L.; Lei, P.; Fan, C.G.; Wang, Z.Y. Experimental investigation on the influence of ramp slope on fire behaviors in a bifurcated tunnel. Tunn. Undergr. Space Technol. 2020, 104, 103522. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, S.; Luo, X.; Lei, J.; Chen, H.X.; Xie, X.D.; Zhang, L.H.; Tu, R. Interaction of two parallel rectangular fires. Proc. Combust. Inst. 2019, 37, 3833–3841. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Xing, S.S.; Chen, R.J.; Chen, L.F.; Li, T.; Mao, P.F. Experimental study on maximum temperature beneath tunnel ceiling under the condition of double fire sources. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2020, 106, 103624. [Google Scholar] [CrossRef]

- Qiang, W.; Shao, M.W.; Huan, L.; Jia, Y.S.; Feng, J.S.; Cong, L.S.; Fei, T. Characterization of ceiling smoke temperature profile and maximum temperature rise induced by double fires in a natural ventilation tunnel. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2020, 96, 103233. [Google Scholar]

- Yi, L.; Xu, Q.; Xu, Z.; Wu, D.X. An experimental study on critical velocity in sloping tunnel with longitudinal ventilation under fire. Tunn. Undergr. Space Technol. 2014, 43, 198–203. [Google Scholar] [CrossRef]

- Li, Y.; Ingason, H. Influence of fire suppression on combustion products in tunnel fires. Fire Saf. J. 2018, 97, 96–110. [Google Scholar] [CrossRef]

- Cong, L.S.; Wei, L.; Wen, J.H.; Mao, H.Z.; Xing, K.Z. A modified thermal radiation model with multiple factors for investigating temperature rise around pool fire. J. Hazard. Mater. 2019, 379, 120801. [Google Scholar]

- Both, C.; Haar, P.; Tan, G.L.; Wolsink, G.M. Evaluation of passive fire protection measures for concrete tunnel linings. In Proceedings of the International Conference & One Day Seminar ‘Tunnel Fires and Escape from Tunnels’, Lyon, France, 5–7 May 1999. [Google Scholar]

- Wang, Y.F.; Yan, F.P. Research on the Maximum Smoke Temperature around the Vault of a Tunnel on Fire. China Saf. Sci. J. (CSSJ) 2007, 17, 39–44. [Google Scholar]

- Hua, G.Y.; Wang, W.; Zhao, Y.H.; Li, L.; Xiao, J. Discussion on Fire Protection Design of Urban Traffic Link Tunnel. Build. Sci. 2008, 24, 4. [Google Scholar]

- Wang, W.; Yan, S.; Liu, J. Studies on temperature induced creep in high strength Q460 steel. Mater. Struct. 2017, 50, 1–14. [Google Scholar] [CrossRef]

- Chirasmita, P.; Mrinmoy, M.; Sankha, K.; Hari, N.M.; Sirshendu, D. Shelf life extension of sugarcane juice by cross flow hollow fibre ultrafiltration. J. Food Eng. 2020, 274, 109880. [Google Scholar]

- Jun, J.C.; Pei, Z.N.; Guang, F.X.; Teng, D. Data fusion method based on recursive least square and improved support for WSN. Meas. Control Technol. 2019, 38, 65–68+74. [Google Scholar] [CrossRef]

- He, X.; Wang, T.; Liu, W.; Luo, T. Measurement data fusion based on optimized weighted least-squares algorithm for multi-target tracking. IEEE Access 2019, 7, 13901–13916. [Google Scholar] [CrossRef]

- Wang, K.; Liu, G.; Tao, Q.; Zhai, M. Efficient Parameters Estimation Method for the Separable Nonlinear Least Squares Problem. Complexity 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Cigada, A.; Ruggieri, D.; Zappa, E. Road and railway tunnel fire hazard: A new measurement method for risk assessment and improvement of transit safety. In Proceedings of the 2005 IEEE International Workshop on Measurement Systems for Homeland Security, Contraband Detection and Personal Safety Workshop, 2005. (IMS 2005), Orlando, FL, USA, 29–30 March 2005; pp. 89–94. [Google Scholar] [CrossRef]

- Parida, B.K.; Carter, J.; Zaouk, A.K.; Punwani, J. Assessment of Fire Hazards and Mitigation Methods in Locomotive Fuel Tanks. In Proceedings of the ASME 2011 Rail Transportation Division Fall Technical Conference, Minneapolis, MN, USA, 21–22 September 2011; pp. 77–86. [Google Scholar] [CrossRef]

- Elsayed, T.; Lehrta, H.; Belhaj, I. Fuzzy inference system for fire and explosion risk assessment of floating storage and offloading vessels. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 171–180. [Google Scholar] [CrossRef]

- Jančaříková, E.; Mikolaj, J.; Danišovič, P. Risk and Incidents Assessment in Slovak Road Tunnels. Procedia Eng. 2017, 192, 376–380. [Google Scholar] [CrossRef]

- Seike, M.; Kawabata, N.; Hasegawa, M. Quantitative assessment method for road tunnel fire safety: Development of an evacuation simulation method using CFD-derived smoke behavior. Saf. Sci. 2017, 94, 116–127. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).