Implementing Lean Construction: A Literature Study of Barriers, Enablers, and Implications

Abstract

1. Introduction

2. Theoretical Background

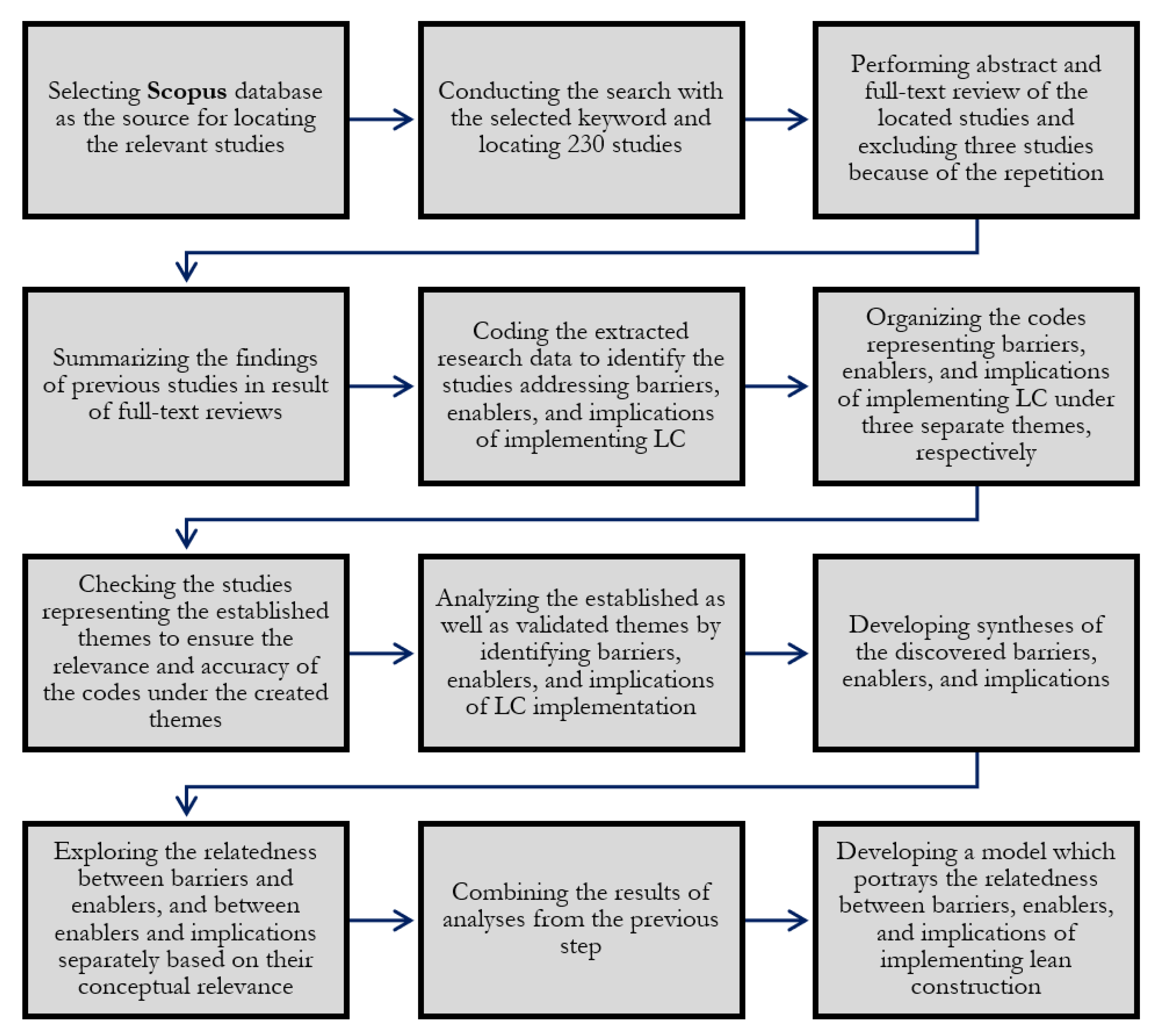

3. Methodology

3.1. Research Design

3.2. Keyword Selection

3.3. Descriptive Statistics

3.4. Thematic and Content Analysis

4. Results

4.1. Barriers and Enablers of Implementing Lean Construction

4.2. Implications of LC Application

4.3. Relatedness between Barriers, Enablers, and Implications of Implementing Lean Construction

5. Discussion

6. Conclusions

- People are the main root cause of the barriers, enablers, and implications of LC adoption and implementation, and investing in, as well as developing, people pay off throughout the project life cycle.

- People directly influence the successful implementation of lean construction on three levels: (i) individual level (traits, motives, and leadership), (ii) corporate level (working culture, capability, process, and change readiness), and (iii) governance level (policies, codes, and regulations).

- A lack of awareness and understanding of LC, resistance to change (management and employees), and a lack of support and commitment from top management are the top three barriers for adopting and implementing lean construction.

- Developing lean culture through promoting lean education, training and research, the application of lean principles tools and techniques, and top management support and commitment to lean construction are the top three enablers for adopting and implementing lean construction.

- Time and cost reduction, increased productivity (at task and project levels) and increased labor productivity seem to be the top three implications of applying lean construction.

- To what extent do contextual differences (e.g., working culture, regulations) affect the adoption and implementation of lean construction?

- What kind of support from regulatory bodies in developing and developed counties can contribute toward the wider application of lean construction?

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. LC implementation Barriers

| Barrier | [26] | [23] | [64] | [59] | [67] | [24] | [62] | [69] | [61] | [63] | [68] | [22] | [60] | [25] | [65] | [66] | [58] | Frequency of Appearance | Rank |

| Lack of awareness and understanding of LC | * | * | * | * | * | * | * | * | * | * | * | * | 12 | 1 | |||||

| Resistance to change (management and employees) | * | * | * | * | * | * | * | * | 8 | 2 | |||||||||

| Lack of support and commitment from top management | * | * | * | * | * | * | 6 | 3 | |||||||||||

| Lack of required competencies both at managerial and employee levels | * | * | * | * | * | * | |||||||||||||

| Financial constraints | * | * | * | * | * | * | |||||||||||||

| Lack of lean consultants, education, and training | * | * | * | * | * | * | 5 | 4 | |||||||||||

| Lack of effective communication between all project participants | * | * | * | * | * | ||||||||||||||

| Insufficient support from the government (providing required policies, codes, and regulations) | * | * | * | * | 4 | 5 | |||||||||||||

| Lack of performance measurement systems | * | * | * | 3 | 6 | ||||||||||||||

| Poor understanding of customer needs and poor customer focus | * | * | * | ||||||||||||||||

| Lack of involvement and transparency among stakeholders | * | * | * | ||||||||||||||||

| Lack of planning for quality | * | * | 2 | 7 | |||||||||||||||

| Project subcontracting | * | * | |||||||||||||||||

| Implementation costs and time | * | * | |||||||||||||||||

| Lack of incentives and motivation | * | * | |||||||||||||||||

| Centralized decision-making | * | * | |||||||||||||||||

| Complexity of lean in eyes of workers | * | * | |||||||||||||||||

| High turnover of workforce | * | * | |||||||||||||||||

| Limited use of off-site construction techniques and prefabrication | * | * | |||||||||||||||||

| Fragmented and cyclic nature of the construction projects | * | * | |||||||||||||||||

| Lack of commitment (managerial) | * | * | |||||||||||||||||

| Lack of appropriate lean technology or tools | * | * | |||||||||||||||||

| Insufficient standardization | * | * | |||||||||||||||||

| Absence of organizational culture representing LC | * | * | |||||||||||||||||

| Traditional design approach | * | * | |||||||||||||||||

| The dominance of the traditional management practice | * | * | |||||||||||||||||

| Lack of information and knowledge sharing and integrated change control | * | * | |||||||||||||||||

| Inefficiency in resource planning | * | * | |||||||||||||||||

| Traditional culture and attitude of employees | * | * | |||||||||||||||||

| Lack of long-term relationships with suppliers | * | 1 | 8 | ||||||||||||||||

| Lack of technical capabilities and green initiatives | * | ||||||||||||||||||

| Not recognizing financial advantage | * | ||||||||||||||||||

| Cultural differences | * | ||||||||||||||||||

| Slow and partially visible results of implementation | * | ||||||||||||||||||

| Inaccurate and incomplete drawings | * | ||||||||||||||||||

| Reluctance of project participants to share risk–reward | * | ||||||||||||||||||

| Lack of long-term philosophy | * | ||||||||||||||||||

| Inadequate administration of the necessary information to generate a learning cycle | * | ||||||||||||||||||

| Hierarchies in organizational structure | * | ||||||||||||||||||

| Lack of waste identification and control | * | ||||||||||||||||||

| Inadequate material delivery performance | * | ||||||||||||||||||

| Lack of integrated procurements | * | ||||||||||||||||||

| Stringent requirements and approvals during contracting | * | ||||||||||||||||||

| Lack of alliances between academy and organizations | * | ||||||||||||||||||

| Size of construction project (it is difficult to implement LC in small-size construction projects due to the required capacity and capability) | * | ||||||||||||||||||

| Lack of sustainable practices | * | ||||||||||||||||||

| Lack of knowledge on how to apply LC techniques for safety improvement | * | ||||||||||||||||||

| Severity of weather | * | ||||||||||||||||||

| Poor materials | * | ||||||||||||||||||

| Fierce market competition environment | * | ||||||||||||||||||

| Tolerance of untidy workplaces | * | ||||||||||||||||||

| Nonrecognition of LC advantages | * | ||||||||||||||||||

| Low informatization | * | ||||||||||||||||||

| Insufficient program planning | * | ||||||||||||||||||

| Lack of effective supervision and control | * | ||||||||||||||||||

| Excessive cost savings during construction | * | ||||||||||||||||||

| Less personal empowerment | * | ||||||||||||||||||

| Avoid making decisions and taking responsibility | * | ||||||||||||||||||

| Insufficient attention to green and environmental protection | * | ||||||||||||||||||

| Cooperation problems outside the construction department | * | ||||||||||||||||||

| Misperception about lean practices | * | ||||||||||||||||||

| Failure in operational excellence | * | ||||||||||||||||||

| Lack of organizational communication | * | ||||||||||||||||||

| Problem in teamwork and diverging aims in lean | * | ||||||||||||||||||

| Nonuse of modern techniques and technologies | * | ||||||||||||||||||

| Lack of trust | * | ||||||||||||||||||

| Choice of contracting mode | * | ||||||||||||||||||

| Lack of integration of design and construction | * |

Appendix B. LC Implementation Enablers

| Enabler | [83] | [78] | [77] | [82] | [9] | [80] | [51] | [72] | [73] | [84] | [52] | [54] | [81] | [74] | [76] | [70] | [71] | [53] | [79] | [75] | Frequency of Appearance | Rank |

| Developing lean culture through promoting lean education, training, and research | * | * | * | * | * | * | * | * | * | 9 | 1 | |||||||||||

| The application of lean principles tools and techniques | * | * | * | * | * | 5 | 2 | |||||||||||||||

| Top management support and commitment to lean construction | * | * | * | * | 4 | 3 | ||||||||||||||||

| Continuous improvement in process and product development | * | * | * | 3 | 4 | |||||||||||||||||

| Creation and management of relevant knowledge | * | * | 2 | 5 | ||||||||||||||||||

| Developing LC-oriented KPI for contractor | * | * | ||||||||||||||||||||

| Improving organizational resilience by establishing LC-oriented leadership and culture, enhancing change readiness, and expanding networks and relationships | * | * | ||||||||||||||||||||

| Adopting alternative procurement methods in project delivery (e.g., design, build) | * | * | ||||||||||||||||||||

| Promoting a culture of teamwork during construction projects | * | * | ||||||||||||||||||||

| Investor/client requirement | * | * | ||||||||||||||||||||

| Stabilizing environment through adoption of last planner system | * | 1 | 6 | |||||||||||||||||||

| Increasing process transparency through visualization tools such as BIM and Kanban | * | |||||||||||||||||||||

| Building trust | * | |||||||||||||||||||||

| Understanding current waste reduction practices at the targeted construction site | * | |||||||||||||||||||||

| Educating all contractors on the project about lean construction and its benefits | * | |||||||||||||||||||||

| Specifying value | * | |||||||||||||||||||||

| Identify value stream | * | |||||||||||||||||||||

| Establish flow of products | * | |||||||||||||||||||||

| Pull production | * | |||||||||||||||||||||

| A proactive interaction with contractor upper management and project organizations | * | |||||||||||||||||||||

| Collaboration among companies | * | |||||||||||||||||||||

| Bottom-up strategy | * | |||||||||||||||||||||

| Adopting 4P Toyota Way model (philosophy, process, people and partners, and problem solving) | * | |||||||||||||||||||||

| Effective changes in decision-making mechanism | * | |||||||||||||||||||||

| Sufficient time | * | |||||||||||||||||||||

| Adopting new construction technologies and methods (e.g., BIM) | * | |||||||||||||||||||||

| Clear definition of client requirements | * | |||||||||||||||||||||

| Applying lean methodology at an early stage of the building project delivery (e.g., planning, design stage) | * | |||||||||||||||||||||

| Coordinating and promoting efforts at a national level (e.g., establishment of National Lean Construction Institute) | * | |||||||||||||||||||||

| Establishing long-term relationships within the supply chain | * | |||||||||||||||||||||

| Collaborative practices | * | |||||||||||||||||||||

| Root cause analysis to investigate problems | * | |||||||||||||||||||||

| Deploying lean construction systematically | * | |||||||||||||||||||||

| Willingness to invest in lean practices | * | |||||||||||||||||||||

| Morning huddles for lean | * | |||||||||||||||||||||

| Effective communication of LC-implementation/application info to the whole company | * | |||||||||||||||||||||

| Showing success from early adopters | * | |||||||||||||||||||||

| Ensuring involvement of company’s HR in implementation process | * | |||||||||||||||||||||

| Establishing a forum for exchanges of experiences | * | |||||||||||||||||||||

| Competent human resources | * | |||||||||||||||||||||

| Effective communication between parties | * | |||||||||||||||||||||

| Support of government and regulatory bodies | * | |||||||||||||||||||||

| Planning it right | * | |||||||||||||||||||||

| Understanding the whole construction life cycle in a non-price factor view | * | |||||||||||||||||||||

| Benchmarking | * |

Appendix C. Implications of LC Implementation

| Implication | [21] | [29] | [19] | [85] | [20] | [89] | [87] | [95] | [88] | [97] | [55] | [28] | [93] | [94] | [27] | [92] | [56] | [30] | [57] | [90] | Frequency of Appearance | Rank |

| Time and cost reduction | * | * | * | * | * | * | * | * | 8 | 1 | ||||||||||||

| Increased productivity (task and project levels) | * | * | * | * | * | 4 | 2 | |||||||||||||||

| Increased labor productivity | * | * | * | 3 | 3 | |||||||||||||||||

| Increased process efficiency | * | * | * | |||||||||||||||||||

| Competence-based selection in bidding phase | * | * | 2 | 4 | ||||||||||||||||||

| Decreased inventory | * | * | ||||||||||||||||||||

| Better operational performance | * | * | ||||||||||||||||||||

| Quality improvement | * | * | ||||||||||||||||||||

| Waste reduction | * | 1 | 5 | |||||||||||||||||||

| Better diffusion of LC at managerial levels of company | * | |||||||||||||||||||||

| Establishment of collaborative climate | * | |||||||||||||||||||||

| Stakeholder satisfaction | * | |||||||||||||||||||||

| Better health and safety | * | |||||||||||||||||||||

| Increased market share | * |

References

- Hauck, A.J.; Walker, D.H.; Hampson, K.D.; Peters, R.J. Project alliancing at national museum of Australia—Collaborative process. J. Constr. Eng. Manag. 2004, 130, 143–152. [Google Scholar] [CrossRef]

- Ibrahim, C.K.I.C.; Costello, S.B.; Wilkinson, S. Application of a team integration performance index in road infrastructure alliance projects. Benchmarking Int. J. 2016, 23, 1341–1362. [Google Scholar] [CrossRef]

- Matthews, O.; Howell, G.A. Integrated project delivery an example of relational contracting. Lean Constr. J. 2005, 2, 46–61. [Google Scholar]

- Moradi, S.; Kähkönen, K.; Klakegg, O.J.; Aaltonen, K. A Competency Model for the Selection and Performance Improvement of Project Managers in Collaborative Construction Projects: Behavioral Studies in Norway and Finland. Buildings 2021, 11, 4. [Google Scholar] [CrossRef]

- Moradi, S.; Kähkönen, K.; Klakegg, O.J.; Aaltonen, K. Profile of Project Managers’ Competencies for Collaborative Construction Projects. In Proceedings of the 37th Annual ARCOM Conference, Glasgow, UK, 6–7 September 2021; pp. 350–359. [Google Scholar]

- Ratajczak, J.; Schimanski, C.P.; Marcher, C.; Riedl, M.; Matt, D.T. Collaborative tool for the construction site to enhance lean project delivery. In Lecture Notes in Computer Science, Proceedings of the International Conference on Cooperative Design, Visualization and Engineering, Hangzhou, China, 21–24 October 2018; Springer: Cham, Switzerland, 2018; pp. 192–199. [Google Scholar]

- Mossman, A. What is lean construction: Another look. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–22 July 2018; pp. 1240–1250. [Google Scholar]

- Mao, X.; Zhang, X. Construction process reengineering by integrating lean principles and computer simulation techniques. J. Constr. Eng. Manag. 2008, 134, 371–381. [Google Scholar] [CrossRef]

- Salazar, R.; Rybkowski, Z.; Ballard, G. An Exploration of Compatibility of U.S. Army Culture and Lean Construction. In Proceedings of the LC3 2017 Volume II—The 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017; pp. 413–420. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of lean and building information modeling in construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Dave, B.; Sacks, R. Project Control Systems for Construction at the Nexus of Lean and BIM. In Lean Construction: Core Concepts and New Frontiers; Tzortzopoulos, P., Kagioglou, M., Koskela, L., Eds.; Routledge: Abingdon, UK, 2020; pp. 54–83. [Google Scholar]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Redwood City, CA, USA, 1992; Volume 72. [Google Scholar]

- Ballard, G. Lean Project Delivery System. White Paper. Lean Constr. J. 2000, 8, 1–6. [Google Scholar]

- Cheng, F. Workflow Analysis for the Lean Construction Process of a Construction Earthmoving Project. In Proceedings of the ICCREM 2015, Luleå, Sweden, 11–12 August 2015; pp. 58–66. [Google Scholar]

- Ballard, G.; Howell, G. Lean project management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- Ballard, G. The Last Planner System. In Lean Construction: Core Concepts and New Frontiers; Tzortzopoulos, P., Kagioglou, M., Koskela, L., Eds.; Routledge: Abingdon, UK, 2020; pp. 45–53. [Google Scholar]

- Moradi, S.; Kähkönen, K.; Sormunen, P. Analytical and Conceptual Perspectives toward Behavioral Elements of Collaborative Delivery Models in Construction Projects. Buildings 2022, 12, 316. [Google Scholar] [CrossRef]

- Moradi, S.; Kähkönen, K. Success in collaborative construction through the lens of project delivery elements. Built Environ. Proj. Asset Manag. 2022, 12, 973–991. [Google Scholar] [CrossRef]

- Dakhli, Z.; Lafhaj, Z.; Bernard, M. Application of lean to the bidding phase in building construction: A French contractor’s experience. Int. J. Lean Six Sigma 2017, 8, 153–180. [Google Scholar] [CrossRef]

- Mohammadi, A.; Igwe, C.; Amador-Jimenez, L.; Nasiri, F. Applying lean construction principles in road maintenance planning and scheduling. Int. J. Constr. Manag. 2020, 22, 2364–2374. [Google Scholar] [CrossRef]

- Ramani, P.V.; Ksd, L.K.L. Application of lean in construction using value stream mapping. Eng. Constr. Archit. Manag. 2019, 28, 216–228. [Google Scholar] [CrossRef]

- Ahmed, S.; Hossain, M.M.; Haq, I. Implementation of lean construction in the construction industry in Bangladesh: Awareness, benefits and challenges. Int. J. Build. Pathol. Adapt. 2021, 39, 368–406. [Google Scholar] [CrossRef]

- Al balkhy, W.; Sweis, R. Barriers to adopting lean construction in the construction industry: A literature review. Int. J. Lean Six Sigma 2020, 12, 210–236. [Google Scholar] [CrossRef]

- Enshassi, A.; Saleh, N.; Mohamed, S. Barriers to the application of lean construction techniques concerning safety improvement in construction projects. Int. J. Constr. Manag. 2021, 21, 1044–1060. [Google Scholar] [CrossRef]

- Ivina, D.; Olsson, N.O.E. Lean Construction Principles and Railway Maintenance Planning. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Khaba, S.; Bhar, C. Modeling the key barriers to lean construction using interpretive structural modeling. J. Model. Manag. 2017, 12, 652–670. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Identifying and managing critical waste factors for lean construction projects. Eng. Manag. J. 2020, 32, 2–13. [Google Scholar] [CrossRef]

- Ibrahim, A.R.; Imtiaz, G.; Mujtaba, B.; Vo, X.V.; Ahmed, Z.U. Operational excellence through lean manufacturing: Considerations for productivity management in Malaysia’s construction industry. J. Transnatl. Manag. 2020, 25, 225–256. [Google Scholar] [CrossRef]

- Nahmens, I. From lean to green construction: A natural extension. In Proceedings of the Construction Research Congress 2009: Building a Sustainable Future, Seattle, WA, USA, 5–7 April 2009; pp. 1058–1067. [Google Scholar]

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A. Lean Construction Implementation in the Saudi Arabian Construction Industry. Constr. Econ. Build. 2017, 17, 46–69. [Google Scholar] [CrossRef]

- Evans, M.; Farrell, P. Barriers to integrating building information modelling (BIM) and lean construction practices on construction mega-projects: A Delphi study. Benchmarking Int. J. 2020, 28, 652–669. [Google Scholar] [CrossRef]

- Fosse, R.; Ballard, G.; Fischer, M. Virtual design and construction: Aligning BIM and lean in practice. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Goyal, M.; Gao, Z. Integration of building information modeling (BIM) and prefabrication for lean construction. In Proceedings of the ICCREM 2018: Innovative Technology and Intelligent Construction, Charleston, SC, USA, 9–10 August 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 78–84. [Google Scholar]

- Nguyen, P.; Akhavian, R. Synergistic effect of integrated project delivery, lean construction, and building information modeling on project performance measures: A quantitative and qualitative analysis. Adv. Civ. Eng. 2019, 2019, 1267048. [Google Scholar] [CrossRef]

- Pandithawatta, T.P.W.S.I.; Zainudeen, N.; Perera, C.S.R. An integrated approach of Lean-Green construction: Sri Lankan perspective. Built Environ. Proj. Asset Manag. 2019, 10, 200–214. [Google Scholar] [CrossRef]

- Wijerathne, M.D.I.R.; Gunasekara, K.A.; Perera, B.A.K.S. Overcoming the challenges of sustainable development in Sri Lanka using lean construction principles. In Proceedings of the 8th World Construction Symposium, Colombo, Sri Lanka, 8–10 November 2019; pp. 473–483. [Google Scholar] [CrossRef]

- Moradi, S.; Sormunen, P. Lean and Sustainable Project Delivery in Building Construction: Development of a Conceptual Framework. Buildings 2022, 12, 1757. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Frosolini, M. A lean approach for real-time planning and monitoring in engineer-to-order construction projects. Buildings 2018, 8, 38. [Google Scholar] [CrossRef]

- Erol, H.H.; Dikmen Toker, İ.; Birgönül, M.T. A Construction Delay Analysis Approach Based on Lean Principles. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Nguyen, T.Q.; Waikar, S.S. A relook at plan reliability measurements in lean construction and new metrics from digitized practical implementation. In Proceedings of the 26th Annual Conference of the International. Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1037–1046. [Google Scholar] [CrossRef]

- Pestana, A.C.V.; Alves, T.D.C.; Barbosa, A.R. Application of lean construction concepts to manage the submittal process in AEC projects. J. Manag. Eng. 2014, 30, 05014006. [Google Scholar] [CrossRef]

- Sacks, R.; Goldin, M. Lean management model for construction of high-rise apartment buildings. J. Constr. Eng. Manag. 2007, 133, 374–384. [Google Scholar] [CrossRef]

- Zimina, D.; Ballard, G.; Pasquire, C. Target value design: Using collaboration and a lean approach to reduce construction cost. Constr. Manag. Econ. 2012, 30, 383–398. [Google Scholar] [CrossRef]

- Besklubova, S.; Zhang, X. Improving construction productivity by integrating the lean concept and the Clancey heuristic model. Sustainability 2019, 11, 4535. [Google Scholar] [CrossRef]

- Issa, U.H.; Alqurashi, M. A model for evaluating causes of wastes and lean implementation in construction projects. J. Civ. Eng. Manag. 2020, 26, 331–342. [Google Scholar] [CrossRef]

- Gómez-Cabrera, A.; Salazar, L.A.; Ponz-Tienda, J.L.; Alarcón, L.F. Lean Tools Proposal to mitigate Delays and Cost Overruns in Construction Projects. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–10 July 2020. [Google Scholar] [CrossRef]

- Singh, J.; Mangal, M.; Cheng, J.C.P. IT for Lean Construction-A Survey in India. In Proceedings of the LC3 2017 Volume II—The 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017; pp. 119–126. [Google Scholar] [CrossRef]

- Forbes, L.H.; Rybkowski, Z.K.; Tsao, C.Y. The evolution of lean construction education (Part 2 of 2): At US-based companies. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1024–1034. [Google Scholar] [CrossRef]

- Rybkowski, Z.K.; Forbes, L.H.; Tsao, C.Y. The evolution of lean construction education (Part 1 of 2): At US-based universities. In Proceedings of the 26th Annual Conference of the International. Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1013–1023. [Google Scholar] [CrossRef]

- Pütz, C.; Lühr, G.J.; Wenzel, M.; Helmus, M. Potential of gamification for lean construction training: An exploratory study. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC29), Lima, Peru, 14–17 July 2021; pp. 259–268. [Google Scholar] [CrossRef]

- Alarcón, L.F.; Diethelm, S.; Rojo, O.; Calderón, R. Assessing the impacts of implementing lean construction Evaluando los impactos de la implementación de lean construction. Rev. Ing. Constr. 2008, 23, 26–33. [Google Scholar] [CrossRef]

- Koohestani, K.; Poshdar, M.; Gonzalez, V.A. Finding the Way to Success in Implementing Lean Construction in an Unfavourable Context. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Uddin, M.M. Lean Construction Quality Assurance Opportunities in Highway Construction. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, W.; Ma, T.; Yang, Z. Improving the efficiency of highway construction project management using lean management. Sustainability 2019, 11, 3646. [Google Scholar] [CrossRef]

- Abbasian-Hosseini, S.A.; Nikakhtar, A.; Ghoddousi, P. Verification of lean construction benefits through simulation modeling: A case study of bricklaying process. KSCE J. Civ. Eng. 2014, 18, 1248–1260. [Google Scholar] [CrossRef]

- Shahbaz, M.S.; Shaikh, F.A. Impact of lean management practices on operational performance: An empirical investigation from construction supply chain of Pakistan. Int. J. Sustain. Constr. Eng. Technol. 2019, 10, 85–92. [Google Scholar]

- Avelar, W.; Meiriño, M.; Tortorella, G.L. The practical relationship between continuous flow and lean construction in SMEs. TQM J. 2019, 32, 362–380. [Google Scholar] [CrossRef]

- Li, H.; Guo, H.L.; Li, Y.; Skitmore, M. From IKEA model to the lean construction concept: A solution to implementation. Int. J. Constr. Manag. 2012, 12, 47–63. [Google Scholar] [CrossRef]

- Koranda, C.; Chong, W.K.; Kim, C.; Chou, J.S.; Kim, C. An investigation of the applicability of sustainability and lean concepts to small construction projects. KSCE J. Civ. Eng. 2012, 16, 699–707. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Lean construction implementation in the Moroccan construction industry: Awareness, benefits and barriers. J. Eng. Des. Technol. 2018, 16, 533–556. [Google Scholar]

- Ahmed, S.; Sobuz, M.H.R. Challenges of implementing lean construction in the construction industry in Bangladesh. Smart Sustain. Built Environ. 2020, 9, 174–207. [Google Scholar] [CrossRef]

- Al Balkhy, W.; Sweis, R.; Lafhaj, Z. Barriers to Adopting Lean Construction in the Construction Industry—The Case of Jordan. Buildings 2021, 11, 222. [Google Scholar] [CrossRef]

- Demirkesen, S.; Wachter, N.; Oprach, S.; Haghsheno, S. Identifying Barriers in Lean Implementation in the Construction Industry. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 157–168. [Google Scholar] [CrossRef]

- Huaman-Orosco, C.; Erazo-Rondinel, A.A. An Exploratory Study of the Main Barriers to Lean Construction Implementation in Peru. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC29), Lima, Peru, 14–17 July 2021; pp. 474–483. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean methodologies and techniques for modular construction: Chronological and critical review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Li, L.; Hao, Y. Problems Encountered in Implementing Lean Construction and Solutions. In Proceedings of the ICCREM 2021, Beijing, China, 16–17 October 2021; pp. 392–397. [Google Scholar]

- Mano, A.P.; da Costa, S.E.G.; de Lima, E.P. Criticality assessment of the barriers to Lean Construction. Int. J. Product. Perform. Manag. 2020, 70, 65–86. [Google Scholar] [CrossRef]

- Thomas, D.; Khanduja, D. ISM–ANP hybrid approach to prioritize the barriers in green lean Six Sigma implementation in construction sector. Int. J. Lean Six Sigma 2022, 13, 502–520. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Z.; Ni, G.; Chen, C.; Wang, W.; Hong, J. Cause analysis of hindering on-site lean construction for prefabricated buildings and corresponding organizational capability evaluation. Adv. Civ. Eng. 2020, 2020, 8876102. [Google Scholar] [CrossRef]

- Yahya, M.A.; Mohamad, M.I. Review on lean principles for rapid construction. J. Teknol. 2011, 54, 1–11. [Google Scholar] [CrossRef]

- Tezel, A.; Koskela, L.; Aziz, Z. Lean construction in small-medium sized enterprises (SMEs): An exploration of the highways supply chain. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017; pp. 845–851. [Google Scholar]

- Zanotti, N.L.; Maranhao, F.L.; Aly, V.L.C. Bottom-up strategy for lean construction on site implementation. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Ankomah, E.N.; Ayarkwa, J.; Agyekum, K. Conceptual framework for capability and capacity building of SMEs for lean construction adoption. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 231–239. [Google Scholar] [CrossRef]

- Al Heet, M.R.A.H.; Alves, T.C.L.; Lakrori, N. Investigation of the use of Lean Construction Practices in Transportation Construction Projects. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Chen, L.; Chen, J.; Zhang, J. Research on Lean Construction System in the Background of Construction Industrialization. In Proceedings of the ICCREM 2018: Innovative Technology and Intelligent Construction, Charleston, SC, USA, 9–10 August 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 132–137. [Google Scholar]

- Darabseh, M. Lean Applications in Construction: Review Article. U. Porto J. Eng. 2019, 5, 29–37. [Google Scholar] [CrossRef]

- Demirkesen, S.; Bayhan, H.G. A lean implementation success model for the construction industry. Eng. Manag. J. 2020, 32, 219–239. [Google Scholar] [CrossRef]

- Habibi Rad, M.; Mojtahedi, M.; Ostwald, M.J.; Wilkinson, S. A Conceptual Framework for Implementing Lean Construction in Infrastructure Recovery Projects. Buildings 2022, 12, 272. [Google Scholar] [CrossRef]

- Karanjawala, K.H.; Baretto, D. Project Delivery through Lean Principles across all disciplines of Construction in a Developing Country Environment. In Proceedings of the 26th Annual Conference of the International. Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1122–1132. [Google Scholar] [CrossRef]

- Maradzano, I.; Dondofema, R.A.; Matope, S. Application of lean principles in the South African construction industry. S. Afr. J. Ind. Eng. 2019, 30, 210–223. [Google Scholar] [CrossRef]

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A.; Olanipekun, A.O.; Coffey, V. Framework for the implementation of lean construction strategies using the interpretive structural modelling (ISM) technique: A case of the Saudi construction industry. Eng. Constr. Archit. Manag. 2019, 27, 1–23. [Google Scholar] [CrossRef]

- Torp, O.; Knudsen, J.B.; Rønneberg, I. Factors Affecting Implementation of Lean Construcxtion. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1261–1271. [Google Scholar] [CrossRef]

- Valente, C.P.; Mourão, C.A.M.A.; Saggin, A.B.; Neto, J.P.B.; Costa, J.M. Achieving Excellence in Lean Implementation at Construction Companies—A Case Study from Brazil. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar] [CrossRef]

- Poshdar, M.; Gonzalez, V.A.; Antunes, R.; Ghodrati, N.; Katebi, M.; Valasiuk, S.; Alqudah, H.; Talebi, S. Diffusion of Lean Construction in Small to Medium-Sized Enterprises of Housing Sector. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 383–392. [Google Scholar] [CrossRef]

- Ko, C.H. Application of lean production system in the construction industry: An empirical study. J. Eng. Appl. Sci. 2010, 5, 71–77. [Google Scholar] [CrossRef]

- Fearne, A.; Fowler, N. Efficiency versus effectiveness in construction supply chains: The dangers of “lean” thinking in isolation. Supply Chain Manag. Int. J. 2006, 11, 283–287. [Google Scholar] [CrossRef]

- Eriksson, P.E. Improving construction supply chain collaboration and performance: A lean construction pilot project. Supply Chain Manag. Int. J. 2010, 15, 394–403. [Google Scholar] [CrossRef]

- Garrett, D.F.; Lee, J. Lean Construction Submittal Process—A Case Study. Qual. Engineering 2010, 23, 84–93. [Google Scholar] [CrossRef]

- Sage, D.; Dainty, A.; Brookes, N. A ‘Strategy-as-Practice’ exploration of lean construction strategizing. Build. Res. Inf. 2012, 40, 221–230. [Google Scholar] [CrossRef]

- Pasquire, C. Positioning Lean within an exploration of engineering construction. Constr. Manag. Econ. 2012, 30, 673–685. [Google Scholar] [CrossRef]

- Bygballe, L.E.; Endresen, M.; Fålun, S. The role of formal and informal mechanisms in implementing lean principles in construction projects. Eng. Constr. Archit. Manag. 2018, 25, 1322–1338. [Google Scholar] [CrossRef]

- Erol, H.; Dikmen, I.; Birgonul, M.T. Measuring the impact of lean construction practices on project duration and variability: A simulation-based study on residential buildings. J. Civ. Eng. Manag. 2017, 23, 241–251. [Google Scholar] [CrossRef]

- Minnullina, A.; Solopova, N. Optimization of activities of road construction company based on lean manufacturing tools. In Proceedings of the E3S Web of Conferences, Kenitra, Morocco, 25–27 December 2020; EDP Sciences: Les Ulis, France, 2020; Volume 157, p. 06003. [Google Scholar]

- Neve, H.H.; Lerche, J.; Wandahl, S. Combining lean methods to improve construction labour efficiency in renovation projects. In Proceedings of the 29th Annual Conference of the International Group for Lean Construction (IGLC29), Lima, Peru, 14–17 July 2021; pp. 647–656. [Google Scholar] [CrossRef]

- Orlov, A.K.; Kankhva, V.S. Lean Construction Concept Used to Develop Infrastructure Facilities for Tourism Clusters. Buildings 2022, 12, 23. [Google Scholar] [CrossRef]

- Sarhan, S.; Elnokaly, A.; Pasquire, C.; Pretlove, S. Lean Construction and Sustainability through IGLC Community: A Critical Systematic Review of 25 Years of Experience. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 933–942. [Google Scholar] [CrossRef]

- Meng, X. Lean management in the context of construction supply chains. Int. J. Prod. Res. 2019, 57, 3784–3798. [Google Scholar] [CrossRef]

- Daramsis, A.; Faour, K.; Richa Abdel Ahad, L.; Salami, G.; Hamzeh, F. A Lean E-Governance Approach to Mitigate Corruption Within Official Processes in the Construction Industry. In Proceedings of the 26th Annual Conference of the International. Group for Lean Construction (IGLC), Chennai, India, 16–22 July 2018; pp. 1251–1260. [Google Scholar] [CrossRef]

- Saunders, M.N.K.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 8th ed.; Pearson Education Limited: Harlow, UK, 2019. [Google Scholar]

- Forbes, L.H.; Ahmed, S.M. Modern Construction: Lean Project Delivery and Integrated Practices; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Oakland, J.S.; Marosszeky, M. Total Construction Management: Lean Quality in Construction Project Delivery; Routledge: Abingdon, UK, 2017. [Google Scholar]

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Comparative analysis between integrated project delivery and lean project delivery. Int. J. Proj. Manag. 2019, 37, 395–409. [Google Scholar] [CrossRef]

| Barrier | Frequency of Appearance | Representing Contexts |

|---|---|---|

| Lack of awareness and understanding of LC | 12 | Bangladesh, China, Hong Kong, India, Jordan, Morocco, Palestine, Sweden, |

| Resistance to change (management and employees) | 8 | Australia, Bangladesh, China, India, Germany, Sweden |

| Lack of support and commitment from top management | 6 | China, Jordan, Germany, India |

| Lack of required competencies both at managerial and employee level | 6 | Bangladesh, China, Morocco |

| Lack of lean consultants, education, and training | 5 | Bangladesh, China, Jordan, India |

| Insufficient funds | 5 | Bangladesh, China, India, Morocco |

| Lack of effective communication among project participants | 5 | Bangladesh, Germany, India, Hong Kong |

| Insufficient support from the government (providing required policies, codes, and regulations) | 4 | India, Palestine, Peru |

| Lack of performance measurement systems | 3 | India, China |

| Poor understanding of customer needs and poor customer focus | 3 | India |

| Lack of involvement and transparency among stakeholders | 3 | Jordan, China |

| Enabler | Frequency of Appearance | Representing Contexts |

| Developing lean culture through promoting lean education, training, and research | 9 | Brazil, Türkiye, the USA, Chile, China, Saudi Arabia, India |

| The application of lean principles tools and techniques | 5 | Türkiye, the USA, Saudi Arabia |

| Top management support and commitment | 4 | Norway, Iran, Saudi Arabia, India |

| Continuous improvement in process and product development | 3 | Chile, South Africa, Saudi Arabia, |

| Creation and management of relevant knowledge | 2 | Brazil, Malaysia |

| Developing LC-oriented KPI for contractors | 2 | Malaysia |

| Improving organizational resilience by establishing LC-oriented leadership and culture, enhancing change readiness, and explaining networks and relationships | 2 | Saudi Arabia |

| Adopting collaborative project delivery models (e.g., alliance, lean project delivery, partnering) | 2 | Saudi Arabia, China |

| Promoting a culture of teamwork | 2 | Saudi Arabia, Malaysia |

| Investor/client requirement | 2 | The UK |

| Implications of LC Application | Frequency of Appearance | Representing Contexts |

|---|---|---|

| Time and cost reduction | 8 | India, Canada, Russia, the USA, Morocco, Türkiye, Brazil |

| Increased productivity (at task and project levels) | 4 | India, the UK, Saudi Arabia, Brazil |

| Increased labor productivity | 3 | Iran, Russia, Denmark |

| Increased process efficiency | 3 | Iran, Morocco, Saudi Arabia |

| Competence-based selection in bidding phase | 2 | Canada, France |

| Decreased inventory | 2 | Taiwan, Saudi Arabia |

| Better operational performance | 2 | Malaysia, Pakistan |

| Quality improvement | 2 | Brazil, Saudi Arabia |

| Waste reduction | 1 | The USA |

| Better diffusion of LC in managerial levels of company | 1 | The UK |

| Establishment of collaborative climate | 1 | Sweden |

| Stakeholder satisfaction | 1 | Saudi Arabia |

| Better health and safety | 1 | Saudi Arabia |

| Increased market share | 1 | Saudi Arabia |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moradi, S.; Sormunen, P. Implementing Lean Construction: A Literature Study of Barriers, Enablers, and Implications. Buildings 2023, 13, 556. https://doi.org/10.3390/buildings13020556

Moradi S, Sormunen P. Implementing Lean Construction: A Literature Study of Barriers, Enablers, and Implications. Buildings. 2023; 13(2):556. https://doi.org/10.3390/buildings13020556

Chicago/Turabian StyleMoradi, Sina, and Piia Sormunen. 2023. "Implementing Lean Construction: A Literature Study of Barriers, Enablers, and Implications" Buildings 13, no. 2: 556. https://doi.org/10.3390/buildings13020556

APA StyleMoradi, S., & Sormunen, P. (2023). Implementing Lean Construction: A Literature Study of Barriers, Enablers, and Implications. Buildings, 13(2), 556. https://doi.org/10.3390/buildings13020556