Valorization of Dredged Sediments and Recycled Concrete Aggregates in Road Subgrade Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Marine Dredged Sediments (SED)

2.2. Recycled Concrete Aggregate (RCA)

2.3. Material Characterization

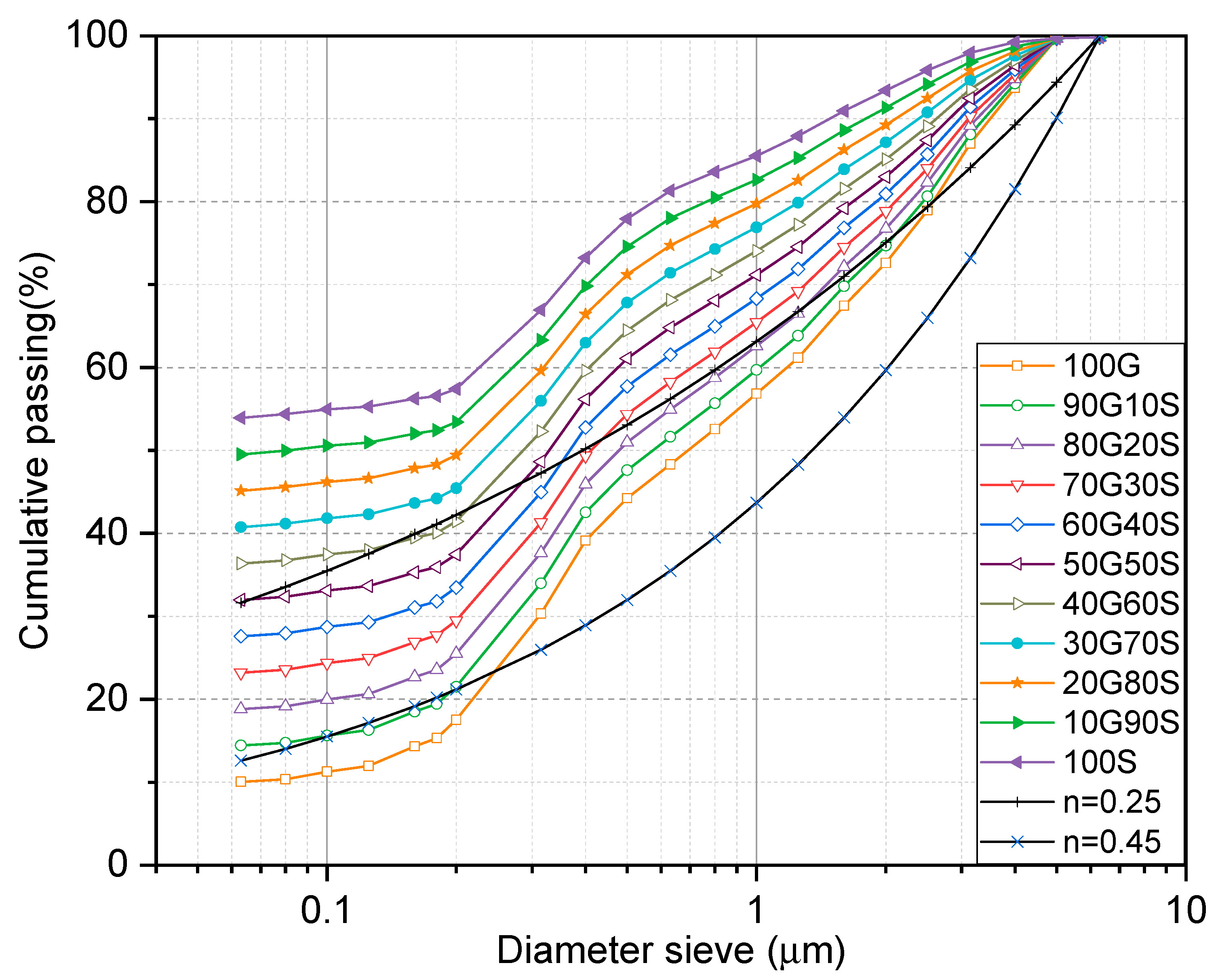

2.3.1. Physical Characterization

2.3.2. Mineralogical Characterization

2.3.3. Hydraulic Binder and Quicklime

2.4. Methods

2.4.1. Mix Design

2.4.2. Geotechnical Classification

2.4.3. Normal Proctor Test and Immediate Bearing Ratio

2.4.4. Mechanical Behavior

Unconfined Compression Strength (UCS)

Indirect Tensile Strength (ITS)

Modulus of Elasticity

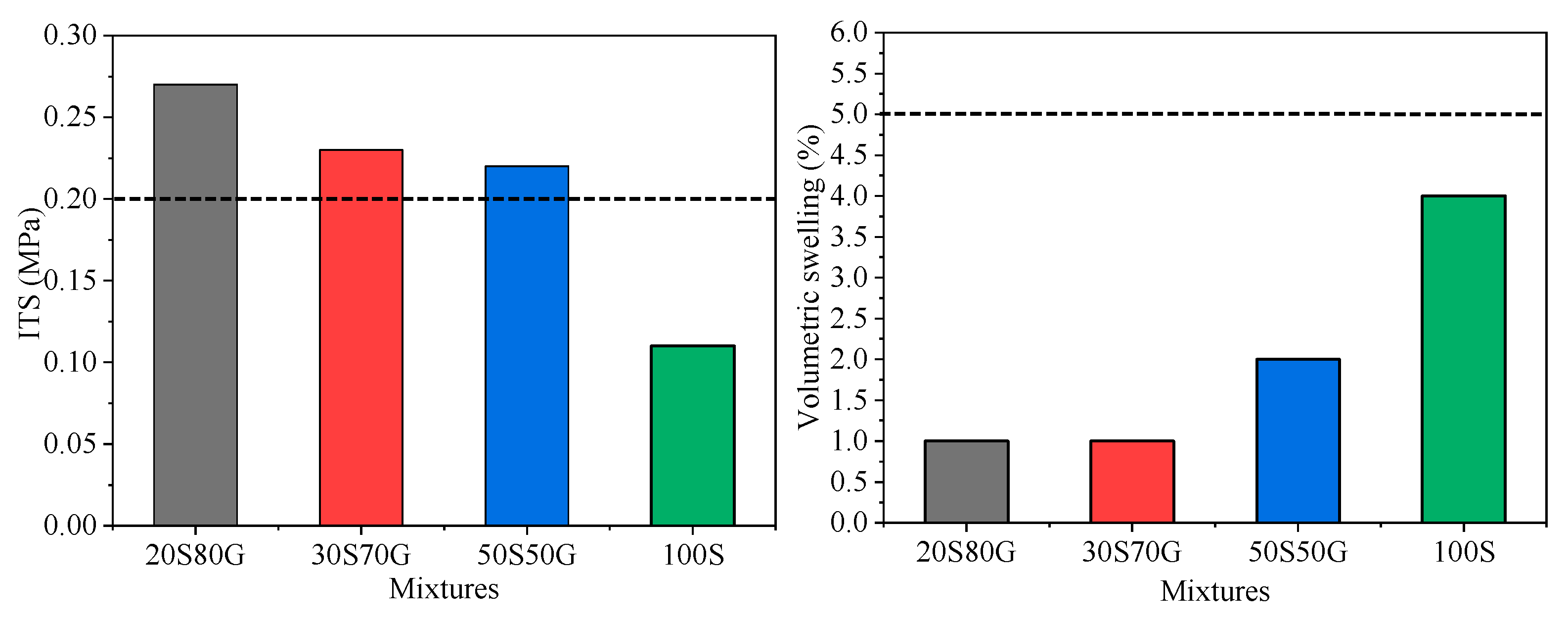

2.4.5. Treatment Suitability

2.4.6. Leaching Test

3. Results and Discussion

3.1. Leaching Tests

3.2. Physical and Geotechnical Characterization of Non-Treated and Treated Mixes

3.3. Designed Material Sustainability

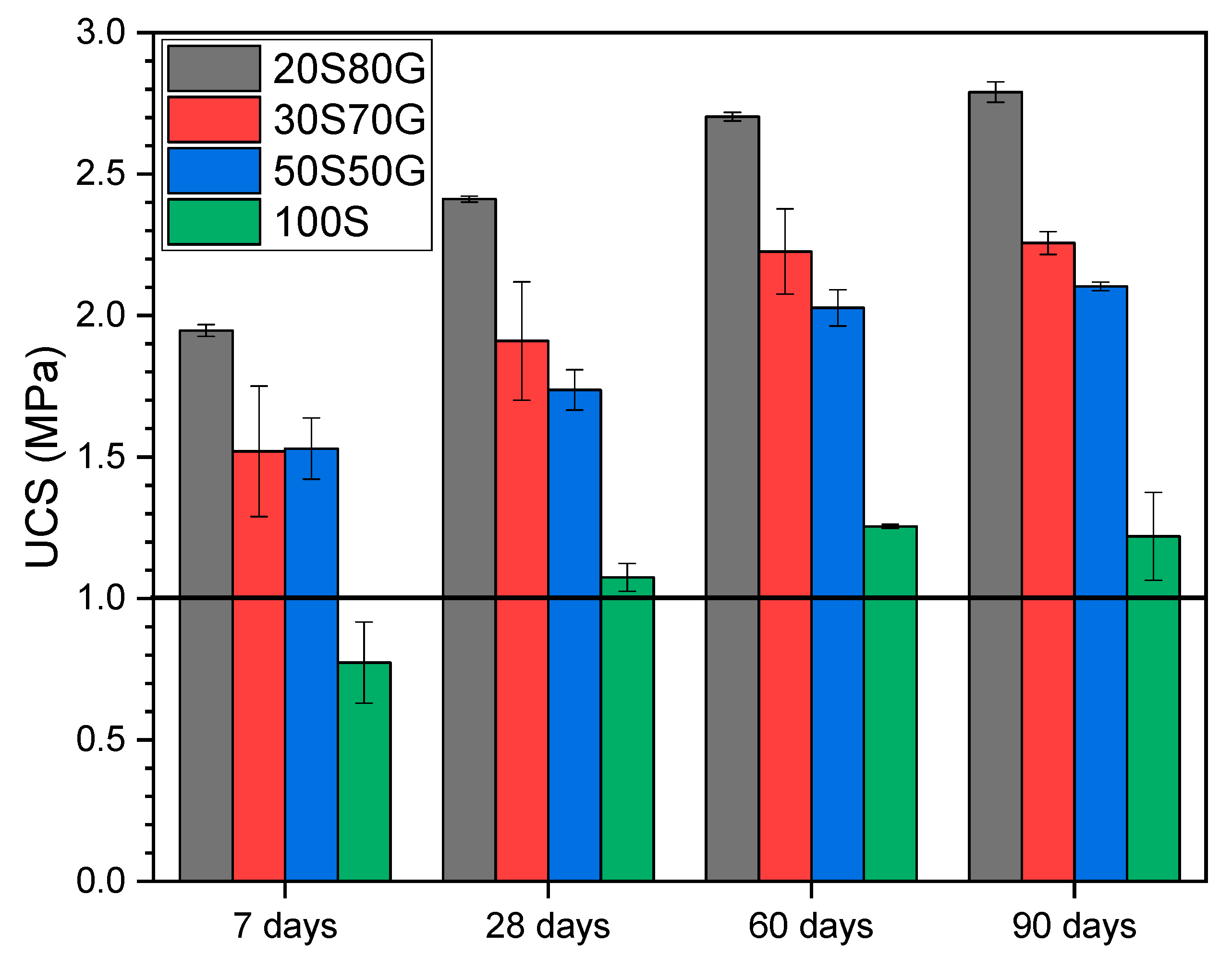

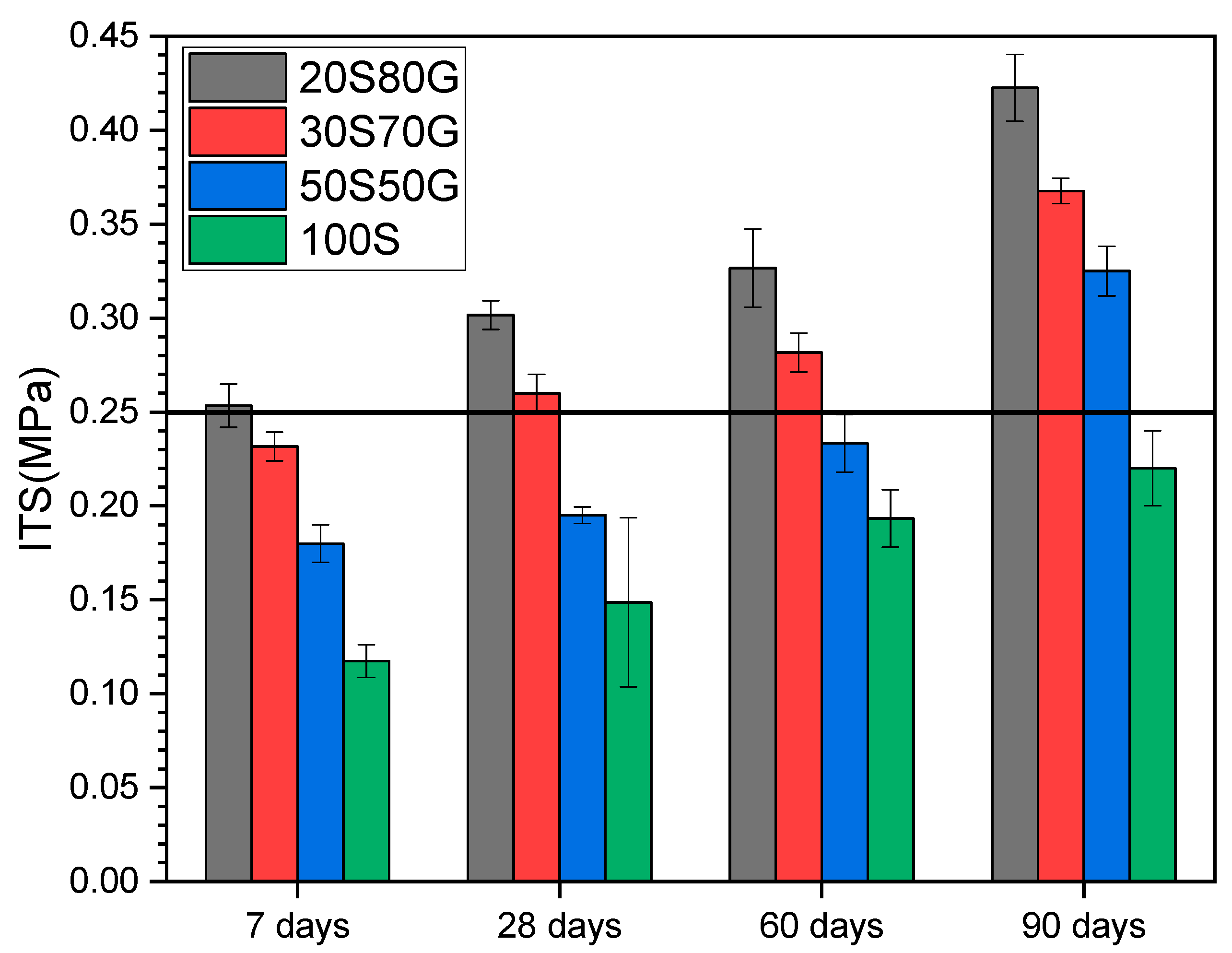

3.4. Mechanical Behavior

- The circulation on the treated layer is allowed when the UCS reaches a value of 1 MPa.

- The frost resistance is considered satisfactory if the ITS value is higher than 0.25 MPa.

- The resistance to immersion at early age is computed using the ratio between the UCS value after 28 days of curing followed by an immersion during 32 days in water at a temperature of 20 °C (USCI) and the UCS value after 60 days in normal curing at 20 °C (UCS60).

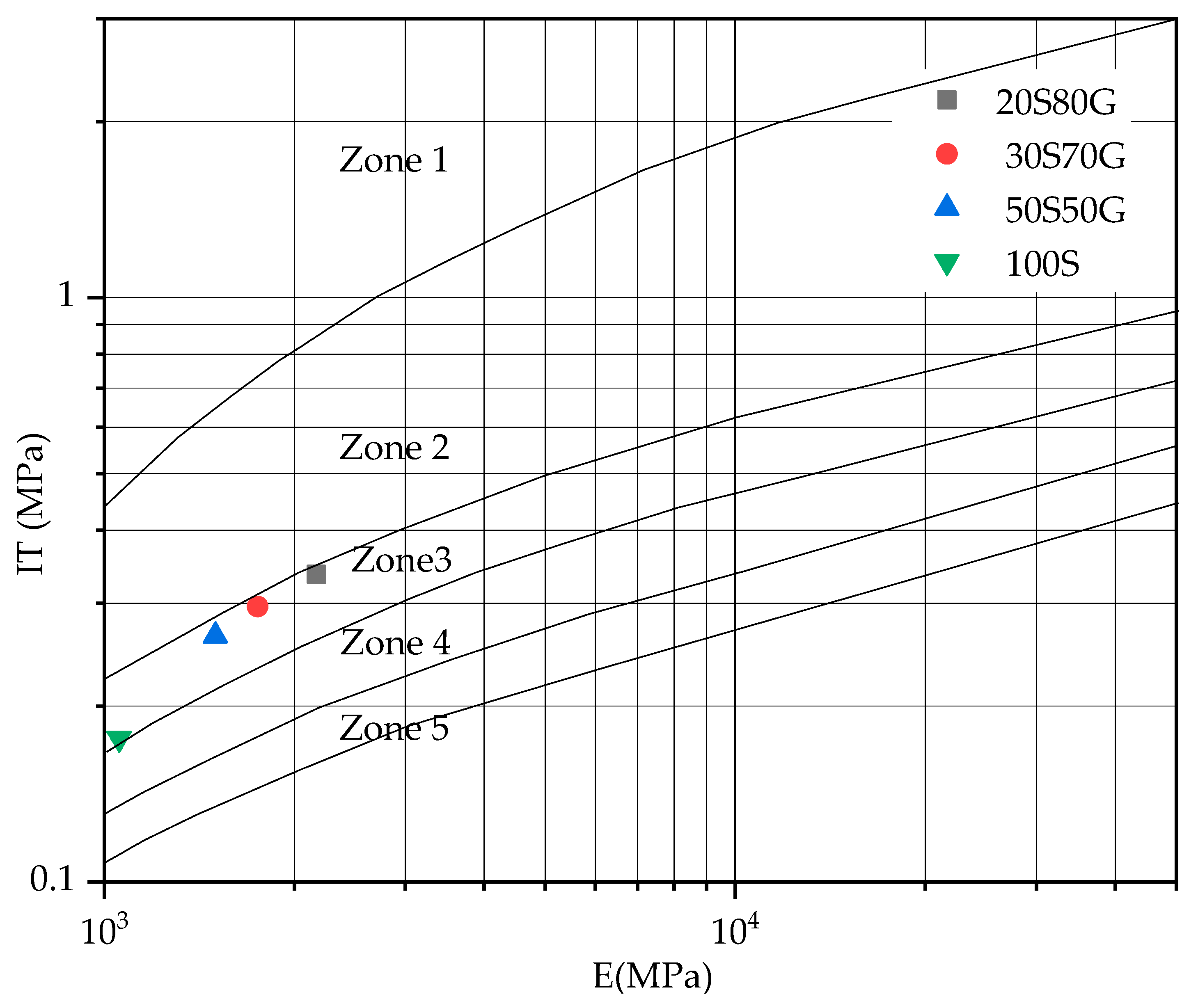

- The mix long-term mechanical behavior is satisfactory when its resistance reaches at most a class of 5.

3.4.1. Trafficability Criteria of Road Sublayers and Frost Resistance

- The organic matter absorbs a portion of the hydraulic binder hydration water, which leads to a decrease in hydration products such as C-S-H, ettringite and portlandite.

- Because of their physical characteristics (low dry density and high fine fraction), the sediments tend to decrease the compactness of the mix and consequently its strength.

- The presence of contaminants in the sediments interacts with the binders (lime and cement), which leads to a delay or inhibition of hydration reactions.

3.4.2. Early Age Immersion Resistance

3.4.3. Long-Term Mechanical Behavior

3.5. Environmental Assessment of Designed Materials

4. Conclusions

- The lime treatment improved the IBR values for the mixes. However, only mix 20S80G (i.e., 20% SED and 80%) is recommended for use in subgrade construction because its IBR reached a value of 20%.

- The mixes showed significant swelling volume reduction after lime treatment. Moreover, the mix swelling volumes were below the threshold of 5% for use in subgrade construction.

- The UCS and ITS values of the mixes increased with curing time. The mixes 20S80G, 30S70G, and 50S50G reached the circulation age requirement after 7 days, while mix 100S reached it after 28 days. On the other hand, mixes 20S80G, 30S70G, 50S50G reached the criterion of 0.25 MPa for use in subgrades after 7, 28, and 60 days, respectively.

- The mixes met the early age immersion resistance criteria for use in subgrade construction. The mix ratios between UCSI and UCS60 were higher than 0.6, which is the criteria for use in subgrade for a soil with an MBV ≥ 0.5 g/100 g.

- The mixes showed adequate long-term mechanical performance for use in subgrade construction, which corresponds to a resistance class of 5 or lower. Mixes 20S80G, 30S70G and 50S50G had a resistance class 3, while mix 100S had a resistance class 4.

- The mixes complied with the leaching thresholds of the SETRA guide, except mix 100S due to fluoride and sulfate amounts exceeding the thresholds. Thus, the mixes can be used in subgrade construction from an environmental point of view.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crocetti, P.; González-Camejo, J.; Li, K.; Foglia, A.; Eusebi, A.L.; Fatone, F. An overview of operations and processes for circular management of dredged sediments. Waste Manag. 2022, 146, 20–35. [Google Scholar] [CrossRef]

- Cabrerizo, A. Caractérisation et Traitement de Matériaux Excavés et de Sédiments Marins et Fluviaux en vue d’une Valorisation en Technique Routière. Ph.D. Thesis, Ecole Nationale Supérieure Mines-Télécom Lille Douai, Douai, France, 2019. [Google Scholar]

- Bellara, S.; Levacher, D.; Mezazigh, S.; Hidjeb, M. Valorisation des sédiments du barrage de Zardezas (Algérie): Caractérisation et aptitude au compactage des sédiments. In Proceedings of the XVIème Journées Nationales Génie Côtier-Génie Civil XVIème, Le Havre, France, 8–10 December 2020; pp. 571–580. [Google Scholar]

- Larouci, A.; Senhadji, Y.; Laoufi, L.; Benazzouk, A. Dredged Dam Raw Sediments Geotechnical Characterization for Beneficial Use in Road Construction. Int. J. Eng. Res. Afr. 2021, 57, 81–98. [Google Scholar] [CrossRef]

- Slama, A.B.; Feki, N.; Levacher, D.; Zairi, M. Valorization of harbor dredged sediment activated with blast furnace slag in road layers. Int. J. Sediment Res. 2021, 36, 127–135. [Google Scholar] [CrossRef]

- Hussan, A.; Levacher, D.; Mezazigh, S.; Jardin, L. Co-valorization of sediments incorporating high and low organic matter with alkali-activated GGBS and hydraulic binder for use in road construction. J. Build. Eng. 2023, 66, 105848. [Google Scholar] [CrossRef]

- Loudini, A.; Ibnoussina, M.; Witam, O.; Limam, A.; Turchanina, O. Valorisation of dredged marine sediments for use as road material. Case Stud. Constr. Mater. 2020, 13, e00455. [Google Scholar] [CrossRef]

- Mkahal, Z.; Mamindy-Pajany, Y.; Maherzi, W.; Abriak, N.-E. Recycling of mineral solid wastes in backfill road materials: Technical and environmental investigations. Waste Biomass Valorization 2022, 13, 667–687. [Google Scholar] [CrossRef]

- Kasmi, A.; Abriak, N.-E.; Benzerzour, M.; Azrar, H. Environmental impact and mechanical behavior study of experimental road made with river sediments: Recycling of river sediments in road construction. J. Mater. Cycles Waste Manag. 2017, 19, 1405–1414. [Google Scholar] [CrossRef]

- Banoune, B.; Melbouci, B.; Rosquoët, F.; Langlet, T. Treatment of river sediments by hydraulic binders for valorization in road construction. Bull. Eng. Geol. Environ. 2016, 75, 1505. [Google Scholar] [CrossRef]

- Hamouche, F.; Zentar, R. Effects of organic matter on mechanical properties of dredged sediments for beneficial use in road construction. Environ. Technol. 2020, 41, 296–308. [Google Scholar] [CrossRef]

- Wang, D.; Abriak, N.E.; Zentar, R. Dredged marine sediments used as novel supply of filling materials for road construction. Mar. Georesources Geotechnol. 2017, 35, 472–480. [Google Scholar] [CrossRef]

- Maherzi, W.; Benzerzour, M.; Mamindy-Pajany, Y.; van Veen, E.; Boutouil, M.; Abriak, N.E. Beneficial reuse of Brest-Harbor (France)-dredged sediment as alternative material in road building: Laboratory investigations. Environ. Technol. 2018, 39, 566–580. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Raman, J.V.M.; Ramasamy, V. Various treatment techniques involved to enhance the recycled coarse aggregate in concrete: A review. Mater. Today Proc. 2021, 45, 6356–6363. [Google Scholar] [CrossRef]

- Gunasekar, S.; Ramesh, N.; Shivani, G. Effective utilisation of construction and demolition waste (Cdw) as recycled aggregate in concrete construction—A critical review. Int. Res. J. Multidiscip. Technovation 2019, 1, 465–469. [Google Scholar]

- Sata, V.; Chindaprasirt, P. Use of construction and demolition waste (CDW) for alkali-activated or geopolymer concrete. In Advances in Construction and Demolition Waste Recycling; Elsevier: Khon Kaen, Thailand, 2020; pp. 385–403. [Google Scholar]

- Schoon, J.; De Buysser, K.; Van Driessche, I.; De Belie, N. Fines extracted from recycled concrete as alternative raw material for Portland cement clinker production. Cem. Concr. Compos. 2015, 58, 70–80. [Google Scholar] [CrossRef]

- Diliberto, C.; Lecomte, A.; Mechling, J.-M.; Izoret, L.; Smith, A. Valorisation of recycled concrete sands in cement raw meal for cement production. Mater. Struct. 2017, 50, 1–12. [Google Scholar] [CrossRef]

- Krour, H.; Trauchessec, R.; Lecomte, A.; Diliberto, C.; Barnes-Davin, L.; Bolze, B.; Delhay, A. Incorporation rate of recycled aggregates in cement raw meals. Constr. Build. Mater. 2020, 248, 118217. [Google Scholar] [CrossRef]

- Oksri-Nelfia, L.; Mahieux, P.-Y.; Amiri, O.; Turcry Ph Lux, J. Reuse of recycled crushed concrete fines as mineral addition in cementitious materials. Mater. Struct. 2016, 49, 3239–3251. [Google Scholar] [CrossRef]

- Bouarroudj, M.E.; Rémond, S.; Bulteel, D.; Potier, G.; Michel, F.; Zhao, Z.; Courard, L. Use of grinded hardened cement pastes as mineral addition for mortars. J. Build. Eng. 2021, 34, 101863. [Google Scholar] [CrossRef]

- Topič, J.; Prošek, Z.; Plachý, T. Influence of increasing amount of recycled concrete powder on mechanical properties of cement paste. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012094. [Google Scholar] [CrossRef]

- Martínez-García, R.; Rojas MIS de Pozo, J.M.M.; Fraile-Fernández, F.J.; Juan-Valdés, A. Evaluation of mechanical characteristics of cement mortar with fine recycled concrete aggregates (FRCA). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- Gonçalves, T.; Silva, R.V.; De Brito, J.; Fernández, J.M.; Esquinas, A.R. Mechanical and durability performance of mortars with fine recycled concrete aggregates and reactive magnesium oxide as partial cement replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Kapoor, K.; Bohroo, A.U.R. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. In Sustainable Engineering; Springer: Singapore, 2019; pp. 337–347. [Google Scholar]

- Silva, S.; Evangelista, L.; De Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. Quality improvement of recycled concrete aggregate by removal of residual mortar: A comprehensive review of approaches adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Zardikawi, O.A.A.; Abdulnafaa, M.D. Utilisation of construction and demolition materials with clay for road pavement subgrade. Road Mater. Pavement Des. 2019, 20, 702–714. [Google Scholar] [CrossRef]

- Guide de Terrassement Routier (GTR); LCPC-SETRA: Paris, France, 1992.

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- ISO 13320:2020; Analyse Granulométrique—Méthodes par Diffraction Laser. ISO International Standards, 2020. Available online: https://www.iso.org/fr/standard/69111.html (accessed on 6 February 2023).

- XP P94-041; Sols: Reconnaissance et Essais—Identification Granulométrique—Méthode de Tamisage par Voie Humide. AFNOR: Paris, France, 1995.

- XP P94-047; Sols: Reconnaissance et Essais—Détermination de la Teneur Pondérale en Matières Organiques d’un Matériau—Méthode par Calcination. AFNOR: Paris, France, 1998.

- NF EN ISO 17892-12; Sols: Reconnaissance et Essais—Détermination des Limites D’Atterberg—Limite de Liquidité à la Coupelle—Limite de Plasticité au Rouleau. AFNOR: Paris, France, 2018.

- NF EN 1097-7; Essais pour Déterminer les Caractéristiques Mécaniques et Physiques des Granulats—Partie 7: Détermination de la Masse Volumique Absolue du Filler—Méthode au Pycnomètre. AFNOR: Paris, France, 2022.

- NF P11-300; Exécution des Terrassements—Classification des Matériaux Utilisables dans la Construction des Remblais et des Couches de forme D’infrastructures Routières. AFNOR: Paris, France, 1992.

- NF EN 13286-47; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 47: Méthode D’essai pour la Détermination de L’indice Portant CALIFORNIEN (CBR), de L’indice de Portance Immédiate (IPI) et du Gonflement Linéaire. AFNOR: Paris, France, 2021.

- NF EN 13286-2; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 2: Méthodes D’essai de Détermination en Laboratoire de la Masse Volumique de Référence et de la Teneur en Eau—Compactage Proctor. AFNOR: Paris, France, 2010.

- NF P94-093; Sols: Reconnaissance et Essais—Détermination des Références de Compactage d’un Matériau—Essai Proctor Normal—Essai Proctor Modifié. AFNOR: Paris, France, 2014.

- NF EN 13286-53; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 53: Méthode de Confection par Compression Axiale des Eprouvettes de Matériaux Traités aux Liants Hydrauliques. AFNOR: Paris, France, 2005.

- NF EN 13286-41; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 41: Méthode D’essai pour la Détermination de la Résistance à la Compression des Mélanges Traités aux Liants Hydrauliques. AFNOR: Paris, France, 2021.

- NF EN 13286-42; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 42: Méthode D’essai pour la Détermination de la Résistance à Traction Indirecte des Mélanges Traités aux Liants Hydrauliques. AFNOR: Paris, France, 2003.

- NF EN 13286-43; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 43: Méthode D’essai pour la Détermination du Module D’élasticité des Mélanges Traités aux Liants Hydrauliques. AFNOR: Paris, France, 2003.

- NF P94-100; Sols: Reconnaissance et Essais—Matériaux Traités à la Chaux et/ou Aux Liants Hydrauliques—Essais D’évaluation de L’aptitude d’un sol au Traitement. AFNOR: Paris, France, 2022.

- NF EN 13286-49; Mélanges Traités et Mélanges Non Traités aux Liants Hydrauliques—Partie 49: Essai de Gonflement Accéléré pour sol Traité à la Chaux et/ou Avec un Liant Hydraulique. AFNOR: Paris, France, 2004.

- Guide de Traitement des Sols (GTS); LCPC-SETRA: Paris, France, 2000.

- NF EN 12457-2; Caractérisation des Déchets—Lixiviation—Essai de Conformité pour Lixiviation des Déchets Fragmentés et des Boues—Partie 2: Essai en Bâchée Unique Avec un Rapport Liquide-Solide de 10 L/kg et une Granularité Inférieure à 4 mm (Sans ou Avec Réduction de la Granularité). AFNOR: Paris, France, 1995.

- Acceptabilité de Matériaux Alternatifs en Technique Routière-Évaluation Environnementale; SETRA: Vénissieux, France, 2011; Available online: https://www.cerema.fr/fr/centre-ressources/boutique/acceptabilite-materiaux-alternatifs-technique-routiere (accessed on 6 February 2023).

- Acceptabilité Environnementale de Matériaux Alternatifs en Technique Routière—Les Matériaux de Déconstruction Issus du BTP; CEREMA: Bron, France, 2016; Available online: https://www.cerema.fr/fr/centre-ressources/boutique/acceptabilite-environnementale-materiaux-alternatifs-1 (accessed on 27 February 2023).

- Djeran-Maigre, I.; Razakamanantsoa, A.; Levacher, D.; Hussain, M.; Delfosse, E. A Relevant Characterization of Usumacinta River Sediments for a Reuse in Earthen Construction and Agriculture. Available online: https://ssrn.com/abstract=4341668 (accessed on 27 February 2023).

- Pu, H.; Mastoi, A.K.; Chen, X.; Song, D.; Qiu, J.; Yang, P. An integrated method for the rapid dewatering and solidification/stabilization of dredged contaminated sediment with a high water content. Front. Environ. Sci. Eng. 2021, 15, 67. [Google Scholar] [CrossRef]

- XP CEN/TS 17693-1; Terrassements—Essais de Traitement de sol—Partie 1: Essai pH pour la Détermination du Besoin en Chaux pour la Stabilisation des sols (Point de Fixation de la Chaux LFP, Optimum de Modification de la Chaux LMO). AFNOR: Paris, France, 1995.

| Parameter | Units | SEDs | RCAs | Testing Standard |

|---|---|---|---|---|

| MBV (g/100 g) | g/100 g | 1.52 | 0.17 | NF P94-068 |

| Organic matter content | % | 7.35 | 3.49 | XP P94-047 |

| Absolute density | g/cm3 | 2.54 | 2.55 | NF EN 1097-7 |

| Initial water content | % | 38.0 | 4.78 | NF P 94-050 |

| Particle size distribution | EN ISO 13320 | |||

| Sand fraction (% > 63µm) | % | 59.9 | 85.9 | |

| Silt fraction (2 µm < % < 63 µm) | % | 35.0 | 12.8 | |

| Clay fraction (% < 2 µm) | % | 5.07 | 1.37 | |

| Atterberg limit | NF P94-051 | |||

| Liquid limit | % | 37.0 | - | |

| Plastic limit | % | 17.0 | - | |

| Plasticity index | % | 20.0 | - |

| After Conservation in Water at 40 °C for 7 Days | ||

|---|---|---|

| VS (%) | ITS (Mpa) | |

| Suitable | VS < 5 | ITS > 0.2 |

| Doubtful | 5 ≤ vs. ≤ 10 | 0.1 ≤ ITS ≤ 0.2 |

| Unsuitable | VS > 10 | ITS < 0.1 |

| Units | Sediment | RCA | SETRA Guidelines for Alternative Materials | CEREMA Guidelines for RCA | |

|---|---|---|---|---|---|

| As | mg/kg | <0.1 | <0.1 | 2 | 0.6 |

| Ba | mg/kg | <0.008 | 0.19 | 100 | 36 |

| Cd | mg/kg | 0.13 | <0.009 | 1 | 0.05 |

| Cr | mg/kg | 0.19 | 0.018 | 10 | 4 |

| Cu | mg/kg | 0.59 | 0.067 | 50 | 10 |

| Mo | mg/kg | <0.09 | <0.09 | 10 | 5.6 |

| Ni | mg/kg | 2.2 | <0.05 | 10 | 0.5 |

| Pb | mg/kg | <0.03 | <0.03 | 10 | 0.6 |

| Sb | mg/kg | <0.06 | <0.06 | 0.7 | 0.6 |

| Se | mg/kg | <0.08 | <0.08 | 0.5 | 0.5 |

| Zn | mg/kg | 25 | <0.01 | 50 | 5 |

| Fluoride | mg/kg | 3 | 6 | 150 | 60 |

| Chloride | mg/kg | 5420 | 196 | 15,000 | 10,000 |

| Sulfate | mg/kg | 18,180 | 3000 | 20,000 | 100,000 |

| Soluble fraction | mg/kg | 34,670 | 6110 | 60,000 |

| Characteristics | Parameter | Units | 20S80G | 30S70G | 50S50G | 100S |

|---|---|---|---|---|---|---|

| Physical | MBV | g/100 g | 0.57 | 0.84 | 0.98 | 1.53 |

| Absolute density | g/cm3 | 2.55 | 2.56 | 2.57 | 2.54 | |

| Particle size distribution | ||||||

| Grain < 80 µm | % | 19.16 | 23.53 | 32.37 | 37.08 | |

| Grain > 2 mm | % | 23.23 | 21.15 | 16.99 | 6.6 | |

| Geotechnical classification | B5 | B5 | B5 | A1 |

| Mixes | ||||

|---|---|---|---|---|

| Sediment (%) | RCA (%) | Quicklime (%) | Cement (%) | |

| 20S80G | 20 | 80 | 1 | 7 |

| 30S70G | 30 | 70 | 1 | 7 |

| 50S50G | 50 | 50 | 1 | 7 |

| 100S | 100 | 0 | 1 | 7 |

| Mixes | 20S80G | 30S70G | 50S50G | 100S |

|---|---|---|---|---|

| UCSI | 1.80 | 1.41 | 1.38 | 0.8 |

| UCS60 | 2.7 | 2.23 | 2.03 | 1.26 |

| UCSI/UCS60 | 0.67 | 0.63 | 0.68 | 0.63 |

| Units | 20S80G | 30S70G | 50S50G | 100S | SETRA Guidelines for Alternative Materials (2011) | |

|---|---|---|---|---|---|---|

| As | mg/kg | <0.1 | <0.1 | 0.13 | 0.19 | 2 |

| Ba | mg/kg | 0.33 | 0.34 | 0.35 | 0.22 | 100 |

| Cd | mg/kg | <0.009 | <0.009 | <0.009 | <0.009 | 1 |

| Cr | mg/kg | 0.29 | 0.27 | 0.21 | 0.24 | 10 |

| Cu | mg/kg | 1,0 | 0.90 | 0.87 | 0.82 | 50 |

| Mo | mg/kg | 0.41 | 0.42 | 0.54 | 0.47 | 10 |

| Ni | mg/kg | 0.33 | 0.34 | 0.39 | 0.38 | 10 |

| Pb | mg/kg | <0.03 | <0.03 | <0.03 | <0.03 | 10 |

| Sb | mg/kg | <0.06 | <0.06 | <0.06 | <0.06 | 0.7 |

| Se | mg/kg | <0.08 | <0.08 | <0.08 | <0.08 | 0.5 |

| Zn | mg/kg | <0.01 | <0.01 | <0.01 | <0.01 | 50 |

| Fluoride | mg/kg | 70 | 77 | 115.5 | 154 | 150 |

| Chloride | mg/kg | 1238 | 1619 | 2687.5 | 3445 | 15,000 |

| Sulfate | mg/kg | 4067 | 5371 | 9265 | 26,340 | 20,000 |

| Soluble fraction | mg/kg | 6785 | 8018 | 14,085 | 36,347 | 60,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abriak, Y.; Maherzi, W.; Benzerzour, M.; Senouci, A.; Rivard, P. Valorization of Dredged Sediments and Recycled Concrete Aggregates in Road Subgrade Construction. Buildings 2023, 13, 646. https://doi.org/10.3390/buildings13030646

Abriak Y, Maherzi W, Benzerzour M, Senouci A, Rivard P. Valorization of Dredged Sediments and Recycled Concrete Aggregates in Road Subgrade Construction. Buildings. 2023; 13(3):646. https://doi.org/10.3390/buildings13030646

Chicago/Turabian StyleAbriak, Yassine, Walid Maherzi, Mahfoud Benzerzour, Ahmed Senouci, and Patrice Rivard. 2023. "Valorization of Dredged Sediments and Recycled Concrete Aggregates in Road Subgrade Construction" Buildings 13, no. 3: 646. https://doi.org/10.3390/buildings13030646