Ensuring Efficient Implementation of Lean Construction Projects Using Building Information Modeling

Abstract

1. Introduction

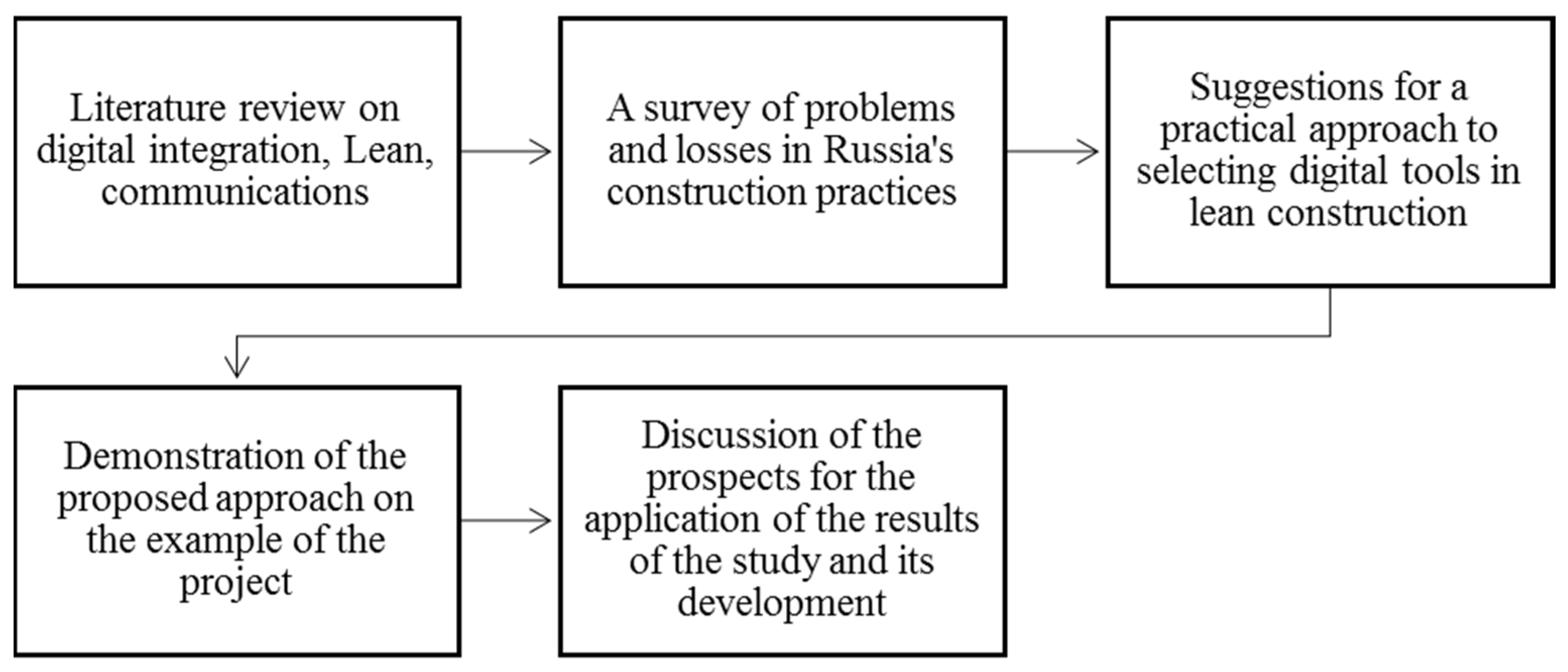

2. Materials and Methods

2.1. Lean Construction in the Value Chain

2.2. Lean Construction and Digitalization

Opinions Differ Slightly on the Methods and Timing of Integration

2.3. Lean Construction, Communication, and Information

2.4. Practice of Interaction and Losses in the Value Chain in Russian Construction

2.5. The Effects of Integrating Lean Construction with BIM Regarding the Improvement of the Interaction between Participants

3. Results

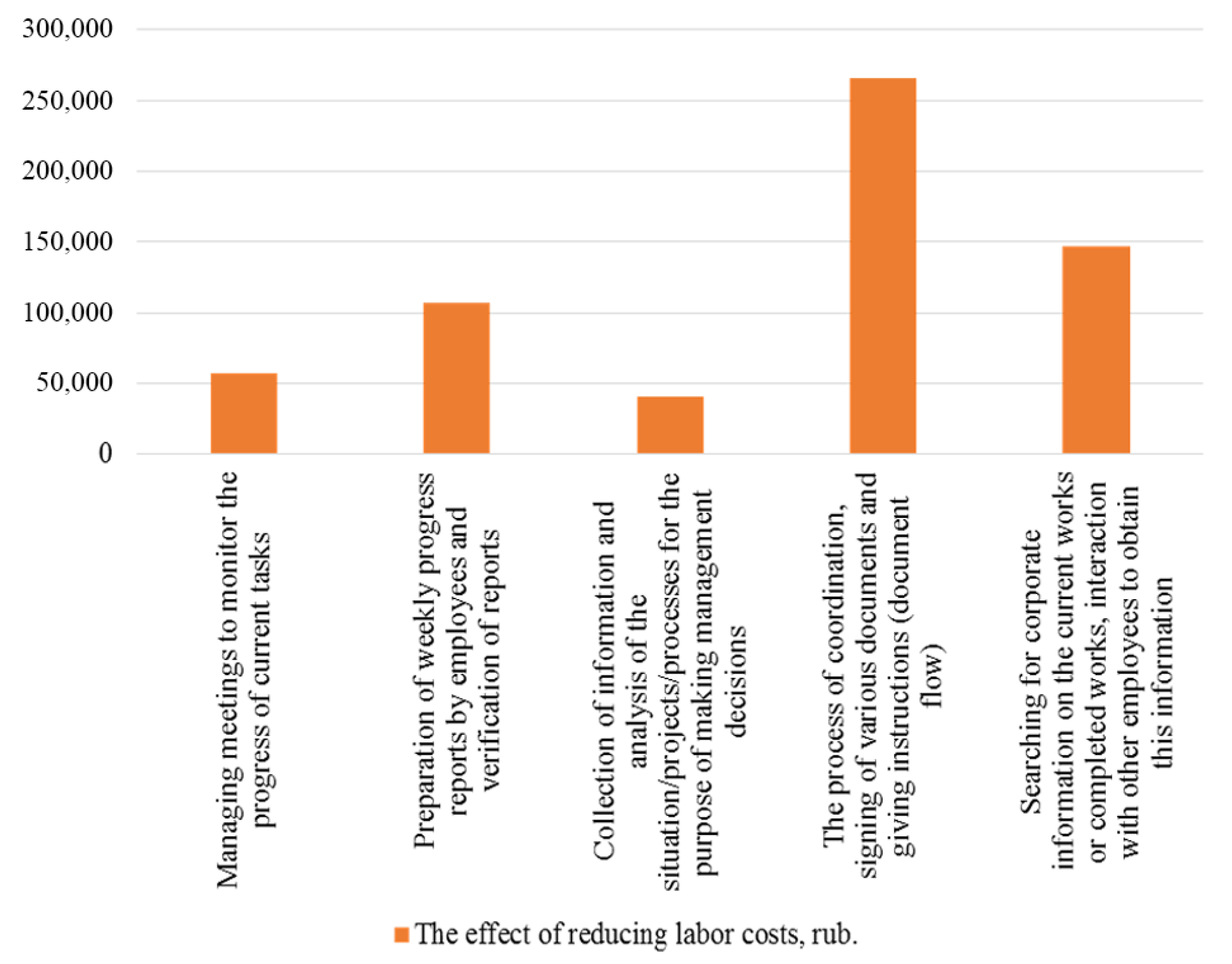

4. Discussion of the New Approach Effects

- —total transaction costs;

- —the number of transactions of j-th type;

- —the cost of one transaction of the j-th type;

- —time spent for the execution of transactions of the j-th type;

- —the cost of a time unit of transactions of the j-th type;

- —costs of the j type determined by expertise.

5. Conclusions

- -

- Increasing the speed of construction by optimizing the interaction of ICP participants and stakeholders and reducing time inter-operational losses;

- -

- Reduction of time and operating financial losses during construction by improving the accuracy of cost estimates; reducing the number of collisions, clarifications, requests for information, changes in the project; and introducing electronic document management, pull scheduling, and integrated management in real-time;

- -

- Increasing labor productivity by reducing time losses and shifting the time employees spend for the preparation for meetings and participation in the workflow to the implementation of kaizen, training, etc.;

- -

- Improving the quality of works and facilities by monitoring the quality and supply of materials in real-time, monitoring hidden works in real-time, continuous monitoring of the Gemba in real-time, etc.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Bank. Annual Report 2022: Helping Countries Adapt to a Changing World; World Bank: Washington, DC, USA, 2022. [Google Scholar]

- World Bank. World Development Report 2020: Trading for Development in the Age of Global Value Chains; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Rodrik, D. New Technologies, Global Value Chains, and the Developing Economies; Pathways for Prosperity Commission Background Paper Series, No. 1. University of Oxford: Oxford, UK, 2018. [Google Scholar]

- Shih, W. Is it time to rethink globalized supply chains? In MIT Sloan Management Review; MIT Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Kankhva, V.; Uvarova, S.; Belyaeva, S. Development of the Scientific and Methodological Assessment Tools of Sustainability of the Investment and Construction Complex in Russia and its Structural Elements in Terms of Organizational and Economic Changes. Procedia Eng. 2016, 165, 1046–1051. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Tech Report 72; Center for Integrated Facility Engineering: Stanford, CA, USA, 1992. [Google Scholar]

- Orlov, A.K.; Kankhva, V.S. Lean Construction Concept Used to Develop Infrastructure Facilities for Tourism Clusters. Buildings 2022, 12, 23. [Google Scholar] [CrossRef]

- Wen, S.; Tang, H.; Ying, F.; Wu, G. Exploring the Global Research Trends of Supply Chain Management of Construction Projects Based on a Bibliometric Analysis: Current Status and Future Prospects. Buildings 2023, 13, 373. [Google Scholar] [CrossRef]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and Locating Components in a Precast Storage Yard Utilizing Radio Frequency Identification Technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Wong, C.K.; Fung, I.W.H.; Tam, C.M. Comparison of Using Mixed-Integer Programming and Genetic Algorithms for Construction Site Facility Layout Planning. J. Constr. Eng. Manag. 2010, 136, 1116–1128. [Google Scholar] [CrossRef]

- Albuquerque, A.T.; Debs, M.K.; Melo, A.M.C. A Cost Optimization-Based Design of Precast Concrete Floors Using Genetic Algorithms. Autom. Constr. 2012, 22, 348–356. [Google Scholar] [CrossRef]

- Singh, S.; Dixit, S.; Sahai, S.; Sao, A.; Kalonia, Y.; Kumar, R.S. Key Benefits of Adopting Lean Manufacturing Principles in Indian Construction Industry. MATEC Web Conf. 2018, 172, 05002. [Google Scholar] [CrossRef]

- London, K.; Pablo, Z. An Actor–Network Theory Approach to Developing an Expanded Conceptualization of Collaboration in Industrialized Building Housing Construction. Constr. Manag. Econ. 2017, 35, 553–577. [Google Scholar] [CrossRef]

- World Bank. World Development Report 2019: The Changing Nature of Work; World Bank: Washington, DC, USA, 2019. [Google Scholar]

- Ustyuzhanina, E.V.; Dementiev, V.E.; Evsukov, S.G. Distribution of power and economic rent in value networks. Econ. Math. Methods 2020, 56, 5–17. (In Russian) [Google Scholar] [CrossRef]

- Dixit, S.; Mandal, S.N.; Sawhney, A.; Singh, S. Area of linkage between lean construction and sustainability in Indian construction industry. Int. J. Civ. Eng. Technol. 2017, 8, 623–636. [Google Scholar]

- Terreno, S.; Asadi, S.; Anumba, C. An Exploration of Synergies between Lean Concepts and BIM in FM: A Review and Directions for Future Research. Buildings 2019, 9, 147. [Google Scholar] [CrossRef]

- Moradi, S.; Sormunen, P. Lean and Sustainable Project Delivery in Building Construction: Development of a Conceptual Framework. Buildings 2022, 12, 1757. [Google Scholar] [CrossRef]

- Lemans Manufacturing Systems of the Future Experience in the Implementation of LEAN and IT Solutions. Digitalization of Manufacturing Experience in the Implementation and Cost-Benefit Analysis—Moscow. 2022. Available online: https://dtmis.spbstu.ru/userfiles/files/pdf/program.pdf?v=2 (accessed on 10 December 2022).

- Porter, M.E.; Heppelmann, J.E. Wie smarte Produkte den Wettbewerb verandern. Harv. Bus. Manag. 2014, 36, 34–60. [Google Scholar]

- Rungi, A.; Del Prete, D. The «Smile Curve»: Where Value is Added along Supply Chains; IMT Lucca EIC Working Paper Series #05/2017; University of Milano: Milan, Italy, 2017. [Google Scholar]

- Mytenkov, S.S.; Zhelenkov, B.A. Digitalization in Russia and the world through the prism of interaction between the state, business and the population Business. Society. Authorities. 2022, 44–45, 141–155. [Google Scholar]

- Abdikeev, N.M.; Moreva, E.L. The main trends in the development of methods and models for the use of digital technologies in the creation of value chains. World New Econ. 2019, 13, 71–80. (In Russian) [Google Scholar] [CrossRef]

- Lekan, A.; Clinton, A.; Fayomi, O.S.I.; James, O. Lean Thinking and Industrial 4.0 Approach to Achieving Construction 4.0 for Industrialization and Technological Development. Buildings 2020, 10, 221. [Google Scholar] [CrossRef]

- Bar Am, J.; Furstenthal, L.; Jorge, F.; Roth, E. Innovation in a Crisis: Why It Is More Critical than Ever; McKinsey Global Institute, 2020. [Google Scholar]

- Banihashemi, S.; Tabadkani, A.; Hosseini, M.R. Integration of Parametric Design into Modular Coordination: A Construction Waste Reduction Workflow. Autom. Constr. 2018, 88, 1–12. [Google Scholar] [CrossRef]

- Dossick, C.S.; Neff, G. Messy talk and clean technology: Communication, problem-solving and collaboration using Building Information Modelling. Eng. Proj. Organ. J. 2011, 2, 83–93. [Google Scholar] [CrossRef]

- MGI. Risk, Resilience, and Rebalancing in Global Value Chains; McKinsey Global Institute: Washington, DC, USA, 2020. [Google Scholar]

- Senthil, J.; Muthukannan, M. Development of lean construction supply chain risk management based on enhanced neural network. Mater. Today Proc. 2021, 56, 1752–1757. [Google Scholar] [CrossRef]

- Forno, A.J.D.; Pereira, F.A.; Forcellini, F.A.; Kipper, L.M. Value Stream Mapping: A study about the problems and challenges found in the literature from the past 15 years about application of Lean tools. Int. J. Adv. Manuf. Technol. 2014, 72, 779–790. [Google Scholar] [CrossRef]

- Orlov, A.K.; Solovieva, E.S. Effectiveness of lean construction methodology application for the implementation of infrastructure projects in tourism clusters. Econ. Entrep. 2021, 129, 446–450. [Google Scholar]

- Bajjou, M.S.; Chafi, A.; Ennadi, A. Development of a Conceptual Framework of Lean Construction Principles: An Input-Output Model. J. Adv. Manuf. Syst. 2019, 18, 1–34. [Google Scholar] [CrossRef]

- Giménez, Z.; Mourgues, C.; Alarcón, L.F.; Mesa, H. Exploring Value Generation in Target Value Design Applying a Value Analysis Model. Buildings 2022, 12, 922. [Google Scholar] [CrossRef]

- Bølviken, T.; Rooke, J.; Koskela, L. The Wastes of Production in Construction—A TFV Based Taxonomy. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 811–822. [Google Scholar]

- Salvatierra, J.; Pasquire, C.; Miron, L. Exploring Value Concept through the IGLC Community: Nineteen Years of Experience. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Ballard, G. Target Value Delivery. In Lean Construction Core Concepts and New Frontiers; Tzortzopoulos, P., Kagioglou, M., Koskela, L., Eds.; Routledge: London, UK, 2020; pp. 149–161. [Google Scholar]

- Urban Planning Code of the Russian Federation.

- Belov, M.V.; Novikov, D.A. Methodology of Complex Activity: Foundations of Understanding and Modelling; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Sacks, R.; Korb, S.; Barak, R. Building Lean, Building BIM: Improving Construction the Tidhar Way; Routledge: London, UK, 2017; p. 420. [Google Scholar]

- Sbiti, M.; Beddiar, K.; Beladjine, D.; Perrault, R.; Mazari, B. Toward BIM and LPS Data Integration for Lean Site Project Management: A State-of-the-Art Review and Recommendations. Buildings 2021, 11, 196. [Google Scholar] [CrossRef]

- Tennakoon, T.; Kulatunga, U.; Jayasena, H.S. Influence of organizational culture on knowledge management in BIM-enabled construction, environments. VINE J. Inf. Knowl. Manag. Syst. 2021, 52, 224–242. [Google Scholar]

- Wu, H.; Lin, X.; Li, X.; Zhang, B.; Li, C.Z.; Duan, H. A Data-Driven Approach to Trace the Development of Lean Construction in Building Projects: Topic Shift and Main Paths. Buildings 2022, 12, 616. [Google Scholar] [CrossRef]

- Afolabi, A.; Ibem, E.; Aduwo, E.; Tunji-Olayeni, P.; Olawumi, O. Critical success factors (CSFs) for e-Procurement adoption in the Nigerian construction industry. Buildings 2019, 9, 47. [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, V.; Rotimi, J.O.B.; Vilasini, N. Lean and BIM Implementation Barriers in New Zealand Construction Practice. Buildings 2022, 12, 1645. [Google Scholar] [CrossRef]

- Ghosh, A.; Chasey, A.D.; Mergenschroer, M. Building Information Modeling for Facilities Management: Current Practices and Future Prospects. In Building Information Modeling; American Society of Civil Engineers (ASCE): New York, NY, USA, 2015; pp. 223–253. [Google Scholar]

- Moradi, S.; Kähkönen, K.; Sormunen, P. Analytical and Conceptual Perspectives toward Behavioral Elements of Collaborative Delivery Models in Construction Projects. Buildings 2022, 12, 316. [Google Scholar] [CrossRef]

- Gorelik, P.I. Lean building as an innovative method of construction management. Constr. Unique Build. 2014, 27, 40–48. [Google Scholar]

- Erol, H.; Dikmen, I.; Birgonul, M.T. Measuring the impact of lean construction practices on project duration and variability: A simulation-based study on residential buildings. J. Civ. Eng. Manag. 2017, 23, 241–251. [Google Scholar] [CrossRef]

- Eroshkin, S.Y.; Kallaur, G.Y.; Papikyan, L.M. Lean construction and BIM model: Complementing each other for better project management. Rev. Bus. Econ. Stud. 2016, 4, 17–22. [Google Scholar]

- Rashidian, S.; Drogemuller, R.; Omrani, S. Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study. Buildings 2023, 13, 281. [Google Scholar] [CrossRef]

- Shildt, L.A. Use of lean construction technology in information modeling of buildings. Econ. Manag. Sci. Pract. J. 2018, 141, 36–41. [Google Scholar]

- Wong, L.S.; Ahmed, M.E.A.M. A critical review of lean construction for cost reduction in complex projects. Jordan J. Civ. Eng. 2018, 12, 707–720. [Google Scholar]

- Eldeep, A.M.; Farag, M.A.M.; El-hafez, L.A. Using BIM as a lean management tool in construction processes—A case study. Ain Shams Eng. J. 2021, 13, 101556. [Google Scholar] [CrossRef]

- Kankhva, V.; Andryunina, Y.; Belyaeva, S.; Sonin, Y. Construction in the digital economy: Prospects and areas of transformation. E3S Web Conf. 2021, 244, 05008. [Google Scholar] [CrossRef]

- Popova, E.S. Lean construction methodology as an innovative approach to management in the construction industry. Masters J. 2016, 1, 141–146. [Google Scholar]

- Panenkov, A.; Lukmanova, I.; Kuzovleva, I.; Bredikhin, V. Methodology of the theory of change management in the implementation of digital transformation of construction: Problems and prospects. E3S Web Conf. 2021, 244, 05005. [Google Scholar] [CrossRef]

- Alexander, K. Facilities Management: Theory and Practice; Routledge: London, UK, 2013. [Google Scholar]

- Love, K.; Pritchard, C.; Maguire, K.; McCarthy, A.; Paddock, P. Qualitative and quantitative approaches to health impact assessment: An analysis of the political and philosophical milieu of the multi-method approach. Crit. Public Health 2005, 15, 275–289. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Gallaher, M.P.; O’Connor, A.C.; Dettbarn, J.J.L.; Gilday, L.T. Cost Analysis of Inadequate Interoperability in the U.S. Capital Facilities Industry; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2004. [Google Scholar]

- Belyaeva, S.V.; Uvarova, S.S.; Kankhva, V.S.; Galeev, K.F. Digitalization of construction: Problems and key areas in modern conditions of import substitution. J. Econ. Entrep. 2022, 140, 1283–1289. (In Russian) [Google Scholar]

- Kensek, K. BIM Guidelines Inform Facilities Management Databases: A Case Study over Time. Buildings 2015, 5, 899–916. [Google Scholar] [CrossRef]

- Moradi, S. Project Managers’ Competencies in Collaborative Construction Projects. Ph.D. Thesis, Tampere University, Tampere, Finland, 2021. Available online: http://urn.fi/URN:ISBN:978-952-03-2002-7 (accessed on 10 January 2022).

- Albalkhy, W.; Sweis, R. Barriers to adopting lean construction in the construction industry: A literature review. Int. J. Lean Six Sigma 2020, 12, 210–236. [Google Scholar] [CrossRef]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. Comparing Team Interactions in Traditional and BIM-Lean Design Management. Buildings 2021, 11, 447. [Google Scholar] [CrossRef]

- Report on the Study “The Level of BIM Application in Russia 2019”. Available online: http://concurator.ru/information/bim_report_2019/?fbclid=IwAR2OVYWwWqYXgNAC8MJeyNK_kg--bboku_TyYuRwefgj4OQ7LAvM-EeQC8Y (accessed on 15 December 2022). (In Russian).

- Arslanbaeva, G.D. Analysis of methods of psychological activation of thinking: Brainstorming and coaching. Their application in business. Acad. J. 2021, 7, 247–252. (In Russian) [Google Scholar]

- Seliverstov, A.S.; Utkin, D.Y.; Postnov, V.V.; Semidotchenko, A.R.; Nikolaeva, K.A.; Polyakova, T.V. Brainstorming as a quality management tool at the enterprise. Young Sci. 2019, 280, 225–227. (In Russian) [Google Scholar]

- Yehuda, B.; Brooks, C.H. Survey response rate levels and trends in organizational research. Hum. Relat. 2008, 61, 1139–1160. [Google Scholar]

- Julsrud, T.E.; Priya Uteng, T. Technopolis, shared resources or controlled mobility? A net-based Delphi-study to explore visions of future urban daily mobility in Norway. Eur. J. Futur. Res. 2015, 3, 10. [Google Scholar]

- Heiko, A. Consensus measurement in Delphi studies: Review and implications for future quality assurance. Technol. Forecast. Soc. Chang. 2012, 79, 1525–1536. [Google Scholar]

- Georgiadou, M.C. An Overview of Benefits and Challenges of Building Information Modeling (BIM) Adoption in U.K. Residential Projects; Construction Innovation: Bradford, UK, 2019; Volume 19, pp. 298–320. [Google Scholar]

- Al-Saeed, Y.; Edwards, D.J.; Scaysbrook, S. Automating Construction Manufacturing Procedures Using BIM Digital Objects (B.D.O.s): Case Study of Knowledge Transfer Partnership Project in the UK; Construction Innovation: Bradford, UK, 2020; Volume 20, pp. 345–377. [Google Scholar]

- Evans, M.; Farrell, P. Barriers to integrating building information modeling (BIM) and lean construction practices on construction mega-projects: A Delphi study. Benchmarking Int. J. 2020, 28, 652–669. [Google Scholar] [CrossRef]

- Solaimani, S.; Sedighi, M. Toward a holistic view on lean sustainable construction: A literature review. J. Clean. Prod. 2020, 248, 119213. [Google Scholar] [CrossRef]

- Brydea, D.; Broquetasb, M.; MarcVolmc, J. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Revunova, S.; Vlasenko, V.; Bukreev, A. Modeling the sustainable development of innovation in transport construction based on the communication approach. IOP Conf. Ser. Earth Environ. Sci. 2017, 90, 012164. [Google Scholar] [CrossRef]

| ICP stages | Description of operations in accordance with ICP stages | Interaction chain (responsible persons) | Deadlines | Recommendations for optimizing the operation |

| Pre-design stage | Development of a project business plan | Customer | Not regulated | The project should have a minimum payback period, parameters necessary to receive government subsidies, concessional loans, or be subject to national projects. Reduce inter-operational losses of time spent on meetings and obtaining approvals |

| Land plot allocation | Customer–Municipal administration | Within 30 days from the date of application submission | ||

| Obtaining credit financing | Customer–bank | 7 to 60 days or more, depending on the complexity of the project and its estimated cost | ||

| Obtaining technical conditions for connection to the supply system | Customer–networks owners | Not regulated | This operation is the most long-lasting and bureaucratically complex at the initial stage. Reduce inter-operational losses of time needed to obtain approvals | |

| Design stage | Tender for design and survey works | Customer | 14 to 30 days, depending on the tender conditions | The customer needs to pay attention not only to the cost of the project but also to the qualifications of the design staff |

| Development of design and estimate documentation | Project designers | 30 days to 1 year and more, depending on the complexity of the project | The heart of any facility is the project. Here, it is necessary to take into account all the assemblies, solutions, and desires to link all this to the existing legislation and regulations. That is why the choice of project designers is one of the first things to pay attention to. Reduce operational and inter-operational losses due to RFI and changes in the project | |

| Tender for technical customer determination | Customer | 14 to 30 days, depending on the tender conditions | It is necessary to be very careful when choosing the technical customer since you entrust some of your responsibilities to it. Reduce inter-operational losses of time spent on meetings | |

| Project appraisal | Technical customer–Project designers–State or commercial expertise | Up to 60 days, provided that There are no comments | The speed and absence of comments from experts depend on the quality of the project Reduce operational and inter-operational losses due to RFI and changes in the project | |

| Construction stage | Obtaining a building permit | Technical customer | Up to 7 days | |

| Tender for general contractor determination | Customer technical customer | 14 to 30 days, depending on the tender conditions | The customer needs to pay attention not only to the cost of work but also to the qualifications of the construction organization | |

| Construction and installation works | General contractor | Deadline according to the work schedule | It is necessary to control fluctuations in the cost of basic materials to quickly solve the issue related to an increase in the cost of the project if the cost of materials exceeds 10% of the estimated cost presented in the estimates. Reduce operational losses using pull scheduling and integrated management. Reduce operational and inter-operational losses due to RFI and changes in the project. Reduce inter-operational losses of time spent on meetings and obtaining approvals | |

| As-built documentation preparation process | Technical customer | Throughout the construction and installation works | ||

| Commissioning | Facility commissioning according to Article 55 of the Town Planning Code | Customer–technical customer | 1 to 2 months |

| Stage | Communication | Problems | Arising Losses | Average Score | Variance | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|---|---|---|

| Pre-design | E-Cu, Cu-O | Low accuracy of project cost estimation | Losses due to the fact that the actual cost exceeds the estimated cost; losses due to low demand | 2.60 | 0.49 | 0.70 | 0.27 |

| Insufficient visualization of CCP | Inter-operation losses due to inaccurate technical specifications provided by the investor and customer | 2.60 | 0.49 | 0.70 | 0.27 | ||

| EA-Cu | Duration of procedures | Inter-operational time losses | 1.90 | 0.32 | 0.57 | 0.30 | |

| Cu-Pd | No front-end engineering design; ambiguous technical specifications; impossibility of taking into account operating parameters during the feasibility study and justification of investments; complexity of solutions for the reconstruction of the environment | Inter-operational losses due to inaccurate technical specifications provided by the investor and customer; time and operational losses due to RF clarifications | 4.50 | 0.50 | 0.71 | 0.16 | |

| Design | Cu-Pd | Ambiguous nature of technical specifications; lack of information on the current cost; design documentation revision or alteration | Time and operational losses due to collisions and re-design; time and operational losses due to RFI clarifications; time losses due to the long-lasting document flow; losses due to the fact that the actual cost exceeds the estimated cost | 4.60 | 0.49 | 0.70 | 0.15 |

| OO-Cu | Lack of information on the current cost; lack of statistics on resources and deadlines; design documentation revision or alteration; a large number of collisions; difficulty in obtaining the opinion | Time and operational losses due to collisions and design changes; time losses due to the long-lasting document flow; losses due to the fact that the actual cost exceeds the estimated cost | 4.50 | 0.50 | 0.71 | 0.16 | |

| EA-Cu | Duration of procedures | Inter-operational time losses | 1.90 | 0.32 | 0.57 | 0.30 | |

| Construction | Co-Cu | Lack of a unified environment for interaction; the need to make changes to the project; non-compliance with the construction deadlines; overstatement of the estimated cost; non-compliance with the quality of the CCP | Time inter-operational and operational losses due to collisions and re-design; time and operational losses due to RFI clarifications; time losses due to the long-lasting document flow; losses due to the fact that the actual cost exceeds the estimated cost; losses due to the extension of the estimated construction period; operational losses due to the reduction in the quality of works and elements | 4.50 | 0.50 | 0.71 | 0.16 |

| OO, E-Cu, Co | Lack of a unified interaction environment; the need to make changes to the project | Time and operational losses due to collisions and re-design; time and operational losses due to RFI clarifications; time inter-operational losses | 3.90 | 0.54 | 0.74 | 0.19 | |

| Co-Su | Lack of accurate data on the cost of resources; overstatement of the construction cost; supply risks; poor quality of materials | Time and operational losses due to disruption of resources supplies and an increase in the duration of operations; losses due to the fact that the actual cost exceeds the estimated cost; operational losses due to the reduction in the quality of works and elements; time inter-operational losses | 4.10 | 0.32 | 0.57 | 0.14 | |

| CS-Co, Cu | Non-compliance with the construction quality; many collisions; complexity of the document exchange process | Operational losses due to the reduction in the quality of works and elements; time and operational losses due to collisions and design changes; inter-operational losses of time | 3.50 | 0.50 | 0.71 | 0.20 | |

| B-Cu | Complex contractual system; complexity of the document exchange process | Inter-operational time losses | 3.10 | 0.54 | 0.74 | 0.24 | |

| EA-Cu | Duration of procedures | Inter-operational time losses | 2.00 | 0.22 | 0.47 | 0.24 | |

| Operation | Cu, O-OO | No operation parameters are taken into account in the project; complexity of the document exchange process; lack of communication with operation systems | Time inter-operational losses; operational losses due to loss of value for buyers; direct losses due to the overrun of costs for CCP operation | 2.60 | 0.49 | 0.70 | 0.27 |

| ICP Life Cycle Stage | Calculation Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Number of Reports, pcs. | Number of Pages per Report, pcs. | Total Number of Pages in the Documentation | Number of Documentation Revisions | Total Number of Pages in the Documentation Considering Revisions | Number of Report Copies | Total Pages of Documentation for the Facility | |

| Design and survey works | 60 | 50 | 3000 | 5 | 15,000 | 4 | 60,000 |

| As-built documentation | 2000 | 24 | 48,000 | 2 | 96,000 | 4 | 384,000 |

| Acts on improvement | 1552 | 24 | 37,248 | 4 | 148,992 | 4 | 595,968 |

| Acts for outdoor networks | 1552 | 24 | 37,248 | 4 | 148,992 | 4 | 595,968 |

| Conclusion on commissioning | 40 | 24 | 960 | 1 | 960 | 4 | 3840 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uvarova, S.S.; Orlov, A.K.; Kankhva, V.S. Ensuring Efficient Implementation of Lean Construction Projects Using Building Information Modeling. Buildings 2023, 13, 770. https://doi.org/10.3390/buildings13030770

Uvarova SS, Orlov AK, Kankhva VS. Ensuring Efficient Implementation of Lean Construction Projects Using Building Information Modeling. Buildings. 2023; 13(3):770. https://doi.org/10.3390/buildings13030770

Chicago/Turabian StyleUvarova, Svetlana S., Alexandr K. Orlov, and Vadim S. Kankhva. 2023. "Ensuring Efficient Implementation of Lean Construction Projects Using Building Information Modeling" Buildings 13, no. 3: 770. https://doi.org/10.3390/buildings13030770

APA StyleUvarova, S. S., Orlov, A. K., & Kankhva, V. S. (2023). Ensuring Efficient Implementation of Lean Construction Projects Using Building Information Modeling. Buildings, 13(3), 770. https://doi.org/10.3390/buildings13030770