1. Introduction

Ultra-High Performance Fiber-Reinforced Concrete (UHPFRC) is a highly advanced material renowned for its exceptional strength, high ductility, and low permeability [

1,

2,

3]. This advancement has led to increasing interest in UHPFRC as a promising solution for rehabilitating and strengthening aged and damaged concrete structures. UHPFRC’s excellent bonding ability with normal strength concrete (NSC) has been particularly noteworthy, making it an attractive option for repair and strengthening applications. Therefore, the objective of this study is to develop a reliable model for predicting the bonding behavior at the interface between NSC and UHPFRC under various loading conditions.

Finite Element (FE) analysis is a vital tool for studying the behavior of composite NSC-UHPFRC members and designing them to enhance their strength and repairability. Despite its widespread use in investigating bonding behavior in composite structures, previous studies have mostly focused on specific conditions.

The cohesive zone model is a popular technique used to model the behavior between NSC and UHPFRC using a thin material layer. This approach allows for the simulation of debonding, crack initiation, and crack propagation that can occur at the interface between NSC and UHPFRC. Tong et al. [

4] developed a 2D eight node quadratic line cohesive element FE model to simulate the thin layer between NSC and UHPFRC, with the parameters calibrated from slant shear. The findings showed good agreement with experimental results in a flexural test of composite NC-UHPC members. Yu et al. [

5] developed a 2D cohesive model with fixed parameters to study the bonding behavior of the NSC-UHPFRC interface. Surface roughness was modeled using representative volume elements (RVEs). The simulated traction-separation curve agreed well with experimental data, with a maximum deviation of around 27%.

Additionally, 3D models have been developed by researchers using cohesive zone models to simulate the bonding behavior between NSC and UHPFRC. For instance, Valikhani et al. [

6] created a 3D FE model using ATENA software with a cohesive element calibrated from a bi-surface shear test. The simulated results matched well with the experimental results in the bi-surface test. Similarly, Hussein et al. [

7] successfully used a cohesive zone model to analyze the direct tensile behavior of HSC-UHPFRC specimens, with results that matched well with the experimental data. Another study by Kadhim et al. [

8] employed a cohesive zone model with contact-target elements in ANSYS software, but the results were not validated. However, while cohesive models have been introduced in some studies, their validity for accurately modeling NSC-UHPFRC composite members under different working conditions is yet to be established.

Perfect bonding using tie constraints is also a common method for modeling the NSC-UHPFRC interface, but it can lead to an overestimation of load-carrying capacity and design errors. According to Farzad et al. [

9], the use of a tie constraint to simulate the bonding interface between NSC and UHPFRC in slant shear and direct shear tests led to overestimated results that were up to 150% different from the experimental data.

Several other models have been developed to simulate the behavior of the NSC-UHPFRC interface. For instance, Lampropoulos et al. [

10] proposed a 3D model with a cohesion and friction coefficient of 1.5 MPa and 1.5, respectively, to simulate the behavior of a composite beam on a well-roughened substrate. However, the model’s validity on the composite beam has not been tested. Farzad et al. [

9] used a contact layer with a thickness of 100 μm and defined its characteristics using the CDP model to model the NSC-UHPFRC interface. They found a maximum error of 18% when comparing the results of this model with experimental data. In addition, Hor Yin et al. [

11] used LS-DYNA to model the NSC-UHPC interface with equivalent beam elements, achieving good agreement between simulated and experimental results for composite beams.

As far as the authors know, no studies have investigated how different working conditions, such as the tensile, shear, and bending behavior of composite members, affect the validity of these models.

This study aims to develop a model for simulating the interfacial bonding between NSC and UHPFRC and integrate it into 3D FE models using ABAQUS software. The goal is to accurately predict the nonlinear behavior of NSC-UHPFRC composite members under various working conditions. The assumption of traction-separation law [

12] is used as a starting point, as it imitates the constitutive behavior of the NSC-UHPFRC interface. Parameters for the interfacial bonding model are then determined through an analytical method based on shear and tensile tests. The interfacial model is subsequently integrated into seven ABAQUS models to verify its accuracy by comparing simulated results with experimental results for shear, tensile, and flexural tests.

The study yielded promising results, indicating that the developed parameters for the surface-based cohesive model in ABAQUS can accurately simulate the bonding behavior of NSC-UHPFRC composite members under shear, tensile, and bending loads. This innovative model holds significant potential for predicting the behavior of concrete members that have been reinforced and repaired with UHPFRC, thereby extending their service life.

This study is structured as follows: In

Section 2, an analytical method is presented to determine specific parameters for the surface-based cohesive model, taking into account the diverse conditions of surface states. In

Section 3, the developed model is applied to investigate the tensile, shear, and flexural behaviors of composite structures, and its accuracy is validated through comparison with experimental data.

Section 4 presents the obtained results and provides a discussion of these results. Finally,

Section 5 summarizes the key findings of the study and discusses their implications.

2. Interfacial Bonding Model at the NC-UHPFRSC Interface

Interfacial debonding phenomena between UHPC and NSC typically occur in three stress cases: pure shear, tensile, and mixed modes of shear and tensile or compressive stresses [

13,

14]. The ASSHTO LRFD Bridge Design Specifications [

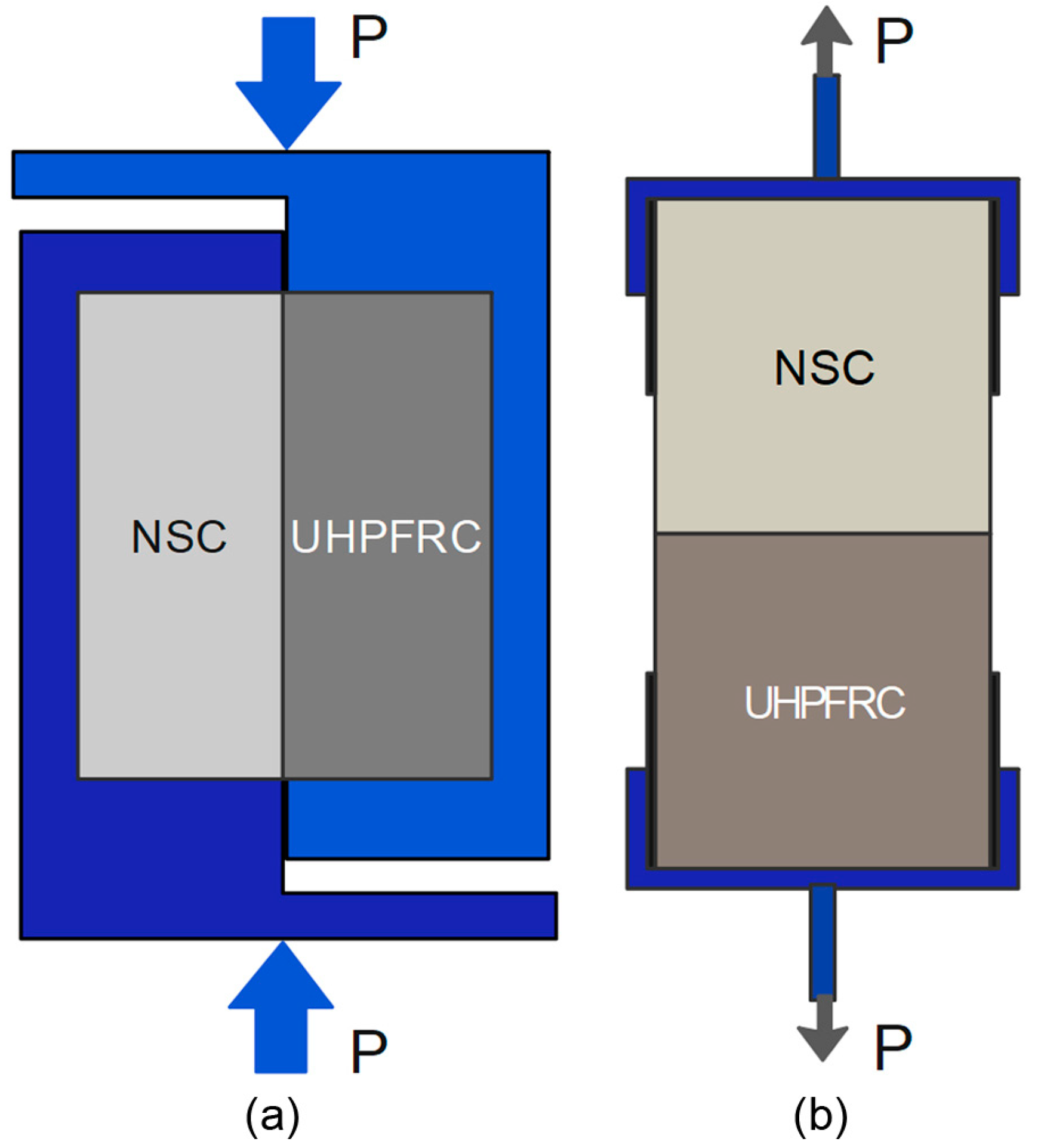

15] outline a shear test (

Figure 1a) for a composite specimen composed of two different materials. The shear strength at the interface of different concretes cast at various times is determined using the following:

where c is the cohesion and A

cv is the area between two layers of concrete. A

vf and f

y denote the area and the yield stress of reinforcement, respectively. µ is the friction coefficient, and P

c is the compressive force perpendicular to the shear plane.

The tensile strength is calculated based on the pull-off test (

Figure 1b) according to ASTM C1583/C1583M [

16] and is shown as follows:

where f

t is the direct tensile strength. T and A are the tensile force and the cross-sectional area of the test specimen, respectively.

The bonded interface between the NSC and UHPFRC in in situ casting can be accurately modeled using cohesive elements and surface-based cohesive behavior in ABAQUS software [

17]. This modeling approach effectively represents the interface, which is usually composed of a thin layer of UHPFRC material, except in cases of abnormal surface roughness. Therefore, neglecting the surface thickness and using the surface-based cohesive behavior to model the interfacial behavior between NSC and UHPFRC is appropriate.

The surface-based cohesive behavior can be simulated using the common bi-linear traction-separation law [

12], as shown in

Figure 2. The parameters K

n(s,t), t

0n(s,t), δ

0n(s,t), and δ

tn(s,t) represent the normal and two tangential stiffnesses, maximum stresses, corresponding displacements to the maximum stress, and maximum displacements at zero stress, respectively. The law of the model includes two stages. In the first stage, the stress at the interface increases linearly up to the peak t

0n(s,t) with the stiffness K. At the peak, damage initiation occurs and is followed by the evolution of that damage. The relationship between traction t

n(s,t) and separation δ in the linear traction-separation law can be described by Equation (3):

ABAQUS offers various criteria to determine damage initiation, which is the point at which the bonding at the interface begins to degrade. In this study, the maximum stress criterion was utilized, where damage initiation occurs when the maximum contact stress ratio reaches one. This criterion is expressed in Equation (4):

The Macaulay bracket notation, denoted by the symbol <>, is used in this context to represent purely compressive stress.

The damage evolution law characterizes the degradation of cohesive stiffness following damage initiation. During this stage, Equation (5) is used to describe the contact stress components at the interface that are affected by a scalar damage variable, D.

The value of the scalar damage variable, D, is zero when there is no damage and one when the bonding has completely failed. Since the maximum stress criterion was utilized, a linear damage evolution model was adopted in this study. When the bonding experiences complete failure, D reaches a value of one, indicating complete plastic displacement. This displacement is determined by the difference between δfn(s,t) and δ0n(s,t).

The elastic behavior is determined by Equation (6):

The nominal traction stress vector, represented by t, includes t

n for the normal traction and t

s and t

t for the two shear tractions. δ

n, δ

s, and δ

t denote corresponding separations. The uncoupled traction-separation behavior is normally utilized to model the interface’s working behavior. This uncoupled behavior is applied when the pure normal separation and the pure shear separation do not affect each other [

17].

For surface-based cohesive and uncoupled behavior, the thickness of the cohesive element is assumed to be equal to one [

17]. Therefore, the elastic behavior can be written as follows:

Figure 3 illustrates the typical load-displacement curve for both the shear bonding test (

Figure 1a) and the pure direct tensile test (

Figure 1b), shown by the blue curve. This curve is approximated as being linear over two segments, OA and AB. This relationship between load P

n(s,t) and displacement d can be expressed using Equation (8):

The ultimate loads of each mode are Pn°, Ps°, and Pt°, with corresponding displacements of dn°, ds°, and dt°, respectively. The highest displacement at the end of each damage evolution is represented by dnf, dsf, and dtf. The differences between the highest and corresponding displacements are denoted as Δn, Δs, and Δt.

The ultimate stresses and corresponding displacements are typically reached at the peak points of each mode’s load-displacement curve. By applying these conditions to Equation (7), the corresponding Equation can be derived as follows:

The interfacial areas between NSC and UHPFRC in the tensile and shear tests are denoted by An and As(At), respectively.

Thus, the normal stiffness and two tangential stiffnesses can be determined from Equation (10), which is derived from Equation (9).

The damage of the interface is defined by using the maximum nominal stress tn°(ts°, tt°) and the total/plastic displacement.

The bonding strength of an interface is primarily determined by its roughness [

18,

19]. In civil engineering, the roughness of a concrete surface refers to the irregularity or variation in its texture. The quantification of a concrete surface’s roughness is commonly determined by its average sand-filling depth, represented as “h” in

Figure 4a. Equation (11) can be used to calculate the value of “h”:

where h represents the average depth of sand filling (mm); V

s is the volume of sand (mm

3); and A

s represents the area of the treated concrete substrate (mm

2).

For example, Feng et al.’s study [

20] investigated the bonding strength of three types of surfaces: smooth, mid-rough, and rough (

Figure 4b–d), which corresponded to sand-filling depths of 0, 0.64, and 1.29 mm, respectively.

Feng et al. [

20] and Hussei et al. [

21] previously investigated the shear and tensile behaviors of NSC-UHPFRC composite specimens with various surfaces. These studies tested NSC-UHPFRC specimens with smooth, mid-rough, and rough interfaces to determine load-displacement behaviors, as described in

Section 3.2 and

Section 3.3.

Table 1 summarizes the experimental results, including the ultimate loads (P

n(s,t)0), surface areas (A

n(s,t)0), displacements (d

n(s,t)0), and maximum plastic displacement (∆) for both shear and tensile tests. Additionally, the table provides the values of tractions and stiffnesses for the three types of surfaces, which were obtained using Equations (9) and (10).

The parameters for the smooth, mid-rough, and rough surfaces of the NSC-UHPFRC interface, which were derived from

Table 1, are presented in

Table 2 for the surface-based cohesive model used in ABAQUS. The input data required to simulate the bonding behavior between NSC and UHPFRC for different surfaces is presented in

Figure 5. This includes the interaction properties and interactions defined in ABAQUS for the FE models.

4. Results and Discussion

4.1. Results Obtained from the Analysis of Shear Tests

Figure 10 shows a strong agreement between the experimental and simulation results for three surface types in terms of peak loads and displacements. The agreement is demonstrated by small deviations between experimental and simulated ultimate loads, measuring 6.8%, 4.1%, and 5.8% for rough, mid-rough, and smooth surfaces, respectively. Corresponding small errors in displacements at ultimate loads are also observed for the same surfaces, measuring 2%, 0.9%, and 2.4%, as shown in

Table 11. The highest deviation of 6.8% is found in the case of the rough surface. It can be explained that in composite members with a rough surface, the strength of the interface between UHPFRC and NSC is stronger than the NSC itself due to the majority of UHPFRC penetrating into the NSC to form the interface. Consequently, the composite member’s shear resistance depends on the NSC’s strength. Therefore, any difference in the strength of the NSC between the EXP and FEM may affect the ultimate load difference between them.

The study found that the load-displacement curves of the experimental and simulation results for the smooth surface were in good agreement. However, the simulation demonstrates a higher interface stiffness for the mid-rough and rough surfaces than the experimental results. This difference is due to the simultaneous participation in shear resistance of both NSC and UHPFRC. The combination of these factors causes the overall stiffness of the interface to change over time. Additionally, defects in the NSC [

37] constitute a crucial factor that unsettles its stiffness under loading.

Furthermore, the separation of the mid-rough and rough specimens in the simulation was observed to occur gradually, while the experimental results indicated that the specimens fractured immediately after reaching the peak load. The discrepancy in the damage evolution phase between FEA and EXP on mid-rough and rough surfaces could be attributed to differences in the concrete material’s damage behavior between the simulation and experiment. In the case of the rough and mid-rough surfaces, the composite members’ damage occurred in the NSC part. However, the CDP model used to model concrete assumes that it is homogeneous and isotropic, neglecting concrete’s potential variations in properties and strengths in different directions as well as the existence of microcracks. Those factors could lead to the difference in the damage evolution stage between FEA and EXP.

Figure 11 illustrates the damage patterns of composite specimens through the visualization of the tensile damage variable “DAMAGET” and the compressive damage variable “DAMAGEC” in the ABAQUS output for three distinct surface types. The simulation results accurately depicted failure modes in all three cases. In the mid-rough and rough surface cases, failure concentrated on both the NSC and interface (

Figure 11a,b). In the smooth surface case, debonding occurred solely at the interface between NSC and UHPFRC (

Figure 11c).

The failures observed between NSC and UHPFRC can be attributed to the formation of chemical bonding and mechanical interlocking. Chemical bonding occurs through the reaction between calcium oxide and silica at the NSC-UHPFRC interface, forming a calcium-silicate-hydrate gel. Mechanical interlocking is formed when UHPFRC penetrates the pores and voids of the NSC surface. On the smooth NSC surface, few pores allow for mechanical interlocking, so bonding is primarily achieved through chemical bonding. However, this bond is weaker than the shear strength of NSC, causing failure to occur at the interface of NSC and UHPFRC. Mechanical interlocking occurs between the NSC and UHPFRC surfaces on a mid-rough or rough NSC surface, creating small bridges that enhance the shear strength of the interface. A rougher NSC surface with a higher roughness degree results in a deeper average sand-fill depth, forming larger UHPFRC small bridges in the NSC. This can cause a larger failure area in the NSC specimen.

The simulation results revealed that crushing failure accounted for the majority of the area compared to cracking failure. This is because the shear force at the interface transmits the compressive load to the NSC specimen. With a higher degree of roughness in the interface between NSC and UHPFRC, more failures occurred in the top flange of the NSC. This is because, as the UHPFRC specimen moves downward, the highest node at the interface between the NSC and UHPFRC experiences a greater load than the lower nodes do. This is due to the compressive strain of each element between nodes, generating a compressive force that reduces the load at the lower node. As a result, the highest node experiences more stress than the lower nodes, which can lead to failure in the top flange of the NSC specimen. Therefore, failure in the NSC specimen occurs first in the top flange compared to other parts.

In the surface-based cohesive model used in this study, a rougher surface was assigned a greater shear strength at the interface in the parameters (

Table 2). Therefore, if an element near the surface is damaged, the load is transmitted to the adjacent element, and failure develops until the corresponding compressive stress is lower than the compressive strength of NSC. In the case of a smooth surface, the compressive stress generated in the NSC by bonding with UHPFRC is lower than its compressive strength, resulting in failure at the interface instead of within the NSC.

The developed FE models are useful for predicting the shear bonding strength at the NSC and UHPFRC interfaces for different levels of roughness. This is particularly beneficial for designing effective strengthening solutions for concrete structures, such as bridge decks, that are being repaired or reinforced using UHPFRC. Accurately predicting the shear strength at the interface can ensure the durability and longevity of the structure, making it an important consideration for engineers.

4.2. Results Obtained from the Analysis of Tensile Tests

Figure 12 shows a high degree of agreement between the simulation and experimental results for the load-displacement curves overall, particularly for stiffness, peak loads, and corresponding displacements on both smooth and mid-rough surfaces. The deviation between EXP and FEA in those comparing variables is less than 3% (

Table 11). Although the simulation and experimental results matched well in terms of stiffness for the rough surface,

Table 11 shows a 13.6% and 15.9% discrepancy for the ultimate load and corresponding displacement, respectively. A discrepancy in the concrete’s tensile strength used in the experiment and simulation could be the reason for the observed difference in ultimate load and corresponding displacement. This is because the rough surface has a higher tensile strength (5.63 MPa) than the NSC (5.36 MPa), as shown in

Table 2. Consequently, the tensile strength of the NSC-UHPFRC composite specimen during tensile testing is primarily determined by the strength of the NSC.

Regarding damage patterns,

Figure 13 demonstrates that the simulation results are consistent with the experimental results. The simulation results show greater damage in the NSC for the mid-rough and rough surfaces. Additionally, on the rough surface, the failure of NSC occurred further away from the interface than on the mid-rough surface. Furthermore, debonding mostly occurred at the NSC and UHPFRC interfaces for the smooth surface.

The reasons for these results can be explained as follows: The rough surface has a larger tensile strength at the interface, causing the tensile strain of elements near the interface to be lower than those farther away during tensile loading. Due to this behavior, the concrete elements farthest from the interface, particularly those located at the position of the steel nipple in the NSC, are more prone to failure. In contrast, the mid-surface and smooth surface have a lower tensile strength at the interface than NSC, leading to a failure tendency at the interface. During failure, the NSC-UHPFRC interface undergoes a reduction in area, which results in an increase in its tensile strength at that specific location. Consequently, some elements of the NSC fail because their tensile strength exceeds the ultimate tensile strength of the NSC. The extent of concrete damage depends on the interface’s tensile strength. As the interface’s tensile strength increases, the concrete’s damaged area also increases. This finding explains why the damaged area of NSC in the mid-rough surface was greater than that in the smooth surface, as shown in

Figure 13b,c.

By accurately predicting the tensile behavior at the HSC-UHPFRC interface, this FE model can be used to optimize interface design and maximize the tensile bonding strength between HSC and UHPC. This optimization can ultimately improve the performance and durability of concrete structures. Additionally, the model can be utilized to simulate different scenarios and loading conditions, enabling engineers to evaluate the structural behavior of the interface and make informed decisions about design modifications and repairs.

Based on the two analyses mentioned above, when the interface between HSC and UHPFRC has a higher roughness level, the concrete substrate experiences either shear or tensile failure, and the composite member’s shear or tensile strength capacity depends on the corresponding strength of the concrete substrate. Therefore, it is recommended that substrate surfaces be prepared with sufficient roughness to ensure that failure occurs in the substrate during the repair and strengthening of concrete members.

4.3. Results Obtained from Analysis of Flexural Test

Figure 14 demonstrates that the load-displacement curves of the simulated results are aligned with the experimental results for both the reference beam and composite beam. This high degree of concordance is evident from the small difference of around 3% between the simulation and experimental results for both peak load and corresponding displacement (

Table 11). Additionally, the FE model captures the ductile behavior of the composite beam as observed in the experimental results, with the initiation of the first crack observed at approximately 22 KN and the first yielding of the reinforcements estimated to occur at approximately 70 KN. However, the simulation results reveal a higher initial stiffness compared to the experimental results. The disparity in the initial stiffness of an RC beam between the experimental and simulated results can be attributed to several factors. One such factor is the presence of voids and defects inside the experimental beam, which can reduce its stiffness [

37]. Additionally, the modeling assumptions made in the simulation, such as the use of the embedded constraint technique, may not accurately reflect the actual response between the reinforcement and concrete, potentially leading to an overestimation of the beam’s stiffness in the simulated model.

Figure 15 demonstrates a strong correlation in damage patterns between the simulation and experimental results. The results indicate that the debonding between the NSC and UHPFRC primarily occurred at the interface, highlighting the critical role of the bond between the two materials in the overall performance of composite beams. Furthermore, the experimental results revealed the presence of crushing damage at the location of applied loads. This damage may be attributed to the high concentration of stresses in this region, which can exceed the material’s load-bearing capacity. These findings underscore the importance of considering both the bond between the NSC and UHPFRC and the distribution of loads and stresses when designing reinforced and retrofitted concrete structures.